System deaeration JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 224 of 2199

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM 4.7L

ENGINE..............................1

DESCRIPTION - COOLING SYSTEM

ROUTING 4.7L ENGINE..................1

DESCRIPTIONÐCOOLING SYSTEM 4.0L

ENGINE..............................1

DESCRIPTIONÐCOOLING SYSTEM

ROUTING 4.0L ENGINE..................1

DESCRIPTIONÐHOSE CLAMPS...........1

OPERATION

OPERATIONÐCOOLING SYSTEM.........2

OPERATIONÐHOSE CLAMPS............2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)...................3

DIAGNOSIS AND TESTINGÐPRELIMINARY

CHECKS.............................3

DIAGNOSIS AND TESTING - COOLING

SYSTEM DIAGNOSIS CHART.............5

DIAGNOSIS AND TESTING - COOLING

SYSTEM LEAKS......................10DIAGNOSIS AND TESTING - COOLING

SYSTEM DEAERATION.................12

STANDARD PROCEDURE

STANDARD PROCEDUREÐDRAINING

COOLING SYSTEM 4.7L ENGINE.........12

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 4.7L ENGINE.........12

STANDARD PROCEDURE - DRAINING

COOLING SYSTEM - 4.0L ENGINE........13

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM - 4.0L ENGINE........13

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT.................13

STANDARD PROCEDURE - COOLING

SYSTEM - REVERSE FLUSHING..........14

SPECIFICATIONS

TORQUE............................14

SPECIAL TOOLS

COOLING...........................15

ACCESSORY DRIVE......................16

ENGINE...............................24

TRANSMISSION.........................55

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM 4.7L

ENGINE

The cooling system consists of the following items:

²Hydraulic cooling fan and fan drive assembly

²Radiator

²Power steering oil cooler

²Radiator pressure cap

²Thermostat

²Coolant reserve/overflow system

²Transmission oil cooler (if equipped with an

automatic transmission)

²Coolant

²Water pump

²Hoses and hose clamps

DESCRIPTION - COOLING SYSTEM ROUTING

4.7L ENGINE

For cooling system routing refer to (Fig. 1).

DESCRIPTIONÐCOOLING SYSTEM 4.0L

ENGINE

The cooling system consists of:

²A radiator

²Mechanical Cooling Fan

²Thermal viscous fan drive-Low disengaged

²Fan shroud (Fig. 2)

²Radiator pressure cap

²Thermostat

²Coolant reserve/overflow system

²Transmission oil cooler (if equipped with an

automatic transmission)

²Coolant

²Water pump

²Hoses and hose clamps

²Accessory drive belt

DESCRIPTIONÐCOOLING SYSTEM ROUTING

4.0L ENGINE

For cooling system routing refer to (Fig. 3).

DESCRIPTIONÐHOSE CLAMPS

The cooling system utilizes both worm drive and

spring type hose clamps. If a spring type clamp

WJCOOLING 7 - 1

Page 235 of 2199

accessory drive belt (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - REMOVAL).

Add coolant to radiator to bring level to within 6.3

mm (1/4 in) of top of thermostat housing.

CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open drain-

cock immediately after test to eliminate boil over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases are leaking into

cooling system, bubbles will appear in coolant. If bub-

bles do not appear, internal combustion gas leakage

is not present.

DIAGNOSIS AND TESTING - COOLING SYSTEM

DEAERATION

As the engine operates, any air trapped in cooling

system gathers under the radiator cap. The next time

the engine is operated, thermal expansion of coolant

will push any trapped air past radiator cap into the

coolant reserve/overflow tank. Here it escapes to the

atmosphere into the tank. When the engine cools

down the coolant, it will be drawn from the reserve/

overflow tank into the radiator to replace any

removed air.

STANDARD PROCEDURE

STANDARD PROCEDUREÐDRAINING COOLING

SYSTEM 4.7L ENGINE

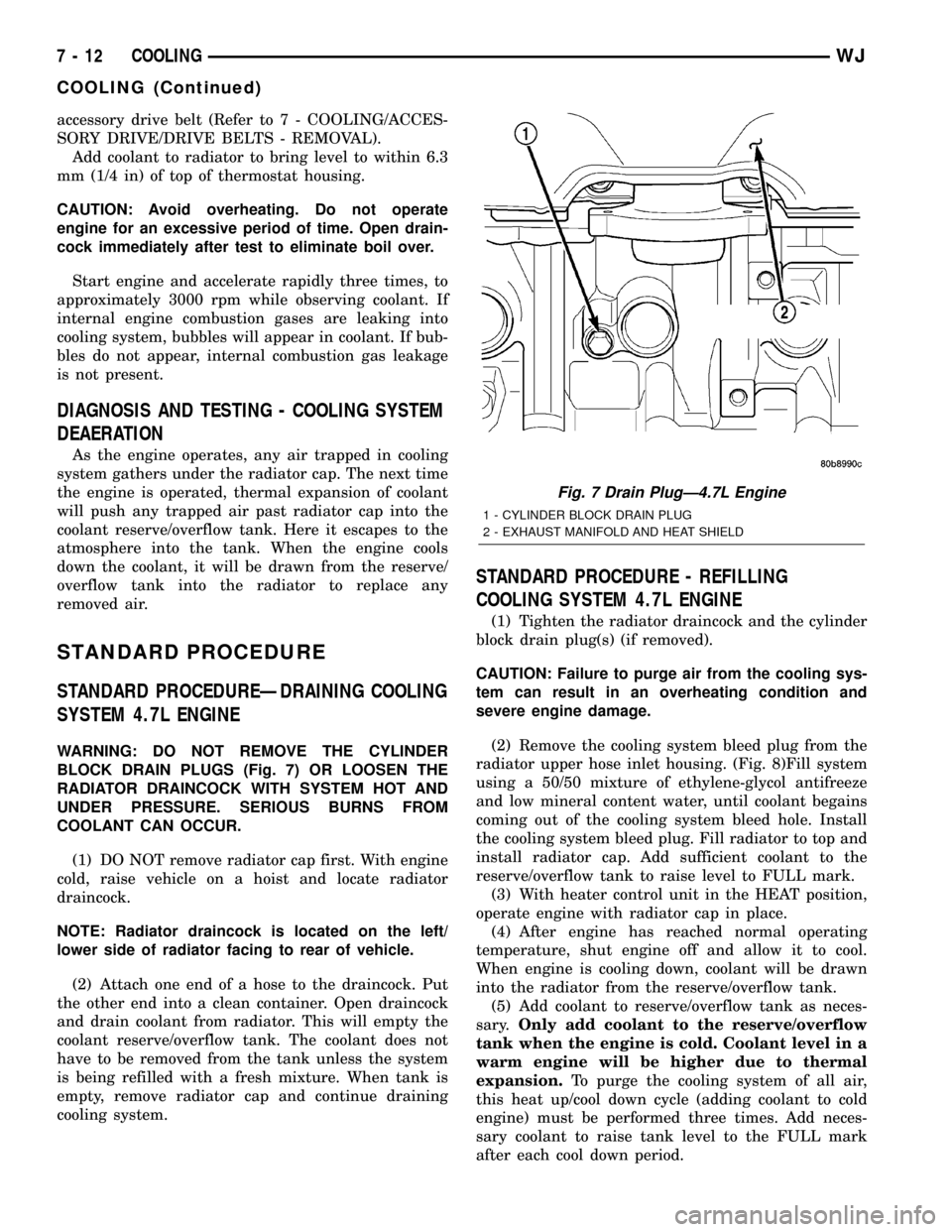

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS (Fig. 7) OR LOOSEN THE

RADIATOR DRAINCOCK WITH SYSTEM HOT AND

UNDER PRESSURE. SERIOUS BURNS FROM

COOLANT CAN OCCUR.

(1) DO NOT remove radiator cap first. With engine

cold, raise vehicle on a hoist and locate radiator

draincock.

NOTE: Radiator draincock is located on the left/

lower side of radiator facing to rear of vehicle.

(2) Attach one end of a hose to the draincock. Put

the other end into a clean container. Open draincock

and drain coolant from radiator. This will empty the

coolant reserve/overflow tank. The coolant does not

have to be removed from the tank unless the system

is being refilled with a fresh mixture. When tank is

empty, remove radiator cap and continue draining

cooling system.

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 4.7L ENGINE

(1) Tighten the radiator draincock and the cylinder

block drain plug(s) (if removed).

CAUTION: Failure to purge air from the cooling sys-

tem can result in an overheating condition and

severe engine damage.

(2) Remove the cooling system bleed plug from the

radiator upper hose inlet housing. (Fig. 8)Fill system

using a 50/50 mixture of ethylene-glycol antifreeze

and low mineral content water, until coolant begains

coming out of the cooling system bleed hole. Install

the cooling system bleed plug. Fill radiator to top and

install radiator cap. Add sufficient coolant to the

reserve/overflow tank to raise level to FULL mark.

(3) With heater control unit in the HEAT position,

operate engine with radiator cap in place.

(4) After engine has reached normal operating

temperature, shut engine off and allow it to cool.

When engine is cooling down, coolant will be drawn

into the radiator from the reserve/overflow tank.

(5) Add coolant to reserve/overflow tank as neces-

sary.Only add coolant to the reserve/overflow

tank when the engine is cold. Coolant level in a

warm engine will be higher due to thermal

expansion.To purge the cooling system of all air,

this heat up/cool down cycle (adding coolant to cold

engine) must be performed three times. Add neces-

sary coolant to raise tank level to the FULL mark

after each cool down period.

Fig. 7 Drain PlugÐ4.7L Engine

1 - CYLINDER BLOCK DRAIN PLUG

2 - EXHAUST MANIFOLD AND HEAT SHIELD

7 - 12 COOLINGWJ

COOLING (Continued)

Page 251 of 2199

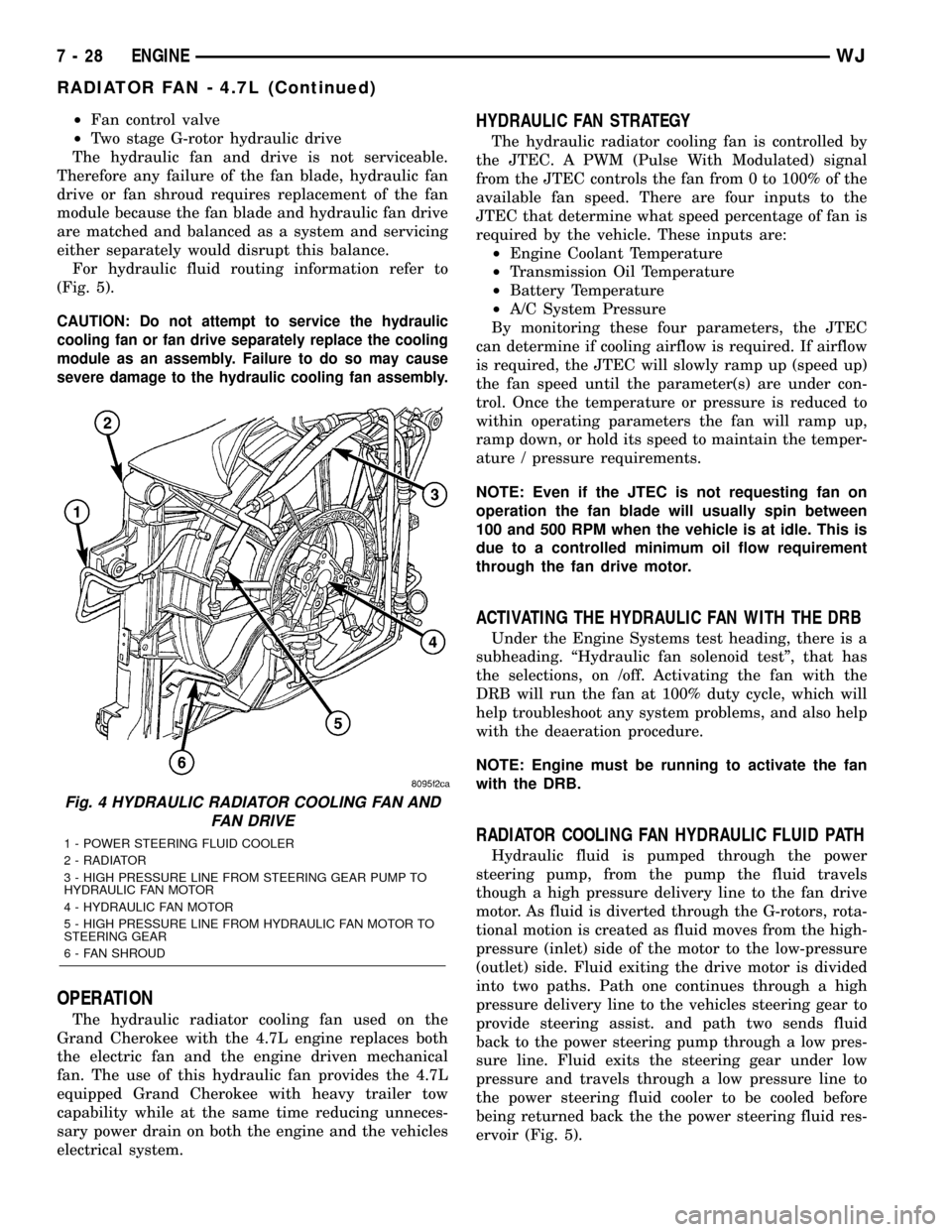

²Fan control valve

²Two stage G-rotor hydraulic drive

The hydraulic fan and drive is not serviceable.

Therefore any failure of the fan blade, hydraulic fan

drive or fan shroud requires replacement of the fan

module because the fan blade and hydraulic fan drive

are matched and balanced as a system and servicing

either separately would disrupt this balance.

For hydraulic fluid routing information refer to

(Fig. 5).

CAUTION: Do not attempt to service the hydraulic

cooling fan or fan drive separately replace the cooling

module as an assembly. Failure to do so may cause

severe damage to the hydraulic cooling fan assembly.

OPERATION

The hydraulic radiator cooling fan used on the

Grand Cherokee with the 4.7L engine replaces both

the electric fan and the engine driven mechanical

fan. The use of this hydraulic fan provides the 4.7L

equipped Grand Cherokee with heavy trailer tow

capability while at the same time reducing unneces-

sary power drain on both the engine and the vehicles

electrical system.

HYDRAULIC FAN STRATEGY

The hydraulic radiator cooling fan is controlled by

the JTEC. A PWM (Pulse With Modulated) signal

from the JTEC controls the fan from 0 to 100% of the

available fan speed. There are four inputs to the

JTEC that determine what speed percentage of fan is

required by the vehicle. These inputs are:

²Engine Coolant Temperature

²Transmission Oil Temperature

²Battery Temperature

²A/C System Pressure

By monitoring these four parameters, the JTEC

can determine if cooling airflow is required. If airflow

is required, the JTEC will slowly ramp up (speed up)

the fan speed until the parameter(s) are under con-

trol. Once the temperature or pressure is reduced to

within operating parameters the fan will ramp up,

ramp down, or hold its speed to maintain the temper-

ature / pressure requirements.

NOTE: Even if the JTEC is not requesting fan on

operation the fan blade will usually spin between

100 and 500 RPM when the vehicle is at idle. This is

due to a controlled minimum oil flow requirement

through the fan drive motor.

ACTIVATING THE HYDRAULIC FAN WITH THE DRB

Under the Engine Systems test heading, there is a

subheading. ªHydraulic fan solenoid testº, that has

the selections, on /off. Activating the fan with the

DRB will run the fan at 100% duty cycle, which will

help troubleshoot any system problems, and also help

with the deaeration procedure.

NOTE: Engine must be running to activate the fan

with the DRB.

RADIATOR COOLING FAN HYDRAULIC FLUID PATH

Hydraulic fluid is pumped through the power

steering pump, from the pump the fluid travels

though a high pressure delivery line to the fan drive

motor. As fluid is diverted through the G-rotors, rota-

tional motion is created as fluid moves from the high-

pressure (inlet) side of the motor to the low-pressure

(outlet) side. Fluid exiting the drive motor is divided

into two paths. Path one continues through a high

pressure delivery line to the vehicles steering gear to

provide steering assist. and path two sends fluid

back to the power steering pump through a low pres-

sure line. Fluid exits the steering gear under low

pressure and travels through a low pressure line to

the power steering fluid cooler to be cooled before

being returned back the the power steering fluid res-

ervoir (Fig. 5).

Fig. 4 HYDRAULIC RADIATOR COOLING FAN AND

FAN DRIVE

1 - POWER STEERING FLUID COOLER

2 - RADIATOR

3 - HIGH PRESSURE LINE FROM STEERING GEAR PUMP TO

HYDRAULIC FAN MOTOR

4 - HYDRAULIC FAN MOTOR

5 - HIGH PRESSURE LINE FROM HYDRAULIC FAN MOTOR TO

STEERING GEAR

6 - FAN SHROUD

7 - 28 ENGINEWJ

RADIATOR FAN - 4.7L (Continued)