Hoses JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 176 of 2199

BRAKES

TABLE OF CONTENTS

page page

BRAKES - BASE........................... 1BRAKES - ABS........................... 41

BRAKES - BASE

TABLE OF CONTENTS

page page

BRAKES - BASE

DESCRIPTION..........................2

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM.............................2

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL

BLEEDING............................5

STANDARD PROCEDURE - PRESSURE

BLEEDING............................5

SPECIFICATIONS

BRAKE COMPONENTS..................6

TORQUE CHART......................6

SPECIAL TOOLS

BASE BRAKES........................7

BRAKE FLUID LEVEL SWITCH

REMOVAL.............................7

INSTALLATION..........................7

RED BRAKE WARN INDICATOR SWITCH

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING - RED BRAKE

WARNING LAMP.......................7

ADJUSTABLE PEDAL SWITCH

REMOVAL.............................8

INSTALLATION..........................8

BRAKE LINES

DESCRIPTION..........................8

DIAGNOSIS AND TESTING - BRAKE HOSES

AND LINES...........................8

STANDARD PROCEDURE

STANDARD PROCEDURE - DOUBLE

INVERTED FLARING....................9

STANDARD PROCEDURE - ISO FLARING . . . 9

BRAKE PADS / SHOES

DESCRIPTION

DESCRIPTION - FRONT DISC BRAKE

SHOES.............................10DESCRIPTION - REAR DISC BRAKE SHOES . 10

OPERATION

OPERATION - FRONT DISC BRAKE SHOES . 10

OPERATION - REAR DISC BRAKE SHOES . . 10

REMOVAL

REMOVAL- FRONT DISC BRAKE SHOES . . . 11

REMOVAL - REAR DISC BRAKE SHOES....12

INSTALLATION

INSTALLATION - FRONT DISC BRAKE

SHOES.............................13

INSTALLATION - REAR DISC BRAKE

SHOES.............................14

DISC BRAKE CALIPERS

REMOVAL

REMOVAL - FRONT DISC BRAKE CALIPER . 14

REMOVAL - REAR DISC BRAKE CALIPER . . 15

DISASSEMBLY

DISASSEMBLY - FRONT DISC BRAKE

CALIPER............................17

DISASSEMBLY - REAR DISC BRAKE

CALIPER............................18

CLEANING - DISC BRAKE CALIPER.........19

INSPECTION - DISC BRAKE CALIPER.......19

ASSEMBLY

ASSEMBLY - FRONT DISC BRAKE CALIPER . 20

ASSEMBLY - REAR DISC BRAKE CALIPER . 21

INSTALLATION

INSTALLATION - FRONT DISC BRAKE

CALIPER............................22

INSTALLATION - REAR DISC BRAKE

CALIPER............................22

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION.....................22

SPECIFICATIONS

BRAKE FLUID........................23

FLUID RESERVOIR

REMOVAL.............................23

WJBRAKES 5 - 1

Page 178 of 2199

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

normal and should not be mistaken for contam-

ination.

(a) If fluid level is abnormally low, look for evi-

dence of leaks at calipers, brake lines, master cyl-

inder, and HCU.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a sub-

stance other than brake fluid. The system seals,

cups, hoses, master cylinder, and HCU will also

have to be replaced after flushing. Use clean brake

fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and lever. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only (do not exceed 25 mph) and note grab,

drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper. If leakage is severe, fluid will be evident at

or around the leaking component.Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS system may also be

the problem with no visual fluid leak.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up, the most

likely causes are worn linings, rotors, or calipers are

not sliding on the slide pins. The proper course of

action is to inspect and replace all worn component.

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However substandard brake hoses can cause

a spongy pedal. The proper course of action is to

bleed the system, and replace substandard quality

brake hoses if suspected.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster, check valve, check

valve seal/grommet or vacuum leak could also cause

a hard pedal or high pedal effort.

PEDAL PULSATION

Pedal pulsation is caused by components that are

loose, or beyond tolerance limits.

The primary cause of pulsation are disc brake

rotors with excessive lateral runout or thickness vari-

ation. Other causes are loose wheel bearings or cali-

pers and worn, damaged tires.

NOTE: Some pedal pulsation may be felt during

ABS activation.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at one

wheel, all wheels, fronts only, or rears only.

Drag is a product of incomplete brake release.

Drag can be minor or severe enough to overheat the

linings, rotors and park brake drums.

Minor drag will usually cause slight surface charring

of the lining. It can also generate hard spots in rotors

and park brake drums from the overheat-cool down pro-

cess. In most cases, the rotors, wheels and tires are

quite warm to the touch after the vehicle is stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors to the

point of replacement. The wheels, tires and brake

components will be extremely hot. In severe cases,

the lining may generate smoke as it chars from over-

heating.

WJBRAKES - BASE 5 - 3

BRAKES - BASE (Continued)

Page 183 of 2199

ADJUSTABLE PEDAL SWITCH

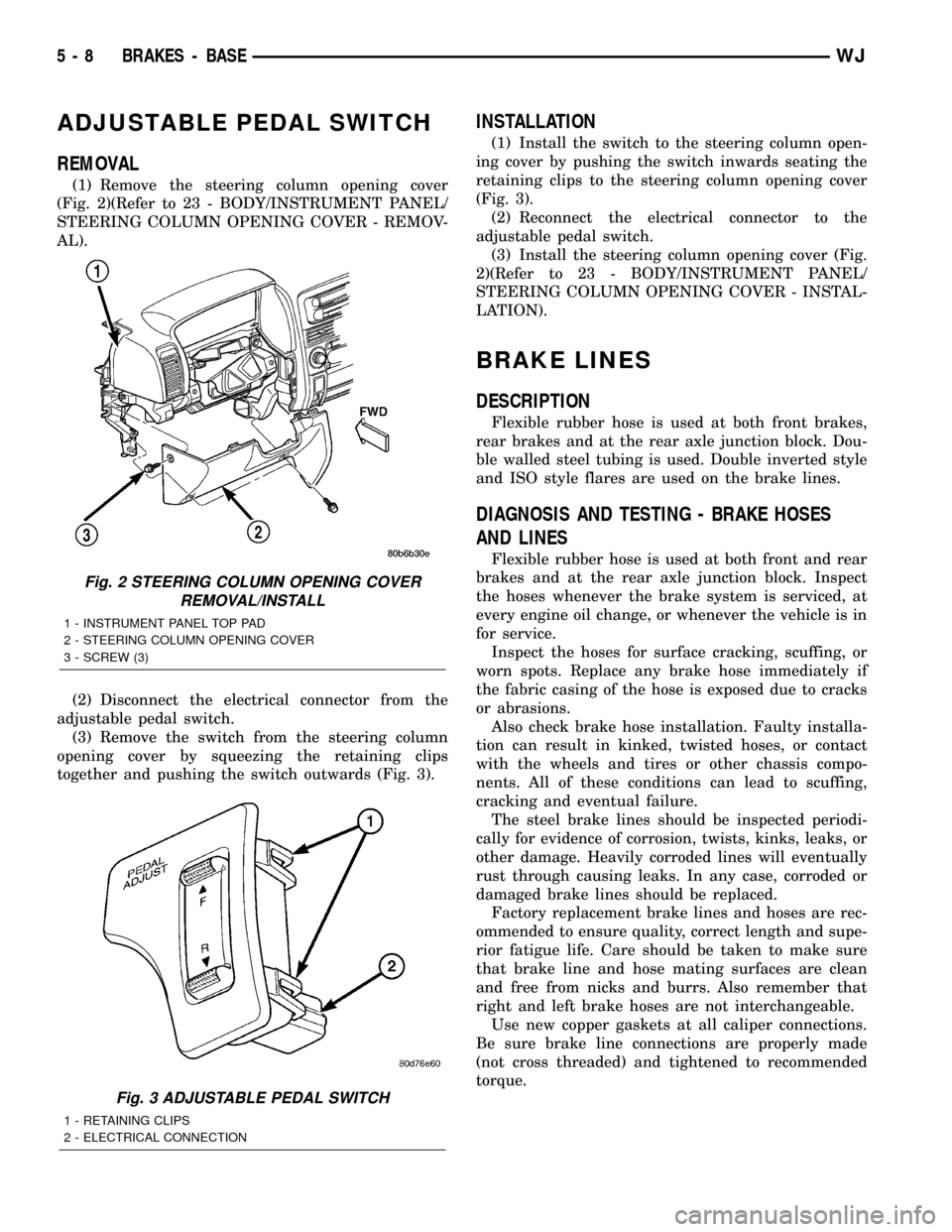

REMOVAL

(1) Remove the steering column opening cover

(Fig. 2)(Refer to 23 - BODY/INSTRUMENT PANEL/

STEERING COLUMN OPENING COVER - REMOV-

AL).

(2) Disconnect the electrical connector from the

adjustable pedal switch.

(3) Remove the switch from the steering column

opening cover by squeezing the retaining clips

together and pushing the switch outwards (Fig. 3).

INSTALLATION

(1) Install the switch to the steering column open-

ing cover by pushing the switch inwards seating the

retaining clips to the steering column opening cover

(Fig. 3).

(2) Reconnect the electrical connector to the

adjustable pedal switch.

(3) Install the steering column opening cover (Fig.

2)(Refer to 23 - BODY/INSTRUMENT PANEL/

STEERING COLUMN OPENING COVER - INSTAL-

LATION).

BRAKE LINES

DESCRIPTION

Flexible rubber hose is used at both front brakes,

rear brakes and at the rear axle junction block. Dou-

ble walled steel tubing is used. Double inverted style

and ISO style flares are used on the brake lines.

DIAGNOSIS AND TESTING - BRAKE HOSES

AND LINES

Flexible rubber hose is used at both front and rear

brakes and at the rear axle junction block. Inspect

the hoses whenever the brake system is serviced, at

every engine oil change, or whenever the vehicle is in

for service.

Inspect the hoses for surface cracking, scuffing, or

worn spots. Replace any brake hose immediately if

the fabric casing of the hose is exposed due to cracks

or abrasions.

Also check brake hose installation. Faulty installa-

tion can result in kinked, twisted hoses, or contact

with the wheels and tires or other chassis compo-

nents. All of these conditions can lead to scuffing,

cracking and eventual failure.

The steel brake lines should be inspected periodi-

cally for evidence of corrosion, twists, kinks, leaks, or

other damage. Heavily corroded lines will eventually

rust through causing leaks. In any case, corroded or

damaged brake lines should be replaced.

Factory replacement brake lines and hoses are rec-

ommended to ensure quality, correct length and supe-

rior fatigue life. Care should be taken to make sure

that brake line and hose mating surfaces are clean

and free from nicks and burrs. Also remember that

right and left brake hoses are not interchangeable.

Use new copper gaskets at all caliper connections.

Be sure brake line connections are properly made

(not cross threaded) and tightened to recommended

torque.

Fig. 2 STEERING COLUMN OPENING COVER

REMOVAL/INSTALL

1 - INSTRUMENT PANEL TOP PAD

2 - STEERING COLUMN OPENING COVER

3 - SCREW (3)

Fig. 3 ADJUSTABLE PEDAL SWITCH

1 - RETAINING CLIPS

2 - ELECTRICAL CONNECTION

5 - 8 BRAKES - BASEWJ

Page 198 of 2199

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder with

reservoir, caliper seals, HCU and all hydraulic fluid

hoses.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

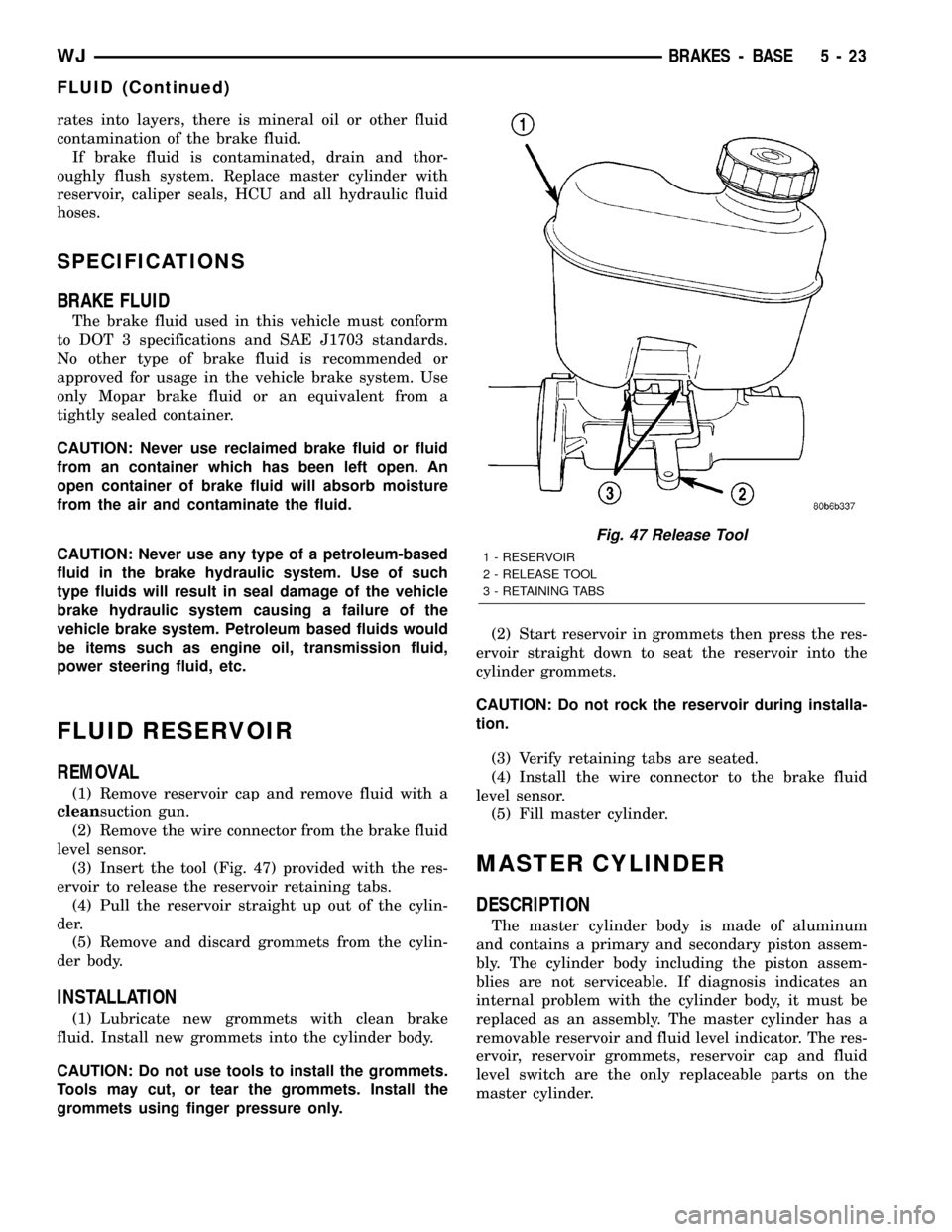

FLUID RESERVOIR

REMOVAL

(1) Remove reservoir cap and remove fluid with a

cleansuction gun.

(2) Remove the wire connector from the brake fluid

level sensor.

(3) Insert the tool (Fig. 47) provided with the res-

ervoir to release the reservoir retaining tabs.

(4) Pull the reservoir straight up out of the cylin-

der.

(5) Remove and discard grommets from the cylin-

der body.

INSTALLATION

(1) Lubricate new grommets with clean brake

fluid. Install new grommets into the cylinder body.

CAUTION: Do not use tools to install the grommets.

Tools may cut, or tear the grommets. Install the

grommets using finger pressure only.(2) Start reservoir in grommets then press the res-

ervoir straight down to seat the reservoir into the

cylinder grommets.

CAUTION: Do not rock the reservoir during installa-

tion.

(3) Verify retaining tabs are seated.

(4) Install the wire connector to the brake fluid

level sensor.

(5) Fill master cylinder.

MASTER CYLINDER

DESCRIPTION

The master cylinder body is made of aluminum

and contains a primary and secondary piston assem-

bly. The cylinder body including the piston assem-

blies are not serviceable. If diagnosis indicates an

internal problem with the cylinder body, it must be

replaced as an assembly. The master cylinder has a

removable reservoir and fluid level indicator. The res-

ervoir, reservoir grommets, reservoir cap and fluid

level switch are the only replaceable parts on the

master cylinder.

Fig. 47 Release Tool

1 - RESERVOIR

2 - RELEASE TOOL

3 - RETAINING TABS

WJBRAKES - BASE 5 - 23

FLUID (Continued)

Page 224 of 2199

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM 4.7L

ENGINE..............................1

DESCRIPTION - COOLING SYSTEM

ROUTING 4.7L ENGINE..................1

DESCRIPTIONÐCOOLING SYSTEM 4.0L

ENGINE..............................1

DESCRIPTIONÐCOOLING SYSTEM

ROUTING 4.0L ENGINE..................1

DESCRIPTIONÐHOSE CLAMPS...........1

OPERATION

OPERATIONÐCOOLING SYSTEM.........2

OPERATIONÐHOSE CLAMPS............2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)...................3

DIAGNOSIS AND TESTINGÐPRELIMINARY

CHECKS.............................3

DIAGNOSIS AND TESTING - COOLING

SYSTEM DIAGNOSIS CHART.............5

DIAGNOSIS AND TESTING - COOLING

SYSTEM LEAKS......................10DIAGNOSIS AND TESTING - COOLING

SYSTEM DEAERATION.................12

STANDARD PROCEDURE

STANDARD PROCEDUREÐDRAINING

COOLING SYSTEM 4.7L ENGINE.........12

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 4.7L ENGINE.........12

STANDARD PROCEDURE - DRAINING

COOLING SYSTEM - 4.0L ENGINE........13

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM - 4.0L ENGINE........13

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT.................13

STANDARD PROCEDURE - COOLING

SYSTEM - REVERSE FLUSHING..........14

SPECIFICATIONS

TORQUE............................14

SPECIAL TOOLS

COOLING...........................15

ACCESSORY DRIVE......................16

ENGINE...............................24

TRANSMISSION.........................55

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM 4.7L

ENGINE

The cooling system consists of the following items:

²Hydraulic cooling fan and fan drive assembly

²Radiator

²Power steering oil cooler

²Radiator pressure cap

²Thermostat

²Coolant reserve/overflow system

²Transmission oil cooler (if equipped with an

automatic transmission)

²Coolant

²Water pump

²Hoses and hose clamps

DESCRIPTION - COOLING SYSTEM ROUTING

4.7L ENGINE

For cooling system routing refer to (Fig. 1).

DESCRIPTIONÐCOOLING SYSTEM 4.0L

ENGINE

The cooling system consists of:

²A radiator

²Mechanical Cooling Fan

²Thermal viscous fan drive-Low disengaged

²Fan shroud (Fig. 2)

²Radiator pressure cap

²Thermostat

²Coolant reserve/overflow system

²Transmission oil cooler (if equipped with an

automatic transmission)

²Coolant

²Water pump

²Hoses and hose clamps

²Accessory drive belt

DESCRIPTIONÐCOOLING SYSTEM ROUTING

4.0L ENGINE

For cooling system routing refer to (Fig. 3).

DESCRIPTIONÐHOSE CLAMPS

The cooling system utilizes both worm drive and

spring type hose clamps. If a spring type clamp

WJCOOLING 7 - 1

Page 229 of 2199

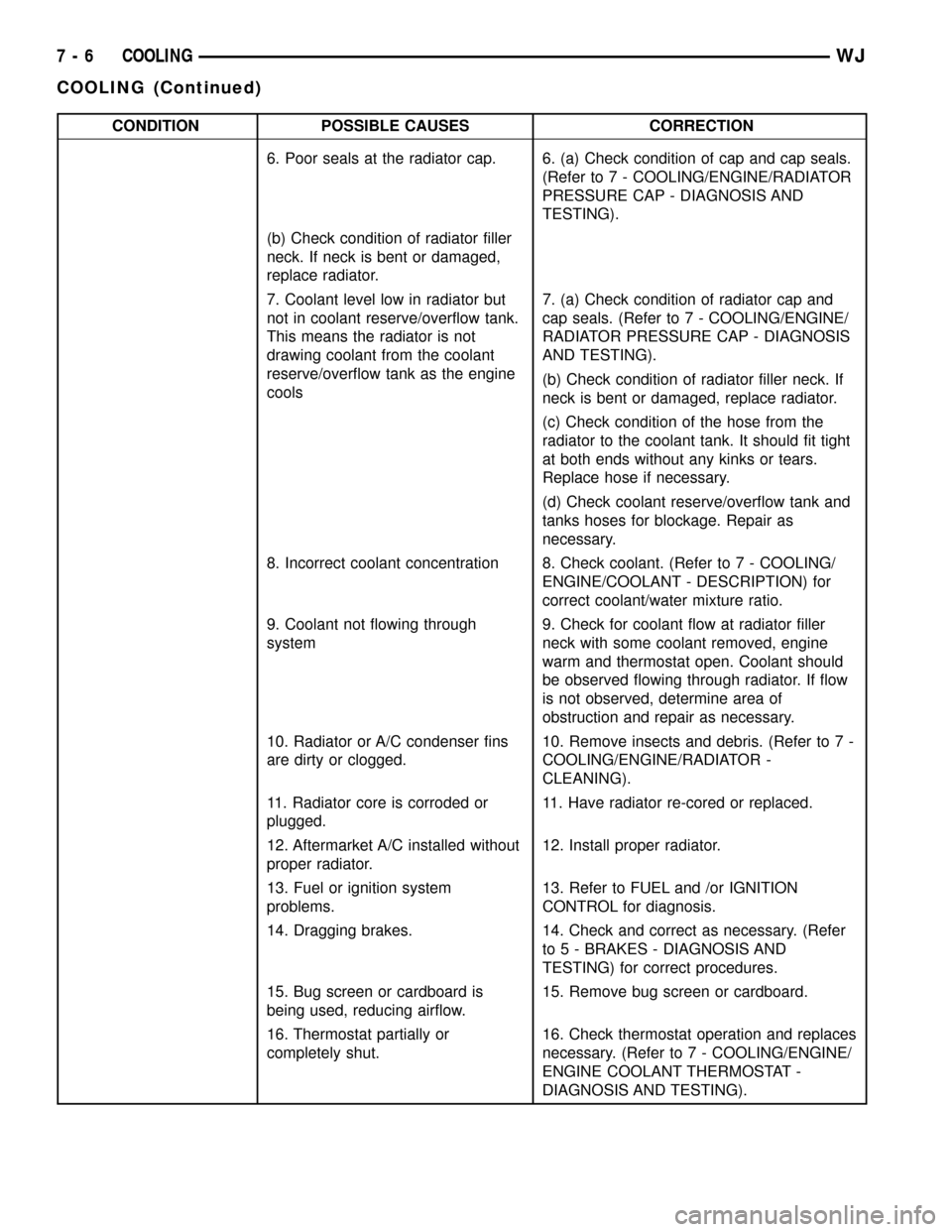

CONDITION POSSIBLE CAUSES CORRECTION

6. Poor seals at the radiator cap. 6. (a) Check condition of cap and cap seals.

(Refer to 7 - COOLING/ENGINE/RADIATOR

PRESSURE CAP - DIAGNOSIS AND

TESTING).

(b) Check condition of radiator filler

neck. If neck is bent or damaged,

replace radiator.

7. Coolant level low in radiator but

not in coolant reserve/overflow tank.

This means the radiator is not

drawing coolant from the coolant

reserve/overflow tank as the engine

cools7. (a) Check condition of radiator cap and

cap seals. (Refer to 7 - COOLING/ENGINE/

RADIATOR PRESSURE CAP - DIAGNOSIS

AND TESTING).

(b) Check condition of radiator filler neck. If

neck is bent or damaged, replace radiator.

(c) Check condition of the hose from the

radiator to the coolant tank. It should fit tight

at both ends without any kinks or tears.

Replace hose if necessary.

(d) Check coolant reserve/overflow tank and

tanks hoses for blockage. Repair as

necessary.

8. Incorrect coolant concentration 8. Check coolant. (Refer to 7 - COOLING/

ENGINE/COOLANT - DESCRIPTION) for

correct coolant/water mixture ratio.

9. Coolant not flowing through

system9. Check for coolant flow at radiator filler

neck with some coolant removed, engine

warm and thermostat open. Coolant should

be observed flowing through radiator. If flow

is not observed, determine area of

obstruction and repair as necessary.

10. Radiator or A/C condenser fins

are dirty or clogged.10. Remove insects and debris. (Refer to 7 -

COOLING/ENGINE/RADIATOR -

CLEANING).

11. Radiator core is corroded or

plugged.11. Have radiator re-cored or replaced.

12. Aftermarket A/C installed without

proper radiator.12. Install proper radiator.

13. Fuel or ignition system

problems.13. Refer to FUEL and /or IGNITION

CONTROL for diagnosis.

14. Dragging brakes. 14. Check and correct as necessary. (Refer

to 5 - BRAKES - DIAGNOSIS AND

TESTING) for correct procedures.

15. Bug screen or cardboard is

being used, reducing airflow.15. Remove bug screen or cardboard.

16. Thermostat partially or

completely shut.16. Check thermostat operation and replaces

necessary. (Refer to 7 - COOLING/ENGINE/

ENGINE COOLANT THERMOSTAT -

DIAGNOSIS AND TESTING).

7 - 6 COOLINGWJ

COOLING (Continued)

Page 231 of 2199

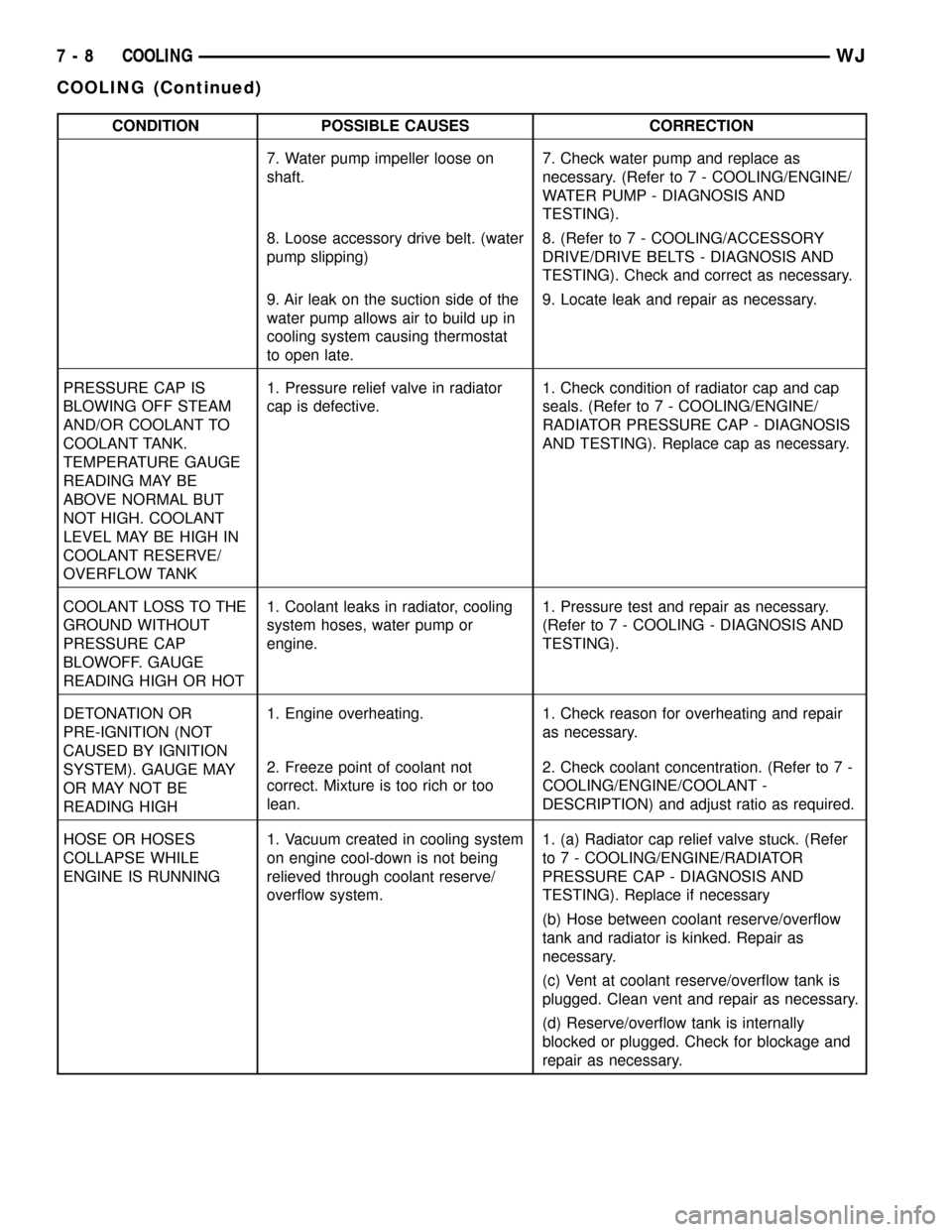

CONDITION POSSIBLE CAUSES CORRECTION

7. Water pump impeller loose on

shaft.7. Check water pump and replace as

necessary. (Refer to 7 - COOLING/ENGINE/

WATER PUMP - DIAGNOSIS AND

TESTING).

8. Loose accessory drive belt. (water

pump slipping)8. (Refer to 7 - COOLING/ACCESSORY

DRIVE/DRIVE BELTS - DIAGNOSIS AND

TESTING). Check and correct as necessary.

9. Air leak on the suction side of the

water pump allows air to build up in

cooling system causing thermostat

to open late.9. Locate leak and repair as necessary.

PRESSURE CAP IS

BLOWING OFF STEAM

AND/OR COOLANT TO

COOLANT TANK.

TEMPERATURE GAUGE

READING MAY BE

ABOVE NORMAL BUT

NOT HIGH. COOLANT

LEVEL MAY BE HIGH IN

COOLANT RESERVE/

OVERFLOW TANK1. Pressure relief valve in radiator

cap is defective.1. Check condition of radiator cap and cap

seals. (Refer to 7 - COOLING/ENGINE/

RADIATOR PRESSURE CAP - DIAGNOSIS

AND TESTING). Replace cap as necessary.

COOLANT LOSS TO THE

GROUND WITHOUT

PRESSURE CAP

BLOWOFF. GAUGE

READING HIGH OR HOT1. Coolant leaks in radiator, cooling

system hoses, water pump or

engine.1. Pressure test and repair as necessary.

(Refer to 7 - COOLING - DIAGNOSIS AND

TESTING).

DETONATION OR

PRE-IGNITION (NOT

CAUSED BY IGNITION

SYSTEM). GAUGE MAY

OR MAY NOT BE

READING HIGH1. Engine overheating. 1. Check reason for overheating and repair

as necessary.

2. Freeze point of coolant not

correct. Mixture is too rich or too

lean.2. Check coolant concentration. (Refer to 7 -

COOLING/ENGINE/COOLANT -

DESCRIPTION) and adjust ratio as required.

HOSE OR HOSES

COLLAPSE WHILE

ENGINE IS RUNNING1. Vacuum created in cooling system

on engine cool-down is not being

relieved through coolant reserve/

overflow system.1. (a) Radiator cap relief valve stuck. (Refer

to 7 - COOLING/ENGINE/RADIATOR

PRESSURE CAP - DIAGNOSIS AND

TESTING). Replace if necessary

(b) Hose between coolant reserve/overflow

tank and radiator is kinked. Repair as

necessary.

(c) Vent at coolant reserve/overflow tank is

plugged. Clean vent and repair as necessary.

(d) Reserve/overflow tank is internally

blocked or plugged. Check for blockage and

repair as necessary.

7 - 8 COOLINGWJ

COOLING (Continued)

Page 232 of 2199

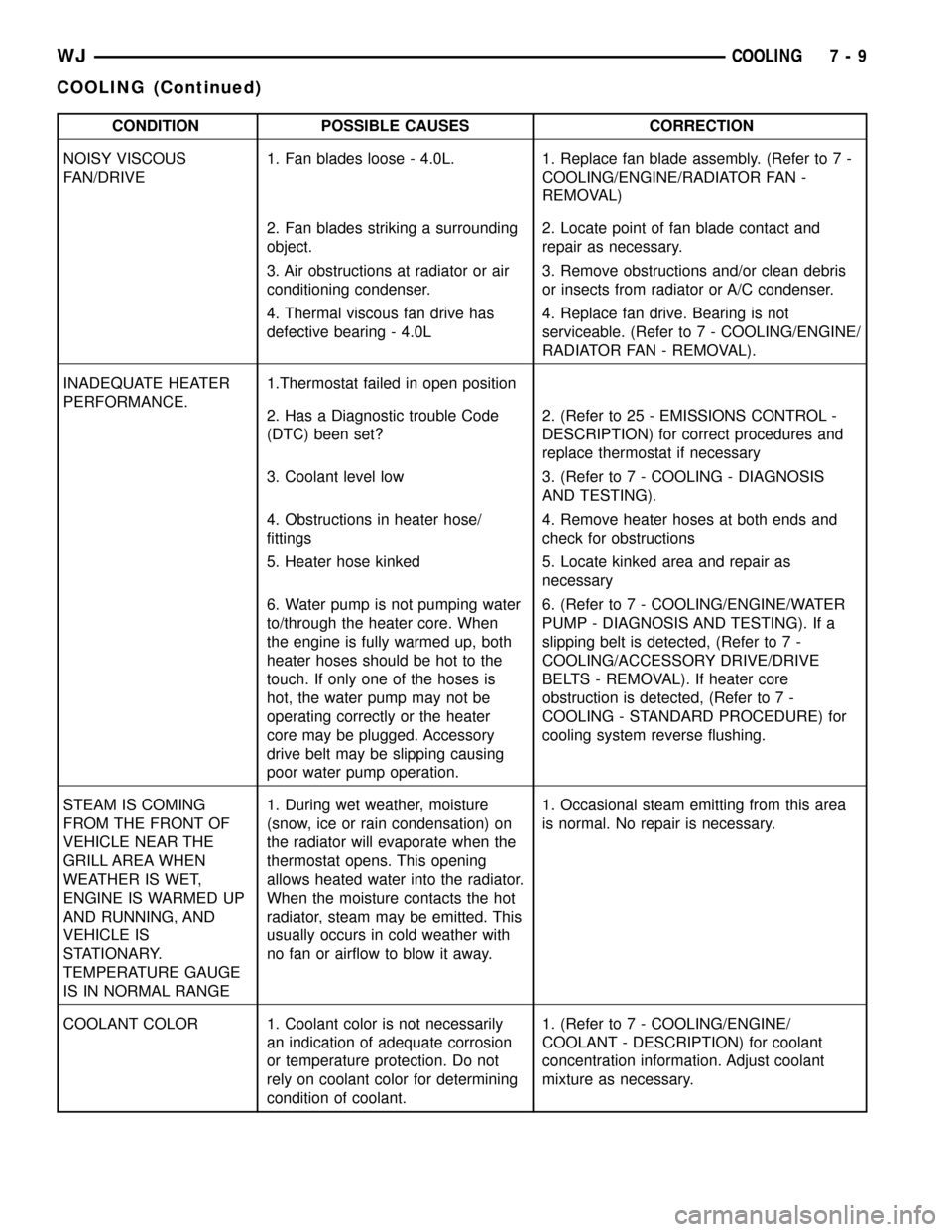

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VISCOUS

FAN/DRIVE1. Fan blades loose - 4.0L. 1. Replace fan blade assembly. (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN -

REMOVAL)

2. Fan blades striking a surrounding

object.2. Locate point of fan blade contact and

repair as necessary.

3. Air obstructions at radiator or air

conditioning condenser.3. Remove obstructions and/or clean debris

or insects from radiator or A/C condenser.

4. Thermal viscous fan drive has

defective bearing - 4.0L4. Replace fan drive. Bearing is not

serviceable. (Refer to 7 - COOLING/ENGINE/

RADIATOR FAN - REMOVAL).

INADEQUATE HEATER

PERFORMANCE.1.Thermostat failed in open position

2. Has a Diagnostic trouble Code

(DTC) been set?2. (Refer to 25 - EMISSIONS CONTROL -

DESCRIPTION) for correct procedures and

replace thermostat if necessary

3. Coolant level low 3. (Refer to 7 - COOLING - DIAGNOSIS

AND TESTING).

4. Obstructions in heater hose/

fittings4. Remove heater hoses at both ends and

check for obstructions

5. Heater hose kinked 5. Locate kinked area and repair as

necessary

6. Water pump is not pumping water

to/through the heater core. When

the engine is fully warmed up, both

heater hoses should be hot to the

touch. If only one of the hoses is

hot, the water pump may not be

operating correctly or the heater

core may be plugged. Accessory

drive belt may be slipping causing

poor water pump operation.6. (Refer to 7 - COOLING/ENGINE/WATER

PUMP - DIAGNOSIS AND TESTING). If a

slipping belt is detected, (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE

BELTS - REMOVAL). If heater core

obstruction is detected, (Refer to 7 -

COOLING - STANDARD PROCEDURE) for

cooling system reverse flushing.

STEAM IS COMING

FROM THE FRONT OF

VEHICLE NEAR THE

GRILL AREA WHEN

WEATHER IS WET,

ENGINE IS WARMED UP

AND RUNNING, AND

VEHICLE IS

STATIONARY.

TEMPERATURE GAUGE

IS IN NORMAL RANGE1. During wet weather, moisture

(snow, ice or rain condensation) on

the radiator will evaporate when the

thermostat opens. This opening

allows heated water into the radiator.

When the moisture contacts the hot

radiator, steam may be emitted. This

usually occurs in cold weather with

no fan or airflow to blow it away.1. Occasional steam emitting from this area

is normal. No repair is necessary.

COOLANT COLOR 1. Coolant color is not necessarily

an indication of adequate corrosion

or temperature protection. Do not

rely on coolant color for determining

condition of coolant.1. (Refer to 7 - COOLING/ENGINE/

COOLANT - DESCRIPTION) for coolant

concentration information. Adjust coolant

mixture as necessary.

WJCOOLING 7 - 9

COOLING (Continued)

Page 234 of 2199

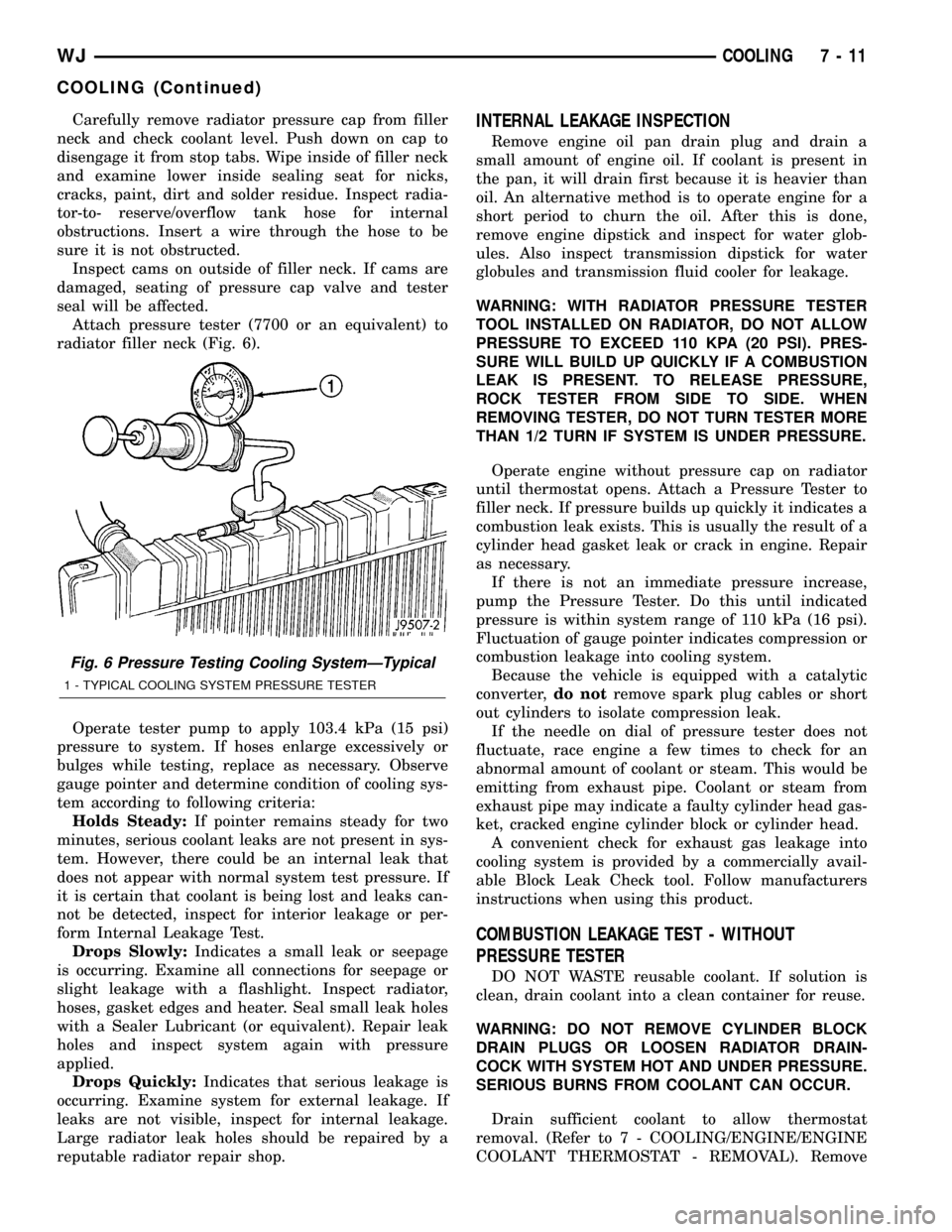

Carefully remove radiator pressure cap from filler

neck and check coolant level. Push down on cap to

disengage it from stop tabs. Wipe inside of filler neck

and examine lower inside sealing seat for nicks,

cracks, paint, dirt and solder residue. Inspect radia-

tor-to- reserve/overflow tank hose for internal

obstructions. Insert a wire through the hose to be

sure it is not obstructed.

Inspect cams on outside of filler neck. If cams are

damaged, seating of pressure cap valve and tester

seal will be affected.

Attach pressure tester (7700 or an equivalent) to

radiator filler neck (Fig. 6).

Operate tester pump to apply 103.4 kPa (15 psi)

pressure to system. If hoses enlarge excessively or

bulges while testing, replace as necessary. Observe

gauge pointer and determine condition of cooling sys-

tem according to following criteria:

Holds Steady:If pointer remains steady for two

minutes, serious coolant leaks are not present in sys-

tem. However, there could be an internal leak that

does not appear with normal system test pressure. If

it is certain that coolant is being lost and leaks can-

not be detected, inspect for interior leakage or per-

form Internal Leakage Test.

Drops Slowly:Indicates a small leak or seepage

is occurring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect radiator,

hoses, gasket edges and heater. Seal small leak holes

with a Sealer Lubricant (or equivalent). Repair leak

holes and inspect system again with pressure

applied.

Drops Quickly:Indicates that serious leakage is

occurring. Examine system for external leakage. If

leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.INTERNAL LEAKAGE INSPECTION

Remove engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove engine dipstick and inspect for water glob-

ules. Also inspect transmission dipstick for water

globules and transmission fluid cooler for leakage.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 110 KPA (20 PSI). PRES-

SURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate engine without pressure cap on radiator

until thermostat opens. Attach a Pressure Tester to

filler neck. If pressure builds up quickly it indicates a

combustion leak exists. This is usually the result of a

cylinder head gasket leak or crack in engine. Repair

as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of gauge pointer indicates compression or

combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter,do notremove spark plug cables or short

out cylinders to isolate compression leak.

If the needle on dial of pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT

PRESSURE TESTER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Drain sufficient coolant to allow thermostat

removal. (Refer to 7 - COOLING/ENGINE/ENGINE

COOLANT THERMOSTAT - REMOVAL). Remove

Fig. 6 Pressure Testing Cooling SystemÐTypical

1 - TYPICAL COOLING SYSTEM PRESSURE TESTER

WJCOOLING 7 - 11

COOLING (Continued)

Page 237 of 2199

corrosion inhibitors called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% distilled water to obtain to obtain a

freeze point of -37ÉC (-35ÉF). If it loses color or

becomes contaminated, drain, flush, and replace with

fresh properly mixed coolant solution.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

STANDARD PROCEDURE - COOLING SYSTEM -

REVERSE FLUSHING

CAUTION: The cooling system normally operates at

97-to-124 kPa (14-to -18 psi) pressure. Exceeding

this pressure may damage the radiator or hoses.

Reverse flushing of the cooling system is the forc-

ing of water through the cooling system. This is done

using air pressure in the opposite direction of normal

coolant flow. It is usually only necessary with very

dirty systems with evidence of partial plugging.

CHEMICAL CLEANING

If visual inspection indicates the formation of

sludge or scaly deposits, use a radiator cleaner

(Mopar Radiator Kleen or equivalent) before flushing.

This will soften scale and other deposits and aid the

flushing operation.

CAUTION: Be sure instructions on the container are

followed.

REVERSE FLUSHING RADIATOR

Disconnect the radiator hoses from the radiator fit-

tings. Attach a section of radiator hose to the radia-

tor bottom outlet fitting and insert the flushing gun.

Connect a water supply hose and air supply hose to

the flushing gun.

CAUTION: The cooling system normally operates at

97-to-124 kPa (14- to-18 psi) pressure. Exceeding

this pressure may damage the radiator or hoses.

Allow the radiator to fill with water. When radiator

is filled, apply air in short blasts allowing radiator to

refill between blasts. Continue this reverse flushing

until clean water flows out through rear of radiator

cooling tube passages. For more information, refer to

operating instructions supplied with flushing equip-

ment. Have radiator cleaned more extensively by a

radiator repair shop.

REVERSE FLUSHING ENGINE

Drain the cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE). Remove the thermostat

housing and thermostat. Install the thermostat hous-

ing. Disconnect the radiator upper hose from the

radiator and attach the flushing gun to the hose. Dis-

connect the radiator lower hose from the water

pump. Attach a lead away hose to the water pump

inlet fitting.

CAUTION: Be sure that the heater control valve is

closed (heat off). This is done to prevent coolant

flow with scale and other deposits from entering

the heater core.

Connect the water supply hose and air supply hose

to the flushing gun. Allow the engine to fill with

water. When the engine is filled, apply air in short

blasts, allowing the system to fill between air blasts.

Continue until clean water flows through the lead

away hose. For more information, refer to operating

instructions supplied with flushing equipment.

Remove the lead away hose, flushing gun, water

supply hose and air supply hose. Remove the thermo-

stat housing (Refer to 7 - COOLING/ENGINE/EN-

GINE COOLANT THERMOSTAT - REMOVAL).

Install the thermostat and housing with a replace-

ment gasket (Refer to 7 - COOLING/ENGINE/EN-

GINE COOLANT THERMOSTAT -

INSTALLATION). Connect the radiator hoses. Refill

the cooling system with the correct antifreeze/water

mixture (Refer to 7 - COOLING - STANDARD PRO-

CEDURE).

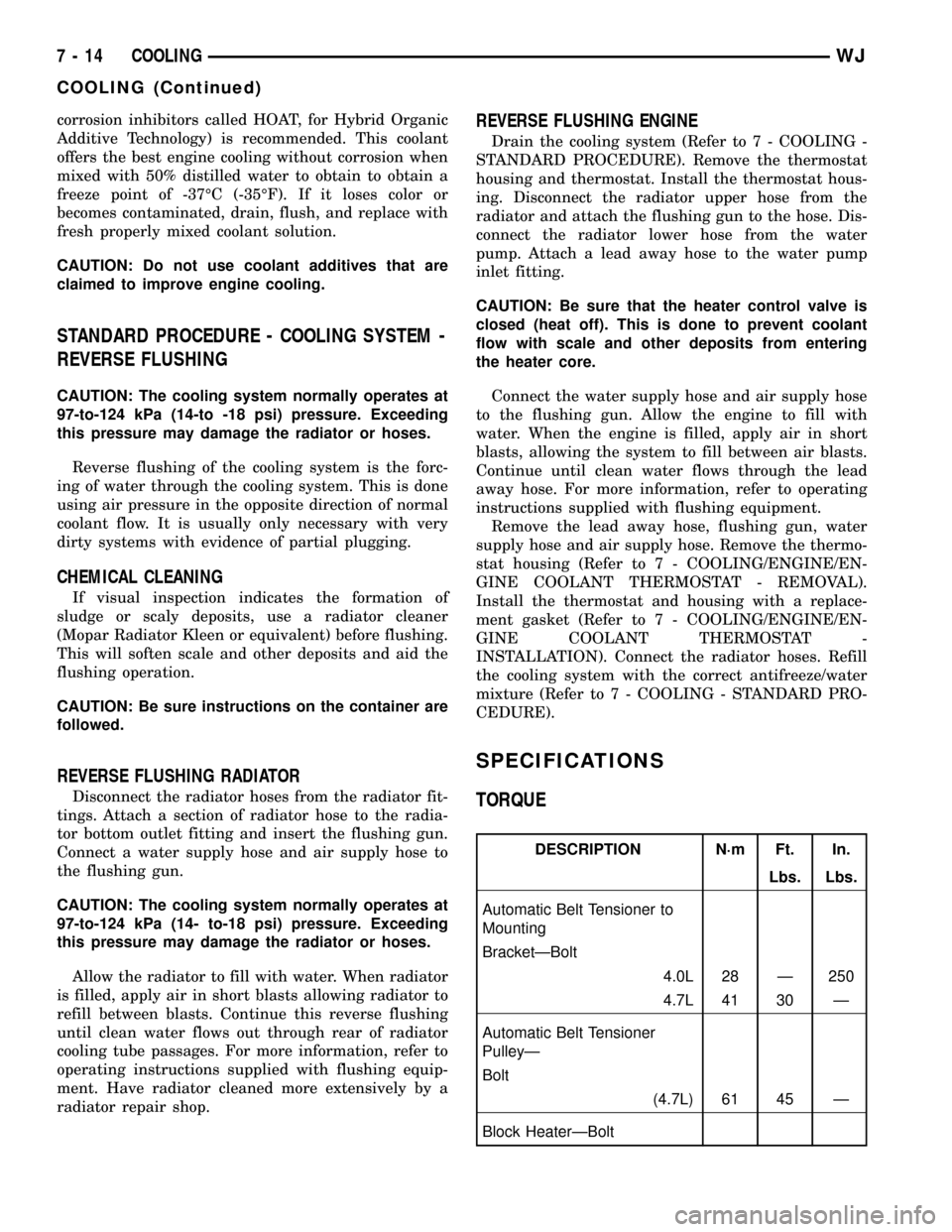

SPECIFICATIONS

TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Automatic Belt Tensioner to

Mounting

BracketÐBolt

4.0L 28 Ð 250

4.7L 41 30 Ð

Automatic Belt Tensioner

PulleyÐ

Bolt

(4.7L) 61 45 Ð

Block HeaterÐBolt

7 - 14 COOLINGWJ

COOLING (Continued)