console removal JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 210 of 2199

CABLES

REMOVAL

REMOVAL - FRONT PARKING BRAKE CABLE

(1) Remove center console,(Refer to 23 - BODY/IN-

TERIOR/FLOOR CONSOLE - REMOVAL).

(2) Lift up rear seat and carpet covering the park-

ing brake cables.

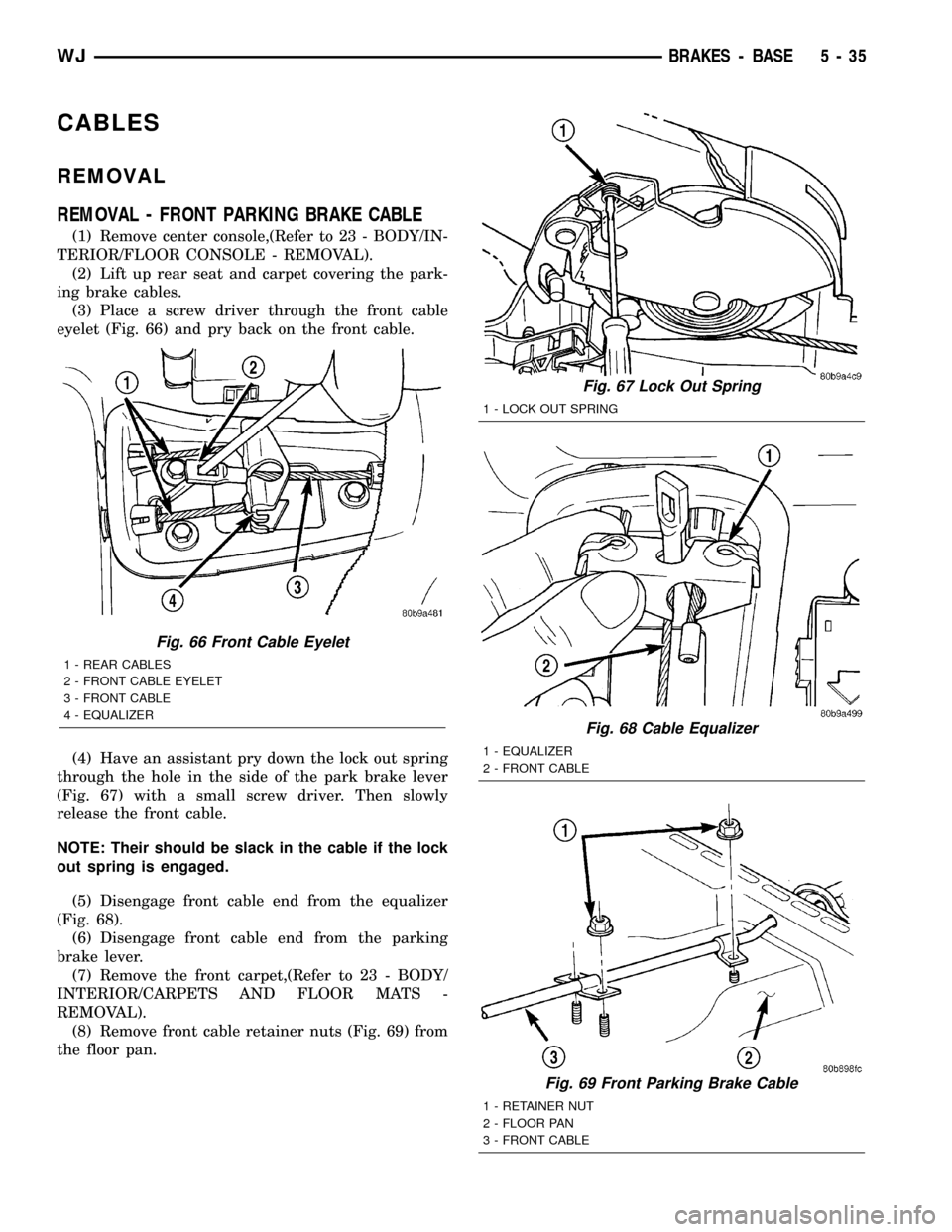

(3) Place a screw driver through the front cable

eyelet (Fig. 66) and pry back on the front cable.

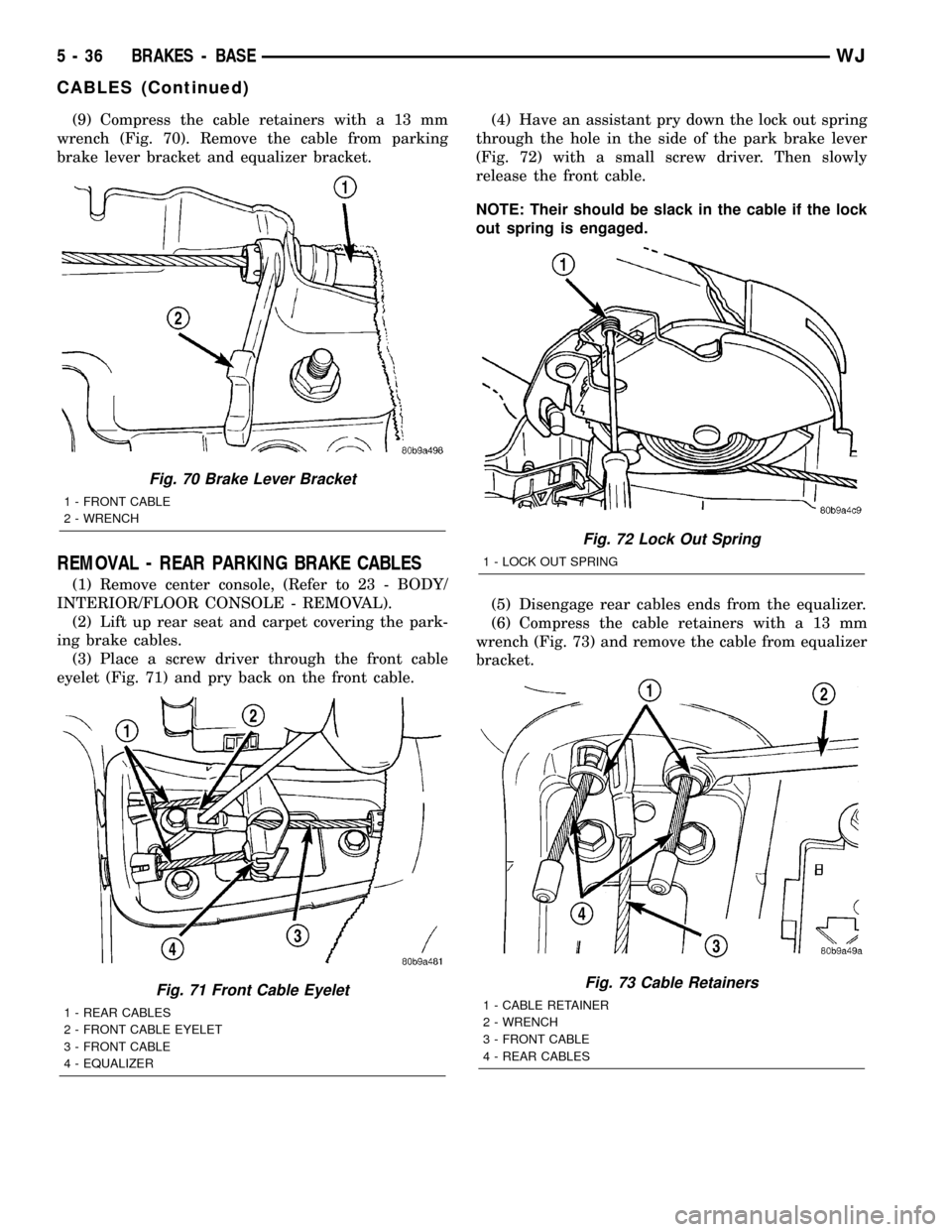

(4) Have an assistant pry down the lock out spring

through the hole in the side of the park brake lever

(Fig. 67) with a small screw driver. Then slowly

release the front cable.

NOTE: Their should be slack in the cable if the lock

out spring is engaged.

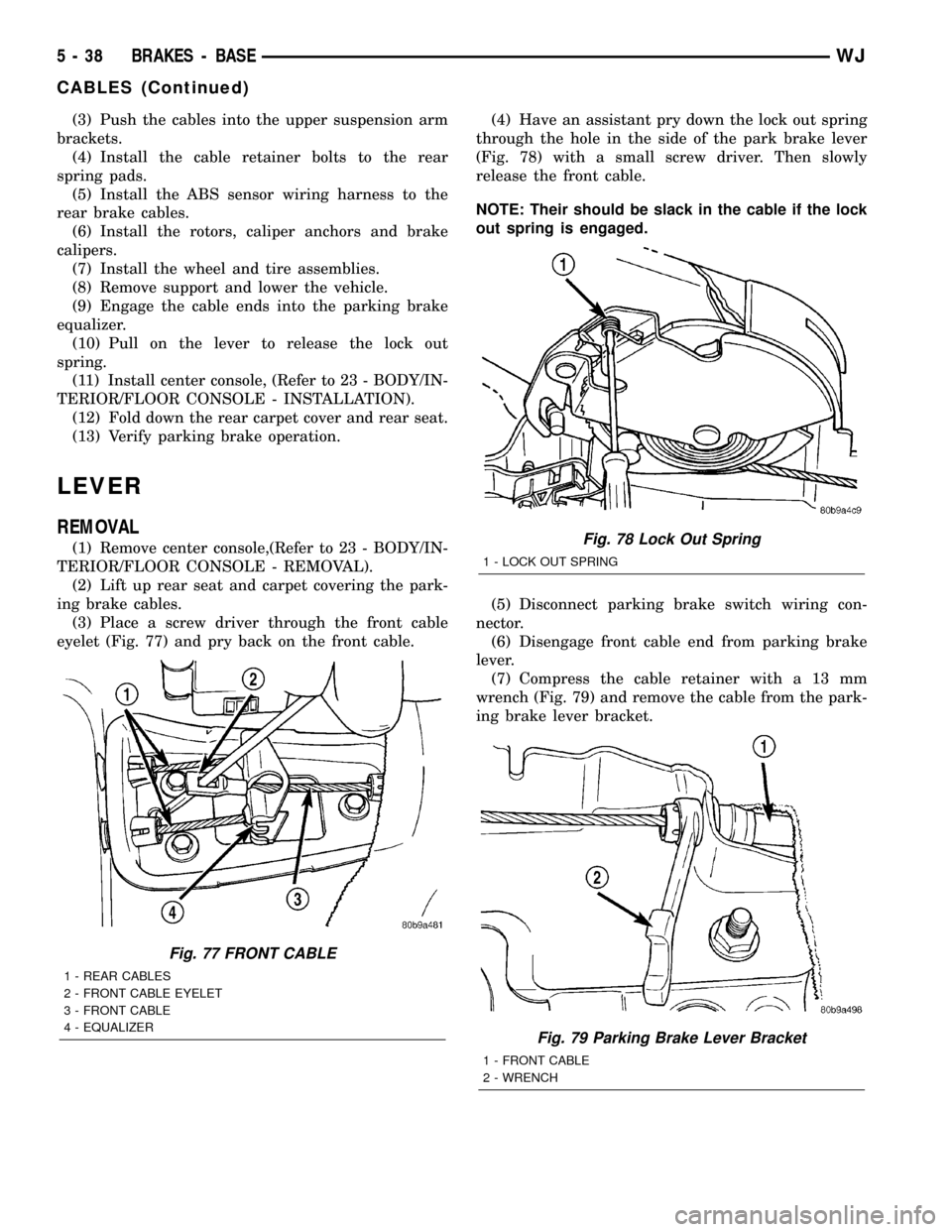

(5) Disengage front cable end from the equalizer

(Fig. 68).

(6) Disengage front cable end from the parking

brake lever.

(7) Remove the front carpet,(Refer to 23 - BODY/

INTERIOR/CARPETS AND FLOOR MATS -

REMOVAL).

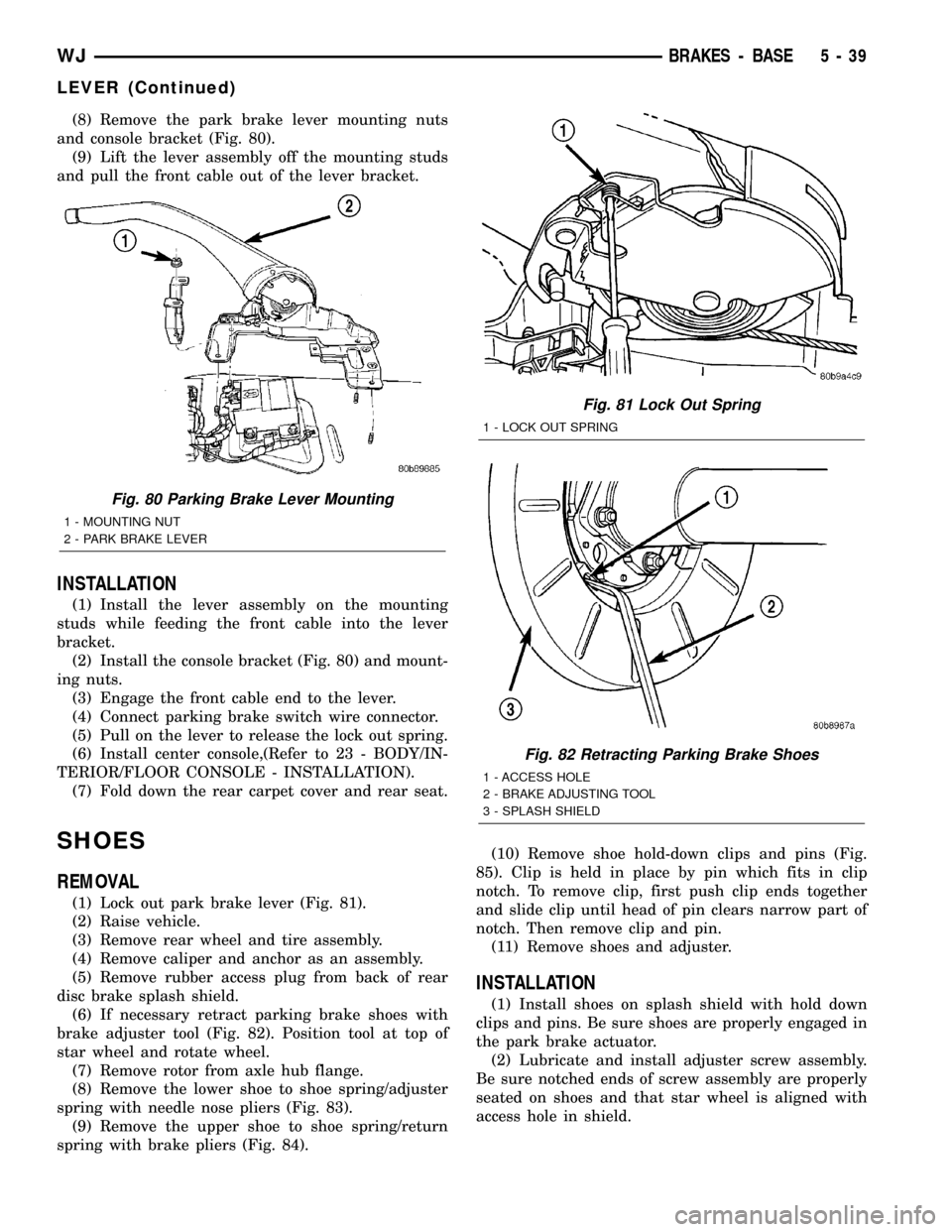

(8) Remove front cable retainer nuts (Fig. 69) from

the floor pan.

Fig. 66 Front Cable Eyelet

1 - REAR CABLES

2 - FRONT CABLE EYELET

3 - FRONT CABLE

4 - EQUALIZER

Fig. 67 Lock Out Spring

1 - LOCK OUT SPRING

Fig. 68 Cable Equalizer

1 - EQUALIZER

2 - FRONT CABLE

Fig. 69 Front Parking Brake Cable

1 - RETAINER NUT

2 - FLOOR PAN

3 - FRONT CABLE

WJBRAKES - BASE 5 - 35

Page 211 of 2199

(9) Compress the cable retainers with a 13 mm

wrench (Fig. 70). Remove the cable from parking

brake lever bracket and equalizer bracket.

REMOVAL - REAR PARKING BRAKE CABLES

(1) Remove center console, (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - REMOVAL).

(2) Lift up rear seat and carpet covering the park-

ing brake cables.

(3) Place a screw driver through the front cable

eyelet (Fig. 71) and pry back on the front cable.(4) Have an assistant pry down the lock out spring

through the hole in the side of the park brake lever

(Fig. 72) with a small screw driver. Then slowly

release the front cable.

NOTE: Their should be slack in the cable if the lock

out spring is engaged.

(5) Disengage rear cables ends from the equalizer.

(6) Compress the cable retainers with a 13 mm

wrench (Fig. 73) and remove the cable from equalizer

bracket.

Fig. 70 Brake Lever Bracket

1 - FRONT CABLE

2 - WRENCH

Fig. 71 Front Cable Eyelet

1 - REAR CABLES

2 - FRONT CABLE EYELET

3 - FRONT CABLE

4 - EQUALIZER

Fig. 72 Lock Out Spring

1 - LOCK OUT SPRING

Fig. 73 Cable Retainers

1 - CABLE RETAINER

2 - WRENCH

3 - FRONT CABLE

4 - REAR CABLES

5 - 36 BRAKES - BASEWJ

CABLES (Continued)

Page 213 of 2199

(3) Push the cables into the upper suspension arm

brackets.

(4) Install the cable retainer bolts to the rear

spring pads.

(5) Install the ABS sensor wiring harness to the

rear brake cables.

(6) Install the rotors, caliper anchors and brake

calipers.

(7) Install the wheel and tire assemblies.

(8) Remove support and lower the vehicle.

(9) Engage the cable ends into the parking brake

equalizer.

(10) Pull on the lever to release the lock out

spring.

(11) Install center console, (Refer to 23 - BODY/IN-

TERIOR/FLOOR CONSOLE - INSTALLATION).

(12) Fold down the rear carpet cover and rear seat.

(13) Verify parking brake operation.

LEVER

REMOVAL

(1) Remove center console,(Refer to 23 - BODY/IN-

TERIOR/FLOOR CONSOLE - REMOVAL).

(2) Lift up rear seat and carpet covering the park-

ing brake cables.

(3) Place a screw driver through the front cable

eyelet (Fig. 77) and pry back on the front cable.(4) Have an assistant pry down the lock out spring

through the hole in the side of the park brake lever

(Fig. 78) with a small screw driver. Then slowly

release the front cable.

NOTE: Their should be slack in the cable if the lock

out spring is engaged.

(5) Disconnect parking brake switch wiring con-

nector.

(6) Disengage front cable end from parking brake

lever.

(7) Compress the cable retainer with a 13 mm

wrench (Fig. 79) and remove the cable from the park-

ing brake lever bracket.

Fig. 77 FRONT CABLE

1 - REAR CABLES

2 - FRONT CABLE EYELET

3 - FRONT CABLE

4 - EQUALIZER

Fig. 78 Lock Out Spring

1 - LOCK OUT SPRING

Fig. 79 Parking Brake Lever Bracket

1 - FRONT CABLE

2 - WRENCH

5 - 38 BRAKES - BASEWJ

CABLES (Continued)

Page 214 of 2199

(8) Remove the park brake lever mounting nuts

and console bracket (Fig. 80).

(9) Lift the lever assembly off the mounting studs

and pull the front cable out of the lever bracket.

INSTALLATION

(1) Install the lever assembly on the mounting

studs while feeding the front cable into the lever

bracket.

(2) Install the console bracket (Fig. 80) and mount-

ing nuts.

(3) Engage the front cable end to the lever.

(4) Connect parking brake switch wire connector.

(5) Pull on the lever to release the lock out spring.

(6) Install center console,(Refer to 23 - BODY/IN-

TERIOR/FLOOR CONSOLE - INSTALLATION).

(7) Fold down the rear carpet cover and rear seat.

SHOES

REMOVAL

(1) Lock out park brake lever (Fig. 81).

(2) Raise vehicle.

(3) Remove rear wheel and tire assembly.

(4) Remove caliper and anchor as an assembly.

(5) Remove rubber access plug from back of rear

disc brake splash shield.

(6) If necessary retract parking brake shoes with

brake adjuster tool (Fig. 82). Position tool at top of

star wheel and rotate wheel.

(7) Remove rotor from axle hub flange.

(8) Remove the lower shoe to shoe spring/adjuster

spring with needle nose pliers (Fig. 83).

(9) Remove the upper shoe to shoe spring/return

spring with brake pliers (Fig. 84).(10) Remove shoe hold-down clips and pins (Fig.

85). Clip is held in place by pin which fits in clip

notch. To remove clip, first push clip ends together

and slide clip until head of pin clears narrow part of

notch. Then remove clip and pin.

(11) Remove shoes and adjuster.

INSTALLATION

(1) Install shoes on splash shield with hold down

clips and pins. Be sure shoes are properly engaged in

the park brake actuator.

(2) Lubricate and install adjuster screw assembly.

Be sure notched ends of screw assembly are properly

seated on shoes and that star wheel is aligned with

access hole in shield.

Fig. 80 Parking Brake Lever Mounting

1 - MOUNTING NUT

2 - PARK BRAKE LEVER

Fig. 81 Lock Out Spring

1 - LOCK OUT SPRING

Fig. 82 Retracting Parking Brake Shoes

1 - ACCESS HOLE

2 - BRAKE ADJUSTING TOOL

3 - SPLASH SHIELD

WJBRAKES - BASE 5 - 39

LEVER (Continued)

Page 390 of 2199

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - HORN SYSTEM . . . 2

HORN

DESCRIPTION..........................3

OPERATION............................3

DIAGNOSIS AND TESTING - HORN..........3

REMOVAL.............................3

INSTALLATION..........................4

HORN RELAY

DESCRIPTION..........................4OPERATION............................4

DIAGNOSIS AND TESTING - HORN RELAY....4

REMOVAL.............................5

INSTALLATION..........................5

HORN SWITCH

DESCRIPTION..........................6

OPERATION............................6

DIAGNOSIS AND TESTING - HORN SWITCH . . . 6

REMOVAL.............................7

INSTALLATION..........................7

HORN SYSTEM

DESCRIPTION

A dual-note electric horn system is standard facto-

ry-installed equipment on this model. The standard

equipment horn system features one low-note horn

unit and one high-note horn unit. The horn system

allows the vehicle operator to provide an audible

warning of the presence or approach of the vehicle to

pedestrians and the drivers of other vehicles in near

proximity. The horn system uses a non-switched

source of battery current so that the system will

remain functional, regardless of the ignition switch

position.

The horn system can also be activated by the Body

Control Module (BCM). The BCM is programmed to

activate the horns in order to provide the following

features:

²Remote Keyless Entry (RKE) system lock

request audible verification (except export)

²RKE system panic mode audible alert

²Vehicle Theft Security System (VTSS) audible

alarm.

This vehicle also offers several customer program-

mable features, which allows the selection of several

optional electronic features to suit individual prefer-

ences. Refer to Overhead Console for more informa-

tion on the customer programmable feature options.

Customer programmable feature options affecting the

horn system include:

²Sound Horn on Lock- Allows the option of

having the horn sound a short chirp as an audible

verification that the RKE system received a valid

Lock request from the RKE transmitter, or having no

audible verification.The horn system includes the following compo-

nents:

²Clockspring

²Horns

²Horn relay

²Horn switch

Certain functions and features of the horn system

rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munications Interface (PCI) data bus network. The

PCI data bus network allows the sharing of sensor

information. This helps to reduce wire harness com-

plexity, internal controller hardware, and component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities. For diagnosis of these electronic modules or of

the PCI data bus network, the use of a DRB scan

tool and the proper Diagnostic Procedures manual

are recommended.

The other electronic modules that may affect horn

system operation are as follows:

²Body Control Module (BCM)(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MODUL

- DESCRIPTION) for more information.

²Electronic Vehicle Information Center

(EVIC)(Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE/ELECTRONIC VEHICLE INFO CENTER

- DESCRIPTION) for more information.

(Refer to 8 - ELECTRICAL/RESTRAINTS/CLOCK-

SPRING - DESCRIPTION) for more information on

this component. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

WJHORN 8H - 1

Page 453 of 2199

LICENSE PLATE LAMP UNIT

REMOVAL.............................18

INSTALLATION.........................19

LEFT MULTI-FUNCTION SWITCH

DESCRIPTION.........................19

OPERATION...........................19

DIAGNOSIS AND TESTING - LEFT MULTI -

FUNCTION SWITCH...................20

REMOVAL

REMOVAL - LEFT MULTI-FUNCTION

SWITCH............................22

REMOVAL - MULTI-FUNCTION SWITCH

MOUNTING HOUSING..................22

INSTALLATION

INSTALLATION - LEFT MULTI-FUNCTION

SWITCH............................23

INSTALLATION - MULTI-FUNCTION SWITCH

MOUNTING HOUSING..................24

PARK/TURN SIGNAL LAMP

REMOVAL - BULBS.....................25INSTALLATION - BULBS..................25

TAIL LAMP

DESCRIPTION.........................25

OPERATION...........................25

REMOVAL

REMOVAL - BULBS....................25

REMOVAL - LAMP.....................25

INSTALLATION

INSTALLATION - BULBS................26

INSTALLATION - LAMP.................26

TURN SIGNAL CANCEL CAM

DESCRIPTION.........................26

OPERATION...........................26

UNDERHOOD LAMP

REMOVAL

REMOVAL - BULB.....................27

REMOVAL - LAMP.....................27

INSTALLATION

INSTALLATION - BULB.................27

INSTALLATION - LAMP.................27

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION - TURN SIGNAL & HAZARD

WARNING SYSTEM

The turn signal and hazard warning system

includes the following major components, which are

described in further detail elsewhere in this service

information:

²Combination Flasher

²Front Side Marker Lamps

²Hazard Warning Switch

²Turn Signal Cancel Cam

²Turn Signal Indicators

²Turn Signal Lamps

²Turn Signal Switch

The turn signal and hazard warning systems also

provide the following features:

²Flash Lights with Lock- This customer pro-

grammable feature flashes the hazard warning lamps

to provide optical verification that the Remote Key-

less Entry (RKE) System has received a valid Lock or

Unlock request from an RKE transmitter. (Refer to 8

- ELECTRICAL/POWER LOCKS - DESCRIPTION -

REMOTE KEYLESS ENTRY SYSTEM).

²Panic Mode Optical Alert- This feature

flashes the hazard warning lamps to provide an opti-

cal alert when the Remote Keyless Entry (RKE) Sys-

tem panic mode is activated by depressing the Panic

button on an RKE transmitter. (Refer to 8 - ELEC-

TRICAL/POWER LOCKS - DESCRIPTION -

REMOTE KEYLESS ENTRY SYSTEM).

²Turn Signal On Warning- This feature pro-

vides the vehicle operator with both visual and audi-

ble reminders when a turn signal has been left

turned on for an extended period. (Refer to 8 - ELEC-TRICAL/OVERHEAD CONSOLE/ELECTRONIC

VEHICLE INFO CENTER - DESCRIPTION).

²Vehicle Theft Security System (VTSS) Opti-

cal Alarm- This feature flashes the hazard warning

lamps to provide an optical alarm when the VTSS is

armed and activated by an unauthorized entry into

the vehicle. (Refer to 8 - ELECTRICAL/VEHICLE

THEFT SECURITY - DESCRIPTION - VEHICLE

THEFT SECURITY SYSTEM).

OPERATION - TURN SIGNAL & HAZARD

WARNING SYSTEM

The turn signal system operates on battery current

received on a fused ignition switch output (run) cir-

cuit so that the turn signals will only operate with

the ignition switch in the On position. The hazard

warning system operates on non-switched battery

current received on a fused B(+) circuit so that the

hazard warning remains operational regardless of

the ignition switch position. When the turn signal

system is activated, the circuitry of the turn signal

switch and the combination flasher will cause the

selected (right or left) turn signal indicator, front

park/turn signal lamp, front side marker lamp and

rear tail/stop/turn signal lamp to flash on and off.

When the hazard warning system is activated, the

circuitry of the hazard warning switch and the com-

bination flasher will cause both the right side and

the left side turn signal indicators, front park/turn

signal lamps, front side marker lamps and rear tail/

stop/turn signal lamps to flash on and off.

The Body Control Module (BCM) can also activate

the hazard warning system lamps by energizing the

combination flasher through a single hard wired con-

nection to the hazard warning switch sense circuit.

The BCM grounds the circuit to energize and de-en-

8L - 2 LAMPS/LIGHTING - EXTERIORWJ

Page 479 of 2199

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

...................................28

COURTESY LAMP

REMOVAL

REMOVAL - BULB.....................29

REMOVAL - LAMP.....................29

INSTALLATION

INSTALLATION - BULB.................29

INSTALLATION - LAMP.................29

DOME LAMP

REMOVAL

REMOVAL - BULB.....................29

REMOVAL - LAMP.....................29

INSTALLATION

INSTALLATION - BULB.................29

INSTALLATION - LAMP.................29

DOOR AJAR SWITCH

DESCRIPTION

DESCRIPTION - DOOR AJAR SWITCH.....29

DESCRIPTION - FLIP UP GLASS AJAR

SWITCH............................29DESCRIPTION - LIFTGATE AJAR SWITCH . . 30

OPERATION

OPERATION - DOOR AJAR SWITCH.......30

OPERATION - FLIP UP GLASS AJAR

SWITCH............................30

OPERATION - LIFTGATE AJAR SWITCH....30

DIAGNOSIS AND TESTING - DOOR AJAR

SWITCH............................30

GLOVE BOX LAMP/SWITCH

REMOVAL.............................31

INSTALLATION.........................31

READING LAMP

DESCRIPTION.........................32

OPERATION...........................32

REMOVAL.............................32

INSTALLATION.........................32

TRANS RANGE INDICATOR ILLUMINATION

DESCRIPTION.........................32

VANITY LAMP

REMOVAL.............................32

INSTALLATION.........................32

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

CAUTION: Do not use bulbs other than the bulbs

listed in the Bulb Application Table. Damage to

lamp can result.

Service procedures for most of the lamps in the

instrument panel, are located in Electrical, Instru-

ment Panel. Some components have lamps that can

only be serviced by an Authorized Service Center

(ASC) after the component is removed from the vehi-

cle.

LAMP BULB TYPE

A/C HEATER NOT SERVICED

ASH RECEIVER 161

CLIMATE CONTROL 74

PASSENGER ASSIST

HANDLE214±2

FRONT READING 192

GLOVE COMPARTMENT 194

TELLTALE/HAZARD LAMP 74

HEATER NOT SERVICED

OVERHEAD CONSOLE 192

RADIO ASC

REAR CARGO 214±2

UNDER PANEL COURTESY 906

CLUSTER ILLUMINATION 103

SUNVISOR VANITY CHRYSLER P/N

6501966

8L - 28 LAMPS/LIGHTING - INTERIORWJ

Page 483 of 2199

READING LAMP

DESCRIPTION

The overhead console in this vehicle is equipped

with two individual reading and courtesy lamps.Each

lamp has its own switch, bulb, reflector and lens; but

both lamps share a common lamp housing within the

overhead console.

The overhead console reading and courtesy lamps

operate on battery current that is provided at all

times, regardless of the ignition switch position. The

ground feed for the lamps is switched through the

integral reading and courtesy lamp switches or

through the door jamb switches.

The reading and courtesy lamp lenses and the

lamp housing and reflector unit are serviced only as

a unit with the overhead console housing.The reading

and courtesy lamp switches, bulb holders and wiring

are only available as part of the overhead console

wire harness.

For service of the reading and courtesy lamp bulbs,

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

INTERIOR/READING LAMP - REMOVAL). For diag-

nosis of the reading and courtesy lamps, refer to the

appropriate wiring information.

OPERATION

All reading and courtesy lamps located in the over-

head console are activated by the door jamb switches.

When all of the doors are closed, these lamps can be

individually activated by depressing the correspond-

ing lens. When any door is open, depressing the lamp

lenses to activate the lamp switches will not turn the

lamps off.

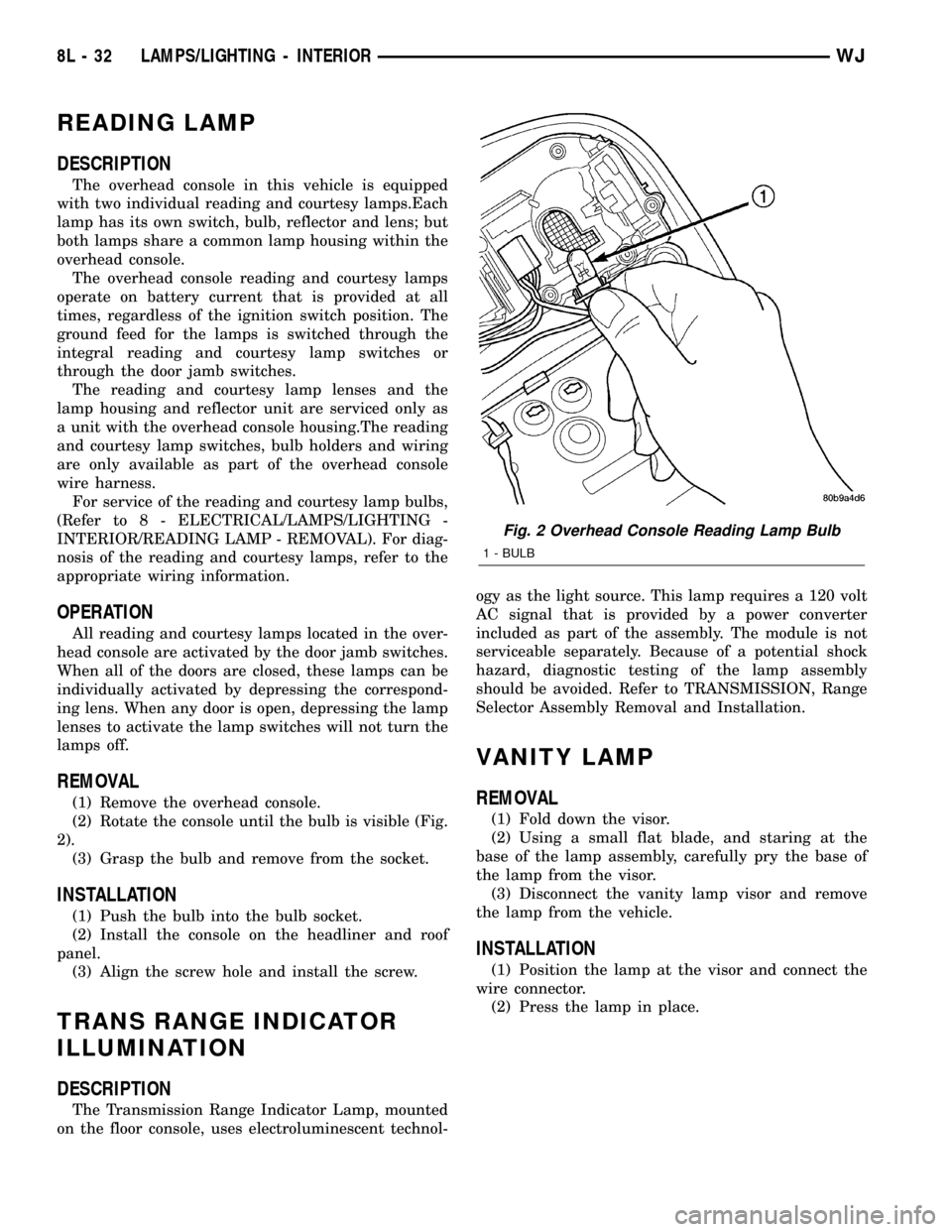

REMOVAL

(1) Remove the overhead console.

(2) Rotate the console until the bulb is visible (Fig.

2).

(3) Grasp the bulb and remove from the socket.

INSTALLATION

(1) Push the bulb into the bulb socket.

(2) Install the console on the headliner and roof

panel.

(3) Align the screw hole and install the screw.

TRANS RANGE INDICATOR

ILLUMINATION

DESCRIPTION

The Transmission Range Indicator Lamp, mounted

on the floor console, uses electroluminescent technol-ogy as the light source. This lamp requires a 120 volt

AC signal that is provided by a power converter

included as part of the assembly. The module is not

serviceable separately. Because of a potential shock

hazard, diagnostic testing of the lamp assembly

should be avoided. Refer to TRANSMISSION, Range

Selector Assembly Removal and Installation.

VANITY LAMP

REMOVAL

(1) Fold down the visor.

(2) Using a small flat blade, and staring at the

base of the lamp assembly, carefully pry the base of

the lamp from the visor.

(3) Disconnect the vanity lamp visor and remove

the lamp from the vehicle.

INSTALLATION

(1) Position the lamp at the visor and connect the

wire connector.

(2) Press the lamp in place.

Fig. 2 Overhead Console Reading Lamp Bulb

1 - BULB

8L - 32 LAMPS/LIGHTING - INTERIORWJ

Page 484 of 2199

MESSAGE SYSTEMS

TABLE OF CONTENTS

page page

OVERHEAD CONSOLE

DESCRIPTION..........................1

OPERATION............................1

STANDARD PROCEDURE

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT.......................1

STANDARD PROCEDURE - COURTESY

LAMP REPLACEMENT..................1

STANDARD PROCEDURE - MODULE LENS

REPLACEMENT.......................2

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING.......................2

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING......................4

STANDARD PROCEDURE - COMPASS

CALIBRATION.........................5

STANDARD PROCEDURE - COMPASS

VARIATION ADJUSTMENT................5

REMOVAL.............................5

INSTALLATION..........................6

SPECIAL TOOLS

OVERHEAD CONSOLE SYSTEMS.........6

ELECTRONIC VEHICLE INFO CENTER

DESCRIPTION..........................6OPERATION............................9

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER.........9

STANDARD PROCEDURE - TIRE PRESSURE

SYSTEM TEST.......................10

REMOVAL.............................10

INSTALLATION.........................10

UNIVERSAL TRANSMITTER

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER.......................11

AMBIENT TEMP SENSOR

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR...............12

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT........12

REMOVAL.............................12

INSTALLATION.........................13

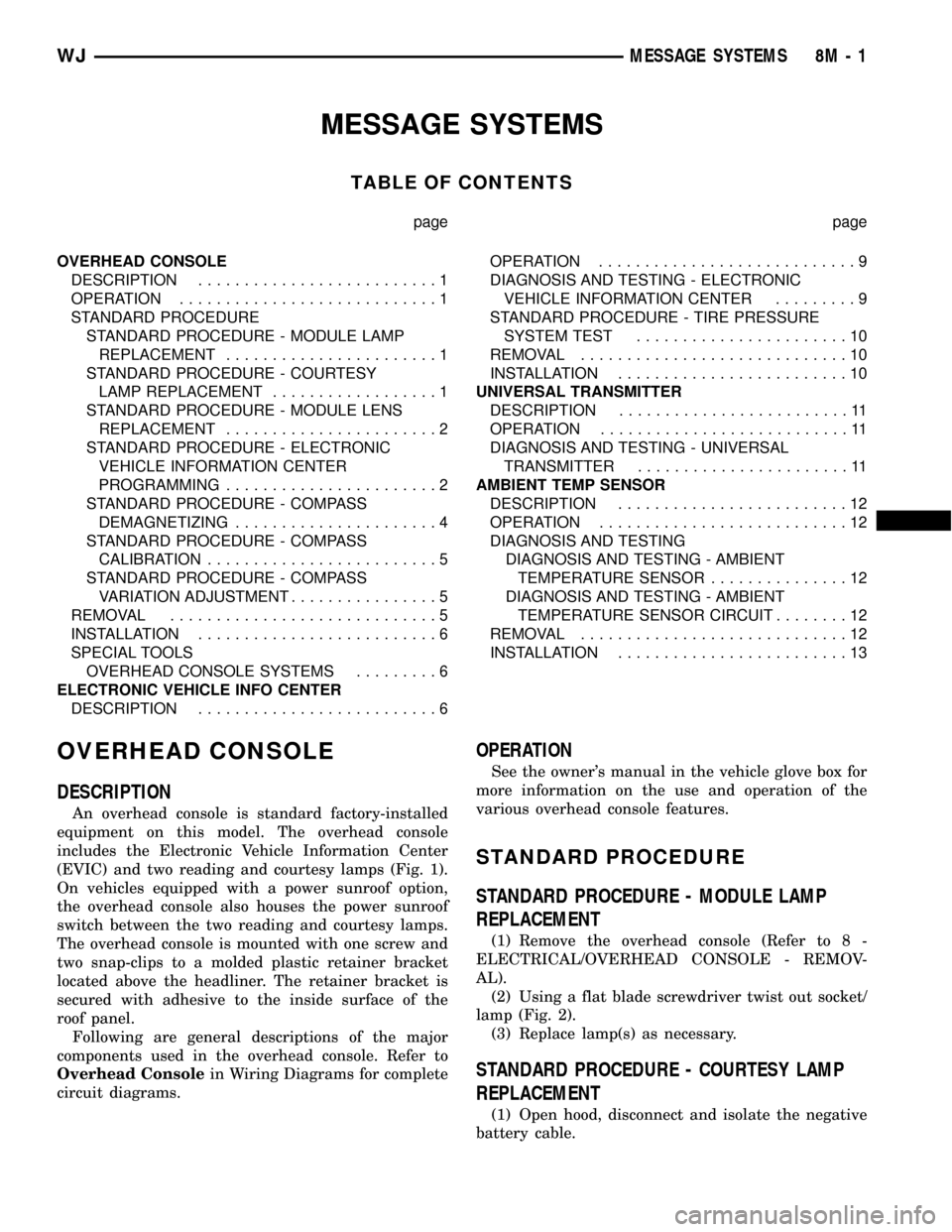

OVERHEAD CONSOLE

DESCRIPTION

An overhead console is standard factory-installed

equipment on this model. The overhead console

includes the Electronic Vehicle Information Center

(EVIC) and two reading and courtesy lamps (Fig. 1).

On vehicles equipped with a power sunroof option,

the overhead console also houses the power sunroof

switch between the two reading and courtesy lamps.

The overhead console is mounted with one screw and

two snap-clips to a molded plastic retainer bracket

located above the headliner. The retainer bracket is

secured with adhesive to the inside surface of the

roof panel.

Following are general descriptions of the major

components used in the overhead console. Refer to

Overhead Consolein Wiring Diagrams for complete

circuit diagrams.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the use and operation of the

various overhead console features.

STANDARD PROCEDURE

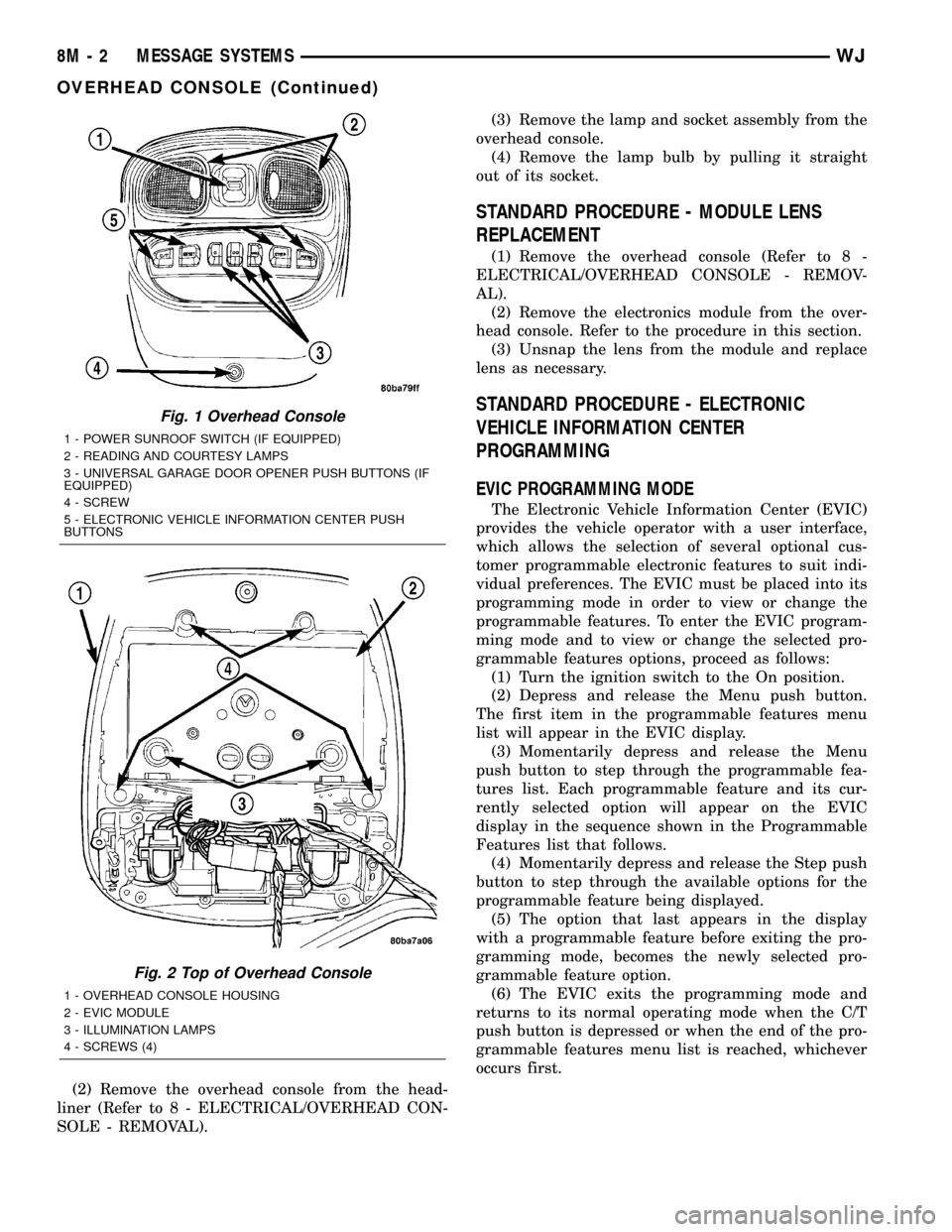

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT

(1) Remove the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOV-

AL).

(2) Using a flat blade screwdriver twist out socket/

lamp (Fig. 2).

(3) Replace lamp(s) as necessary.

STANDARD PROCEDURE - COURTESY LAMP

REPLACEMENT

(1) Open hood, disconnect and isolate the negative

battery cable.

WJMESSAGE SYSTEMS 8M - 1

Page 485 of 2199

(2) Remove the overhead console from the head-

liner (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).(3) Remove the lamp and socket assembly from the

overhead console.

(4) Remove the lamp bulb by pulling it straight

out of its socket.

STANDARD PROCEDURE - MODULE LENS

REPLACEMENT

(1) Remove the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOV-

AL).

(2) Remove the electronics module from the over-

head console. Refer to the procedure in this section.

(3) Unsnap the lens from the module and replace

lens as necessary.

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING

EVIC PROGRAMMING MODE

The Electronic Vehicle Information Center (EVIC)

provides the vehicle operator with a user interface,

which allows the selection of several optional cus-

tomer programmable electronic features to suit indi-

vidual preferences. The EVIC must be placed into its

programming mode in order to view or change the

programmable features. To enter the EVIC program-

ming mode and to view or change the selected pro-

grammable features options, proceed as follows:

(1) Turn the ignition switch to the On position.

(2) Depress and release the Menu push button.

The first item in the programmable features menu

list will appear in the EVIC display.

(3) Momentarily depress and release the Menu

push button to step through the programmable fea-

tures list. Each programmable feature and its cur-

rently selected option will appear on the EVIC

display in the sequence shown in the Programmable

Features list that follows.

(4) Momentarily depress and release the Step push

button to step through the available options for the

programmable feature being displayed.

(5) The option that last appears in the display

with a programmable feature before exiting the pro-

gramming mode, becomes the newly selected pro-

grammable feature option.

(6) The EVIC exits the programming mode and

returns to its normal operating mode when the C/T

push button is depressed or when the end of the pro-

grammable features menu list is reached, whichever

occurs first.

Fig. 1 Overhead Console

1 - POWER SUNROOF SWITCH (IF EQUIPPED)

2 - READING AND COURTESY LAMPS

3 - UNIVERSAL GARAGE DOOR OPENER PUSH BUTTONS (IF

EQUIPPED)

4 - SCREW

5 - ELECTRONIC VEHICLE INFORMATION CENTER PUSH

BUTTONS

Fig. 2 Top of Overhead Console

1 - OVERHEAD CONSOLE HOUSING

2 - EVIC MODULE

3 - ILLUMINATION LAMPS

4 - SCREWS (4)

8M - 2 MESSAGE SYSTEMSWJ

OVERHEAD CONSOLE (Continued)