clock JEEP GRAND CHEROKEE 2017 WK2 / 4.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2017 WK2 / 4.GPages: 372

Page 39 of 372

EXTERIOR LIGHTS

Headlight Switch

The headlight switch is located on the left

side of the instrument panel, next to the

steering wheel. The headlight switch controls

the operation of the headlights, parking

lights, instrument panel lights, cargo lights

and fog lights (if equipped).

Headlights

To turn on the headlights, rotate the head-

light switch clockwise. When the headlight

switch is on, the parking lights, taillights,

license plate light and instrument panellights are also turned on. To turn off the

headlights, rotate the headlight switch back

to the O (Off) position.

NOTE:

• Your vehicle is equipped with plastic

headlight and fog light (if equipped)

lenses that are lighter and less susceptible

to stone breakage than glass lights. Plastic

is not as scratch resistant as glass and

therefore different lens cleaning proce-

dures must be followed.

• To minimize the possibility of scratching the lenses and reducing light output, avoid

wiping with a dry cloth. To remove road

dirt, wash with a mild soap solution fol-

lowed by rinsing.

CAUTION!

Do not use abrasive cleaning components,

solvents, steel wool or other abrasive ma-

terials to clean the lenses.

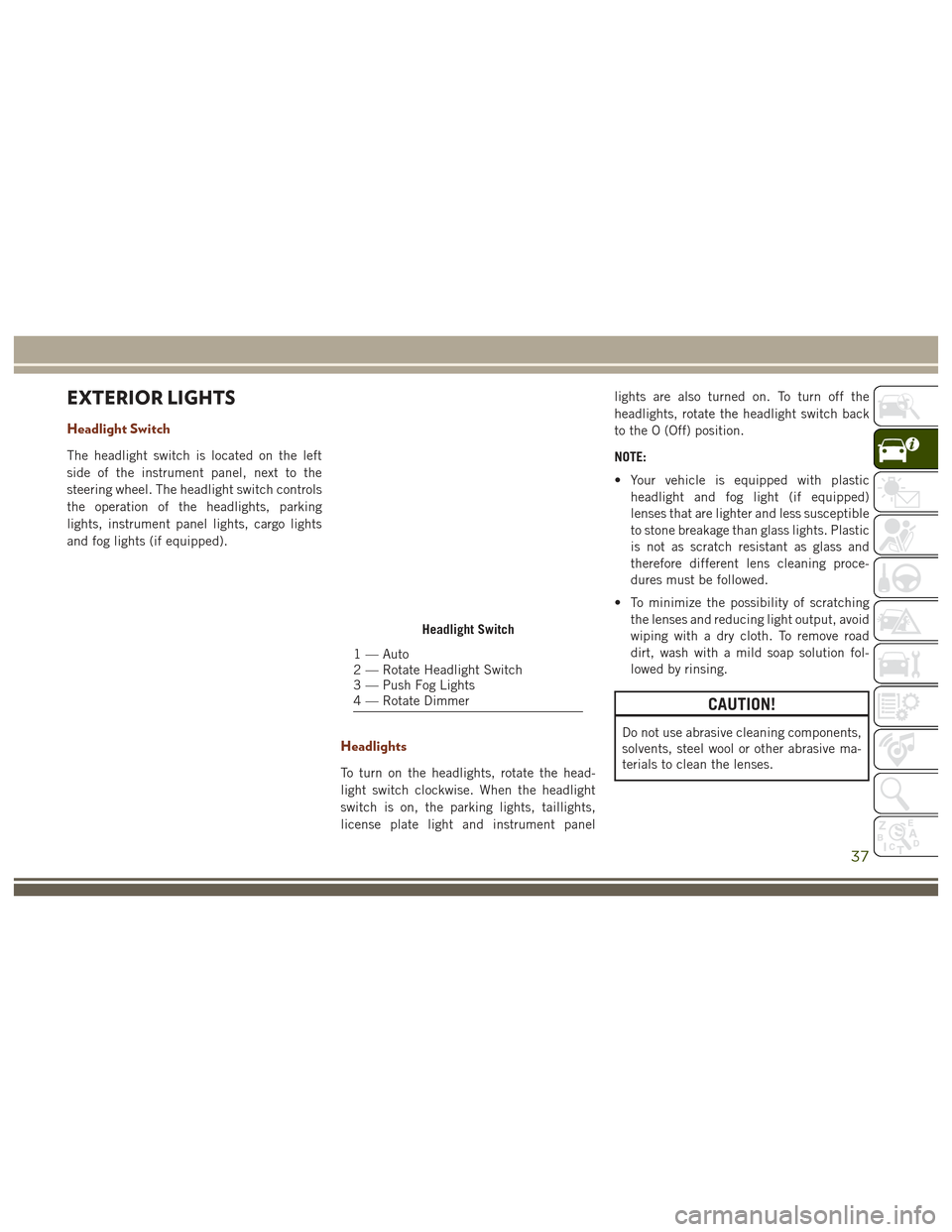

Headlight Switch

1 — Auto

2 — Rotate Headlight Switch

3 — Push Fog Lights

4 — Rotate Dimmer

37

Page 41 of 372

If the windshield or Automatic High Beam

Headlamp Control mirror is replaced, the

mirror must be re-aimed to ensure proper

performance. See your local authorized

dealer.

Parking Lights And Panel Lights

To turn on the parking lights and instrument

panel lights, rotate the headlight switch

clockwise. To turn off the parking lights,

rotate the headlight switch back to the O (Off)

position.

Headlight Delay

To aid in your exit, your vehicle is equipped

with a headlight delay that will leave the

headlights on for approximately up to 90 sec-

onds. This delay is initiated when the ignition

is turned OFF while the headlight switch is

on, and then the headlight switch is cycled

off. Headlight delay can be cancelled by

either turning the headlight switch on then

off, or by turning the ignition ON.NOTE:

This feature can be programmed through the

Uconnect system. Refer to “Uconnect Set-

tings” in “Multimedia” for further informa-

tion.

Fog Lights

The fog lights are turned on by rotating the

headlight switch to the parking light or head-

light position and pushing in the headlight

rotary control.

The fog lights will operate only when the

parking lights are on or when the vehicle

headlights are on low beam. An indicator

light located in the instrument cluster display

will illuminate when the fog lights are on. The

fog lights will turn off when the switch is

pushed a second time, when the headlight

switch is rotated to the off position, or the

high beam is selected.

Turn Signals

Move the multifunction lever up or down and

the arrows on each side of the instrument

cluster display flash to show proper operation

of the front and rear turn signal lights.

NOTE:

If either light remains on and does not flash,

or there is a very fast flash rate, check for a

defective outside light bulb. If an indicator

fails to light when the lever is moved, it would

suggest that the indicator bulb is defective.

Fog Light Operation

39

Page 50 of 372

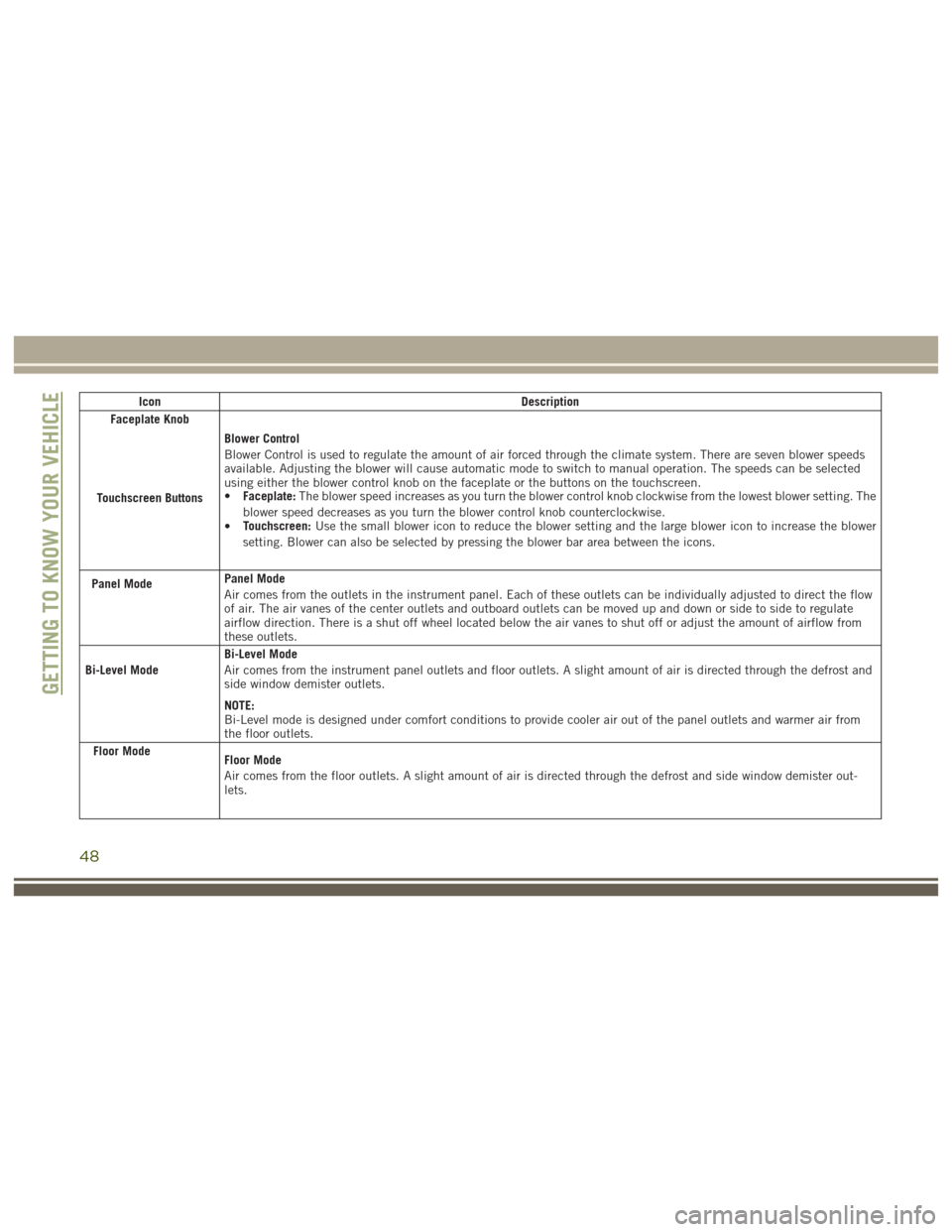

IconDescription

Faceplate Knob

Touchscreen Buttons

Blower Control

Blower Control is used to regulate the amount of air forced through the climate system. There are seven blower speeds

available. Adjusting the blower will cause automatic mode to switch to manual operation. The speeds can be selected

using either the blower control knob on the faceplate or the buttons on the touchscreen.

• Faceplate: The blower speed increases as you turn the blower control knob clockwise from the lowest blower setting. The

blower speed decreases as you turn the blower control knob counterclockwise.

• Touchscreen:

Use the small blower icon to reduce the blower setting and the large blower icon to increase the blower

setting. Blower can also be selected by pressing the blower bar area between the icons.

Panel Mode

Panel Mode

Air comes from the outlets in the instrument panel. Each of these outlets can be individually adjusted to direct the flow

of air. The air vanes of the center outlets and outboard outlets can be moved up and down or side to side to regulate

airflow direction. There is a shut off wheel located below the air vanes to shut off or adjust the amount of airflow from

these outlets.

Bi-Level Mode

Bi-Level Mode

Air comes from the instrument panel outlets and floor outlets. A slight amount of air is directed through the defrost and

side window demister outlets.

NOTE:

Bi-Level mode is designed under comfort conditions to provide cooler air out of the panel outlets and warmer air from

the floor outlets.

Floor Mode

Floor Mode

Air comes from the floor outlets. A slight amount of air is directed through the defrost and side window demister out-

lets.

GETTING TO KNOW YOUR VEHICLE

48

Page 197 of 372

Trailer Towing Weights (Maximum Trailer Weight Ratings) — SRT

Engine/TransmissionGCWR (Gross Combined Wt.

Rating) Frontal Area Max. GTW (Gross Trailer Wt.) Max. Trailer Tongue Wt. (See

Note)

6.4L Automatic 12,600 lbs (5 715 kg) 55 sq ft (5.11 sq m) 7,200 lbs (3 265 kg) 720 lbs (327 kg) Refer to local laws for maximum trailer towing speeds.

NOTE:

• The trailer tongue weight must be consid-ered as part of the combined weight of

occupants and cargo, and should never

exceed the weight referenced on the Tire

and Loading Information placard. Refer to

“Tires” in “Servicing And Maintenance” in

your Owner’s Manual at

www.jeep.com/en/owners/manuals/ for

further information.

• The manufacturer does not recommend using the run flat feature while driving a

vehicle loaded at full capacity or towing a

trailer.Trailer Hitch Receiver Cover Removal

(Summit Models) — If Equipped

Your vehicle may be equipped with a trailer

hitch receiver cover, this must be removed to

access the trailer hitch receiver (if equipped).

This hitch receiver cover is located at the

bottom center of the rear fascia.

1. Turn the two locking retainers located at

the bottom of the hitch receiver cover a

1/4 turn counterclockwise.

NOTE:

Use a suitable tool such as a coin in the

slot of the locking retainer if needed for

added leverage.

Hitch Receiver Cover

1 — Hitch Receiver Cover Tab Loca-

tions

2 — Locking Retainers

195

Page 198 of 372

2. Pull the bottom of the cover outward (to-wards you), pull downwards to disengage

the tabs located at the top of the hitch

receiver cover.

To reinstall the hitch receiver cover after

towing repeat the procedure in reverse order.

NOTE:

Be sure to engage all tabs of the hitch re-

ceiver cover in the bumper fascia prior to

installation.Trailer Hitch Receiver Cover Removal

(SRT Models) — If Equipped

Your vehicle may be equipped with a trailer

hitch receiver cover, this must be removed to

access the trailer hitch receiver (if equipped).

This hitch receiver cover is located at the

bottom center of the rear fascia.

1. Turn the two locking retainers located at the bottom of the hitch receiver cover a

1/4 turn counterclockwise.

NOTE:

Use a suitable tool such as a coin in the

slot of the locking retainer if needed for

added leverage.

Hitch Receiver Cover

Hitch Receiver Cover

1 — Hitch Receiver Cover Tab Loca-

tions

2 — Locking Retainers

STARTING AND OPERATING

196

Page 208 of 372

Bulb Replacement

High Intensity Discharge Headlamps (HID)

—

If Equipped

The headlamps are a type of high voltage

discharge tube. High voltage can remain in

the circuit even with the headlamp switch off

and the key removed. Because of this, you

should not attempt to service a headlamp bulb

yourself. If a headlamp bulb fails, take your

vehicle to an authorized dealer for service.

WARNING!

A transient high voltage occurs at the bulb

sockets of High Intensity Discharge (HID)

headlamps when the headlamp switch is

turned ON. It may cause serious electrical

shock or electrocution if not serviced prop-

erly. See your authorized dealer for ser-

vice. NOTE:

On vehicles equipped with High Intensity

Discharge (HID) headlamps, when the head-

lamps are turned on, there is a blue hue to

the lamps. This diminishes and becomes

more white after approximately 10 seconds,

as the system charges.

Halogen Headlamps — If Equipped

1. Open the hood.

2. Turn the low or high beam bulb one–

quarter turn counterclockwise to remove

from housing.

3. Disconnect the electrical connector and replace the bulb.

CAUTION!

Do not touch the new bulb with your fin-

gers. Oil contamination will severely

shorten bulb life. If the bulb comes in

contact with any oily surface, clean the

bulb with rubbing alcohol.

Front Turn Signal Lamp

1. Open the hood.

2. Turn the turn signal bulb one–quarter turncounterclockwise to remove from

housing.

3. Disconnect the electrical connector and replace the bulb.

CAUTION!

Do not touch the new bulb with your fin-

gers. Oil contamination will severely

shorten bulb life. If the bulb comes in

contact with any oily surface, clean the

bulb with rubbing alcohol.

Front Fog Lamps

1. Reach through the cutout in the splashshield and disconnect the wiring harness

from the fog lamp connector.

2. Firmly grasp the bulb by the two latches and squeeze them together to unlock the

bulb from the back of the front fog lamp

housing.

IN CASE OF EMERGENCY

206

Page 209 of 372

3. Pull the bulb straight out from the keyedopening in the housing.

CAUTION!

•Do not touch the new bulb with your

fingers. Oil contamination will severely

shorten bulb life. If the bulb comes in

contact with any oily surface, clean the

bulb with rubbing alcohol.

• Always use the correct bulb size and type for replacement. An incorrect bulb size

or type may overheat and cause damage

to the lamp, the socket or the lamp

wiring.

4. Align the index tabs of the front fog lamp bulb with the slots in the collar of the bulb

opening on the back of the front fog lamp

housing.

5. Insert the bulb into the housing until the index tabs are engaged in the slots of the

collar.

6. Firmly and evenly push the bulb straight into the lamp housing until both tabs snap

firmly into place and are fully engaged. 7. Connect the wiring harness to the front fog

lamp connector.

Rear Tail, Stop, and Turn Signal Lamps

1. Raise the liftgate.

2. Remove the two push-pins from the taillamp housing.

3. Grasp the tail lamp and pull firmly rear- ward to disengage the lamp from the ap-

erture panel. 4. Twist socket counter clockwise and re-

move from lamp.

5. Pull the bulb to remove it from the socket.

6. Replace the bulb, reinstall the socket, and reattach the lamp assembly.

Tail Lamp Push Pins

Rear Of Tail Lamp

1 — Rear Stop Lamp Bulb Socket

2 — LED Tail Connector – Do Not Re-

move

3 — Rear Turn Signal Bulb Socket

207

Page 210 of 372

Rear Liftgate Mounted Tail Lamp

1. Raise the liftgate.

2. Use a suitable tool to pry the lower trimfrom the liftgate. 3. Continue removing the trim.

4. Disconnect the two trim panel lights.

5. Tail lamps are now visible. Rotate sock-

et(s) counter clockwise.

6. Remove/replace bulb(s).

7. Reinstall the socket(s).

8. Reverse process to reinstall the liftgatetrim.

Rear Liftgate Tail Lamps

Liftgate Lower Trim

Rear Of Liftgate Tail Lamp

1 — Auxiliary LED Tail Connector – Do

Not Remove

2 — Backup Bulb Socket

IN CASE OF EMERGENCY

208

Page 221 of 372

5. For a rear tire, place the jack in the slot onthe rear tie-down bracket, just forward of

the rear tire (as indicated by the triangular

lift point symbol on the sill molding). Do

not raise the vehicle until you are sure the

jack is fully engaged. 6. Raise the vehicle by turning the jack

screw clockwise. Raise the vehicle only

until the tire just clears the surface and

enough clearance is obtained to install

the spare tire. Minimum tire lift provides

maximum stability.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

WARNING!

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

7. Remove the lug nuts and wheel.

8. Position the spare wheel/tire on the ve- hicle and install the lug nuts with the

cone-shaped end toward the wheel.

Lightly tighten the nuts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in serious

injury.Front Jacking LocationRear Jacking Location

219

Page 222 of 372

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.

9. Lower the vehicle by turning the jack screw counterclockwise, and remove the

jack and wheel blocks. 10. Finish tightening the lug nuts. Push

down on the wrench while at the end of

the handle for increased leverage.

Tighten the lug nuts in a star pattern

until each nut has been tightened twice.

The correct tightness of each lug nut is

130 ft-lbs (176 N·m). If in doubt about

the correct tightness, have them

checked with a torque wrench by your

authorized dealer or service station.

NOTE:

For the SRT model the correct wheel nut

tightness is 110 ft lbs (149 N·m).

11. Lower the jack to the fully closed posi- tion and return it and the tools to the

proper positions in the foam tray.

12. Remove the small center cap and se- curely store the road wheel in the cargo

area. 13. Have the aluminum road wheel and tire

repaired as soon as possible, properly

secure the spare tire with the special

wing nut torqued to 3.7 ft-lbs (5 N·m),

reinstall the jack and tool kit foam tray,

and latch the rear load floor cover.

NOTE:

Do not drive with the spare tire installed for

more than 50 miles (80 km) at a max speed

of 50 mph (80 km/h).

Installing Spare Wheel/Tire

Spare Tire

IN CASE OF EMERGENCY

220