display JEEP GRAND CHEROKEE 2003 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1871 of 2199

TIRE PRESSURE MONITORING

DESCRIPTION

The EVIC will monitor the tire pressure signals

from the five tire sensors and determine if any tire

has gone below the low pressure threshold or raised

above the high pressure threshold. Refer to the table

below.

LOW TIRE PRESSURE THRESHOLDS

SYSTEM STATUS

INDICATORTIRE PRESSURE

ON 179 kPa (26 PSI)

OFF 214 kPa (31 PSI)

HIGH TIRE PRESSURE THRESHOLDS

SYSTEM STATUS

INDICATORTIRE PRESSURE

ON 310 kPa (45 PSI)

OFF 276 kPa (40 PSI)

The Remote Tire Pressure Monitors (RTPM) are

not internally serviceable. For a Sensor Failure or

Low Battery fault, the RTPM must be replaced.

OPERATION

If equipped with the Tire Pressure Monitoring Sys-

tem, each of the vehicle's five wheels will have a

valve stem with a pressure sensor and radio trans-

mitter built in. Signals from the tire pressure sensors

are received and interpreted by the Electronic Vehi-

cle Information Center (EVIC). A sensor in a

mounted wheel will broadcast its detected pressure

once per minute when the vehicle is moving faster

than 40 km/h (25 mph). The spare tire sensor will

broadcast once every hour. Each sensor's broadcast is

uniquely coded so that the EVIC can determine loca-

tion. The individual tire pressures can be displayed

graphically on the EVIC

DIAGNOSIS AND TESTING - TIRE PRESSURE

MONITORING SYSTEM

All Tire Pressure Monitoring System Faults are

specific to one location. If a9BATTERY LOW9or

9SENSOR FAILURE9fault is detected, the location

will be displayed. The appropriate sensor/transmitter

can then be replaced. If a single sensor/transmitter

cannot be detected by the EVIC, replace that sensor

transmitter. If none of the sensors/transmitters can

be detected, refer to symptoms in the EVIC section.

For additional system description and diagnosis,

refer to Tire Pressure Monitoring in the Body Diag-

nostic manual.

SENSOR

REMOVAL - TIRE PRESSURE SENSOR/

TRANSMITTER

(1) Remove the tire/wheel from the vehicle.

CAUTION: When removing the stick on balancing

weights from the wheel, do not use an abrasive

cleaner or a cleaner which will damage the protec-

tive finish on the wheel.

(2) Remove the balancing weights from the wheel.

NOTE: The cap used on this valve stem contains an

O-ring seal to prevent contamination and moisture

from entering the valve stem. Retain this valve stem

cap for re-use. Do not substitute a regular valve

stem cap in its place.

(3) Remove the cap from the valve stem.

NOTE: The valve stem used on this vehicle is made

of aluminum and the core is nickel plated brass.

The original valve stem core must be reinstalled

and not substituted for a valve stem core made of a

different material. This is required to prevent corro-

sion in the valve stem caused by the different met-

als.

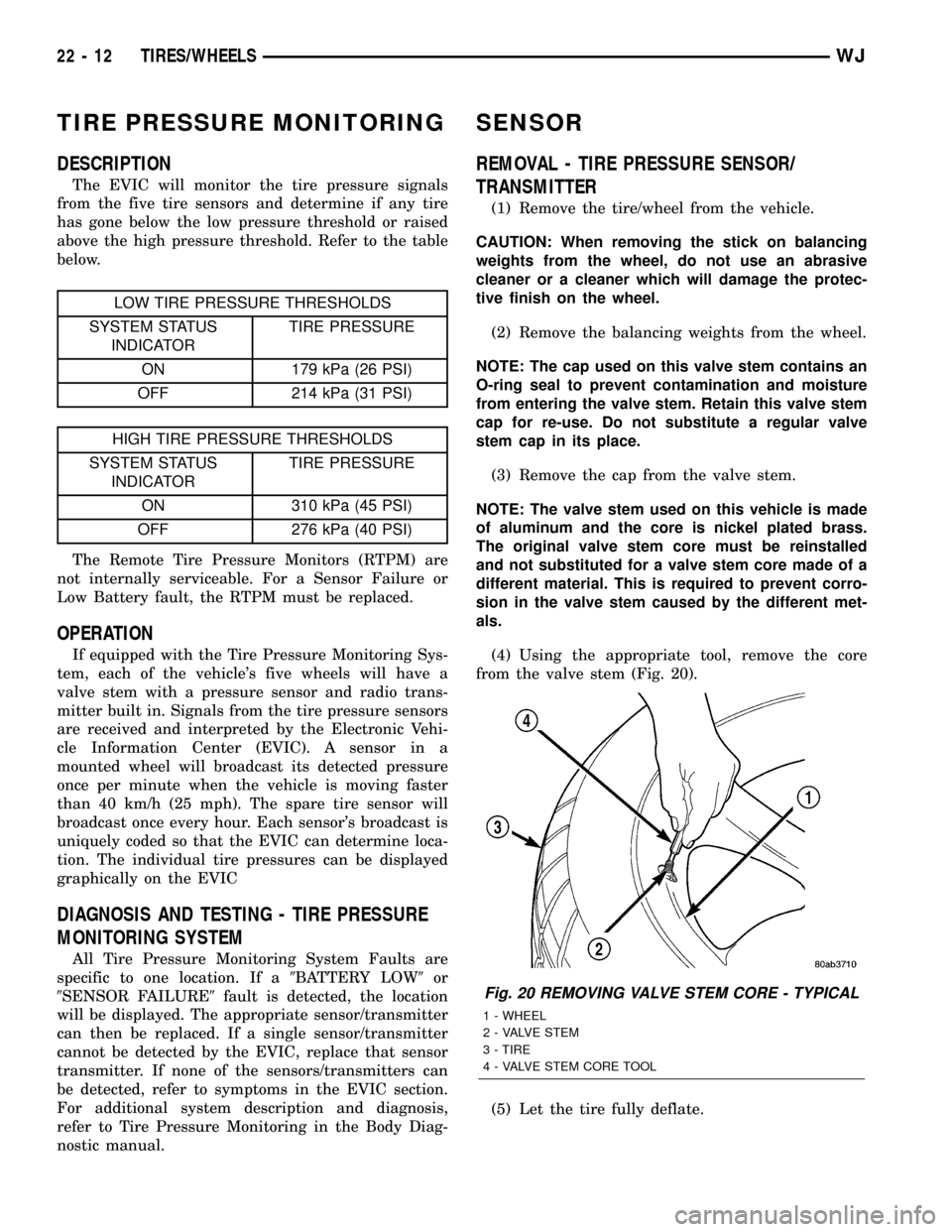

(4) Using the appropriate tool, remove the core

from the valve stem (Fig. 20).

(5) Let the tire fully deflate.

Fig. 20 REMOVING VALVE STEM CORE - TYPICAL

1 - WHEEL

2 - VALVE STEM

3 - TIRE

4 - VALVE STEM CORE TOOL

22 - 12 TIRES/WHEELSWJ

Page 2094 of 2199

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

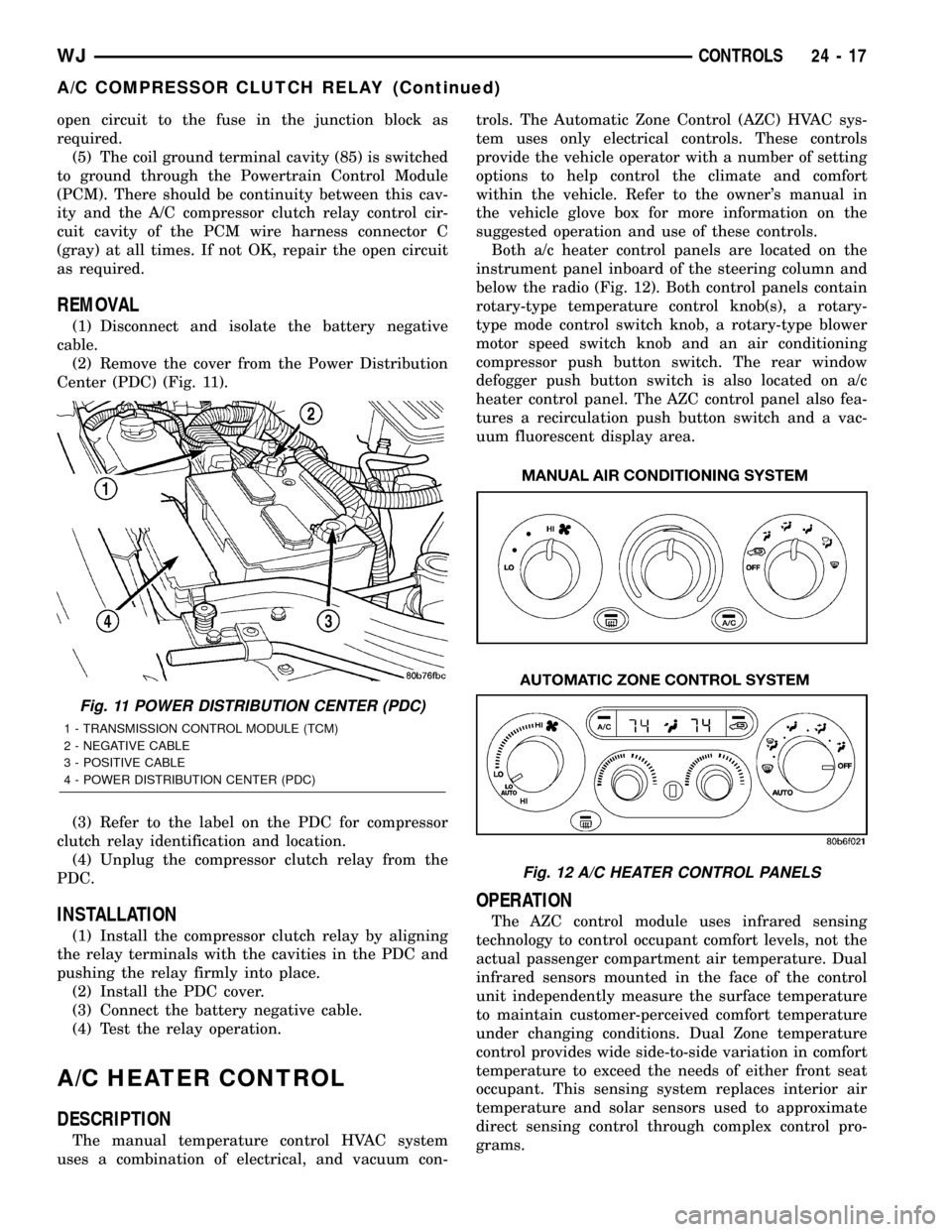

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 11).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C HEATER CONTROL

DESCRIPTION

The manual temperature control HVAC system

uses a combination of electrical, and vacuum con-trols. The Automatic Zone Control (AZC) HVAC sys-

tem uses only electrical controls. These controls

provide the vehicle operator with a number of setting

options to help control the climate and comfort

within the vehicle. Refer to the owner's manual in

the vehicle glove box for more information on the

suggested operation and use of these controls.

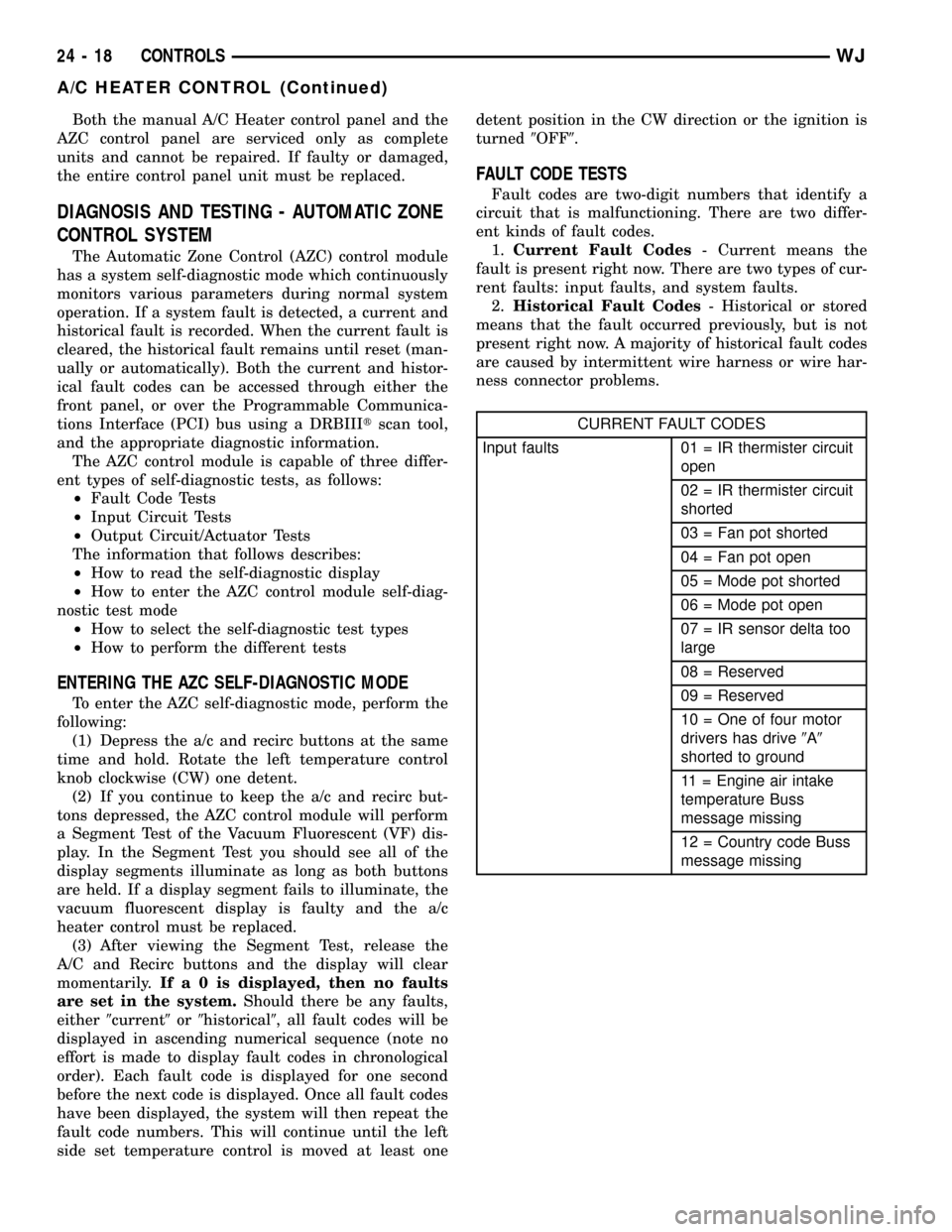

Both a/c heater control panels are located on the

instrument panel inboard of the steering column and

below the radio (Fig. 12). Both control panels contain

rotary-type temperature control knob(s), a rotary-

type mode control switch knob, a rotary-type blower

motor speed switch knob and an air conditioning

compressor push button switch. The rear window

defogger push button switch is also located on a/c

heater control panel. The AZC control panel also fea-

tures a recirculation push button switch and a vac-

uum fluorescent display area.

OPERATION

The AZC control module uses infrared sensing

technology to control occupant comfort levels, not the

actual passenger compartment air temperature. Dual

infrared sensors mounted in the face of the control

unit independently measure the surface temperature

to maintain customer-perceived comfort temperature

under changing conditions. Dual Zone temperature

control provides wide side-to-side variation in comfort

temperature to exceed the needs of either front seat

occupant. This sensing system replaces interior air

temperature and solar sensors used to approximate

direct sensing control through complex control pro-

grams.

Fig. 11 POWER DISTRIBUTION CENTER (PDC)

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - NEGATIVE CABLE

3 - POSITIVE CABLE

4 - POWER DISTRIBUTION CENTER (PDC)

Fig. 12 A/C HEATER CONTROL PANELS

WJCONTROLS 24 - 17

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 2095 of 2199

Both the manual A/C Heater control panel and the

AZC control panel are serviced only as complete

units and cannot be repaired. If faulty or damaged,

the entire control panel unit must be replaced.

DIAGNOSIS AND TESTING - AUTOMATIC ZONE

CONTROL SYSTEM

The Automatic Zone Control (AZC) control module

has a system self-diagnostic mode which continuously

monitors various parameters during normal system

operation. If a system fault is detected, a current and

historical fault is recorded. When the current fault is

cleared, the historical fault remains until reset (man-

ually or automatically). Both the current and histor-

ical fault codes can be accessed through either the

front panel, or over the Programmable Communica-

tions Interface (PCI) bus using a DRBIIItscan tool,

and the appropriate diagnostic information.

The AZC control module is capable of three differ-

ent types of self-diagnostic tests, as follows:

²Fault Code Tests

²Input Circuit Tests

²Output Circuit/Actuator Tests

The information that follows describes:

²How to read the self-diagnostic display

²How to enter the AZC control module self-diag-

nostic test mode

²How to select the self-diagnostic test types

²How to perform the different tests

ENTERING THE AZC SELF-DIAGNOSTIC MODE

To enter the AZC self-diagnostic mode, perform the

following:

(1) Depress the a/c and recirc buttons at the same

time and hold. Rotate the left temperature control

knob clockwise (CW) one detent.

(2) If you continue to keep the a/c and recirc but-

tons depressed, the AZC control module will perform

a Segment Test of the Vacuum Fluorescent (VF) dis-

play. In the Segment Test you should see all of the

display segments illuminate as long as both buttons

are held. If a display segment fails to illuminate, the

vacuum fluorescent display is faulty and the a/c

heater control must be replaced.

(3) After viewing the Segment Test, release the

A/C and Recirc buttons and the display will clear

momentarily.Ifa0isdisplayed, then no faults

are set in the system.Should there be any faults,

either9current9or9historical9, all fault codes will be

displayed in ascending numerical sequence (note no

effort is made to display fault codes in chronological

order). Each fault code is displayed for one second

before the next code is displayed. Once all fault codes

have been displayed, the system will then repeat the

fault code numbers. This will continue until the left

side set temperature control is moved at least onedetent position in the CW direction or the ignition is

turned9OFF9.

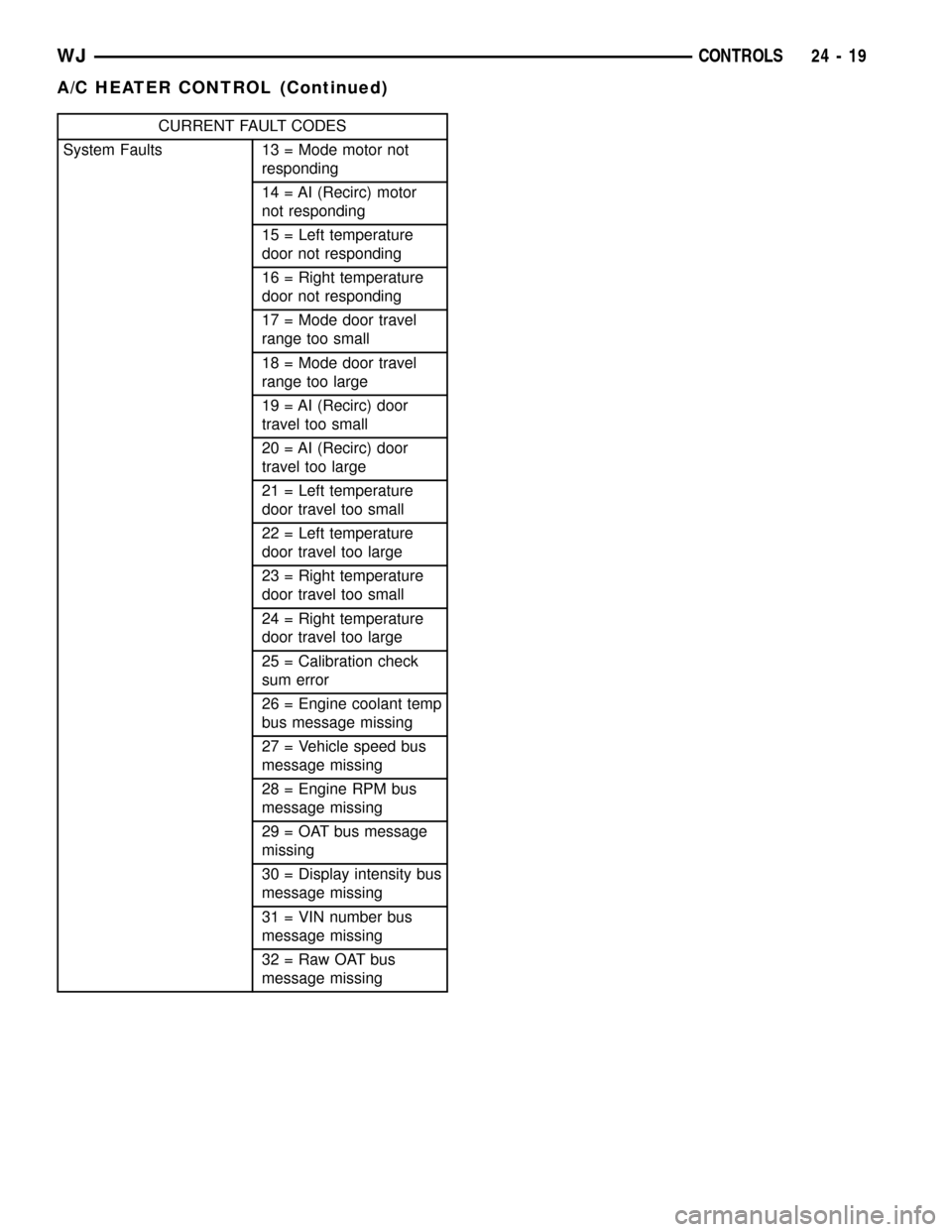

FAULT CODE TESTS

Fault codes are two-digit numbers that identify a

circuit that is malfunctioning. There are two differ-

ent kinds of fault codes.

1.Current Fault Codes- Current means the

fault is present right now. There are two types of cur-

rent faults: input faults, and system faults.

2.Historical Fault Codes- Historical or stored

means that the fault occurred previously, but is not

present right now. A majority of historical fault codes

are caused by intermittent wire harness or wire har-

ness connector problems.

CURRENT FAULT CODES

Input faults 01 = IR thermister circuit

open

02 = IR thermister circuit

shorted

03 = Fan pot shorted

04 = Fan pot open

05 = Mode pot shorted

06 = Mode pot open

07 = IR sensor delta too

large

08 = Reserved

09 = Reserved

10 = One of four motor

drivers has drive9A9

shorted to ground

11 = Engine air intake

temperature Buss

message missing

12 = Country code Buss

message missing

24 - 18 CONTROLSWJ

A/C HEATER CONTROL (Continued)

Page 2096 of 2199

CURRENT FAULT CODES

System Faults 13 = Mode motor not

responding

14 = AI (Recirc) motor

not responding

15 = Left temperature

door not responding

16 = Right temperature

door not responding

17 = Mode door travel

range too small

18 = Mode door travel

range too large

19 = AI (Recirc) door

travel too small

20 = AI (Recirc) door

travel too large

21 = Left temperature

door travel too small

22 = Left temperature

door travel too large

23 = Right temperature

door travel too small

24 = Right temperature

door travel too large

25 = Calibration check

sum error

26 = Engine coolant temp

bus message missing

27 = Vehicle speed bus

message missing

28 = Engine RPM bus

message missing

29 = OAT bus message

missing

30 = Display intensity bus

message missing

31 = VIN number bus

message missing

32 = Raw OAT bus

message missing

WJCONTROLS 24 - 19

A/C HEATER CONTROL (Continued)

Page 2097 of 2199

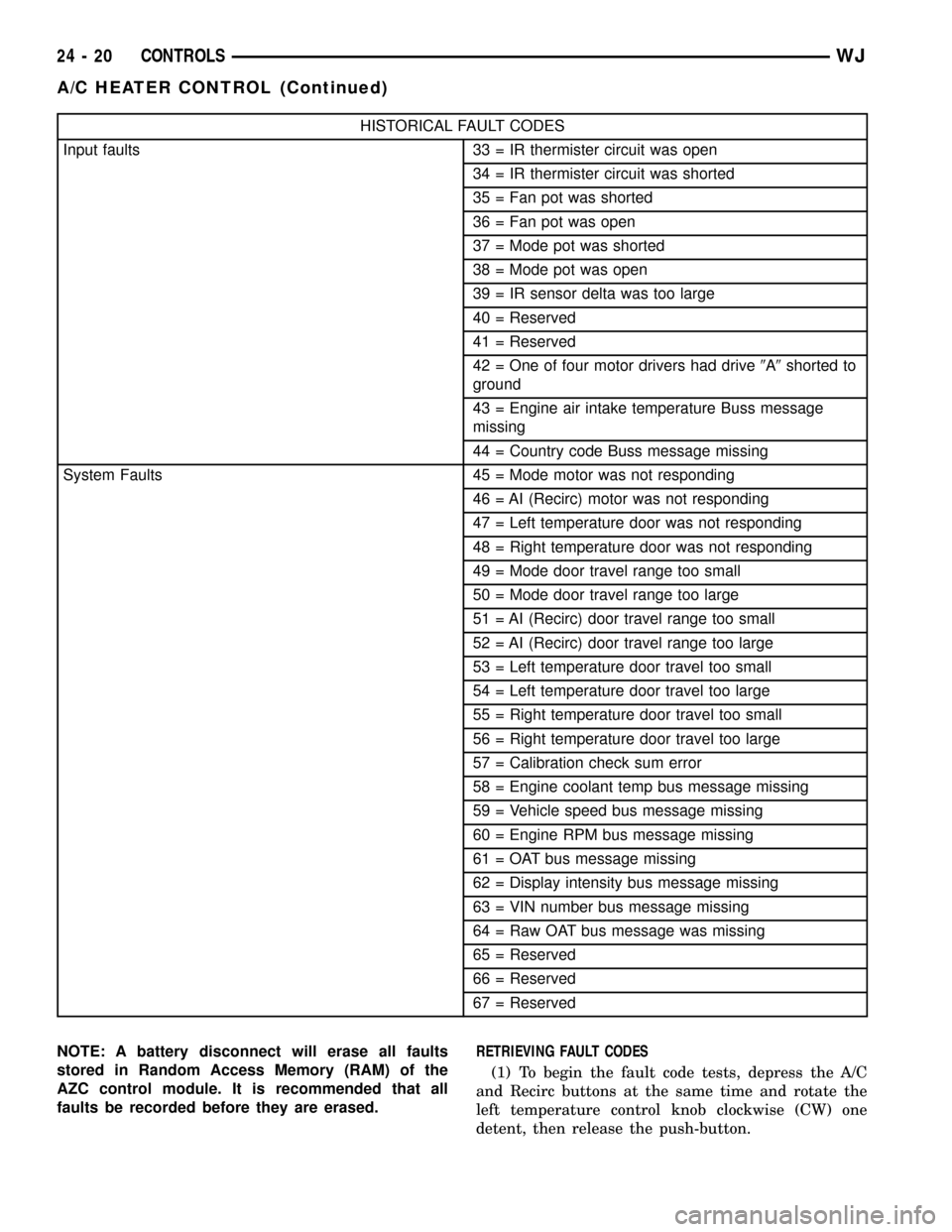

HISTORICAL FAULT CODES

Input faults 33 = IR thermister circuit was open

34 = IR thermister circuit was shorted

35 = Fan pot was shorted

36 = Fan pot was open

37 = Mode pot was shorted

38 = Mode pot was open

39 = IR sensor delta was too large

40 = Reserved

41 = Reserved

42 = One of four motor drivers had drive9A9shorted to

ground

43 = Engine air intake temperature Buss message

missing

44 = Country code Buss message missing

System Faults 45 = Mode motor was not responding

46 = AI (Recirc) motor was not responding

47 = Left temperature door was not responding

48 = Right temperature door was not responding

49 = Mode door travel range too small

50 = Mode door travel range too large

51 = AI (Recirc) door travel range too small

52 = AI (Recirc) door travel range too large

53 = Left temperature door travel too small

54 = Left temperature door travel too large

55 = Right temperature door travel too small

56 = Right temperature door travel too large

57 = Calibration check sum error

58 = Engine coolant temp bus message missing

59 = Vehicle speed bus message missing

60 = Engine RPM bus message missing

61 = OAT bus message missing

62 = Display intensity bus message missing

63 = VIN number bus message missing

64 = Raw OAT bus message was missing

65 = Reserved

66 = Reserved

67 = Reserved

NOTE: A battery disconnect will erase all faults

stored in Random Access Memory (RAM) of the

AZC control module. It is recommended that all

faults be recorded before they are erased.RETRIEVING FAULT CODES

(1) To begin the fault code tests, depress the A/C

and Recirc buttons at the same time and rotate the

left temperature control knob clockwise (CW) one

detent, then release the push-button.

24 - 20 CONTROLSWJ

A/C HEATER CONTROL (Continued)

Page 2098 of 2199

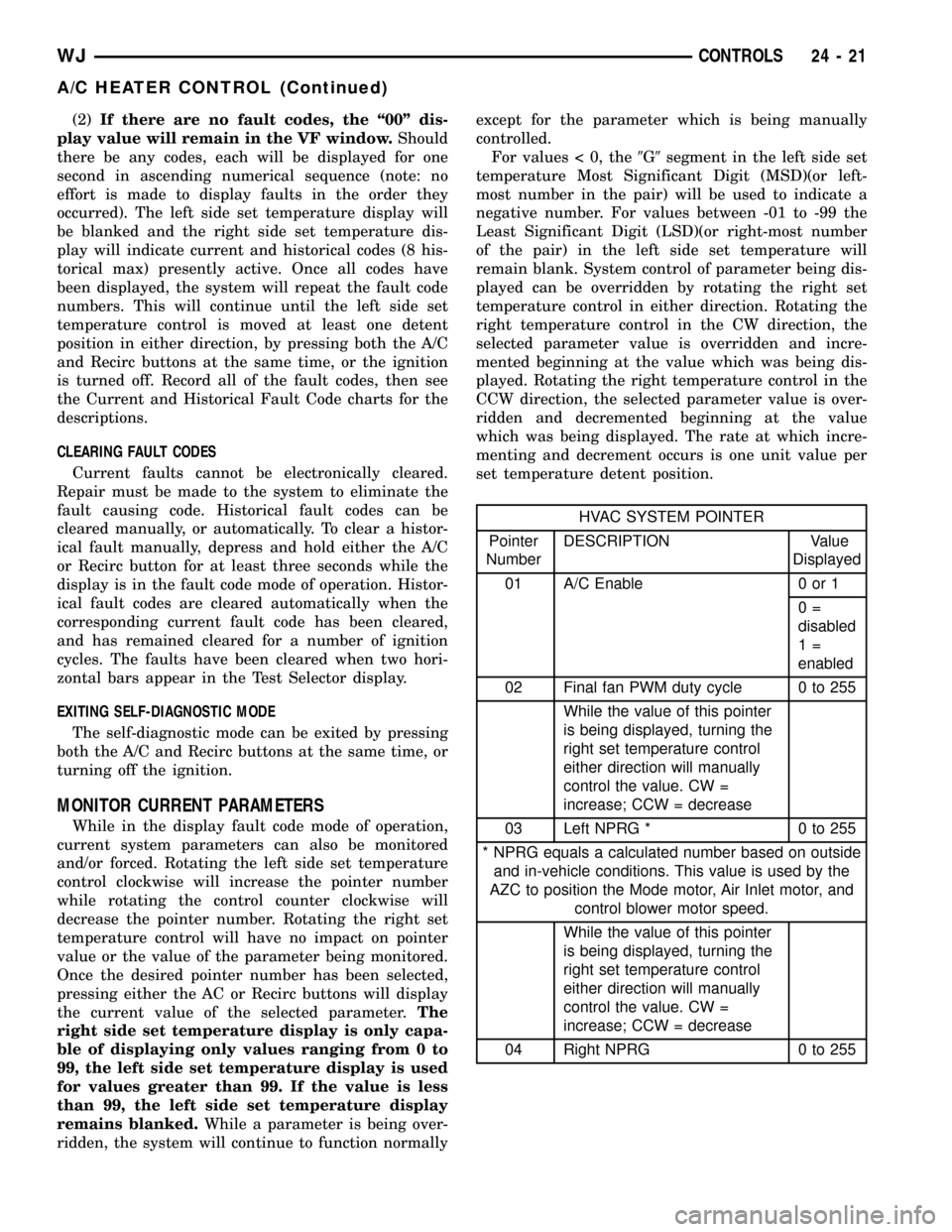

(2)If there are no fault codes, the ª00º dis-

play value will remain in the VF window.Should

there be any codes, each will be displayed for one

second in ascending numerical sequence (note: no

effort is made to display faults in the order they

occurred). The left side set temperature display will

be blanked and the right side set temperature dis-

play will indicate current and historical codes (8 his-

torical max) presently active. Once all codes have

been displayed, the system will repeat the fault code

numbers. This will continue until the left side set

temperature control is moved at least one detent

position in either direction, by pressing both the A/C

and Recirc buttons at the same time, or the ignition

is turned off. Record all of the fault codes, then see

the Current and Historical Fault Code charts for the

descriptions.

CLEARING FAULT CODES

Current faults cannot be electronically cleared.

Repair must be made to the system to eliminate the

fault causing code. Historical fault codes can be

cleared manually, or automatically. To clear a histor-

ical fault manually, depress and hold either the A/C

or Recirc button for at least three seconds while the

display is in the fault code mode of operation. Histor-

ical fault codes are cleared automatically when the

corresponding current fault code has been cleared,

and has remained cleared for a number of ignition

cycles. The faults have been cleared when two hori-

zontal bars appear in the Test Selector display.

EXITING SELF-DIAGNOSTIC MODE

The self-diagnostic mode can be exited by pressing

both the A/C and Recirc buttons at the same time, or

turning off the ignition.

MONITOR CURRENT PARAMETERS

While in the display fault code mode of operation,

current system parameters can also be monitored

and/or forced. Rotating the left side set temperature

control clockwise will increase the pointer number

while rotating the control counter clockwise will

decrease the pointer number. Rotating the right set

temperature control will have no impact on pointer

value or the value of the parameter being monitored.

Once the desired pointer number has been selected,

pressing either the AC or Recirc buttons will display

the current value of the selected parameter.The

right side set temperature display is only capa-

ble of displaying only values ranging from 0 to

99, the left side set temperature display is used

for values greater than 99. If the value is less

than 99, the left side set temperature display

remains blanked.While a parameter is being over-

ridden, the system will continue to function normallyexcept for the parameter which is being manually

controlled.

For values < 0, the9G9segment in the left side set

temperature Most Significant Digit (MSD)(or left-

most number in the pair) will be used to indicate a

negative number. For values between -01 to -99 the

Least Significant Digit (LSD)(or right-most number

of the pair) in the left side set temperature will

remain blank. System control of parameter being dis-

played can be overridden by rotating the right set

temperature control in either direction. Rotating the

right temperature control in the CW direction, the

selected parameter value is overridden and incre-

mented beginning at the value which was being dis-

played. Rotating the right temperature control in the

CCW direction, the selected parameter value is over-

ridden and decremented beginning at the value

which was being displayed. The rate at which incre-

menting and decrement occurs is one unit value per

set temperature detent position.

HVAC SYSTEM POINTER

Pointer

NumberDESCRIPTION Value

Displayed

01 A/C Enable 0 or 1

0=

disabled

1=

enabled

02 Final fan PWM duty cycle 0 to 255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

03 Left NPRG * 0 to 255

* NPRG equals a calculated number based on outside

and in-vehicle conditions. This value is used by the

AZC to position the Mode motor, Air Inlet motor, and

control blower motor speed.

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

04 Right NPRG 0 to 255

WJCONTROLS 24 - 21

A/C HEATER CONTROL (Continued)

Page 2099 of 2199

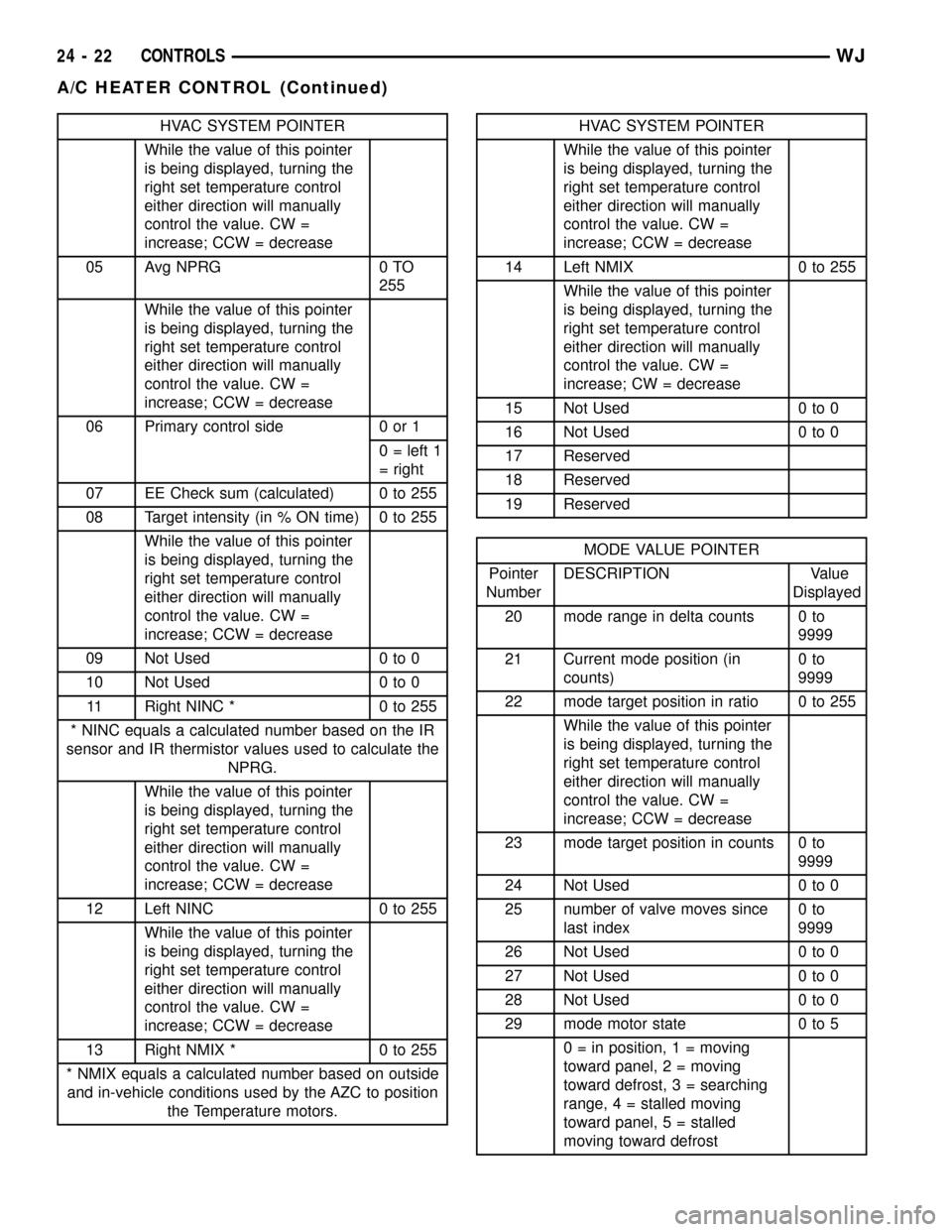

HVAC SYSTEM POINTER

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

05 Avg NPRG 0 TO

255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

06 Primary control side 0 or 1

0 = left 1

= right

07 EE Check sum (calculated) 0 to 255

08 Target intensity (in % ON time) 0 to 255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

09 Not Used 0 to 0

10 Not Used 0 to 0

11 Right NINC * 0 to 255

* NINC equals a calculated number based on the IR

sensor and IR thermistor values used to calculate the

NPRG.

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

12 Left NINC 0 to 255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

13 Right NMIX * 0 to 255

* NMIX equals a calculated number based on outside

and in-vehicle conditions used by the AZC to position

the Temperature motors.HVAC SYSTEM POINTER

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

14 Left NMIX 0 to 255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CW = decrease

15 Not Used 0 to 0

16 Not Used 0 to 0

17 Reserved

18 Reserved

19 Reserved

MODE VALUE POINTER

Pointer

NumberDESCRIPTION Value

Displayed

20 mode range in delta counts 0 to

9999

21 Current mode position (in

counts)0to

9999

22 mode target position in ratio 0 to 255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

23 mode target position in counts 0 to

9999

24 Not Used 0 to 0

25 number of valve moves since

last index0to

9999

26 Not Used 0 to 0

27 Not Used 0 to 0

28 Not Used 0 to 0

29 mode motor state 0 to 5

0 = in position, 1 = moving

toward panel, 2 = moving

toward defrost, 3 = searching

range, 4 = stalled moving

toward panel, 5 = stalled

moving toward defrost

24 - 22 CONTROLSWJ

A/C HEATER CONTROL (Continued)

Page 2100 of 2199

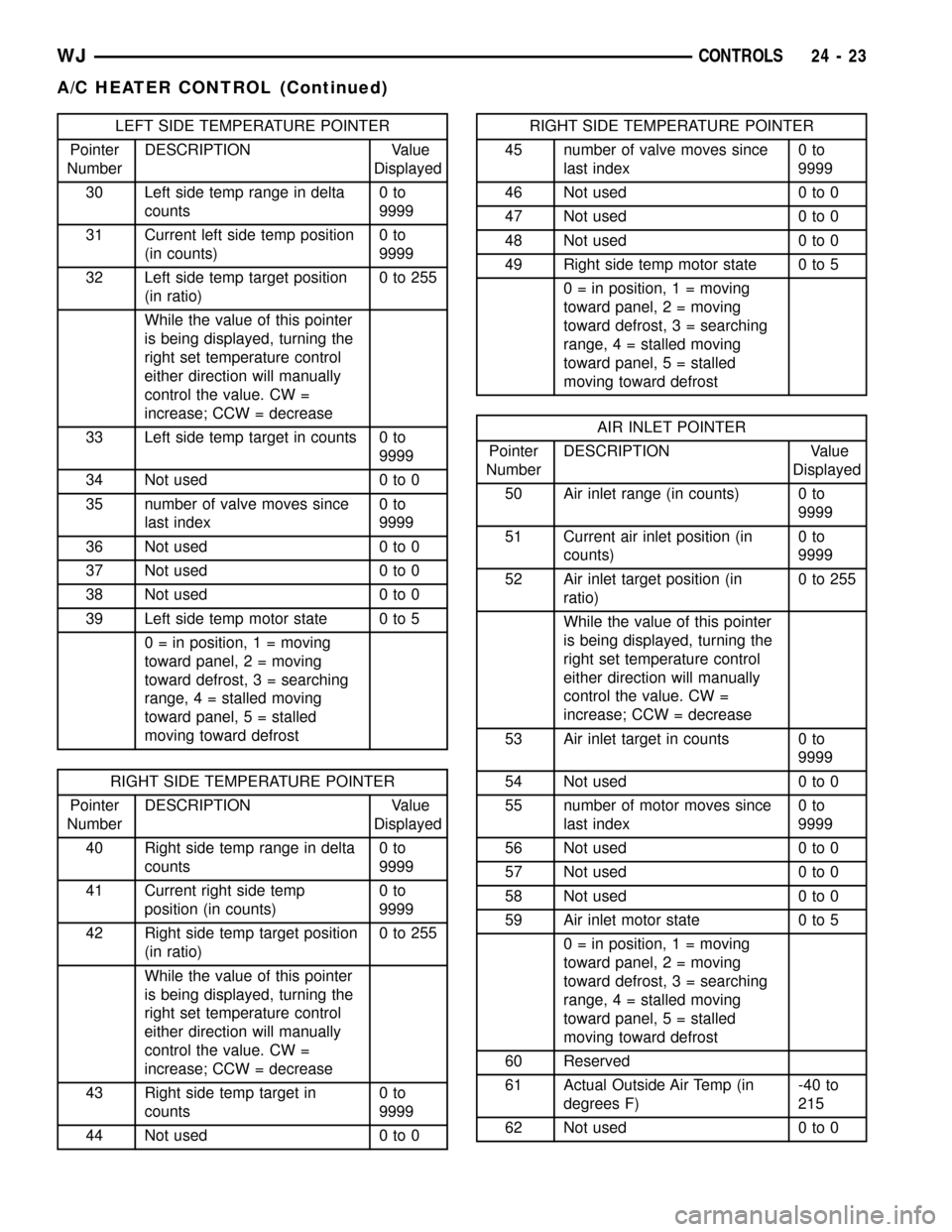

LEFT SIDE TEMPERATURE POINTER

Pointer

NumberDESCRIPTION Value

Displayed

30 Left side temp range in delta

counts0to

9999

31 Current left side temp position

(in counts)0to

9999

32 Left side temp target position

(in ratio)0to255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

33 Left side temp target in counts 0 to

9999

34 Not used 0 to 0

35 number of valve moves since

last index0to

9999

36 Not used 0 to 0

37 Not used 0 to 0

38 Not used 0 to 0

39 Left side temp motor state 0 to 5

0 = in position, 1 = moving

toward panel, 2 = moving

toward defrost, 3 = searching

range, 4 = stalled moving

toward panel, 5 = stalled

moving toward defrost

RIGHT SIDE TEMPERATURE POINTER

Pointer

NumberDESCRIPTION Value

Displayed

40 Right side temp range in delta

counts0to

9999

41 Current right side temp

position (in counts)0to

9999

42 Right side temp target position

(in ratio)0to255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

43 Right side temp target in

counts0to

9999

44 Not used 0 to 0

RIGHT SIDE TEMPERATURE POINTER

45 number of valve moves since

last index0to

9999

46 Not used 0 to 0

47 Not used 0 to 0

48 Not used 0 to 0

49 Right side temp motor state 0 to 5

0 = in position, 1 = moving

toward panel, 2 = moving

toward defrost, 3 = searching

range, 4 = stalled moving

toward panel, 5 = stalled

moving toward defrost

AIR INLET POINTER

Pointer

NumberDESCRIPTION Value

Displayed

50 Air inlet range (in counts) 0 to

9999

51 Current air inlet position (in

counts)0to

9999

52 Air inlet target position (in

ratio)0to255

While the value of this pointer

is being displayed, turning the

right set temperature control

either direction will manually

control the value. CW =

increase; CCW = decrease

53 Air inlet target in counts 0 to

9999

54 Not used 0 to 0

55 number of motor moves since

last index0to

9999

56 Not used 0 to 0

57 Not used 0 to 0

58 Not used 0 to 0

59 Air inlet motor state 0 to 5

0 = in position, 1 = moving

toward panel, 2 = moving

toward defrost, 3 = searching

range, 4 = stalled moving

toward panel, 5 = stalled

moving toward defrost

60 Reserved

61 Actual Outside Air Temp (in

degrees F)-40 to

215

62 Not used 0 to 0

WJCONTROLS 24 - 23

A/C HEATER CONTROL (Continued)

Page 2101 of 2199

AIR INLET POINTER

63 Engine Intake Air Temperature

(in degrees F)-40 to

215

64 Vehicle speed in MPH 0 to 255

65 Engine RPM/100 -0 to 82

66 Engine Coolant Temp - 40 (in

degrees F)-40 to

215

67 Country Code 0 to 255

68 Not used 0 to 0

69 Not used 0 to 0

IR SENSOR POINTER

Pointer

NumberDESCRIPTION Value

Displayed

70 Thermistor temp (in degrees) -40 to

215

71 Left side sensor A/D (filtered) 0 to 255

72 Right side sensor A/D (filtered) 0 to 255

73 Left side temp (in degrees F) -40 to

140

74 Right side temp (in degrees F) -40 to

140

75 Not used 0 to 0

76 Not used 0 to 0

77 Not used 0 to 0

78 Not used 0 to 0

79 Not used 0 to 0

IDENTIFICATION POINTER

Pointer

NumberDESCRIPTION Value

Displayed

80 ROM bit pattern number (digits

1,2,3 & 4)0to

9999

81 ROM bit pattern number (digits

5,6,7 & 8)0to

9999

82 CAL bit pattern number (digits

1,2,3 & 4)0to

9999

83 CAL bit pattern number (digits

5,6,7 & 8)0to

9999

84 Not used 0 to 0

85 Not used 0 to 0

86 Not used 0 to 0

87 Not used 0 to 0

88 Not used 0 to 0

89 Not used 0 to 0

OUTPUT CIRCUIT/ACTUATOR TESTS

In the Output Circuit/Actuator Test mode, the out-

put circuits can be viewed, monitored, overridden,

and tested. If a failure occurs in an output circuit,

test the circuit by overriding the system. Test the

actuator through its full range of operation.

(1) To begin the Output Circuit/Actuator Tests you

must be in the Select Test mode.

(2) With a ª00º value displayed in the Test Selector

and no stick man, turn the rotary temperature con-

trol knob until the test number you are looking for

appears in the Test Selector display. See the Circuit

Testing charts for a listing of the test numbers, test

items, test types, system tested, and displayed val-

ues.

(3) To see the output value, depress the a/c or

recirc button. The values displayed will represent the

output from the AZC control module.

(4) To enter the actuator test, depress the a/c or

recirc button. Then, rotate the right temperature set

knob to the desired position.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center upper, and center lower

bezels from the instrument panel. Refer to Instru-

ment Panel System for the procedures.

(3) Remove the 4 screws that secure the a/c heater

control to the instrument panel (Fig. 13).

(4) Pull the a/c heater control assembly away from

the instrument panel far enough to access the con-

nections on the back of the control.

(5) Unplug the wire and/or vacuum harness con-

nectors from the back of the a/c heater control (Fig.

14).

(6) Remove the a/c heater control from the instru-

ment panel.

24 - 24 CONTROLSWJ

A/C HEATER CONTROL (Continued)

Page 2156 of 2199

EMISSIONS CONTROL

TABLE OF CONTENTS

page page

EMISSIONS CONTROL

DESCRIPTION

DESCRIPTION - EMISSION CONTROL

SYSTEM.............................1

DESCRIPTION - STATE DISPLAY TEST

MODE...............................2

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE...............................2

DESCRIPTION - DIAGNOSTIC TROUBLE

CODES..............................2DESCRIPTION - TASK MANAGER.........17

DESCRIPTION - MONITORED SYSTEMS . . . 17

DESCRIPTION - TRIP DEFINITION........19

DESCRIPTION - COMPONENT MONITORS . . 19

DESCRIPTION - NON-MONITORED

CIRCUITS...........................20

DESCRIPTION - HIGH AND LOW LIMITS . . . 20

DESCRIPTION - LOAD VALUE...........20

OPERATION - TASK MANAGER............21

EVAPORATIVE EMISSIONS................24

EMISSIONS CONTROL

DESCRIPTION

DESCRIPTION - EMISSION CONTROL SYSTEM

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a prob-

lem with a monitored circuit often enough to indicate an

actual problem, it stores a Diagnostic Trouble Code

(DTC) in the PCM's memory. If the code applies to a

non-emissions related component or system, and the

problem is repaired or ceases to exist, the PCM cancels

the code after 40 warm-up cycles. Diagnostic trouble

codes that affect vehicle emissions illuminate the Mal-

function Indicator (check engine) Lamp. Refer to Mal-

function Indicator Lamp in this section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored cir-

cuit even though a malfunction has occurred. This may

happen because one of the DTC criteria for the circuit

has not been met.For example

,assume the diagnostic

trouble code criteria requires the PCM to monitor the

circuit only when the engine operates between 750 and

2000 RPM. Suppose the sensor's output circuit shorts to

ground when engine operates above 2400 RPM (result-

ing in 0 volt input to the PCM). Because the condition

happens at an engine speed above the maximum thresh-

old (2000 rpm), the PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

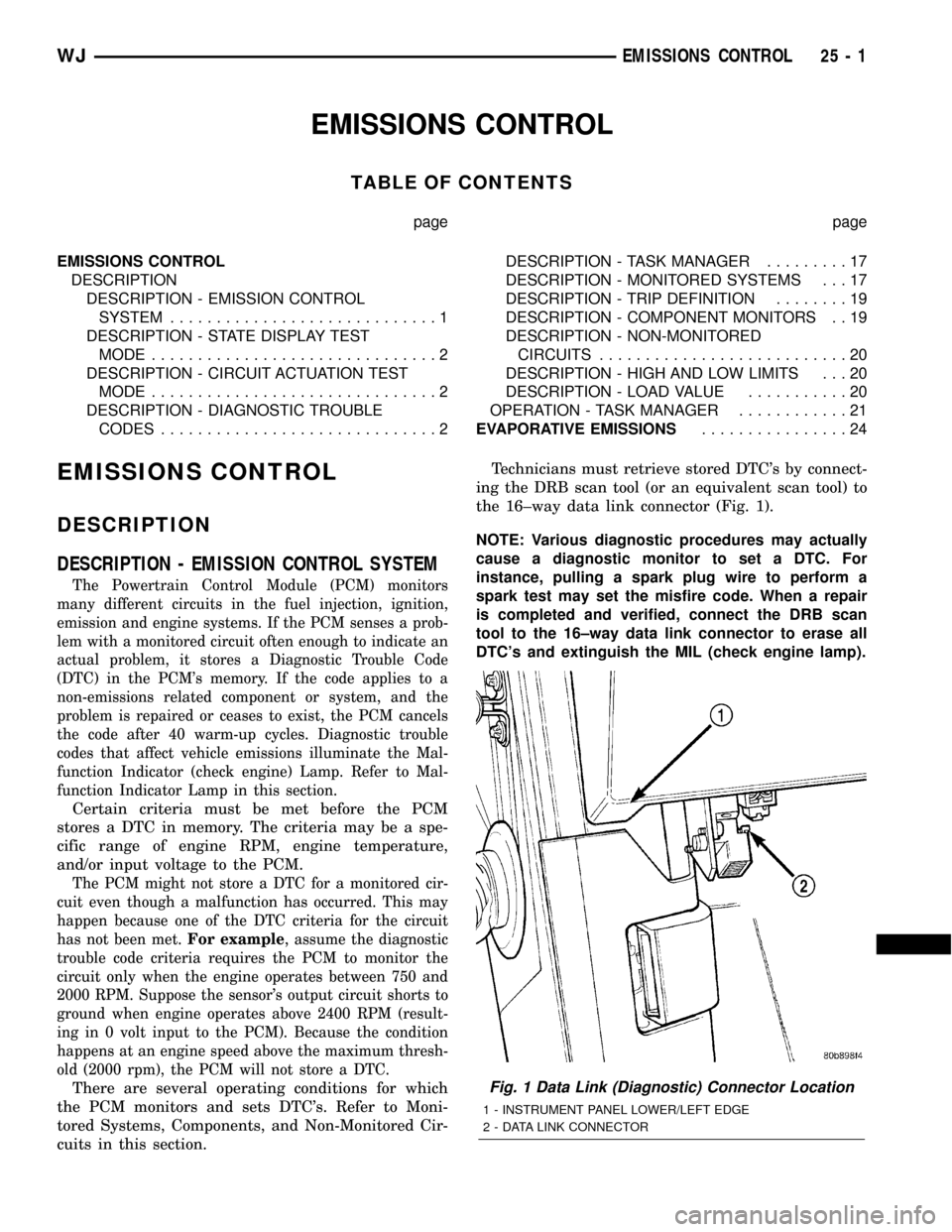

cuits in this section.Technicians must retrieve stored DTC's by connect-

ing the DRB scan tool (or an equivalent scan tool) to

the 16±way data link connector (Fig. 1).

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, connect the DRB scan

tool to the 16±way data link connector to erase all

DTC's and extinguish the MIL (check engine lamp).Fig. 1 Data Link (Diagnostic) Connector Location

1 - INSTRUMENT PANEL LOWER/LEFT EDGE

2 - DATA LINK CONNECTOR

WJEMISSIONS CONTROL 25 - 1