Steering column JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 20 of 2199

²Do not allow towing equipment to contact the

disabled vehicle's fuel tank.

²Do not allow anyone under the disabled vehicle

while it is lifted by the towing device.

²Do not allow passengers to ride in a vehicle

being towed.

²Always observe state and local laws regarding

towing regulations.

²Do not tow a vehicle in a manner that could

jeopardize the safety of the operator, pedestrians or

other motorists.

²Do not attach tow chains, T-hooks, or J-hooks to

a bumper, steering linkage, drive shafts or a non-re-

inforced frame hole.

²Do not tow a heavily loaded vehicle. Use a flat-

bed device to transport a loaded vehicle.

TWO-WHEEL-DRIVE VEHICLE TOWING

DaimlerChrysler Corporation recommends that a

vehicle be towed with the rear end lifted, whenever

possible.

WARNING: WHEN TOWING A DISABLED VEHICLE

AND THE DRIVE WHEELS ARE SECURED IN A

WHEEL LIFT OR TOW DOLLIES, ENSURE THE

TRANSMISSION IS IN THE PARK POSITION (AUTO-

MATIC TRANSMISSION) OR A FORWARD DRIVE

GEAR (MANUAL TRANSMISSION).

WARNING: ENSURE VEHICLE IS ON A LEVEL SUR-

FACE OR THE WHEELS ARE BLOCKED TO PRE-

VENT VEHICLE FROM ROLLING.

TWO WHEEL DRIVE TOWING-REAR END LIFTED

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

2WD vehicles can be towed with the front wheels

on the surface for extended distances at speeds not

exceeding 48 km/h (30 mph).

(1) Attach wheel lift device to rear wheels.

(2) Place the transmission in neutral.

(3) Raise vehicle to towing position.

(4) Attach safety chains. Route chains so not to

interfere with tail pipe when vehicle is lifted.

(5) Turn the ignition switch to the OFF position to

unlock the steering wheel.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(6) Secure steering wheel in straight ahead posi-

tion with a clamp device designed for towing.

(7) Place transmission in park.

TWO WHEEL DRIVE TOWING-FRONT END LIFTED

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

(1) Attach wheel lift device to rear wheels.

(2) Place the transmission in neutral.

(3) Raise the rear of the vehicle off the ground and

install tow dollies under rear wheels.

(4) Attach wheel lift device to front wheels and

raise vehicle to towing position.

(5) Attach the safety chains.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

(7) Secure steering wheel in straight ahead posi-

tion with a clamp device designed for towing.

(8) Place transmission in park.

FOUR-WHEEL-DRIVE VEHICLE TOWING

DaimlerChrysler Corporation recommends that a

4WD vehicle be transported on a flat-bed device. A

Wheel-lift device can be used providedthe trailing

wheels are off the ground and positioned in

tow dollies.

WARNING: WHEN TOWING A DISABLED VEHICLE

AND THE DRIVE WHEELS ARE SECURED IN A

WHEEL LIFT OR TOW DOLLIES, ENSURE THE

TRANSMISSION IS IN THE PARK POSITION.

CAUTION: Many vehicles are equipped with air

dams, spoilers, and/or ground effect panels. To

avoid component damage, a wheel-lift towing vehi-

cle or a flat-bed hauling vehicle is recommended.

FOUR WHEEL DRIVE TOWINGÐREAR END LIFTED

WARNING: ENSURE VEHICLE IS ON A LEVEL SUR-

FACE OR THE WHEELS ARE BLOCKED TO PRE-

VENT VEHICLE FROM ROLLING.

(1) Attach wheel lift device to front wheels.

(2) Place the transmission in neutral.

(3) Raise the front of the vehicle off the ground

and install tow dollies under front wheels.

(4) Attach wheel lift device to rear wheels and

raise vehicle to towing position.

(5) Attach safety chains. Route chains so not to

interfere with tail pipe when vehicle is lifted.

WJLUBRICATION & MAINTENANCE 0 - 9

TOWING (Continued)

Page 21 of 2199

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(7) Secure steering wheel in straight ahead posi-

tion with a clamp device designed for towing.

(8) Place transmission in park.

FOUR WHEEL DRIVE TOWINGÐFRONT END

LIFTED

WARNING: ENSURE VEHICLE IS ON A LEVEL SUR-

FACE OR THE WHEELS ARE BLOCKED TO PRE-

VENT VEHICLE FROM ROLLING.

(1) Attach wheel lift device to rear wheels.(2) Place the transmission in neutral.

(3) Raise the rear of the vehicle off the ground and

install tow dollies under rear wheels.

(4) Attach wheel lift device to front wheels and

raise vehicle to towing position.

(5) Attach the safety chains.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

(7) Secure steering wheel in straight ahead posi-

tion with a clamp device designed for towing.

(8) Place transmission in park.

0 - 10 LUBRICATION & MAINTENANCEWJ

TOWING (Continued)

Page 22 of 2199

SUSPENSION

TABLE OF CONTENTS

page page

SUSPENSION

DIAGNOSIS AND TESTING - SUSPENSION

AND STEERING SYSTEM................1WHEEL ALIGNMENT......................3

FRONT.................................6

REAR.................................17

SUSPENSION

DIAGNOSIS AND TESTING - SUSPENSION AND

STEERING SYSTEM

CONDITION POSSIBLE CAUSES CORRECTION

FRONT END NOISE 1. Loose or worn wheel bearings. 1. Adjust or replace wheel bearings.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

EXCESSIVE PLAY IN

STEERING1. Loose or worn wheel bearings. 1. Adjust or replace wheel bearings.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Loose or worn steering gear. 3. Adjust or replace steering gear.

FRONT WHEELS SHIMMY 1. Loose or worn wheel bearings. 1. Adjust or replace wheel bearings.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Tires worn or out of balance. 3. Replace or balance tires.

4. Alignment. 4. Align vehicle to specifications.

5. Leaking steering dampener. 5. Replace steering dampener.

VEHICLE INSTABILITY 1. Loose or worn wheel bearings. 1. Adjust or replace wheel bearings.

2. Loose or worn steering or

suspension components.2. Tighten or replace components as

necessary.

3. Tire pressure. 3. Adjust tire pressure.

4. Alignment. 4. Align vehicle to specifications.

EXCESSIVE STEERING

EFFORT1. Loose or worn steering gear. 1. Adjust or replace steering gear.

2. Power steering fluid low. 2. Add fluid and repair leak.

3. Column coupler binding. 3. Replace coupler.

4. Tire pressure. 4. Adjust tire pressure.

5. Alignment. 5. Align vehicle to specifications.

WJSUSPENSION 2 - 1

Page 183 of 2199

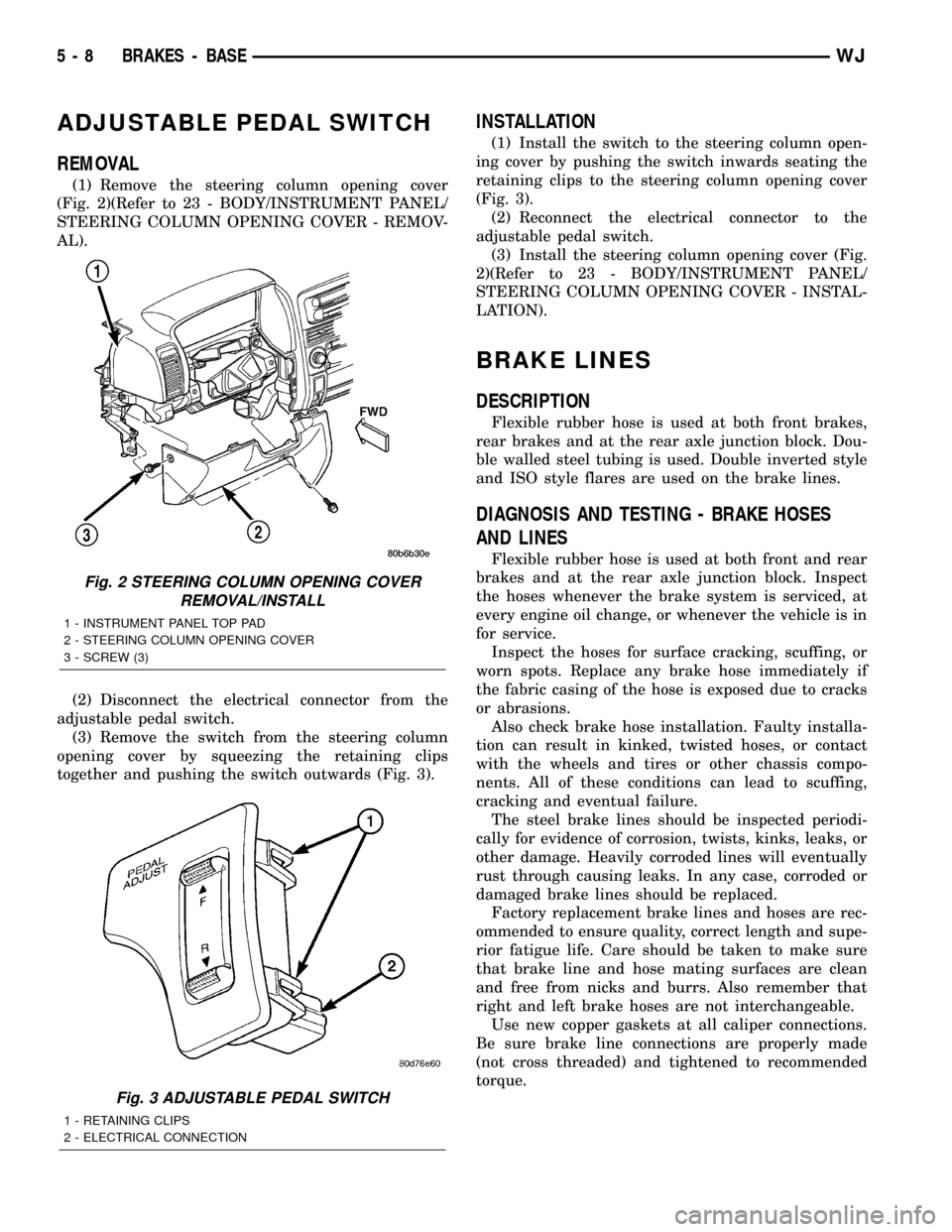

ADJUSTABLE PEDAL SWITCH

REMOVAL

(1) Remove the steering column opening cover

(Fig. 2)(Refer to 23 - BODY/INSTRUMENT PANEL/

STEERING COLUMN OPENING COVER - REMOV-

AL).

(2) Disconnect the electrical connector from the

adjustable pedal switch.

(3) Remove the switch from the steering column

opening cover by squeezing the retaining clips

together and pushing the switch outwards (Fig. 3).

INSTALLATION

(1) Install the switch to the steering column open-

ing cover by pushing the switch inwards seating the

retaining clips to the steering column opening cover

(Fig. 3).

(2) Reconnect the electrical connector to the

adjustable pedal switch.

(3) Install the steering column opening cover (Fig.

2)(Refer to 23 - BODY/INSTRUMENT PANEL/

STEERING COLUMN OPENING COVER - INSTAL-

LATION).

BRAKE LINES

DESCRIPTION

Flexible rubber hose is used at both front brakes,

rear brakes and at the rear axle junction block. Dou-

ble walled steel tubing is used. Double inverted style

and ISO style flares are used on the brake lines.

DIAGNOSIS AND TESTING - BRAKE HOSES

AND LINES

Flexible rubber hose is used at both front and rear

brakes and at the rear axle junction block. Inspect

the hoses whenever the brake system is serviced, at

every engine oil change, or whenever the vehicle is in

for service.

Inspect the hoses for surface cracking, scuffing, or

worn spots. Replace any brake hose immediately if

the fabric casing of the hose is exposed due to cracks

or abrasions.

Also check brake hose installation. Faulty installa-

tion can result in kinked, twisted hoses, or contact

with the wheels and tires or other chassis compo-

nents. All of these conditions can lead to scuffing,

cracking and eventual failure.

The steel brake lines should be inspected periodi-

cally for evidence of corrosion, twists, kinks, leaks, or

other damage. Heavily corroded lines will eventually

rust through causing leaks. In any case, corroded or

damaged brake lines should be replaced.

Factory replacement brake lines and hoses are rec-

ommended to ensure quality, correct length and supe-

rior fatigue life. Care should be taken to make sure

that brake line and hose mating surfaces are clean

and free from nicks and burrs. Also remember that

right and left brake hoses are not interchangeable.

Use new copper gaskets at all caliper connections.

Be sure brake line connections are properly made

(not cross threaded) and tightened to recommended

torque.

Fig. 2 STEERING COLUMN OPENING COVER

REMOVAL/INSTALL

1 - INSTRUMENT PANEL TOP PAD

2 - STEERING COLUMN OPENING COVER

3 - SCREW (3)

Fig. 3 ADJUSTABLE PEDAL SWITCH

1 - RETAINING CLIPS

2 - ELECTRICAL CONNECTION

5 - 8 BRAKES - BASEWJ

Page 202 of 2199

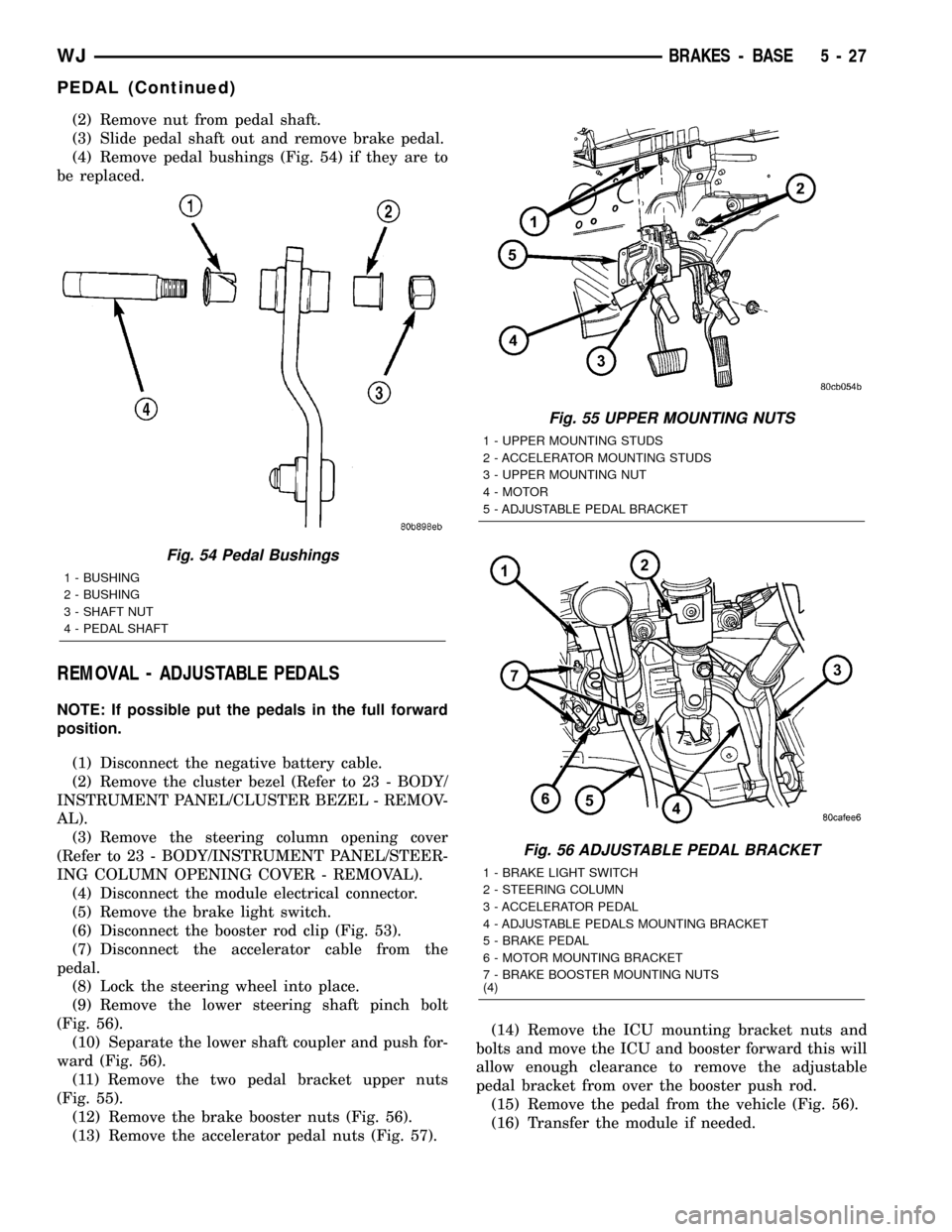

(2) Remove nut from pedal shaft.

(3) Slide pedal shaft out and remove brake pedal.

(4) Remove pedal bushings (Fig. 54) if they are to

be replaced.

REMOVAL - ADJUSTABLE PEDALS

NOTE: If possible put the pedals in the full forward

position.

(1) Disconnect the negative battery cable.

(2) Remove the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(4) Disconnect the module electrical connector.

(5) Remove the brake light switch.

(6) Disconnect the booster rod clip (Fig. 53).

(7) Disconnect the accelerator cable from the

pedal.

(8) Lock the steering wheel into place.

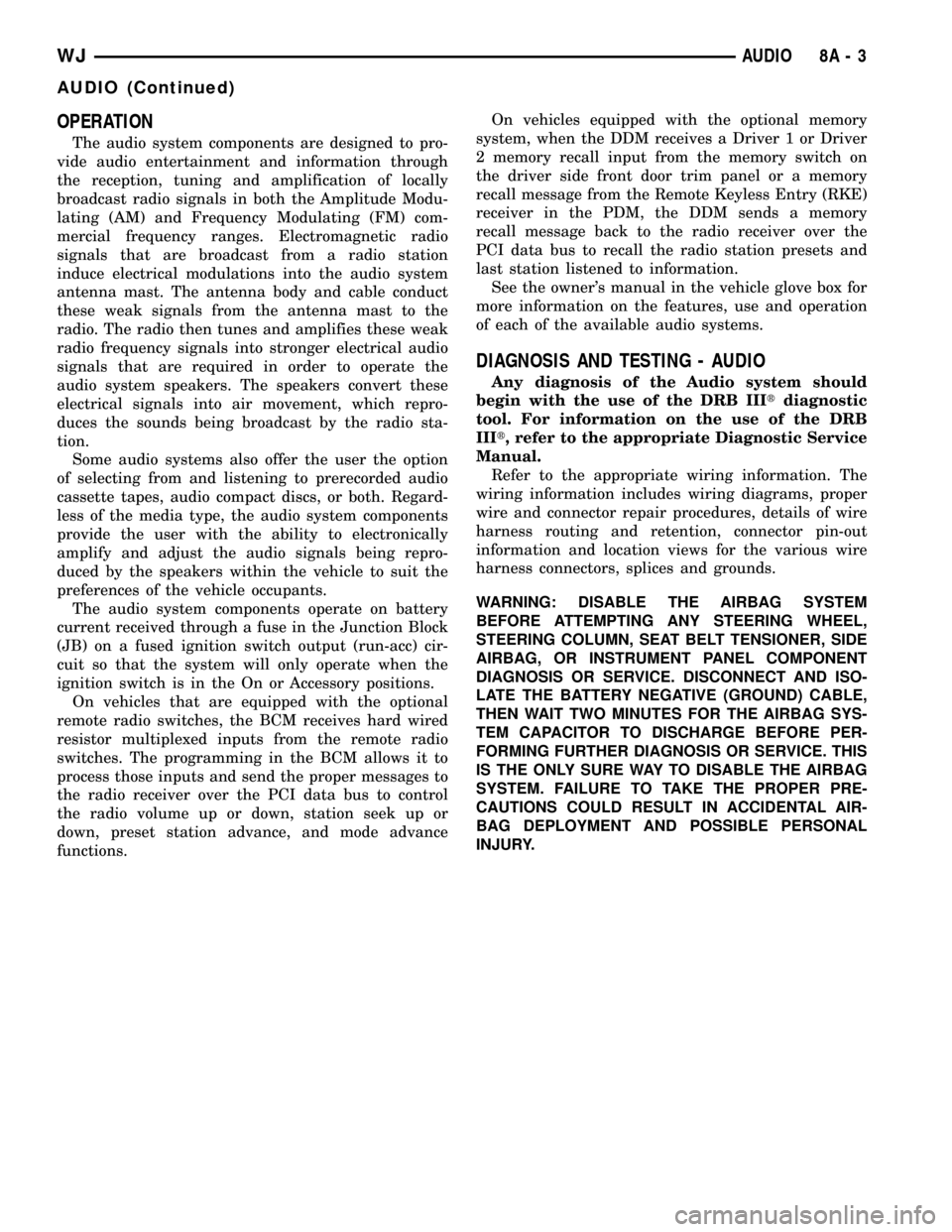

(9) Remove the lower steering shaft pinch bolt

(Fig. 56).

(10) Separate the lower shaft coupler and push for-

ward (Fig. 56).

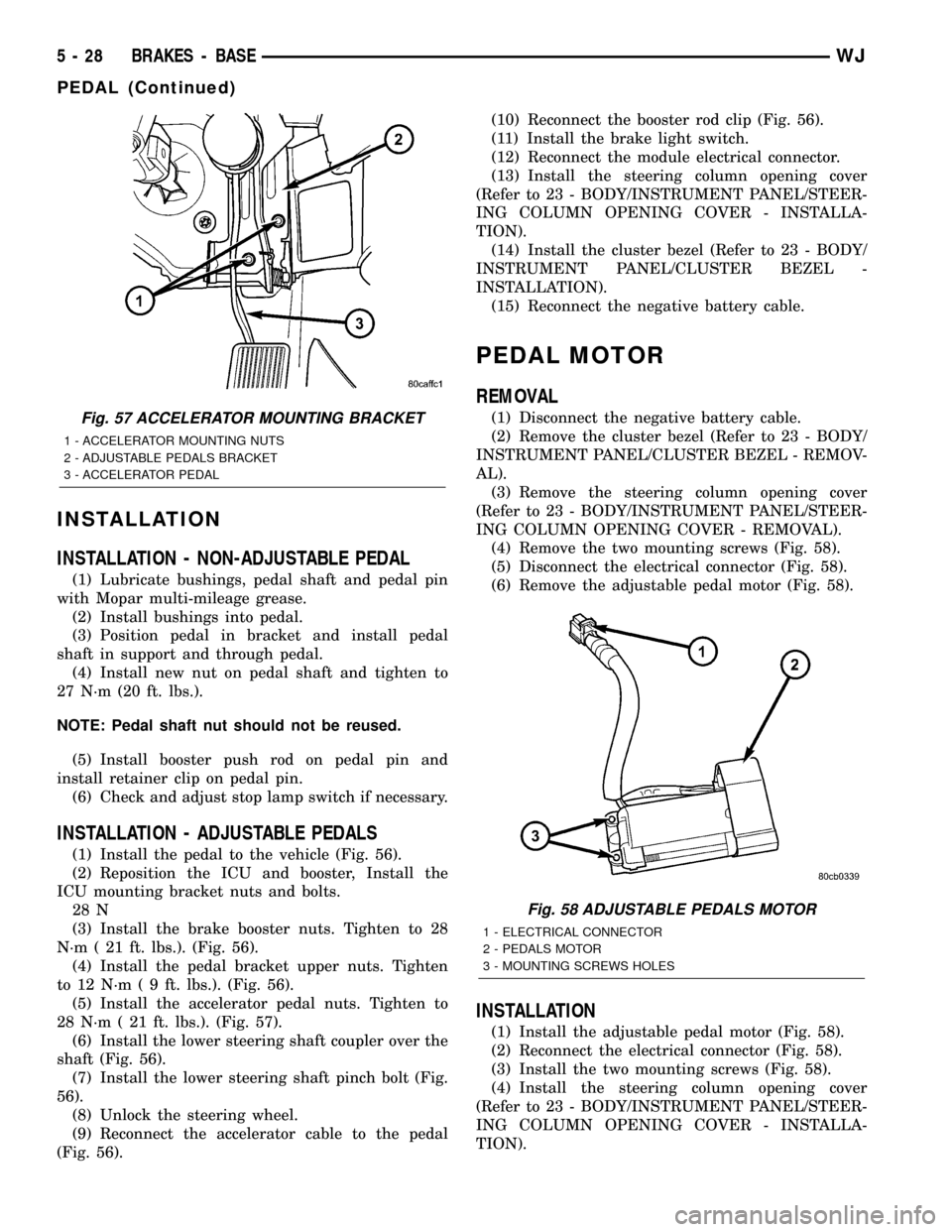

(11) Remove the two pedal bracket upper nuts

(Fig. 55).

(12) Remove the brake booster nuts (Fig. 56).

(13) Remove the accelerator pedal nuts (Fig. 57).(14) Remove the ICU mounting bracket nuts and

bolts and move the ICU and booster forward this will

allow enough clearance to remove the adjustable

pedal bracket from over the booster push rod.

(15) Remove the pedal from the vehicle (Fig. 56).

(16) Transfer the module if needed.

Fig. 54 Pedal Bushings

1 - BUSHING

2 - BUSHING

3 - SHAFT NUT

4 - PEDAL SHAFT

Fig. 55 UPPER MOUNTING NUTS

1 - UPPER MOUNTING STUDS

2 - ACCELERATOR MOUNTING STUDS

3 - UPPER MOUNTING NUT

4 - MOTOR

5 - ADJUSTABLE PEDAL BRACKET

Fig. 56 ADJUSTABLE PEDAL BRACKET

1 - BRAKE LIGHT SWITCH

2 - STEERING COLUMN

3 - ACCELERATOR PEDAL

4 - ADJUSTABLE PEDALS MOUNTING BRACKET

5 - BRAKE PEDAL

6 - MOTOR MOUNTING BRACKET

7 - BRAKE BOOSTER MOUNTING NUTS

(4)

WJBRAKES - BASE 5 - 27

PEDAL (Continued)

Page 203 of 2199

INSTALLATION

INSTALLATION - NON-ADJUSTABLE PEDAL

(1) Lubricate bushings, pedal shaft and pedal pin

with Mopar multi-mileage grease.

(2) Install bushings into pedal.

(3) Position pedal in bracket and install pedal

shaft in support and through pedal.

(4) Install new nut on pedal shaft and tighten to

27 N´m (20 ft. lbs.).

NOTE: Pedal shaft nut should not be reused.

(5) Install booster push rod on pedal pin and

install retainer clip on pedal pin.

(6) Check and adjust stop lamp switch if necessary.

INSTALLATION - ADJUSTABLE PEDALS

(1) Install the pedal to the vehicle (Fig. 56).

(2) Reposition the ICU and booster, Install the

ICU mounting bracket nuts and bolts.

28 N

(3) Install the brake booster nuts. Tighten to 28

N´m ( 21 ft. lbs.). (Fig. 56).

(4) Install the pedal bracket upper nuts. Tighten

to 12 N´m ( 9 ft. lbs.). (Fig. 56).

(5) Install the accelerator pedal nuts. Tighten to

28 N´m ( 21 ft. lbs.). (Fig. 57).

(6) Install the lower steering shaft coupler over the

shaft (Fig. 56).

(7) Install the lower steering shaft pinch bolt (Fig.

56).

(8) Unlock the steering wheel.

(9) Reconnect the accelerator cable to the pedal

(Fig. 56).(10) Reconnect the booster rod clip (Fig. 56).

(11) Install the brake light switch.

(12) Reconnect the module electrical connector.

(13) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(14) Install the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(15) Reconnect the negative battery cable.

PEDAL MOTOR

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(4) Remove the two mounting screws (Fig. 58).

(5) Disconnect the electrical connector (Fig. 58).

(6) Remove the adjustable pedal motor (Fig. 58).

INSTALLATION

(1) Install the adjustable pedal motor (Fig. 58).

(2) Reconnect the electrical connector (Fig. 58).

(3) Install the two mounting screws (Fig. 58).

(4) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

Fig. 57 ACCELERATOR MOUNTING BRACKET

1 - ACCELERATOR MOUNTING NUTS

2 - ADJUSTABLE PEDALS BRACKET

3 - ACCELERATOR PEDAL

Fig. 58 ADJUSTABLE PEDALS MOTOR

1 - ELECTRICAL CONNECTOR

2 - PEDALS MOTOR

3 - MOUNTING SCREWS HOLES

5 - 28 BRAKES - BASEWJ

PEDAL (Continued)

Page 282 of 2199

OPERATION

The audio system components are designed to pro-

vide audio entertainment and information through

the reception, tuning and amplification of locally

broadcast radio signals in both the Amplitude Modu-

lating (AM) and Frequency Modulating (FM) com-

mercial frequency ranges. Electromagnetic radio

signals that are broadcast from a radio station

induce electrical modulations into the audio system

antenna mast. The antenna body and cable conduct

these weak signals from the antenna mast to the

radio. The radio then tunes and amplifies these weak

radio frequency signals into stronger electrical audio

signals that are required in order to operate the

audio system speakers. The speakers convert these

electrical signals into air movement, which repro-

duces the sounds being broadcast by the radio sta-

tion.

Some audio systems also offer the user the option

of selecting from and listening to prerecorded audio

cassette tapes, audio compact discs, or both. Regard-

less of the media type, the audio system components

provide the user with the ability to electronically

amplify and adjust the audio signals being repro-

duced by the speakers within the vehicle to suit the

preferences of the vehicle occupants.

The audio system components operate on battery

current received through a fuse in the Junction Block

(JB) on a fused ignition switch output (run-acc) cir-

cuit so that the system will only operate when the

ignition switch is in the On or Accessory positions.

On vehicles that are equipped with the optional

remote radio switches, the BCM receives hard wired

resistor multiplexed inputs from the remote radio

switches. The programming in the BCM allows it to

process those inputs and send the proper messages to

the radio receiver over the PCI data bus to control

the radio volume up or down, station seek up or

down, preset station advance, and mode advance

functions.On vehicles equipped with the optional memory

system, when the DDM receives a Driver 1 or Driver

2 memory recall input from the memory switch on

the driver side front door trim panel or a memory

recall message from the Remote Keyless Entry (RKE)

receiver in the PDM, the DDM sends a memory

recall message back to the radio receiver over the

PCI data bus to recall the radio station presets and

last station listened to information.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of each of the available audio systems.

DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WJAUDIO 8A - 3

AUDIO (Continued)

Page 286 of 2199

ANTENNA BODY & CABLE

DESCRIPTION

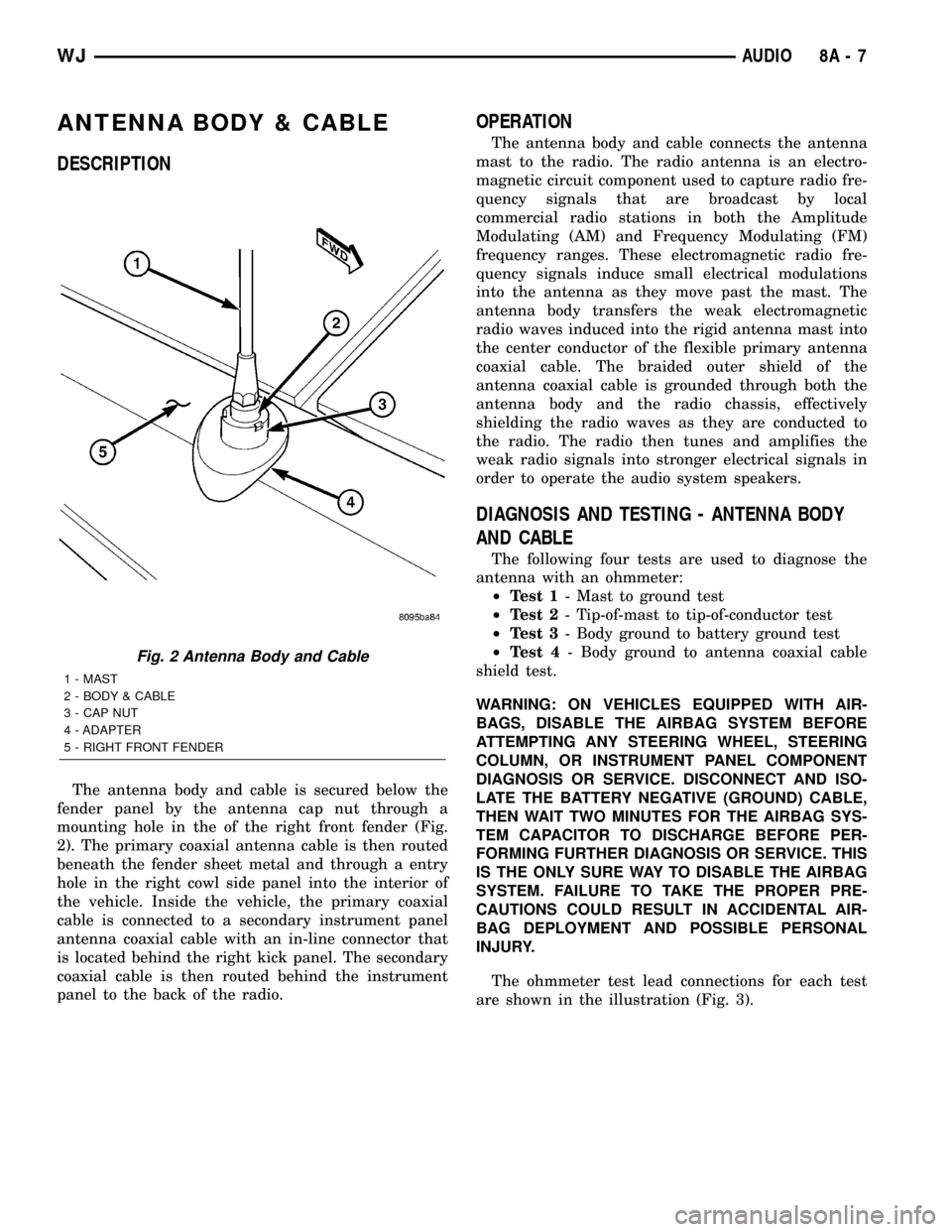

The antenna body and cable is secured below the

fender panel by the antenna cap nut through a

mounting hole in the of the right front fender (Fig.

2). The primary coaxial antenna cable is then routed

beneath the fender sheet metal and through a entry

hole in the right cowl side panel into the interior of

the vehicle. Inside the vehicle, the primary coaxial

cable is connected to a secondary instrument panel

antenna coaxial cable with an in-line connector that

is located behind the right kick panel. The secondary

coaxial cable is then routed behind the instrument

panel to the back of the radio.

OPERATION

The antenna body and cable connects the antenna

mast to the radio. The radio antenna is an electro-

magnetic circuit component used to capture radio fre-

quency signals that are broadcast by local

commercial radio stations in both the Amplitude

Modulating (AM) and Frequency Modulating (FM)

frequency ranges. These electromagnetic radio fre-

quency signals induce small electrical modulations

into the antenna as they move past the mast. The

antenna body transfers the weak electromagnetic

radio waves induced into the rigid antenna mast into

the center conductor of the flexible primary antenna

coaxial cable. The braided outer shield of the

antenna coaxial cable is grounded through both the

antenna body and the radio chassis, effectively

shielding the radio waves as they are conducted to

the radio. The radio then tunes and amplifies the

weak radio signals into stronger electrical signals in

order to operate the audio system speakers.

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE

The following four tests are used to diagnose the

antenna with an ohmmeter:

²Test 1- Mast to ground test

²Test 2- Tip-of-mast to tip-of-conductor test

²Test 3- Body ground to battery ground test

²Test 4- Body ground to antenna coaxial cable

shield test.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The ohmmeter test lead connections for each test

are shown in the illustration (Fig. 3).

Fig. 2 Antenna Body and Cable

1 - MAST

2 - BODY & CABLE

3 - CAP NUT

4 - ADAPTER

5 - RIGHT FRONT FENDER

WJAUDIO 8A - 7

Page 288 of 2199

(2) Touch one ohmmeter test lead to a good clean

ground point on the vehicle fender. Touch the other

test lead to the outer crimp on the antenna coaxial

cable connector under the right end of the instru-

ment panel near the right cowl side inner panel.

Check the ohmmeter reading for continuity.

(3) There should be continuity. The ohmmeter

should register less than one ohm resistance. High or

infinite resistance indicates a loose, corroded, or

damaged connection between the antenna body and

the vehicle body or between the antenna body and

the antenna coaxial cable shield. If not OK, clean the

antenna body to fender mating surfaces and tighten

the antenna cap nut to specifications.

(4) Check the resistance again with an ohmmeter.

If the resistance is still more then one ohm, replace

the faulty antenna body and cable.

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the scuff plate from the right front

door sill. (Refer to 23 - BODY/INTERIOR/DOOR

SILL SCUFF PLATE - REMOVAL) for the proce-

dures.

(3) Remove the trim panel from the right inner

cowl side.(Refer to 23 - BODY/INTERIOR/COWL

TRIM - REMOVAL) for the procedures.

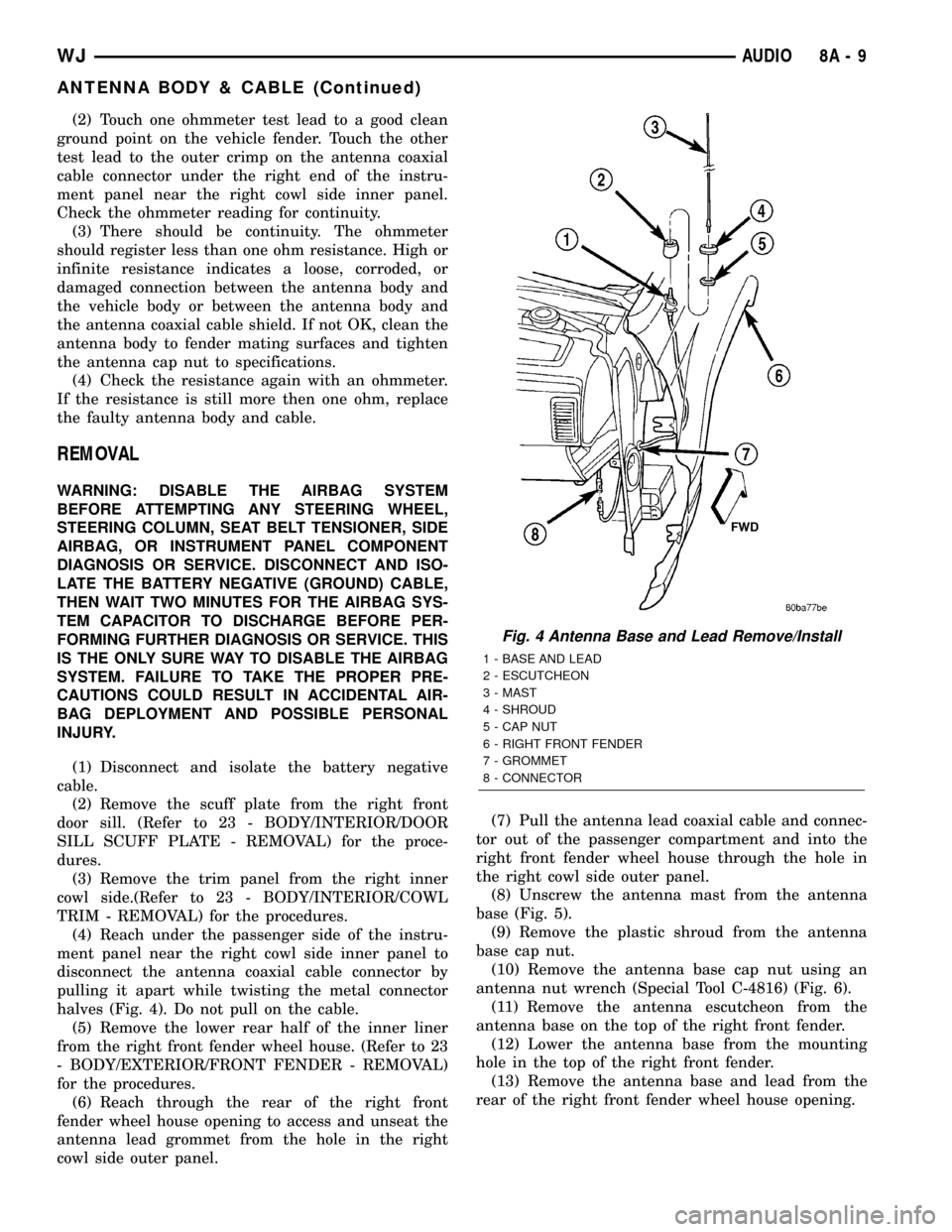

(4) Reach under the passenger side of the instru-

ment panel near the right cowl side inner panel to

disconnect the antenna coaxial cable connector by

pulling it apart while twisting the metal connector

halves (Fig. 4). Do not pull on the cable.

(5) Remove the lower rear half of the inner liner

from the right front fender wheel house. (Refer to 23

- BODY/EXTERIOR/FRONT FENDER - REMOVAL)

for the procedures.

(6) Reach through the rear of the right front

fender wheel house opening to access and unseat the

antenna lead grommet from the hole in the right

cowl side outer panel.(7) Pull the antenna lead coaxial cable and connec-

tor out of the passenger compartment and into the

right front fender wheel house through the hole in

the right cowl side outer panel.

(8) Unscrew the antenna mast from the antenna

base (Fig. 5).

(9) Remove the plastic shroud from the antenna

base cap nut.

(10) Remove the antenna base cap nut using an

antenna nut wrench (Special Tool C-4816) (Fig. 6).

(11) Remove the antenna escutcheon from the

antenna base on the top of the right front fender.

(12) Lower the antenna base from the mounting

hole in the top of the right front fender.

(13) Remove the antenna base and lead from the

rear of the right front fender wheel house opening.

Fig. 4 Antenna Base and Lead Remove/Install

1 - BASE AND LEAD

2 - ESCUTCHEON

3 - MAST

4 - SHROUD

5 - CAP NUT

6 - RIGHT FRONT FENDER

7 - GROMMET

8 - CONNECTOR

WJAUDIO 8A - 9

ANTENNA BODY & CABLE (Continued)

Page 292 of 2199

The CD changer can only be serviced by an autho-

rized radio repair station. See the latest Warranty

Policies and Procedures manual for a current listing

of authorized radio repair stations.

OPERATION

The CD changer will only operate when the igni-

tion switch is in the On or Accessory positions, and

the radio is turned on. For more information on the

features, loading procedures and radio control func-

tions for the operation of the CD changer, see the

owner's manual in the vehicle glove box.

DIAGNOSIS AND TESTING - CD CHANGER

Following are tests that will help to diagnose the

hard wired components and circuits of the Compact

Disc (CD) changer unit. However, these tests may not

prove conclusive in the diagnosis of this unit. In

order to obtain conclusive testing of the CD changer

unit, the Programmable Communications Interface

(PCI) data bus network, the CD changer unit, the

radio receiver unit and any other electronic modules

that provide inputs to, or receive outputs from the

audio system must be checked.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, SEAT BELT TENSIONER, SIDE

AIRBAG, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

COMPACT DISC CHANGER INOPERATIVE

(1) Turn the ignition switch to the On position.

Turn the radio receiver on and check its operation. If

OK, go to Step 2. If not OK, (Refer to 8 - ELECTRI-

CAL/AUDIO/RADIO - OPERATION).(2) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the right body wire harness connector

from the CD changer connector receptacle. Check for

continuity between the power ground (Z17) circuit of

the right body wire harness connector for the CD

changer and a good ground. There should be continu-

ity. If OK, go to Step 3. If not OK, repair the open

power ground circuit to the radio receiver as

required.

(3) Reconnect the battery negative cable. Check for

battery voltage at the B(+) circuit cavity of the right

body wire harness connector for the CD changer. If

OK, go to Step 4. If not OK, go to Step 5.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the ignition switch out-

put circuit cavity of the right body wire harness con-

nector for the CD changer. If OK, use a DRB scan

tool and the proper Diagnostic Procedures manual for

further diagnosis. If not OK, go to Step 6.

(5) Disconnect and isolate the battery negative

cable. Remove the radio receiver from the instrument

panel. Disconnect the 10 pin cable connector from the

radio receiver, but do not disconnect the other wire

harness connectors. Reconnect the battery negative

cable. Check for battery voltage at the B(+) circuit

cavity of the 10 pin connector receptacle on the radio

receiver. If OK, repair the open B(+) circuit to the CD

changer as required. If not OK, check for a shorted

B(+) circuit to the CD changer and repair as

required, then replace the faulty radio receiver.

(6) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the radio receiver from the instrument

panel. Disconnect the 10 pin cable connector from the

radio receiver, but do not disconnect the other wire

harness connectors. Reconnect the battery negative

cable. Turn the ignition switch to the On position.

Check for battery voltage at the ignition switch out-

put circuit cavity of the 10 pin connector receptacle

on the radio receiver. If OK, repair the open ignition

switch output circuit to the CD changer as required.

If not OK, check for a shorted ignition switch output

circuit to the CD changer and repair as required,

then replace the faulty radio receiver.

NO SOUND OR ONLY ONE CHANNEL SOUND

FROM CD CHANGER

(1) Turn the ignition switch to the On position.

Turn the radio receiver on and check its audio output

operation. If OK, go to Step 2. If not OK, (Refer to 8

- ELECTRICAL/AUDIO/SPEAKER - OPERATION).

(2) Disconnect and isolate the battery negative

cable. Disconnect the right body wire harness connec-

tor from the CD changer connector receptacle.

Remove the radio receiver from the instrument

WJAUDIO 8A - 13

CD CHANGER (Continued)