spare wheel JEEP GRAND CHEROKEE 2017 WK2 / 4.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2017 WK2 / 4.GPages: 372

Page 87 of 372

Each tire, including the spare (if provided),

should be checked monthly when cold and

inflated to the inflation pressure recom-

mended by the vehicle manufacturer on the

vehicle placard or tire inflation pressure la-

bel. If your vehicle has tires of a different size

than the size indicated on the vehicle placard

or tire inflation pressure label, you should

determine the proper tire inflation pressure

for those tires.

As an added safety feature, your vehicle has

been equipped with a Tire Pressure Monitor-

ing System (TPMS) that illuminates a low tire

pressure telltale when one or more of your

tires is significantly under-inflated. Accord-

ingly, when the low tire pressure telltale illu-

minates, you should stop and check your tires

as soon as possible and inflate them to the

proper pressure. Driving on a significantly

under-inflated tire causes the tire to overheat

and can lead to tire failure. Under-inflation

also reduces fuel efficiency and tire tread

life, and may affect the vehicle’s handling

and stopping ability.Please note that the TPMS is not a substitute

for proper tire maintenance, and it is the

driver’s responsibility to maintain correct tire

pressure, even if under-inflation has not

reached the level to trigger illumination of the

TPMS low tire pressure telltale.

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate when

the system is not operating properly. The

TPMS malfunction indicator is combined

with the low tire pressure telltale. When the

system detects a malfunction, the telltale will

flash for approximately one minute and then

remain continuously illuminated. This se-

quence will continue upon subsequent ve-

hicle start-ups as long as the malfunction

exists. When the malfunction indicator is

illuminated, the system may not be able to

detect or signal low tire pressure as intended.

TPMS malfunctions may occur for a variety of

reasons, including the installation of replace-

ment or alternate tires or wheels on the ve-

hicle that prevent the TPMS from functioning

properly. Always check the TPMS malfunc-

tion telltale after replacing one or more tiresor wheels on your vehicle, to ensure that the

replacement or alternate tires and wheels

allow the TPMS to continue to function

properly.

CAUTION!

The TPMS has been optimized for the

original equipment tires and wheels.

TPMS pressures and warning have been

established for the tire size equipped on

your vehicle. Undesirable system opera-

tion or sensor damage may result when

using replacement equipment that is not

of the same size, type, and/or style. After-

market wheels can cause sensor damage.

Using aftermarket tire sealants may cause

the Tire Pressure Monitoring System

(TPMS) sensor to become inoperable. Af-

ter using an aftermarket tire sealant it is

recommended that you take your vehicle to

an authorized dealer to have your sensor

function checked.

85

Page 112 of 372

is then followed by a graphic display, with “-

-“ in place of the pressure value(s), indicat-

ing which Tire Pressure Monitoring Sensor(s)

is not being received.

If the ignition switch is cycled, this sequence

will repeat, providing the system fault still

exists. If the system fault no longer exists, the

Tire Pressure Monitoring Telltale Light will no

longer flash, the "SERVICE TPM SYSTEM"

message will not be present, and a pressure

value will be displayed instead of dashes. A

system fault can occur by any of the follow-

ing:

• Jamming due to electronic devices or driv-ing next to facilities emitting the same

Radio Frequencies as the TPM sensors.

• Installing some form of aftermarket win- dow tinting that affects radio wave signals.

• Lots of snow or ice around the wheels or wheel housings.

• Using tire chains on the vehicle.

• Using wheels/tires not equipped with TPM sensors. NOTE:

There is no tire pressure monitoring sensor in

the spare tire. The TPMS will not be able to

monitor the tire pressure. If you install the

spare tire in place of a road tire that has a

pressure below the low-pressure warning

limit, upon the next ignition switch cycle, the

Tire Pressure Monitoring Telltale Light will

remain ON, a chime will sound, and the

instrument cluster display will still display a

pressure value in the different color graphic

display and an "Inflate to XXX kPa" message

will be displayed. After driving the vehicle for

up to 20 minutes above 15 mph (24 km/h),

the Tire Pressure Monitoring Telltale Light

will flash on and off for 75 seconds and then

remain on solid. In addition, the instrument

cluster display will display a “SERVICE TPM

SYSTEM" message for five seconds and then

display dashes (- -) in place of the pressure

value. For each subsequent ignition switch

cycle, a chime will sound, the Tire Pressure

Monitoring Telltale Light will flash on and off

for 75 seconds and then remain on solid, and

the instrument cluster display will display a

"SERVICE TPM SYSTEM" message for five

seconds and then display dashes (- -) in place of the pressure value. Once you repair or

replace the original road tire, and reinstall it

on the vehicle in place of the spare tire, the

TPMS will update automatically.

In addition, the Tire Pressure Monitoring Tell-

tale Light will turn OFF and the graphic in the

instrument cluster display will display a new

pressure value instead of dashes (- -), as long

as no tire pressure is below the low-pressure

warning limit in any of the four active road

tires. The vehicle may need to be driven for

up to 20 minutes above 15 mph (24 km/h) in

order for the TPMS to receive this informa-

tion.

TPMS Deactivation — If Equipped

The TPMS can be deactivated if replacing all

four wheel and tire assemblies (road tires)

with wheel and tire assemblies that do not

have TPMS Sensors, such as when installing

winter wheel and tire assemblies on your

vehicle.

To deactivate the TPMS, first, replace all four

wheel and tire assemblies (road tires) with

tires not equipped with Tire Pressure Moni-

toring (TPM) Sensors. Then, drive the vehicle

SAFETY

110

Page 147 of 372

WARNING!

clutch pedal (if present) to check for

interference. If your floor mat interferes

with the operation of any pedal, or is not

secure to the floor, remove the floor mat

from the vehicle and place the floor mat

in your trunk.

• ONLY use the passenger’s side floor mat

on the passenger’s side floor area.

• ALWAYS make sure objects cannot fall

or slide into the driver’s side floor area

when the vehicle is moving. Objects can

become trapped under accelerator,

brake, or clutch pedals and could cause

a loss of vehicle control.

• NEVER place any objects under the floor

mat (e.g., towels, keys, etc.). These ob-

jects could change the position of the

floor mat and may cause interference

with the accelerator, brake, or clutch

pedals.

• If the vehicle carpet has been removed

and re-installed, always properly attach

WARNING!

carpet to the floor and check the floor

mat fasteners are secure to the vehicle

carpet. Fully depress each pedal to

check for interference with the accelera-

tor, brake, or clutch pedals then re-

install the floor mats.

• It is recommended to only use mild soap

and water to clean your floor mats. After

cleaning, always check your floor mat

has been properly installed and is se-

cured to your vehicle using the floor mat

fasteners by lightly pulling mat.

Periodic Safety Checks You Should Make

Outside The Vehicle

Tires

Examine tires for excessive tread wear and

uneven wear patterns. Check for stones,

nails, glass, or other objects lodged in the

tread or sidewall. Inspect the tread for cuts and cracks. Inspect sidewalls for cuts,

cracks, and bulges. Check the wheel nuts for

tightness. Check the tires (including spare)

for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and lock-

ing.

Fluid Leaks

Check area under vehicle after overnight

parking for fuel, engine coolant, oil, or other

fluid leaks. Also, if gasoline fumes are de-

tected or if fuel, power steering fluid (if

equipped), or brake fluid leaks are sus-

pected. The cause should be located and

corrected immediately.

145

Page 170 of 372

After the engine is turned off, it may be

noticed that the air suspension system oper-

ates briefly, this is normal. The system is

correcting the position of the vehicle to en-

sure a proper appearance.

To assist with changing a spare tire, the

Quadra-Lift air suspension system has a fea-

ture which allows the automatic leveling to

be disabled. Refer to “Uconnect Settings” in

“Multimedia” for further information.

NOTE:

If equipped with a touch screen radio all

enabling/disabling of air suspension features

must be done through the radio. Refer to

“Uconnect Settings” in “Multimedia” for fur-

ther information.

WARNING!

The air suspension system uses a high

pressure volume of air to operate the sys-

tem. To avoid personal injury or damage to

the system, see your authorized dealer for

service.

Air Suspension Modes

The Air Suspension system has multiple

modes to protect the system in unique situa-

tions:

Tire/Jack Mode

To assist with changing a spare tire, the air

suspension system has a feature which al-

lows the automatic leveling to be disabled.

Refer to “Uconnect Settings” in “Multime-

dia” for further information.

NOTE:

This mode is intended to be enabled with

engine running.

Transport Mode

To assist with flat bed towing, the air suspen-

sion system has a feature which will put the

vehicle into Entry/Exit height and disable the

automatic load leveling system. Refer to

“Uconnect Settings” in “Multimedia” for fur-

ther information.

NOTE:

This mode is intended to be enabled with

engine running.Wheel Alignment Mode

Before performing a wheel alignment this

mode must be enabled. Refer to “Uconnect

Settings” in “Multimedia” for further infor-

mation.

NOTE:

This mode is intended to be enabled with

engine running.

If equipped with a touch screen radio all

enabling/disabling of air suspension features

must be done through the radio. Refer to

“Uconnect Settings” in “Multimedia” for fur-

ther information.

Instrument Cluster Display Messages

When the appropriate conditions exist, a

message will appear in the instrument clus-

ter. Refer to “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel” for

further information.

Operation

The indicator lamps 3 through 6 will illumi-

nate to show the current position of the

vehicle. Flashing indicator lamps will show a

position which the system is working to

STARTING AND OPERATING

168

Page 205 of 372

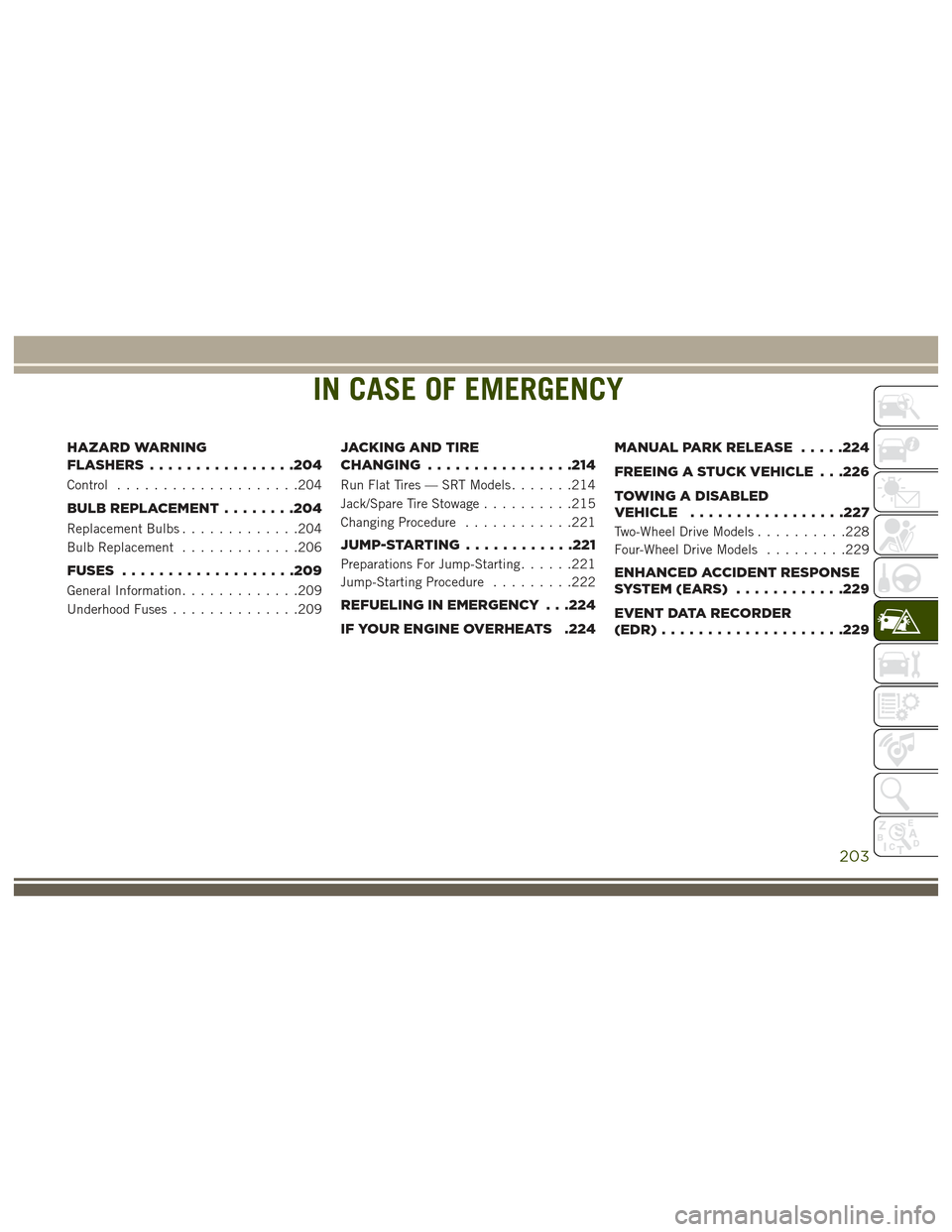

IN CASE OF EMERGENCY

HAZARD WARNING

FLASHERS................204

Control....................204

BULB REPLACEMENT ........204

Replacement Bulbs.............204

Bulb Replacement .............206

FUSES ...................209

General Information.............209

Underhood Fuses ..............209

JACKING AND TIRE

CHANGING............... .214

Run Flat Tires — SRT Models .......214

Jack/Spare Tire Stowage ..........215

Changing Procedure ............221

JUMP-STARTING............221

Preparations For Jump-Starting ......221

Jump-Starting Procedure .........222

REFUELING IN EMERGENCY . . .224

IF YOUR ENGINE OVERHEATS .224 MANUAL PARK RELEASE

.....224

FREEING A STUCK VEHICLE . . .226

TOWING A DISABLED

VEHICLE ................ .227

Two-Wheel Drive Models..........228

Four-Wheel Drive Models .........229

ENHANCED ACCIDENT RESPONSE

SYSTEM(EARS) ........... .229

EVENT DATA RECORDER

(EDR)................... .229

IN CASE OF EMERGENCY

203

Page 219 of 372

Jacking Instructions

WARNING!

Carefully follow these tire changing warn-

ings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface asfar from the edge of the roadway as

possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Chock the wheel diagonally opposite the

wheel to be raised.

• Set the parking brake firmly and set an

automatic transmission in PARK.

• Never start or run the engine with the

vehicle on a jack.

• Do not let anyone sit in the vehicle when

it is on a jack.

• Do not get under the vehicle when it is

on a jack. If you need to get under a

raised vehicle, take it to a service center

where it can be raised on a lift.

• Only use the jack in the positions indi-

cated and for lifting this vehicle during a

tire change.

WARNING!

• If working on or near a roadway, beextremely careful of motor traffic.

• To assure that spare tires, flat or in-

flated, are securely stowed, spares must

be stowed with the valve stem facing the

ground.

CAUTION!

Do not attempt to raise the vehicle by

jacking on locations other than those indi-

cated in the Jacking Instructions for this

vehicle.

1. Remove the spare tire, jack, and tools from storage. 2. Loosen (but do not remove) the wheel lug

nuts by turning them to the left, one turn,

while the wheel is still on the ground.

3. Assemble the jack and jacking tools.

Warning Label

Jack And Tools Assembled

217

Page 221 of 372

5. For a rear tire, place the jack in the slot onthe rear tie-down bracket, just forward of

the rear tire (as indicated by the triangular

lift point symbol on the sill molding). Do

not raise the vehicle until you are sure the

jack is fully engaged. 6. Raise the vehicle by turning the jack

screw clockwise. Raise the vehicle only

until the tire just clears the surface and

enough clearance is obtained to install

the spare tire. Minimum tire lift provides

maximum stability.

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

WARNING!

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

7. Remove the lug nuts and wheel.

8. Position the spare wheel/tire on the ve- hicle and install the lug nuts with the

cone-shaped end toward the wheel.

Lightly tighten the nuts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in serious

injury.Front Jacking LocationRear Jacking Location

219

Page 222 of 372

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the spare tire is

mounted incorrectly.

9. Lower the vehicle by turning the jack screw counterclockwise, and remove the

jack and wheel blocks. 10. Finish tightening the lug nuts. Push

down on the wrench while at the end of

the handle for increased leverage.

Tighten the lug nuts in a star pattern

until each nut has been tightened twice.

The correct tightness of each lug nut is

130 ft-lbs (176 N·m). If in doubt about

the correct tightness, have them

checked with a torque wrench by your

authorized dealer or service station.

NOTE:

For the SRT model the correct wheel nut

tightness is 110 ft lbs (149 N·m).

11. Lower the jack to the fully closed posi- tion and return it and the tools to the

proper positions in the foam tray.

12. Remove the small center cap and se- curely store the road wheel in the cargo

area. 13. Have the aluminum road wheel and tire

repaired as soon as possible, properly

secure the spare tire with the special

wing nut torqued to 3.7 ft-lbs (5 N·m),

reinstall the jack and tool kit foam tray,

and latch the rear load floor cover.

NOTE:

Do not drive with the spare tire installed for

more than 50 miles (80 km) at a max speed

of 50 mph (80 km/h).

Installing Spare Wheel/Tire

Spare Tire

IN CASE OF EMERGENCY

220

Page 223 of 372

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

Changing Procedure

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with thecone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in per-

sonal injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased leverage. Tighten the

lug nuts in a star pattern until each nut

has been tightened twice. The correct

tightness of each lug nut is 130 ft-lbs

(176 N·m). If in doubt about the correct

tightness, have them checked with a

torque wrench by your authorized dealer

or service station.

NOTE:

For the SRT model the correct wheel nut

tightness is 110 ft lbs (149 N·m).

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.JUMP-STARTING

If your vehicle has a discharged battery it can

be jump-started using a set of jumper cables

and a battery in another vehicle or by using a

portable battery booster pack. Jump-starting

can be dangerous if done improperly so

please follow the procedures in this section

carefully.

WARNING!

Do not attempt jump-starting if the battery

is frozen. It could rupture or explode and

cause personal injury.

CAUTION!

Do not use a portable battery booster pack

or any other booster source with a system

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.

NOTE:

When using a portable battery booster pack

follow the manufacturer's operating instruc-

tions and precautions.

Preparations For Jump-Starting

The battery in your vehicle is located under

the passenger's front seat. There are remote

locations located under the hood to assist in

jump-starting.

221

Page 267 of 372

Dark Vapor Or Black Satin Chrome Wheels

CAUTION!

If your vehicle is equipped with Dark Vapor

or Black Satin Chrome wheels DO NOT

USE wheel cleaners, abrasives or polishing

compounds. They will permanently dam-

age this finish and such damage is not

covered by the New Vehicle Limited War-

ranty. USE ONLY MILD SOAP AND WATER

WITH A SOFT CLOTH. Used on a regular

basis this is all that is required to maintain

this finish.

Tire Chains (Traction Devices)

Use of traction devices require sufficient tire-

to-body clearance. Follow these recommen-

dations to guard against damage.

• Traction device must be of proper size forthe tire, as recommended by the traction

device manufacturer.

• Install on Rear Tires Only • Due to limited clearance, Thule XG-12 Pro

or equivalent is recommended on P245/

70/R17, P265/60R18 or

265/50R20 tires.

WARNING!

Using tires of different size and type (M+S,

Snow) between front and rear axles can

cause unpredictable handling. You could

lose control and have a collision.

CAUTION!

To avoid damage to your vehicle or tires,

observe the following precautions:

• Because of restricted traction deviceclearance between tires and other sus-

pension components, it is important that

only traction devices in good condition

are used. Broken devices can cause se-

rious damage. Stop the vehicle immedi-

ately if noise occurs that could indicate

device breakage. Remove the damaged

parts of the device before further use.

CAUTION!

• Install device as tightly as possible andthen retighten after driving about ½ mile

(0.8 km).

• Do not exceed 30 mph (48 km/h).

• Drive cautiously and avoid severe turns

and large bumps, especially with a

loaded vehicle.

• Do not drive for a prolonged period on

dry pavement.

• Observe the traction device manufactur-

er’s instructions on the method of instal-

lation, operating speed, and conditions

for use. Always use the suggested oper-

ating speed of the device manufacturer’s

if it is less than 30 mph (48 km/h).

• Do not use traction devices on a com-

pact spare tire.

Tire Rotation Recommendations

The tires on the front and rear of your vehicle

operate at different loads and perform differ-

ent steering, handling, and braking func-

tions. For these reasons, they wear at unequal

rates.

265