gas type JEEP GRAND CHEROKEE 2003 WJ / 2.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1684 of 2199

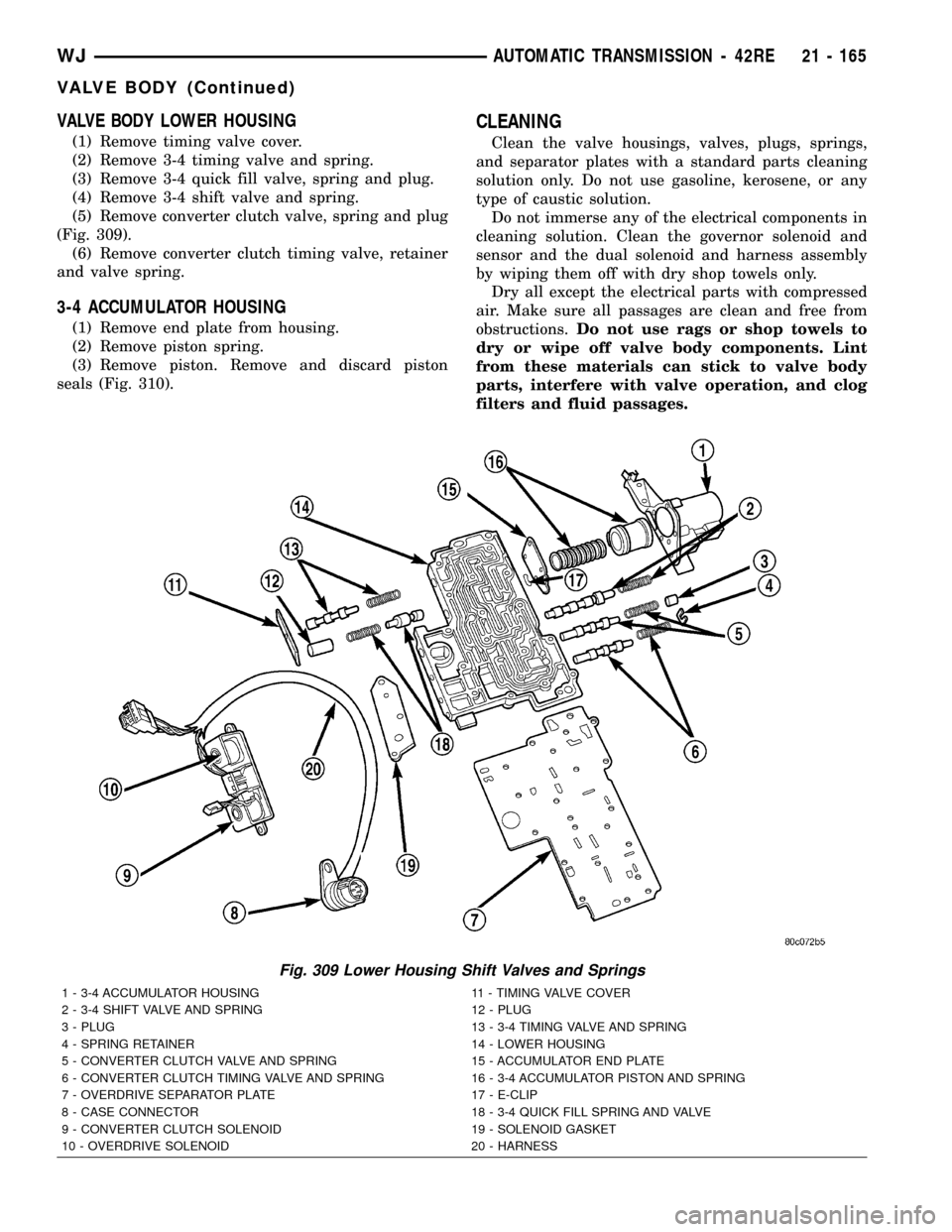

VALVE BODY LOWER HOUSING

(1) Remove timing valve cover.

(2) Remove 3-4 timing valve and spring.

(3) Remove 3-4 quick fill valve, spring and plug.

(4) Remove 3-4 shift valve and spring.

(5) Remove converter clutch valve, spring and plug

(Fig. 309).

(6) Remove converter clutch timing valve, retainer

and valve spring.

3-4 ACCUMULATOR HOUSING

(1) Remove end plate from housing.

(2) Remove piston spring.

(3) Remove piston. Remove and discard piston

seals (Fig. 310).

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaning

solution only. Do not use gasoline, kerosene, or any

type of caustic solution.

Do not immerse any of the electrical components in

cleaning solution. Clean the governor solenoid and

sensor and the dual solenoid and harness assembly

by wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

Fig. 309 Lower Housing Shift Valves and Springs

1 - 3-4 ACCUMULATOR HOUSING 11 - TIMING VALVE COVER

2 - 3-4 SHIFT VALVE AND SPRING 12 - PLUG

3 - PLUG 13 - 3-4 TIMING VALVE AND SPRING

4 - SPRING RETAINER 14 - LOWER HOUSING

5 - CONVERTER CLUTCH VALVE AND SPRING 15 - ACCUMULATOR END PLATE

6 - CONVERTER CLUTCH TIMING VALVE AND SPRING 16 - 3-4 ACCUMULATOR PISTON AND SPRING

7 - OVERDRIVE SEPARATOR PLATE 17 - E-CLIP

8 - CASE CONNECTOR 18 - 3-4 QUICK FILL SPRING AND VALVE

9 - CONVERTER CLUTCH SOLENOID 19 - SOLENOID GASKET

10 - OVERDRIVE SOLENOID 20 - HARNESS

WJAUTOMATIC TRANSMISSION - 42RE 21 - 165

VALVE BODY (Continued)

Page 1693 of 2199

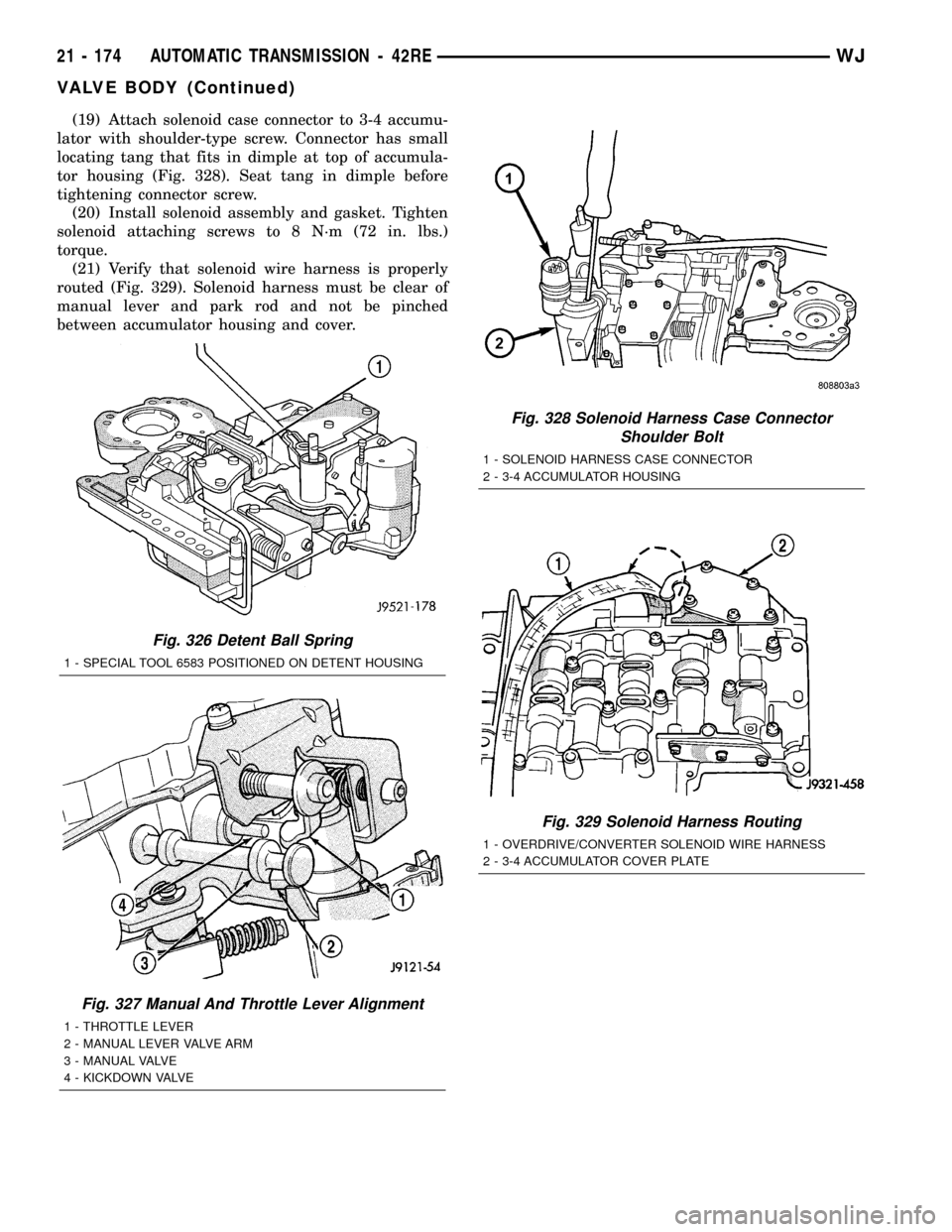

(19) Attach solenoid case connector to 3-4 accumu-

lator with shoulder-type screw. Connector has small

locating tang that fits in dimple at top of accumula-

tor housing (Fig. 328). Seat tang in dimple before

tightening connector screw.

(20) Install solenoid assembly and gasket. Tighten

solenoid attaching screws to 8 N´m (72 in. lbs.)

torque.

(21) Verify that solenoid wire harness is properly

routed (Fig. 329). Solenoid harness must be clear of

manual lever and park rod and not be pinched

between accumulator housing and cover.

Fig. 326 Detent Ball Spring

1 - SPECIAL TOOL 6583 POSITIONED ON DETENT HOUSING

Fig. 327 Manual And Throttle Lever Alignment

1 - THROTTLE LEVER

2 - MANUAL LEVER VALVE ARM

3 - MANUAL VALVE

4 - KICKDOWN VALVE

Fig. 328 Solenoid Harness Case Connector

Shoulder Bolt

1 - SOLENOID HARNESS CASE CONNECTOR

2 - 3-4 ACCUMULATOR HOUSING

Fig. 329 Solenoid Harness Routing

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

21 - 174 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1694 of 2199

GOVERNOR BODY, SENSOR AND SOLENOID

(1) Turn valve body assembly over so accumulator

side of transfer plate is facing down.

(2) Install new O-rings on governor pressure sole-

noid and sensor.

(3) Lubricate solenoid and sensor O-rings with

clean transmission fluid.

(4) Install governor pressure sensor in governor

body.

(5) Install governor pressure solenoid in governor

body. Push solenoid in until it snaps into place in

body.

(6) Position governor body gasket on transfer

plate.

(7) Install retainer plate on governor body and

around solenoid. Be sure solenoid connector is posi-

tioned in retainer cutout.

(8) Align screw holes in governor body and trans-

fer plate. Then install and tighten governor body

screws to 4 N´m (35 in. lbs.) torque.

(9) Connect harness wires to governor pressure

solenoid and governor pressure sensor.

(10) Install fluid filter and pan.

(11) Lower vehicle.

(12) Fill transmission with recommended fluid and

road test vehicle to verify repair.

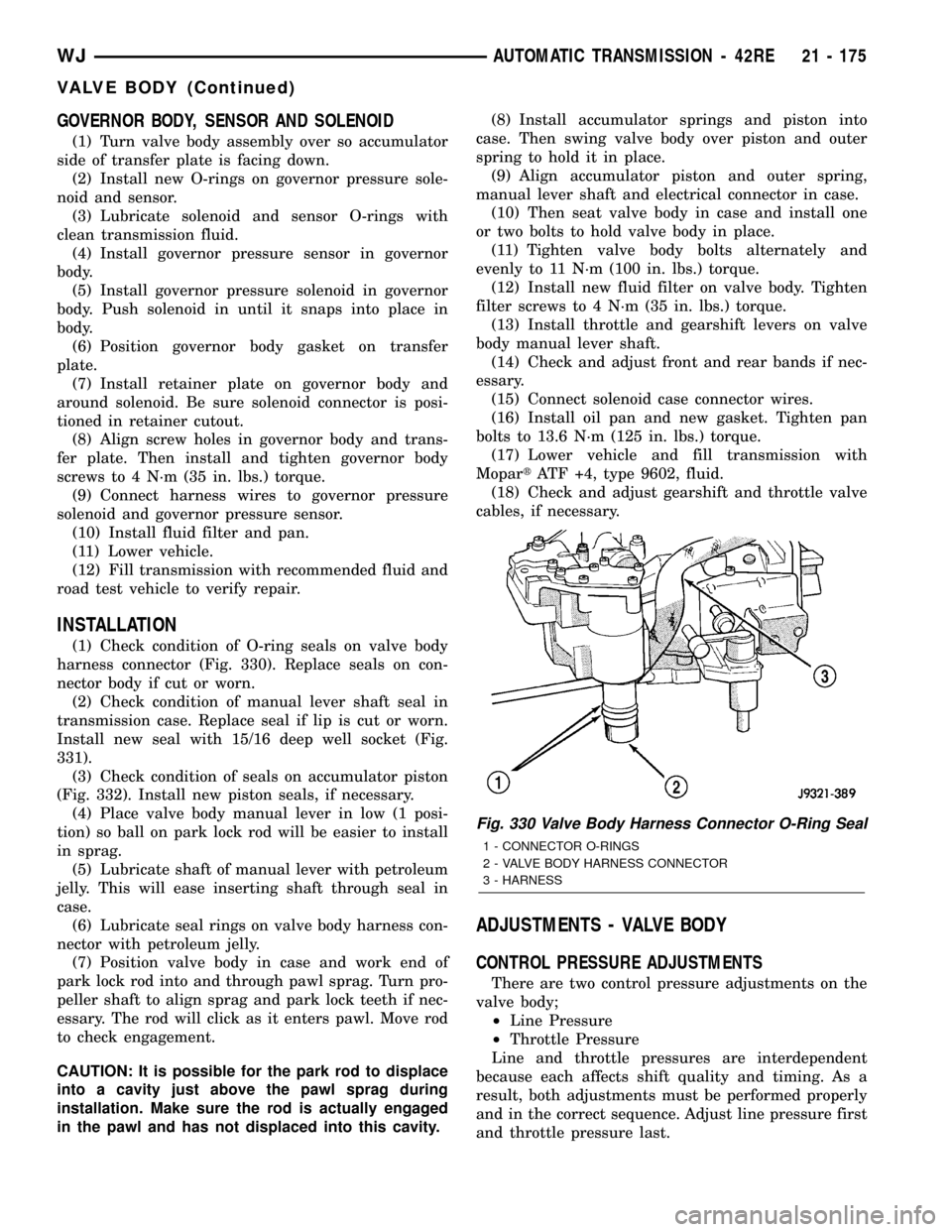

INSTALLATION

(1) Check condition of O-ring seals on valve body

harness connector (Fig. 330). Replace seals on con-

nector body if cut or worn.

(2) Check condition of manual lever shaft seal in

transmission case. Replace seal if lip is cut or worn.

Install new seal with 15/16 deep well socket (Fig.

331).

(3) Check condition of seals on accumulator piston

(Fig. 332). Install new piston seals, if necessary.

(4) Place valve body manual lever in low (1 posi-

tion) so ball on park lock rod will be easier to install

in sprag.

(5) Lubricate shaft of manual lever with petroleum

jelly. This will ease inserting shaft through seal in

case.

(6) Lubricate seal rings on valve body harness con-

nector with petroleum jelly.

(7) Position valve body in case and work end of

park lock rod into and through pawl sprag. Turn pro-

peller shaft to align sprag and park lock teeth if nec-

essary. The rod will click as it enters pawl. Move rod

to check engagement.

CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into this cavity.(8) Install accumulator springs and piston into

case. Then swing valve body over piston and outer

spring to hold it in place.

(9) Align accumulator piston and outer spring,

manual lever shaft and electrical connector in case.

(10) Then seat valve body in case and install one

or two bolts to hold valve body in place.

(11) Tighten valve body bolts alternately and

evenly to 11 N´m (100 in. lbs.) torque.

(12) Install new fluid filter on valve body. Tighten

filter screws to 4 N´m (35 in. lbs.) torque.

(13) Install throttle and gearshift levers on valve

body manual lever shaft.

(14) Check and adjust front and rear bands if nec-

essary.

(15) Connect solenoid case connector wires.

(16) Install oil pan and new gasket. Tighten pan

bolts to 13.6 N´m (125 in. lbs.) torque.

(17) Lower vehicle and fill transmission with

MopartATF +4, type 9602, fluid.

(18) Check and adjust gearshift and throttle valve

cables, if necessary.

ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

Fig. 330 Valve Body Harness Connector O-Ring Seal

1 - CONNECTOR O-RINGS

2 - VALVE BODY HARNESS CONNECTOR

3 - HARNESS

WJAUTOMATIC TRANSMISSION - 42RE 21 - 175

VALVE BODY (Continued)

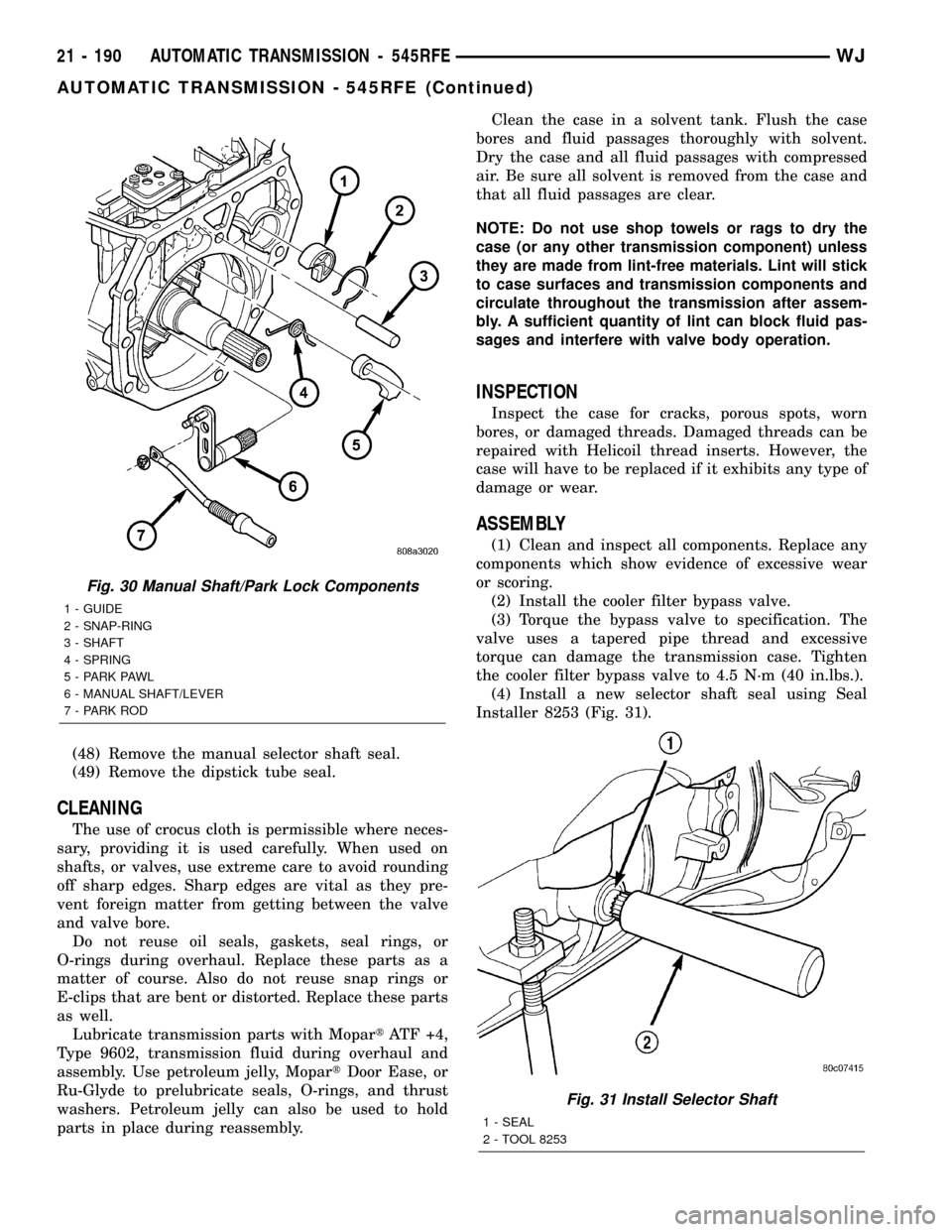

Page 1709 of 2199

(48) Remove the manual selector shaft seal.

(49) Remove the dipstick tube seal.

CLEANING

The use of crocus cloth is permissible where neces-

sary, providing it is used carefully. When used on

shafts, or valves, use extreme care to avoid rounding

off sharp edges. Sharp edges are vital as they pre-

vent foreign matter from getting between the valve

and valve bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or

E-clips that are bent or distorted. Replace these parts

as well.

Lubricate transmission parts with MopartATF +4,

Type 9602, transmission fluid during overhaul and

assembly. Use petroleum jelly, MopartDoor Ease, or

Ru-Glyde to prelubricate seals, O-rings, and thrust

washers. Petroleum jelly can also be used to hold

parts in place during reassembly.Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent.

Dry the case and all fluid passages with compressed

air. Be sure all solvent is removed from the case and

that all fluid passages are clear.

NOTE: Do not use shop towels or rags to dry the

case (or any other transmission component) unless

they are made from lint-free materials. Lint will stick

to case surfaces and transmission components and

circulate throughout the transmission after assem-

bly. A sufficient quantity of lint can block fluid pas-

sages and interfere with valve body operation.

INSPECTION

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

ASSEMBLY

(1) Clean and inspect all components. Replace any

components which show evidence of excessive wear

or scoring.

(2) Install the cooler filter bypass valve.

(3) Torque the bypass valve to specification. The

valve uses a tapered pipe thread and excessive

torque can damage the transmission case. Tighten

the cooler filter bypass valve to 4.5 N´m (40 in.lbs.).

(4) Install a new selector shaft seal using Seal

Installer 8253 (Fig. 31).

Fig. 30 Manual Shaft/Park Lock Components

1 - GUIDE

2 - SNAP-RING

3 - SHAFT

4 - SPRING

5 - PARK PAWL

6 - MANUAL SHAFT/LEVER

7 - PARK ROD

Fig. 31 Install Selector Shaft

1 - SEAL

2 - TOOL 8253

21 - 190 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1749 of 2199

STANDARD PROCEDURE - FLUID AND FILTER

REPLACEMENT

For proper service intervals (Refer to LUBRICA-

TION & MAINTENANCE/MAINTENANCE SCHED-

ULES - DESCRIPTION).

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Place a large diameter shallow drain pan

beneath the transmission pan.

(3) Remove bolts holding front and sides of pan to

transmission.

(4)

Loosen bolts holding rear of pan to transmission.

(5) Slowly separate front of pan away from trans-

mission allowing the fluid to drain into drain pan.

(6) Hold up pan and remove remaining bolts hold-

ing pan to transmission.

(7) While holding pan level, lower pan away from

transmission.

(8) Pour remaining fluid in pan into drain pan.

(9)

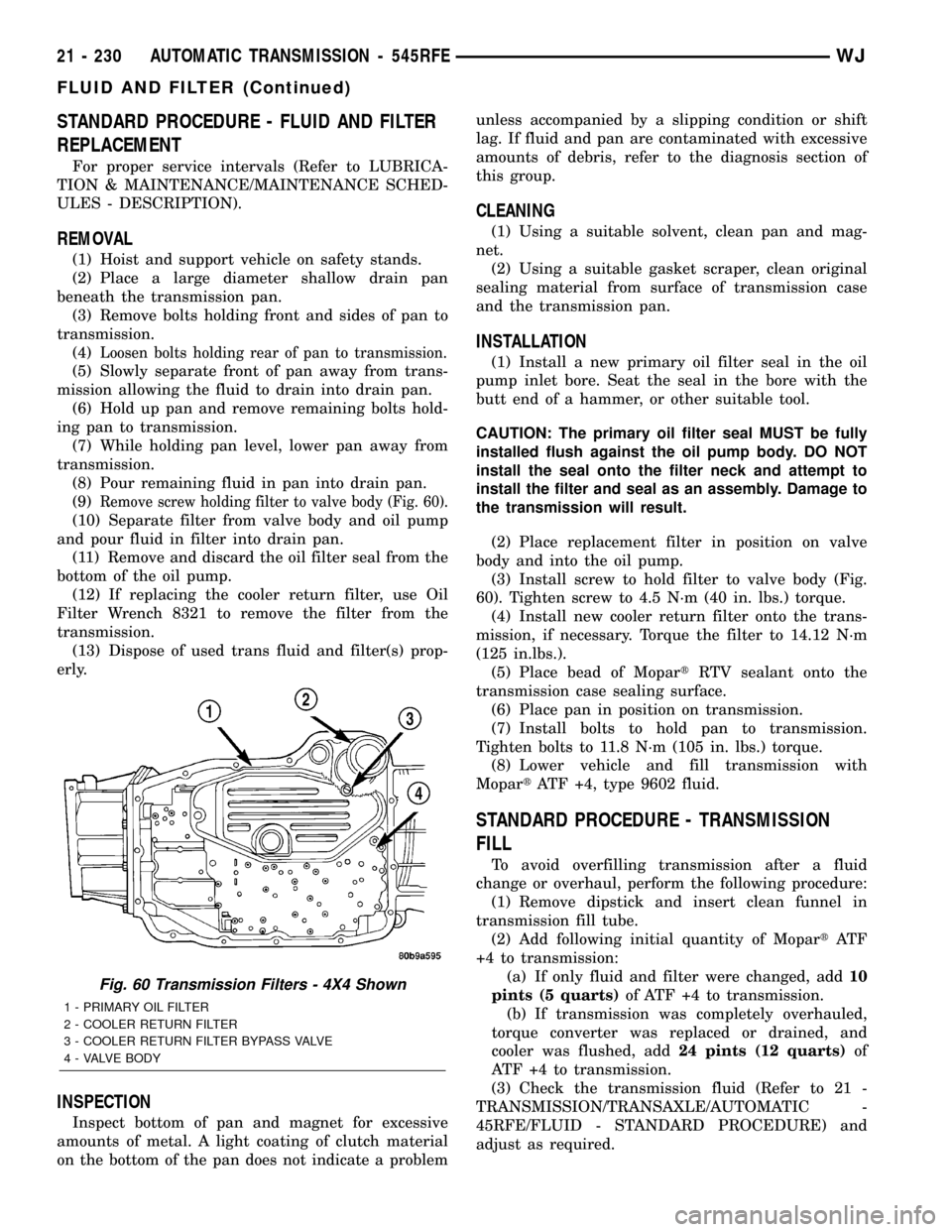

Remove screw holding filter to valve body (Fig. 60).

(10) Separate filter from valve body and oil pump

and pour fluid in filter into drain pan.

(11) Remove and discard the oil filter seal from the

bottom of the oil pump.

(12) If replacing the cooler return filter, use Oil

Filter Wrench 8321 to remove the filter from the

transmission.

(13) Dispose of used trans fluid and filter(s) prop-

erly.

INSPECTION

Inspect bottom of pan and magnet for excessive

amounts of metal. A light coating of clutch material

on the bottom of the pan does not indicate a problemunless accompanied by a slipping condition or shift

lag. If fluid and pan are contaminated with excessive

amounts of debris, refer to the diagnosis section of

this group.

CLEANING

(1) Using a suitable solvent, clean pan and mag-

net.

(2) Using a suitable gasket scraper, clean original

sealing material from surface of transmission case

and the transmission pan.

INSTALLATION

(1) Install a new primary oil filter seal in the oil

pump inlet bore. Seat the seal in the bore with the

butt end of a hammer, or other suitable tool.

CAUTION: The primary oil filter seal MUST be fully

installed flush against the oil pump body. DO NOT

install the seal onto the filter neck and attempt to

install the filter and seal as an assembly. Damage to

the transmission will result.

(2) Place replacement filter in position on valve

body and into the oil pump.

(3) Install screw to hold filter to valve body (Fig.

60). Tighten screw to 4.5 N´m (40 in. lbs.) torque.

(4) Install new cooler return filter onto the trans-

mission, if necessary. Torque the filter to 14.12 N´m

(125 in.lbs.).

(5) Place bead of MopartRTV sealant onto the

transmission case sealing surface.

(6) Place pan in position on transmission.

(7) Install bolts to hold pan to transmission.

Tighten bolts to 11.8 N´m (105 in. lbs.) torque.

(8) Lower vehicle and fill transmission with

MopartATF +4, type 9602 fluid.

STANDARD PROCEDURE - TRANSMISSION

FILL

To avoid overfilling transmission after a fluid

change or overhaul, perform the following procedure:

(1) Remove dipstick and insert clean funnel in

transmission fill tube.

(2) Add following initial quantity of MopartAT F

+4 to transmission:

(a) If only fluid and filter were changed, add10

pints (5 quarts)of ATF +4 to transmission.

(b) If transmission was completely overhauled,

torque converter was replaced or drained, and

cooler was flushed, add24 pints (12 quarts)of

ATF +4 to transmission.

(3) Check the transmission fluid (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

45RFE/FLUID - STANDARD PROCEDURE) and

adjust as required.

Fig. 60 Transmission Filters - 4X4 Shown

1 - PRIMARY OIL FILTER

2 - COOLER RETURN FILTER

3 - COOLER RETURN FILTER BYPASS VALVE

4 - VALVE BODY

21 - 230 AUTOMATIC TRANSMISSION - 545RFEWJ

FLUID AND FILTER (Continued)

Page 1796 of 2199

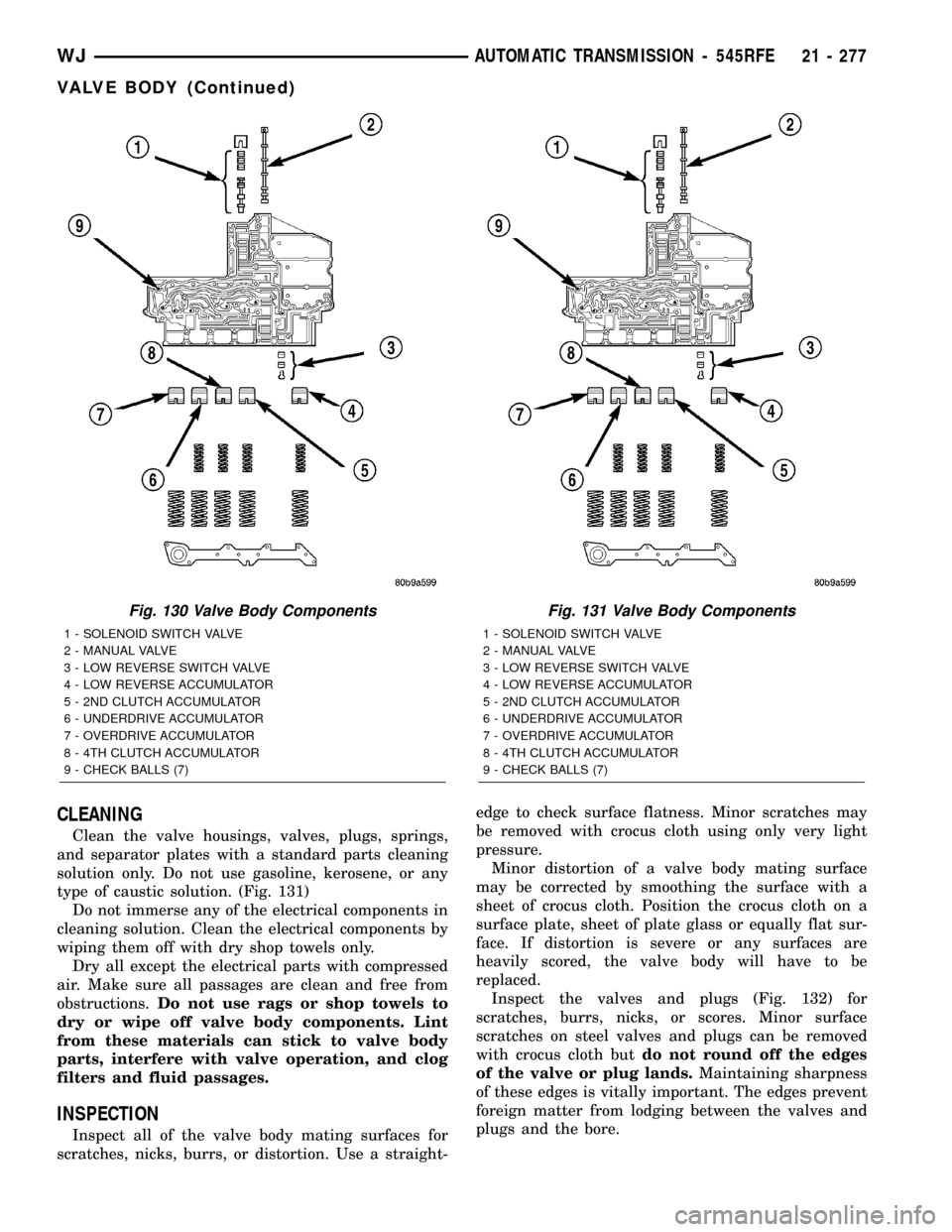

CLEANING

Clean the valve housings, valves, plugs, springs,

and separator plates with a standard parts cleaning

solution only. Do not use gasoline, kerosene, or any

type of caustic solution. (Fig. 131)

Do not immerse any of the electrical components in

cleaning solution. Clean the electrical components by

wiping them off with dry shop towels only.

Dry all except the electrical parts with compressed

air. Make sure all passages are clean and free from

obstructions.Do not use rags or shop towels to

dry or wipe off valve body components. Lint

from these materials can stick to valve body

parts, interfere with valve operation, and clog

filters and fluid passages.

INSPECTION

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.

Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with a

sheet of crocus cloth. Position the crocus cloth on a

surface plate, sheet of plate glass or equally flat sur-

face. If distortion is severe or any surfaces are

heavily scored, the valve body will have to be

replaced.

Inspect the valves and plugs (Fig. 132) for

scratches, burrs, nicks, or scores. Minor surface

scratches on steel valves and plugs can be removed

with crocus cloth butdo not round off the edges

of the valve or plug lands.Maintaining sharpness

of these edges is vitally important. The edges prevent

foreign matter from lodging between the valves and

plugs and the bore.

Fig. 130 Valve Body Components

1 - SOLENOID SWITCH VALVE

2 - MANUAL VALVE

3 - LOW REVERSE SWITCH VALVE

4 - LOW REVERSE ACCUMULATOR

5 - 2ND CLUTCH ACCUMULATOR

6 - UNDERDRIVE ACCUMULATOR

7 - OVERDRIVE ACCUMULATOR

8 - 4TH CLUTCH ACCUMULATOR

9 - CHECK BALLS (7)

Fig. 131 Valve Body Components

1 - SOLENOID SWITCH VALVE

2 - MANUAL VALVE

3 - LOW REVERSE SWITCH VALVE

4 - LOW REVERSE ACCUMULATOR

5 - 2ND CLUTCH ACCUMULATOR

6 - UNDERDRIVE ACCUMULATOR

7 - OVERDRIVE ACCUMULATOR

8 - 4TH CLUTCH ACCUMULATOR

9 - CHECK BALLS (7)

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 277

VALVE BODY (Continued)

Page 1875 of 2199

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will notalways seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during high

cross winds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

Wind noise can also be caused by improperly fitted

exterior moldings or body ornamentation. Loose

moldings can flutter, creating a buzzing or chattering

noise. An open cavity or protruding edge can create a

whistling or howling noise. Inspect the exterior of the

vehicle to verify that these conditions do not exist.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If compo-

nent alignment or sealing is necessary, refer to the

appropriate section of this group for proper proce-

dures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location

of the wind noise.

(2) Apply 50 mm (2 in.) masking tape in 150 mm

(6 in.) lengths along weatherstrips, weld seams or

moldings. After each length is applied, drive the vehi-

cle. If noise goes away after a piece of tape is applied,

remove tape, locate, and repair defect.

POSSIBLE CAUSE OF WIND NOISE

²Moldings standing away from body surface can

catch wind and whistle.

²Gaps in sealed areas behind overhanging body

flanges can cause wind-rushing sounds.

²Misaligned movable components.

²Missing or improperly installed plugs in pillars.

²Weld burn through holes.

STANDARD PROCEDURE

STANDARD PROCEDURE - BODY LUBRICATION

All mechanisms and linkages should be lubricated

when necessary. This will maintain ease of operation

and provide protection against rust and excessive

wear. The weatherstrip seals should be lubricated to

prolong their life as well as to improve door sealing.

All applicable exterior and interior vehicle operat-

ing mechanisms should be inspected and cleaned.

Pivot/sliding contact areas on the mechanisms should

then be lubricated.

(1) When necessary, lubricate the operating mech-

anisms with the specified lubricants.

23 - 2 BODYWJ

BODY (Continued)

Page 2130 of 2199

CAUTION

CAUTION

CAUTION: Liquid refrigerant is corrosive to metal

surfaces. Follow the operating instructions supplied

with the service equipment being used.

Never add R-12 to a refrigerant system designed to

use R-134a. Damage to the system will result.

R-12 refrigerant oil must not be mixed with R-134a

refrigerant oil. They are not compatible.

Do not use R-12 equipment or parts on the R-134a

system. Damage to the system will result.

Do not overcharge the refrigerant system. This will

cause excessive compressor head pressure and

can cause noise and system failure.

Recover the refrigerant before opening any fitting

or connection. Open the fittings with caution, even

after the system has been discharged. Never open

or loosen a connection before recovering the refrig-

erant.

The refrigerant system must always be evacuated

before charging.

Do not open the refrigerant system or uncap a

replacement component until you are ready to ser-

vice the system. This will prevent contamination in

the system.

Before disconnecting a component, clean the out-

side of the fittings thoroughly to prevent contami-

nation from entering the refrigerant system.

Immediately after disconnecting a component from

the refrigerant system, seal the open fittings with a

cap or plug.

Before connecting an open refrigerant fitting,

always install a new seal or gasket. Coat the fitting

and seal with clean refrigerant oil before connect-

ing.

Do not remove the sealing caps from a replacement

component until it is to be installed.

When installing a refrigerant line, avoid sharp

bends that may restrict refrigerant flow. Position the

refrigerant lines away from exhaust system compo-

nents or any sharp edges, which may damage the

line.

Tighten refrigerant fittings only to the specified

torque. The aluminum fittings used in the refriger-

ant system will not tolerate overtightening.

When disconnecting a refrigerant fitting, use a

wrench on both halves of the fitting. This will pre-

vent twisting of the refrigerant lines or tubes.

Refrigerant oil will absorb moisture from the atmo-

sphere if left uncapped. Do not open a container of

refrigerant oil until you are ready to use it. Replace

the cap on the oil container immediately after using.

Store refrigerant oil only in a clean, airtight, and

moisture-free container.Keep service tools and the work area clean. Con-

tamination of the refrigerant system through care-

less work habits must be avoided.REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS

Kinks or sharp bends in the refrigerant plumbing

will reduce the capacity of the entire system. High

pressures are produced in the system when it is oper-

ating. Extreme care must be exercised to make sure

that all refrigerant system connections are pressure

tight.

A good rule for the flexible hose refrigerant lines is

to keep the radius of all bends at least ten times the

diameter of the hose. Sharp bends will reduce the

flow of refrigerant. The flexible hose lines should be

routed so they are at least 80 millimeters (3 inches)

from the exhaust manifold. It is a good practice to

inspect all flexible refrigerant system hose lines at

least once a year to make sure they are in good con-

dition and properly routed.

There are two types of refrigerant fittings:

²All fittings with O-rings need to be coated with

refrigerant oil before installation. Use only O-rings

that are the correct size and approved for use with

R-134a refrigerant. Failure to do so may result in a

leak.

²Unified plumbing connections with gaskets can-

not be serviced with O-rings. The gaskets are not

reusable and new gaskets do not require lubrication

before installing.

Using the proper tools when making a refrigerant

plumbing connection is very important. Improper

tools or improper use of the tools can damage the

refrigerant fittings. Always use two wrenches when

loosening or tightening tube fittings. Use one wrench

to hold one side of the connection stationary, while

loosening or tightening the other side of the connec-

tion with a second wrench.

The refrigerant must be recovered completely from

the system before opening any fitting or connection.

Open the fittings with caution, even after the refrig-

erant has been recovered. If any pressure is noticed

as a fitting is loosened, tighten the fitting and

recover the refrigerant from the system again.

Do not discharge refrigerant into the atmosphere.

Use an R-134a refrigerant recovery/recycling device

that meets SAE Standard J2210.

The refrigerant system will remain chemically sta-

ble as long as pure, moisture-free R-134a refrigerant

and refrigerant oil is used. Dirt, moisture, or air can

upset this chemical stability. Operational troubles or

serious damage can occur if foreign material is

present in the refrigerant system.

When it is necessary to open the refrigerant sys-

tem, have everything needed to service the system

WJPLUMBING 24 - 53

PLUMBING (Continued)

Page 2142 of 2199

ING & AIR CONDITIONING/CONTROLS/A/C

PRESSURE TRANSDUCER - INSTALLATION).

(9) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(10) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

(11) Connect the negative battery cable.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.

High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

(1) Remove the tape or plugs from the discharge

line block fitting and the manifold on the compressor.

Install the discharge line block fitting to the manifold

on the compressor. Tighten the mounting bolt to 25.4

N´m (225 in. lbs.).

(2) Remove the tape or plugs from the refrigerant

line fittings on the condenser inlet and the discharge

line. Connect the discharge line to the condenser

inlet. Tighten the retaining nut to 28 N´m (250 in.

lbs.).

(3) Install the a/c high pressure transducer(Refer

to 24 - HEATING & AIR CONDITIONING/CON-

TROLS/A/C PRESSURE TRANSDUCER - INSTAL-

LATION).

(4) Connect the battery negative cable.

(5) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)(6) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

A/C EXPANSION VALVE

DESCRIPTION

The ªHº valve type thermal expansion valve (TXV)

is located at the front of the heater-A/C housing

between the liquid and suction lines and the evapo-

rator coil.

The expansion valve is a factory calibrated unit

and cannot be adjusted or repaired. If faulty or dam-

aged, the expansion valve must be replaced.

OPERATION

High-pressure, high temperature liquid refrigerant

from the liquid line passes through the expansion

valve orifice, converting it inot a low-pressure, low-

temperature mixture of liquid and gas before it

enters the evaporator coil. A temperature sensor in

the expansion valve control head monitors the tem-

perature of the refrigerant leaving the evaporator coil

throught the suction line, and adjusts the orifice size

at the liquid line to let the proper amoount of refrig-

erant into the evaporator coil to meet the vehicle

cooling requirements. Controlling the refrigerant flow

through the evaporator ensures that none of the

refrigerant leaving the evaporator is still in a liquid

state, which could damage the compressor.

DIAGNOSIS AND TESTING - A/C EXPANSION

VALVE

The expansion valve is located on the engine side

of the dash panel near the shock tower.

The expansion valve can fail in three different

positions (open, closed or restricted).

In an Open Position: this will result in a noisy

compressor or no cooling. The cause can be broken

spring, broken ball or excessive moisture in the A/C

system. If the spring or ball are found to be defective,

replace the expansion valve. If excessive moisture is

found in the A/C system, recycle the refrigerant.

In a Closed Position: There will be low suction

pressure and no cooling. This may be caused by a

failed power dome or excessive moisture in the A/C

system. If the power dome on the expansion valve is

found to be defective replace the expansion valve. If

excessive moisture is found recycle the refrigerant.

A Restricted Orifice: There will be low suction

pressure and no cooling. This may be caused by

debris in the refrigerant system. If debris is believed

to be the cause, recycle the refrigerant and replace

the expansion valve and the receiver/drier.

WJPLUMBING 24 - 65

A/C DISCHARGE LINE (Continued)

Page 2152 of 2199

REFRIGERANT

DESCRIPTION

The refrigerant used in this air conditioning sys-

tem is a HydroFluoroCarbon (HFC), type R-134a.

Unlike R-12, which is a ChloroFluoroCarbon (CFC),

R-134a refrigerant does not contain ozone-depleting

chlorine. R-134a refrigerant is a non-toxic, non-flam-

mable, clear, and colorless liquefied gas.

Even though R-134a does not contain chlorine, it

must be reclaimed and recycled just like CFC-type

refrigerants. This is because R-134a is a greenhouse

gas and can contribute to global warming.

OPERATION

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 added to an R-134a refrigerant

system will cause compressor failure, refrigerant oil

sludge or poor air conditioning system performance.

In addition, the PolyAlkylene Glycol (PAG) synthetic

refrigerant oils used in an R-134a refrigerant system

are not compatible with the mineral-based refriger-

ant oils used in an R-12 refrigerant system.

R-134a refrigerant system service ports, service

tool couplers and refrigerant dispensing bottles have

all been designed with unique fittings to ensure that

an R-134a system is not accidentally contaminated

with the wrong refrigerant (R-12). There are also

labels posted in the engine compartment of the vehi-

cle and on the compressor identifying to service tech-

nicians that the air conditioning system is equipped

with R-134a.

REFRIGERANT OIL

DESCRIPTION

The refrigerant oil used in R-134a refrigerant sys-

tems is a synthetic-based, PolyAlkylene Glycol (PAG),

wax-free lubricant. Mineral-based R-12 refrigerant

oils are not compatible with PAG oils, and should

never be introduced to an R-134a refrigerant system.

There are different PAG oils available, and each

contains a different additive package. The 10PA17

compressor used in this vehicle is designed to use an

ND8 PAG refrigerant oil. Use only refrigerant oil of

this same type to service the refrigerant system.

OPERATION

After performing any refrigerant recovery or recy-

cling operation, always replenish the refrigerant sys-

tem with the same amount of the recommended

refrigerant oil as was removed. Too little refrigerant

oil can cause compressor damage, and too much can

reduce air conditioning system performance.PAG refrigerant oil is much more hygroscopic than

mineral oil, and will absorb any moisture it comes

into contact with, even moisture in the air. The PAG

oil container should always be kept tightly capped

until it is ready to be used. After use, recap the oil

container immediately to prevent moisture contami-

nation.

STANDARD PROCEDURE - REFRIGERANT OIL

LEVEL

When an air conditioning system is assembled at

the factory, all components except the compressor are

refrigerant oil free. After the refrigerant system has

been charged and operated, the refrigerant oil in the

compressor is dispersed throughout the refrigerant

system. The accumulator, evaporator, condenser, and

compressor will each retain a significant amount of

the needed refrigerant oil.

It is important to have the correct amount of oil in

the refrigerant system. This ensures proper lubrica-

tion of the compressor. Too little oil will result in

damage to the compressor. Too much oil will reduce

the cooling capacity of the air conditioning system.

It will not be necessary to check the oil level in the

compressor or to add oil, unless there has been an oil

loss. An oil loss may occur due to a rupture or leak

from a refrigerant line, a connector fitting, a compo-

nent, or a component seal. If a leak occurs, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system after the repair has been made.

Refrigerant oil loss will be evident at the leak point

by the presence of a wet, shiny surface around the

leak.

Refrigerant oil must be added when a accumulator,

evaporator coil, or condenser are replaced. See the

Refrigerant Oil Capacities chart. When a compressor

is replaced, the refrigerant oil must be drained from

the old compressor and measured. Drain all of the

refrigerant oil from the new compressor, then fill the

new compressor with the same amount of refrigerant

oil that was drained out of the old compressor.

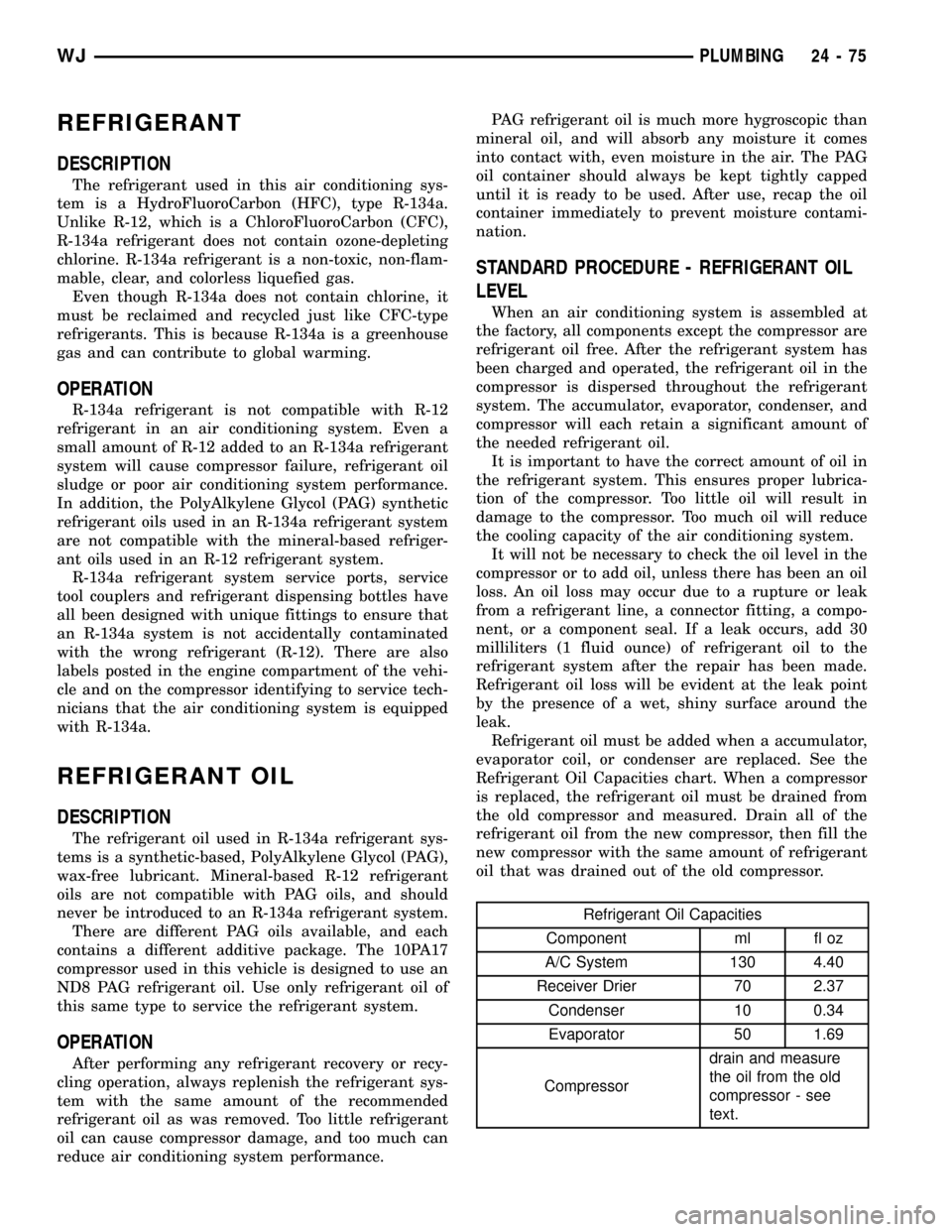

Refrigerant Oil Capacities

Component ml fl oz

A/C System 130 4.40

Receiver Drier 70 2.37

Condenser 10 0.34

Evaporator 50 1.69

Compressordrain and measure

the oil from the old

compressor - see

text.

WJPLUMBING 24 - 75