Brake light fuse JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 315 of 2199

(5) Connect the two instrument panel wire harness

connectors to the BCM.

(6) Reinstall the instrument panel fuse cover to

the bottom of the BCM and JB unit. (Refer to 8 -

ELECTRICAL/POWER DISTRIBUTION/FUSE

COVER - INSTALLATION).

(7) Connect the battery negative cable.

COMMUNICATION

DESCRIPTION

The Programmable Communication Interface (PCI)

data bus system is a single wire multiplex system

used for vehicle communications. Multiplexing is a

system that enables the transmission of several mes-

sages over a single channel or circuit.

Many of the control modules in a vehicle require

information from the same sensing device. Multiplex-

ing reduces wire harness complexity, sensor current

loads and controller hardware because each sensing

device is connected to only one controller, which

reads and distributes the sensor information to the

other controllers over the data bus. Also, because

each controller on the data bus can access the con-

troller sensor inputs to every other controller on the

data bus, more function and feature capabilities are

possible.

A multiplex system allows the information flowing

between controllers to be monitored using a diagnos-

tic scan tool. This system allows a control module to

broadcast message data out onto the bus where all

other control modules can read the messages that are

being sent. When a module reads a message on the

data bus that it requires, it relays that message to

its microprocessor. Each module ignores the mes-

sages on the data bus that it dosen't recognize.

OPERATION

Data exchange between modules is achieved by

serial transmission of encoded data over a single wire

broadcast network. The PCI data bus messages are

carried over the bus in the form of Variable Pulse

Width Modulated (VPWM) signals. The PCI data bus

speed is an average 10.4 Kilo-bits per second (Kbps).

The voltage network used to transmit messages

requires biasing and termination. Each module on

the PCI data bus system provides its own biasing

and termination. Each module (also referred to as a

node) terminates the bus through a terminating

resistor and a terminating capacitor. The Powertrain

Control Module (PCM) is the only dominant node for

the PCI data bus system.

The PCI bus uses low and high voltage levels to

generate signals. The voltage on the buss varies

between zero and seven and one-half volts. The lowand high voltage levels are generated by means of

variable-pulse width modulation to form signals of

varying length.

When a module is transmitting on the bus, it is

reading the bus at the same time to ensure message

integrity.

Each module is capable of transmitting and receiv-

ing data simultaneously.

The PCI data bus can be monitored using the

DRBIIItscan tool. It is possible for the bus to pass

all DRBIIIttests and still be faulty if the voltage

parameters are all within the specified range and

false messages are being sent.

CONTROLLER ANTILOCK

BRAKE

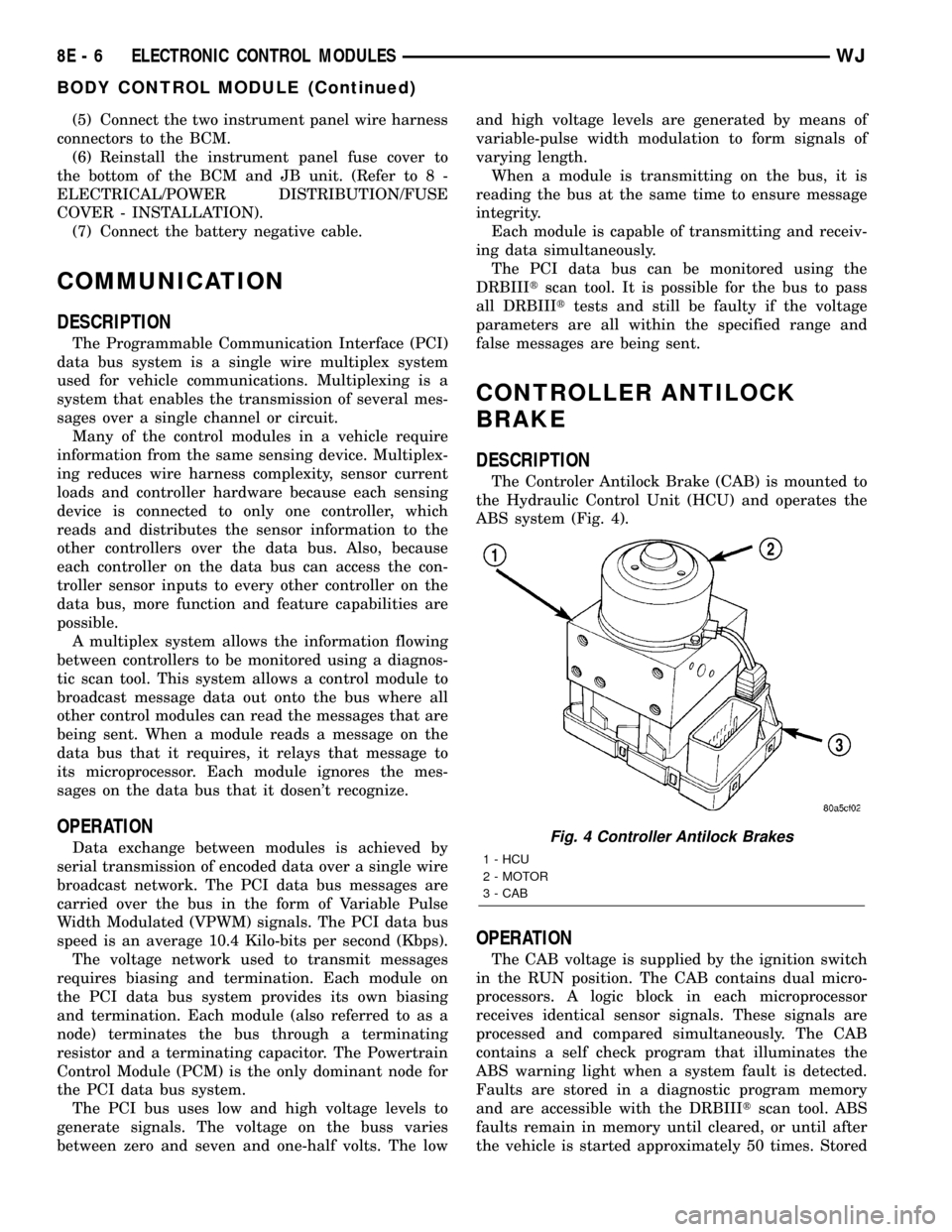

DESCRIPTION

The Controler Antilock Brake (CAB) is mounted to

the Hydraulic Control Unit (HCU) and operates the

ABS system (Fig. 4).

OPERATION

The CAB voltage is supplied by the ignition switch

in the RUN position. The CAB contains dual micro-

processors. A logic block in each microprocessor

receives identical sensor signals. These signals are

processed and compared simultaneously. The CAB

contains a self check program that illuminates the

ABS warning light when a system fault is detected.

Faults are stored in a diagnostic program memory

and are accessible with the DRBIIItscan tool. ABS

faults remain in memory until cleared, or until after

the vehicle is started approximately 50 times. Stored

Fig. 4 Controller Antilock Brakes

1 - HCU

2 - MOTOR

3 - CAB

8E - 6 ELECTRONIC CONTROL MODULESWJ

BODY CONTROL MODULE (Continued)

Page 421 of 2199

The VFD is diagnosed using the EMIC self-diag-

nostic actuator test. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus and

the data bus message inputs to the EMIC that con-

trol the VFD functions requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation. Specific operation details for the odometer

and trip odometer functions of the VFD may be found

elsewhere in this service information.

INDICATORS

Indicators are located in various positions within

the EMIC and are all connected to the EMIC circuit

board. The turn signal indicators are hard wired. The

brake indicator is controlled by PCI data bus mes-

sages from the Controller Antilock Brake (CAB) as

well as by hard wired park brake switch and brake

fluid level switch inputs to the EMIC. The Malfunc-

tion Indicator Lamp (MIL) is normally controlled by

PCI data bus messages from the Powertrain Control

Module (PCM); however, if the EMIC loses PCI data

bus communication, the EMIC circuitry will automat-

ically turn the MIL on until PCI data bus communi-

cation is restored. The EMIC uses PCI data bus

messages from the Airbag Control Module (ACM), the

BCM, the PCM, the CAB, the Sentry Key Immobi-

lizer Module (SKIM), and the Transmission Control

Module (TCM) to control all of the remaining indica-

tors.

The various indicators are controlled by different

strategies; some receive fused ignition switch output

from the EMIC circuitry and have a switched ground,

others are grounded through the EMIC circuitry and

have a switched battery feed, while still others are

completely controlled by the EMIC microprocessor

based upon various hard wired and electronic mes-

sage inputs. Some indicators are illuminated at a

fixed intensity, while the illumination intensity of

others is synchronized with that of the EMIC general

illumination lamps.

The hard wired indicators are diagnosed using con-

ventional diagnostic methods. The EMIC and PCI

bus message controlled indicators are diagnosed

using the EMIC self-diagnostic actuator test. (Refer

to 8 - ELECTRICAL/INSTRUMENT CLUSTER -

DIAGNOSIS AND TESTING). Proper testing of the

PCI data bus and the electronic data bus message

inputs to the EMIC that control each indicator

require the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information. Specific details of

the operation for each indicator may be found else-

where in this service information.CLUSTER ILLUMINATION

Two types of general cluster illumination are avail-

able in this model. Base versions of the EMIC have

several incandescent illumination lamps, while pre-

mium versions of the EMIC have a single electro-lu-

minescent lamp. Both types of lamps provide cluster

back lighting whenever the exterior lighting is

turned On with the control knob on the left (lighting)

multi-function switch control stalk. The illumination

intensity of these lamps is adjusted by the EMIC

microprocessor based upon electronic dimming level

messages received from the Body Control Module

(BCM) over the PCI data bus. The BCM provides

electronic dimming level messages to the EMIC

based upon internal programming and inputs it

receives when the control ring on the left (lighting)

multi-function switch control stalk is rotated (down

to dim, up to brighten) to one of six available minor

detent positions.

The incandescent illumination lamps receive bat-

tery current at all times, while the ground for these

lamps is controlled by a 12-volt Pulse Width Modu-

lated (PWM) output of the EMIC electronic circuitry.

The illumination intensity of these bulbs and of the

vacuum-fluorescent electronic display are controlled

by the instrument cluster microprocessor based upon

dimming level messages received from the Body Con-

trol Module (BCM) over the PCI data bus. The BCM

uses inputs from the headlamp and panel dimmer

switches within the left (lighting) multi-function

switch control stalk and internal programming to

decide what dimming level message is required. The

BCM then sends the proper dimming level messages

to the EMIC over the PCI data bus.

The electro-luminescent lamp unit consists of lay-

ers of phosphor, carbon, idium tin oxide, and dielec-

tric applied by a silk-screen process between two

polyester membranes and includes a short pigtail

wire and connector. The lamp pigtail wire is con-

nected to a small connector receptacle on the EMIC

circuit board through a small clearance hole in the

cluster housing rear cover. The EMIC electronic cir-

cuitry also uses a PWM strategy to control the illu-

mination intensity of this lamp; however, the EMIC

powers this lamp with an Alternating Current (AC)

rated at 80 volts rms (root mean squared) and 415

Hertz, which excites the phosphor particles causing

them to luminesce.

The BCM also has several hard wired panel lamp

driver outputs and sends the proper panel lamps

dimming level messages over the PCI data bus to

coordinate the illumination intensity of all of the

instrument panel lighting and the VFDs of other

electronic modules on the PCI data bus. Vehicles

equipped with the Auto Headlamps option have an

automatic parade mode. In this mode, the BCM uses

8J - 6 INSTRUMENT CLUSTERWJ

INSTRUMENT CLUSTER (Continued)

Page 429 of 2199

tor will be turned on for the duration of the test to

confirm the functionality of the bulb and the cluster

control circuitry.

²ABS Diagnostic Test- The ABS indicator is

blinked on and off based upon lamp-on and lamp-off

messages from the CAB during the performance of

the ABS diagnostic tests.

The CAB continually monitors the ABS circuits

and sensors to decide whether the system is in good

operating condition. The CAB then sends the proper

ABS indicator lamp-on or lamp-off messages to the

instrument cluster. If the ABS indicator fails to light

during the bulb test, replace the bulb with a known

good unit. If the CAB sends an ABS indicator

lamp-on message after the bulb test, it indicates that

the CAB has detected a system malfunction and/or

that the ABS system has become inoperative. The

CAB will store a Diagnostic Trouble Code (DTC) for

any malfunction it detects. Each time the ABS indi-

cator fails to illuminate due to an open or short in

the cluster ABS indicator circuit or bulb, the cluster

sends a message notifying the CAB of the condition,

then the instrument cluster and the CAB will each

store a DTC. For proper diagnosis of the anti-lock

brake system, the CAB, the PCI data bus, or the

electronic message inputs to the instrument cluster

that control the ABS indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

AIRBAG INDICATOR

DESCRIPTION

An airbag indicator is standard equipment on all

instrument clusters. However, the instrument cluster

is programmed to automatically enable this indicator

only on vehicles equipped with the airbag system,

which is not available in some markets. The airbag

indicator is located on the upper edge of the instru-

ment cluster, between the speedometer and the

tachometer. The airbag indicator consists of the

words ªAIR BAGº imprinted on a red lens. The lens

is located behind a cutout in the opaque layer of the

instrument cluster overlay. The dark outer layer of

the overlay prevents the indicator from being clearly

visible when it is not illuminated. The ªAIR BAGº

text appears silhouetted against a red field through

the translucent outer layer of the overlay when the

indicator is illuminated from behind by a Light Emit-

ting Diode (LED), which is soldered onto the instru-

ment cluster electronic circuit board. The airbag

indicator lens is serviced as a unit with the instru-

ment cluster lens, hood and mask unit.

OPERATION

The airbag indicator gives an indication to the

vehicle operator when the airbag system is faulty or

inoperative. The airbag indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Airbag Control

Module (ACM) over the Programmable Communica-

tions Interface (PCI) data bus. The airbag indicator

Light Emitting Diode (LED) is completely controlled

by the instrument cluster logic circuit, and that logic

will only allow this indicator to operate when the

instrument cluster receives a battery current input

on the fused ignition switch output (run-start) cir-

cuit. Therefore, the indicator will always be off when

the ignition switch is in any position except On or

Start. The LED only illuminates when it is switched

to ground by the instrument cluster transistor. The

instrument cluster will turn on the airbag indicator

for the following reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the ACM sends an elec-

tronic airbag indicator lamp-on message to the clus-

ter which will illuminate the airbag indicator for

about six seconds as a bulb test. The entire six sec-

ond bulb test is a function of the ACM.

²Airbag Indicator Lamp-On Message- Each

time the cluster receives an airbag indicator lamp-on

message from the ACM, the airbag indicator will be

illuminated. The indicator remains illuminated for

about twelve seconds or until the cluster receives an

airbag indicator lamp-off message from the ACM,

whichever is longer.

²Communication Error- If the cluster receives

no airbag indicator lamp-on or lamp-off messages for

six consecutive seconds, the airbag indicator is illu-

minated. The indicator remains illuminated until the

cluster receives a single valid airbag indicator lamp-

off message from the ACM.

²Actuator Test- Each time the cluster is put

through the actuator test, the airbag indicator will be

turned on, then off again during the bulb check por-

tion of the test to confirm the functionality of the

LED and the cluster control circuitry. The actuator

test illumination of the airbag indicator is also a

function of the ACM.

The ACM continually monitors the airbag system

circuits and sensors to decide whether the system is

in good operating condition. The ACM then sends the

proper airbag indicator lamp-on or lamp-off messages

to the instrument cluster. If the ACM sends an air-

bag indicator lamp-on message after the bulb test, it

indicates that the ACM has detected a system mal-

function. Such a malfunction could mean that the

airbags may not deploy when required, or may

deploy when not required. The ACM will store a

8J - 14 INSTRUMENT CLUSTERWJ

ABS INDICATOR (Continued)

Page 430 of 2199

Diagnostic Trouble Code (DTC) for any malfunction it

detects. Each time the airbag indicator fails to illu-

minate due to an open or short in the cluster airbag

indicator circuit, the cluster sends a message notify-

ing the ACM of the condition, then the instrument

cluster and the ACM will each store a DTC. For

proper diagnosis of the airbag system, the ACM, the

PCI data bus, or the electronic message inputs to the

instrument cluster that control the airbag indicator,

a DRBIIItscan tool is required. Refer to the appro-

priate diagnostic information.

BRAKE/PARK BRAKE

INDICATOR

DESCRIPTION

A brake indicator is standard equipment on all

instrument clusters. The brake indicator is located

near the left edge of the instrument cluster, to the

left of the tachometer. There are two versions of the

brake indicator. The version used depends upon the

market for which the vehicle is manufactured. The

version of the brake indicator used for vehicles man-

ufactured for the United States consists of the word

ªBRAKEº imprinted on a red lens. The Rest-Of-World

(ROW) market version of this indicator has two

International Control and Display Symbol icons

imprinted on the red lens; one is the icon for ªBrake

Failureº, and the other is the icon for ªParking

Brakeº. In either case, the lens is located behind a

cutout in the opaque layer of the instrument cluster

overlay. The dark outer layer of the overlay prevents

the indicator from being clearly visible when it is not

illuminated. The ªBRAKEº text or the two icons

appear silhouetted against a red field through the

translucent outer layer of the overlay when the indi-

cator is illuminated from behind by a Light Emitting

Diode (LED), which is soldered onto the instrument

cluster electronic circuit board. The brake indicator

lens is serviced as a unit with the instrument cluster

lens, hood and mask unit.

OPERATION

The brake indicator gives an indication to the vehi-

cle operator when the parking brake is applied, when

the fluid level of the brake hydraulic system is low,

or if there are certain malfunctions of the Anti-lock

Brake System (ABS). This indicator is controlled by a

transistor on the instrument cluster electronic circuit

board based upon cluster programming, electronic

messages received by the cluster from the Controller

Anti-lock Brake (CAB) over the Programmable Com-

munications Interface (PCI) data bus, and a hard

wired input to the cluster from the park brake

switch. The brake indicator Light Emitting Diode(LED) is completely controlled by the instrument

cluster logic circuit, and that logic will only allow

this indicator to operate when the instrument cluster

receives a battery current input on the fused ignition

switch output (run-start) circuit. Therefore, the indi-

cator will always be off when the ignition switch is in

any position except On or Start. The LED only illu-

minates when it is provided a path to ground by the

instrument cluster transistor. The instrument cluster

will turn on the brake indicator for the following rea-

sons:

²Bulb Test- Each time the ignition switch is

turned to the On position the brake indicator is illu-

minated by the instrument cluster for about three

seconds as a bulb test.

²Brake Indicator Lamp-On Message- Each

time the cluster receives a brake indicator lamp-on

message from the CAB, the brake indicator will be

illuminated. The indicator remains illuminated until

the cluster receives a brake indicator lamp-off mes-

sage from the CAB.

²Park Brake Switch Input- Each time the

cluster logic circuit detects ground on the park brake

switch sense circuit (park brake switch closed = park

brake applied or not fully released) the brake indica-

tor is illuminated. The indicator remains illuminated

until the park brake switch sense input to the cluster

is an open circuit (park brake switch open = park

brake fully released), or until the ignition switch is

turned to the Off position, whichever occurs first.

²Communication Error- If the cluster receives

no brake indicator lamp-on or lamp-off messages

from the CAB for six consecutive seconds, the brake

indicator is illuminated. The indicator remains illu-

minated until the cluster receives a single valid

brake indicator lamp-off message from the CAB.

²Actuator Test- Each time the cluster is put

through the actuator test, the brake indicator will be

turned on for the duration of the test to confirm the

functionality of the LED and the cluster control cir-

cuitry.

The park brake switch on the park brake pedal

mechanism provides a hard wired ground input to

the instrument cluster circuitry through the red

brake warning indicator driver circuit whenever the

park brake is applied or not fully released. The CAB

continually monitors the input from the brake fluid

level switch and the circuits of the anti-lock brake

system, then sends the proper brake indicator

lamp-on or lamp-off messages to the instrument clus-

ter. If the CAB sends a brake indicator lamp-on mes-

sage after the bulb test, it indicates that the CAB

has detected a brake hydraulic system malfunction

and/or that the ABS system has become inoperative.

The CAB will store a Diagnostic Trouble Code (DTC)

for any malfunction it detects.

WJINSTRUMENT CLUSTER 8J - 15

AIRBAG INDICATOR (Continued)

Page 446 of 2199

OPERATION

The speedometer gives an indication to the vehicle

operator of the vehicle road speed. This gauge is con-

trolled by the instrument cluster electronic circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Program-

mable Communications Interface (PCI) data bus. The

speedometer is an air core magnetic unit that

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (run-start) circuit whenever the igni-

tion switch is in the On or Start positions. The clus-

ter is programmed to move the gauge needle back to

the low end of the scale after the ignition switch is

turned to the Off position. The instrument cluster

circuitry controls the gauge needle position and pro-

vides the following features:

²Vehicle Speed Message- Each time the clus-

ter receives a vehicle speed message from the PCM it

will calculate the correct vehicle speed reading and

position the gauge needle at that speed position on

the gauge scale. The cluster will receive a new vehi-

cle speed message and reposition the gauge pointer

accordingly about every 86 milliseconds. The gauge

needle will continue to be positioned at the actual

vehicle speed position on the gauge scale until the

ignition switch is turned to the Off position.

²Communication Error- If the cluster fails to

receive a speedometer message, it will hold the gauge

needle at the last indication for about six seconds, or

until the ignition switch is turned to the Off position,

whichever occurs first. If a new speed message is not

received after about six seconds, the gauge needle

will return to the far left (low) end of the scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept across the entire gauge scale and back in order

to confirm the functionality of the gauge and the

cluster control circuitry.

The PCM continually monitors the vehicle speed

information received from the Controller Anti-lock

Brake (CAB) to determine the vehicle road speed,

then sends the proper vehicle speed messages to the

instrument cluster. For further diagnosis of the

speedometer or the instrument cluster circuitry that

controls the gauge, (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - DIAGNOSIS AND TEST-

ING). For proper diagnosis of the CAB, the PCM, the

PCI data bus, or the electronic message inputs to the

instrument cluster that control the speedometer, a

DRBIIItscan tool is required. Refer to the appropri-

ate diagnostic information.

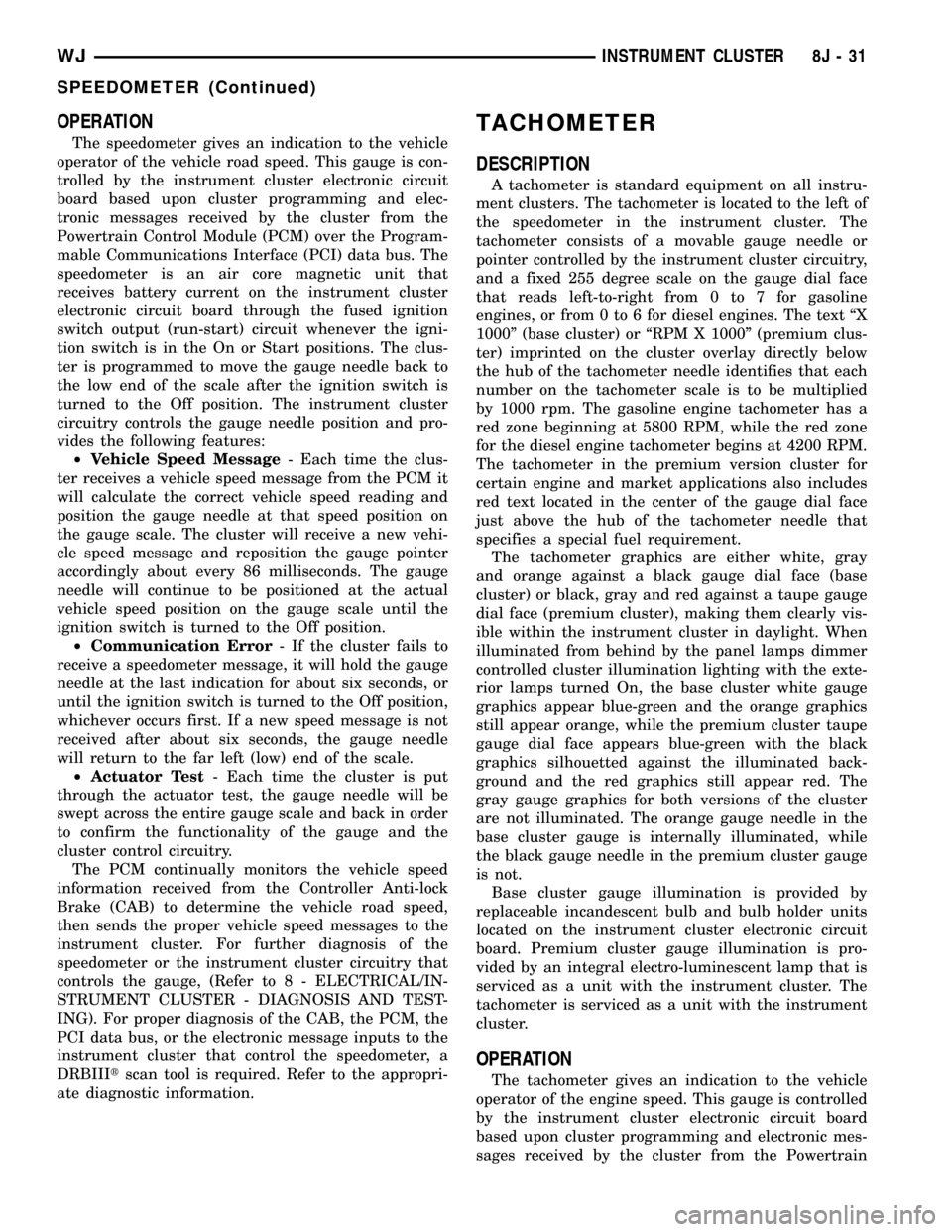

TACHOMETER

DESCRIPTION

A tachometer is standard equipment on all instru-

ment clusters. The tachometer is located to the left of

the speedometer in the instrument cluster. The

tachometer consists of a movable gauge needle or

pointer controlled by the instrument cluster circuitry,

and a fixed 255 degree scale on the gauge dial face

that reads left-to-right from 0 to 7 for gasoline

engines, or from 0 to 6 for diesel engines. The text ªX

1000º (base cluster) or ªRPM X 1000º (premium clus-

ter) imprinted on the cluster overlay directly below

the hub of the tachometer needle identifies that each

number on the tachometer scale is to be multiplied

by 1000 rpm. The gasoline engine tachometer has a

red zone beginning at 5800 RPM, while the red zone

for the diesel engine tachometer begins at 4200 RPM.

The tachometer in the premium version cluster for

certain engine and market applications also includes

red text located in the center of the gauge dial face

just above the hub of the tachometer needle that

specifies a special fuel requirement.

The tachometer graphics are either white, gray

and orange against a black gauge dial face (base

cluster) or black, gray and red against a taupe gauge

dial face (premium cluster), making them clearly vis-

ible within the instrument cluster in daylight. When

illuminated from behind by the panel lamps dimmer

controlled cluster illumination lighting with the exte-

rior lamps turned On, the base cluster white gauge

graphics appear blue-green and the orange graphics

still appear orange, while the premium cluster taupe

gauge dial face appears blue-green with the black

graphics silhouetted against the illuminated back-

ground and the red graphics still appear red. The

gray gauge graphics for both versions of the cluster

are not illuminated. The orange gauge needle in the

base cluster gauge is internally illuminated, while

the black gauge needle in the premium cluster gauge

is not.

Base cluster gauge illumination is provided by

replaceable incandescent bulb and bulb holder units

located on the instrument cluster electronic circuit

board. Premium cluster gauge illumination is pro-

vided by an integral electro-luminescent lamp that is

serviced as a unit with the instrument cluster. The

tachometer is serviced as a unit with the instrument

cluster.

OPERATION

The tachometer gives an indication to the vehicle

operator of the engine speed. This gauge is controlled

by the instrument cluster electronic circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Powertrain

WJINSTRUMENT CLUSTER 8J - 31

SPEEDOMETER (Continued)

Page 465 of 2199

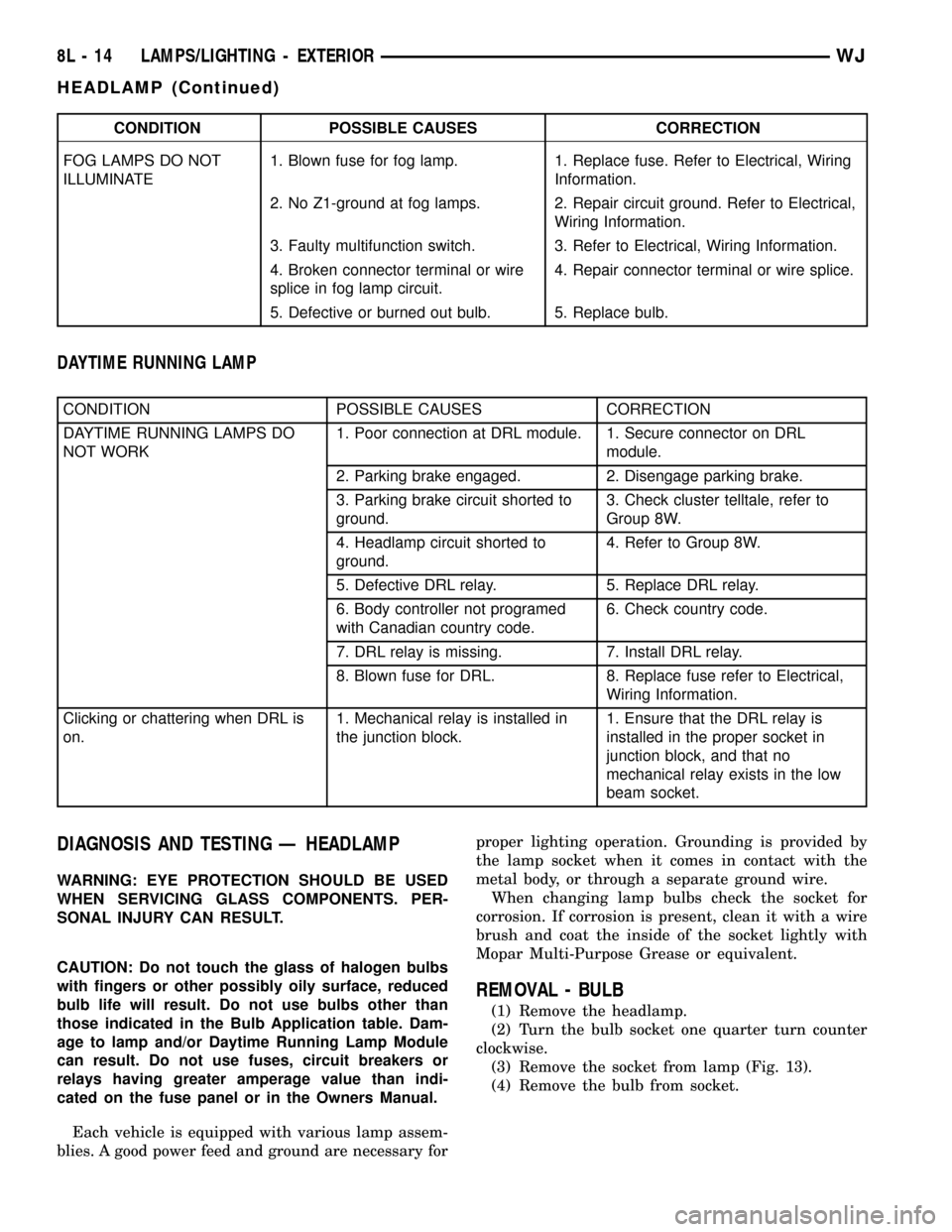

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS DO NOT

ILLUMINATE1. Blown fuse for fog lamp. 1. Replace fuse. Refer to Electrical, Wiring

Information.

2. No Z1-ground at fog lamps. 2. Repair circuit ground. Refer to Electrical,

Wiring Information.

3. Faulty multifunction switch. 3. Refer to Electrical, Wiring Information.

4. Broken connector terminal or wire

splice in fog lamp circuit.4. Repair connector terminal or wire splice.

5. Defective or burned out bulb. 5. Replace bulb.

DAYTIME RUNNING LAMP

CONDITION POSSIBLE CAUSES CORRECTION

DAYTIME RUNNING LAMPS DO

NOT WORK1. Poor connection at DRL module. 1. Secure connector on DRL

module.

2. Parking brake engaged. 2. Disengage parking brake.

3. Parking brake circuit shorted to

ground.3. Check cluster telltale, refer to

Group 8W.

4. Headlamp circuit shorted to

ground.4. Refer to Group 8W.

5. Defective DRL relay. 5. Replace DRL relay.

6. Body controller not programed

with Canadian country code.6. Check country code.

7. DRL relay is missing. 7. Install DRL relay.

8. Blown fuse for DRL. 8. Replace fuse refer to Electrical,

Wiring Information.

Clicking or chattering when DRL is

on.1. Mechanical relay is installed in

the junction block.1. Ensure that the DRL relay is

installed in the proper socket in

junction block, and that no

mechanical relay exists in the low

beam socket.

DIAGNOSIS AND TESTING Ð HEADLAMP

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result. Do not use bulbs other than

those indicated in the Bulb Application table. Dam-

age to lamp and/or Daytime Running Lamp Module

can result. Do not use fuses, circuit breakers or

relays having greater amperage value than indi-

cated on the fuse panel or in the Owners Manual.

Each vehicle is equipped with various lamp assem-

blies. A good power feed and ground are necessary forproper lighting operation. Grounding is provided by

the lamp socket when it comes in contact with the

metal body, or through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush and coat the inside of the socket lightly with

Mopar Multi-Purpose Grease or equivalent.

REMOVAL - BULB

(1) Remove the headlamp.

(2) Turn the bulb socket one quarter turn counter

clockwise.

(3) Remove the socket from lamp (Fig. 13).

(4) Remove the bulb from socket.

8L - 14 LAMPS/LIGHTING - EXTERIORWJ

HEADLAMP (Continued)

Page 661 of 2199

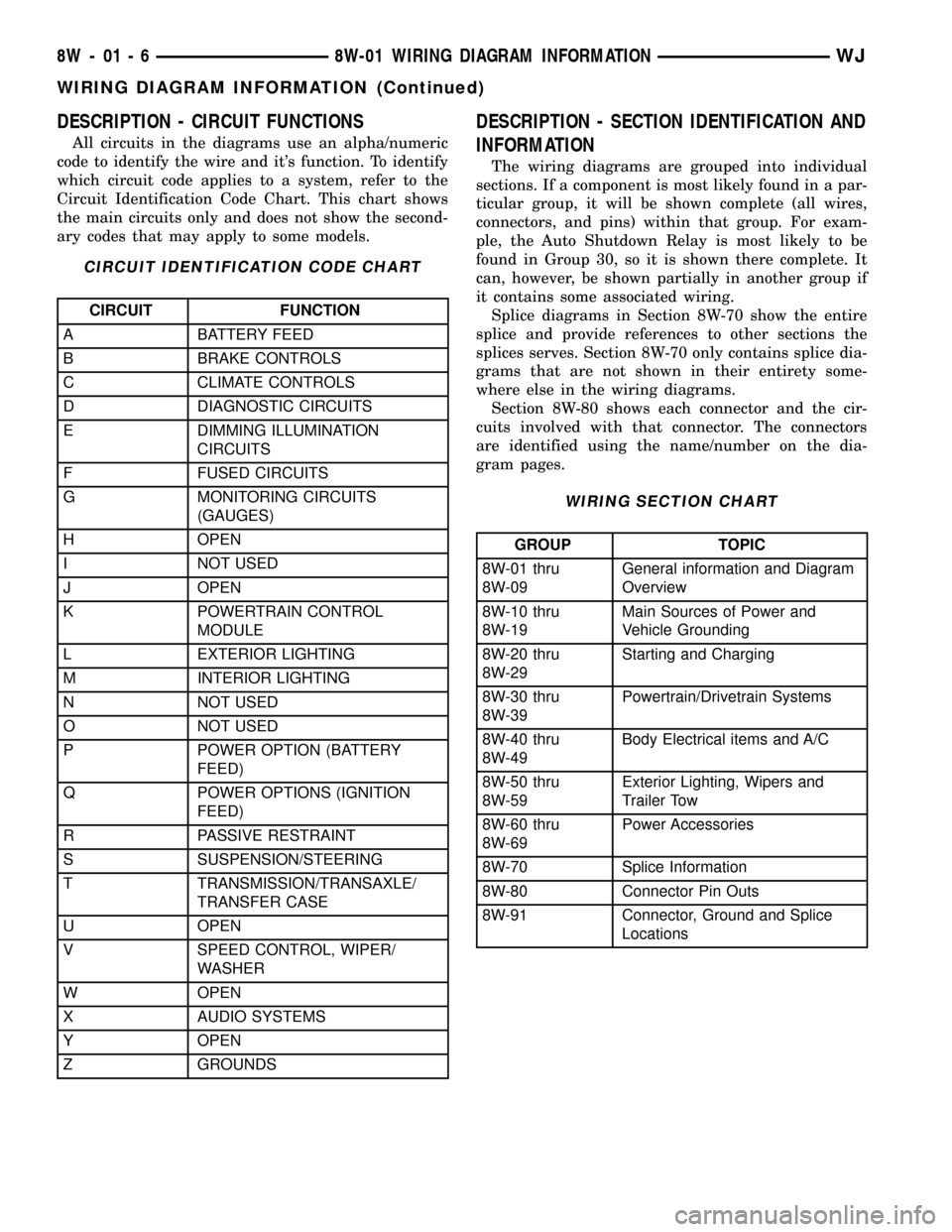

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONWJ

WIRING DIAGRAM INFORMATION (Continued)

Page 672 of 2199

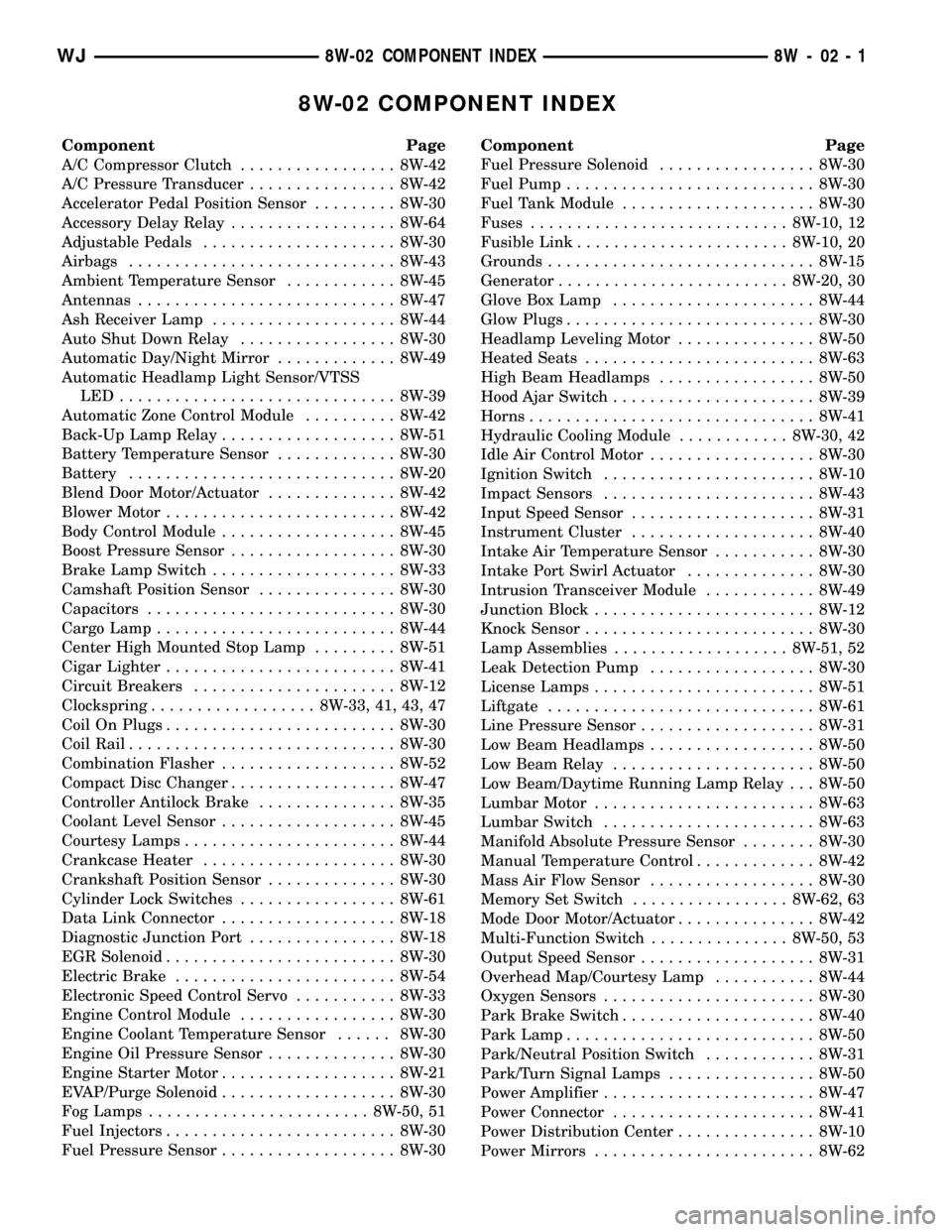

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch................. 8W-42

A/C Pressure Transducer................ 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Accessory Delay Relay.................. 8W-64

Adjustable Pedals..................... 8W-30

Airbags............................. 8W-43

Ambient Temperature Sensor............ 8W-45

Antennas............................ 8W-47

Ash Receiver Lamp.................... 8W-44

Auto Shut Down Relay................. 8W-30

Automatic Day/Night Mirror............. 8W-49

Automatic Headlamp Light Sensor/VTSS

LED.............................. 8W-39

Automatic Zone Control Module.......... 8W-42

Back-Up Lamp Relay................... 8W-51

Battery Temperature Sensor............. 8W-30

Battery............................. 8W-20

Blend Door Motor/Actuator.............. 8W-42

Blower Motor......................... 8W-42

Body Control Module................... 8W-45

Boost Pressure Sensor.................. 8W-30

Brake Lamp Switch.................... 8W-33

Camshaft Position Sensor............... 8W-30

Capacitors........................... 8W-30

Cargo Lamp.......................... 8W-44

Center High Mounted Stop Lamp......... 8W-51

Cigar Lighter......................... 8W-41

Circuit Breakers...................... 8W-12

Clockspring.................. 8W-33, 41, 43, 47

Coil On Plugs......................... 8W-30

Coil Rail............................. 8W-30

Combination Flasher................... 8W-52

Compact Disc Changer.................. 8W-47

Controller Antilock Brake............... 8W-35

Coolant Level Sensor................... 8W-45

Courtesy Lamps....................... 8W-44

Crankcase Heater..................... 8W-30

Crankshaft Position Sensor.............. 8W-30

Cylinder Lock Switches................. 8W-61

Data Link Connector................... 8W-18

Diagnostic Junction Port................ 8W-18

EGR Solenoid......................... 8W-30

Electric Brake........................ 8W-54

Electronic Speed Control Servo........... 8W-33

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor...... 8W-30

Engine Oil Pressure Sensor.............. 8W-30

Engine Starter Motor................... 8W-21

EVAP/Purge Solenoid................... 8W-30

Fog Lamps........................ 8W-50, 51

Fuel Injectors......................... 8W-30

Fuel Pressure Sensor................... 8W-30Component Page

Fuel Pressure Solenoid................. 8W-30

Fuel Pump........................... 8W-30

Fuel Tank Module..................... 8W-30

Fuses............................ 8W-10, 12

Fusible Link....................... 8W-10, 20

Grounds............................. 8W-15

Generator......................... 8W-20, 30

Glove Box Lamp...................... 8W-44

Glow Plugs........................... 8W-30

Headlamp Leveling Motor............... 8W-50

Heated Seats......................... 8W-63

High Beam Headlamps................. 8W-50

Hood Ajar Switch...................... 8W-39

Horns............................... 8W-41

Hydraulic Cooling Module............ 8W-30, 42

Idle Air Control Motor.................. 8W-30

Ignition Switch....................... 8W-10

Impact Sensors....................... 8W-43

Input Speed Sensor.................... 8W-31

Instrument Cluster.................... 8W-40

Intake Air Temperature Sensor........... 8W-30

Intake Port Swirl Actuator.............. 8W-30

Intrusion Transceiver Module............ 8W-49

Junction Block........................ 8W-12

Knock Sensor......................... 8W-30

Lamp Assemblies................... 8W-51, 52

Leak Detection Pump.................. 8W-30

License Lamps........................ 8W-51

Liftgate............................. 8W-61

Line Pressure Sensor................... 8W-31

Low Beam Headlamps.................. 8W-50

Low Beam Relay...................... 8W-50

Low Beam/Daytime Running Lamp Relay . . . 8W-50

Lumbar Motor........................ 8W-63

Lumbar Switch....................... 8W-63

Manifold Absolute Pressure Sensor........ 8W-30

Manual Temperature Control............. 8W-42

Mass Air Flow Sensor.................. 8W-30

Memory Set Switch................. 8W-62, 63

Mode Door Motor/Actuator............... 8W-42

Multi-Function Switch............... 8W-50, 53

Output Speed Sensor................... 8W-31

Overhead Map/Courtesy Lamp........... 8W-44

Oxygen Sensors....................... 8W-30

Park Brake Switch..................... 8W-40

Park Lamp........................... 8W-50

Park/Neutral Position Switch............ 8W-31

Park/Turn Signal Lamps................ 8W-50

Power Amplifier....................... 8W-47

Power Connector...................... 8W-41

Power Distribution Center............... 8W-10

Power Mirrors........................ 8W-62

WJ8W-02 COMPONENT INDEX 8W - 02 - 1

Page 674 of 2199

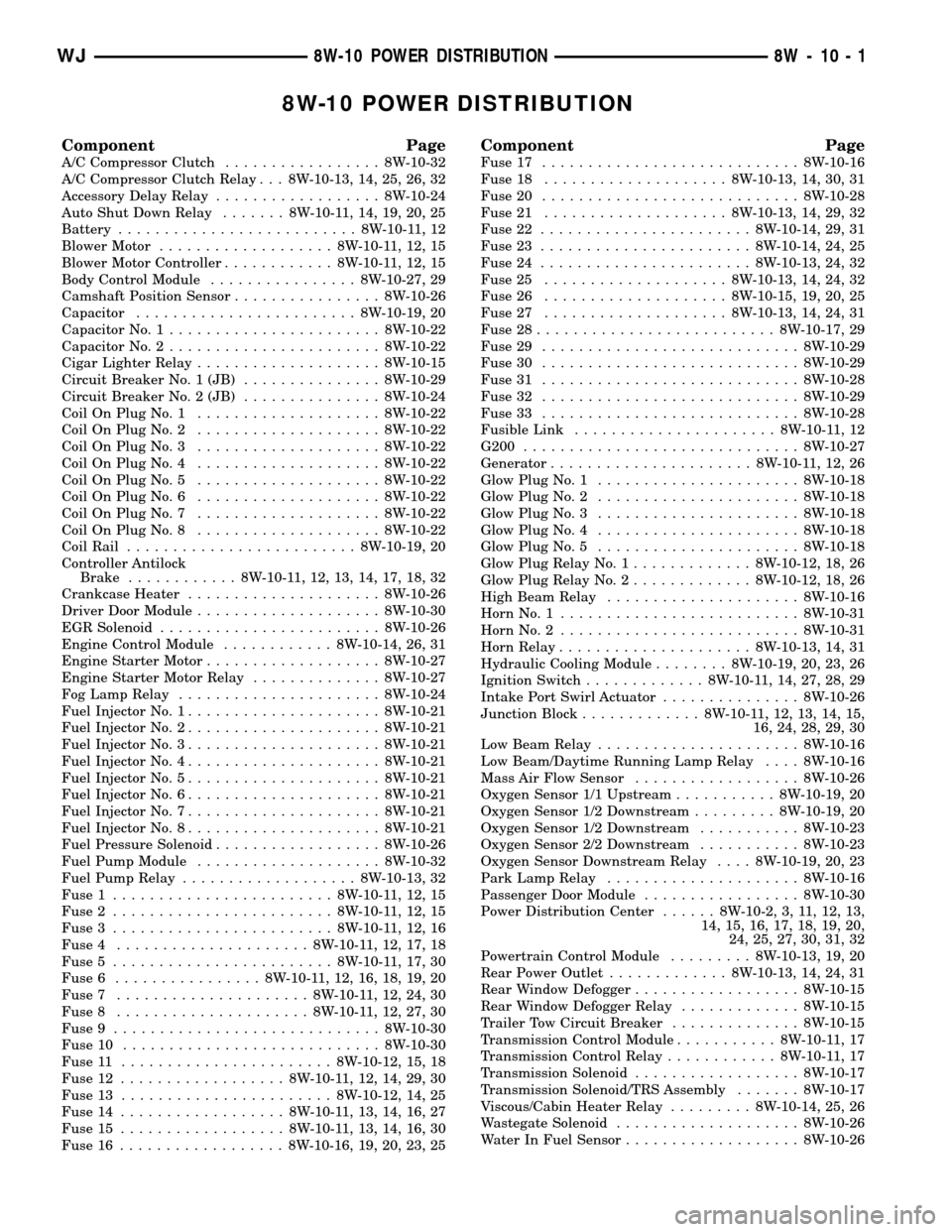

8W-10 POWER DISTRIBUTION

Component Page

A/C Compressor Clutch................. 8W-10-32

A/C Compressor Clutch Relay . . . 8W-10-13, 14, 25, 26, 32

Accessory Delay Relay.................. 8W-10-24

Auto Shut Down Relay....... 8W-10-11, 14, 19, 20, 25

Battery.......................... 8W-10-11, 12

Blower Motor................... 8W-10-11, 12, 15

Blower Motor Controller............ 8W-10-11, 12, 15

Body Control Module................ 8W-10-27, 29

Camshaft Position Sensor................ 8W-10-26

Capacitor........................ 8W-10-19, 20

Capacitor No. 1....................... 8W-10-22

Capacitor No. 2....................... 8W-10-22

Cigar Lighter Relay.................... 8W-10-15

Circuit Breaker No. 1 (JB)............... 8W-10-29

Circuit Breaker No. 2 (JB)............... 8W-10-24

Coil On Plug No. 1.................... 8W-10-22

Coil On Plug No. 2.................... 8W-10-22

Coil On Plug No. 3.................... 8W-10-22

Coil On Plug No. 4.................... 8W-10-22

Coil On Plug No. 5.................... 8W-10-22

Coil On Plug No. 6.................... 8W-10-22

Coil On Plug No. 7.................... 8W-10-22

Coil On Plug No. 8.................... 8W-10-22

Coil Rail......................... 8W-10-19, 20

Controller Antilock

Brake............ 8W-10-11, 12, 13, 14, 17, 18, 32

Crankcase Heater..................... 8W-10-26

Driver Door Module.................... 8W-10-30

EGR Solenoid........................ 8W-10-26

Engine Control Module............ 8W-10-14, 26, 31

Engine Starter Motor................... 8W-10-27

Engine Starter Motor Relay.............. 8W-10-27

Fog Lamp Relay...................... 8W-10-24

Fuel Injector No. 1..................... 8W-10-21

Fuel Injector No. 2..................... 8W-10-21

Fuel Injector No. 3..................... 8W-10-21

Fuel Injector No. 4..................... 8W-10-21

Fuel Injector No. 5..................... 8W-10-21

Fuel Injector No. 6..................... 8W-10-21

Fuel Injector No. 7..................... 8W-10-21

Fuel Injector No. 8..................... 8W-10-21

Fuel Pressure Solenoid.................. 8W-10-26

Fuel Pump Module.................... 8W-10-32

Fuel Pump Relay................... 8W-10-13, 32

Fuse 1........................ 8W-10-11, 12, 15

Fuse 2........................ 8W-10-11, 12, 15

Fuse 3........................ 8W-10-11, 12, 16

Fuse 4..................... 8W-10-11, 12, 17, 18

Fuse 5........................ 8W-10-11, 17, 30

Fuse 6................ 8W-10-11, 12, 16, 18, 19, 20

Fuse 7..................... 8W-10-11, 12, 24, 30

Fuse 8..................... 8W-10-11, 12, 27, 30

Fuse 9............................. 8W-10-30

Fuse 10............................ 8W-10-30

Fuse 11....................... 8W-10-12, 15, 18

Fuse 12.................. 8W-10-11, 12, 14, 29, 30

Fuse 13....................... 8W-10-12, 14, 25

Fuse 14.................. 8W-10-11, 13, 14, 16, 27

Fuse 15.................. 8W-10-11, 13, 14, 16, 30

Fuse 16.................. 8W-10-16, 19, 20, 23, 25

Component Page

Fuse 17............................ 8W-10-16

Fuse 18.................... 8W-10-13, 14, 30, 31

Fuse 20............................ 8W-10-28

Fuse 21.................... 8W-10-13, 14, 29, 32

Fuse 22....................... 8W-10-14, 29, 31

Fuse 23....................... 8W-10-14, 24, 25

Fuse 24....................... 8W-10-13, 24, 32

Fuse 25.................... 8W-10-13, 14, 24, 32

Fuse 26.................... 8W-10-15, 19, 20, 25

Fuse 27.................... 8W-10-13, 14, 24, 31

Fuse 28.......................... 8W-10-17, 29

Fuse 29............................ 8W-10-29

Fuse 30............................ 8W-10-29

Fuse 31............................ 8W-10-28

Fuse 32............................ 8W-10-29

Fuse 33............................ 8W-10-28

Fusible Link...................... 8W-10-11, 12

G200.............................. 8W-10-27

Generator...................... 8W-10-11, 12, 26

Glow Plug No. 1...................... 8W-10-18

Glow Plug No. 2...................... 8W-10-18

Glow Plug No. 3...................... 8W-10-18

Glow Plug No. 4...................... 8W-10-18

Glow Plug No. 5...................... 8W-10-18

Glow Plug Relay No. 1............. 8W-10-12, 18, 26

Glow Plug Relay No. 2............. 8W-10-12, 18, 26

High Beam Relay..................... 8W-10-16

Horn No. 1.......................... 8W-10-31

Horn No. 2.......................... 8W-10-31

Horn Relay..................... 8W-10-13, 14, 31

Hydraulic Cooling Module........ 8W-10-19, 20, 23, 26

Ignition Switch............. 8W-10-11, 14, 27, 28, 29

Intake Port Swirl Actuator............... 8W-10-26

Junction Block............. 8W-10-11, 12, 13, 14, 15,

16, 24, 28, 29, 30

Low Beam Relay...................... 8W-10-16

Low Beam/Daytime Running Lamp Relay.... 8W-10-16

Mass Air Flow Sensor.................. 8W-10-26

Oxygen Sensor 1/1 Upstream........... 8W-10-19, 20

Oxygen Sensor 1/2 Downstream......... 8W-10-19, 20

Oxygen Sensor 1/2 Downstream........... 8W-10-23

Oxygen Sensor 2/2 Downstream........... 8W-10-23

Oxygen Sensor Downstream Relay.... 8W-10-19, 20, 23

Park Lamp Relay..................... 8W-10-16

Passenger Door Module................. 8W-10-30

Power Distribution Center...... 8W-10-2, 3, 11, 12, 13,

14, 15, 16, 17, 18, 19, 20,

24, 25, 27, 30, 31, 32

Powertrain Control Module......... 8W-10-13, 19, 20

Rear Power Outlet............. 8W-10-13, 14, 24, 31

Rear Window Defogger.................. 8W-10-15

Rear Window Defogger Relay............. 8W-10-15

Trailer Tow Circuit Breaker.............. 8W-10-15

Transmission Control Module........... 8W-10-11, 17

Transmission Control Relay............ 8W-10-11, 17

Transmission Solenoid.................. 8W-10-17

Transmission Solenoid/TRS Assembly....... 8W-10-17

Viscous/Cabin Heater Relay......... 8W-10-14, 25, 26

Wastegate Solenoid.................... 8W-10-26

Water In Fuel Sensor................... 8W-10-26

WJ8W-10 POWER DISTRIBUTION 8W - 10 - 1

Page 706 of 2199

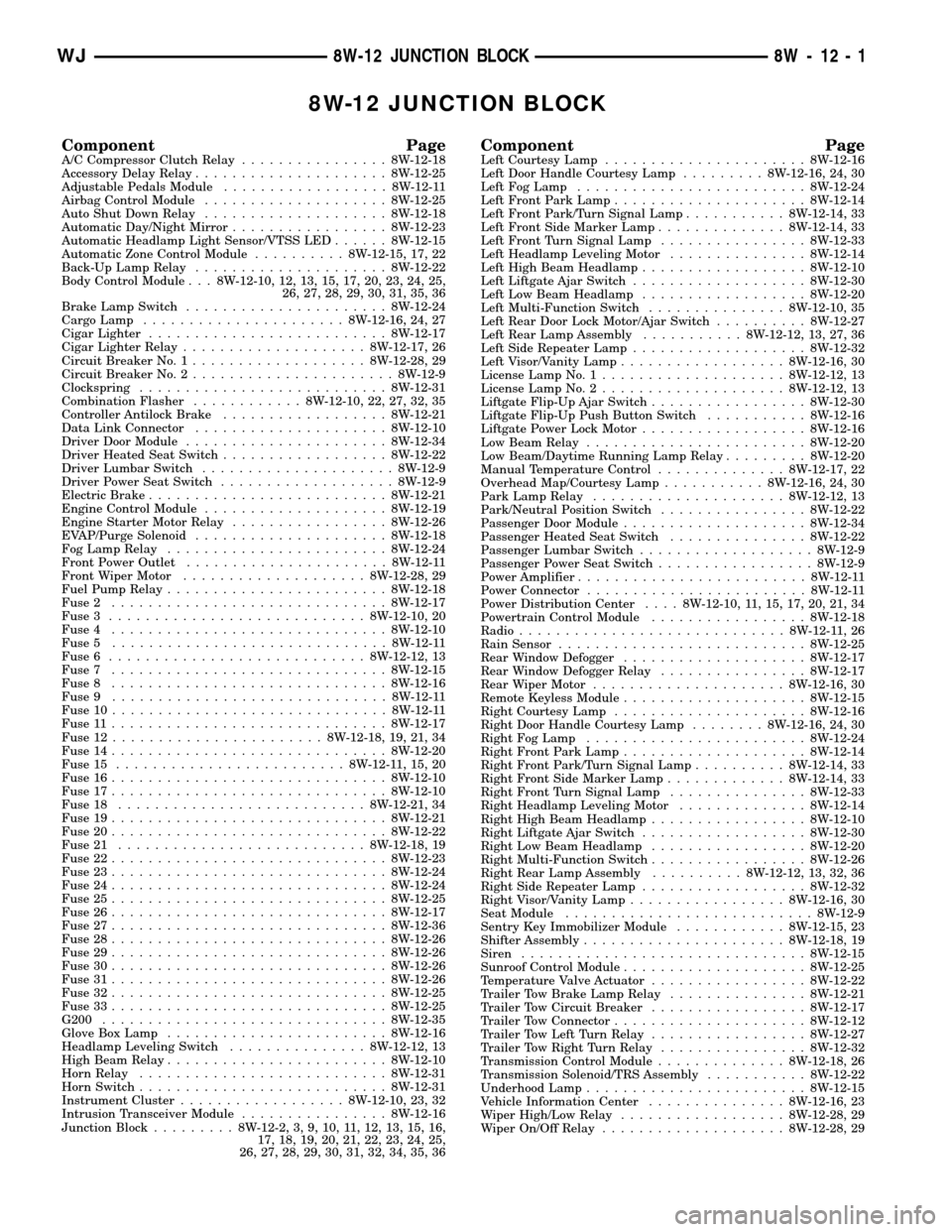

8W-12 JUNCTION BLOCK

Component PageA/C Compressor Clutch Relay................8W-12-18

Accessory Delay Relay.....................8W-12-25

Adjustable Pedals Module..................8W-12-11

Airbag Control Module....................8W-12-25

Auto Shut Down Relay....................8W-12-18

Automatic Day/Night Mirror.................8W-12-23

Automatic Headlamp Light Sensor/VTSS LED......8W-12-15

Automatic Zone Control Module..........8W-12-15, 17, 22

Back-Up Lamp Relay.....................8W-12-22

Body Control Module . . . 8W-12-10, 12, 13, 15, 17, 20, 23, 24, 25,

26, 27, 28, 29, 30, 31, 35, 36

Brake Lamp Switch......................8W-12-24

Cargo Lamp......................8W-12-16, 24, 27

Cigar Lighter..........................8W-12-17

Cigar Lighter Relay....................8W-12-17, 26

Circuit Breaker No. 1...................8W-12-28, 29

Circuit Breaker No. 2......................8W-12-9

Clockspring...........................8W-12-31

Combination Flasher............8W-12-10, 22, 27, 32, 35

Controller Antilock Brake..................8W-12-21

Data Link Connector.....................8W-12-10

Driver Door Module......................8W-12-34

Driver Heated Seat Switch..................8W-12-22

Driver Lumbar Switch.....................8W-12-9

Driver Power Seat Switch...................8W-12-9

Electric Brake..........................8W-12-21

Engine Control Module....................8W-12-19

Engine Starter Motor Relay.................8W-12-26

EVAP/Purge Solenoid.....................8W-12-18

Fog Lamp Relay........................8W-12-24

Front Power Outlet......................8W-12-11

Front Wiper Motor....................8W-12-28, 29

Fuel Pump Relay........................8W-12-18

Fuse 2..............................8W-12-17

Fuse 3............................8W-12-10, 20

Fuse 4..............................8W-12-10

Fuse 5..............................8W-12-11

Fuse 6............................8W-12-12, 13

Fuse 7..............................8W-12-15

Fuse 8..............................8W-12-16

Fuse 9..............................8W-12-11

Fuse 10..............................8W-12-11

Fuse 11..............................8W-12-17

Fuse 12.......................8W-12-18, 19, 21, 34

Fuse 14..............................8W-12-20

Fuse 15.........................8W-12-11, 15, 20

Fuse 16..............................8W-12-10

Fuse 17..............................8W-12-10

Fuse 18...........................8W-12-21, 34

Fuse 19..............................8W-12-21

Fuse 20..............................8W-12-22

Fuse 21...........................8W-12-18, 19

Fuse 22..............................8W-12-23

Fuse 23..............................8W-12-24

Fuse 24..............................8W-12-24

Fuse 25..............................8W-12-25

Fuse 26..............................8W-12-17

Fuse 27..............................8W-12-36

Fuse 28..............................8W-12-26

Fuse 29..............................8W-12-26

Fuse 30..............................8W-12-26

Fuse 31..............................8W-12-26

Fuse 32..............................8W-12-25

Fuse 33..............................8W-12-25

G200...............................8W-12-35

Glove Box Lamp........................8W-12-16

Headlamp Leveling Switch...............8W-12-12, 13

High Beam Relay........................8W-12-10

Horn Relay...........................8W-12-31

Horn Switch...........................8W-12-31

Instrument Cluster..................8W-12-10, 23, 32

Intrusion Transceiver Module................8W-12-16

Junction Block.........8W-12-2, 3, 9, 10, 11, 12, 13, 15, 16,

17, 18, 19, 20, 21, 22, 23, 24, 25,

26, 27, 28, 29, 30, 31, 32, 34, 35, 36Component PageLeft Courtesy Lamp......................8W-12-16

Left Door Handle Courtesy Lamp.........8W-12-16, 24, 30

Left Fog Lamp.........................8W-12-24

Left Front Park Lamp.....................8W-12-14

Left Front Park/Turn Signal Lamp...........8W-12-14, 33

Left Front Side Marker Lamp..............8W-12-14, 33

Left Front Turn Signal Lamp................8W-12-33

Left Headlamp Leveling Motor...............8W-12-14

Left High Beam Headlamp..................8W-12-10

Left Liftgate Ajar Switch...................8W-12-30

Left Low Beam Headlamp..................8W-12-20

Left Multi-Function Switch...............8W-12-10, 35

Left Rear Door Lock Motor/Ajar Switch..........8W-12-27

Left Rear Lamp Assembly...........8W-12-12, 13, 27, 36

Left Side Repeater Lamp...................8W-12-32

Left Visor/Vanity Lamp..................8W-12-16, 30

License Lamp No. 1....................8W-12-12, 13

License Lamp No. 2....................8W-12-12, 13

Liftgate Flip-Up Ajar Switch.................8W-12-30

Liftgate Flip-Up Push Button Switch...........8W-12-16

Liftgate Power Lock Motor..................8W-12-16

Low Beam Relay........................8W-12-20

Low Beam/Daytime Running Lamp Relay.........8W-12-20

Manual Temperature Control..............8W-12-17, 22

Overhead Map/Courtesy Lamp...........8W-12-16, 24, 30

Park Lamp Relay.....................8W-12-12, 13

Park/Neutral Position Switch................8W-12-22

Passenger Door Module....................8W-12-34

Passenger Heated Seat Switch...............8W-12-22

Passenger Lumbar Switch...................8W-12-9

Passenger Power Seat Switch.................8W-12-9

Power Amplifier.........................8W-12-11

Power Connector........................8W-12-11

Power Distribution Center....8W-12-10, 11, 15, 17, 20, 21, 34

Powertrain Control Module.................8W-12-18

Radio.............................8W-12-11, 26

Rain Sensor...........................8W-12-25

Rear Window Defogger....................8W-12-17

Rear Window Defogger Relay................8W-12-17

Rear Wiper Motor.....................8W-12-16, 30

Remote Keyless Module....................8W-12-15

Right Courtesy Lamp.....................8W-12-16

Right Door Handle Courtesy Lamp........8W-12-16, 24, 30

Right Fog Lamp........................8W-12-24

Right Front Park Lamp....................8W-12-14

Right Front Park/Turn Signal Lamp..........8W-12-14, 33

Right Front Side Marker Lamp.............8W-12-14, 33

Right Front Turn Signal Lamp...............8W-12-33

Right Headlamp Leveling Motor..............8W-12-14

Right High Beam Headlamp.................8W-12-10

Right Liftgate Ajar Switch..................8W-12-30

Right Low Beam Headlamp.................8W-12-20

Right Multi-Function Switch.................8W-12-26

Right Rear Lamp Assembly..........8W-12-12, 13, 32, 36

Right Side Repeater Lamp..................8W-12-32

Right Visor/Vanity Lamp.................8W-12-16, 30

Seat Module...........................8W-12-9

Sentry Key Immobilizer Module............8W-12-15, 23

Shifter Assembly......................8W-12-18, 19

Siren...............................8W-12-15

Sunroof Control Module....................8W-12-25

Temperature Valve Actuator.................8W-12-22

Trailer Tow Brake Lamp Relay...............8W-12-21

Trailer Tow Circuit Breaker.................8W-12-17

Trailer Tow Connector.....................8W-12-12

Trailer Tow Left Turn Relay.................8W-12-27

Trailer Tow Right Turn Relay................8W-12-32

Transmission Control Module..............8W-12-18, 26

Transmission Solenoid/TRS Assembly...........8W-12-22

Underhood Lamp........................8W-12-15

Vehicle Information Center...............8W-12-16, 23

Wiper High/Low Relay..................8W-12-28, 29

Wiper On/Off Relay....................8W-12-28, 29

WJ8W-12 JUNCTION BLOCK 8W - 12 - 1