engine JEEP GRAND CHEROKEE 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2018, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2018Pages: 368, PDF Size: 5.72 MB

Page 247 of 368

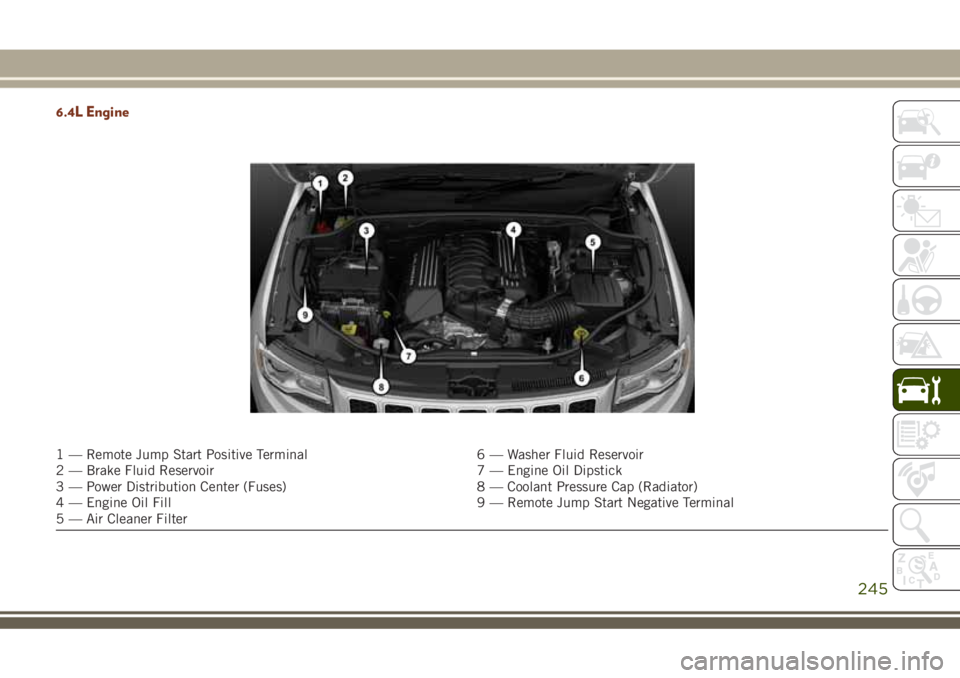

6.4L Engine

1 — Remote Jump Start Positive Terminal 6 — Washer Fluid Reservoir

2 — Brake Fluid Reservoir 7 — Engine Oil Dipstick

3 — Power Distribution Center (Fuses) 8 — Coolant Pressure Cap (Radiator)

4 — Engine Oil Fill 9 — Remote Jump Start Negative Terminal

5 — Air Cleaner Filter

245

Page 248 of 368

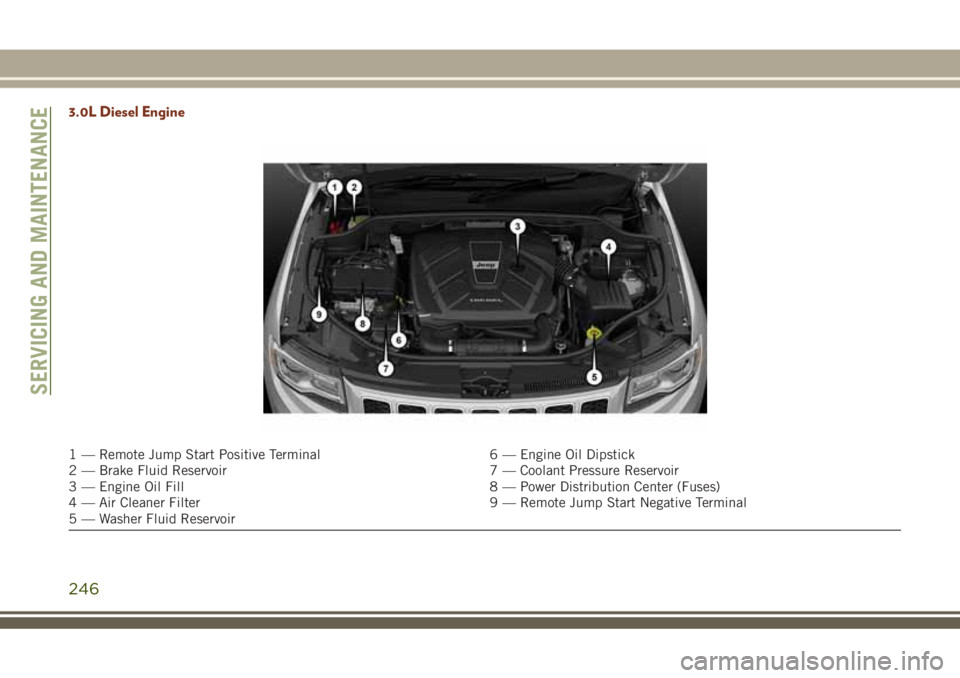

3.0L Diesel Engine

1 — Remote Jump Start Positive Terminal 6 — Engine Oil Dipstick

2 — Brake Fluid Reservoir 7 — Coolant Pressure Reservoir

3 — Engine Oil Fill 8 — Power Distribution Center (Fuses)

4 — Air Cleaner Filter 9 — Remote Jump Start Negative Terminal

5 — Washer Fluid Reservoir

SERVICING AND MAINTENANCE

246

Page 249 of 368

Checking Oil Level — Gasoline Engine

To assure proper lubrication of your vehicle’s

engine, the engine oil must be maintained at

the correct level. Check the oil level at regular

intervals, such as every fuel stop. The best

time to check the engine oil level is about five

minutes after a fully warmed up engine is

shut off.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil

level readings. Always maintain the oil level

within the SAFE zone on the dipstick. Adding

one quart of oil when the reading is at the

bottom of the SAFE zone will result in a

reading at the top of the safe zone on these

engines.

CAUTION!

Overfilling or underfilling the crankcase

will cause aeration or loss of oil pressure.

This could damage your engine.

Checking Oil Level — 3.0 Diesel Engine

To assure proper lubrication of your vehicle's

engine, the engine oil must be maintained at

the correct level. Check the oil level at regular

intervals. The best time to check the oil level

is before starting the engine after it has been

parked overnight. When checking oil after

operating the engine, first ensure the engine

is at full operating temperature, then wait for

five minutes after engine shutdown to check

the oil.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil

level readings. Add oil only when the level on

the dipstick is below the “MIN” mark. The

total capacity from the MIN mark to the MAX

mark is 1 qt (1 L).

CAUTION!

Overfilling or underfilling the crankcase

will cause oil aeration or loss of oil pres-

sure. This could damage your engine.NOTE:

It is possible for your oil level to be slightly

higher than a previous check. This would be

due to diesel fuel that may temporarily be in

the crankcase due to operation of the diesel

particulate filter regeneration strategy. This

fuel will evaporate out under normal opera-

tion.

Never operate the engine with oil level below

the “MIN” mark or above the upper “MAX”

mark.

Adding Washer Fluid

The instrument cluster display will indicate

when the washer fluid level is low. When the

sensor detects a low fluid level, the wind-

shield will light on the vehicle graphic outline

and the “WASHER FLUID LOW” message

will be displayed.

The fluid reservoir for the windshield washers

and the rear window washer is shared. The

fluid reservoir is located in the engine com-

partment, be sure to check the fluid level at

regular intervals. Fill the reservoir with wind-

shield washer solvent only (not radiator anti-

freeze). When refilling the washer fluid reser-

247

Page 253 of 368

CAUTION!

The cabin air filter is identified with an

arrow to indicate airflow direction through

the filter. Failure to properly install the

filter will result in the need to replace it

more often.

8. Reinstall the glove compartment door on

the door hinge and reattach the tension

tether by inserting the tether clip in the

glove compartment and sliding the clip

away from the face of the glove compart-

ment door.

9. Push the door to the near closed position

to reengage the glove compartment travel

stops.

NOTE:

Ensure the glove compartment door

hinges and glove compartment travel

stops are fully engaged.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades

and the windshield periodically with a sponge

or soft cloth and a mild nonabrasive cleaner.

This will remove accumulations of salt or road

film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using

the wipers to remove salt or dirt from a dry

windshield.

Avoid using the wiper blades to remove frost

or ice from the windshield. Keep the blade

rubber out of contact with petroleum prod-

ucts such as engine oil, gasoline, etc.

NOTE:

Life expectancy of wiper blades varies de-

pending on geographical area and frequency

of use. Poor performance of blades may be

present with chattering, marks, water lines or

wet spots. If any of these conditions are

present, clean the wiper blades or replace as

necessary.The wiper blades and wiper arms should be

inspected periodically, not just when wiper

performance problems are experienced. This

inspection should include the following

points:

• Wear Or Uneven Edges

• Foreign Material

• Hardening Or Cracking

• Deformation Or Fatigue

If a wiper blade or wiper arm is damaged,

replace the affected wiper arm or blade with a

new unit. Do not attempt to repair a wiper

arm or blade that is damaged.

Front Wiper Blade Removal/Installation

CAUTION!

Do not allow the wiper arm to spring back

against the glass without the wiper blade

in place or the glass may be damaged.

251

Page 256 of 368

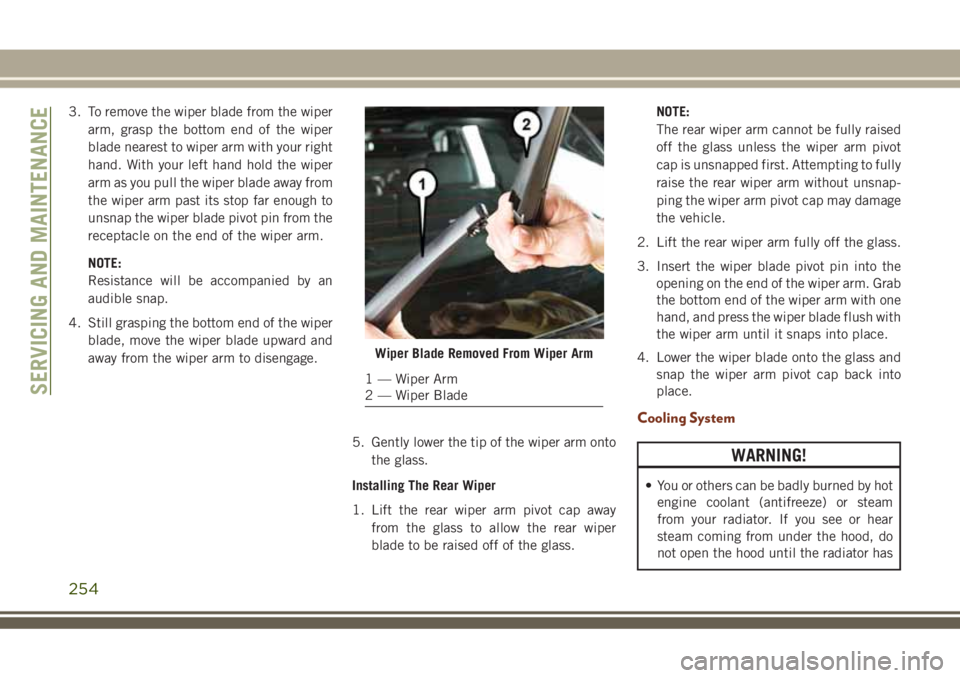

3. To remove the wiper blade from the wiper

arm, grasp the bottom end of the wiper

blade nearest to wiper arm with your right

hand. With your left hand hold the wiper

arm as you pull the wiper blade away from

the wiper arm past its stop far enough to

unsnap the wiper blade pivot pin from the

receptacle on the end of the wiper arm.

NOTE:

Resistance will be accompanied by an

audible snap.

4. Still grasping the bottom end of the wiper

blade, move the wiper blade upward and

away from the wiper arm to disengage.

5. Gently lower the tip of the wiper arm onto

the glass.

Installing The Rear Wiper

1. Lift the rear wiper arm pivot cap away

from the glass to allow the rear wiper

blade to be raised off of the glass.NOTE:

The rear wiper arm cannot be fully raised

off the glass unless the wiper arm pivot

cap is unsnapped first. Attempting to fully

raise the rear wiper arm without unsnap-

ping the wiper arm pivot cap may damage

the vehicle.

2. Lift the rear wiper arm fully off the glass.

3. Insert the wiper blade pivot pin into the

opening on the end of the wiper arm. Grab

the bottom end of the wiper arm with one

hand, and press the wiper blade flush with

the wiper arm until it snaps into place.

4. Lower the wiper blade onto the glass and

snap the wiper arm pivot cap back into

place.

Cooling System

WARNING!

• You or others can be badly burned by hot

engine coolant (antifreeze) or steam

from your radiator. If you see or hear

steam coming from under the hood, do

not open the hood until the radiator has

Wiper Blade Removed From Wiper Arm

1 — Wiper Arm

2 — Wiper BladeSERVICING AND MAINTENANCE

254

Page 257 of 368

WARNING!

had time to cool. Never open a cooling

system pressure cap when the radiator

or coolant bottle is hot.

• Keep hands, tools, clothing, and jewelry

away from the radiator cooling fan when

the hood is raised. The fan starts auto-

matically and may start at any time,

whether the engine is running or not.

• When working near the radiator cooling

fan, disconnect the fan motor lead or

turn the ignition to the OFF mode. The

fan is temperature controlled and can

start at any time the ignition is in the ON

mode.

Engine Coolant Checks

Check the engine coolant (antifreeze) protec-

tion every 12 months (before the onset of

freezing weather, where applicable). If the

engine coolant (antifreeze) is dirty, the sys-

tem should be drained, flushed, and refilled

with fresh OAT coolant (conforming to

MS.90032) by an authorized dealer. Check

the front of the A/C condenser for any accu-mulation of bugs, leaves, etc. If dirty, clean

by gently spraying water from a garden hose

vertically down the face of the condenser.

Check the engine cooling system hoses for

brittle rubber, cracking, tears, cuts, and

tightness of the connection at the coolant

recovery bottle and radiator. Inspect the en-

tire system for leaks. DO NOT REMOVE THE

COOLANT PRESSURE CAP WHEN THE

COOLING SYSTEM IS HOT.

RAISING THE VEHICLE

In the case where it is necessary to raise the

vehicle, go to an authorized dealer or service

station.

TIRES

Tires — General Information

Tire Pressure

Proper tire inflation pressure is essential to

the safe and satisfactory operation of your

vehicle. Four primary areas are affected by

improper tire pressure:

• Safety and Vehicle Stability• Economy

• Tread Wear

• Ride Comfort

Safety

WARNING!

• Improperly inflated tires are dangerous

and can cause collisions.

• Underinflation increases tire flexing and

can result in overheating and tire failure.

• Overinflation reduces a tire's ability to

cushion shock. Objects on the road and

chuckholes can cause damage that re-

sult in tire failure.

• Overinflated or underinflated tires can

affect vehicle handling and can fail sud-

denly, resulting in loss of vehicle control.

• Unequal tire pressures can cause steer-

ing problems. You could lose control of

your vehicle.

• Unequal tire pressures from one side of

the vehicle to the other can cause the

vehicle to drift to the right or left.

255

Page 267 of 368

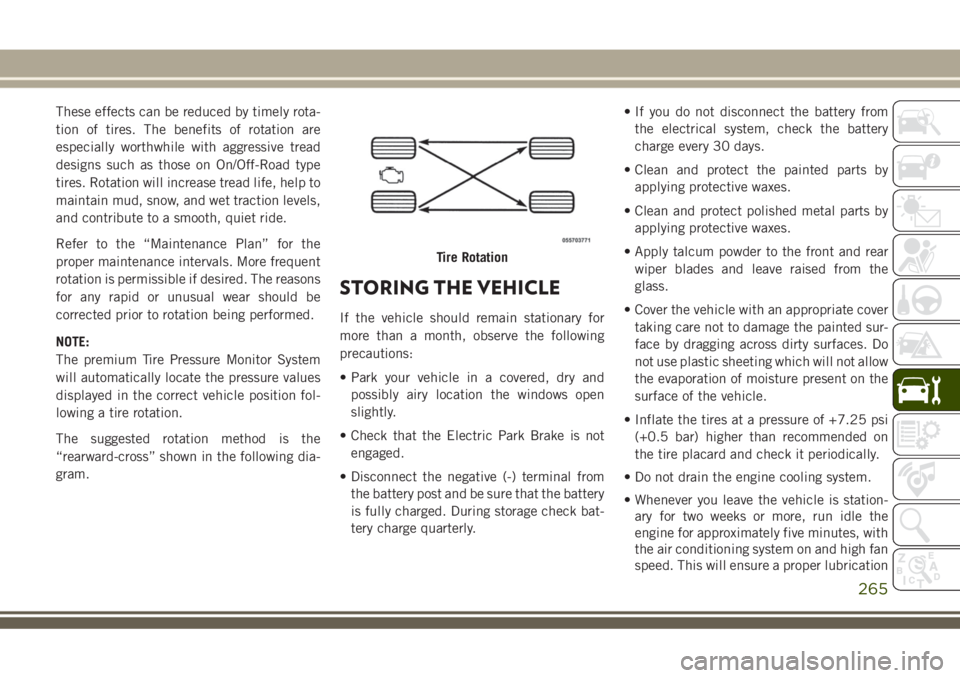

These effects can be reduced by timely rota-

tion of tires. The benefits of rotation are

especially worthwhile with aggressive tread

designs such as those on On/Off-Road type

tires. Rotation will increase tread life, help to

maintain mud, snow, and wet traction levels,

and contribute to a smooth, quiet ride.

Refer to the “Maintenance Plan” for the

proper maintenance intervals. More frequent

rotation is permissible if desired. The reasons

for any rapid or unusual wear should be

corrected prior to rotation being performed.

NOTE:

The premium Tire Pressure Monitor System

will automatically locate the pressure values

displayed in the correct vehicle position fol-

lowing a tire rotation.

The suggested rotation method is the

“rearward-cross” shown in the following dia-

gram.

STORING THE VEHICLE

If the vehicle should remain stationary for

more than a month, observe the following

precautions:

• Park your vehicle in a covered, dry and

possibly airy location the windows open

slightly.

• Check that the Electric Park Brake is not

engaged.

• Disconnect the negative (-) terminal from

the battery post and be sure that the battery

is fully charged. During storage check bat-

tery charge quarterly.• If you do not disconnect the battery from

the electrical system, check the battery

charge every 30 days.

• Clean and protect the painted parts by

applying protective waxes.

• Clean and protect polished metal parts by

applying protective waxes.

• Apply talcum powder to the front and rear

wiper blades and leave raised from the

glass.

• Cover the vehicle with an appropriate cover

taking care not to damage the painted sur-

face by dragging across dirty surfaces. Do

not use plastic sheeting which will not allow

the evaporation of moisture present on the

surface of the vehicle.

• Inflate the tires at a pressure of +7.25 psi

(+0.5 bar) higher than recommended on

the tire placard and check it periodically.

• Do not drain the engine cooling system.

• Whenever you leave the vehicle is station-

ary for two weeks or more, run idle the

engine for approximately five minutes, with

the air conditioning system on and high fan

speed. This will ensure a proper lubrication

Tire Rotation

265

Page 268 of 368

of the system, thus minimizing the possi-

bility of damage to the compressor when

the vehicle is put back into operation.

NOTE:

When the vehicle has not been started or

driven for at least 30 days, an Extended Park

Start Procedure is required to start the ve-

hicle. Refer to “Starting The Engine” in

“Starting And Operating” for further

information.

CAUTION!

Before removal of the positive and nega-

tive terminals to the battery, wait at least a

minute with ignition switch in the OFF

position and close the driver’s door. When

reconnecting the positive and negative ter-

minals to the battery be sure the ignition

switch is in the OFF position and the

driver’s door is closed.

BODYWORK

Preserving The Bodywork

Washing

• Wash your vehicle regularly. Always wash

your vehicle in the shade using a mild car

wash soap, and rinse the panels completely

with clear water.

• Use a high quality cleaner wax to remove

road film, stains and to protect your paint

finish. Take care never to scratch the paint.

• Avoid using abrasive compounds and power

buffing that may diminish the gloss or thin

out the paint finish.

CAUTION!

• Do not use abrasive or strong cleaning

materials such as steel wool or scouring

powder that will scratch metal and

painted surfaces.

• Use of power washers exceeding

1,200 psi (8,274 kPa) can result in

damage or removal of paint and decals.

Special Care

• If you drive on salted or dusty roads or if you

drive near the ocean, hose off the undercar-

riage at least once a month.

• It is important that the drain holes in the

lower edges of the doors, rocker panels, and

trunk be kept clear and open.

• If you detect any stone chips or scratches in

the paint, touch them up immediately. The

cost of such repairs is considered the re-

sponsibility of the owner.

• If your vehicle is damaged due to a collision

or similar cause that destroys the paint and

protective coating, have your vehicle re-

paired as soon as possible. The cost of such

repairs is considered the responsibility of

the owner.

•

If you carry special cargo such as chemicals,

fertilizers, de-icer salt, etc., be sure that such

materials are well packaged and sealed.

•If a lot of driving is done on gravel roads,

consider mud or stone shields behind each

wheel.

• An authorized dealer has touch up paint to

match the color of your vehicle.

SERVICING AND MAINTENANCE

266

Page 271 of 368

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA.......270

Vehicle Identification Number......270

WHEEL AND TIRE TORQUE SPECI-

FICATIONS................270

Torque Specifications............271

FUEL REQUIREMENTS — GASOLINE

ENGINES..................271

3.6L Engine.................271

5.7L Engine.................272

6.2L/6.4L Engine..............272

Methanol...................272

Ethanol....................273

Reformulated Gasoline..........273Do Not Use E-85 In Non-Flex Fuel

Vehicles....................273

CNG And LP Fuel System

Modifications.................273

Materials Added To Fuel.........273

Fuel Icon Identification Compliant To

EN16942...................274

Carbon Monoxide Warnings........275FUEL REQUIREMENTS – DIESEL EN-

GINE.....................275

Fuel Icon Identification Compliant To

EN16942...................276

NON-SRT FLUID CAPACITIES. . .278SRT FLUID CAPACITIES.......279

FLUIDS AND LUBRICANTS NON-

SRT......................279

Engine....................280

Chassis....................281

FLUIDS AND LUBRICANTS —

SRT......................282

Engine.....................282

Chassis....................282

MOPAR ACCESSORIES.......283

Authentic Accessories By Mopar.....283

TECHNICAL SPECIFICATIONS

269

Page 273 of 368

nuts/bolts should be torqued using a properly

calibrated torque wrench using a high quality

six sided (hex) deep wall socket.

Torque Specifications

Base Model Vehicle

Lug Nut/Bolt

Torque**Lug Nut/Bolt

SizeLug Nut/Bolt

Socket Size

130 Ft-Lbs

(176 N·m)M14 x 1.50 22 mm

SRT Model Vehicle

Lug Nut/Bolt

Torque**Lug Nut/Bolt

SizeLug Nut/Bolt

Socket Size

110 Ft-Lbs

(149 N·m)M14 x 1.50 22 mm

**Use only your authorized dealer recom-

mended lug nuts/bolts and clean or remove

any dirt or oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion

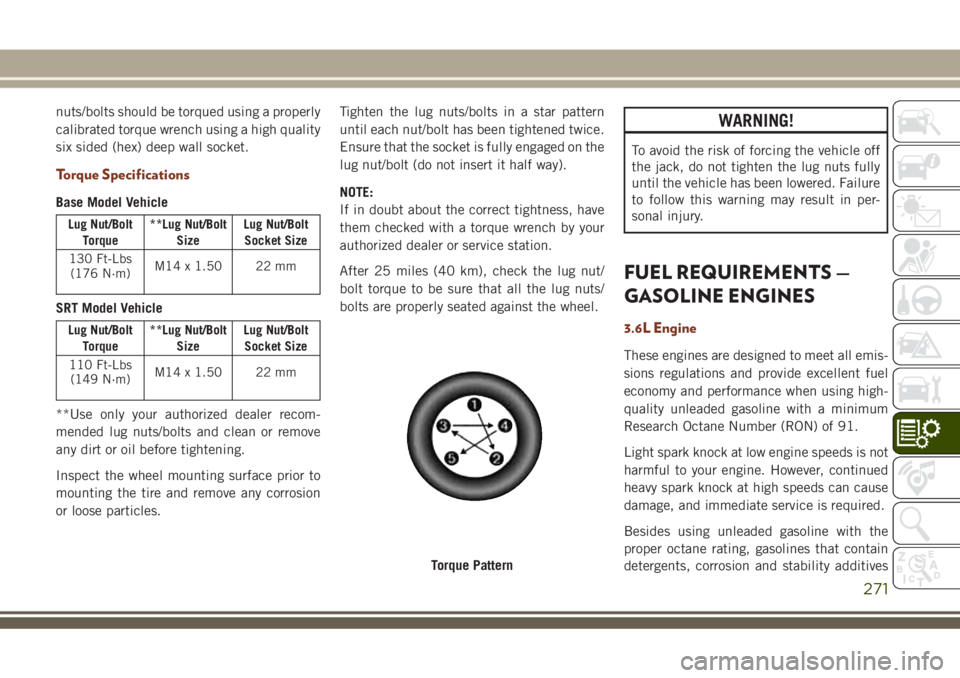

or loose particles.Tighten the lug nuts/bolts in a star pattern

until each nut/bolt has been tightened twice.

Ensure that the socket is fully engaged on the

lug nut/bolt (do not insert it half way).

NOTE:

If in doubt about the correct tightness, have

them checked with a torque wrench by your

authorized dealer or service station.

After 25 miles (40 km), check the lug nut/

bolt torque to be sure that all the lug nuts/

bolts are properly seated against the wheel.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the lug nuts fully

until the vehicle has been lowered. Failure

to follow this warning may result in per-

sonal injury.

FUEL REQUIREMENTS —

GASOLINE ENGINES

3.6L Engine

These engines are designed to meet all emis-

sions regulations and provide excellent fuel

economy and performance when using high-

quality unleaded gasoline with a minimum

Research Octane Number (RON) of 91.

Light spark knock at low engine speeds is not

harmful to your engine. However, continued

heavy spark knock at high speeds can cause

damage, and immediate service is required.

Besides using unleaded gasoline with the

proper octane rating, gasolines that contain

detergents, corrosion and stability additives

Torque Pattern

271