Key JEEP GRAND CHEROKEE 2003 WJ / 2.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 504 of 2199

If not OK, replace the faulty liftgate latch actuator

(brainplate) unit.

(5) Disconnect the liftgate wire harness connector

for the liftgate flip-up glass release switch from the

switch connector receptacle. With the liftgate latch

unlocked, check for battery voltage at the liftgate

flip-up glass limit switch output circuit cavity of the

liftgate wire harness connector for the release switch.

If OK, go to Step 6. If not OK, repair the open lift-

gate flip-up glass limit switch output circuit between

the release switch and the limit switch as required.

(6) Check for continuity between the two terminals

of the liftgate flip-up glass release switch. There

should be no continuity. Depress the switch, there

should now be continuity. If OK, go to Step 7. If not

OK, replace the faulty liftgate flip-up glass release

switch.

(7) Disconnect the liftgate wire harness connector

for the liftgate flip-up glass latch motor from the

motor connector receptacle. Check for continuity

between the ground circuit cavity of the liftgate wire

harness connector for the latch motor and a good

ground. There should be continuity. If OK, go to Step

8. If not OK, repair the open ground circuit to ground

as required.

(8) With the liftgate latch unlocked and the flip-up

glass release switch depressed, check for battery volt-

age at the liftgate flip-up glass release switch output

circuit cavity of the liftgate wire harness connector

for the latch motor. If OK, replace the faulty liftgate

flip-up glass latch unit. If not OK, repair the open

liftgate flip-up glass release switch output circuit

between the latch motor and the release switch as

required.

DOOR CYLINDER LOCK

SWITCH

DESCRIPTION

The driver cylinder lock switch is integral to the

key lock cylinder inside the driver side front door.

The driver cylinder lock switch is a resistive multi-

plexed switch that is hard wired between a body

ground and the Driver Door Module (DDM) through

the front door wire harness. It maintains a path to

ground, and changes voltages through an internal

resistor when the lock cylinder is rotated to the lock

or unlock position.

The driver cylinder lock switch cannot be adjusted

or repaired and, if faulty or damaged, the driver side

front door lock cylinder unit must be replaced. (Refer

to 23 - BODY/DOOR - FRONT/LOCK CYLINDER -

REMOVAL) and (Refer to 23 - BODY/DOOR -

FRONT/LOCK CYLINDER - INSTALLATION). Refer

to the appropriate wiring information. The wiringinformation includes wiring diagrams, proper wire

and connector repair procedures, further details on

wire harness routing and retention, as well as pin-

out and location views for the various wire harness

connectors, splices and grounds.

OPERATION

The driver cylinder lock switch is actuated by the

key lock cylinder when the key is inserted in the lock

cylinder and turned to the unlock position. The

driver cylinder lock switch maintains a path to

ground and changes voltages through an internal

resistor for the DDM when the driver door key lock

cylinder is in the lock or unlock position. The DDM

reads the switch status through an internal pull-up,

then sends the proper switch status messages to

other electronic modules over the Programmable

Communications Interface (PCI) data bus network.

The driver cylinder lock switch unlock status mes-

sage is used by the BCM as an input for Vehicle

Theft Security System (VTSS) operation and interior

lighting.

POWER LOCK MOTOR

DESCRIPTION

Power operated front door, rear door, and liftgate

locking mechanisms are standard equipment on this

model. The lock mechanisms are actuated by a

reversible electric motor mounted within each door

and the liftgate. The power lock motors for the doors

are integral to the door latch units. The liftgate

power lock motor is a separate unit secured to the

latch brainplate near the center of the liftgate and

operates the liftgate latch lock mechanism through a

connecting linkage rod.

The power lock motors for the four doors cannot be

adjusted or repaired and, if faulty or damaged, the

entire door latch unit must be replaced. The liftgate

power lock motor cannot be adjusted or repaired and,

if faulty or damaged, the entire liftgate latch actua-

tor (brainplate) unit must be replaced.

OPERATION

The driver side front door power lock motor is con-

trolled by the Driver Door Module (DDM). The

remaining power door lock motors and the liftgate

power lock motor are controlled by the Passenger

Door Module (PDM). A positive and negative battery

connection to the two motor terminals will cause the

power lock motor plunger to move in one direction.

Reversing the current through these same two con-

nections will cause the power lock motor plunger to

move in the opposite direction.

WJPOWER LOCKS 8N - 7

POWER LOCKS (Continued)

Page 506 of 2199

REMOTE KEYLESS ENTRY

MODULE

DESCRIPTION

The Remote Keyless Entry (RKE) receiver is a

radio frequency unit contained within the Passenger

Door Module (PDM). The PDM also contains the pro-

gram logic circuitry for the RKE system. The PDM is

secured with screws to the back of the trim panel

inside the passenger side front door. The RKE

receiver has a memory function to retain the vehicle

access codes of up to four RKE transmitters. The

receiver is designed to retain the transmitter codes in

memory, even if the battery is disconnected.

For diagnosis of the RKE receiver, the PDM, or the

Programmable Communications Interface (PCI) data

bus a DRBIIItscan tool and the appropriate diagnos-

tic information are required. The RKE receiver is

only serviced as a unit with the PDM and, if faulty

or damaged, the entire PDM unit must be replaced.

(Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/DOOR MODULE - DESCRIP-

TION).

OPERATION

The RKE receiver is energized by one of three mes-

sages from the RKE transmitter: Unlock, Lock, or

Panic. The PDM circuitry responds to these messages

to lock or unlock the power lock motors that it con-

trols. The PDM circuitry also sends Lock, Unlock,

and Panic messages to other electronic modules over

the Programmable Communications Interface (PCI)

data bus. These messages will result in the Driver

Door Module (DDM) locking or unlocking the driver

side front door, and the other electronic modules in

the vehicle responding as their programming dic-

tates.

REMOTE KEYLESS ENTRY

TRANSMITTER

DESCRIPTION

The Remote Keyless Entry (RKE) system Radio

Frequency (RF) transmitter is equipped with three

buttons, labeled Lock, Unlock, and Panic. It is also

equipped with a key ring and is designed to serve as

a key fob. The operating range of the transmitter

radio signal is up to 10 meters (30 feet) from the

RKE receiver.

Each RKE transmitter has a different vehicle

access code, which must be programmed into the

memory of the RKE receiver in the vehicle in order

to operate the RKE system. Two transmitters are

provided with the vehicle, but the RKE receiver canretain the access codes of up to four transmitters in

its memory. (Refer to 8 - ELECTRICAL/POWER

LOCKS/REMOTE KEYLESS ENTRY TRANSMIT-

TER - STANDARD PROCEDURE - RKE TRANS-

MITTER PROGRAMMING).

In addition, the RKE transmitters for vehicles

equipped with the optional Memory System are color-

coded and have a number ª1º or ª2º molded into the

transmitter case to coincide with the ªDriver 1

(Black)º and ªDriver 2 (Gray)º buttons of the memory

switch on the driver side front door trim panel. These

transmitters must also have their access codes pro-

grammed into the RKE receiver so that they coincide

with the ªDriver 1º and ªDriver 2º buttons of the

memory switch. (Refer to 8 - ELECTRICAL/POWER

SEATS - DESCRIPTION - MEMORY SYSTEM).

The RKE transmitter operates on two Panasonic

CR2016 (or equivalent) batteries. Typical battery life

is from one to two years. The RKE transmitter can-

not be repaired and, if faulty or damaged, it must be

replaced.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the Remote Keyless Entry (RKE) transmitters.

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY TRANSMITTER

(1) Replace the Remote Keyless Entry (RKE)

transmitter batteries. (Refer to 8 - ELECTRICAL/

POWER LOCKS/REMOTE KEYLESS ENTRY

TRANSMITTER - STANDARD PROCEDURE - RKE

TRANSMITTER BATTERIES). Test each of the RKE

transmitter functions. If OK, discard the faulty bat-

teries. If not OK, go to Step 2.

(2) Program the suspect RKE transmitter and

another known good transmitter into the RKE

receiver. Use a DRBIIItscan tool, as described in the

appropriate diagnostic information. (Refer to 8 -

ELECTRICAL/POWER LOCKS/REMOTE KEYLESS

ENTRY TRANSMITTER - STANDARD PROCE-

DURE - RKE TRANSMITTER PROGRAMMING).

(3) Test the RKE system operation with both

transmitters. If both transmitters fail to operate the

power lock system, use a DRBIIItscan tool and the

appropriate diagnostic information for further diag-

nosis of the RKE system. If the known good RKE

transmitter operates the power locks and the suspect

transmitter does not, replace the faulty RKE trans-

mitter.

NOTE: Be certain to perform the RKE Transmitter

Programming procedure again following this test.

This procedure will erase the access code of the

test transmitter from the RKE receiver.

WJPOWER LOCKS 8N - 9

Page 507 of 2199

STANDARD PROCEDURE

STANDARD PROCEDURE - RKE TRANSMITTER

PROGRAMMING

To program the Remote Keyless Entry (RKE)

transmitter access codes into the RKE receiver in the

Passenger Door Module (PDM) requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

STANDARD PROCEDURE - RKE TRANSMITTER

BATTERIES

The Remote Keyless Entry (RKE) transmitter case

snaps open and shut for battery access. To replace

the RKE transmitter batteries:

(1) Using a trim stick or a thin coin, gently pry at

the notch in the center seam of the RKE transmitter

case halves near the key ring until the two halves

unsnap.

(2) Lift the back half of the transmitter case off of

the RKE transmitter.

(3) Remove the two batteries from the RKE trans-

mitter.(4) Replace the two batteries with new Panasonic

CR2016, or their equivalent. Be certain that the bat-

teries are installed with their polarity correctly ori-

ented.

(5) Align the two RKE transmitter case halves

with each other, and squeeze them firmly and evenly

together until they snap back into place.

NOTE: The RKE system for this model uses a roll-

ing code security strategy. This strategy requires

that synchronization be maintained between the

RKE transmitter and the RKE receiver. RKE trans-

mitter battery removal or replacement can cause a

loss of synchronization. If the RKE receiver fails to

respond to the RKE transmitter following battery

removal or replacement, depress and release the

RKE transmitter Unlock button repeatedly while lis-

tening carefully for the power door locks in the

vehicle to cycle. After between five and eight

presses of the Unlock button, the power door locks

should cycle, indicating that re-synchronization has

occurred.

8N - 10 POWER LOCKSWJ

REMOTE KEYLESS ENTRY TRANSMITTER (Continued)

Page 509 of 2199

ULES/DRIVER DOOR MODULE - DESCRIPTION)

for more information.

²Passenger Door Module (PDM)(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/DRIVER DOOR MODULE - DESCRIPTION)

for more information.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

OPERATION

The Driver Door Module (DDM) and the Passenger

Door Module (PDM) each contain the power mirror

control logic for the mirror on its respective door. The

DDM also houses the power mirror switch. Each door

module controls the positioning of its respective out-

side mirror through hard wired outputs to that mir-

ror. When the power mirror switch on the DDM is

used to position the passenger side outside mirror,

the DDM sends mirror positioning messages to the

PDM over the Programmable Communications Inter-

face (PCI) data bus. The PDM responds to these mes-

sages by sending control outputs to move the

passenger side mirror accordingly.

Both the PDM and DDM respond to the defogger

switch status messages sent by the Body Control

Module (BCM) over the PCI data bus to control the

electric heater grids of their respective mirrors.

(Refer to 8 - ELECTRICAL/HEATED MIRRORS -

DESCRIPTION) for more information on this fea-

ture.

On models equipped with the optional memory sys-

tem, each door module also receives a hard wired

input from the two power mirror motor position

potentiometers that are integral to each power mir-

ror. Each door module then stores the Driver 1 and

Driver 2 mirror position information for its respective

mirror. When the DDM receives a Driver 1 or Driver

2 memory recall message from the memory switch on

the driver side front door trim panel or from the

Remote Keyless Entry (RKE) receiver in the PDM,

the DDM positions the driver side mirror and sends

a memory recall message back to the PDM over the

PCI data bus to position the passenger side mirror.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the power mirror system.

DIAGNOSIS AND TESTING - POWER MIRRORS

Following are tests that will help to diagnose the

hard wired components and circuits of the power mir-

ror system. However, these tests may not prove con-

clusive in the diagnosis of this system. In order toobtain conclusive testing of the power mirror system,

the Programmable Communications Interface (PCI)

data bus network and all of the electronic modules

that provide inputs to, or receive outputs from the

power mirror system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the power mirror system requires the use of

a DRB scan tool and the proper Diagnostic Proce-

dures manual. The DRB scan tool can provide confir-

mation that the PCI data bus is functional, that all

of the electronic modules are sending and receiving

the proper messages on the PCI data bus, that the

power mirror motors are being sent the proper hard

wired outputs, and that the mirror position potenti-

ometers are returning the proper outputs to the door

modules for them to perform their power mirror sys-

tem functions.

AUTOMATIC DAY/NIGHT

MIRROR

DESCRIPTION

DESCRIPTION - REAR VIEW MIRROR

An automatic day/night mirror system is an avail-

able factory-installed option on this model. The auto-

matic dimming inside day/night rear view mirror

system is a completely self-contained unit that

replaces the standard equipment inside rear view

mirror. This system will automatically change the

reflectance of the inside rear view mirror to protect

the driver from the unwanted headlight glare of

trailing vehicles while driving at night. The auto-

matic day/night inside mirror receives ignition

switched battery current through a fuse in the junc-

tion block, and will only operate when the ignition

switch is in the On position.

Vehicles equipped with the automatic day/night

mirror system are also available with an optional fac-

tory-installed automatic dimming outside rear view

mirror for the driver side of the vehicle. (Refer to 8 -

ELECTRICAL/POWER MIRRORS/SIDEVIEW MIR-

ROR - DESCRIPTION) for more information on this

option.

The automatic day/night mirror sensitivity cannot

be repaired or adjusted. If any component of this unit

is faulty or damaged, the entire automatic day/night

inside rear view mirror unit must be replaced. Refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, details of wire har-

ness routing and retention, connector pin-out infor-

mation and location views for the various wire

harness connectors, splices and grounds.

8N - 12 POWER MIRRORSWJ

POWER MIRRORS (Continued)

Page 516 of 2199

²Ten-way power drivers and passenger seats

with Memory- This power seat option is standard

on Overland models and optional on Limited models.

This option includes a six-way adjustable seat cush-

ion track with power seat back recliners and power

lumbar supports. Heated Seats are standard with

this option.

Refer toHeated Seat Systemfor more informa-

tion on the heated seat option. Refer toMemory

Systemin the Memory System section of this group

for more information on the memory system.

The power seat system includes the following com-

ponents:

²Power lumbar adjuster (ten-way power seat

only)

²Power lumbar switch (ten-way power seat only)

²Power seat recliner (ten-way power seat only)

²Power seat switch

²Power seat track.

Refer toPower Seatin Wiring Diagrams for com-

plete circuit diagrams. Following are general descrip-

tions of the major components in the power seat/

memory seat system.

DESCRIPTION - MEMORY SYSTEM

An electronic memory system is standard equip-

ment on the Limited model. The memory system is

able to store and recall the driver side power seat

positions (including the power recliner position), and

both outside power mirror positions for two drivers.

For vehicles with a radio connected to the Program-

mable Communications Interface (PCI) data bus net-

work, the memory system is also able to store and

recall up to twenty - ten AM and ten FM - radio sta-

tion presets for two drivers. The memory system also

will store and recall the last station listened to for

each driver, even if it is not one of the twenty preset

stations.

The memory system will automatically return to

all of these settings when the corresponding num-

bered and color-coded button (Driver 1 - Black, or

Driver 2 - Gray) of the memory switch on the driver

side front door trim panel is depressed, or when the

doors are unlocked using the corresponding num-

bered and color-coded (Driver 1 - Black, or Driver 2 -

Gray) Remote Keyless Entry (RKE) transmitter. A

customer programmable feature of the memory sys-

tem allows the RKE recall of memory features to be

disabled in cases where there are more than two

drivers of the vehicle.

The memory system also has a customer program-

mable easy exit feature that will move the driver

seat rearward 55 millimeters (two inches) or to the

end of its travel, whichever occurs first, when the key

is removed from the ignition switch lock cylinder.A Memory Seat Module (MSM) or Memory Heated

Seat Module (MHSM) are used on this model to con-

trol and integrate the many electronic functions and

features included in the memory system. On vehicles

equipped with the heated seat system option, the

MHSM also controls the functions and features of

that system.

The memory system includes the following compo-

nents:

²Memory seat module (or memory heated seat

module)

²Memory switch

²Position potentiometers on both outside power

mirrors

²Position potentiometers on the driver side power

seat track and power seat recliner motors.

²Radio receiver (if PCI data bus capable).

Certain functions and features of the memory sys-

tem rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munications Interface (PCI) data bus network. The

PCI data bus network allows the sharing of sensor

information. This helps to reduce wire harness com-

plexity, internal controller hardware, and component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities. For diagnosis of these electronic modules or of

the PCI data bus network, the use of a DRBtscan

tool and the proper Diagnostic Procedures manual

are recommended.

The other electronic modules that may affect mem-

ory system operation are as follows:

²Body Control Module (BCM)- Refer toBody

Control Modulein Electronic Control Modules for

more information.

²Driver Door Module (DDM)- Refer toDoor

Modulein Electronic Control Modules for more

information.

²Electronic Vehicle Information Center

(EVIC)- Refer toElectronic Vehicle Information

Centerin Overhead Console Systems for more infor-

mation.

²Passenger Door Module (PDM)- Refer to

Door Modulein Electronic Control Modules for

more information.

²Powertrain Control Module (PCM)- Refer to

Powertrain Control Modulein Electronic Control

Modules for more information.

²Radio Receiver- Refer toRadio Receiverin

Audio Systems for more information.

Refer toHeated Seat Systemfor more informa-

tion on this system. Refer toRemote Keyless Entry

Systemin Power Lock Systems for more information

on the RKE system. Refer toPower Mirrorin

Power Mirror Systems for more information on the

WJPOWER SEAT SYSTEM 8N - 19

POWER SEAT SYSTEM (Continued)

Page 517 of 2199

mirror position potentiometers. Refer toPower Seat

TrackandPower Seat Reclinerin the Power Seat

System section of this group for more information on

the driver side power seat position potentiometers.

Refer toPower Seatin Wiring Diagrams for com-

plete circuit diagrams. Following are general descrip-

tions of the remaining major components in the

factory-installed memory system.

OPERATION

OPERATION - POWER SEAT SYSTEM

The power seat system allows the driver and/or

front passenger seating positions to be adjusted elec-

trically and independently using the separate power

seat switches found on the outboard seat cushion

side shield of each front seat. See the owner's manual

in the vehicle glove box for more information on the

features, use and operation of the power seat system.

OPERATION - MEMORY SYSTEM

See the owner's manual in the vehicle glove box for

more information on the features, use and operation of

the memory system. For diagnosis of the MSM, the PCI

data bus, or the other electronic modules on the PCI

data bus that provide inputs and outputs for the mem-

ory system, the use of a DRBtscan tool and the proper

Diagnostic Procedures manual are recommended.

DRIVER AND PASSENGER DOOR MODULES

The Driver Door Module (DDM) monitors the mem-

ory switch through a hard wired circuit. It also mon-

itors the unlock messages from the Remote Keyless

Entry (RKE) receiver in the Passenger Door Module

(PDM) sent over the Programmable Communications

Interface (PCI) data bus. The DDM is programmed to

send memory recall messages and memory system

status messages over the PCI data bus to the other

electronic modules when it detects a memory recall

request.

Refer toDoor Modulein Electronic Control Mod-

ules for more information on the DDM and PDM.

ELECTRONIC VEHICLE INFORMATION CENTER

The Electronic Vehicle Information Center (EVIC)

serves as the user interface for the memory system. It

displays memory system status messages and provides

the user with the means for enabling and disabling

the many customer programmable features available

on the vehicle, including those for the memory system.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the EVIC. Refer toElectronic Vehicle Informa-

tion Centerin Overhead Console Systems for more

information on the EVIC.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER SEAT

SYSTEM

Following are tests that will help to diagnose the

hard wired components and circuits of the power seat

system. However, if the vehicle is also equipped with

the optional memory system, these tests may not

prove conclusive in the diagnosis of the driver side

power seat. In order to obtain conclusive testing of

the driver side power seat with the memory system

option, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the driver side power seat with the memory

system option requires the use of a DRBtscan tool

and the proper Diagnostic Procedures manual. The

DRBtscan tool can provide confirmation that the

PCI data bus is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages on the PCI data bus, and that the memory sys-

tem is receiving the proper hard wired inputs and

relaying the proper hard wired outputs to perform its

driver side power seat functions.

Before any testing of the power seat system is

attempted, the battery should be fully-charged and

all of the power seat system wire harness connections

and pins cleaned and tightened to ensure proper cir-

cuit continuity and ground paths. For complete cir-

cuit diagrams, refer toPower Seatin Wiring

Diagrams.

With the dome lamp on, apply the power seat

switch in the direction of the failure. If the dome

lamp dims, the seat may be jamming. Check under

and behind the seat for binding or obstructions. If

the dome lamp does not dim, proceed with testing of

the individual components and circuits.

DIAGNOSIS & TESTING - MEMORY SYSTEM

Following are tests that will help to diagnose the

components and circuits that provide hard wired

inputs to the memory system. However, these tests

may not prove conclusive in the diagnosis of this sys-

tem. In order to obtain conclusive testing of the

memory system, the Programmable Communications

Interface (PCI) data bus network and all of the elec-

tronic modules that provide inputs to, or receive out-

puts from the memory system components must be

checked.

The most reliable, efficient, and accurate means to

diagnose the memory system requires the use of a

DRBtscan tool and the proper Diagnostic Proce-

dures manual. The DRBtscan tool can provide con-

firmation that the PCI data bus is functional, that all

8N - 20 POWER SEAT SYSTEMWJ

POWER SEAT SYSTEM (Continued)

Page 524 of 2199

(LED) for visibility, and are also color-coded to coin-

cide with the color-coded Driver 1 and Driver 2

Remote Keyless Entry (RKE) transmitters. The

Driver 1 memory switch button and RKE transmitter

are black, and the Driver 2 memory switch button

and RKE transmitter are gray. The memory switch

Set button also has an LED that will illuminate and

flash to indicate that the memory system is in the set

mode. This LED will automatically be extinguished

when a set request has been successfully completed.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory switch. For diagnosis of the memory

switch, the DDM or the PCI data bus, the use of a

DRB scan tool and the proper Diagnostic Procedures

manual are recommended.

DIAGNOSIS AND TESTING - MEMORY SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side front door trim panel.

Refer to the Body section for the procedure.

(3) Disconnect the memory switch wire harness

connector from the driver door module connector

receptacle.

(4) Use an ohmmeter to test the resistances of the

memory switch in each switch position. See the Mem-

ory Switch Test chart MEMORY SWITCH TEST . If

OK, refer toMemory System Diagnosis and Test-

ingin this group. If not OK, replace the faulty mem-

ory switch.

MEMORY SWITCH TEST

MEMORY

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

RANGE

(OHMS)

NEUTRAL A&D 14000 1%

MEMORY 1 A&B 4600 1%

MEMORY 2 A&B 1700 1%

SET A&B 300 1%

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim panel from the driver side

front door. Refer toFront Door Trim Panelin Body

for the procedure.

(3) Disconnect the memory switch wire harness

connector from the driver door module connector

receptacle.

(4) Remove the two screws that secure the memory

switch to the back of the driver side front door trim

panel.(5) Remove the memory switch from the back of

the driver side front door trim panel.

INSTALLATION

(1) Position the memory switch onto the back of

the driver side front door trim panel.

(2) Install and tighten the two screws that secure

the memory switch to the back of the driver side

front door trim panel. Tighten the screws to 2.2 N´m

(20 in. lbs.).

(3) Reconnect the memory switch wire harness

connector to the driver door module connector recep-

tacle.

(4) Install the trim panel onto the driver side front

door. Refer toFront Door Trim Panelin Body for

the procedure.

(5) Reconnect the battery negative cable.

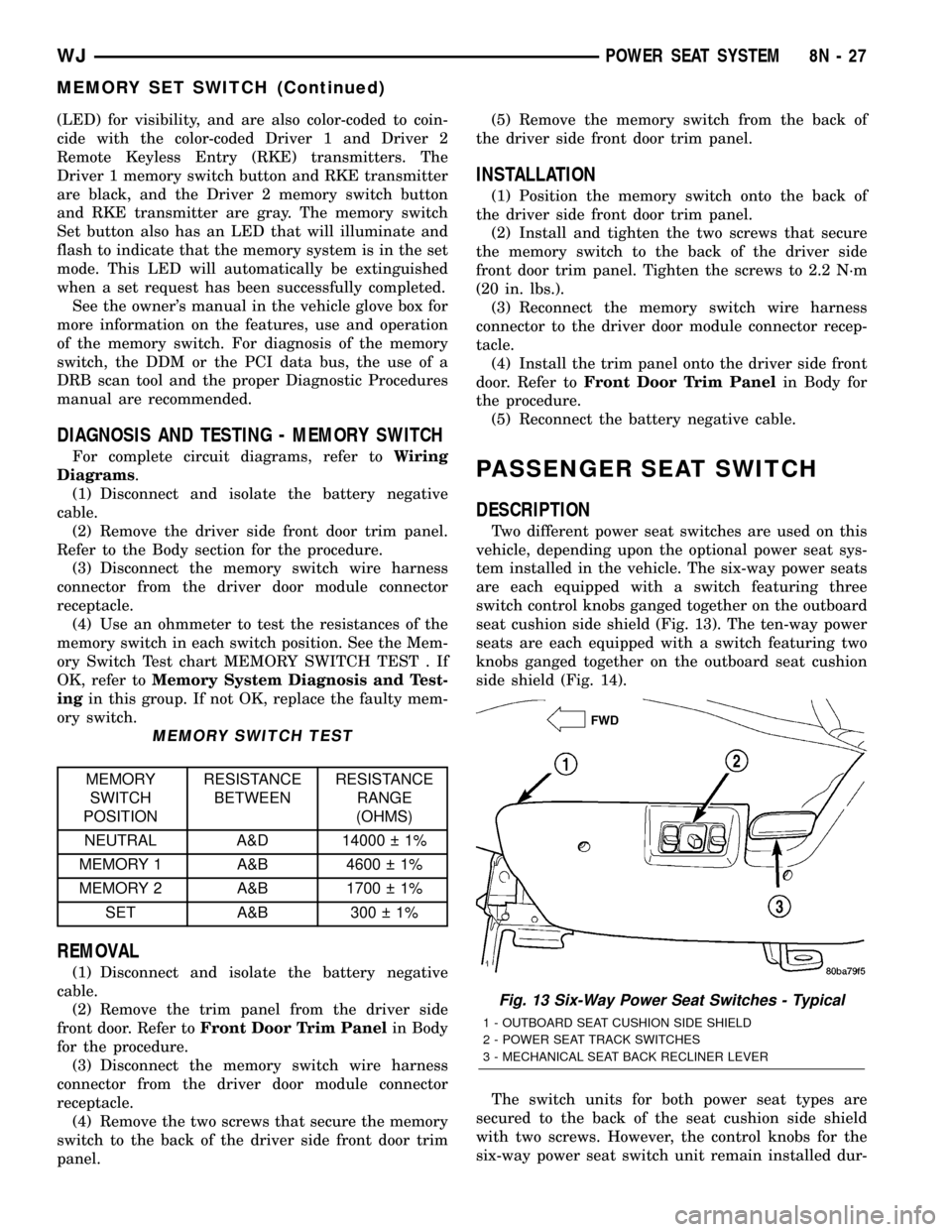

PASSENGER SEAT SWITCH

DESCRIPTION

Two different power seat switches are used on this

vehicle, depending upon the optional power seat sys-

tem installed in the vehicle. The six-way power seats

are each equipped with a switch featuring three

switch control knobs ganged together on the outboard

seat cushion side shield (Fig. 13). The ten-way power

seats are each equipped with a switch featuring two

knobs ganged together on the outboard seat cushion

side shield (Fig. 14).

The switch units for both power seat types are

secured to the back of the seat cushion side shield

with two screws. However, the control knobs for the

six-way power seat switch unit remain installed dur-

Fig. 13 Six-Way Power Seat Switches - Typical

1 - OUTBOARD SEAT CUSHION SIDE SHIELD

2 - POWER SEAT TRACK SWITCHES

3 - MECHANICAL SEAT BACK RECLINER LEVER

WJPOWER SEAT SYSTEM 8N - 27

MEMORY SET SWITCH (Continued)

Page 549 of 2199

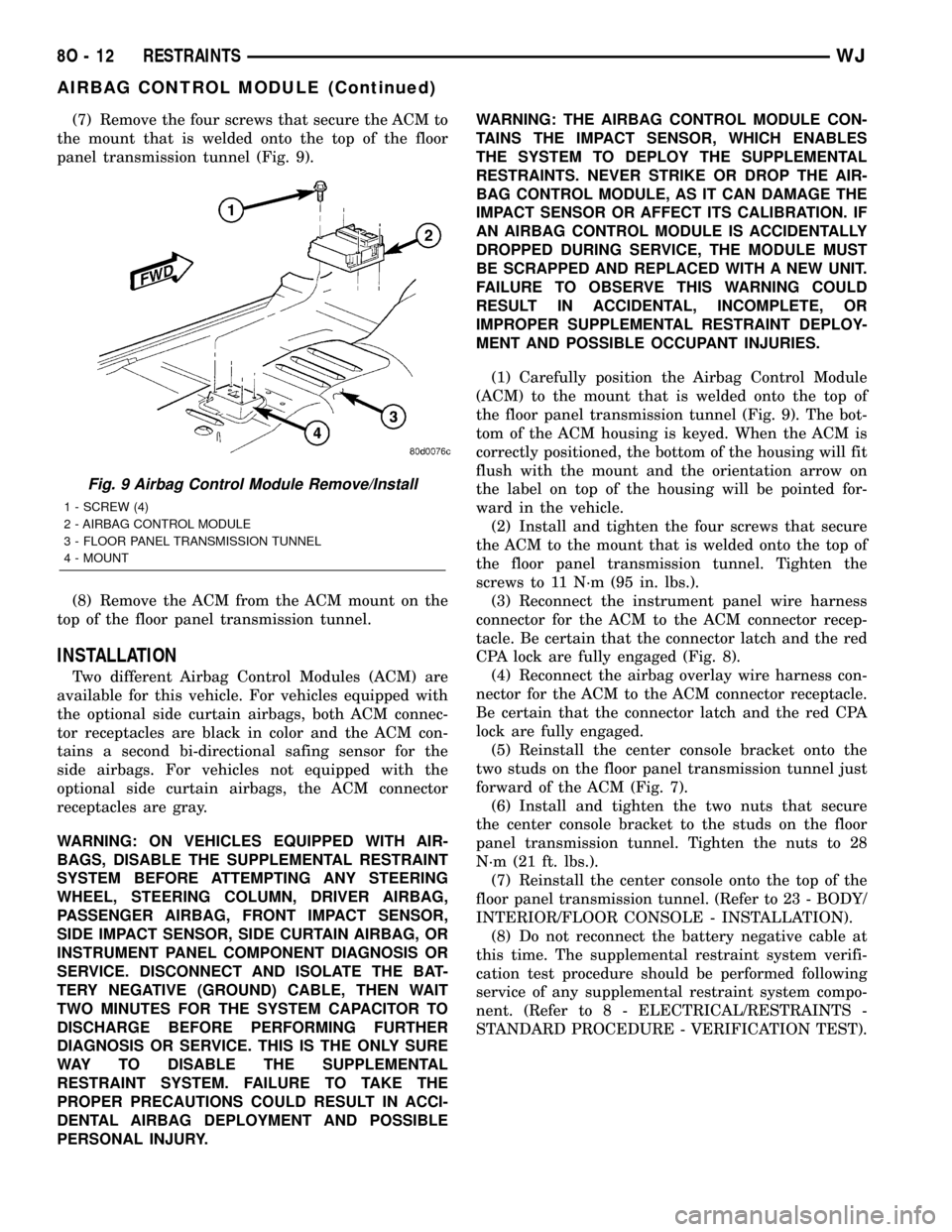

(7) Remove the four screws that secure the ACM to

the mount that is welded onto the top of the floor

panel transmission tunnel (Fig. 9).

(8) Remove the ACM from the ACM mount on the

top of the floor panel transmission tunnel.

INSTALLATION

Two different Airbag Control Modules (ACM) are

available for this vehicle. For vehicles equipped with

the optional side curtain airbags, both ACM connec-

tor receptacles are black in color and the ACM con-

tains a second bi-directional safing sensor for the

side airbags. For vehicles not equipped with the

optional side curtain airbags, the ACM connector

receptacles are gray.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.WARNING: THE AIRBAG CONTROL MODULE CON-

TAINS THE IMPACT SENSOR, WHICH ENABLES

THE SYSTEM TO DEPLOY THE SUPPLEMENTAL

RESTRAINTS. NEVER STRIKE OR DROP THE AIR-

BAG CONTROL MODULE, AS IT CAN DAMAGE THE

IMPACT SENSOR OR AFFECT ITS CALIBRATION. IF

AN AIRBAG CONTROL MODULE IS ACCIDENTALLY

DROPPED DURING SERVICE, THE MODULE MUST

BE SCRAPPED AND REPLACED WITH A NEW UNIT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN ACCIDENTAL, INCOMPLETE, OR

IMPROPER SUPPLEMENTAL RESTRAINT DEPLOY-

MENT AND POSSIBLE OCCUPANT INJURIES.

(1) Carefully position the Airbag Control Module

(ACM) to the mount that is welded onto the top of

the floor panel transmission tunnel (Fig. 9). The bot-

tom of the ACM housing is keyed. When the ACM is

correctly positioned, the bottom of the housing will fit

flush with the mount and the orientation arrow on

the label on top of the housing will be pointed for-

ward in the vehicle.

(2) Install and tighten the four screws that secure

the ACM to the mount that is welded onto the top of

the floor panel transmission tunnel. Tighten the

screws to 11 N´m (95 in. lbs.).

(3) Reconnect the instrument panel wire harness

connector for the ACM to the ACM connector recep-

tacle. Be certain that the connector latch and the red

CPA lock are fully engaged (Fig. 8).

(4) Reconnect the airbag overlay wire harness con-

nector for the ACM to the ACM connector receptacle.

Be certain that the connector latch and the red CPA

lock are fully engaged.

(5) Reinstall the center console bracket onto the

two studs on the floor panel transmission tunnel just

forward of the ACM (Fig. 7).

(6) Install and tighten the two nuts that secure

the center console bracket to the studs on the floor

panel transmission tunnel. Tighten the nuts to 28

N´m (21 ft. lbs.).

(7) Reinstall the center console onto the top of the

floor panel transmission tunnel. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - INSTALLATION).

(8) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

Fig. 9 Airbag Control Module Remove/Install

1 - SCREW (4)

2 - AIRBAG CONTROL MODULE

3 - FLOOR PANEL TRANSMISSION TUNNEL

4 - MOUNT

8O - 12 RESTRAINTSWJ

AIRBAG CONTROL MODULE (Continued)

Page 552 of 2199

OPERATION

The clockspring is a mechanical electrical circuit

component that is used to provide continuous electri-

cal continuity between the fixed instrument panel

wire harness and the electrical components mounted

on or in the rotating steering wheel. On this model

the rotating electrical components include the driver

airbag, the horn switch, the speed control switches,

and the remote radio switches, if the vehicle is so

equipped. The clockspring case is positioned and

secured to the multi-function switch mounting hous-

ing on the upper steering column housing by two

screws. The two connector receptacles on the tail of

the fixed clockspring case connect the clockspring to

the vehicle electrical system through two take outs

with connectors from the instrument panel wire har-

ness. The clockspring rotor is movable and is keyed

to the hub of the steering wheel by two large flats

that are molded into the rotor hub. The three pins

(two round and one oblong) on the lower surface of

the clockspring rotor hub engage and index the clock-

spring rotor to the turn signal cancel cam. The turn

signal cancel cam is integral to the multi-function

switch mounting housing and is keyed to the upper

steering column shaft. Two short, yellow-sleeved pig-

tail wires on the upper surface of the clockspring

rotor connect the clockspring to the driver airbag,

while a steering wheel wire harness connects the two

connector receptacles on the upper surface of the

clockspring rotor to the horn switch, the two speed

control switches, and the remote radio switches on

vehicles that are so equipped.

Like the clockspring in a timepiece, the clockspring

tape has travel limits and can be damaged by being

wound too tightly during full stop-to-stop steering

wheel rotation. To prevent this from occurring, the

clockspring must be centered when it is installed on

the steering column. Centering the clockspring

indexes the clockspring tape to the movable steering

components so that the tape can operate within its

designed travel limits. However, if the clockspring is

removed from the steering column or if the steering

shaft is disconnected from the steering gear, the

clockspring spool can change position relative to the

movable steering components and must be re-cen-

tered following completion of the service or the tape

may be damaged. Service replacement clocksprings

are shipped pre-centered and with a locking pin

installed. This locking pin should not be removed

until the clockspring has been installed on the steer-

ing column. If the locking pin is removed before the

clockspring is installed on a steering column, the

clockspring centering procedure must be performed.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCK-

SPRING - STANDARD PROCEDURE - CLOCK-

SPRING CENTERING).

STANDARD PROCEDURE - CLOCKSPRING

CENTERING

The clockspring is designed to wind and unwind

when the steering wheel is rotated, but is only

designed to rotate the same number of turns (about

five complete rotations) as the steering wheel can be

turned from stop to stop. Centering the clockspring

indexes the clockspring tape to other steering compo-

nents so that it can operate within its designed

travel limits. The rotor of a centered clockspring can

be rotated two and one-half turns in either direction

from the centered position, without damaging the

clockspring tape.

However, if the clockspring is removed for service

or if the steering column is disconnected from the

steering gear, the clockspring tape can change posi-

tion relative to the other steering components. The

clockspring must then be re-centered following com-

pletion of such service or the clockspring tape may be

damaged. Service replacement clocksprings are

shipped pre-centered and with a molded plastic lock-

ing pin installed. This locking pin should not be

removed until the clockspring has been installed on

the steering column. If the locking pin is removed

before the clockspring is installed on a steering col-

umn, the clockspring centering procedure must be

performed.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Place the front wheels in the straight-ahead

position.

(2) Remove the clockspring from the steering col-

umn. (Refer to 8 - ELECTRICAL/RESTRAINTS/

CLOCKSPRING - REMOVAL).

WJRESTRAINTS 8O - 15

CLOCKSPRING (Continued)

Page 555 of 2199

(3) Align and seat the one pin and the two mount-

ing ears on the clockspring case to their respective

holes in the multi-function switch mounting housing.

(4) Install and tighten the two clockspring mount-

ing screws. Tighten the screws to 2.5 N´m (22 in.

lbs.).

(5) Reconnect the two instrument panel wire har-

ness connectors for the clockspring to the two connec-

tor receptacles below the steering column on the back

of the clockspring case.

(6) Position the lower tilting steering column

shroud onto the steering column (Fig. 16).

(7) Install and tighten the screw that secures the

lower tilting steering column shroud to the multi-

function switch mounting housing. Tighten the screw

to 2 N´m (17 in. lbs.).

(8) Position the upper tilting column shroud onto

the steering column with the hazard warning switch

button inserted through the hole in the upper surface

of the shroud. Align the upper tilting steering column

shroud to the lower shroud and snap the two shroud

halves together.

(9) Align the snap features on the upper and lower

shrouds and apply hand pressure to snap them

together.

(10) Reinstall the steering wheel onto the steering

column. (Refer to 19 - STEERING/COLUMN/STEER-

ING WHEEL - INSTALLATION).

(11)

Reconnect the steering wheel wire harness con-

nectors to the upper clockspring connector receptacles.

(12) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

DRIVER AIRBAG

DESCRIPTION

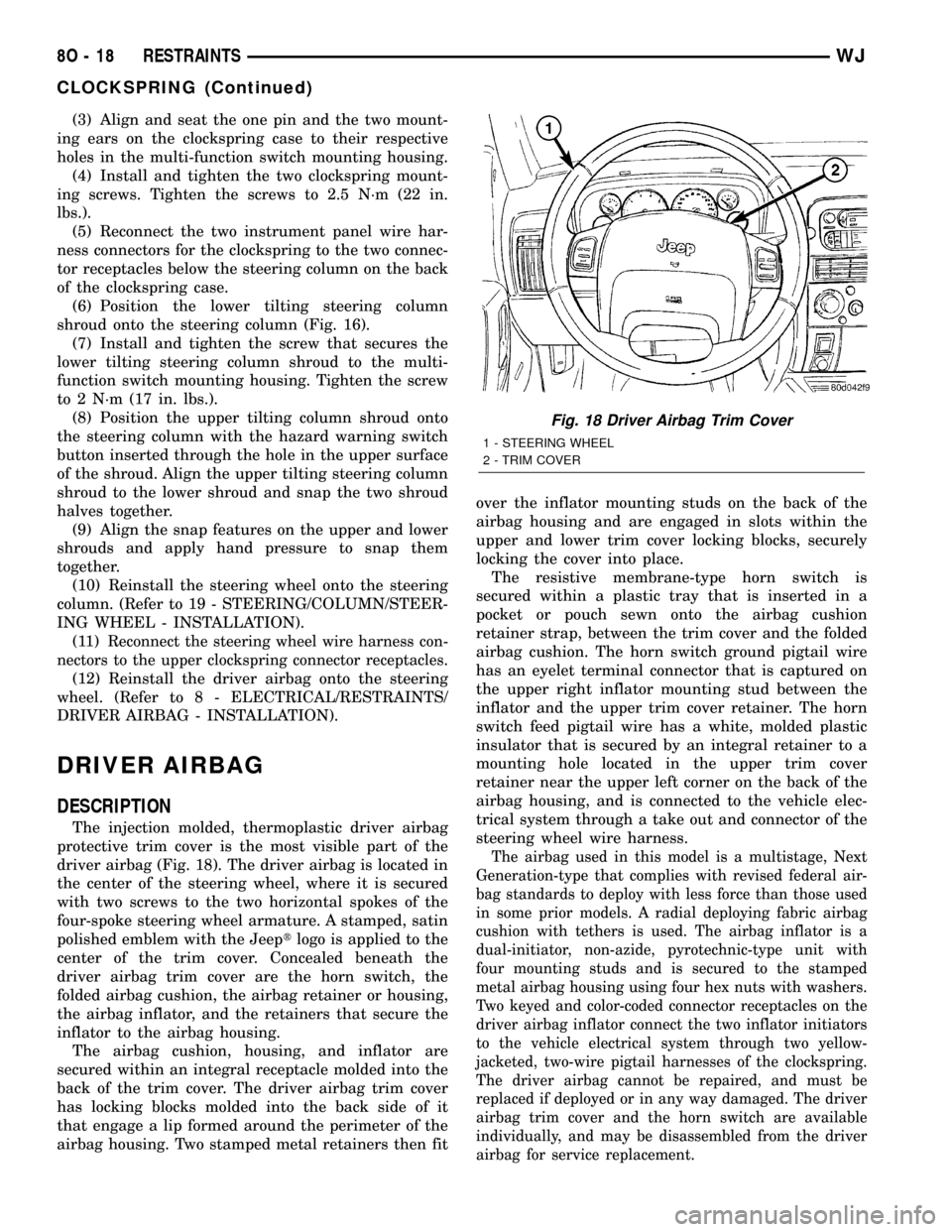

The injection molded, thermoplastic driver airbag

protective trim cover is the most visible part of the

driver airbag (Fig. 18). The driver airbag is located in

the center of the steering wheel, where it is secured

with two screws to the two horizontal spokes of the

four-spoke steering wheel armature. A stamped, satin

polished emblem with the Jeeptlogo is applied to the

center of the trim cover. Concealed beneath the

driver airbag trim cover are the horn switch, the

folded airbag cushion, the airbag retainer or housing,

the airbag inflator, and the retainers that secure the

inflator to the airbag housing.

The airbag cushion, housing, and inflator are

secured within an integral receptacle molded into the

back of the trim cover. The driver airbag trim cover

has locking blocks molded into the back side of it

that engage a lip formed around the perimeter of the

airbag housing. Two stamped metal retainers then fitover the inflator mounting studs on the back of the

airbag housing and are engaged in slots within the

upper and lower trim cover locking blocks, securely

locking the cover into place.

The resistive membrane-type horn switch is

secured within a plastic tray that is inserted in a

pocket or pouch sewn onto the airbag cushion

retainer strap, between the trim cover and the folded

airbag cushion. The horn switch ground pigtail wire

has an eyelet terminal connector that is captured on

the upper right inflator mounting stud between the

inflator and the upper trim cover retainer. The horn

switch feed pigtail wire has a white, molded plastic

insulator that is secured by an integral retainer to a

mounting hole located in the upper trim cover

retainer near the upper left corner on the back of the

airbag housing, and is connected to the vehicle elec-

trical system through a take out and connector of the

steering wheel wire harness.

The airbag used in this model is a multistage, Next

Generation-type that complies with revised federal air-

bag standards to deploy with less force than those used

in some prior models. A radial deploying fabric airbag

cushion with tethers is used. The airbag inflator is a

dual-initiator, non-azide, pyrotechnic-type unit with

four mounting studs and is secured to the stamped

metal airbag housing using four hex nuts with washers.

Two keyed and color-coded connector receptacles on the

driver airbag inflator connect the two inflator initiators

to the vehicle electrical system through two yellow-

jacketed, two-wire pigtail harnesses of the clockspring.

The driver airbag cannot be repaired, and must be

replaced if deployed or in any way damaged. The driver

airbag trim cover and the horn switch are available

individually, and may be disassembled from the driver

airbag for service replacement.

Fig. 18 Driver Airbag Trim Cover

1 - STEERING WHEEL

2 - TRIM COVER

8O - 18 RESTRAINTSWJ

CLOCKSPRING (Continued)