ECU JEEP GRAND CHEROKEE 2003 WJ / 2.G Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 294 of 2199

(2) Install the four mounting nuts. Tighten the

nuts to 12 N´m (105 in. lbs.).

(3) Reconnect the right body wire harness connec-

tor.

(4) Position the compact disc changer storage bin

onto the right side quarter trim panel.

(5) Using both hands push the compact disc

changer storage bin firmly and evenly toward the

right side quarter trim panel far enough to engage

the hooks on the bin with the slots in the panel.

(6) Using both hands push the compact disc

changer storage bin firmly and evenly downward far

enough to align the screw holes in the bin with the

mounting holes in the right side quarter trim panel.

(7) Install the two screws that secure the top of

the compact disc changer storage bin. Tighten the

screws to 1.7 N´m (15 in. lbs.).

(8) Reconnect the battery negative cable.

INSTRUMENT PANEL

ANTENNA CABLE

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the scuff plate from the right front

door sill. (Refer to 23 - BODY/INTERIOR/DOOR

SILL SCUFF PLATE - REMOVAL) for the proce-

dures.

(3) Remove the trim panel from the right inner

cowl side. (Refer to 23 - BODY/INTERIOR/COWL

TRIM - REMOVAL) for the procedures.

(4) Reach under the passenger side of the instru-

ment panel near the right cowl side inner panel to

disconnect the antenna coaxial cable connector by

pulling it apart while twisting the metal connector

halves. Do not pull on the cable.

(5) Disengage the antenna cable retainer from the

mounting hole in the wire harness mounting tab

under the passenger side end of the instrument

panel.

(6) Remove the radio receiver from the instrument

panel. (Refer to 8 - ELECTRICAL/AUDIO/RADIO -

REMOVAL) for the procedures.(7) Remove the passenger side airbag module from

the instrument panel. (Refer to 8 - ELECTRICAL/

RESTRAINTS/PASSENGER AIRBAG - REMOVAL)

for the procedures.

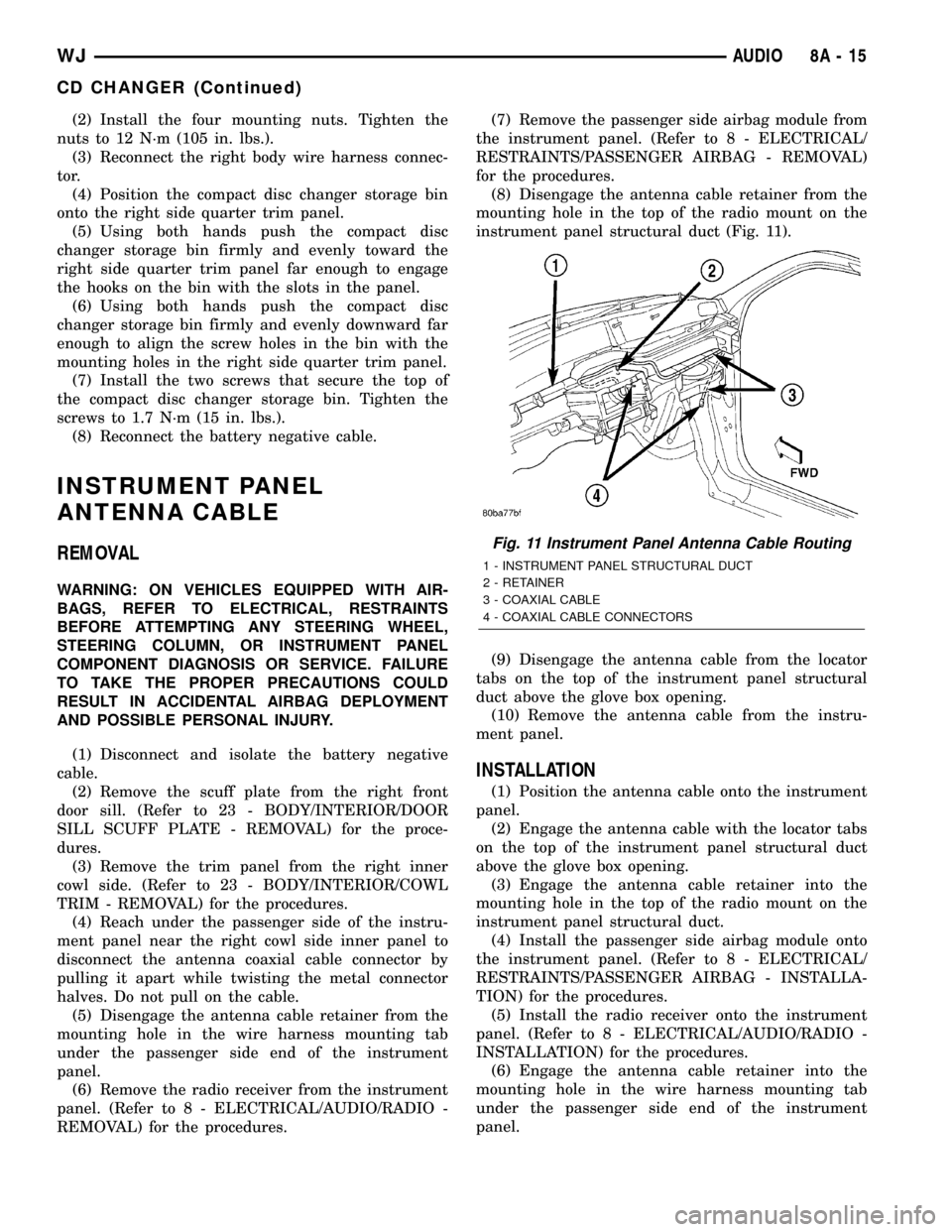

(8) Disengage the antenna cable retainer from the

mounting hole in the top of the radio mount on the

instrument panel structural duct (Fig. 11).

(9) Disengage the antenna cable from the locator

tabs on the top of the instrument panel structural

duct above the glove box opening.

(10) Remove the antenna cable from the instru-

ment panel.

INSTALLATION

(1) Position the antenna cable onto the instrument

panel.

(2) Engage the antenna cable with the locator tabs

on the top of the instrument panel structural duct

above the glove box opening.

(3) Engage the antenna cable retainer into the

mounting hole in the top of the radio mount on the

instrument panel structural duct.

(4) Install the passenger side airbag module onto

the instrument panel. (Refer to 8 - ELECTRICAL/

RESTRAINTS/PASSENGER AIRBAG - INSTALLA-

TION) for the procedures.

(5) Install the radio receiver onto the instrument

panel. (Refer to 8 - ELECTRICAL/AUDIO/RADIO -

INSTALLATION) for the procedures.

(6) Engage the antenna cable retainer into the

mounting hole in the wire harness mounting tab

under the passenger side end of the instrument

panel.

Fig. 11 Instrument Panel Antenna Cable Routing

1 - INSTRUMENT PANEL STRUCTURAL DUCT

2 - RETAINER

3 - COAXIAL CABLE

4 - COAXIAL CABLE CONNECTORS

WJAUDIO 8A - 15

CD CHANGER (Continued)

Page 296 of 2199

problem being diagnosed is related to one of the

symptoms listed below, be certain to check the

remote radio switches and circuits. (Refer to 8 -

ELECTRICAL/AUDIO/REMOTE SWITCHES -

OPERATION).

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Mode (AM, FM, CD, CD changer) changes with

no remote radio switch input

²Remote radio switch inoperative.

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CAUTION: The speaker output of the radio receiver

is a ªfloating groundº system. Do not allow any

speaker lead to short to ground, as damage to the

radio receiver may result.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the Power Dis-

tribution Center (PDC) fuse as required.

(3) Check the fused ignition switch output (acc/

run) fuse in the junction block. If OK, go to Step 4. If

not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (acc/run) fuse in the junction block. If OK, go

to Step 5. If not OK, repair the open fused ignition

switch output (acc/run) circuit to the ignition switch

as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the radio receiver from the instrument

panel, but do not disconnect the wire harness connec-

tors. Check for continuity between the radio receiver

chassis and a good ground. There should be continu-

ity. If OK, go to Step 6. If not OK, repair the open

ground circuit to ground as required.

(6) Test the radio receiver antenna. (Refer to 8 -

ELECTRICAL/AUDIO/ANTENNA BODY & CABLE -

DIAGNOSIS AND TESTING). If OK, go to Step 7. If

not OK, replace the faulty antenna or coaxial cable

as required.

(7) Connect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (acc/run)

circuit cavity of the 22 pin radio wire harness connec-

tor. If OK, go to Step 8. If not OK, repair the open

fused ignition switch output (acc/run) circuit to the

junction block fuse as required.

(8) Turn the ignition switch to the Off position.

Check for battery voltage at the fused B(+) circuit

cavity of the 22 pin radio wire harness connector. If

OK, replace the faulty radio receiver. If not OK,

repair the open fused B(+) circuit to the junction

block fuse as required.

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

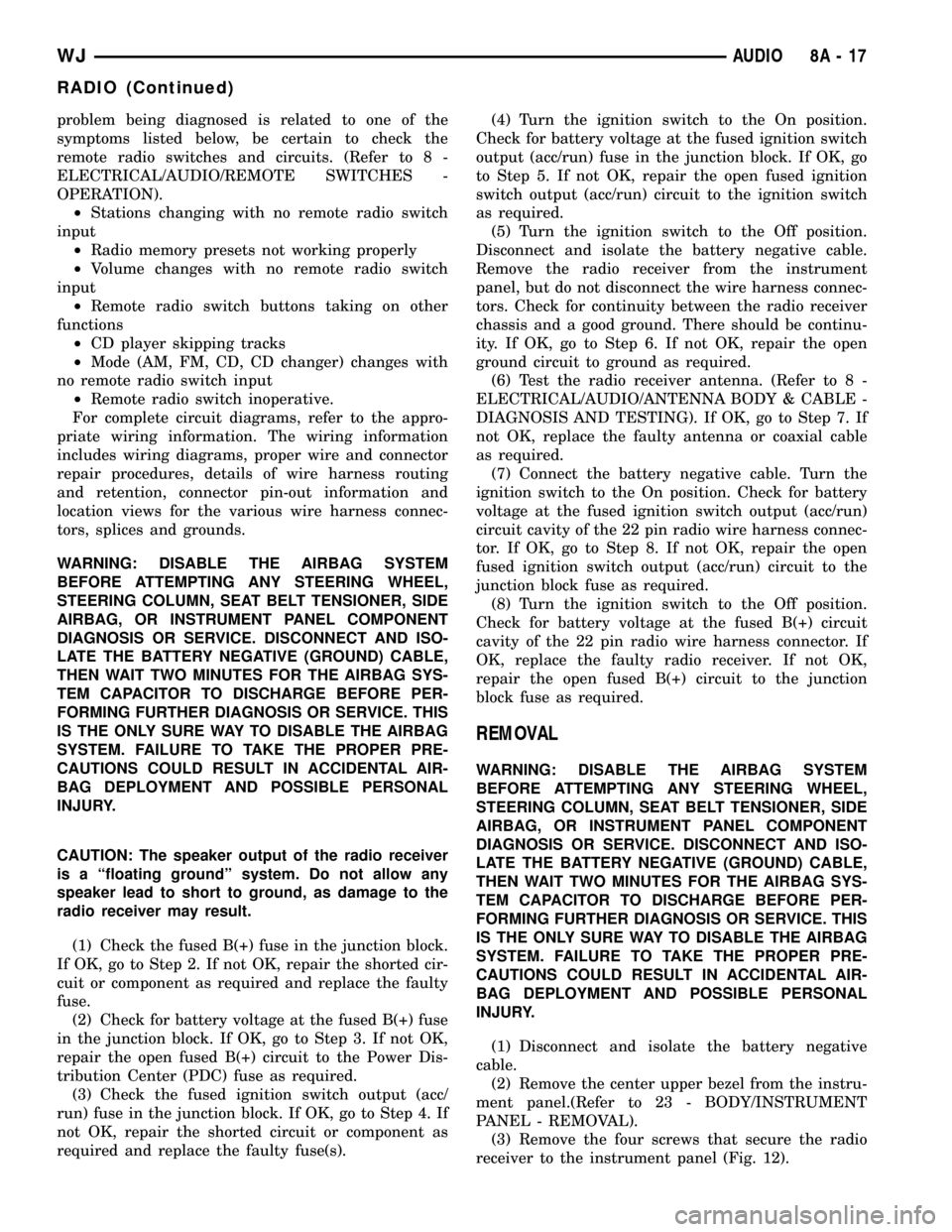

(2) Remove the center upper bezel from the instru-

ment panel.(Refer to 23 - BODY/INSTRUMENT

PANEL - REMOVAL).

(3) Remove the four screws that secure the radio

receiver to the instrument panel (Fig. 12).

WJAUDIO 8A - 17

RADIO (Continued)

Page 297 of 2199

(4) Disconnect the instrument panel wire harness

connectors and the antenna coaxial cable connector

from the receptacles on the rear of the radio receiver.

(5) Remove the radio receiver from the instrument

panel.

INSTALLATION

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the radio receiver to the instrument

panel.

(2) Reconnect the instrument panel wire harness

connectors and the antenna coaxial cable connector

to the receptacles on the rear of the radio receiver.

(3) Install the four mounting screws. Tighten the

screws to 2.2 N´m (20 in. lbs.).(4) Install the center upper bezel onto the instru-

ment panel. (Refer to 23 - BODY/INSTRUMENT

PANEL - INSTALLATION) for the procedures.

(5) Reconnect the battery negative cable.

RADIO NOISE SUPPRESSION

GROUND STRAP

DESCRIPTION

Radio Frequency Interference (RFI) and Electro-

Magnetic Interference (EMI) noise suppression is

accomplished primarily through circuitry internal to

the radio receivers. These internal suppression

devices are only serviced as part of the radio receiver.

External suppression devices that are used on this

vehicle to control RFI or EMI noise include the fol-

lowing:

²Radio antenna base ground

²Radio receiver chassis ground wire or strap

²Engine-to-body ground strap(s)

²Exhaust system-to-body and transmission

ground strap (4.7L engines only)

²Resistor-type spark plugs

²Radio suppression-type secondary ignition wir-

ing.

For more information on the spark plugs and sec-

ondary ignition components, refer to Ignition System

in Ignition System.

REMOVAL

REMOVAL - ENGINE-TO-BODY GROUND

STRAP

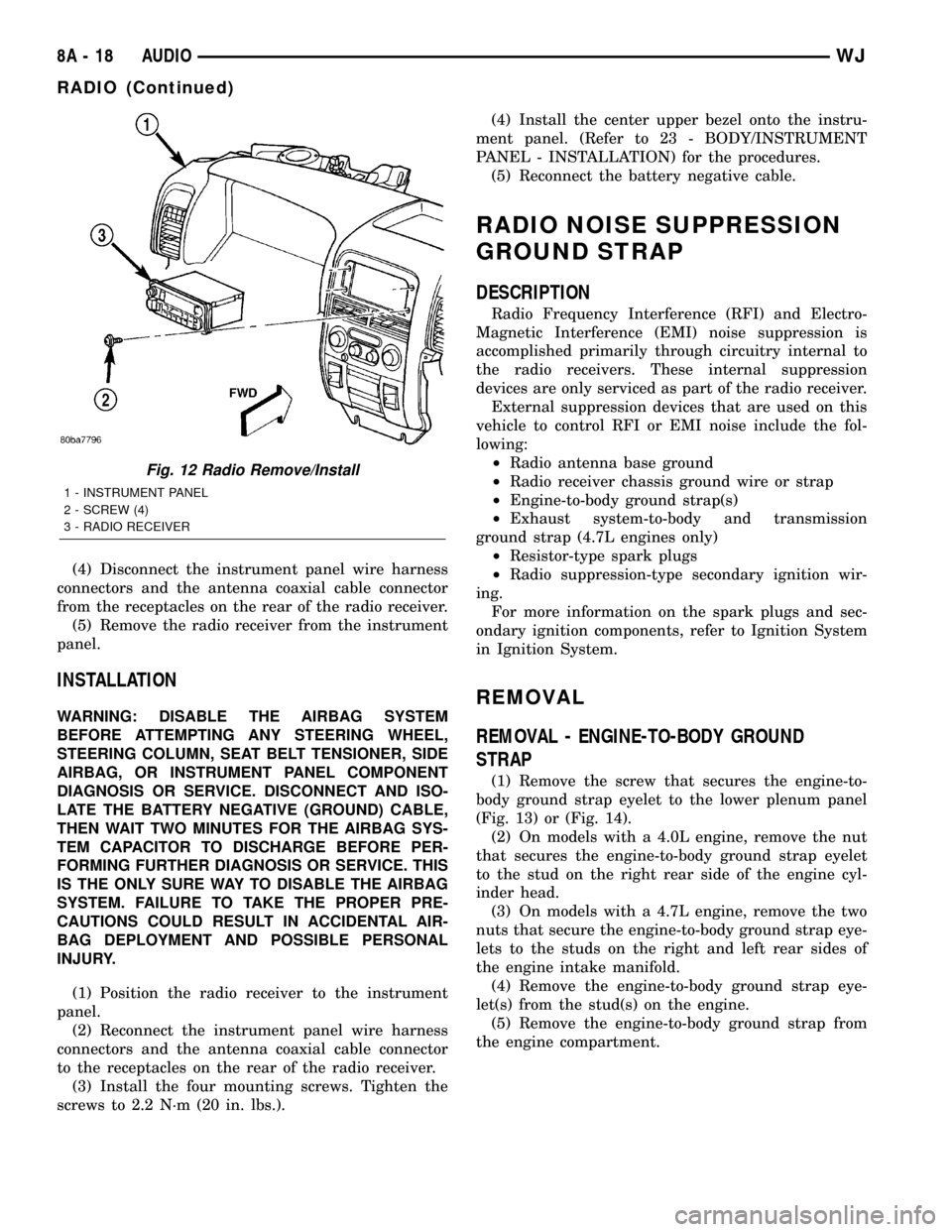

(1) Remove the screw that secures the engine-to-

body ground strap eyelet to the lower plenum panel

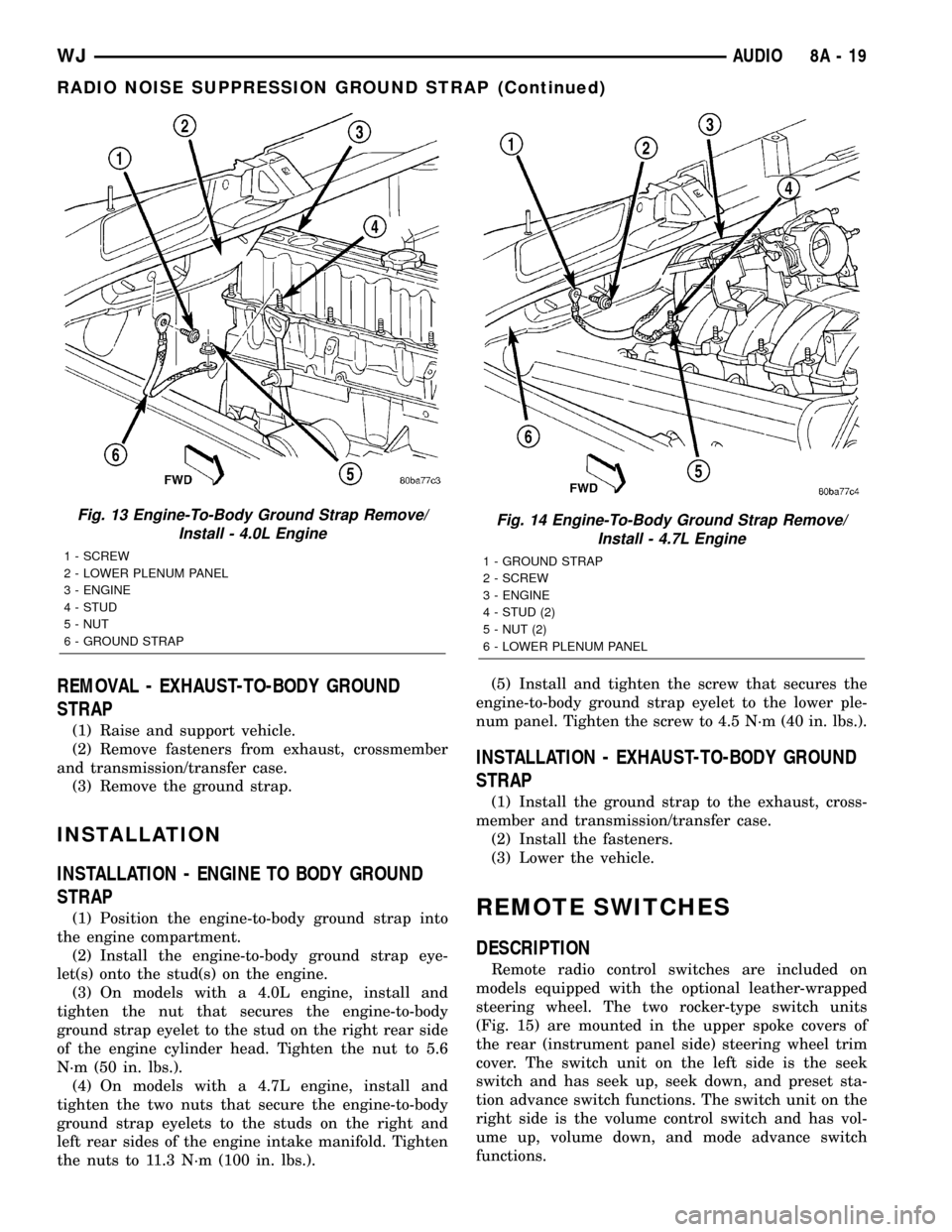

(Fig. 13) or (Fig. 14).

(2) On models with a 4.0L engine, remove the nut

that secures the engine-to-body ground strap eyelet

to the stud on the right rear side of the engine cyl-

inder head.

(3) On models with a 4.7L engine, remove the two

nuts that secure the engine-to-body ground strap eye-

lets to the studs on the right and left rear sides of

the engine intake manifold.

(4) Remove the engine-to-body ground strap eye-

let(s) from the stud(s) on the engine.

(5) Remove the engine-to-body ground strap from

the engine compartment.

Fig. 12 Radio Remove/Install

1 - INSTRUMENT PANEL

2 - SCREW (4)

3 - RADIO RECEIVER

8A - 18 AUDIOWJ

RADIO (Continued)

Page 298 of 2199

REMOVAL - EXHAUST-TO-BODY GROUND

STRAP

(1) Raise and support vehicle.

(2) Remove fasteners from exhaust, crossmember

and transmission/transfer case.

(3) Remove the ground strap.

INSTALLATION

INSTALLATION - ENGINE TO BODY GROUND

STRAP

(1) Position the engine-to-body ground strap into

the engine compartment.

(2) Install the engine-to-body ground strap eye-

let(s) onto the stud(s) on the engine.

(3) On models with a 4.0L engine, install and

tighten the nut that secures the engine-to-body

ground strap eyelet to the stud on the right rear side

of the engine cylinder head. Tighten the nut to 5.6

N´m (50 in. lbs.).

(4) On models with a 4.7L engine, install and

tighten the two nuts that secure the engine-to-body

ground strap eyelets to the studs on the right and

left rear sides of the engine intake manifold. Tighten

the nuts to 11.3 N´m (100 in. lbs.).(5) Install and tighten the screw that secures the

engine-to-body ground strap eyelet to the lower ple-

num panel. Tighten the screw to 4.5 N´m (40 in. lbs.).

INSTALLATION - EXHAUST-TO-BODY GROUND

STRAP

(1) Install the ground strap to the exhaust, cross-

member and transmission/transfer case.

(2) Install the fasteners.

(3) Lower the vehicle.

REMOTE SWITCHES

DESCRIPTION

Remote radio control switches are included on

models equipped with the optional leather-wrapped

steering wheel. The two rocker-type switch units

(Fig. 15) are mounted in the upper spoke covers of

the rear (instrument panel side) steering wheel trim

cover. The switch unit on the left side is the seek

switch and has seek up, seek down, and preset sta-

tion advance switch functions. The switch unit on the

right side is the volume control switch and has vol-

ume up, volume down, and mode advance switch

functions.

Fig. 13 Engine-To-Body Ground Strap Remove/

Install - 4.0L Engine

1 - SCREW

2 - LOWER PLENUM PANEL

3 - ENGINE

4 - STUD

5 - NUT

6 - GROUND STRAP

Fig. 14 Engine-To-Body Ground Strap Remove/

Install - 4.7L Engine

1 - GROUND STRAP

2 - SCREW

3 - ENGINE

4 - STUD (2)

5 - NUT (2)

6 - LOWER PLENUM PANEL

WJAUDIO 8A - 19

RADIO NOISE SUPPRESSION GROUND STRAP (Continued)

Page 303 of 2199

at the enable signal to amplifier circuit cavity of the

power amplifier wire harness connector. If OK, go to

Step 12. If not OK, repair the open enable signal to

amplifier circuit to the radio receiver as required.

(12) Turn the radio receiver off. Turn the ignition

switch to the Off position. Disconnect and isolate the

battery negative cable. For each inoperative speaker

location, check both the amplified feed (+) circuit and

the amplified return (±) circuit cavities of the power

amplifier wire harness connectors for continuity to

ground. In each case there should be no continuity. If

OK, go to Step 13. If not OK, repair the shorted

amplified feed (+) and/or amplified return (±) cir-

cuit(s) to the speaker as required.

(13) For each inoperative speaker location, check

the resistance between the amplified feed (+) circuit

and the amplified return (±) circuit cavities of the

power amplifier wire harness connectors. The meter

should read between 2 and 3 ohms (speaker resis-

tance). If OK, replace the faulty power amplifier. If

not OK, go to Step 14.

(14) Disconnect the speaker wire harness connec-

tor at the inoperative speaker. Check for continuity

between the amplified feed (+) circuit cavities of the

speaker wire harness connector and the power ampli-

fier wire harness connector. Repeat the check

between the amplified return (±) circuit cavities of

the speaker wire harness connector and the power

amplifier wire harness connector. In each case there

should be continuity. If OK, replace the faulty

speaker. If not OK, repair the open amplified feed (+)

and/or amplified return (±) circuit(s) as required.

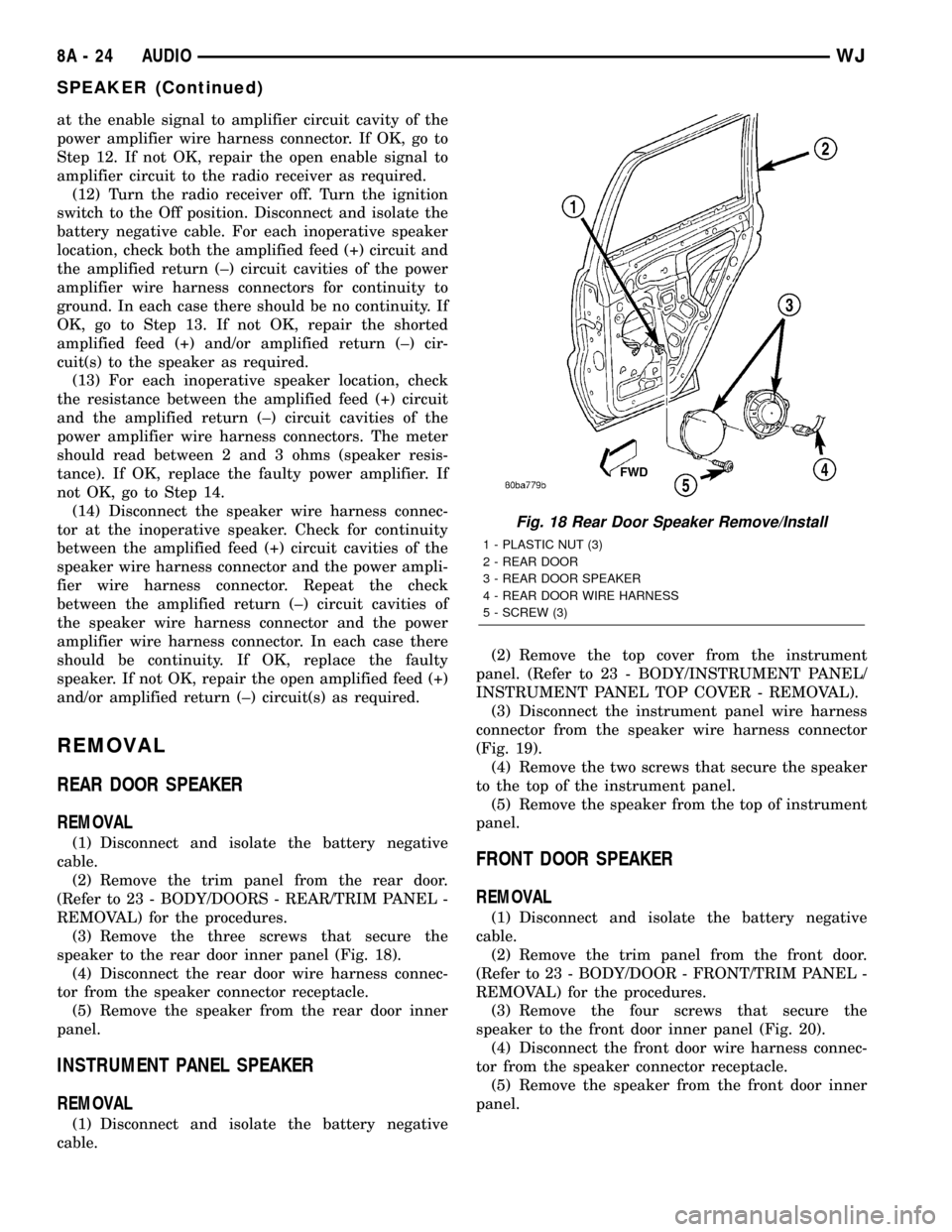

REMOVAL

REAR DOOR SPEAKER

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim panel from the rear door.

(Refer to 23 - BODY/DOORS - REAR/TRIM PANEL -

REMOVAL) for the procedures.

(3) Remove the three screws that secure the

speaker to the rear door inner panel (Fig. 18).

(4) Disconnect the rear door wire harness connec-

tor from the speaker connector receptacle.

(5) Remove the speaker from the rear door inner

panel.

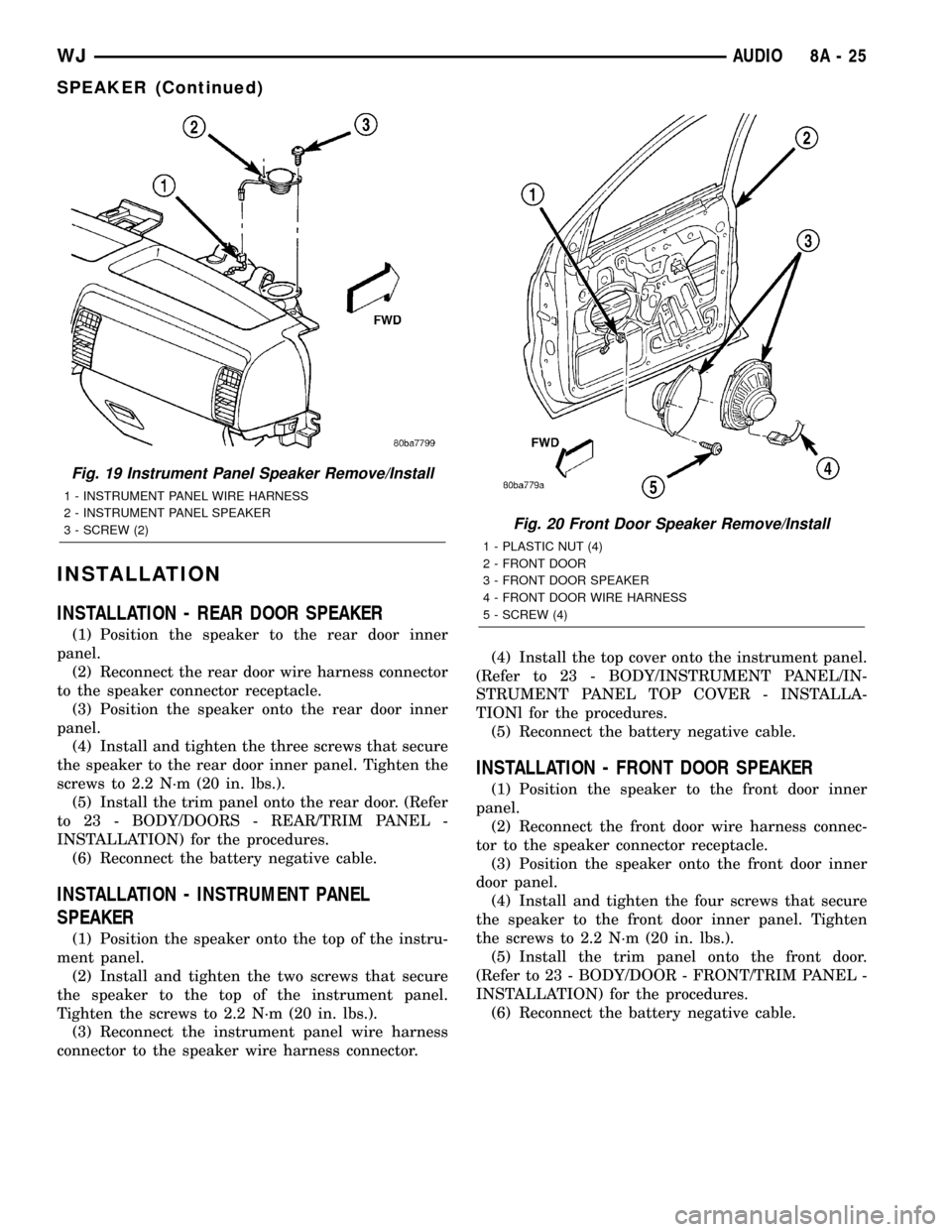

INSTRUMENT PANEL SPEAKER

REMOVAL

(1) Disconnect and isolate the battery negative

cable.(2) Remove the top cover from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL TOP COVER - REMOVAL).

(3) Disconnect the instrument panel wire harness

connector from the speaker wire harness connector

(Fig. 19).

(4) Remove the two screws that secure the speaker

to the top of the instrument panel.

(5) Remove the speaker from the top of instrument

panel.

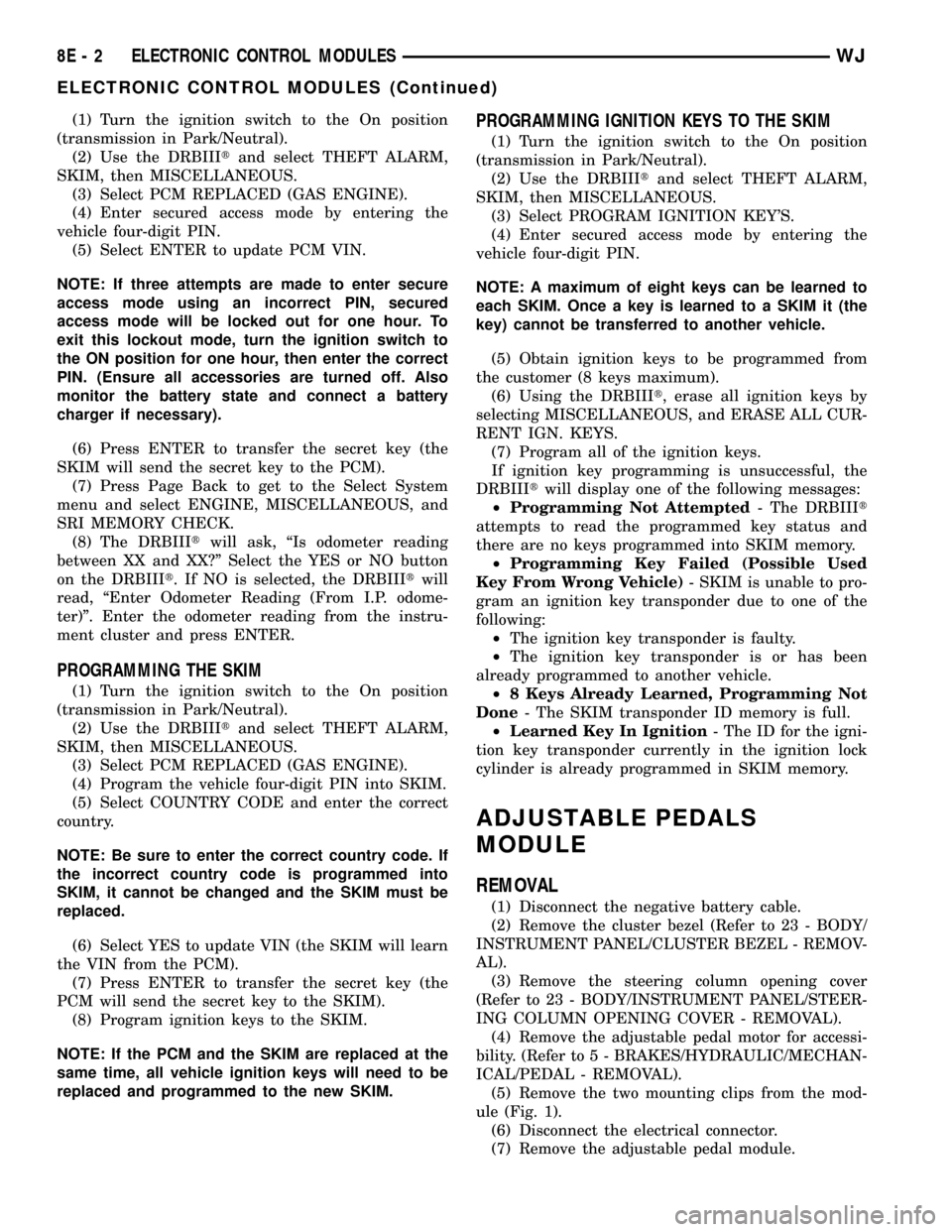

FRONT DOOR SPEAKER

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim panel from the front door.

(Refer to 23 - BODY/DOOR - FRONT/TRIM PANEL -

REMOVAL) for the procedures.

(3) Remove the four screws that secure the

speaker to the front door inner panel (Fig. 20).

(4) Disconnect the front door wire harness connec-

tor from the speaker connector receptacle.

(5) Remove the speaker from the front door inner

panel.

Fig. 18 Rear Door Speaker Remove/Install

1 - PLASTIC NUT (3)

2 - REAR DOOR

3 - REAR DOOR SPEAKER

4 - REAR DOOR WIRE HARNESS

5 - SCREW (3)

8A - 24 AUDIOWJ

SPEAKER (Continued)

Page 304 of 2199

INSTALLATION

INSTALLATION - REAR DOOR SPEAKER

(1) Position the speaker to the rear door inner

panel.

(2) Reconnect the rear door wire harness connector

to the speaker connector receptacle.

(3) Position the speaker onto the rear door inner

panel.

(4) Install and tighten the three screws that secure

the speaker to the rear door inner panel. Tighten the

screws to 2.2 N´m (20 in. lbs.).

(5) Install the trim panel onto the rear door. (Refer

to 23 - BODY/DOORS - REAR/TRIM PANEL -

INSTALLATION) for the procedures.

(6) Reconnect the battery negative cable.

INSTALLATION - INSTRUMENT PANEL

SPEAKER

(1) Position the speaker onto the top of the instru-

ment panel.

(2) Install and tighten the two screws that secure

the speaker to the top of the instrument panel.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(3) Reconnect the instrument panel wire harness

connector to the speaker wire harness connector.(4) Install the top cover onto the instrument panel.

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL TOP COVER - INSTALLA-

TIONl for the procedures.

(5) Reconnect the battery negative cable.

INSTALLATION - FRONT DOOR SPEAKER

(1) Position the speaker to the front door inner

panel.

(2) Reconnect the front door wire harness connec-

tor to the speaker connector receptacle.

(3) Position the speaker onto the front door inner

door panel.

(4) Install and tighten the four screws that secure

the speaker to the front door inner panel. Tighten

the screws to 2.2 N´m (20 in. lbs.).

(5) Install the trim panel onto the front door.

(Refer to 23 - BODY/DOOR - FRONT/TRIM PANEL -

INSTALLATION) for the procedures.

(6) Reconnect the battery negative cable.

Fig. 19 Instrument Panel Speaker Remove/Install

1 - INSTRUMENT PANEL WIRE HARNESS

2 - INSTRUMENT PANEL SPEAKER

3 - SCREW (2)

Fig. 20 Front Door Speaker Remove/Install

1 - PLASTIC NUT (4)

2 - FRONT DOOR

3 - FRONT DOOR SPEAKER

4 - FRONT DOOR WIRE HARNESS

5 - SCREW (4)

WJAUDIO 8A - 25

SPEAKER (Continued)

Page 311 of 2199

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

(5) Select ENTER to update PCM VIN.

NOTE: If three attempts are made to enter secure

access mode using an incorrect PIN, secured

access mode will be locked out for one hour. To

exit this lockout mode, turn the ignition switch to

the ON position for one hour, then enter the correct

PIN. (Ensure all accessories are turned off. Also

monitor the battery state and connect a battery

charger if necessary).

(6) Press ENTER to transfer the secret key (the

SKIM will send the secret key to the PCM).

(7) Press Page Back to get to the Select System

menu and select ENGINE, MISCELLANEOUS, and

SRI MEMORY CHECK.

(8) The DRBIIItwill ask, ªIs odometer reading

between XX and XX?º Select the YES or NO button

on the DRBIIIt. If NO is selected, the DRBIIItwill

read, ªEnter Odometer Reading (From I.P. odome-

ter)º. Enter the odometer reading from the instru-

ment cluster and press ENTER.

PROGRAMMING THE SKIM

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Program the vehicle four-digit PIN into SKIM.

(5) Select COUNTRY CODE and enter the correct

country.

NOTE: Be sure to enter the correct country code. If

the incorrect country code is programmed into

SKIM, it cannot be changed and the SKIM must be

replaced.

(6) Select YES to update VIN (the SKIM will learn

the VIN from the PCM).

(7) Press ENTER to transfer the secret key (the

PCM will send the secret key to the SKIM).

(8) Program ignition keys to the SKIM.

NOTE: If the PCM and the SKIM are replaced at the

same time, all vehicle ignition keys will need to be

replaced and programmed to the new SKIM.

PROGRAMMING IGNITION KEYS TO THE SKIM

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PROGRAM IGNITION KEY'S.

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

NOTE: A maximum of eight keys can be learned to

each SKIM. Once a key is learned to a SKIM it (the

key) cannot be transferred to another vehicle.

(5) Obtain ignition keys to be programmed from

the customer (8 keys maximum).

(6) Using the DRBIIIt, erase all ignition keys by

selecting MISCELLANEOUS, and ERASE ALL CUR-

RENT IGN. KEYS.

(7) Program all of the ignition keys.

If ignition key programming is unsuccessful, the

DRBIIItwill display one of the following messages:

²Programming Not Attempted- The DRBIIIt

attempts to read the programmed key status and

there are no keys programmed into SKIM memory.

²Programming Key Failed (Possible Used

Key From Wrong Vehicle)- SKIM is unable to pro-

gram an ignition key transponder due to one of the

following:

²The ignition key transponder is faulty.

²The ignition key transponder is or has been

already programmed to another vehicle.

²8 Keys Already Learned, Programming Not

Done- The SKIM transponder ID memory is full.

²Learned Key In Ignition- The ID for the igni-

tion key transponder currently in the ignition lock

cylinder is already programmed in SKIM memory.

ADJUSTABLE PEDALS

MODULE

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(4) Remove the adjustable pedal motor for accessi-

bility. (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/PEDAL - REMOVAL).

(5) Remove the two mounting clips from the mod-

ule (Fig. 1).

(6) Disconnect the electrical connector.

(7) Remove the adjustable pedal module.

8E - 2 ELECTRONIC CONTROL MODULESWJ

ELECTRONIC CONTROL MODULES (Continued)

Page 314 of 2199

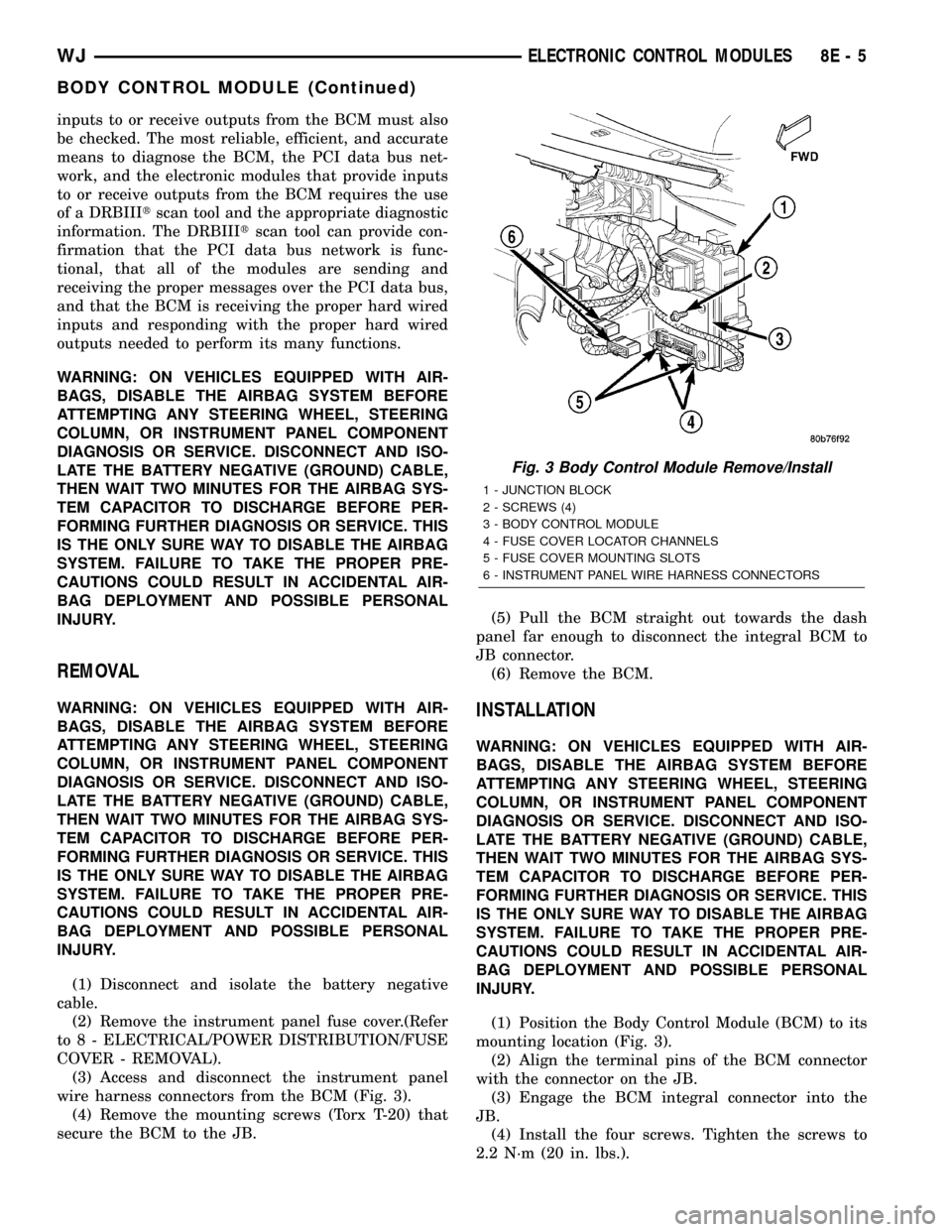

inputs to or receive outputs from the BCM must also

be checked. The most reliable, efficient, and accurate

means to diagnose the BCM, the PCI data bus net-

work, and the electronic modules that provide inputs

to or receive outputs from the BCM requires the use

of a DRBIIItscan tool and the appropriate diagnostic

information. The DRBIIItscan tool can provide con-

firmation that the PCI data bus network is func-

tional, that all of the modules are sending and

receiving the proper messages over the PCI data bus,

and that the BCM is receiving the proper hard wired

inputs and responding with the proper hard wired

outputs needed to perform its many functions.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel fuse cover.(Refer

to 8 - ELECTRICAL/POWER DISTRIBUTION/FUSE

COVER - REMOVAL).

(3) Access and disconnect the instrument panel

wire harness connectors from the BCM (Fig. 3).

(4) Remove the mounting screws (Torx T-20) that

secure the BCM to the JB.(5) Pull the BCM straight out towards the dash

panel far enough to disconnect the integral BCM to

JB connector.

(6) Remove the BCM.INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the Body Control Module (BCM) to its

mounting location (Fig. 3).

(2) Align the terminal pins of the BCM connector

with the connector on the JB.

(3) Engage the BCM integral connector into the

JB.

(4) Install the four screws. Tighten the screws to

2.2 N´m (20 in. lbs.).

Fig. 3 Body Control Module Remove/Install

1 - JUNCTION BLOCK

2 - SCREWS (4)

3 - BODY CONTROL MODULE

4 - FUSE COVER LOCATOR CHANNELS

5 - FUSE COVER MOUNTING SLOTS

6 - INSTRUMENT PANEL WIRE HARNESS CONNECTORS

WJELECTRONIC CONTROL MODULES 8E - 5

BODY CONTROL MODULE (Continued)

Page 327 of 2199

sponder through a tuned antenna ring integral to the

SKIM housing. If this antenna ring is not mounted

properly around the ignition lock cylinder housing,

communication problems between the SKIM and the

transponder may arise. These communication prob-

lems will result in Sentry Key transponder-related

faults. The SKIM also communicates over the Pro-

grammable Communications Interface (PCI) data bus

with the Powertrain Control Module (PCM), the Elec-

troMechanical Instrument Cluster (EMIC), the Body

Control Module (BCM), and/or the DRBIIItscan tool.

The SKIM retains in memory the ID numbers of

any Sentry Key transponder that is programmed into

it. A maximum of eight transponders can be pro-

grammed into the SKIM. For added system security,

each SKIM is programmed with a unique Secret Key

code. This code is stored in memory, sent over the

PCI data bus to the PCM, and is encoded to the tran-

sponder of every Sentry Key that is programmed into

the SKIM. Another security code, called a PIN, is

used to gain access to the SKIM Secured Access

Mode. The Secured Access Mode is required during

service to perform the SKIS initialization and Sentry

Key transponder programming procedures. The

SKIM also stores the Vehicle Identification Number

(VIN) in its memory, which it learns through a PCI

data bus message from the PCM during SKIS initial-

ization.

In the event that a SKIM replacement is required,

the Secret Key code can be transferred to the new

SKIM from the PCM using the DRBIIItscan tool

and the SKIS replacement procedure. Proper comple-

tion of the SKIS initialization will allow the existing

Sentry Keys to be programmed into the new SKIM so

that new keys will not be required. In the event that

the original Secret Key code cannot be recovered,

SKIM replacement will also require new Sentry

Keys. The DRBIIItscan tool will alert the technician

during the SKIS replacement procedure if new Sen-

try Keys are required.

When the ignition switch is turned to the On posi-

tion, the SKIM transmits an RF signal to the tran-

sponder in the ignition key. The SKIM then waits for

an RF signal response from the transponder. If the

response received identifies the key as valid, the

SKIM sends a valid key message to the PCM over

the PCI data bus. If the response received identifies

the key as invalid, or if no response is received from

the key transponder, the SKIM sends an invalid key

message to the PCM. The PCM will enable or disable

engine operation based upon the status of the SKIM

messages. It is important to note that the default

condition in the PCM is an invalid key; therefore, if

no message is received from the SKIM by the PCM,

the engine will be disabled and the vehicle immobi-

lized after two seconds of running.The SKIM also sends indicator light status mes-

sages to the EMIC over the PCI data bus to tell the

EMIC how to operate the SKIS indicator. This indi-

cator light status message tells the EMIC to turn the

indicator on for about three seconds each time the

ignition switch is turned to the On position as a bulb

test. After completion of the bulb test, the SKIM

sends indicator light status messages to the EMIC to

turn the indicator off, turn the indicator on, or to

flash the indicator on and off. If the SKIS indicator

lamp flashes or stays on solid after the bulb test, it

signifies a SKIS fault. If the SKIM detects a system

malfunction and/or the SKIS has become inoperative,

the SKIS indicator will stay on solid. If the SKIM

detects an invalid key or if a key transponder-related

fault exists, the SKIS indicator will flash. If the vehi-

cle is equipped with the Customer Learn transponder

programming feature, the SKIM will also send mes-

sages to the EMIC to flash the SKIS indicator lamp,

and to the BCM to generate a single audible chime

tone whenever the Customer Learn programming

mode is being utilized. (Refer to 8 - ELECTRICAL/

VEHICLE THEFT SECURITY - STANDARD PRO-

CEDURE - SENTRY KEY TRANSPONDER

PROGRAMMING).

The SKIS performs a self-test each time the igni-

tion switch is turned to the On position, and will

store fault information in the form of Diagnostic

Trouble Codes (DTC's) in SKIM memory if a system

malfunction is detected. The SKIM can be diagnosed,

and any stored DTC's can be retrieved using a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

8E - 18 ELECTRONIC CONTROL MODULESWJ

SENTRY KEY IMMOBILIZER MODULE (Continued)

Page 328 of 2199

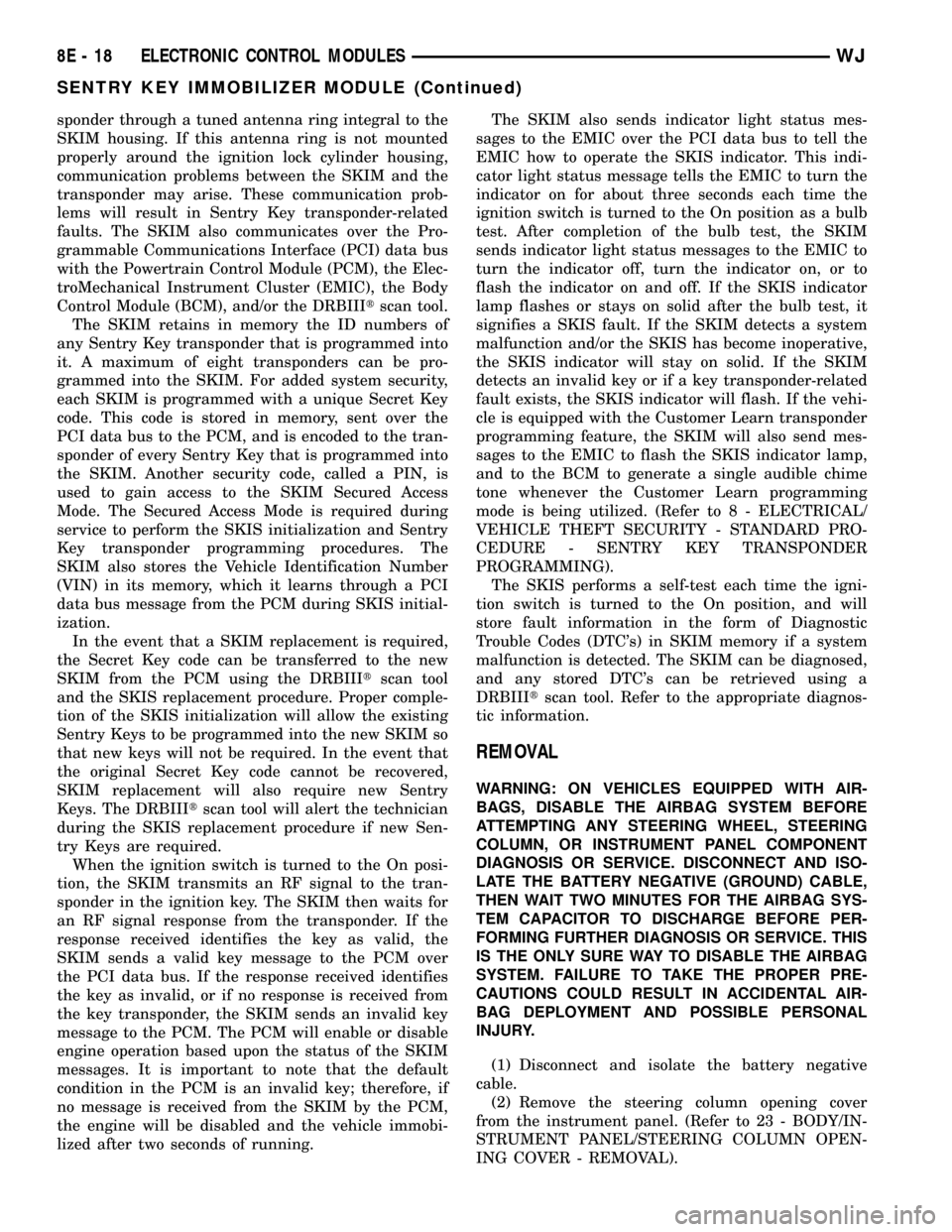

(3) Disconnect the instrument panel wire harness

connector from the SKIM connector.

(4) Remove the screw that secures the SKIM to

the bottom of the steering column housing (Fig. 16).

(5) Disengage the antenna ring of the SKIM from

around the ignition lock cylinder housing.

(6) Remove the SKIM from the steering column.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the SKIM to the underside of the

steering column (Fig. 16).

(2) Engage the antenna ring of the SKIM around

the ignition lock cylinder housing.

(3) Install and tighten the screw that secures the

SKIM to the bottom of the steering column hous-

ing.Tighten the screw to 3.4 N´m (30 in lbs.).

(4) Reconnect the instrument panel wire harness

connector to the SKIM connector.(5) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(6) Reconnect the battery negative cable.

(7) Perform the SKIS Replacement procedure

using the DRBIIIt.

(8) Perform the SKIS Initialization Procedure

using the DRBIIIt.

TRANSMISSION CONTROL

MODULE

DESCRIPTION

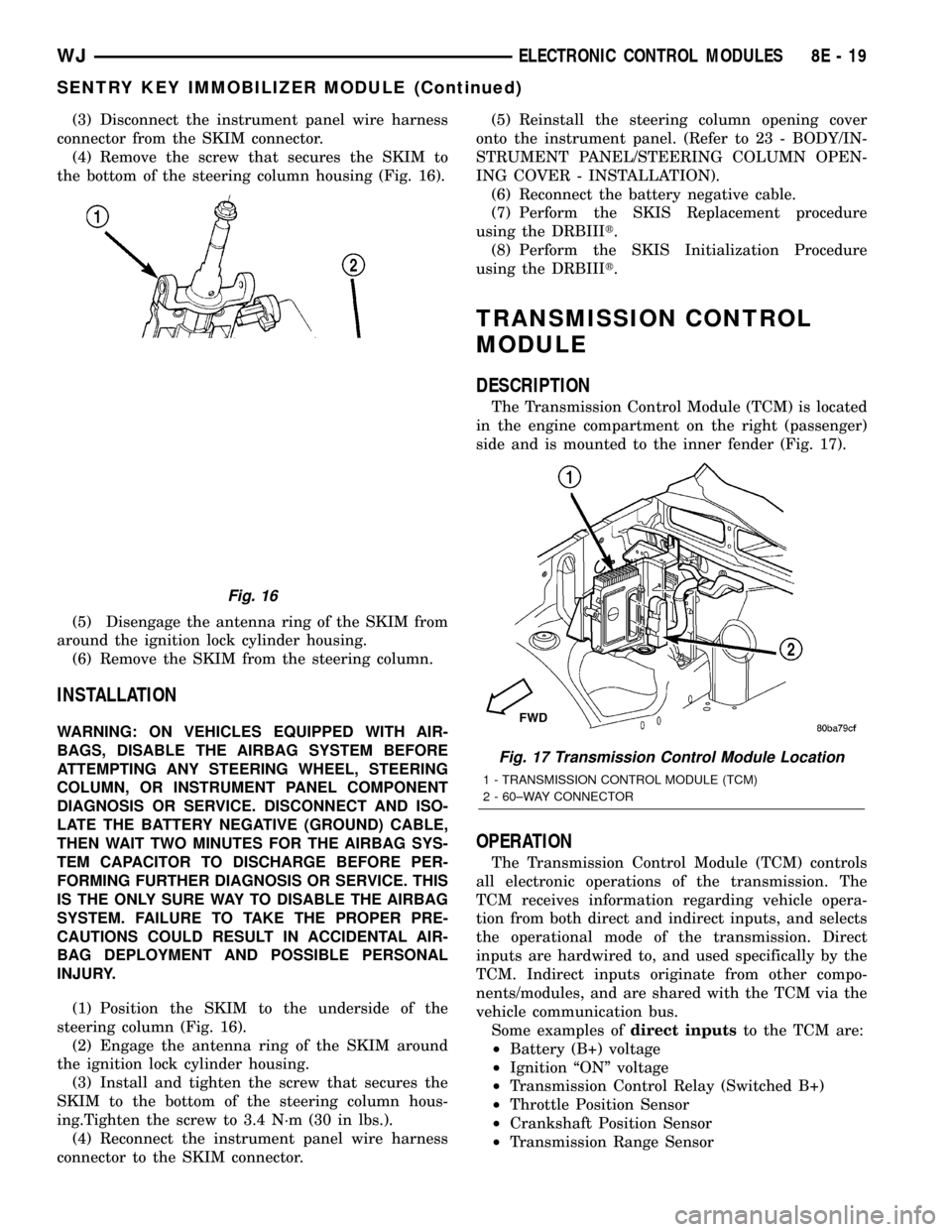

The Transmission Control Module (TCM) is located

in the engine compartment on the right (passenger)

side and is mounted to the inner fender (Fig. 17).

OPERATION

The Transmission Control Module (TCM) controls

all electronic operations of the transmission. The

TCM receives information regarding vehicle opera-

tion from both direct and indirect inputs, and selects

the operational mode of the transmission. Direct

inputs are hardwired to, and used specifically by the

TCM. Indirect inputs originate from other compo-

nents/modules, and are shared with the TCM via the

vehicle communication bus.

Some examples ofdirect inputsto the TCM are:

²Battery (B+) voltage

²Ignition ªONº voltage

²Transmission Control Relay (Switched B+)

²Throttle Position Sensor

²Crankshaft Position Sensor

²Transmission Range Sensor

Fig. 16

Fig. 17 Transmission Control Module Location

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - 60±WAY CONNECTOR

WJELECTRONIC CONTROL MODULES 8E - 19

SENTRY KEY IMMOBILIZER MODULE (Continued)