frame JEEP GRAND CHEROKEE 2003 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1959 of 2199

(8) Position head restraint release button caps on

head restraint sleeves and press to secure.

(9) Install head restraint (Refer to 23 - BODY/

SEATS/FRONT HEADREST - INSTALLATION).

FRONT SEAT CUSHION/COVER

REMOVAL

(1) Remove seat from vehicle (Refer to 23 - BODY/

SEATS/FRONT SEAT - REMOVAL).

(2) Remove seat back (Refer to 23 - BODY/SEATS/

FRONT SEAT BACK - REMOVAL).

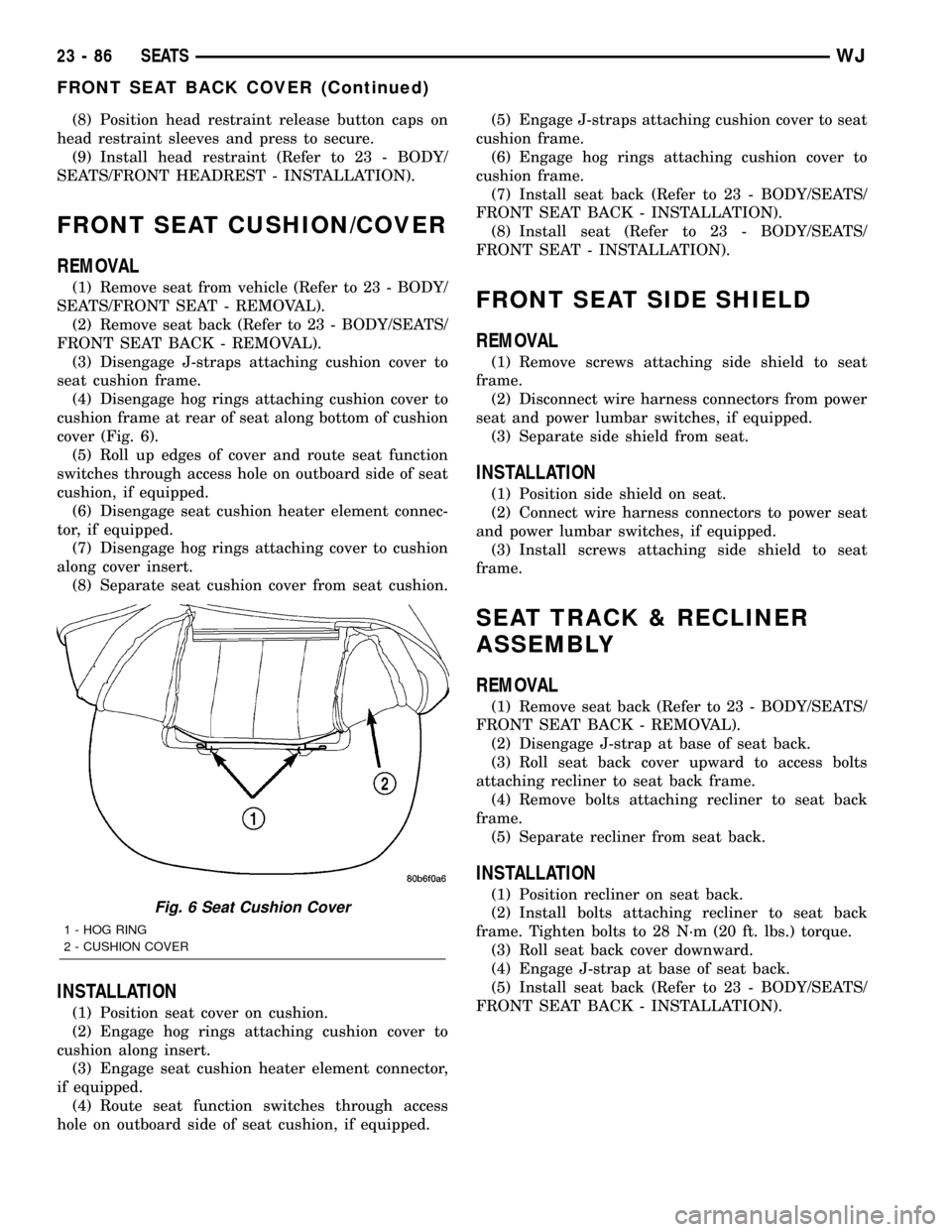

(3) Disengage J-straps attaching cushion cover to

seat cushion frame.

(4) Disengage hog rings attaching cushion cover to

cushion frame at rear of seat along bottom of cushion

cover (Fig. 6).

(5) Roll up edges of cover and route seat function

switches through access hole on outboard side of seat

cushion, if equipped.

(6) Disengage seat cushion heater element connec-

tor, if equipped.

(7) Disengage hog rings attaching cover to cushion

along cover insert.

(8) Separate seat cushion cover from seat cushion.

INSTALLATION

(1) Position seat cover on cushion.

(2) Engage hog rings attaching cushion cover to

cushion along insert.

(3) Engage seat cushion heater element connector,

if equipped.

(4) Route seat function switches through access

hole on outboard side of seat cushion, if equipped.(5) Engage J-straps attaching cushion cover to seat

cushion frame.

(6) Engage hog rings attaching cushion cover to

cushion frame.

(7) Install seat back (Refer to 23 - BODY/SEATS/

FRONT SEAT BACK - INSTALLATION).

(8) Install seat (Refer to 23 - BODY/SEATS/

FRONT SEAT - INSTALLATION).

FRONT SEAT SIDE SHIELD

REMOVAL

(1) Remove screws attaching side shield to seat

frame.

(2) Disconnect wire harness connectors from power

seat and power lumbar switches, if equipped.

(3) Separate side shield from seat.

INSTALLATION

(1) Position side shield on seat.

(2) Connect wire harness connectors to power seat

and power lumbar switches, if equipped.

(3) Install screws attaching side shield to seat

frame.

SEAT TRACK & RECLINER

ASSEMBLY

REMOVAL

(1) Remove seat back (Refer to 23 - BODY/SEATS/

FRONT SEAT BACK - REMOVAL).

(2) Disengage J-strap at base of seat back.

(3) Roll seat back cover upward to access bolts

attaching recliner to seat back frame.

(4) Remove bolts attaching recliner to seat back

frame.

(5) Separate recliner from seat back.

INSTALLATION

(1) Position recliner on seat back.

(2) Install bolts attaching recliner to seat back

frame. Tighten bolts to 28 N´m (20 ft. lbs.) torque.

(3) Roll seat back cover downward.

(4) Engage J-strap at base of seat back.

(5) Install seat back (Refer to 23 - BODY/SEATS/

FRONT SEAT BACK - INSTALLATION).Fig. 6 Seat Cushion Cover

1 - HOG RING

2 - CUSHION COVER

23 - 86 SEATSWJ

FRONT SEAT BACK COVER (Continued)

Page 1960 of 2199

SEAT TRACK ADJUSTER

REMOVAL

(1) Remove seat (Refer to 23 - BODY/SEATS/

FRONT SEAT - REMOVAL).

(2) Remove side shield (Refer to 23 - BODY/

SEATS/FRONT SEAT SIDE SHIELD - REMOVAL).

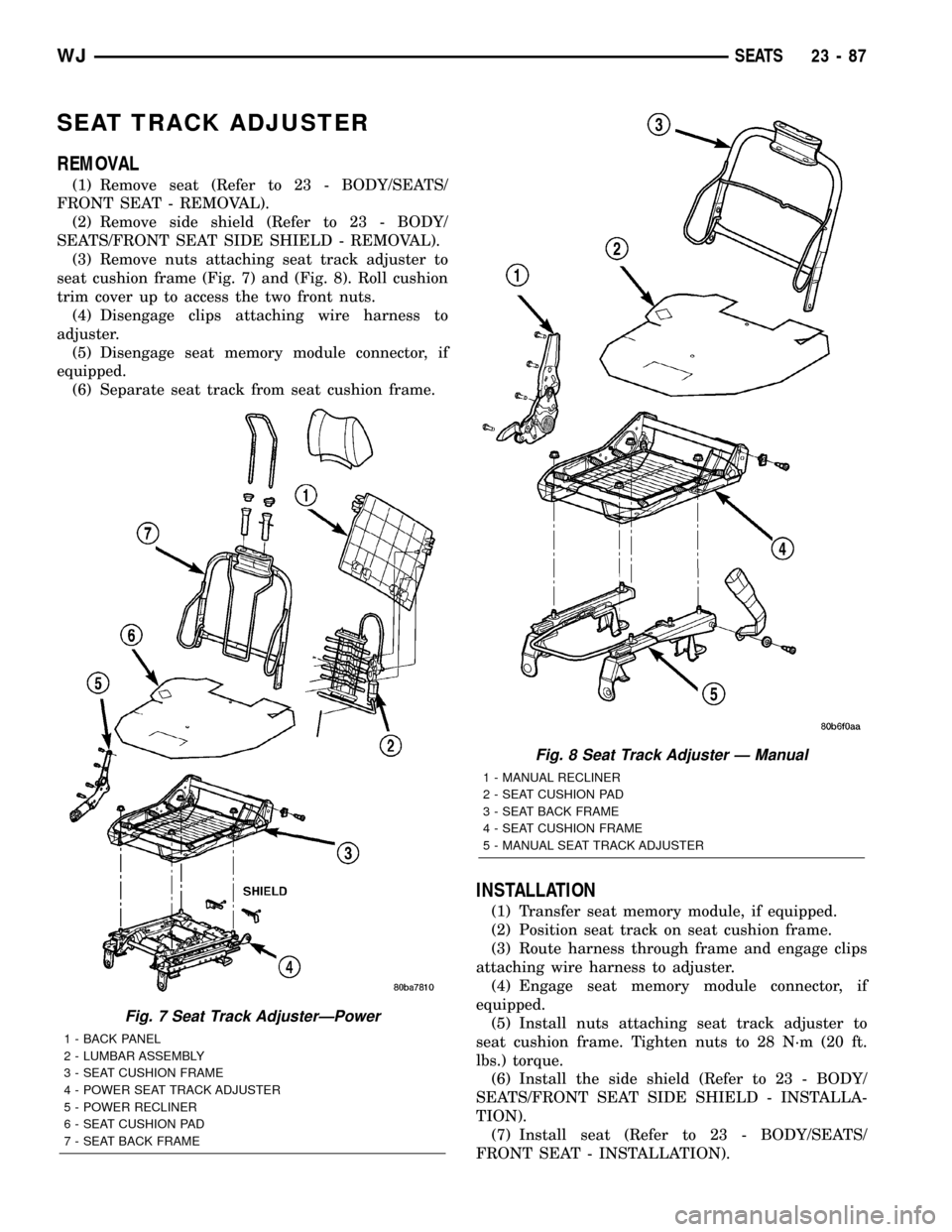

(3) Remove nuts attaching seat track adjuster to

seat cushion frame (Fig. 7) and (Fig. 8). Roll cushion

trim cover up to access the two front nuts.

(4) Disengage clips attaching wire harness to

adjuster.

(5) Disengage seat memory module connector, if

equipped.

(6) Separate seat track from seat cushion frame.

INSTALLATION

(1) Transfer seat memory module, if equipped.

(2) Position seat track on seat cushion frame.

(3) Route harness through frame and engage clips

attaching wire harness to adjuster.

(4) Engage seat memory module connector, if

equipped.

(5) Install nuts attaching seat track adjuster to

seat cushion frame. Tighten nuts to 28 N´m (20 ft.

lbs.) torque.

(6) Install the side shield (Refer to 23 - BODY/

SEATS/FRONT SEAT SIDE SHIELD - INSTALLA-

TION).

(7) Install seat (Refer to 23 - BODY/SEATS/

FRONT SEAT - INSTALLATION).

Fig. 7 Seat Track AdjusterÐPower

1 - BACK PANEL

2 - LUMBAR ASSEMBLY

3 - SEAT CUSHION FRAME

4 - POWER SEAT TRACK ADJUSTER

5 - POWER RECLINER

6 - SEAT CUSHION PAD

7 - SEAT BACK FRAME

Fig. 8 Seat Track Adjuster Ð Manual

1 - MANUAL RECLINER

2 - SEAT CUSHION PAD

3 - SEAT BACK FRAME

4 - SEAT CUSHION FRAME

5 - MANUAL SEAT TRACK ADJUSTER

WJSEATS 23 - 87

Page 1962 of 2199

REAR HEADREST SLEEVE

REMOVAL

(1) Remove seat back (Refer to 23 - BODY/SEATS/

REAR SEAT BACK - REMOVAL).

(2) Remove head rest (Refer to 23 - BODY/SEATS/

REAR HEADREST - REMOVAL).

(3) Remove head rest caps.

(4) Remove seat back cover (Refer to 23 - BODY/

SEATS/REAR SEAT BACK COVER - REMOVAL).

(5) Rotate head rest sleeve 1/4 turn counter-clock-

wise to release retaining tab.

(6) Pull sleeve from seat back frame.

INSTALLATION

(1) Position sleeve in seat back frame.

(2) Rotate head rest sleeve 1/4 turn clockwise to

engage retaining tab.

(3) Install seat back cover (Refer to 23 - BODY/

SEATS/REAR SEAT BACK COVER - INSTALLA-

TION).

(4) Install head rest caps.

NOTE: The head rest cap with the taller button is

always on the inboard side of the seat back.

(5) Install the head rest (Refer to 23 - BODY/

SEATS/REAR HEADREST - INSTALLATION).

NOTE: The folding head rest release knob is always

on the outboard side.

(6) Install the seat back (Refer to 23 - BODY/

SEATS/REAR SEAT BACK - INSTALLATION).

REAR SEAT BACK

REMOVAL

(1) Move rear seat cushions to forward cargo posi-

tion.

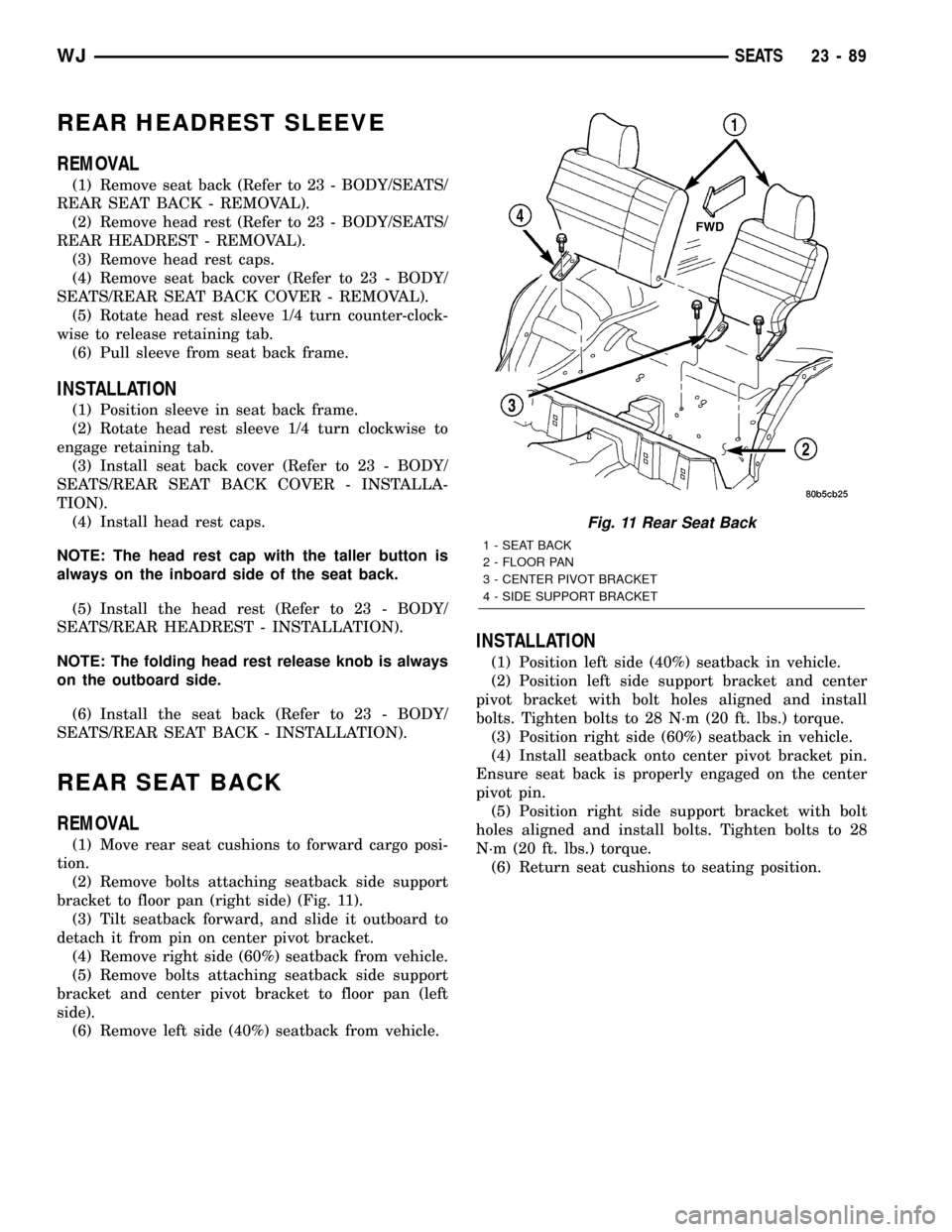

(2) Remove bolts attaching seatback side support

bracket to floor pan (right side) (Fig. 11).

(3) Tilt seatback forward, and slide it outboard to

detach it from pin on center pivot bracket.

(4) Remove right side (60%) seatback from vehicle.

(5) Remove bolts attaching seatback side support

bracket and center pivot bracket to floor pan (left

side).

(6) Remove left side (40%) seatback from vehicle.

INSTALLATION

(1) Position left side (40%) seatback in vehicle.

(2) Position left side support bracket and center

pivot bracket with bolt holes aligned and install

bolts. Tighten bolts to 28 N´m (20 ft. lbs.) torque.

(3) Position right side (60%) seatback in vehicle.

(4) Install seatback onto center pivot bracket pin.

Ensure seat back is properly engaged on the center

pivot pin.

(5) Position right side support bracket with bolt

holes aligned and install bolts. Tighten bolts to 28

N´m (20 ft. lbs.) torque.

(6) Return seat cushions to seating position.

Fig. 11 Rear Seat Back

1 - SEAT BACK

2 - FLOOR PAN

3 - CENTER PIVOT BRACKET

4 - SIDE SUPPORT BRACKET

WJSEATS 23 - 89

Page 1963 of 2199

REAR SEAT BACK COVER

REMOVAL

(1) Remove seat back (Refer to 23 - BODY/SEATS/

REAR SEAT BACK - REMOVAL).

(2) Remove head restraint (Refer to 23 - BODY/

SEATS/REAR HEADREST - REMOVAL).

(3) Remove head restraint caps.

(4) Disengage J-straps on outboard side of seat

back.

(5) Disengage J-straps at base of seat back.

(6) Remove screws attaching latch release handle

to seat back frame.

(7) Roll seat back cover upward.

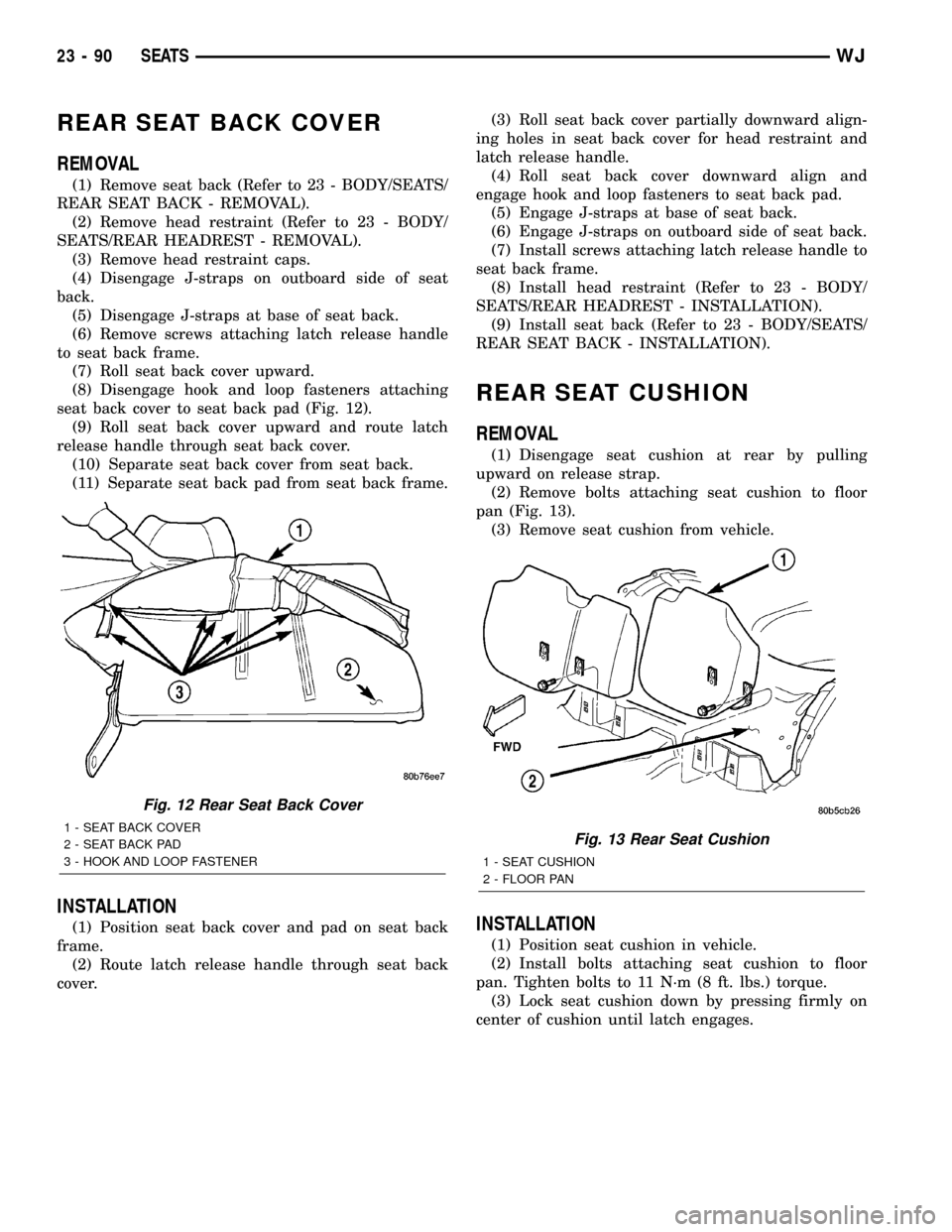

(8) Disengage hook and loop fasteners attaching

seat back cover to seat back pad (Fig. 12).

(9) Roll seat back cover upward and route latch

release handle through seat back cover.

(10) Separate seat back cover from seat back.

(11) Separate seat back pad from seat back frame.

INSTALLATION

(1) Position seat back cover and pad on seat back

frame.

(2) Route latch release handle through seat back

cover.(3) Roll seat back cover partially downward align-

ing holes in seat back cover for head restraint and

latch release handle.

(4) Roll seat back cover downward align and

engage hook and loop fasteners to seat back pad.

(5) Engage J-straps at base of seat back.

(6) Engage J-straps on outboard side of seat back.

(7) Install screws attaching latch release handle to

seat back frame.

(8) Install head restraint (Refer to 23 - BODY/

SEATS/REAR HEADREST - INSTALLATION).

(9) Install seat back (Refer to 23 - BODY/SEATS/

REAR SEAT BACK - INSTALLATION).

REAR SEAT CUSHION

REMOVAL

(1) Disengage seat cushion at rear by pulling

upward on release strap.

(2) Remove bolts attaching seat cushion to floor

pan (Fig. 13).

(3) Remove seat cushion from vehicle.

INSTALLATION

(1) Position seat cushion in vehicle.

(2) Install bolts attaching seat cushion to floor

pan. Tighten bolts to 11 N´m (8 ft. lbs.) torque.

(3) Lock seat cushion down by pressing firmly on

center of cushion until latch engages.

Fig. 12 Rear Seat Back Cover

1 - SEAT BACK COVER

2 - SEAT BACK PAD

3 - HOOK AND LOOP FASTENERFig. 13 Rear Seat Cushion

1 - SEAT CUSHION

2 - FLOOR PAN

23 - 90 SEATSWJ

Page 1964 of 2199

REAR SEAT CUSHION COVER

REMOVAL

(1) Remove rear seat cushion (Refer to 23 - BODY/

SEATS/REAR SEAT CUSHION - REMOVAL).

(2) From the underside of the seat, disengage

J-straps attaching cover to seat cushion base panel.

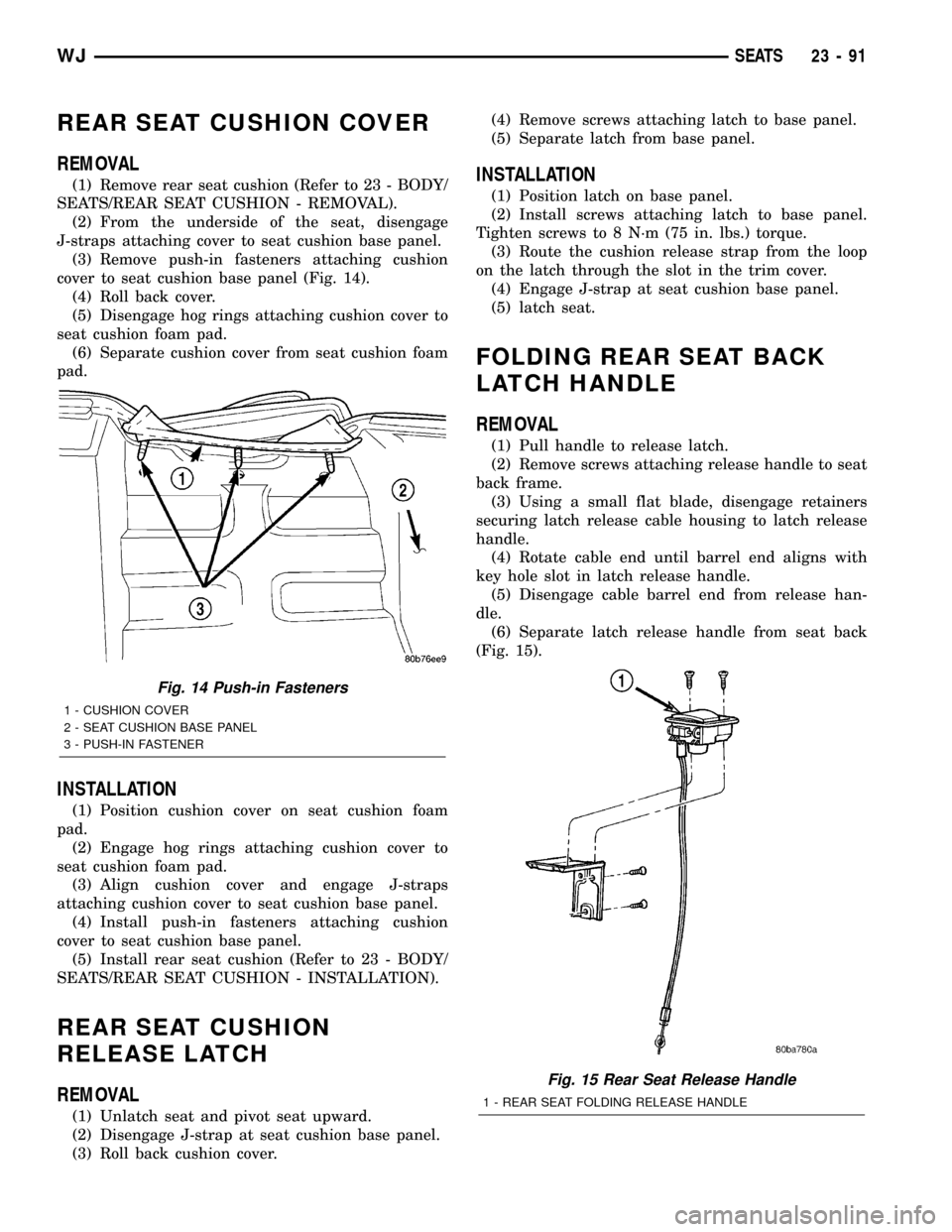

(3) Remove push-in fasteners attaching cushion

cover to seat cushion base panel (Fig. 14).

(4) Roll back cover.

(5) Disengage hog rings attaching cushion cover to

seat cushion foam pad.

(6) Separate cushion cover from seat cushion foam

pad.

INSTALLATION

(1) Position cushion cover on seat cushion foam

pad.

(2) Engage hog rings attaching cushion cover to

seat cushion foam pad.

(3) Align cushion cover and engage J-straps

attaching cushion cover to seat cushion base panel.

(4) Install push-in fasteners attaching cushion

cover to seat cushion base panel.

(5) Install rear seat cushion (Refer to 23 - BODY/

SEATS/REAR SEAT CUSHION - INSTALLATION).

REAR SEAT CUSHION

RELEASE LATCH

REMOVAL

(1) Unlatch seat and pivot seat upward.

(2) Disengage J-strap at seat cushion base panel.

(3) Roll back cushion cover.(4) Remove screws attaching latch to base panel.

(5) Separate latch from base panel.

INSTALLATION

(1) Position latch on base panel.

(2) Install screws attaching latch to base panel.

Tighten screws to 8 N´m (75 in. lbs.) torque.

(3) Route the cushion release strap from the loop

on the latch through the slot in the trim cover.

(4) Engage J-strap at seat cushion base panel.

(5) latch seat.

FOLDING REAR SEAT BACK

LATCH HANDLE

REMOVAL

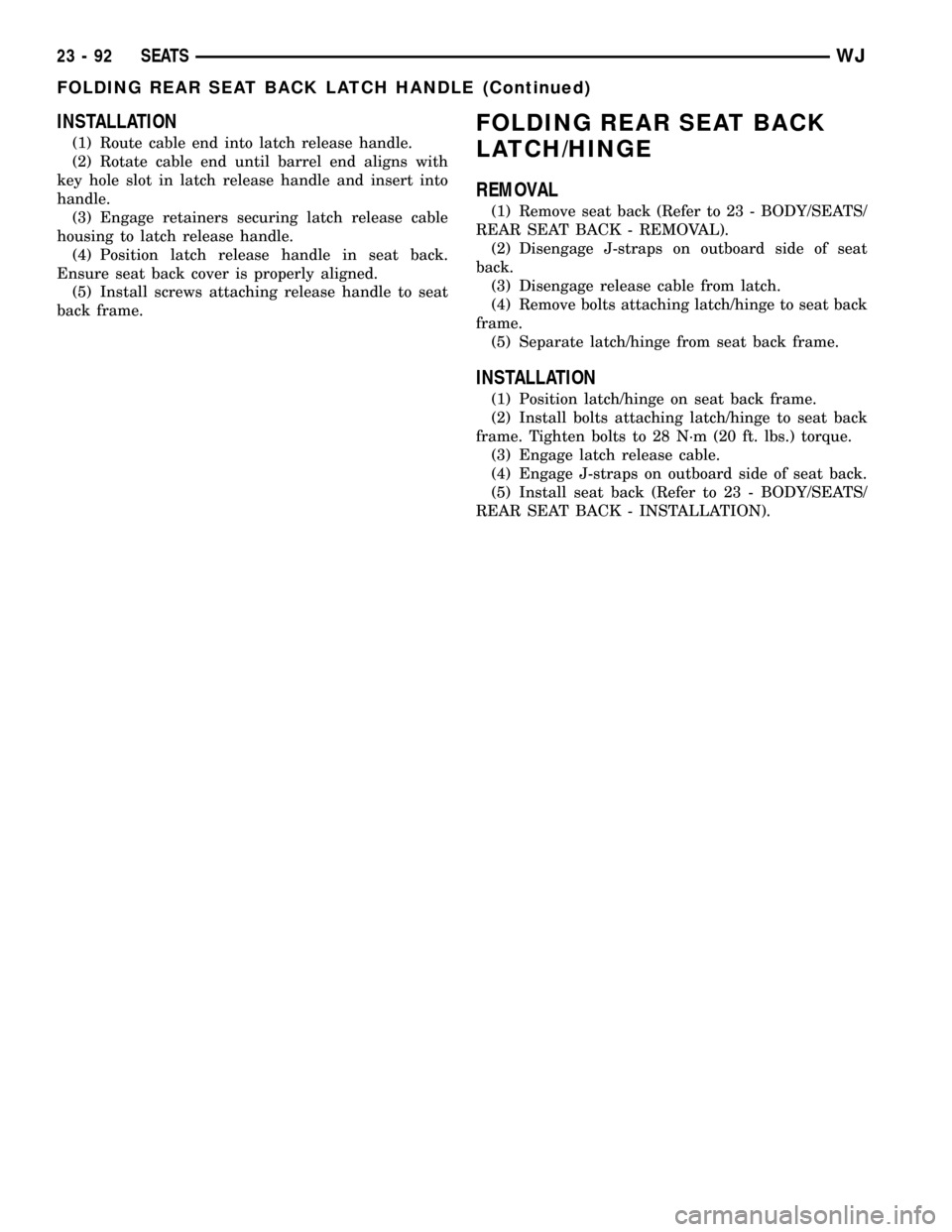

(1) Pull handle to release latch.

(2) Remove screws attaching release handle to seat

back frame.

(3) Using a small flat blade, disengage retainers

securing latch release cable housing to latch release

handle.

(4) Rotate cable end until barrel end aligns with

key hole slot in latch release handle.

(5) Disengage cable barrel end from release han-

dle.

(6) Separate latch release handle from seat back

(Fig. 15).

Fig. 14 Push-in Fasteners

1 - CUSHION COVER

2 - SEAT CUSHION BASE PANEL

3 - PUSH-IN FASTENER

Fig. 15 Rear Seat Release Handle

1 - REAR SEAT FOLDING RELEASE HANDLE

WJSEATS 23 - 91

Page 1965 of 2199

INSTALLATION

(1) Route cable end into latch release handle.

(2) Rotate cable end until barrel end aligns with

key hole slot in latch release handle and insert into

handle.

(3) Engage retainers securing latch release cable

housing to latch release handle.

(4) Position latch release handle in seat back.

Ensure seat back cover is properly aligned.

(5) Install screws attaching release handle to seat

back frame.

FOLDING REAR SEAT BACK

LATCH/HINGE

REMOVAL

(1) Remove seat back (Refer to 23 - BODY/SEATS/

REAR SEAT BACK - REMOVAL).

(2) Disengage J-straps on outboard side of seat

back.

(3) Disengage release cable from latch.

(4) Remove bolts attaching latch/hinge to seat back

frame.

(5) Separate latch/hinge from seat back frame.

INSTALLATION

(1) Position latch/hinge on seat back frame.

(2) Install bolts attaching latch/hinge to seat back

frame. Tighten bolts to 28 N´m (20 ft. lbs.) torque.

(3) Engage latch release cable.

(4) Engage J-straps on outboard side of seat back.

(5) Install seat back (Refer to 23 - BODY/SEATS/

REAR SEAT BACK - INSTALLATION).

23 - 92 SEATSWJ

FOLDING REAR SEAT BACK LATCH HANDLE (Continued)

Page 1966 of 2199

STATIONARY GLASS

TABLE OF CONTENTS

page page

DOOR GLASS

REMOVAL.............................93

INSTALLATION.........................93

QUARTER WINDOW

REMOVAL.............................93INSTALLATION.........................93

WINDSHIELD

REMOVAL.............................94

INSTALLATION.........................95

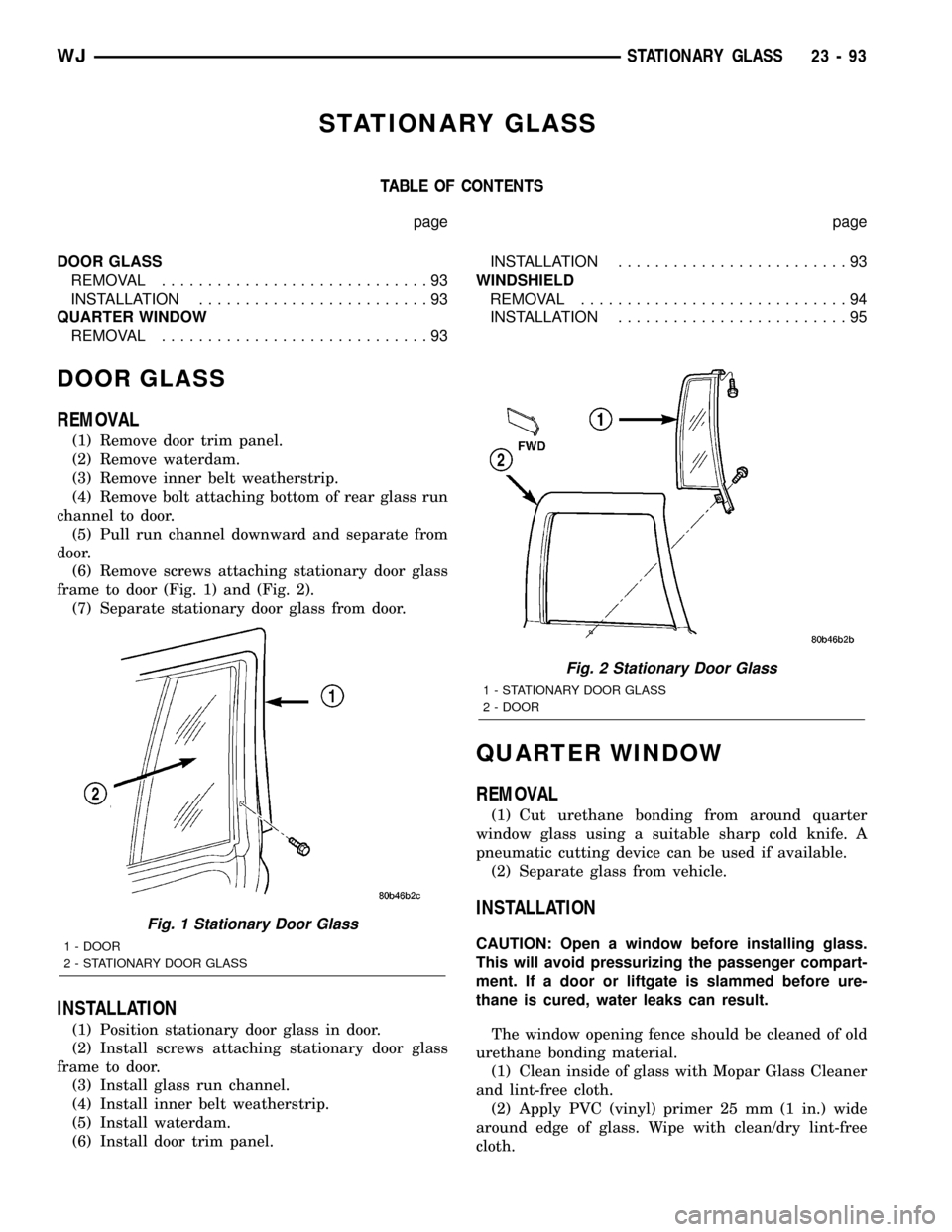

DOOR GLASS

REMOVAL

(1) Remove door trim panel.

(2) Remove waterdam.

(3) Remove inner belt weatherstrip.

(4) Remove bolt attaching bottom of rear glass run

channel to door.

(5) Pull run channel downward and separate from

door.

(6) Remove screws attaching stationary door glass

frame to door (Fig. 1) and (Fig. 2).

(7) Separate stationary door glass from door.

INSTALLATION

(1) Position stationary door glass in door.

(2) Install screws attaching stationary door glass

frame to door.

(3) Install glass run channel.

(4) Install inner belt weatherstrip.

(5) Install waterdam.

(6) Install door trim panel.

QUARTER WINDOW

REMOVAL

(1) Cut urethane bonding from around quarter

window glass using a suitable sharp cold knife. A

pneumatic cutting device can be used if available.

(2) Separate glass from vehicle.

INSTALLATION

CAUTION: Open a window before installing glass.

This will avoid pressurizing the passenger compart-

ment. If a door or liftgate is slammed before ure-

thane is cured, water leaks can result.

The window opening fence should be cleaned of old

urethane bonding material.

(1) Clean inside of glass with Mopar Glass Cleaner

and lint-free cloth.

(2) Apply PVC (vinyl) primer 25 mm (1 in.) wide

around edge of glass. Wipe with clean/dry lint-free

cloth.

Fig. 1 Stationary Door Glass

1 - DOOR

2 - STATIONARY DOOR GLASS

Fig. 2 Stationary Door Glass

1 - STATIONARY DOOR GLASS

2 - DOOR

WJSTATIONARY GLASS 23 - 93

Page 1972 of 2199

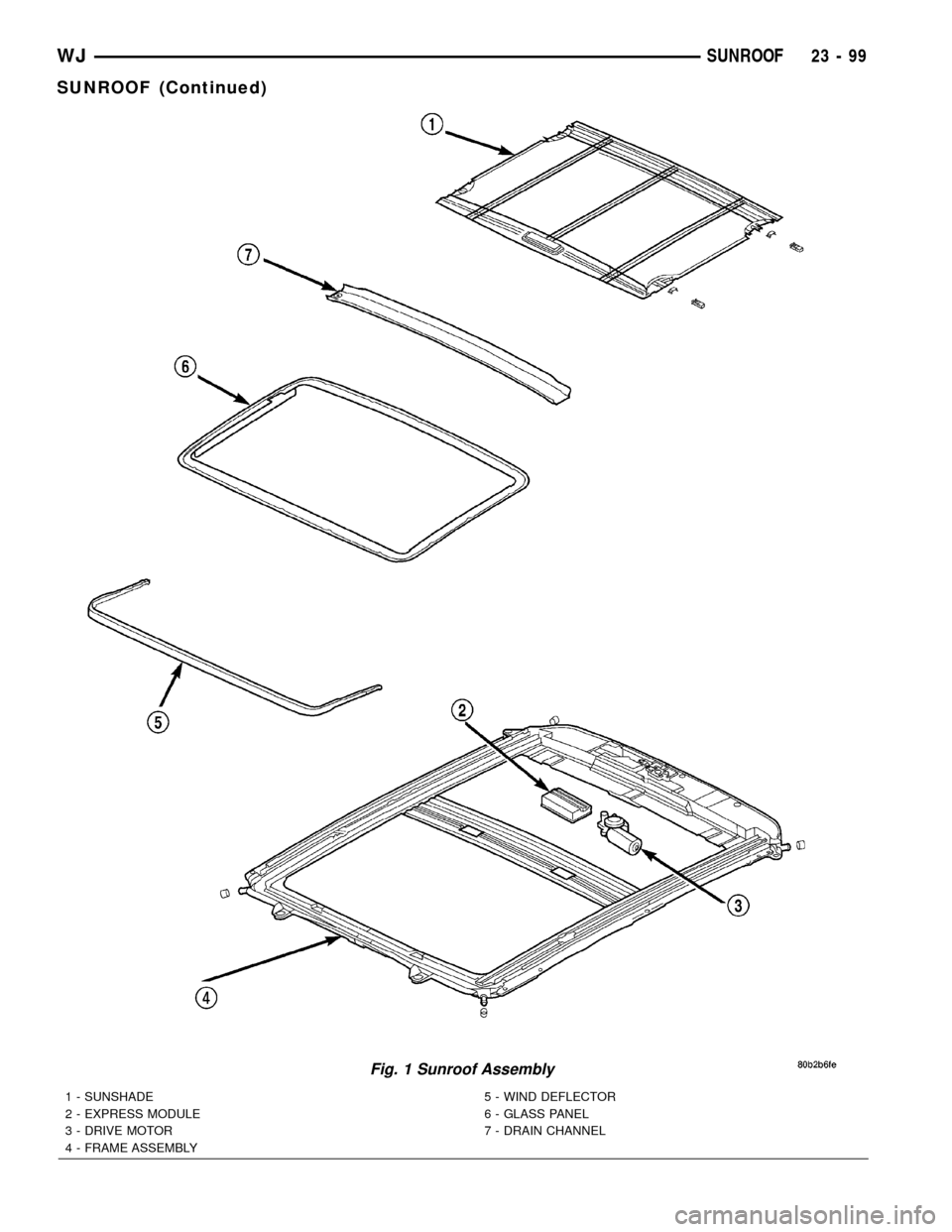

Fig. 1 Sunroof Assembly

1 - SUNSHADE

2 - EXPRESS MODULE

3 - DRIVE MOTOR

4 - FRAME ASSEMBLY5 - WIND DEFLECTOR

6 - GLASS PANEL

7 - DRAIN CHANNEL

WJSUNROOF 23 - 99

SUNROOF (Continued)

Page 2157 of 2199

DESCRIPTION - STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. Connect

the DRB scan tool to the data link connector and

access the state display screen. Then access either

State Display Inputs and Outputs or State Display

Sensors.

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly. Connect the DRB scan tool to the data link

connector and access the Actuators screen.

DESCRIPTION - DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

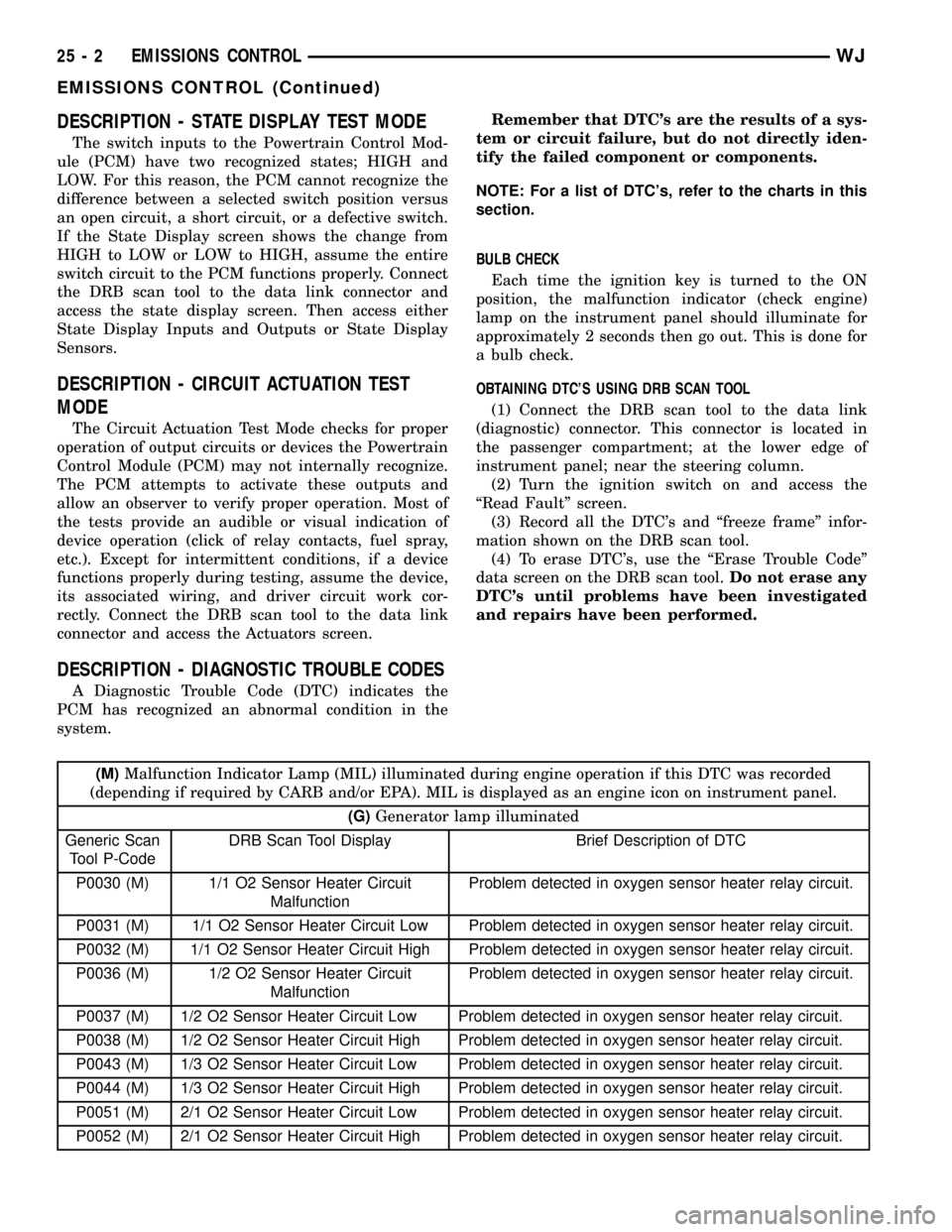

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0030 (M) 1/1 O2 Sensor Heater Circuit

MalfunctionProblem detected in oxygen sensor heater relay circuit.

P0031 (M) 1/1 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0032 (M) 1/1 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0036 (M) 1/2 O2 Sensor Heater Circuit

MalfunctionProblem detected in oxygen sensor heater relay circuit.

P0037 (M) 1/2 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0038 (M) 1/2 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0043 (M) 1/3 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0044 (M) 1/3 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0051 (M) 2/1 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0052 (M) 2/1 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

25 - 2 EMISSIONS CONTROLWJ

EMISSIONS CONTROL (Continued)

Page 2176 of 2199

OPERATION - TASK MANAGER

The Task Manager determines which tests happen

when and which functions occur when. Many of the

diagnostic steps required by OBD II must be per-

formed under specific operating conditions. The Task

Manager software organizes and prioritizes the diag-

nostic procedures. The job of the Task Manager is to

determine if conditions are appropriate for tests to be

run, monitor the parameters for a trip for each test,

and record the results of the test. Following are the

responsibilities of the Task Manager software:

²Test Sequence

²MIL Illumination

²Diagnostic Trouble Codes (DTCs)

²Trip Indicator

²Freeze Frame Data Storage

²Similar Conditions Window

Test Sequence

In many instances, emissions systems must fail

diagnostic tests more than once before the PCM illu-

minates the MIL. These tests are know as 'two trip

monitors.' Other tests that turn the MIL lamp on

after a single failure are known as 'one trip moni-

tors.' A trip is defined as 'start the vehicle and oper-

ate it to meet the criteria necessary to run the given

monitor.'

Many of the diagnostic tests must be performed

under certain operating conditions. However, there

are times when tests cannot be run because another

test is in progress (conflict), another test has failed

(pending) or the Task Manager has set a fault that

may cause a failure of the test (suspend).

²Pending

Under some situations the Task Manager will not

run a monitor if the MIL is illuminated and a fault is

stored from another monitor. In these situations, the

Task Manager postpones monitorspendingresolu-

tion of the original fault. The Task Manager does not

run the test until the problem is remedied.

For example, when the MIL is illuminated for an

Oxygen Sensor fault, the Task Manager does not run

the Catalyst Monitor until the Oxygen Sensor fault is

remedied. Since the Catalyst Monitor is based on sig-

nals from the Oxygen Sensor, running the test would

produce inaccurate results.

²Conflict

There are situations when the Task Manager does

not run a test if another monitor is in progress. In

these situations, the effects of another monitor run-

ning could result in an erroneous failure. If thiscon-

flictis present, the monitor is not run until the

conflicting condition passes. Most likely the monitor

will run later after the conflicting monitor has

passed.

For example, if the Fuel System Monitor is inprogress, the Task Manager does not run the EGR

Monitor. Since both tests monitor changes in air/fuel

ratio and adaptive fuel compensation, the monitors

will conflict with each other.

²Suspend

Occasionally the Task Manager may not allow a two

trip fault to mature. The Task Manager willsus-

pendthe maturing of a fault if a condition exists

that may induce an erroneous failure. This prevents

illuminating the MIL for the wrong fault and allows

more precis diagnosis.

For example, if the PCM is storing a one trip fault

for the Oxygen Sensor and the EGR monitor, the

Task Manager may still run the EGR Monitor but

will suspend the results until the Oxygen Sensor

Monitor either passes or fails. At that point the Task

Manager can determine if the EGR system is actu-

ally failing or if an Oxygen Sensor is failing.MIL Illumination

The PCM Task Manager carries out the illumina-

tion of the MIL. The Task Manager triggers MIL illu-

mination upon test failure, depending on monitor

failure criteria.

The Task Manager Screen shows both a Requested

MIL state and an Actual MIL state. When the MIL is

illuminated upon completion of a test for a third trip,

the Requested MIL state changes to OFF. However,

the MIL remains illuminated until the next key

cycle. (On some vehicles, the MIL will actually turn

OFF during the third key cycle) During the key cycle

for the third good trip, the Requested MIL state is

OFF, while the Actual MIL state is ON. After the

next key cycle, the MIL is not illuminated and both

MIL states read OFF.

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different

priorities according to regulations. As a result, the

priorities determine MIL illumination and DTC era-

sure. DTCs are entered according to individual prior-

ity. DTCs with a higher priority overwrite lower

priority DTCs.

Priorities

²Priority 0 ÐNon-emissions related trouble codes

²Priority 1 Ð One trip failure of a two trip fault

for non-fuel system and non-misfire.

²Priority 2 Ð One trip failure of a two trip fault

for fuel system (rich/lean) or misfire.

²Priority3ÐTwotrip failure for a non-fuel sys-

tem and non-misfire or matured one trip comprehen-

sive component fault.

²Priority4ÐTwotrip failure or matured fault

for fuel system (rich/lean) and misfire or one trip cat-

alyst damaging misfire.

WJEMISSIONS CONTROL 25 - 21

EMISSIONS CONTROL (Continued)