Transmission part location JEEP GRAND CHEROKEE 2003 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1285 of 2199

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

The crankshaft rear main bearing oil seal consists

of two half pieces of viton with a single lip that effec-

tively seals the rear of the crankshaft. Replace the

upper and lower seal halves as a unit to ensure leak-

free operation.

(1) Remove transmission inspection cover.

(2) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL)

(3) Remove main bearing cap brace.

(4) Remove rear main bearing cap (No.7).

(5) Push upper seal out of the groove. Ensure that

the crankshaft and seal groove are not damaged.

(6) Remove lower half of the seal from the bearing

cap.

INSTALLATION

The crankshaft rear main bearing oil seal consists

of two half pieces of viton with a single lip that effec-

tively seals the rear of the crankshaft. Replace the

upper and lower seal halves as a unit to ensure leak-

free operation.

(1) Wipe the seal surface area of the crankshaft

until it is clean.

(2) Apply a thin coat of engine oil.

(3) Coat lip of the seal with engine oil.

(4) Carefully position the upper seal into the

groove in the cylinder block. The lip of the seal faces

toward the front of the engine.

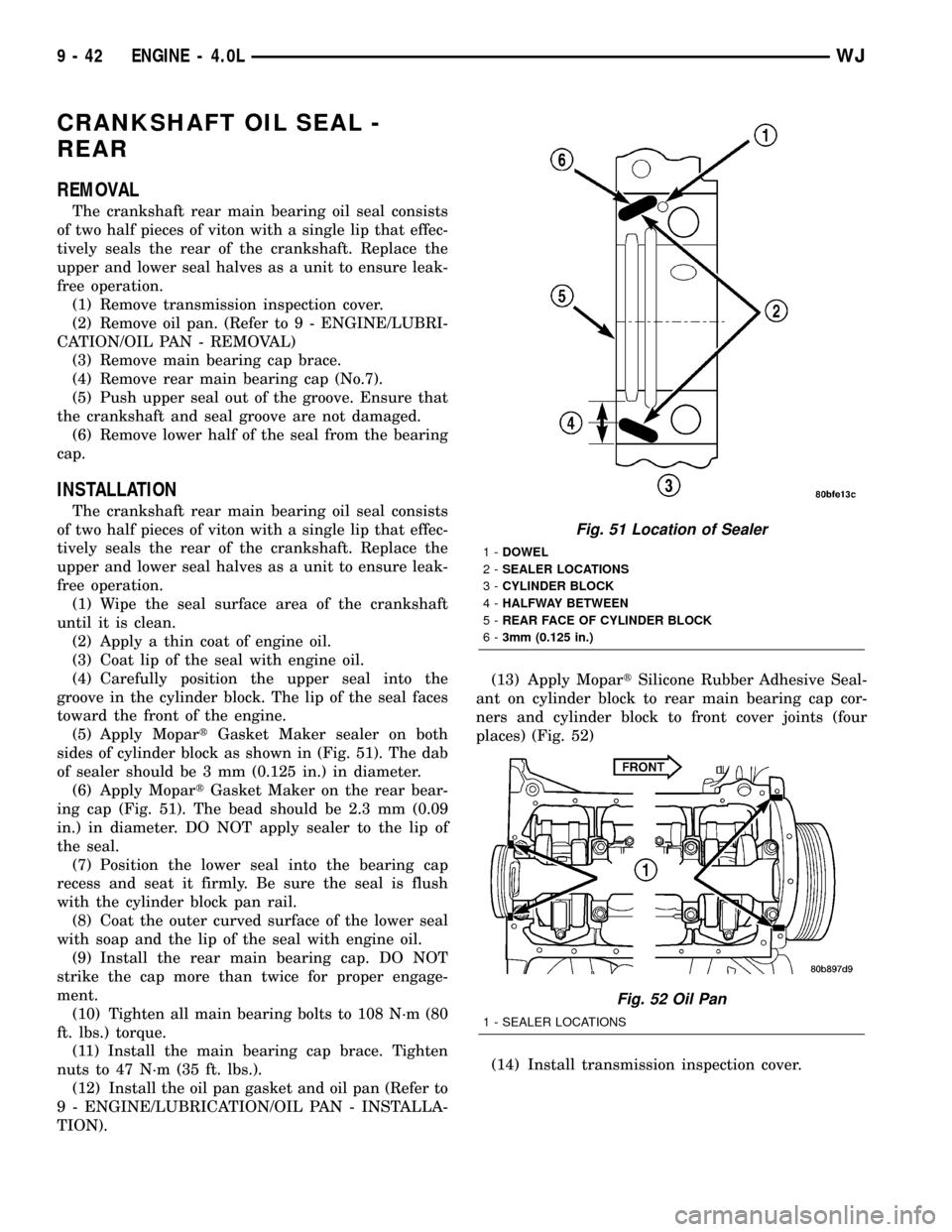

(5) Apply MopartGasket Maker sealer on both

sides of cylinder block as shown in (Fig. 51). The dab

of sealer should be 3 mm (0.125 in.) in diameter.

(6) Apply MopartGasket Maker on the rear bear-

ing cap (Fig. 51). The bead should be 2.3 mm (0.09

in.) in diameter. DO NOT apply sealer to the lip of

the seal.

(7) Position the lower seal into the bearing cap

recess and seat it firmly. Be sure the seal is flush

with the cylinder block pan rail.

(8) Coat the outer curved surface of the lower seal

with soap and the lip of the seal with engine oil.

(9) Install the rear main bearing cap. DO NOT

strike the cap more than twice for proper engage-

ment.

(10) Tighten all main bearing bolts to 108 N´m (80

ft. lbs.) torque.

(11) Install the main bearing cap brace. Tighten

nuts to 47 N´m (35 ft. lbs.).

(12) Install the oil pan gasket and oil pan (Refer to

9 - ENGINE/LUBRICATION/OIL PAN - INSTALLA-

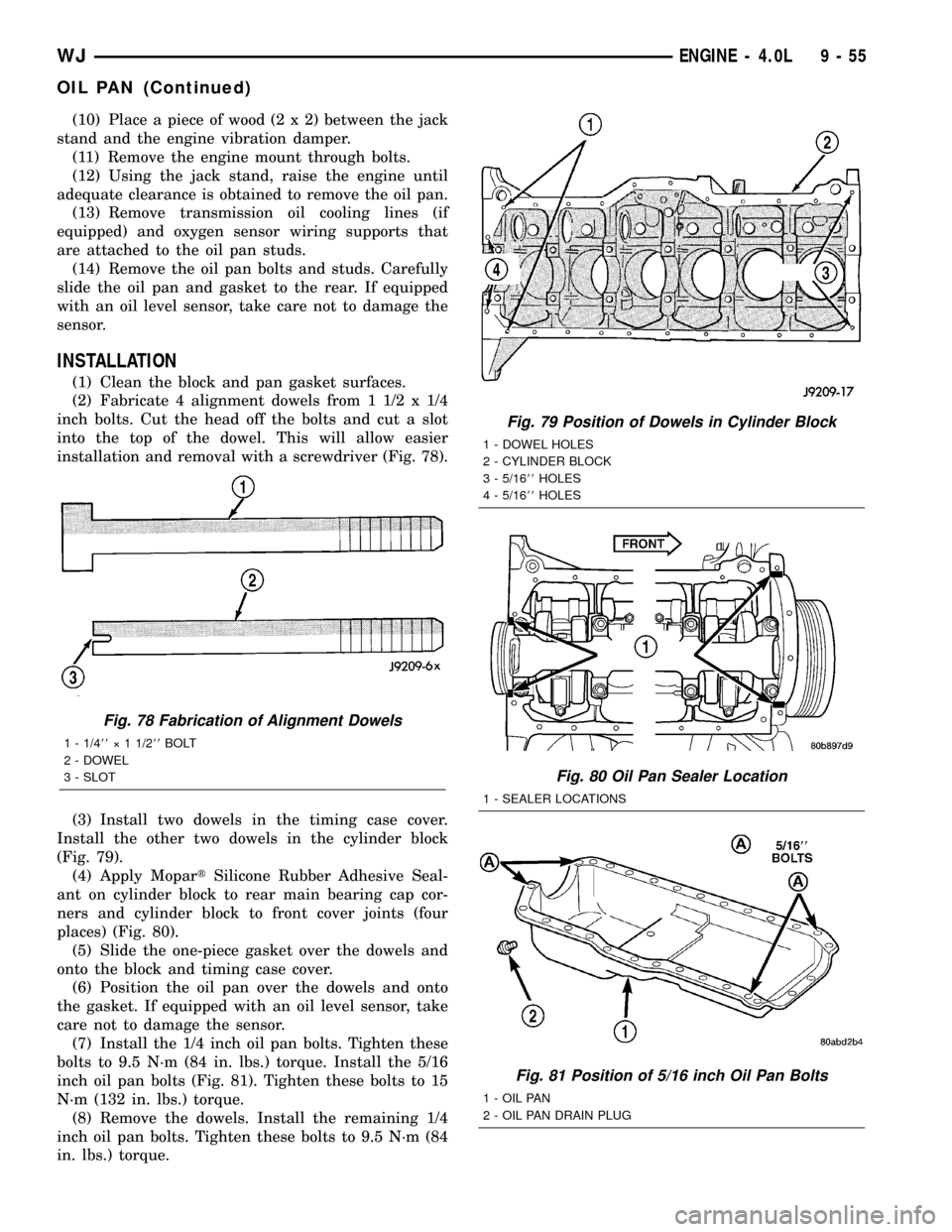

TION).(13) Apply MopartSilicone Rubber Adhesive Seal-

ant on cylinder block to rear main bearing cap cor-

ners and cylinder block to front cover joints (four

places) (Fig. 52)

(14) Install transmission inspection cover.

Fig. 51 Location of Sealer

1-DOWEL

2-SEALER LOCATIONS

3-CYLINDER BLOCK

4-HALFWAY BETWEEN

5-REAR FACE OF CYLINDER BLOCK

6-3mm (0.125 in.)

Fig. 52 Oil Pan

1 - SEALER LOCATIONS

9 - 42 ENGINE - 4.0LWJ

Page 1298 of 2199

(10) Place a piece of wood (2 x 2) between the jack

stand and the engine vibration damper.

(11) Remove the engine mount through bolts.

(12) Using the jack stand, raise the engine until

adequate clearance is obtained to remove the oil pan.

(13) Remove transmission oil cooling lines (if

equipped) and oxygen sensor wiring supports that

are attached to the oil pan studs.

(14) Remove the oil pan bolts and studs. Carefully

slide the oil pan and gasket to the rear. If equipped

with an oil level sensor, take care not to damage the

sensor.

INSTALLATION

(1) Clean the block and pan gasket surfaces.

(2) Fabricate 4 alignment dowels from 1 1/2 x 1/4

inch bolts. Cut the head off the bolts and cut a slot

into the top of the dowel. This will allow easier

installation and removal with a screwdriver (Fig. 78).

(3) Install two dowels in the timing case cover.

Install the other two dowels in the cylinder block

(Fig. 79).

(4) Apply MopartSilicone Rubber Adhesive Seal-

ant on cylinder block to rear main bearing cap cor-

ners and cylinder block to front cover joints (four

places) (Fig. 80).

(5) Slide the one-piece gasket over the dowels and

onto the block and timing case cover.

(6) Position the oil pan over the dowels and onto

the gasket. If equipped with an oil level sensor, take

care not to damage the sensor.

(7) Install the 1/4 inch oil pan bolts. Tighten these

bolts to 9.5 N´m (84 in. lbs.) torque. Install the 5/16

inch oil pan bolts (Fig. 81). Tighten these bolts to 15

N´m (132 in. lbs.) torque.

(8) Remove the dowels. Install the remaining 1/4

inch oil pan bolts. Tighten these bolts to 9.5 N´m (84

in. lbs.) torque.

Fig. 78 Fabrication of Alignment Dowels

1 - 1/488ý 1 1/288BOLT

2 - DOWEL

3 - SLOT

Fig. 79 Position of Dowels in Cylinder Block

1 - DOWEL HOLES

2 - CYLINDER BLOCK

3 - 5/1688HOLES

4 - 5/1688HOLES

Fig. 80 Oil Pan Sealer Location

1 - SEALER LOCATIONS

Fig. 81 Position of 5/16 inch Oil Pan Bolts

1 - OIL PAN

2 - OIL PAN DRAIN PLUG

WJENGINE - 4.0L 9 - 55

OIL PAN (Continued)

Page 1313 of 2199

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of airwhen squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

²Metal scraper

9 - 70 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1524 of 2199

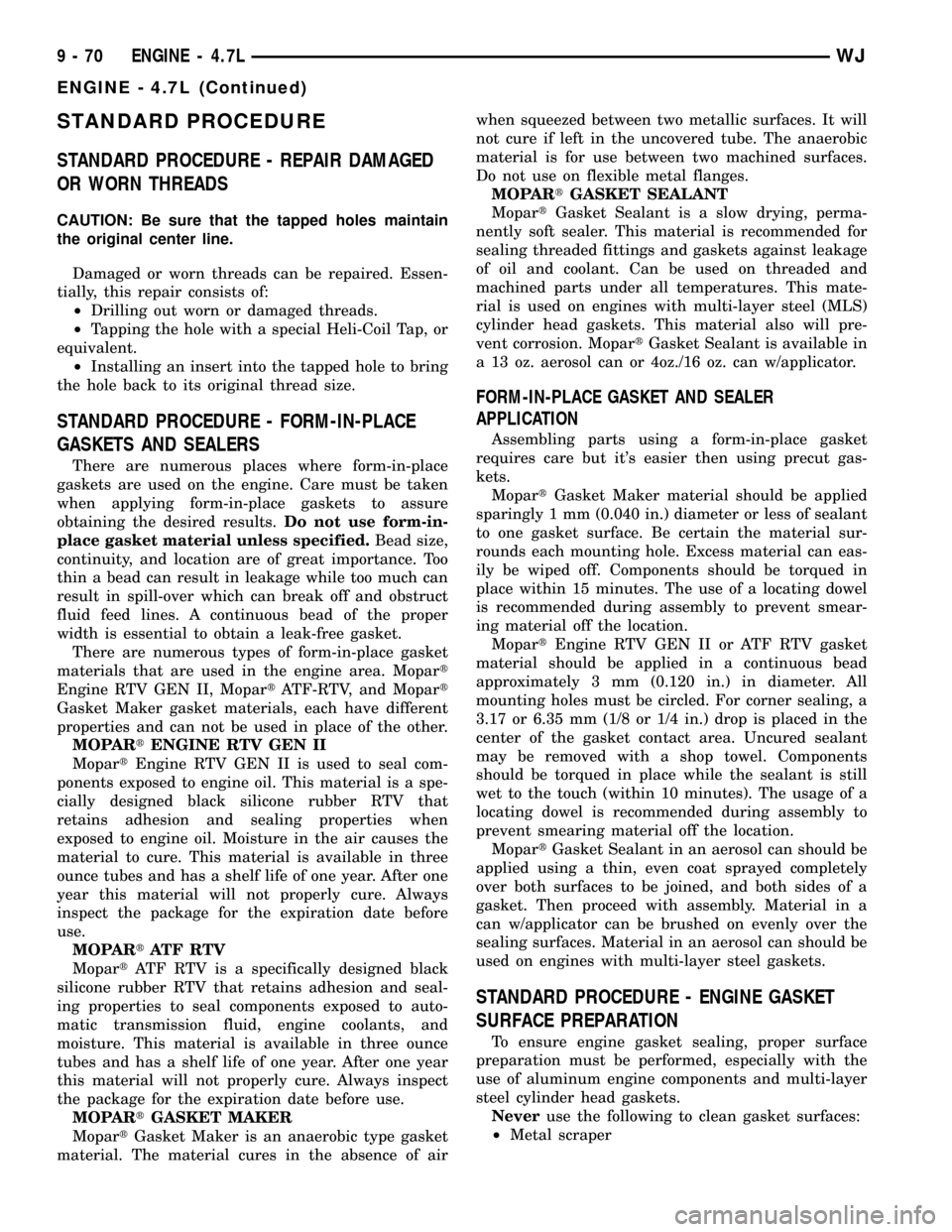

IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan gas-

ket surface (Fig. 2). Refer to this information when

ordering replacement parts.

GEAR RATIOS The 42RE gear ratios are:

1st.................................2.74:1

2nd................................1.54:1

3rd.................................1.00:1

4th.................................0.69:1

Rev.................................2.21:1

OPERATION

The application of each driving or holding compo-

nent is controlled by the valve body based upon the

manual lever position, throttle pressure, and gover-

nor pressure. The governor pressure is a variable

pressure input to the valve body and is one of the

signals that a shift is necessary. First through fourth

gear are obtained by selectively applying and releas-

ing the different clutches and bands. Engine power is

thereby routed to the various planetary gear assem-

blies which combine with the overrunning clutch

assemblies to generate the different gear ratios. The

torque converter clutch is hydraulically applied and

is released when fluid is vented from the hydraulic

circuit by the torque converter control (TCC) solenoid

on the valve body. The torque converter clutch is con-

trolled by the Powertrain Control Module (PCM). The

torque converter clutch engages in fourth gear, and

in third gear under various conditions, such as when

the O/D switch is OFF, when the vehicle is cruising

on a level surface after the vehicle has warmed up.

The torque converter clutch will disengage momen-

tarily when an increase in engine load is sensed by

the PCM, such as when the vehicle begins to go

uphill or the throttle pressure is increased. The

torque converter clutch feature increases fuel econ-

omy and reduces the transmission fluid temperature.

Since the overdrive clutch is applied in fourth gear

only and the direct clutch is applied in all ranges

except fourth gear, the transmission operation for

park, neutral, and first through third gear will be

described first. Once these powerflows are described,

the third to fourth shift sequence will be described.

1 - CONVERTER CLUTCH 15 - HOUSING

2 - TORQUE CONVERTER 16 - REAR BEARING

3 - OIL PUMP AND REACTION SHAFT SUPPORT ASSEMBLY 17 - OUTPUT SHAFT

4 - FRONT BAND 18 - SEAL

5 - FRONT CLUTCH 19 - OVERDRIVE OVERRUNNING CLUTCH

6 - DRIVING SHELL 20 - OVERDRIVE PLANETARY GEAR

7 - REAR BAND 21 - DIRECT CLUTCH SPRING

8 - TRANSMISSION OVERRUNNING CLUTCH 22 - OVERDRIVE CLUTCH PISTON

9 - OVERDRIVE UNIT 23 - VALVE BODY ASSEMBLY

10 - PISTON RETAINER 24 - FILTER

11 - OVERDRIVE CLUTCH 25 - FRONT PLANETARY GEAR

12 - DIRECT CLUTCH 26 - REAR CLUTCH

13 - INTERMEDIATE SHAFT 27 - TRANSMISSION

14 - FRONT BEARING 28 - REAR PLANETARY GEAR

Fig. 2 Transmission Part And Serial Number

Location

1 - PART NUMBER

2 - BUILD DATE

3 - SERIAL NUMBER

WJAUTOMATIC TRANSMISSION - 42RE 21 - 5

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1556 of 2199

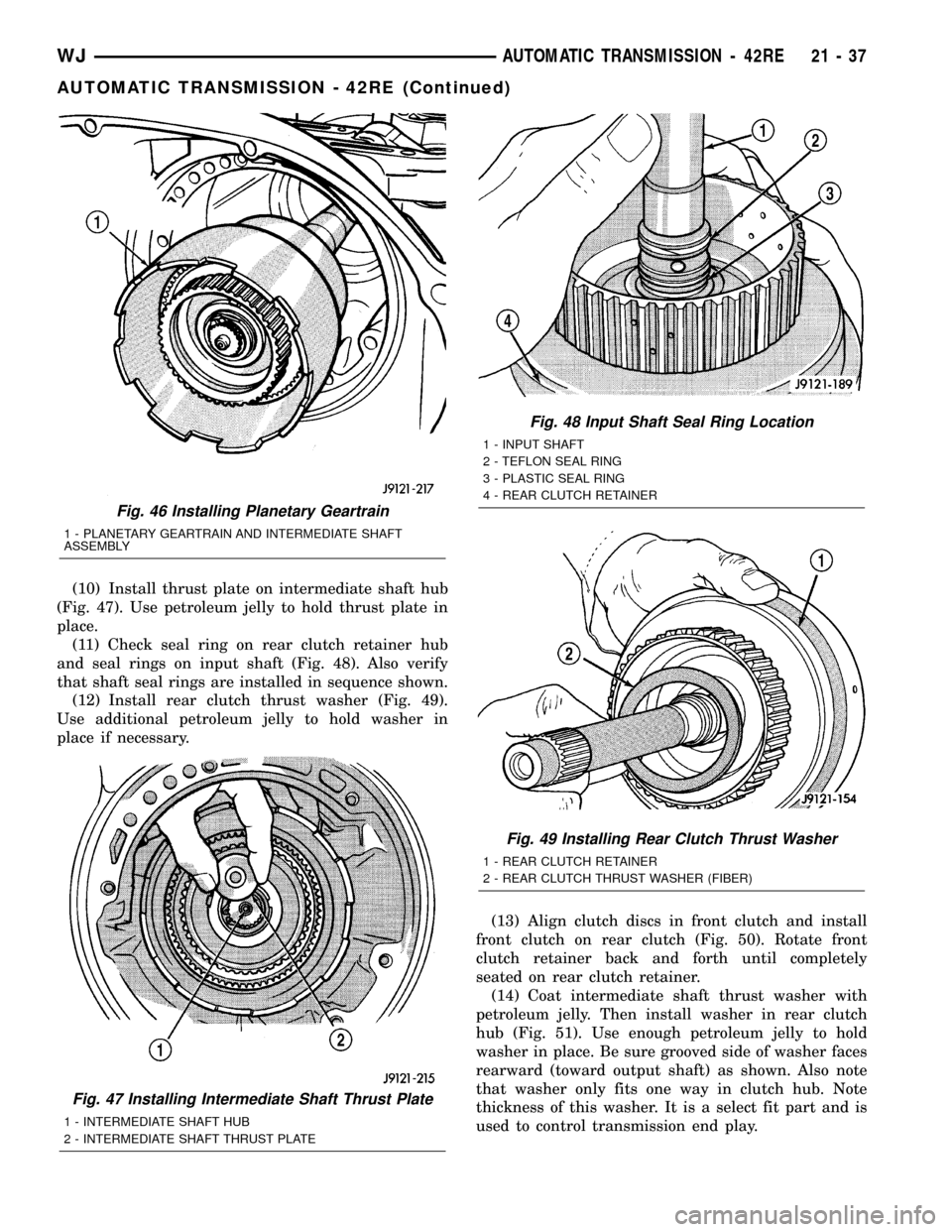

(10) Install thrust plate on intermediate shaft hub

(Fig. 47). Use petroleum jelly to hold thrust plate in

place.

(11) Check seal ring on rear clutch retainer hub

and seal rings on input shaft (Fig. 48). Also verify

that shaft seal rings are installed in sequence shown.

(12) Install rear clutch thrust washer (Fig. 49).

Use additional petroleum jelly to hold washer in

place if necessary.

(13) Align clutch discs in front clutch and install

front clutch on rear clutch (Fig. 50). Rotate front

clutch retainer back and forth until completely

seated on rear clutch retainer.

(14) Coat intermediate shaft thrust washer with

petroleum jelly. Then install washer in rear clutch

hub (Fig. 51). Use enough petroleum jelly to hold

washer in place. Be sure grooved side of washer faces

rearward (toward output shaft) as shown. Also note

that washer only fits one way in clutch hub. Note

thickness of this washer. It is a select fit part and is

used to control transmission end play.

Fig. 46 Installing Planetary Geartrain

1 - PLANETARY GEARTRAIN AND INTERMEDIATE SHAFT

ASSEMBLY

Fig. 47 Installing Intermediate Shaft Thrust Plate

1 - INTERMEDIATE SHAFT HUB

2 - INTERMEDIATE SHAFT THRUST PLATE

Fig. 48 Input Shaft Seal Ring Location

1 - INPUT SHAFT

2 - TEFLON SEAL RING

3 - PLASTIC SEAL RING

4 - REAR CLUTCH RETAINER

Fig. 49 Installing Rear Clutch Thrust Washer

1 - REAR CLUTCH RETAINER

2 - REAR CLUTCH THRUST WASHER (FIBER)

WJAUTOMATIC TRANSMISSION - 42RE 21 - 37

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1581 of 2199

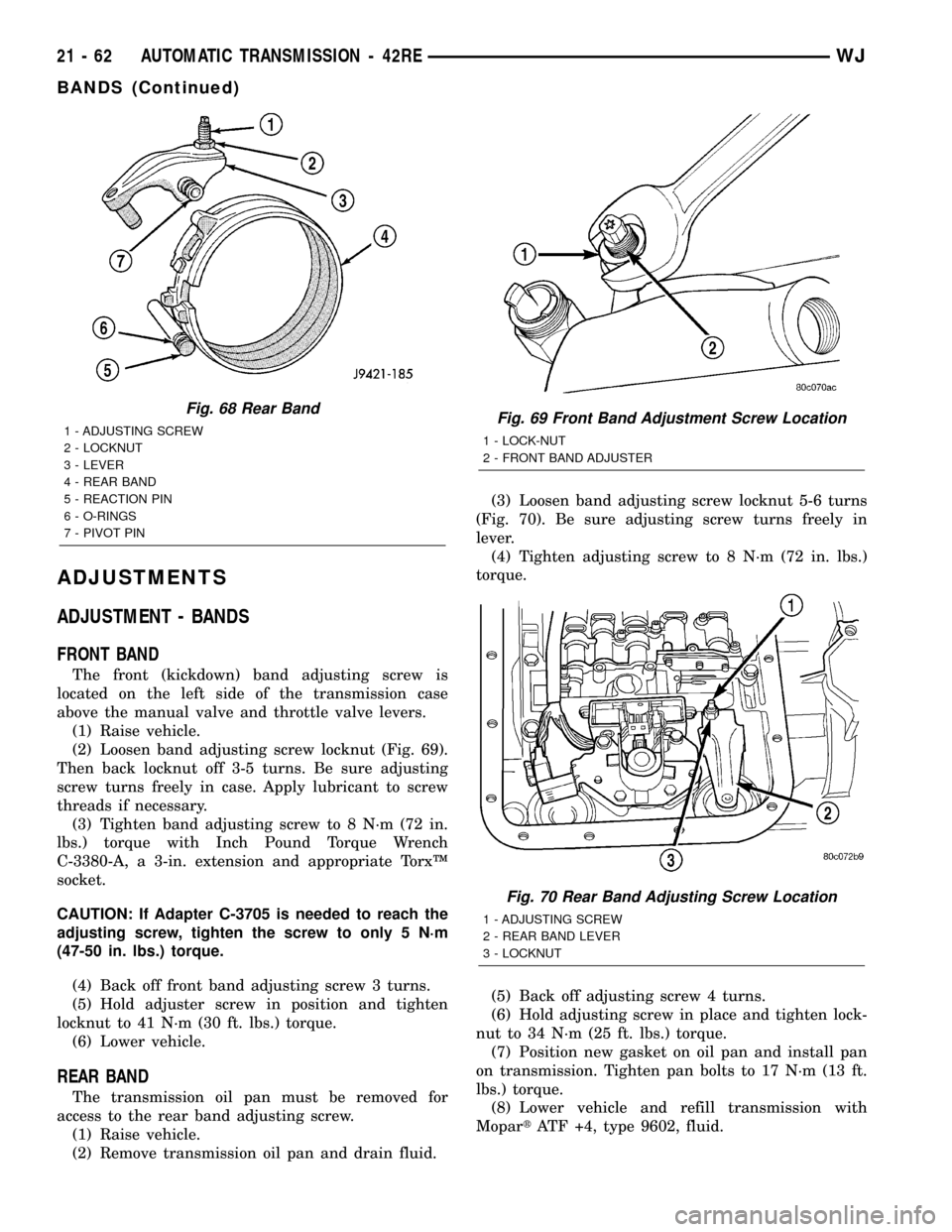

ADJUSTMENTS

ADJUSTMENT - BANDS

FRONT BAND

The front (kickdown) band adjusting screw is

located on the left side of the transmission case

above the manual valve and throttle valve levers.

(1) Raise vehicle.

(2) Loosen band adjusting screw locknut (Fig. 69).

Then back locknut off 3-5 turns. Be sure adjusting

screw turns freely in case. Apply lubricant to screw

threads if necessary.

(3) Tighten band adjusting screw to 8 N´m (72 in.

lbs.) torque with Inch Pound Torque Wrench

C-3380-A, a 3-in. extension and appropriate TorxŸ

socket.

CAUTION: If Adapter C-3705 is needed to reach the

adjusting screw, tighten the screw to only 5 N´m

(47-50 in. lbs.) torque.

(4) Back off front band adjusting screw 3 turns.

(5) Hold adjuster screw in position and tighten

locknut to 41 N´m (30 ft. lbs.) torque.

(6) Lower vehicle.

REAR BAND

The transmission oil pan must be removed for

access to the rear band adjusting screw.

(1) Raise vehicle.

(2) Remove transmission oil pan and drain fluid.(3) Loosen band adjusting screw locknut 5-6 turns

(Fig. 70). Be sure adjusting screw turns freely in

lever.

(4) Tighten adjusting screw to 8 N´m (72 in. lbs.)

torque.

(5) Back off adjusting screw 4 turns.

(6) Hold adjusting screw in place and tighten lock-

nut to 34 N´m (25 ft. lbs.) torque.

(7) Position new gasket on oil pan and install pan

on transmission. Tighten pan bolts to 17 N´m (13 ft.

lbs.) torque.

(8) Lower vehicle and refill transmission with

MopartATF +4, type 9602, fluid.

Fig. 68 Rear Band

1 - ADJUSTING SCREW

2 - LOCKNUT

3 - LEVER

4 - REAR BAND

5 - REACTION PIN

6 - O-RINGS

7 - PIVOT PINFig. 69 Front Band Adjustment Screw Location

1 - LOCK-NUT

2 - FRONT BAND ADJUSTER

Fig. 70 Rear Band Adjusting Screw Location

1 - ADJUSTING SCREW

2 - REAR BAND LEVER

3 - LOCKNUT

21 - 62 AUTOMATIC TRANSMISSION - 42REWJ

BANDS (Continued)

Page 1607 of 2199

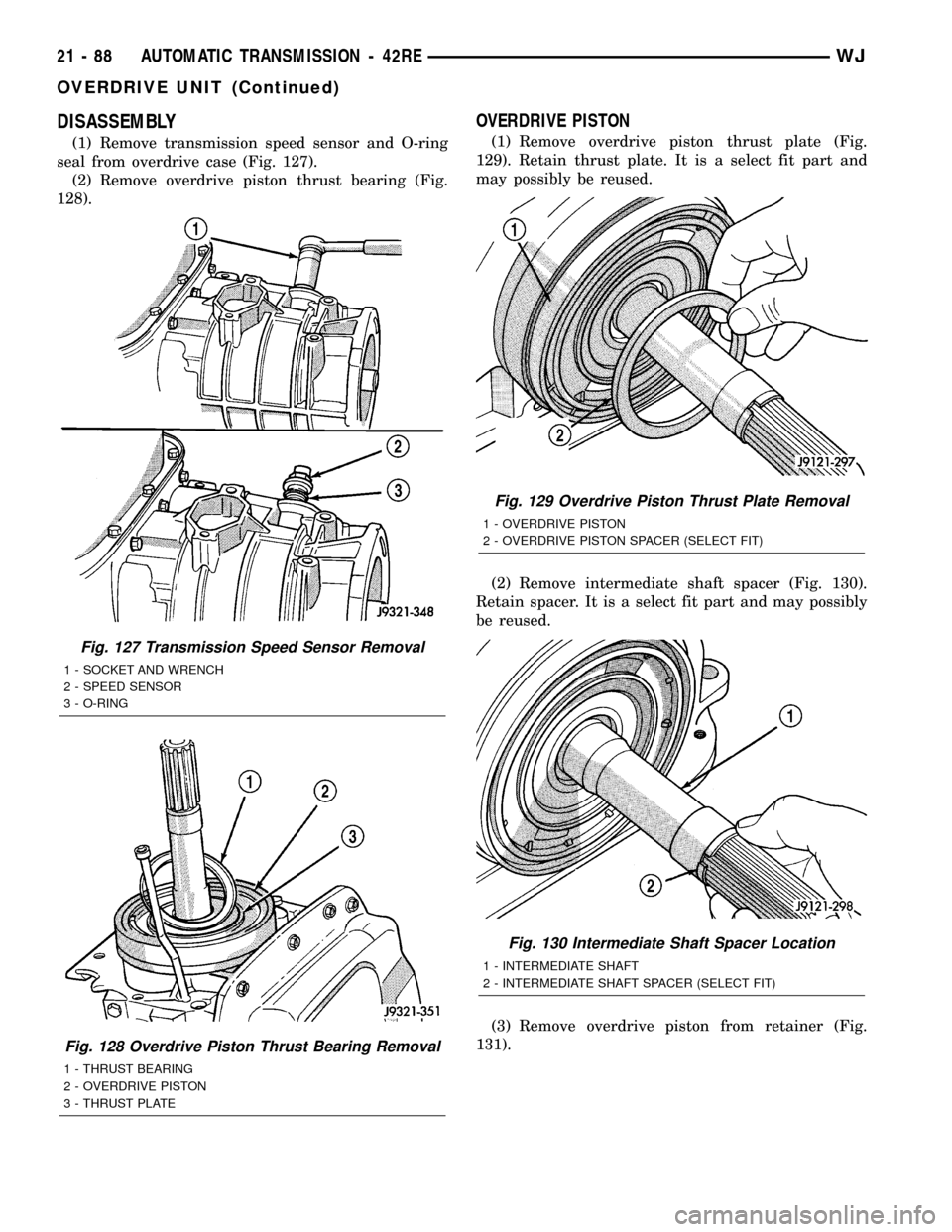

DISASSEMBLY

(1) Remove transmission speed sensor and O-ring

seal from overdrive case (Fig. 127).

(2) Remove overdrive piston thrust bearing (Fig.

128).

OVERDRIVE PISTON

(1) Remove overdrive piston thrust plate (Fig.

129). Retain thrust plate. It is a select fit part and

may possibly be reused.

(2) Remove intermediate shaft spacer (Fig. 130).

Retain spacer. It is a select fit part and may possibly

be reused.

(3) Remove overdrive piston from retainer (Fig.

131).

Fig. 127 Transmission Speed Sensor Removal

1 - SOCKET AND WRENCH

2 - SPEED SENSOR

3 - O-RING

Fig. 128 Overdrive Piston Thrust Bearing Removal

1 - THRUST BEARING

2 - OVERDRIVE PISTON

3 - THRUST PLATE

Fig. 129 Overdrive Piston Thrust Plate Removal

1 - OVERDRIVE PISTON

2 - OVERDRIVE PISTON SPACER (SELECT FIT)

Fig. 130 Intermediate Shaft Spacer Location

1 - INTERMEDIATE SHAFT

2 - INTERMEDIATE SHAFT SPACER (SELECT FIT)

21 - 88 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)

Page 1625 of 2199

between the rollers and cam. This increased clear-

ance between the rollers and cam results in a free-

wheeling condition. When the inner race attempts to

rotate counterclockwise, the action causes the rollers

to roll in the same direction as the race, aided by the

pushing of the springs. As the rollers try to move in

the same direction as the inner race, they are

wedged between the inner and outer races due to the

design of the cam. In this condition, the clutch is

locked and acts as one unit.

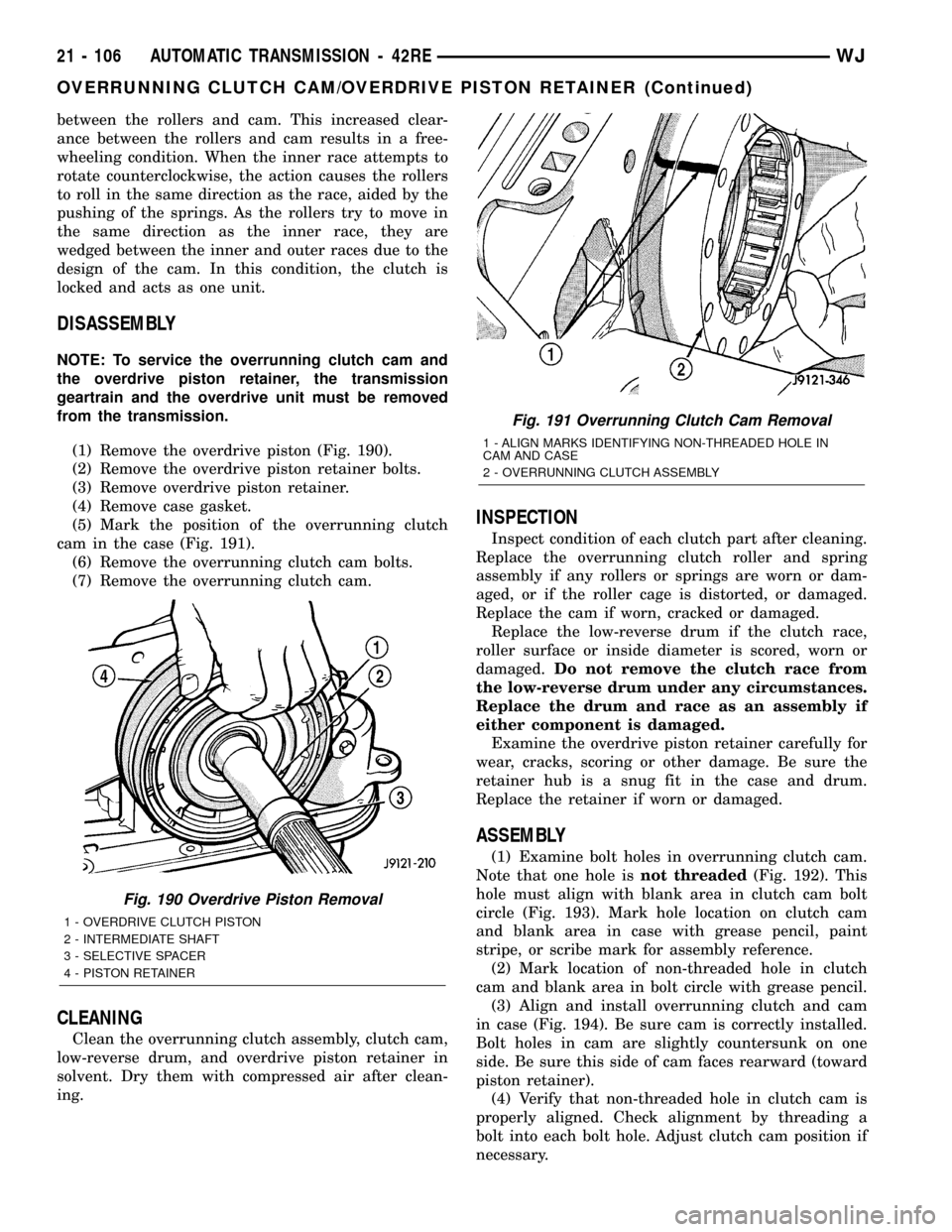

DISASSEMBLY

NOTE: To service the overrunning clutch cam and

the overdrive piston retainer, the transmission

geartrain and the overdrive unit must be removed

from the transmission.

(1) Remove the overdrive piston (Fig. 190).

(2) Remove the overdrive piston retainer bolts.

(3) Remove overdrive piston retainer.

(4) Remove case gasket.

(5) Mark the position of the overrunning clutch

cam in the case (Fig. 191).

(6) Remove the overrunning clutch cam bolts.

(7) Remove the overrunning clutch cam.

CLEANING

Clean the overrunning clutch assembly, clutch cam,

low-reverse drum, and overdrive piston retainer in

solvent. Dry them with compressed air after clean-

ing.

INSPECTION

Inspect condition of each clutch part after cleaning.

Replace the overrunning clutch roller and spring

assembly if any rollers or springs are worn or dam-

aged, or if the roller cage is distorted, or damaged.

Replace the cam if worn, cracked or damaged.

Replace the low-reverse drum if the clutch race,

roller surface or inside diameter is scored, worn or

damaged.Do not remove the clutch race from

the low-reverse drum under any circumstances.

Replace the drum and race as an assembly if

either component is damaged.

Examine the overdrive piston retainer carefully for

wear, cracks, scoring or other damage. Be sure the

retainer hub is a snug fit in the case and drum.

Replace the retainer if worn or damaged.

ASSEMBLY

(1) Examine bolt holes in overrunning clutch cam.

Note that one hole isnot threaded(Fig. 192). This

hole must align with blank area in clutch cam bolt

circle (Fig. 193). Mark hole location on clutch cam

and blank area in case with grease pencil, paint

stripe, or scribe mark for assembly reference.

(2) Mark location of non-threaded hole in clutch

cam and blank area in bolt circle with grease pencil.

(3) Align and install overrunning clutch and cam

in case (Fig. 194). Be sure cam is correctly installed.

Bolt holes in cam are slightly countersunk on one

side. Be sure this side of cam faces rearward (toward

piston retainer).

(4) Verify that non-threaded hole in clutch cam is

properly aligned. Check alignment by threading a

bolt into each bolt hole. Adjust clutch cam position if

necessary.

Fig. 190 Overdrive Piston Removal

1 - OVERDRIVE CLUTCH PISTON

2 - INTERMEDIATE SHAFT

3 - SELECTIVE SPACER

4 - PISTON RETAINER

Fig. 191 Overrunning Clutch Cam Removal

1 - ALIGN MARKS IDENTIFYING NON-THREADED HOLE IN

CAM AND CASE

2 - OVERRUNNING CLUTCH ASSEMBLY

21 - 106 AUTOMATIC TRANSMISSION - 42REWJ

OVERRUNNING CLUTCH CAM/OVERDRIVE PISTON RETAINER (Continued)

Page 1632 of 2199

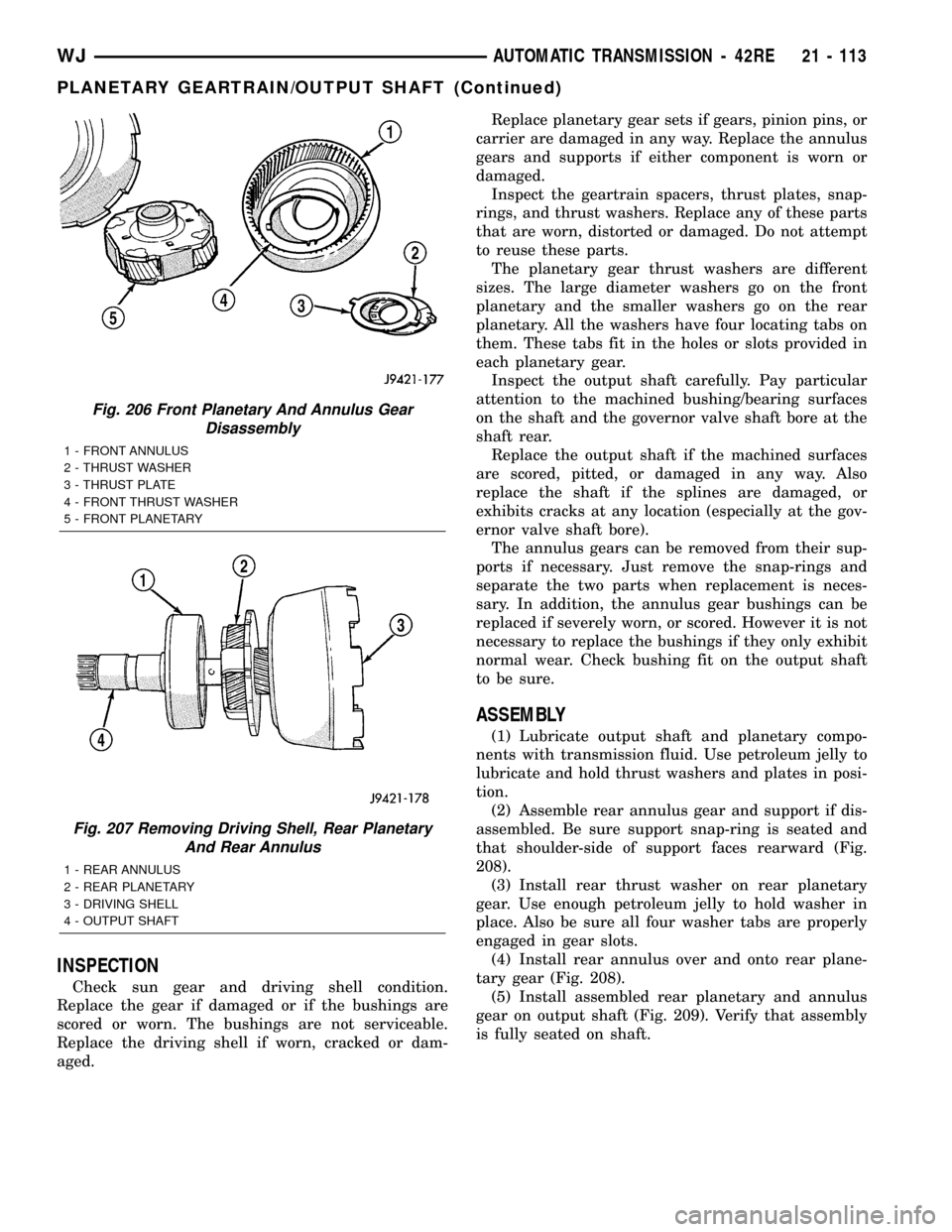

INSPECTION

Check sun gear and driving shell condition.

Replace the gear if damaged or if the bushings are

scored or worn. The bushings are not serviceable.

Replace the driving shell if worn, cracked or dam-

aged.Replace planetary gear sets if gears, pinion pins, or

carrier are damaged in any way. Replace the annulus

gears and supports if either component is worn or

damaged.

Inspect the geartrain spacers, thrust plates, snap-

rings, and thrust washers. Replace any of these parts

that are worn, distorted or damaged. Do not attempt

to reuse these parts.

The planetary gear thrust washers are different

sizes. The large diameter washers go on the front

planetary and the smaller washers go on the rear

planetary. All the washers have four locating tabs on

them. These tabs fit in the holes or slots provided in

each planetary gear.

Inspect the output shaft carefully. Pay particular

attention to the machined bushing/bearing surfaces

on the shaft and the governor valve shaft bore at the

shaft rear.

Replace the output shaft if the machined surfaces

are scored, pitted, or damaged in any way. Also

replace the shaft if the splines are damaged, or

exhibits cracks at any location (especially at the gov-

ernor valve shaft bore).

The annulus gears can be removed from their sup-

ports if necessary. Just remove the snap-rings and

separate the two parts when replacement is neces-

sary. In addition, the annulus gear bushings can be

replaced if severely worn, or scored. However it is not

necessary to replace the bushings if they only exhibit

normal wear. Check bushing fit on the output shaft

to be sure.

ASSEMBLY

(1) Lubricate output shaft and planetary compo-

nents with transmission fluid. Use petroleum jelly to

lubricate and hold thrust washers and plates in posi-

tion.

(2) Assemble rear annulus gear and support if dis-

assembled. Be sure support snap-ring is seated and

that shoulder-side of support faces rearward (Fig.

208).

(3) Install rear thrust washer on rear planetary

gear. Use enough petroleum jelly to hold washer in

place. Also be sure all four washer tabs are properly

engaged in gear slots.

(4) Install rear annulus over and onto rear plane-

tary gear (Fig. 208).

(5) Install assembled rear planetary and annulus

gear on output shaft (Fig. 209). Verify that assembly

is fully seated on shaft.

Fig. 206 Front Planetary And Annulus Gear

Disassembly

1 - FRONT ANNULUS

2 - THRUST WASHER

3 - THRUST PLATE

4 - FRONT THRUST WASHER

5 - FRONT PLANETARY

Fig. 207 Removing Driving Shell, Rear Planetary

And Rear Annulus

1 - REAR ANNULUS

2 - REAR PLANETARY

3 - DRIVING SHELL

4 - OUTPUT SHAFT

WJAUTOMATIC TRANSMISSION - 42RE 21 - 113

PLANETARY GEARTRAIN/OUTPUT SHAFT (Continued)

Page 1650 of 2199

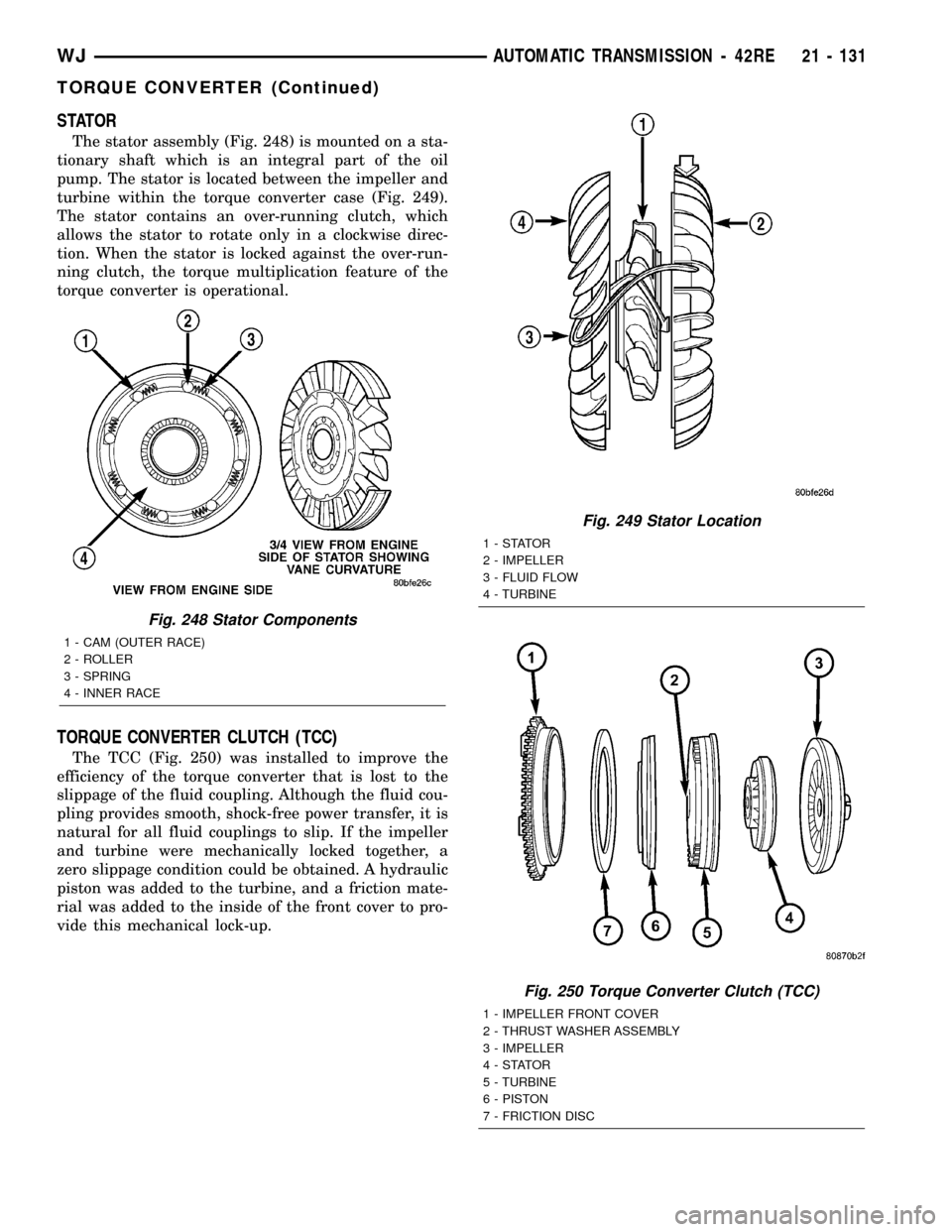

STATOR

The stator assembly (Fig. 248) is mounted on a sta-

tionary shaft which is an integral part of the oil

pump. The stator is located between the impeller and

turbine within the torque converter case (Fig. 249).

The stator contains an over-running clutch, which

allows the stator to rotate only in a clockwise direc-

tion. When the stator is locked against the over-run-

ning clutch, the torque multiplication feature of the

torque converter is operational.

TORQUE CONVERTER CLUTCH (TCC)

The TCC (Fig. 250) was installed to improve the

efficiency of the torque converter that is lost to the

slippage of the fluid coupling. Although the fluid cou-

pling provides smooth, shock-free power transfer, it is

natural for all fluid couplings to slip. If the impeller

and turbine were mechanically locked together, a

zero slippage condition could be obtained. A hydraulic

piston was added to the turbine, and a friction mate-

rial was added to the inside of the front cover to pro-

vide this mechanical lock-up.

Fig. 248 Stator Components

1 - CAM (OUTER RACE)

2 - ROLLER

3 - SPRING

4 - INNER RACE

Fig. 249 Stator Location

1-STATOR

2 - IMPELLER

3 - FLUID FLOW

4 - TURBINE

Fig. 250 Torque Converter Clutch (TCC)

1 - IMPELLER FRONT COVER

2 - THRUST WASHER ASSEMBLY

3 - IMPELLER

4-STATOR

5 - TURBINE

6 - PISTON

7 - FRICTION DISC

WJAUTOMATIC TRANSMISSION - 42RE 21 - 131

TORQUE CONVERTER (Continued)