lock JEEP GRAND CHEROKEE 2016 WK2 / 4.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2016, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2016 WK2 / 4.GPages: 276, PDF Size: 10.84 MB

Page 168 of 276

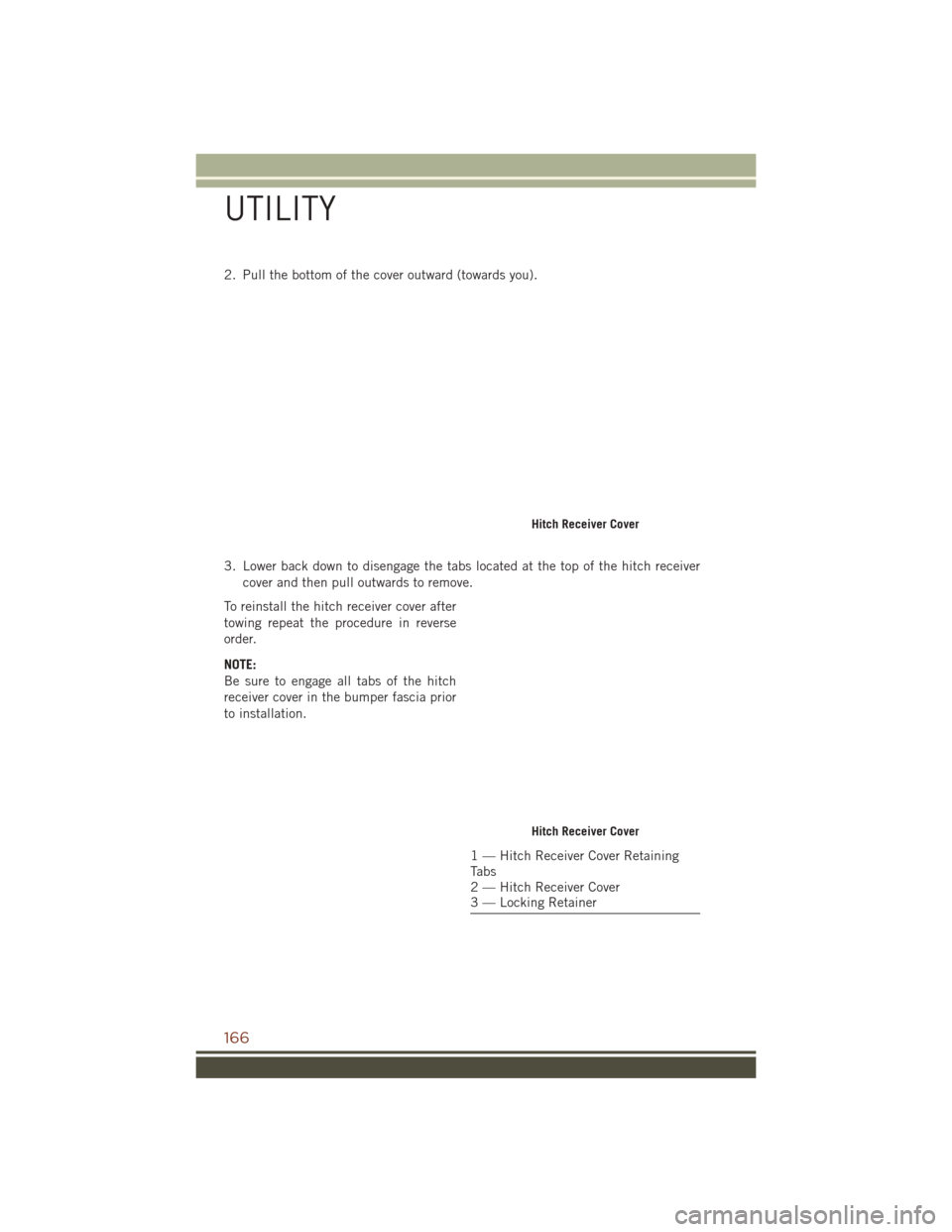

2. Pull the bottom of the cover outward (towards you).

3. Lower back down to disengage the tabs located at the top of the hitch receivercover and then pull outwards to remove.

To reinstall the hitch receiver cover after

towing repeat the procedure in reverse

order.

NOTE:

Be sure to engage all tabs of the hitch

receiver cover in the bumper fascia prior

to installation.

Hitch Receiver Cover

Hitch Receiver Cover

1 — Hitch Receiver Cover Retaining

Tabs

2 — Hitch Receiver Cover

3 — Locking Retainer

UTILITY

166

Page 183 of 276

CAUTION!

If the “Water in Fuel Indicator Light” remains on, DO NOT START the engine

before you drain the water from the fuel filters to avoid engine damage. Refer to

“Maintenance Procedures/Draining Fuel/Water Separator Filter” in “Maintaining

Your Vehicle” in your Diesel Supplement on the DVD for further information.

Extreme Cold Weather

The engine block heater is a resistance heater installed in the water jacket of the

engine. It requires a 110–115 Volt AC electrical outlet with a grounded, three-wire

extension cord.

Its use is recommended for environments that routinely fall below -10°F. It should be

used when the vehicle has not been running overnight or longer periods and should

be plugged in two hours prior to start. Its use is required for cold starts with

temperatures under -20°F.

A 12 Volt heater built into the fuel filter housing aids in preventing fuel gelling. It is

controlled by a built-in thermostat.

A Diesel Pre-Heat system both improves engine starting and reduces the amount of

white smoke generated by a warming engine.

NOTE:

The engine block heater cord is a factory installed option. If your vehicle is not

equipped, heater cords are available from your authorized MOPAR dealer.

Water In Fuel Message

If a Water In Fuel message orindicator appears in the cluster and a chime

sounds five times, the fuel/water separator will need to be drained immediately to

prevent engine damage.

Refer to “Draining Fuel Water Separator” in this guide for draining instructions or see

your dealer.

DIESEL

181

Page 184 of 276

DIESEL FUEL FILTERS/WATER SEPARATOR

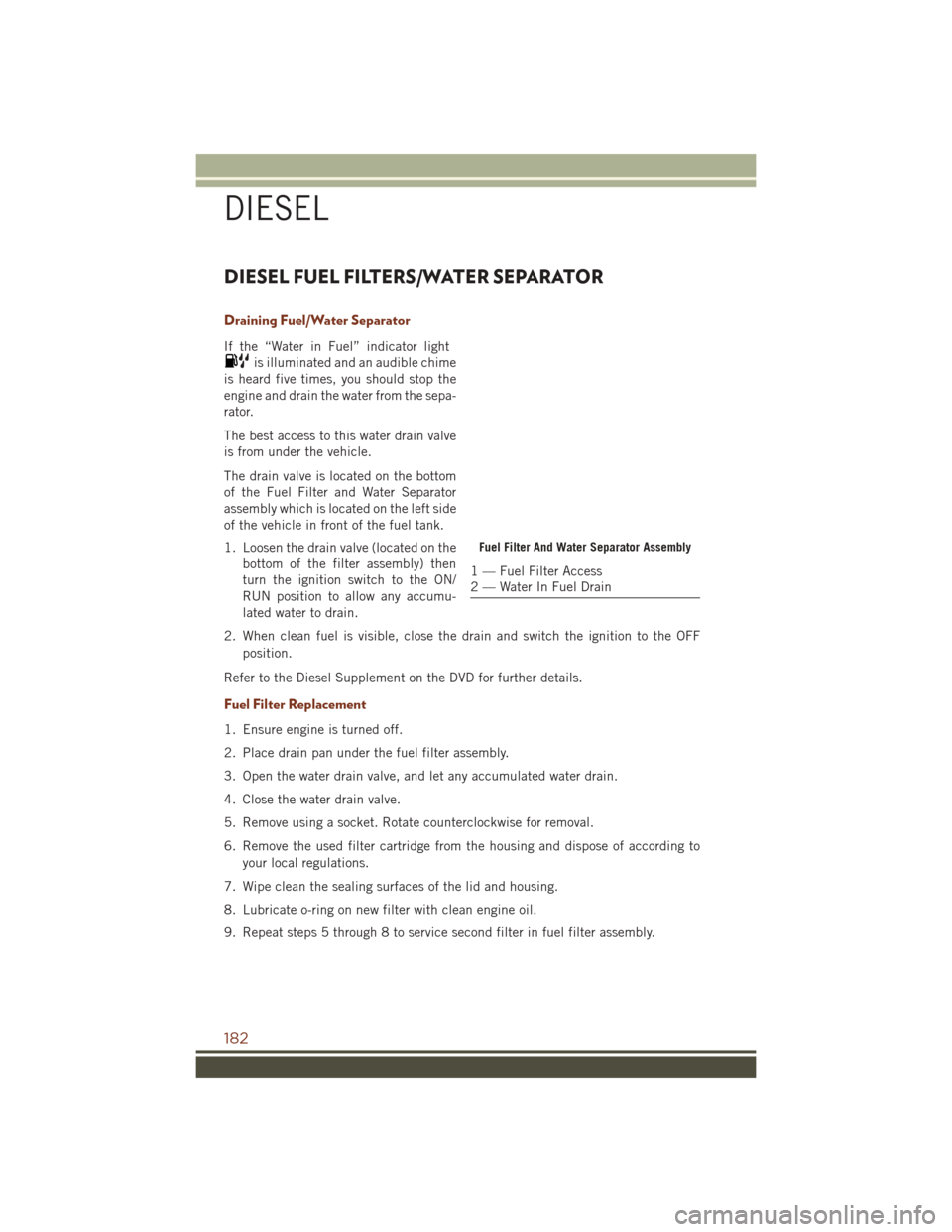

Draining Fuel/Water Separator

If the “Water in Fuel” indicator light

is illuminated and an audible chime

is heard five times, you should stop the

engine and drain the water from the sepa-

rator.

The best access to this water drain valve

is from under the vehicle.

The drain valve is located on the bottom

of the Fuel Filter and Water Separator

assembly which is located on the left side

of the vehicle in front of the fuel tank.

1. Loosen the drain valve (located on the bottom of the filter assembly) then

turn the ignition switch to the ON/

RUN position to allow any accumu-

lated water to drain.

2. When clean fuel is visible, close the drain and switch the ignition to the OFF position.

Refer to the Diesel Supplement on the DVD for further details.

Fuel Filter Replacement

1. Ensure engine is turned off.

2. Place drain pan under the fuel filter assembly.

3. Open the water drain valve, and let any accumulated water drain.

4. Close the water drain valve.

5. Remove using a socket. Rotate counterclockwise for removal.

6. Remove the used filter cartridge from the housing and dispose of according to your local regulations.

7. Wipe clean the sealing surfaces of the lid and housing.

8. Lubricate o-ring on new filter with clean engine oil.

9. Repeat steps 5 through 8 to service second filter in fuel filter assembly.

Fuel Filter And Water Separator Assembly

1 — Fuel Filter Access

2 — Water In Fuel Drain

DIESEL

182

Page 192 of 276

– Transmission Temperature Warning Light

This light indicates that there is excessive transmission fluid temperature that might

occur with severe usage such as trailer towing. If this light turns on, stop the vehicle

and run the engine at idle, with the transmission in NEUTRAL, until the light turns

off. Once the light turns off, you may continue to drive normally.

CAUTION!

Continuous driving with the Transmission Temperature Warning Light illuminated

will eventually cause severe transmission damage or transmission failure.

WARNING!

If you continue operating the vehicle when the Transmission Temperature Warning

Light is illuminated you could cause the fluid to boil over, come in contact with hot

engine or exhaust components and cause a fire.

– Anti-Lock Brake (ABS) Light

This light monitors the Anti-Lock Brake System (ABS). The light will turn on when the

ignition switch is turned to the ON/RUN position and may stay on for as long as four

seconds.

If the ABS light remains on or turns on while driving, it indicates that the Anti-Lock

portion of the brake system is not functioning and that service is required. However,

the conventional brake system will continue to operate normally if the BRAKE

warning light is not on.

If the ABS light is on, the brake system should be serviced as soon as possible to

restore the benefits of Anti-Lock brakes. If the ABS light does not turn on when the

ignition switch is turned to the ON/RUN position, have the light inspected by an

authorized dealer.

– Air Bag Warning Light

This light will turn on for four to eight seconds as a bulb check when the ignition

switch is first turned to the ON/RUN position. If the light is either not on during

starting, stays on, or turns on while driving, have the system inspected at an

authorized dealer as soon as possible. Refer to “Occupant Restraints” in “Things To

Know Before Starting Your Vehicle” in your Owner’s Manual on the DVD for further

information.

NOTE:

The Air Bag System is designed to be maintenance free.

WHAT TO DO IN EMERGENCIES

190

Page 195 of 276

– Brake Warning Light

This light monitors various brake functions, including brake fluid level and parking

brake application. If the brake light turns on, it may indicate that the parking brake

is applied, that the brake fluid level is low, or that there is a problem with the brake

system master cylinder reservoir.

If the light remains on when the parking brake has been disengaged, and the fluid

level is at the full mark on the master cylinder reservoir, it indicates a possible brake

hydraulic system malfunction or that a problem with the Brake Booster has been

detected by the Anti-Lock Brake System (ABS)/Electronic Stability Control (ESC)

system. In this case, the light will remain on until the condition has been corrected.

If the problem is related to the brake booster, the ABS pump will run when applying

the brake, and a brake pedal pulsation may be felt during each stop.

The dual brake system provides a reserve braking capacity in the event of a failure to

a portion of the hydraulic system. A leak in either half of the dual brake system is

indicated by the Brake Warning Light, which will turn on when the brake fluid level

in the master cylinder has dropped below a specified level. The light will remain on

until the cause is corrected.

Vehicles equipped with the Anti-Lock Brake System (ABS) are also equipped with

Electronic Brake Force Distribution (EBD). In the event of an EBD failure, the Brake

Warning Light will turn on along with the ABS Light. Immediate repair to the ABS

system is required.

Operation of the Brake Warning Light can be checked by turning the ignition switch

from the OFF position to the ON/RUN position. The light should illuminate for

approximately two seconds. The light should then turn off unless the parking brake

is applied or a brake fault is detected. If the light does not illuminate, have the light

inspected by an authorized dealer.

The light also will turn on when the parking brake is applied with the ignition switch

in the ON/RUN position.

NOTE:

This light shows only that the parking brake is applied. It does not show the degree

of brake application.

WARNING!

Driving a vehicle with the red brake light on is dangerous. Part of the brake system

may have failed. It will take longer to stop the vehicle. You could have a collision.

Have the vehicle checked immediately.

WHAT TO DO IN EMERGENCIES

193

Page 198 of 276

– Door Open Indicator

This indicator will illuminate when a door(s) is left open and not fully closed.

– Electronic Stability Control (ESC) OFF Indicator Light

This light indicates the Electronic Stability Control (ESC) is off.

– Windshield Washer Fluid Low Indicator

This indicator will illuminate when the windshield washer fluid is low.

– Hood Open Indicator

This indicator will illuminate when the hood is left open and not fully closed.

– Liftgate Ajar Indicator — If Equipped

This indicator will illuminate when the liftgate is left ajar and not fully closed.

Engine Oil Life Reset

Oil Change Required

Your vehicle is equipped with an engine oil change indicator system. The “Oil Change

Required” message will display in the DID for five seconds after a single chime has

sounded, to indicate the next scheduled oil change interval. The engine oil change

indicator system is duty cycle based, which means the engine oil change interval may

fluctuate, dependent upon your personal driving style.

Unless reset, this message will continue to display each time you turn the ignition

switch to the ON/RUN position or cycle the ignition to the ON/RUN position if

equipped with Keyless Enter-N-Go. To turn off the message temporarily, push and

release the OK button. To reset the oil change indicator system (after performing the

scheduled maintenance) refer to the following procedure.

Vehicles Equipped With Keyless Enter-N-Go

1. Without pushing the brake pedal, push the ENGINE START/STOP button andplace the ignition to the ON/RUN position (do not start the engine.)

2. Fully depress the accelerator pedal, slowly, three times within 10 seconds.

3. Without pushing the brake pedal, push the ENGINE START/STOP button once to return the ignition to the OFF/LOCK position.

NOTE:

If the indicator message illuminates when you start the vehicle, the oil change

indicator system did not reset. If necessary, repeat this procedure.

NOTE:

It can also be reset using the Oil Life menu in Vehicle Info.

WHAT TO DO IN EMERGENCIES

196

Page 202 of 276

Preparations For Jacking

CAUTION!

Always lift or jack the vehicle from the correct jacking points. Failure to follow this

information could cause damage to the vehicle or underbody components.

NOTE:

To assist with changing a spare tire, the air suspension system (if equipped) has a

feature which allows the automatic leveling to be disabled.

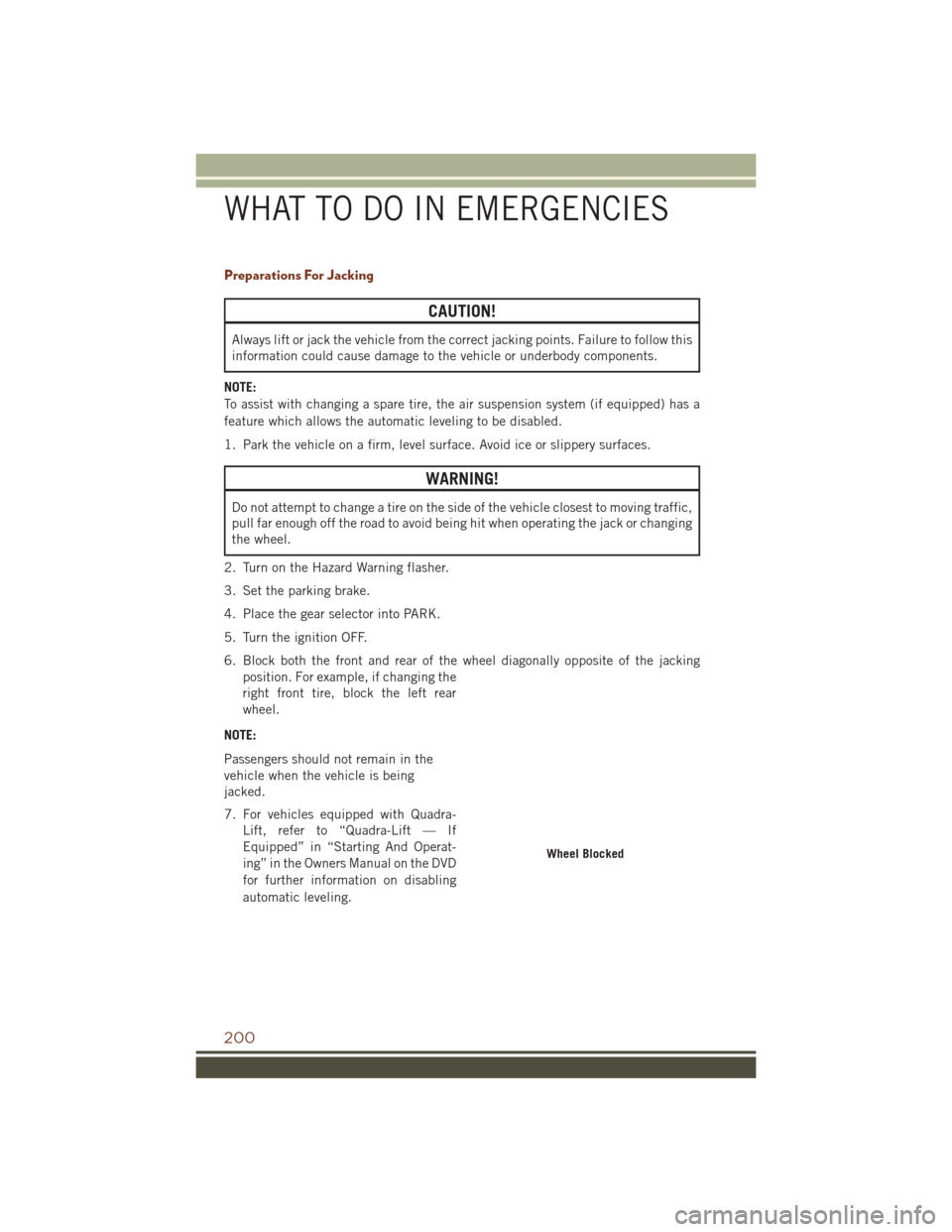

1. Park the vehicle on a firm, level surface. Avoid ice or slippery surfaces.

WARNING!

Do not attempt to change a tire on the side of the vehicle closest to moving traffic,

pull far enough off the road to avoid being hit when operating the jack or changing

the wheel.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the gear selector into PARK.

5. Turn the ignition OFF.

6. Block both the front and rear of the wheel diagonally opposite of the jacking position. For example, if changing the

right front tire, block the left rear

wheel.

NOTE:

Passengers should not remain in the

vehicle when the vehicle is being

jacked.

7. For vehicles equipped with Quadra- Lift, refer to “Quadra-Lift — If

Equipped” in “Starting And Operat-

ing” in the Owners Manual on the DVD

for further information on disabling

automatic leveling.

Wheel Blocked

WHAT TO DO IN EMERGENCIES

200

Page 205 of 276

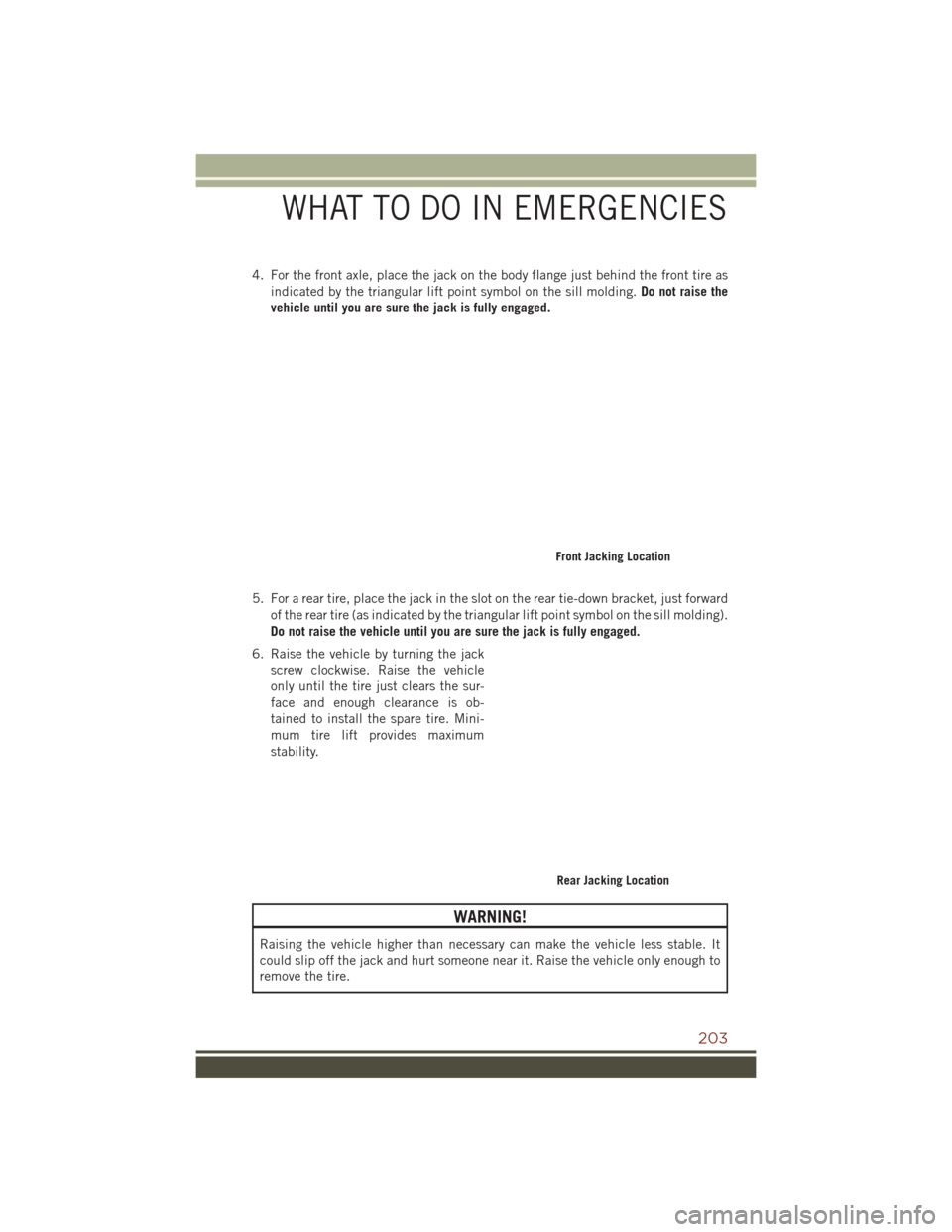

4. For the front axle, place the jack on the body flange just behind the front tire asindicated by the triangular lift point symbol on the sill molding. Do not raise the

vehicle until you are sure the jack is fully engaged.

5. For a rear tire, place the jack in the slot on the rear tie-down bracket, just forward of the rear tire (as indicated by the triangular lift point symbol on the sill molding).

Do not raise the vehicle until you are sure the jack is fully engaged.

6. Raise the vehicle by turning the jack screw clockwise. Raise the vehicle

only until the tire just clears the sur-

face and enough clearance is ob-

tained to install the spare tire. Mini-

mum tire lift provides maximum

stability.

WARNING!

Raising the vehicle higher than necessary can make the vehicle less stable. It

could slip off the jack and hurt someone near it. Raise the vehicle only enough to

remove the tire.

Front Jacking Location

Rear Jacking Location

WHAT TO DO IN EMERGENCIES

203

Page 206 of 276

7. Remove the lug nuts and wheel.

8. Position the spare wheel/tire on the vehicle and install the lug nuts with thecone-shaped end toward the wheel. Lightly tighten the nuts.

CAUTION!

Be sure to mount the spare tire with the valve stem facing outward. The vehicle

could be damaged if the spare tire is mounted incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure to follow this warning may result in

serious injury.

9. Lower the vehicle by turning the jack screw counterclockwise, and remove the jack and wheel blocks.

10. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. The correct tightness of each lug nut is 130 ft-lbs

(176 N·m). If in doubt about the correct tightness, have them checked with a

torque wrench by your authorized dealer or service station.

NOTE:

For the SRT model the correct wheel nut tightness is 110 ft lbs (149 N·m).

11. Lower the jack to the fully closed position and return it and the tools to the proper positions in the foam tray.

Installing Spare Wheel/Tire

WHAT TO DO IN EMERGENCIES

204

Page 207 of 276

12. Remove the small center cap and securely store the road wheel in the cargo area.

13. Have the aluminum road wheel andtire repaired as soon as possible,

properly secure the spare tire with

the special wing nut torqued to

3.7 ft-lbs (5 N·m), reinstall the jack

and tool kit foam tray, and latch the

rear load floor cover.

NOTE:

Do not drive with the spare tire installed

for more than 50 miles (80 km) at a max

speed of 50 mph (80 km/h).

WARNING!

A loose tire or jack thrown forward in a collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired or replaced immediately.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure to follow this warning may result in

personal injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the lug nuts in a star pattern until each nut

has been tightened twice. The correct tightness of each lug nut is 130 ft-lbs

(176 N·m). If in doubt about the correct tightness, have them checked with a

torque wrench by your authorized dealer or service station.

NOTE:

For the SRT model the correct wheel nut tightness is 110 ft lbs (149 N·m).

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly seated against the wheel.

Spare Tire

WHAT TO DO IN EMERGENCIES

205