Tire sensor JEEP GRAND CHEROKEE 2003 WJ / 2.G Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 627 of 2199

(1) Position the Rain Sensor Module (RSM) above

the inside rear view mirror (Fig. 15).

(2) Reconnect the overhead wire harness connector

for the RSM to the module connector receptacle.

(3) Position the RSM to the bracket on the wind-

shield above the inside rear view mirror.

(4) Using hand pressure, press the spring clips on

each side of the RSM until they snap over the

bracket on the windshield.

NOTE: The spring clips on the RSM will become

deformed after numerous (about ten) removal and

installation cycles. If the spring clips become

deformed, the RSM must be replaced with a new

unit.

(5) Align and engage the top of the trim cover over

the top of the RSM.

(6) Using hand pressure, press the bottom of the

trim cover toward the windshield glass until it snaps

over the bottom of the RSM.

(7) Reconnect the battery negative cable.

RIGHT MULTI-FUNCTION

SWITCH

DESCRIPTION

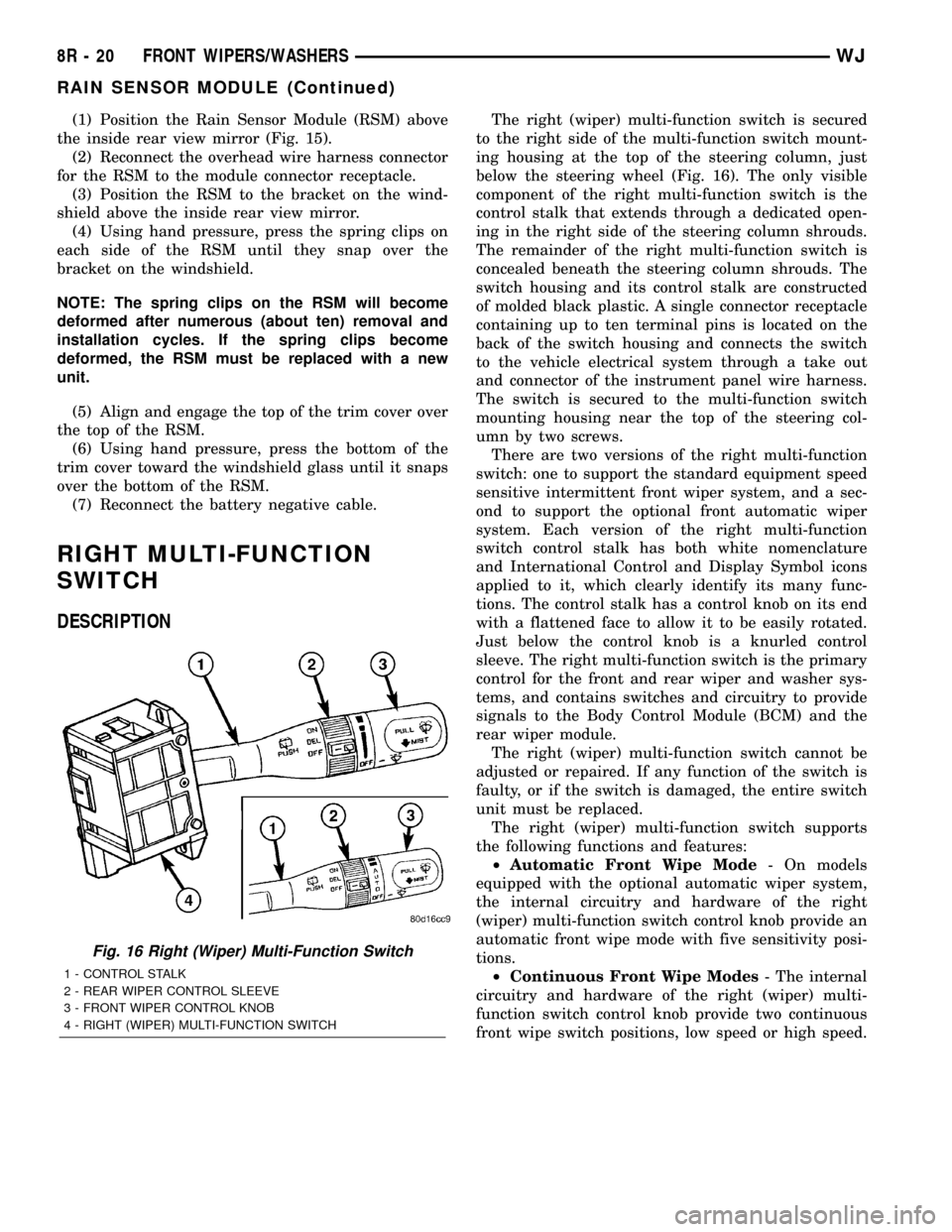

The right (wiper) multi-function switch is secured

to the right side of the multi-function switch mount-

ing housing at the top of the steering column, just

below the steering wheel (Fig. 16). The only visible

component of the right multi-function switch is the

control stalk that extends through a dedicated open-

ing in the right side of the steering column shrouds.

The remainder of the right multi-function switch is

concealed beneath the steering column shrouds. The

switch housing and its control stalk are constructed

of molded black plastic. A single connector receptacle

containing up to ten terminal pins is located on the

back of the switch housing and connects the switch

to the vehicle electrical system through a take out

and connector of the instrument panel wire harness.

The switch is secured to the multi-function switch

mounting housing near the top of the steering col-

umn by two screws.

There are two versions of the right multi-function

switch: one to support the standard equipment speed

sensitive intermittent front wiper system, and a sec-

ond to support the optional front automatic wiper

system. Each version of the right multi-function

switch control stalk has both white nomenclature

and International Control and Display Symbol icons

applied to it, which clearly identify its many func-

tions. The control stalk has a control knob on its end

with a flattened face to allow it to be easily rotated.

Just below the control knob is a knurled control

sleeve. The right multi-function switch is the primary

control for the front and rear wiper and washer sys-

tems, and contains switches and circuitry to provide

signals to the Body Control Module (BCM) and the

rear wiper module.

The right (wiper) multi-function switch cannot be

adjusted or repaired. If any function of the switch is

faulty, or if the switch is damaged, the entire switch

unit must be replaced.

The right (wiper) multi-function switch supports

the following functions and features:

²Automatic Front Wipe Mode- On models

equipped with the optional automatic wiper system,

the internal circuitry and hardware of the right

(wiper) multi-function switch control knob provide an

automatic front wipe mode with five sensitivity posi-

tions.

²Continuous Front Wipe Modes- The internal

circuitry and hardware of the right (wiper) multi-

function switch control knob provide two continuous

front wipe switch positions, low speed or high speed.

Fig. 16 Right (Wiper) Multi-Function Switch

1 - CONTROL STALK

2 - REAR WIPER CONTROL SLEEVE

3 - FRONT WIPER CONTROL KNOB

4 - RIGHT (WIPER) MULTI-FUNCTION SWITCH

8R - 20 FRONT WIPERS/WASHERSWJ

RAIN SENSOR MODULE (Continued)

Page 1372 of 2199

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. (Refer to 9 - ENGINE - DIAGNOSIS AND

TESTING), under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

DIAGNOSIS AND TESTINGÐENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat inspection.If the oil leak source is not pos-

itively identified at this time, proceed with the air

leak detection test method.

Air Leak Detection Test Method

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(5) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

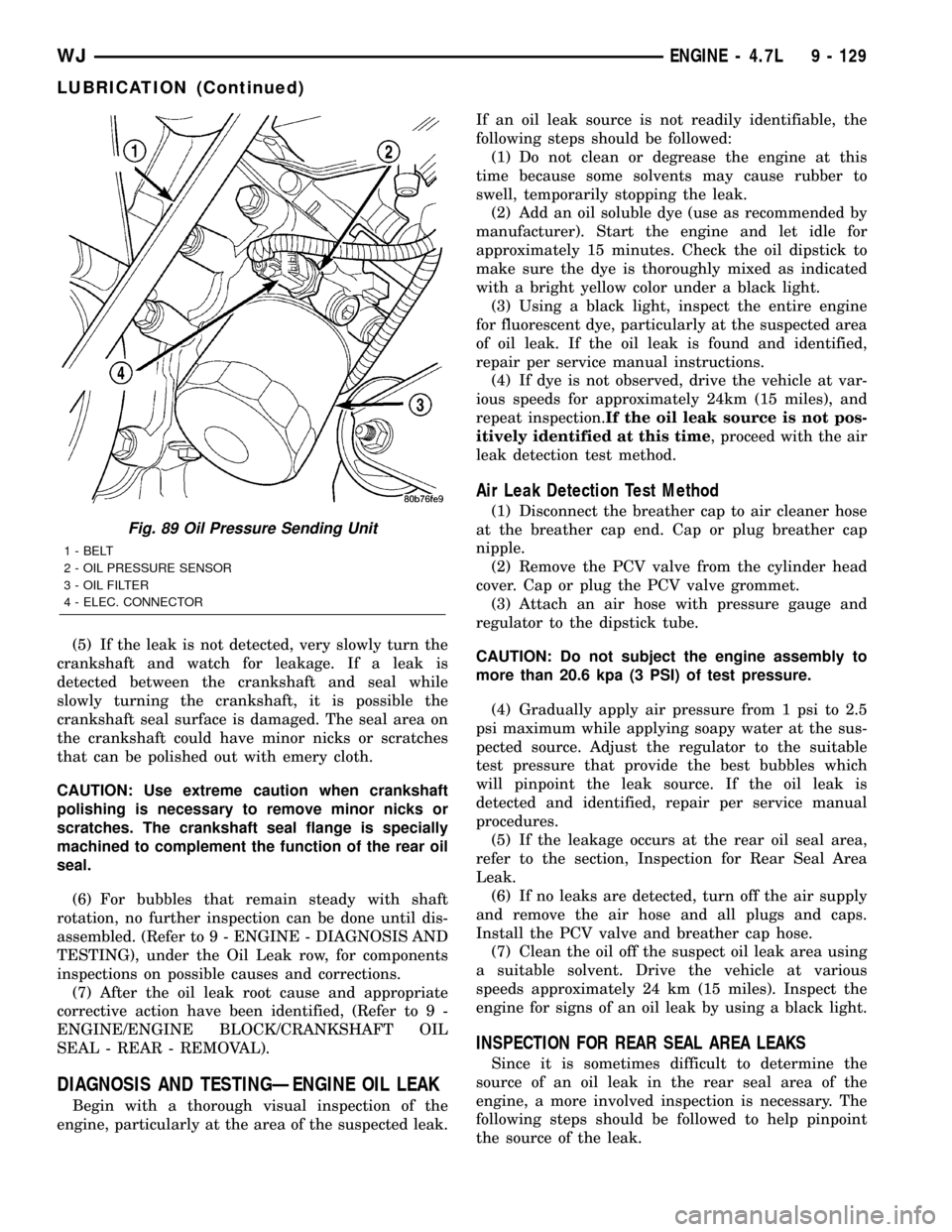

Fig. 89 Oil Pressure Sending Unit

1 - BELT

2 - OIL PRESSURE SENSOR

3 - OIL FILTER

4 - ELEC. CONNECTOR

WJENGINE - 4.7L 9 - 129

LUBRICATION (Continued)

Page 1432 of 2199

(e) Use DRB scan tool to power fuel pump. If

pressure is now within specifications, replace fuel

filter/fuel pressure regulator.

(f) If pressure is still low, replace fuel pump

module.

(4) If operating pressure is above 54.2 psi, electric

fuel pump is OK, but fuel pressure regulator is defec-

tive. Replace fuel filter/fuel pressure regulator.

(5) Install test port cap to fuel rail test port.

FUEL PUMP MODULE

DESCRIPTION

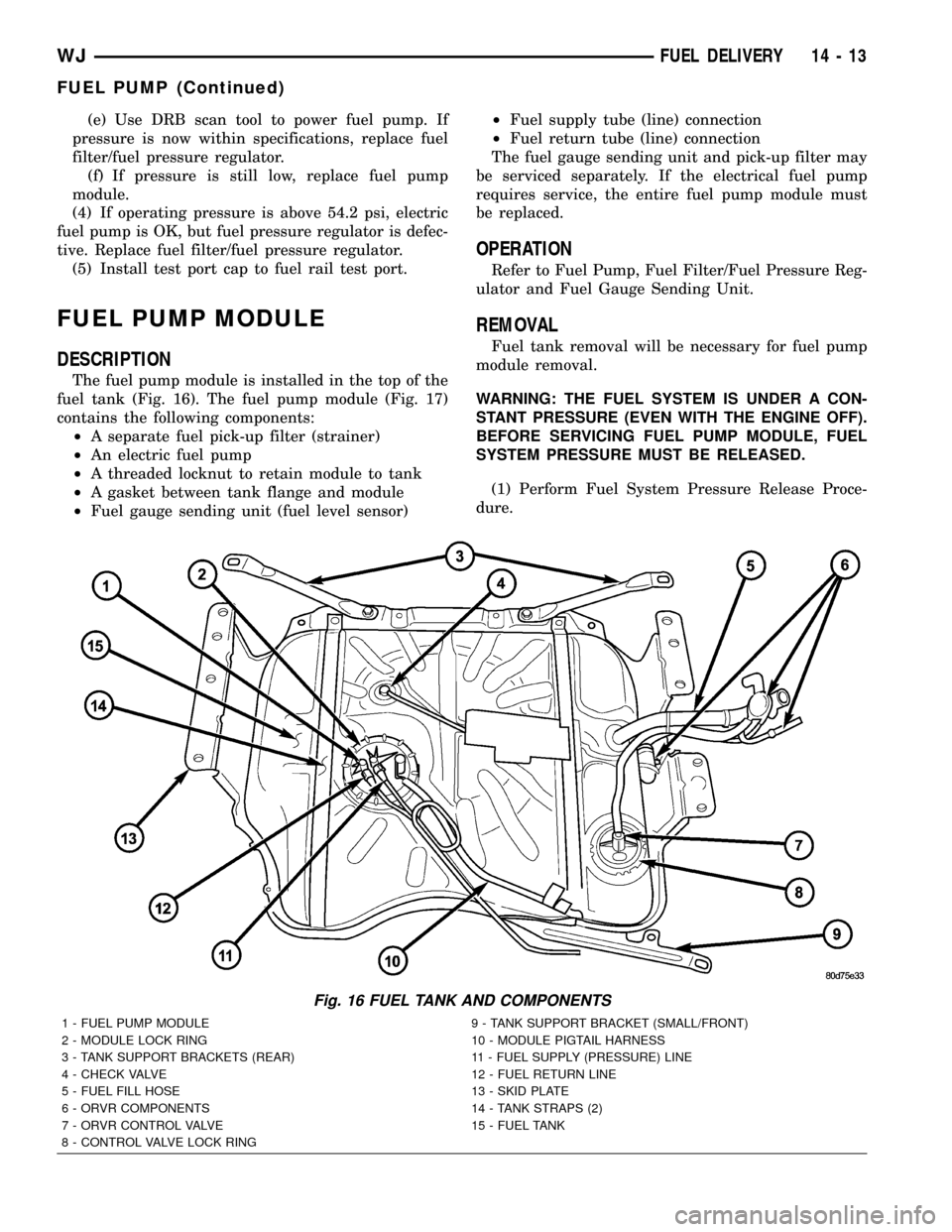

The fuel pump module is installed in the top of the

fuel tank (Fig. 16). The fuel pump module (Fig. 17)

contains the following components:

²A separate fuel pick-up filter (strainer)

²An electric fuel pump

²A threaded locknut to retain module to tank

²A gasket between tank flange and module

²Fuel gauge sending unit (fuel level sensor)²Fuel supply tube (line) connection

²Fuel return tube (line) connection

The fuel gauge sending unit and pick-up filter may

be serviced separately. If the electrical fuel pump

requires service, the entire fuel pump module must

be replaced.

OPERATION

Refer to Fuel Pump, Fuel Filter/Fuel Pressure Reg-

ulator and Fuel Gauge Sending Unit.

REMOVAL

Fuel tank removal will be necessary for fuel pump

module removal.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING FUEL PUMP MODULE, FUEL

SYSTEM PRESSURE MUST BE RELEASED.

(1) Perform Fuel System Pressure Release Proce-

dure.

Fig. 16 FUEL TANK AND COMPONENTS

1 - FUEL PUMP MODULE 9 - TANK SUPPORT BRACKET (SMALL/FRONT)

2 - MODULE LOCK RING 10 - MODULE PIGTAIL HARNESS

3 - TANK SUPPORT BRACKETS (REAR) 11 - FUEL SUPPLY (PRESSURE) LINE

4 - CHECK VALVE 12 - FUEL RETURN LINE

5 - FUEL FILL HOSE 13 - SKID PLATE

6 - ORVR COMPONENTS 14 - TANK STRAPS (2)

7 - ORVR CONTROL VALVE 15 - FUEL TANK

8 - CONTROL VALVE LOCK RING

WJFUEL DELIVERY 14 - 13

FUEL PUMP (Continued)

Page 1546 of 2199

REMOVAL

The overdrive unit can be removed and serviced

separately. It is not necessary to remove the entire

transmission assembly to perform overdrive unit

repairs.

If only the overdrive unit requires service, refer to

Overdrive Removal for proper procedures.

CAUTION: The transmission and torque converter

must be removed as an assembly to avoid compo-

nent damage. The converter driveplate, pump bush-

ing, or oil seal can be damaged if the converter is

left attached to the driveplate during removal. Be

sure to remove the transmission and converter as

an assembly.

(1) Disconnect battery negative cable.

(2) Disconnect and lower or remove necessary

exhaust components.

(3) Disconnect fluid cooler lines at transmission.

(4) Remove starter motor. (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - REMOVAL)

(5) Disconnect and remove crankshaft position sen-

sor. (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION/CRANKSHAFT POSITION SENSOR -

REMOVAL) Retain sensor attaching bolts.

CAUTION: The crankshaft position sensor will be

damaged if the transmission is removed, or

installed, while the sensor is still bolted to the

engine block, or transmission (4.0L only). To avoid

damage, be sure to remove the sensor before

removing the transmission.

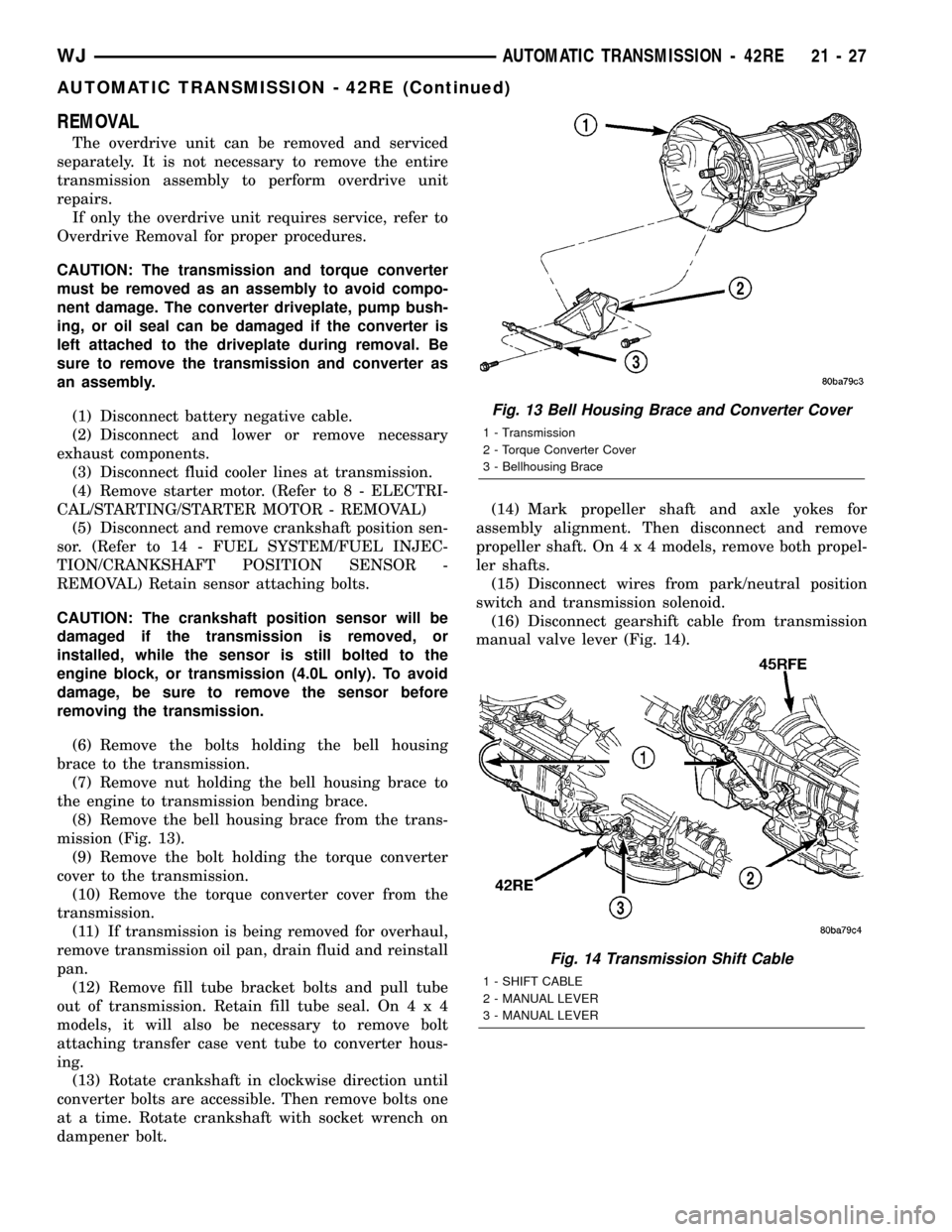

(6) Remove the bolts holding the bell housing

brace to the transmission.

(7) Remove nut holding the bell housing brace to

the engine to transmission bending brace.

(8) Remove the bell housing brace from the trans-

mission (Fig. 13).

(9) Remove the bolt holding the torque converter

cover to the transmission.

(10) Remove the torque converter cover from the

transmission.

(11) If transmission is being removed for overhaul,

remove transmission oil pan, drain fluid and reinstall

pan.

(12) Remove fill tube bracket bolts and pull tube

out of transmission. Retain fill tube seal. On4x4

models, it will also be necessary to remove bolt

attaching transfer case vent tube to converter hous-

ing.

(13) Rotate crankshaft in clockwise direction until

converter bolts are accessible. Then remove bolts one

at a time. Rotate crankshaft with socket wrench on

dampener bolt.(14) Mark propeller shaft and axle yokes for

assembly alignment. Then disconnect and remove

propeller shaft. On4x4models, remove both propel-

ler shafts.

(15) Disconnect wires from park/neutral position

switch and transmission solenoid.

(16) Disconnect gearshift cable from transmission

manual valve lever (Fig. 14).

Fig. 13 Bell Housing Brace and Converter Cover

1 - Transmission

2 - Torque Converter Cover

3 - Bellhousing Brace

Fig. 14 Transmission Shift Cable

1 - SHIFT CABLE

2 - MANUAL LEVER

3 - MANUAL LEVER

WJAUTOMATIC TRANSMISSION - 42RE 21 - 27

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1860 of 2199

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND

WHEEL RUNOUT......................1

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE AND

WHEEL BALANCE......................2

STANDARD PROCEDURE - MATCH

MOUNTING...........................4

STANDARD PROCEDURE - TIRE ROTATION . 5

STANDARD PROCEDURE - WHEEL

INSTALLATION........................5

TIRES

DESCRIPTION

DESCRIPTION - TIRES..................6

DESCRIPTION - RADIAL±PLY TIRES.......6

DESCRIPTION - TIRE INFLATION

PRESSURES..........................6

DESCRIPTION - TIRE PRESSURE FOR

HIGH SPEED..........................7

DESCRIPTION - REPLACEMENT TIRES.....7

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRESSURE

GAUGES.............................8

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS..........................8

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS...........................8

DIAGNOSIS AND TESTING - TIRE NOISE

OR VIBRATION........................8STANDARD PROCEDURE - REPAIRING

LEAKS...............................8

CLEANING.............................9

SPECIFICATIONS

TIRES...............................9

SPECIFICATIONS -.....................9

SPARE TIRE

DESCRIPTION - SPARE / TEMPORARY TIRE . . 10

WHEELS

DESCRIPTION.........................10

DIAGNOSIS AND TESTING - WHEEL

INSPECTION.........................10

STANDARD PROCEDURE - WHEEL

REPLACEMENT.......................10

SPECIFICATIONS

TORQUE CHART......................11

STUDS

REMOVAL.............................11

INSTALLATION.........................11

TIRE PRESSURE MONITORING

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING - TIRE PRESSURE

MONITORING SYSTEM.................12

SENSOR

REMOVAL - TIRE PRESSURE SENSOR/

TRANSMITTER.......................12

INSTALLATION - TIRE PRESSURE SENSOR/

TRANSMITTER.......................13

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

RUNOUT

Radial runout is the difference between the high

and low points on the tire or wheel (Fig. 1).

Lateral runout is thewobbleof the tire or wheel.

Radial runout of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral runout of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate

the wheel and tire assembly on the mounting studs

(See Method 1). If this does not reduce runout to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

METHOD 1 (RELOCATE WHEEL ON HUB)

(1) Drive vehicle a short distance to eliminate tire

flat spotting from a parked position.

(2) Check wheel bearings and adjust if adjustable

or replace if necessary.

(3) Check the wheel mounting surface.

(4) Relocate wheel on the mounting, two studs

over from the original position.

(5) Tighten wheel nuts until all are properly

torqued, to eliminate brake distortion.

(6) Check radial runout. If still excessive, mark

tire sidewall, wheel, and stud at point of maximum

runout and proceed to Method 2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

NOTE: Rotating the tire on wheel is particularly

effective when there is runout in both tire and

wheel.

WJTIRES/WHEELS 22 - 1

Page 1871 of 2199

TIRE PRESSURE MONITORING

DESCRIPTION

The EVIC will monitor the tire pressure signals

from the five tire sensors and determine if any tire

has gone below the low pressure threshold or raised

above the high pressure threshold. Refer to the table

below.

LOW TIRE PRESSURE THRESHOLDS

SYSTEM STATUS

INDICATORTIRE PRESSURE

ON 179 kPa (26 PSI)

OFF 214 kPa (31 PSI)

HIGH TIRE PRESSURE THRESHOLDS

SYSTEM STATUS

INDICATORTIRE PRESSURE

ON 310 kPa (45 PSI)

OFF 276 kPa (40 PSI)

The Remote Tire Pressure Monitors (RTPM) are

not internally serviceable. For a Sensor Failure or

Low Battery fault, the RTPM must be replaced.

OPERATION

If equipped with the Tire Pressure Monitoring Sys-

tem, each of the vehicle's five wheels will have a

valve stem with a pressure sensor and radio trans-

mitter built in. Signals from the tire pressure sensors

are received and interpreted by the Electronic Vehi-

cle Information Center (EVIC). A sensor in a

mounted wheel will broadcast its detected pressure

once per minute when the vehicle is moving faster

than 40 km/h (25 mph). The spare tire sensor will

broadcast once every hour. Each sensor's broadcast is

uniquely coded so that the EVIC can determine loca-

tion. The individual tire pressures can be displayed

graphically on the EVIC

DIAGNOSIS AND TESTING - TIRE PRESSURE

MONITORING SYSTEM

All Tire Pressure Monitoring System Faults are

specific to one location. If a9BATTERY LOW9or

9SENSOR FAILURE9fault is detected, the location

will be displayed. The appropriate sensor/transmitter

can then be replaced. If a single sensor/transmitter

cannot be detected by the EVIC, replace that sensor

transmitter. If none of the sensors/transmitters can

be detected, refer to symptoms in the EVIC section.

For additional system description and diagnosis,

refer to Tire Pressure Monitoring in the Body Diag-

nostic manual.

SENSOR

REMOVAL - TIRE PRESSURE SENSOR/

TRANSMITTER

(1) Remove the tire/wheel from the vehicle.

CAUTION: When removing the stick on balancing

weights from the wheel, do not use an abrasive

cleaner or a cleaner which will damage the protec-

tive finish on the wheel.

(2) Remove the balancing weights from the wheel.

NOTE: The cap used on this valve stem contains an

O-ring seal to prevent contamination and moisture

from entering the valve stem. Retain this valve stem

cap for re-use. Do not substitute a regular valve

stem cap in its place.

(3) Remove the cap from the valve stem.

NOTE: The valve stem used on this vehicle is made

of aluminum and the core is nickel plated brass.

The original valve stem core must be reinstalled

and not substituted for a valve stem core made of a

different material. This is required to prevent corro-

sion in the valve stem caused by the different met-

als.

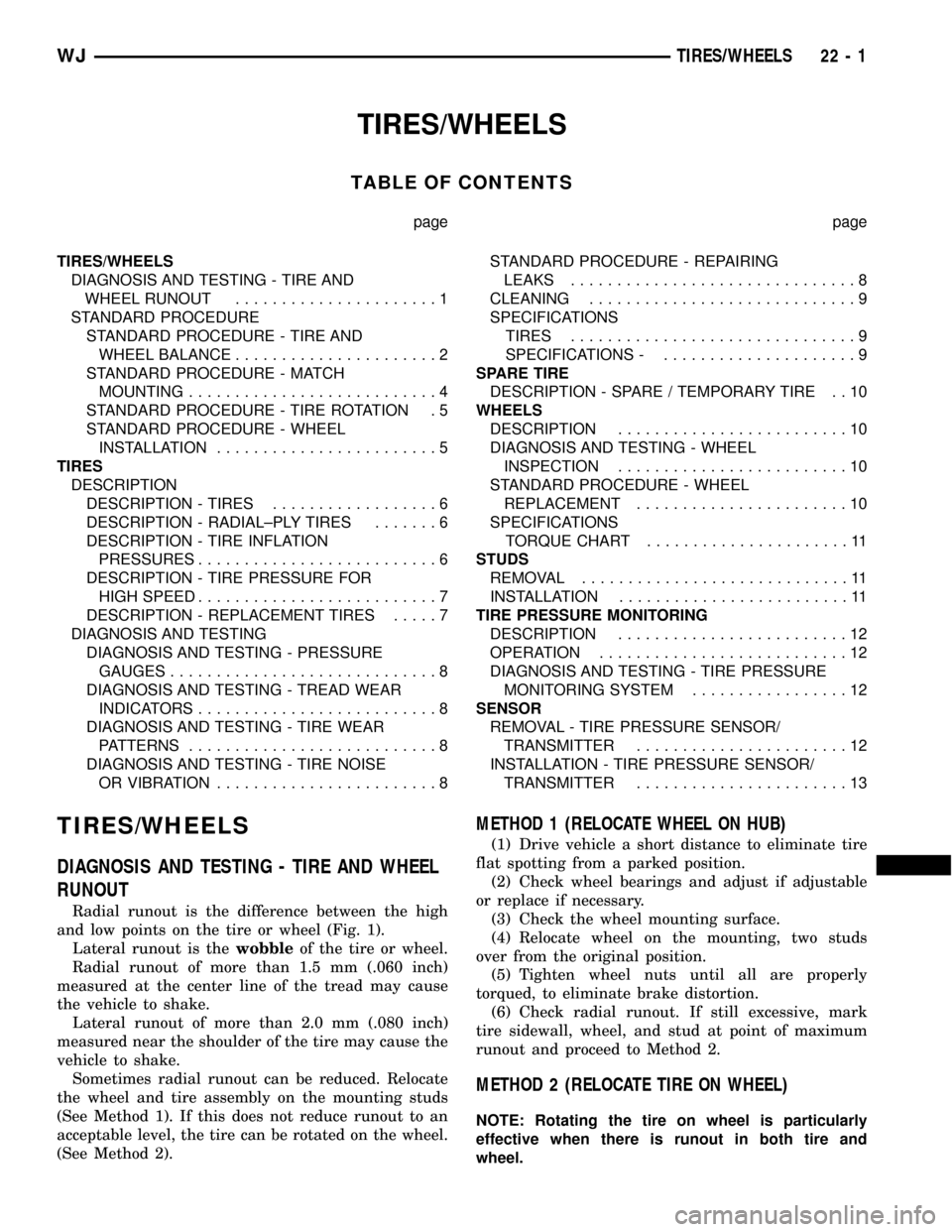

(4) Using the appropriate tool, remove the core

from the valve stem (Fig. 20).

(5) Let the tire fully deflate.

Fig. 20 REMOVING VALVE STEM CORE - TYPICAL

1 - WHEEL

2 - VALVE STEM

3 - TIRE

4 - VALVE STEM CORE TOOL

22 - 12 TIRES/WHEELSWJ

Page 1872 of 2199

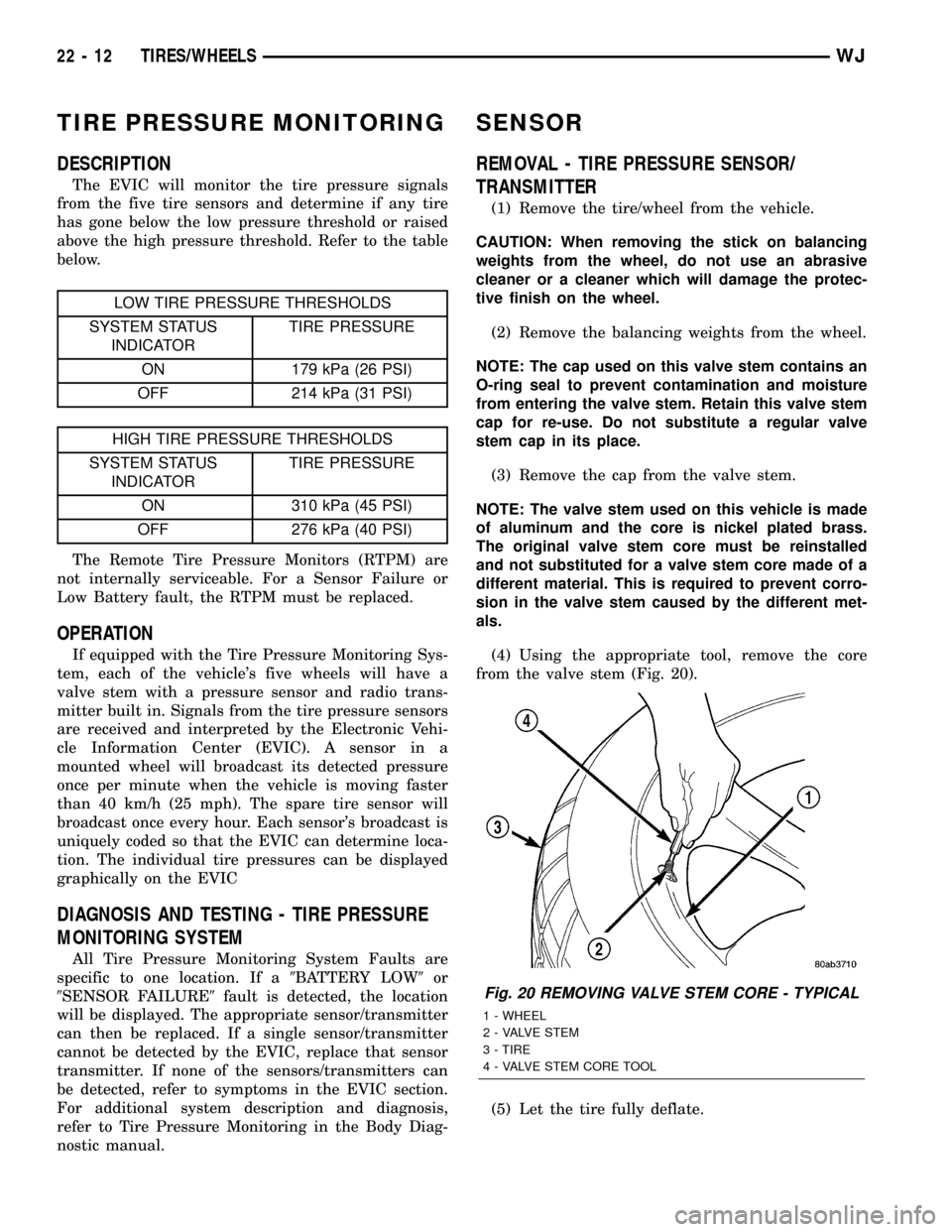

CAUTION: The pressure transmitter must be

removed from the wheel and dropped into the tire

prior to breaking the bead and dismounting the tire.

Failure to do this will greatly increase the risk of

damaging the pressure transducer when servicing

the tire.

(6) Remove nut mounting valve stem of pressure

sensor/transmitter to the wheel (Fig. 21). Drop sen-

sor/transmitter into tire.

CAUTION: When breaking the top and bottom bead

of the tire off the wheel, care must be used so the

bead breaking mechanism on the tire changer does

not damage the wheel. This includes the surface of

the wheel flange on the inside of the wheel.

(7) Using the tire changer manufacturers proce-

dure, first break down the upper bead of the tire.

Then break down the bottom bead of the tire.

CAUTION: When dismounting the upper tire bead

from the wheel, the proper procedure must be used.

Not using the proper procedure will result in dam-

age to the wheel and tire.(8) Dismount the upper bead of the tire from the

wheel.The upper bead must be fully dis-

mounted from the wheel to remove the tire

pressure transmitter from the inside of the tire.

The bottom bead of the tire does not need to be

removed from the wheel.

(9) Pull upward on the tire (Fig. 22). Reach into

the tire and remove the pressure sensor/transmitter

from inside the tire.

INSTALLATION - TIRE PRESSURE SENSOR/

TRANSMITTER

NOTE: When installing the tire pressure sensor/

transmitter, inspect the sealing O-ring at the bottom

of the valve stem for any sign of damage or deteri-

oration. Replace O-ring if necessary, before install-

ing the pressure transmitter on the wheel. Also, be

sure the surface of the wheel that the O-ring seals

against is clean and not damaged.

Fig. 21 VALVE STEM/PRESSURE TRANSMITTER -

TYPICAL

1 - NUT

2 - WHEEL

3 - TIRE

4 - VALVE STEM

Fig. 22 PRESSURE TRANSMITTER REMOVAL -

TYPICAL

1 - TIRE

2 - WHEEL

3 - PRESSURE TRANSMITTER

WJTIRES/WHEELS 22 - 13

SENSOR (Continued)

Page 1873 of 2199

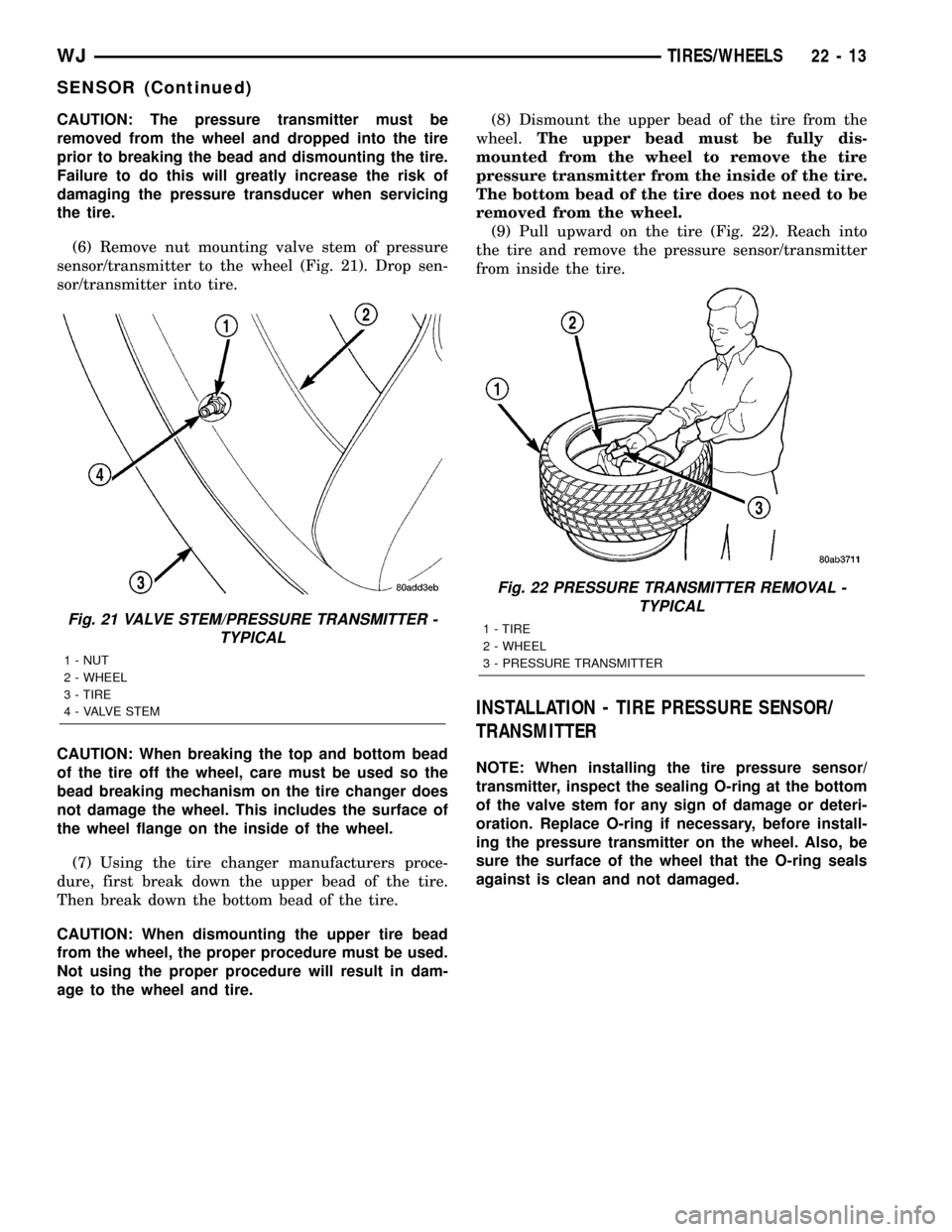

(1) Install the tire pressure sensor/transmitter on

the wheel (Fig. 23).

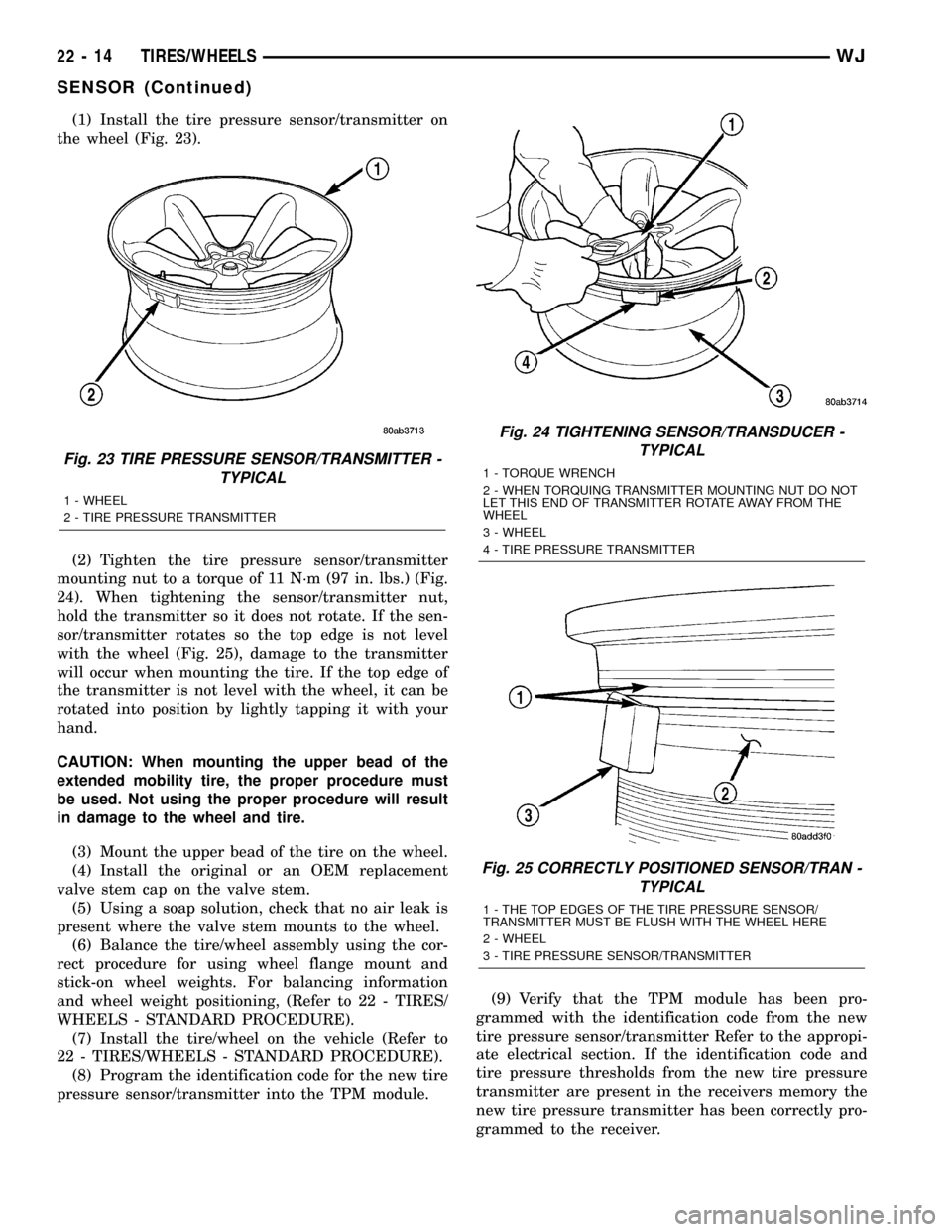

(2) Tighten the tire pressure sensor/transmitter

mounting nut to a torque of 11 N´m (97 in. lbs.) (Fig.

24). When tightening the sensor/transmitter nut,

hold the transmitter so it does not rotate. If the sen-

sor/transmitter rotates so the top edge is not level

with the wheel (Fig. 25), damage to the transmitter

will occur when mounting the tire. If the top edge of

the transmitter is not level with the wheel, it can be

rotated into position by lightly tapping it with your

hand.

CAUTION: When mounting the upper bead of the

extended mobility tire, the proper procedure must

be used. Not using the proper procedure will result

in damage to the wheel and tire.

(3) Mount the upper bead of the tire on the wheel.

(4) Install the original or an OEM replacement

valve stem cap on the valve stem.

(5) Using a soap solution, check that no air leak is

present where the valve stem mounts to the wheel.

(6) Balance the tire/wheel assembly using the cor-

rect procedure for using wheel flange mount and

stick-on wheel weights. For balancing information

and wheel weight positioning, (Refer to 22 - TIRES/

WHEELS - STANDARD PROCEDURE).

(7) Install the tire/wheel on the vehicle (Refer to

22 - TIRES/WHEELS - STANDARD PROCEDURE).

(8) Program the identification code for the new tire

pressure sensor/transmitter into the TPM module.(9) Verify that the TPM module has been pro-

grammed with the identification code from the new

tire pressure sensor/transmitter Refer to the appropi-

ate electrical section. If the identification code and

tire pressure thresholds from the new tire pressure

transmitter are present in the receivers memory the

new tire pressure transmitter has been correctly pro-

grammed to the receiver.

Fig. 23 TIRE PRESSURE SENSOR/TRANSMITTER -

TYPICAL

1 - WHEEL

2 - TIRE PRESSURE TRANSMITTER

Fig. 24 TIGHTENING SENSOR/TRANSDUCER -

TYPICAL

1 - TORQUE WRENCH

2 - WHEN TORQUING TRANSMITTER MOUNTING NUT DO NOT

LET THIS END OF TRANSMITTER ROTATE AWAY FROM THE

WHEEL

3 - WHEEL

4 - TIRE PRESSURE TRANSMITTER

Fig. 25 CORRECTLY POSITIONED SENSOR/TRAN -

TYPICAL

1 - THE TOP EDGES OF THE TIRE PRESSURE SENSOR/

TRANSMITTER MUST BE FLUSH WITH THE WHEEL HERE

2 - WHEEL

3 - TIRE PRESSURE SENSOR/TRANSMITTER

22 - 14 TIRES/WHEELSWJ

SENSOR (Continued)

Page 2095 of 2199

Both the manual A/C Heater control panel and the

AZC control panel are serviced only as complete

units and cannot be repaired. If faulty or damaged,

the entire control panel unit must be replaced.

DIAGNOSIS AND TESTING - AUTOMATIC ZONE

CONTROL SYSTEM

The Automatic Zone Control (AZC) control module

has a system self-diagnostic mode which continuously

monitors various parameters during normal system

operation. If a system fault is detected, a current and

historical fault is recorded. When the current fault is

cleared, the historical fault remains until reset (man-

ually or automatically). Both the current and histor-

ical fault codes can be accessed through either the

front panel, or over the Programmable Communica-

tions Interface (PCI) bus using a DRBIIItscan tool,

and the appropriate diagnostic information.

The AZC control module is capable of three differ-

ent types of self-diagnostic tests, as follows:

²Fault Code Tests

²Input Circuit Tests

²Output Circuit/Actuator Tests

The information that follows describes:

²How to read the self-diagnostic display

²How to enter the AZC control module self-diag-

nostic test mode

²How to select the self-diagnostic test types

²How to perform the different tests

ENTERING THE AZC SELF-DIAGNOSTIC MODE

To enter the AZC self-diagnostic mode, perform the

following:

(1) Depress the a/c and recirc buttons at the same

time and hold. Rotate the left temperature control

knob clockwise (CW) one detent.

(2) If you continue to keep the a/c and recirc but-

tons depressed, the AZC control module will perform

a Segment Test of the Vacuum Fluorescent (VF) dis-

play. In the Segment Test you should see all of the

display segments illuminate as long as both buttons

are held. If a display segment fails to illuminate, the

vacuum fluorescent display is faulty and the a/c

heater control must be replaced.

(3) After viewing the Segment Test, release the

A/C and Recirc buttons and the display will clear

momentarily.Ifa0isdisplayed, then no faults

are set in the system.Should there be any faults,

either9current9or9historical9, all fault codes will be

displayed in ascending numerical sequence (note no

effort is made to display fault codes in chronological

order). Each fault code is displayed for one second

before the next code is displayed. Once all fault codes

have been displayed, the system will then repeat the

fault code numbers. This will continue until the left

side set temperature control is moved at least onedetent position in the CW direction or the ignition is

turned9OFF9.

FAULT CODE TESTS

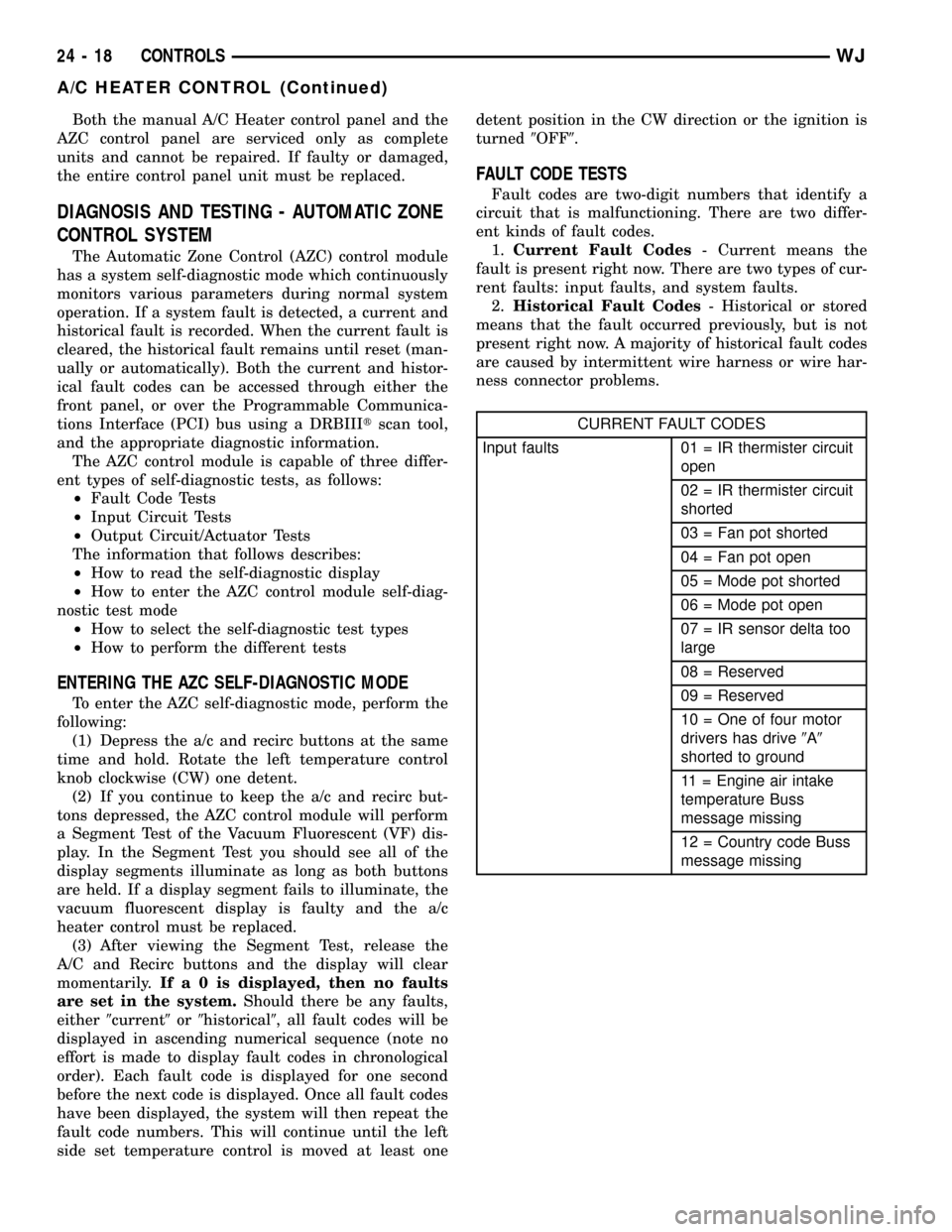

Fault codes are two-digit numbers that identify a

circuit that is malfunctioning. There are two differ-

ent kinds of fault codes.

1.Current Fault Codes- Current means the

fault is present right now. There are two types of cur-

rent faults: input faults, and system faults.

2.Historical Fault Codes- Historical or stored

means that the fault occurred previously, but is not

present right now. A majority of historical fault codes

are caused by intermittent wire harness or wire har-

ness connector problems.

CURRENT FAULT CODES

Input faults 01 = IR thermister circuit

open

02 = IR thermister circuit

shorted

03 = Fan pot shorted

04 = Fan pot open

05 = Mode pot shorted

06 = Mode pot open

07 = IR sensor delta too

large

08 = Reserved

09 = Reserved

10 = One of four motor

drivers has drive9A9

shorted to ground

11 = Engine air intake

temperature Buss

message missing

12 = Country code Buss

message missing

24 - 18 CONTROLSWJ

A/C HEATER CONTROL (Continued)

Page 2142 of 2199

ING & AIR CONDITIONING/CONTROLS/A/C

PRESSURE TRANSDUCER - INSTALLATION).

(9) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(10) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

(11) Connect the negative battery cable.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.

High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

(1) Remove the tape or plugs from the discharge

line block fitting and the manifold on the compressor.

Install the discharge line block fitting to the manifold

on the compressor. Tighten the mounting bolt to 25.4

N´m (225 in. lbs.).

(2) Remove the tape or plugs from the refrigerant

line fittings on the condenser inlet and the discharge

line. Connect the discharge line to the condenser

inlet. Tighten the retaining nut to 28 N´m (250 in.

lbs.).

(3) Install the a/c high pressure transducer(Refer

to 24 - HEATING & AIR CONDITIONING/CON-

TROLS/A/C PRESSURE TRANSDUCER - INSTAL-

LATION).

(4) Connect the battery negative cable.

(5) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)(6) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

A/C EXPANSION VALVE

DESCRIPTION

The ªHº valve type thermal expansion valve (TXV)

is located at the front of the heater-A/C housing

between the liquid and suction lines and the evapo-

rator coil.

The expansion valve is a factory calibrated unit

and cannot be adjusted or repaired. If faulty or dam-

aged, the expansion valve must be replaced.

OPERATION

High-pressure, high temperature liquid refrigerant

from the liquid line passes through the expansion

valve orifice, converting it inot a low-pressure, low-

temperature mixture of liquid and gas before it

enters the evaporator coil. A temperature sensor in

the expansion valve control head monitors the tem-

perature of the refrigerant leaving the evaporator coil

throught the suction line, and adjusts the orifice size

at the liquid line to let the proper amoount of refrig-

erant into the evaporator coil to meet the vehicle

cooling requirements. Controlling the refrigerant flow

through the evaporator ensures that none of the

refrigerant leaving the evaporator is still in a liquid

state, which could damage the compressor.

DIAGNOSIS AND TESTING - A/C EXPANSION

VALVE

The expansion valve is located on the engine side

of the dash panel near the shock tower.

The expansion valve can fail in three different

positions (open, closed or restricted).

In an Open Position: this will result in a noisy

compressor or no cooling. The cause can be broken

spring, broken ball or excessive moisture in the A/C

system. If the spring or ball are found to be defective,

replace the expansion valve. If excessive moisture is

found in the A/C system, recycle the refrigerant.

In a Closed Position: There will be low suction

pressure and no cooling. This may be caused by a

failed power dome or excessive moisture in the A/C

system. If the power dome on the expansion valve is

found to be defective replace the expansion valve. If

excessive moisture is found recycle the refrigerant.

A Restricted Orifice: There will be low suction

pressure and no cooling. This may be caused by

debris in the refrigerant system. If debris is believed

to be the cause, recycle the refrigerant and replace

the expansion valve and the receiver/drier.

WJPLUMBING 24 - 65

A/C DISCHARGE LINE (Continued)