steering pump standard procedure JEEP GRAND CHEROKEE 2003 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1510 of 2199

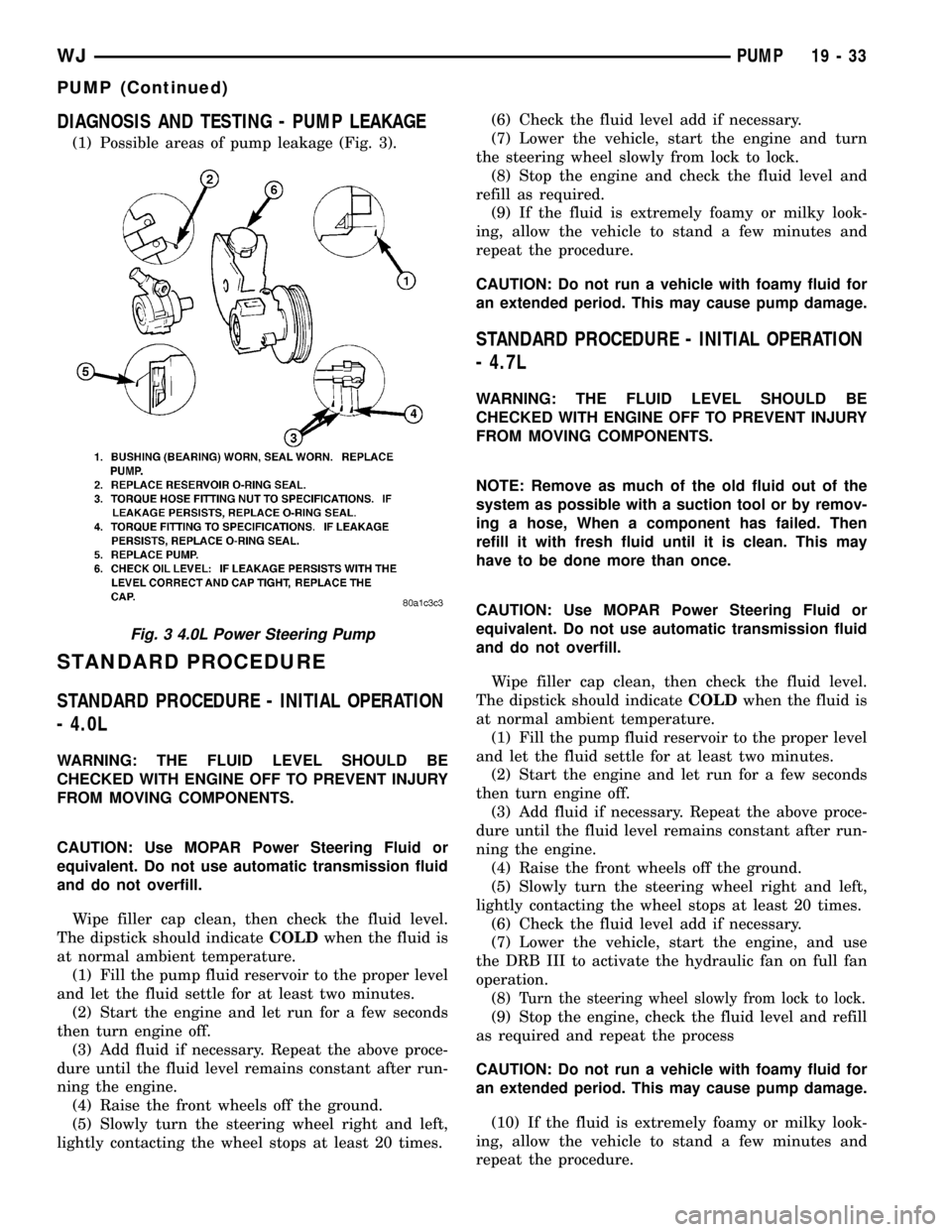

DIAGNOSIS AND TESTING - PUMP LEAKAGE

(1) Possible areas of pump leakage (Fig. 3).

STANDARD PROCEDURE

STANDARD PROCEDURE - INITIAL OPERATION

- 4.0L

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

CAUTION: Use MOPAR Power Steering Fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal ambient temperature.

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two minutes.

(2) Start the engine and let run for a few seconds

then turn engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops at least 20 times.(6) Check the fluid level add if necessary.

(7) Lower the vehicle, start the engine and turn

the steering wheel slowly from lock to lock.

(8) Stop the engine and check the fluid level and

refill as required.

(9) If the fluid is extremely foamy or milky look-

ing, allow the vehicle to stand a few minutes and

repeat the procedure.

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

STANDARD PROCEDURE - INITIAL OPERATION

- 4.7L

WARNING: THE FLUID LEVEL SHOULD BE

CHECKED WITH ENGINE OFF TO PREVENT INJURY

FROM MOVING COMPONENTS.

NOTE: Remove as much of the old fluid out of the

system as possible with a suction tool or by remov-

ing a hose, When a component has failed. Then

refill it with fresh fluid until it is clean. This may

have to be done more than once.

CAUTION: Use MOPAR Power Steering Fluid or

equivalent. Do not use automatic transmission fluid

and do not overfill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateCOLDwhen the fluid is

at normal ambient temperature.

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two minutes.

(2) Start the engine and let run for a few seconds

then turn engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops at least 20 times.

(6) Check the fluid level add if necessary.

(7) Lower the vehicle, start the engine, and use

the DRB III to activate the hydraulic fan on full fan

operation.

(8)

Turn the steering wheel slowly from lock to lock.

(9) Stop the engine, check the fluid level and refill

as required and repeat the process

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

(10) If the fluid is extremely foamy or milky look-

ing, allow the vehicle to stand a few minutes and

repeat the procedure.

Fig. 3 4.0L Power Steering Pump

WJPUMP 19 - 33

PUMP (Continued)

Page 1511 of 2199

(11) While the vehicle is in park, use the DRB III

to activate the hydraulic fan to full fan operation and

briefly rev the engine up to 3000 rpm to fully engage

the hydraulic fan.

(12) Check the fluid level add if necessary.

REMOVAL

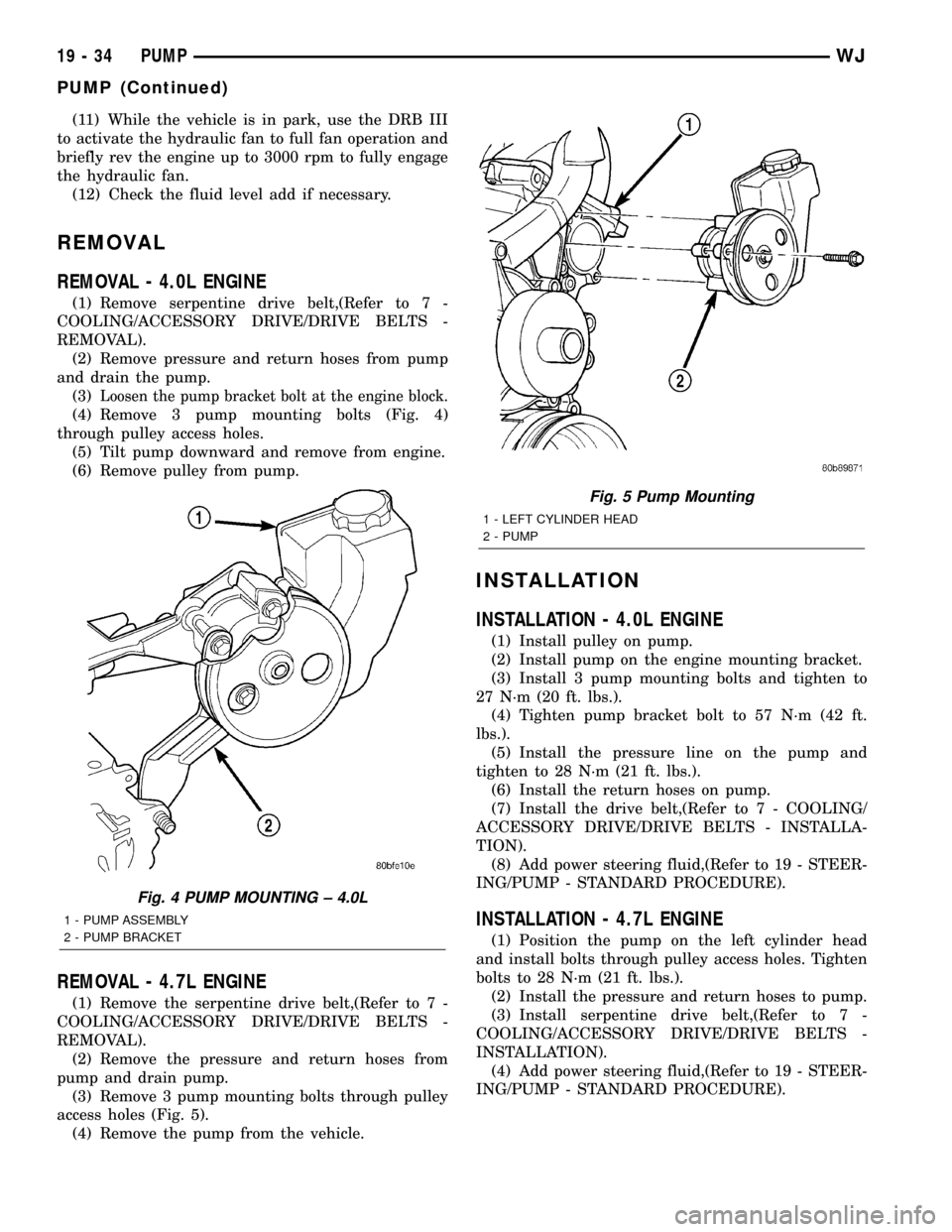

REMOVAL - 4.0L ENGINE

(1) Remove serpentine drive belt,(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove pressure and return hoses from pump

and drain the pump.

(3)

Loosen the pump bracket bolt at the engine block.

(4) Remove 3 pump mounting bolts (Fig. 4)

through pulley access holes.

(5) Tilt pump downward and remove from engine.

(6) Remove pulley from pump.

REMOVAL - 4.7L ENGINE

(1) Remove the serpentine drive belt,(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(2) Remove the pressure and return hoses from

pump and drain pump.

(3) Remove 3 pump mounting bolts through pulley

access holes (Fig. 5).

(4) Remove the pump from the vehicle.

INSTALLATION

INSTALLATION - 4.0L ENGINE

(1) Install pulley on pump.

(2) Install pump on the engine mounting bracket.

(3) Install 3 pump mounting bolts and tighten to

27 N´m (20 ft. lbs.).

(4) Tighten pump bracket bolt to 57 N´m (42 ft.

lbs.).

(5) Install the pressure line on the pump and

tighten to 28 N´m (21 ft. lbs.).

(6) Install the return hoses on pump.

(7) Install the drive belt,(Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(8) Add power steering fluid,(Refer to 19 - STEER-

ING/PUMP - STANDARD PROCEDURE).

INSTALLATION - 4.7L ENGINE

(1) Position the pump on the left cylinder head

and install bolts through pulley access holes. Tighten

bolts to 28 N´m (21 ft. lbs.).

(2) Install the pressure and return hoses to pump.

(3) Install serpentine drive belt,(Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(4) Add power steering fluid,(Refer to 19 - STEER-

ING/PUMP - STANDARD PROCEDURE).

Fig. 4 PUMP MOUNTING ± 4.0L

1 - PUMP ASSEMBLY

2 - PUMP BRACKET

Fig. 5 Pump Mounting

1 - LEFT CYLINDER HEAD

2 - PUMP

19 - 34 PUMPWJ

PUMP (Continued)

Page 1519 of 2199

INSTALLATION

NOTE: The pulley is marked front for installation.

CAUTION: On vehicles equipped with the 4.0L or

4.7L, Do not reuse the old power steering pump

pulley it is not intended for reuse. A new pulley

must be installed if removed.

(1) Replace pulley if bent, cracked, or loose.

(2) Install pulley on pump with Installer C-4063-B

or equivalent installer (Fig. 15). The front edge of the

pulley hub must be flush with the end of the shaft.

Ensure the tool and pulley are aligned with the

pump shaft.(3) Install pump assembly.

(4) With Serpentine Belt, run engine until warm (5

min.) and note any belt chirp. If chirp exists, move

pulley outward approximately 0.5 mm (0.020 in.). If

noise increases, press on 1.0 mm (0.040 in.).Be

careful that pulley does not contact mounting

bolts.

RESERVOIR

REMOVAL

(1) Remove power steering pump.

(2) Clean exterior of pump.

(3) Clamp the pump body in a soft jaw vice.

NOTE: Use new retaining clips for installation.

(4) Pry up tab and slide the retaining clips off (Fig.

16).

(5) Remove fluid reservoir from pump body.

Remove and discard O-ring seal.

INSTALLATION

(1) Lubricate new O-ring Seal with Mopar Power

Steering Fluid or equivalent.

(2) Install O-ring seal in housing.

(3) Install reservoir onto housing.

(4) Slide and tap innewreservoir retainer clips

until tab locks to housing.

(5) Install power steering pump.

(6) Add power steering fluid,(Refer to 19 - STEER-

ING/PUMP - STANDARD PROCEDURE).

Fig. 14 Pulley Removal

1 - POWER STEERING PUMP DRIVE PULLEY

2 - SPECIAL TOOL C-4333

Fig. 15 Pulley Installation

1 - POWER STEERING PUMP DRIVE PULLEY

2 - SPECIAL TOOL C-4063±B

Fig. 16 Pump Reservoir Clips

1 - RESERVOIR

2 - RETAINING CLIPS

19 - 42 PUMPWJ

PULLEY (Continued)