engine JEEP GRAND CHEROKEE 2018 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2018, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2018Pages: 368, PDF Size: 5.72 MB

Page 196 of 368

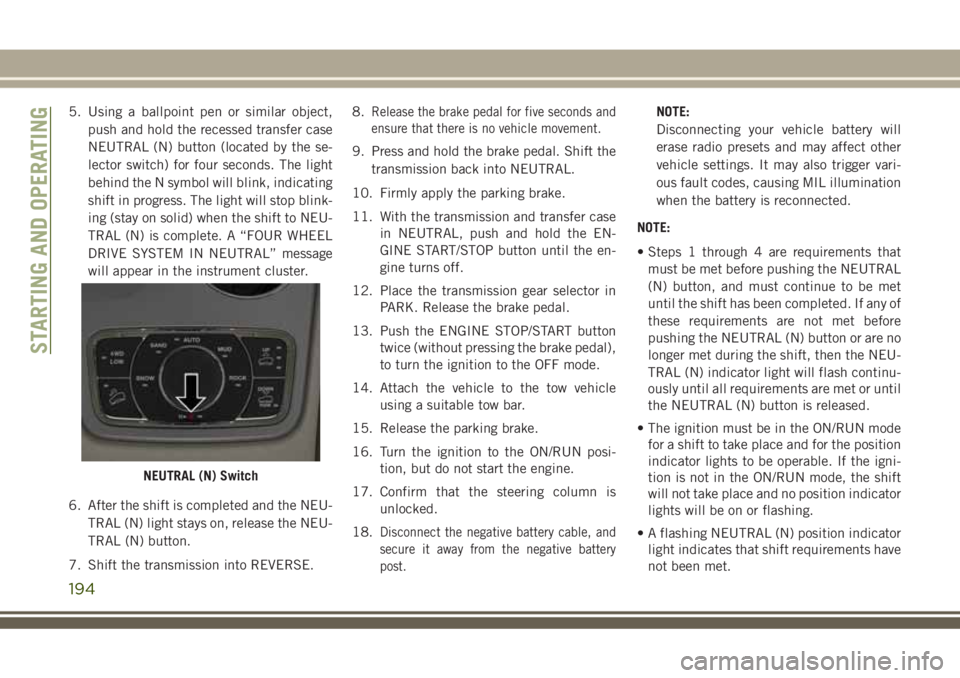

5. Using a ballpoint pen or similar object,

push and hold the recessed transfer case

NEUTRAL (N) button (located by the se-

lector switch) for four seconds. The light

behind the N symbol will blink, indicating

shift in progress. The light will stop blink-

ing (stay on solid) when the shift to NEU-

TRAL (N) is complete. A “FOUR WHEEL

DRIVE SYSTEM IN NEUTRAL” message

will appear in the instrument cluster.

6. After the shift is completed and the NEU-

TRAL (N) light stays on, release the NEU-

TRAL (N) button.

7. Shift the transmission into REVERSE.8.Release the brake pedal for five seconds and

ensure that there is no vehicle movement.

9. Press and hold the brake pedal. Shift the

transmission back into NEUTRAL.

10. Firmly apply the parking brake.

11. With the transmission and transfer case

in NEUTRAL, push and hold the EN-

GINE START/STOP button until the en-

gine turns off.

12. Place the transmission gear selector in

PARK. Release the brake pedal.

13. Push the ENGINE STOP/START button

twice (without pressing the brake pedal),

to turn the ignition to the OFF mode.

14. Attach the vehicle to the tow vehicle

using a suitable tow bar.

15. Release the parking brake.

16. Turn the ignition to the ON/RUN posi-

tion, but do not start the engine.

17. Confirm that the steering column is

unlocked.

18.

Disconnect the negative battery cable, and

secure it away from the negative battery

post.

NOTE:

Disconnecting your vehicle battery will

erase radio presets and may affect other

vehicle settings. It may also trigger vari-

ous fault codes, causing MIL illumination

when the battery is reconnected.

NOTE:

• Steps 1 through 4 are requirements that

must be met before pushing the NEUTRAL

(N) button, and must continue to be met

until the shift has been completed. If any of

these requirements are not met before

pushing the NEUTRAL (N) button or are no

longer met during the shift, then the NEU-

TRAL (N) indicator light will flash continu-

ously until all requirements are met or until

the NEUTRAL (N) button is released.

• The ignition must be in the ON/RUN mode

for a shift to take place and for the position

indicator lights to be operable. If the igni-

tion is not in the ON/RUN mode, the shift

will not take place and no position indicator

lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator

light indicates that shift requirements have

not been met.

NEUTRAL (N) Switch

STARTING AND OPERATING

194

Page 197 of 368

• If the vehicle is equipped with Quadra-Lift

air suspension, the engine should be

started and left running for a minimum of

60 seconds (with all the doors closed) at

least once every 24 hours. This process

allows the air suspension to adjust the

vehicle’s ride height to compensate for

temperature effects.

Shifting Out Of NEUTRAL (N)

Use the following procedure to prepare your

vehicle for normal usage.

1. Bring the vehicle to a complete stop, leav-

ing it connected to the tow vehicle.

2. Firmly apply the parking brake.

3. Reconnect the negative battery cable.

4. Turn the ignition to the LOCK/OFF mode.

5. Start the engine.

6. Press and hold the brake pedal.

7. Shift the transmission into NEUTRAL.

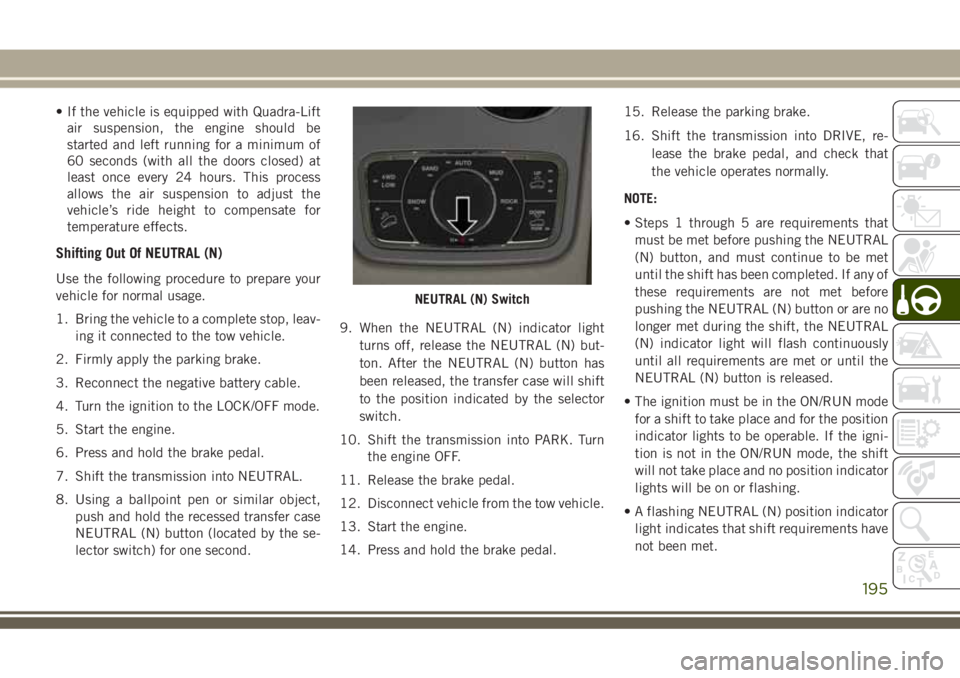

8. Using a ballpoint pen or similar object,

push and hold the recessed transfer case

NEUTRAL (N) button (located by the se-

lector switch) for one second.9. When the NEUTRAL (N) indicator light

turns off, release the NEUTRAL (N) but-

ton. After the NEUTRAL (N) button has

been released, the transfer case will shift

to the position indicated by the selector

switch.

10. Shift the transmission into PARK. Turn

the engine OFF.

11. Release the brake pedal.

12. Disconnect vehicle from the tow vehicle.

13. Start the engine.

14. Press and hold the brake pedal.15. Release the parking brake.

16. Shift the transmission into DRIVE, re-

lease the brake pedal, and check that

the vehicle operates normally.

NOTE:

• Steps 1 through 5 are requirements that

must be met before pushing the NEUTRAL

(N) button, and must continue to be met

until the shift has been completed. If any of

these requirements are not met before

pushing the NEUTRAL (N) button or are no

longer met during the shift, the NEUTRAL

(N) indicator light will flash continuously

until all requirements are met or until the

NEUTRAL (N) button is released.

• The ignition must be in the ON/RUN mode

for a shift to take place and for the position

indicator lights to be operable. If the igni-

tion is not in the ON/RUN mode, the shift

will not take place and no position indicator

lights will be on or flashing.

• A flashing NEUTRAL (N) position indicator

light indicates that shift requirements have

not been met.

NEUTRAL (N) Switch

195

Page 199 of 368

IN CASE OF EMERGENCY

HAZARD WARNING FLASHERS .198

Control....................198

BULB REPLACEMENT........198

Replacement Bulbs.............198

Bulb Replacement.............200

FUSES...................204

General Information.............204

Underhood Fuses..............204

JACKING AND TIRE CHANGING. .209

Run Flat Tires — SRT Models.......209

Jack Location................209Preparations For Jacking.........210

Jacking Instructions............210

Road Tire Installation............214

Declaration Of Conformance.......214

Jack Usage Precautions..........217

JUMP STARTING............217

Preparations For Jump Start........218

Jump Starting Procedure..........219

REFUELING IN EMERGENCY . . .220

IF YOUR ENGINE OVERHEATS .220

MANUAL PARK RELEASE......221FREEING A STUCK VEHICLE . . .222

TOWING A DISABLED VEHICLE .223

Without The Key Fob............225

Two-Wheel Drive Models..........225

Four-Wheel Drive Models.........225

Tow Eye Usage — If Equipped......226

Emergency Tow Hooks — If Equipped .227

ENHANCED ACCIDENT RESPONSE

SYSTEM (EARS)............228

EVENT DATA RECORDER (EDR) .228

IN CASE OF EMERGENCY

197

Page 206 of 368

FUSES

WARNING!

• When replacing a blown fuse, always use

an appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a

blown fuse with metal wires or any other

material. Do not place a fuse inside a

circuit breaker cavity or vice versa. Fail-

ure to use proper fuses may result in

serious personal injury, fire and/or prop-

erty damage.

• Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or disen-

gaged.

• If the replaced fuse blows again, contact

an authorized dealer.

• If a general protection fuse for safety

systems (air bag system, braking sys-

WARNING!

tem), power unit systems (engine sys-

tem, transmission system) or steering

system blows, contact an authorized

dealer.

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check

the fuse element inside the blade fuse for a

break/melt.

Also, please be aware that when using power

outlets for extended periods of time with the

engine off may result in vehicle battery dis-

charge.

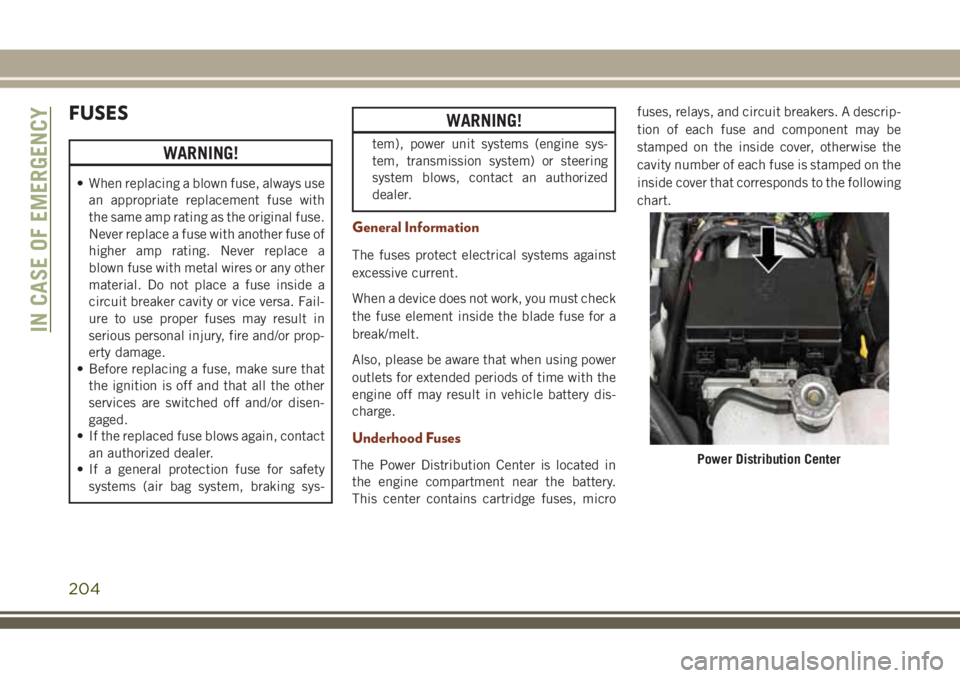

Underhood Fuses

The Power Distribution Center is located in

the engine compartment near the battery.

This center contains cartridge fuses, microfuses, relays, and circuit breakers. A descrip-

tion of each fuse and component may be

stamped on the inside cover, otherwise the

cavity number of each fuse is stamped on the

inside cover that corresponds to the following

chart.Power Distribution Center

IN CASE OF EMERGENCY

204

Page 207 of 368

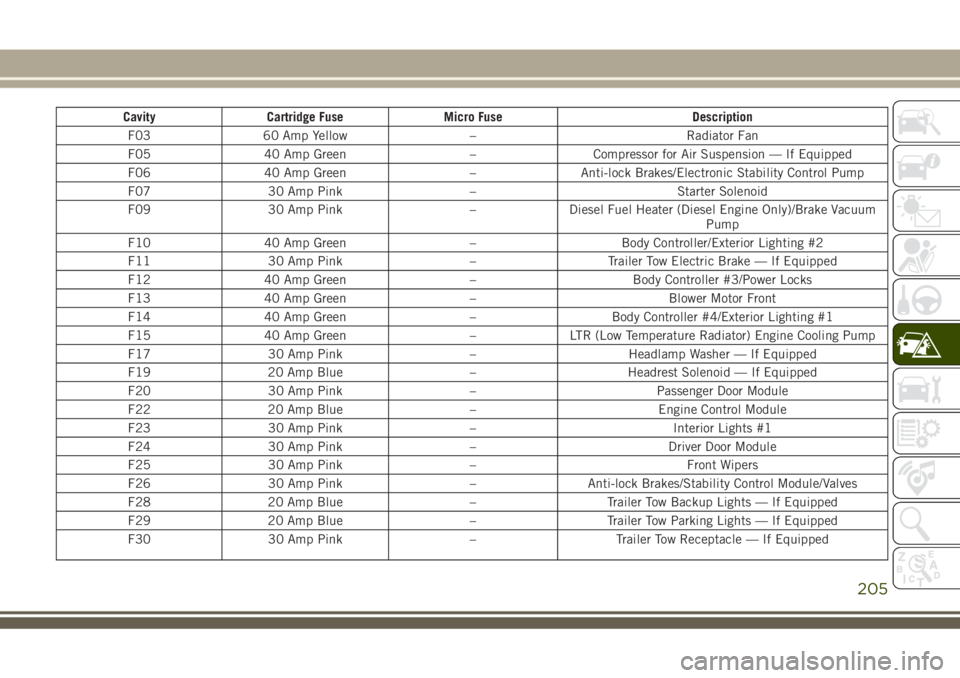

Cavity Cartridge Fuse Micro Fuse Description

F03 60 Amp Yellow – Radiator Fan

F05 40 Amp Green – Compressor for Air Suspension — If Equipped

F06 40 Amp Green – Anti-lock Brakes/Electronic Stability Control Pump

F07 30 Amp Pink – Starter Solenoid

F09 30 Amp Pink – Diesel Fuel Heater (Diesel Engine Only)/Brake Vacuum

Pump

F10 40 Amp Green – Body Controller/Exterior Lighting #2

F11 30 Amp Pink – Trailer Tow Electric Brake — If Equipped

F12 40 Amp Green – Body Controller #3/Power Locks

F13 40 Amp Green – Blower Motor Front

F14 40 Amp Green – Body Controller #4/Exterior Lighting #1

F15 40 Amp Green – LTR (Low Temperature Radiator) Engine Cooling Pump

F17 30 Amp Pink – Headlamp Washer — If Equipped

F19 20 Amp Blue – Headrest Solenoid — If Equipped

F20 30 Amp Pink – Passenger Door Module

F22 20 Amp Blue – Engine Control Module

F23 30 Amp Pink – Interior Lights #1

F24 30 Amp Pink – Driver Door Module

F25 30 Amp Pink – Front Wipers

F26 30 Amp Pink – Anti-lock Brakes/Stability Control Module/Valves

F28 20 Amp Blue – Trailer Tow Backup Lights — If Equipped

F29 20 Amp Blue – Trailer Tow Parking Lights — If Equipped

F30 30 Amp Pink – Trailer Tow Receptacle — If Equipped

205

Page 208 of 368

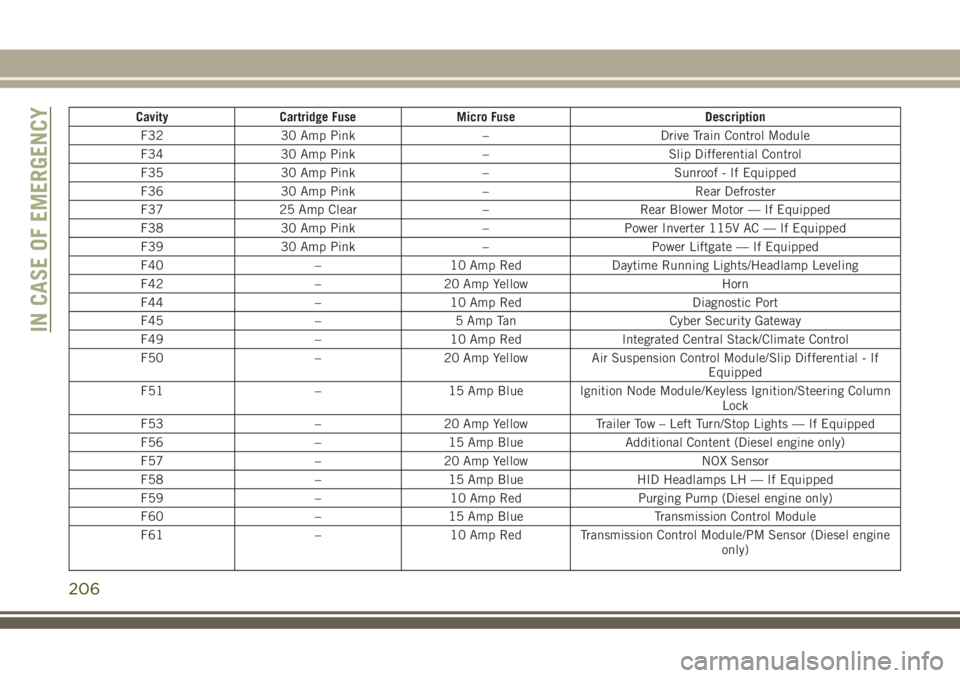

Cavity Cartridge Fuse Micro Fuse Description

F32 30 Amp Pink – Drive Train Control Module

F34 30 Amp Pink – Slip Differential Control

F35 30 Amp Pink – Sunroof - If Equipped

F36 30 Amp Pink – Rear Defroster

F37 25 Amp Clear – Rear Blower Motor — If Equipped

F38 30 Amp Pink – Power Inverter 115V AC — If Equipped

F39 30 Amp Pink – Power Liftgate — If Equipped

F40 – 10 Amp Red Daytime Running Lights/Headlamp Leveling

F42 – 20 Amp Yellow Horn

F44 – 10 Amp Red Diagnostic Port

F45 – 5 Amp Tan Cyber Security Gateway

F49 – 10 Amp Red Integrated Central Stack/Climate Control

F50 – 20 Amp Yellow Air Suspension Control Module/Slip Differential - If

Equipped

F51 – 15 Amp Blue Ignition Node Module/Keyless Ignition/Steering Column

Lock

F53 – 20 Amp Yellow Trailer Tow – Left Turn/Stop Lights — If Equipped

F56 – 15 Amp Blue Additional Content (Diesel engine only)

F57 – 20 Amp Yellow NOX Sensor

F58 – 15 Amp Blue HID Headlamps LH — If Equipped

F59 – 10 Amp Red Purging Pump (Diesel engine only)

F60 – 15 Amp Blue Transmission Control Module

F61 – 10 Amp Red Transmission Control Module/PM Sensor (Diesel engine

only)

IN CASE OF EMERGENCY

206

Page 209 of 368

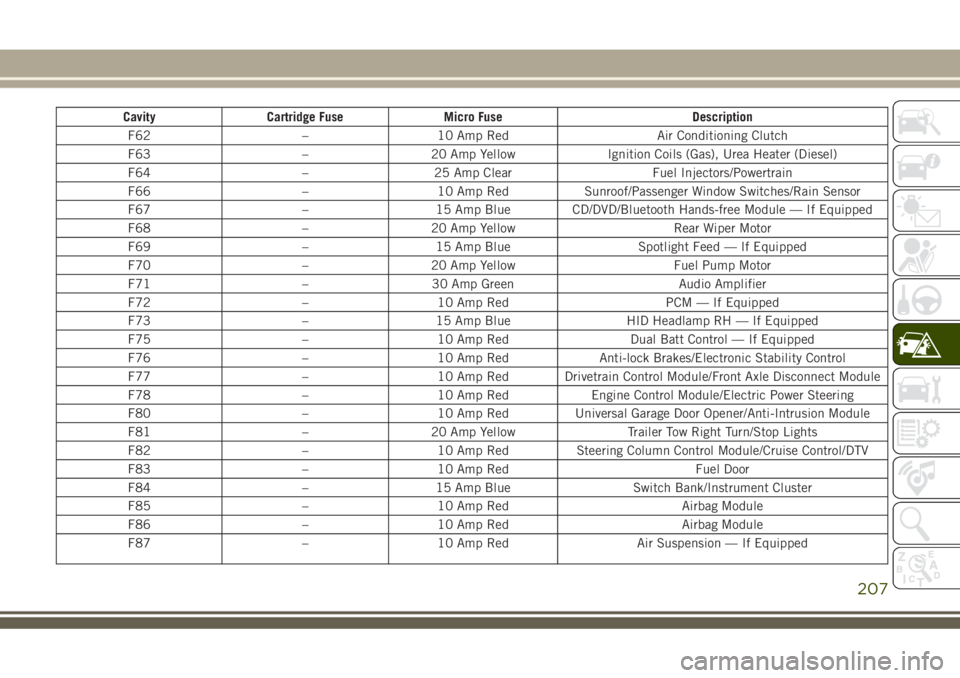

Cavity Cartridge Fuse Micro Fuse Description

F62 – 10 Amp Red Air Conditioning Clutch

F63 – 20 Amp Yellow Ignition Coils (Gas), Urea Heater (Diesel)

F64 – 25 Amp Clear Fuel Injectors/Powertrain

F66 – 10 Amp Red Sunroof/Passenger Window Switches/Rain Sensor

F67 – 15 Amp Blue CD/DVD/Bluetooth Hands-free Module — If Equipped

F68 – 20 Amp Yellow Rear Wiper Motor

F69 – 15 Amp Blue Spotlight Feed — If Equipped

F70 – 20 Amp Yellow Fuel Pump Motor

F71 – 30 Amp Green Audio Amplifier

F72 – 10 Amp Red PCM — If Equipped

F73 – 15 Amp Blue HID Headlamp RH — If Equipped

F75 – 10 Amp Red Dual Batt Control — If Equipped

F76 – 10 Amp Red Anti-lock Brakes/Electronic Stability Control

F77 – 10 Amp Red Drivetrain Control Module/Front Axle Disconnect Module

F78 – 10 Amp Red Engine Control Module/Electric Power Steering

F80 – 10 Amp Red Universal Garage Door Opener/Anti-Intrusion Module

F81 – 20 Amp Yellow Trailer Tow Right Turn/Stop Lights

F82 – 10 Amp Red Steering Column Control Module/Cruise Control/DTV

F83 – 10 Amp Red Fuel Door

F84 – 15 Amp Blue Switch Bank/Instrument Cluster

F85 – 10 Amp Red Airbag Module

F86 – 10 Amp Red Airbag Module

F87 – 10 Amp Red Air Suspension — If Equipped

207

Page 210 of 368

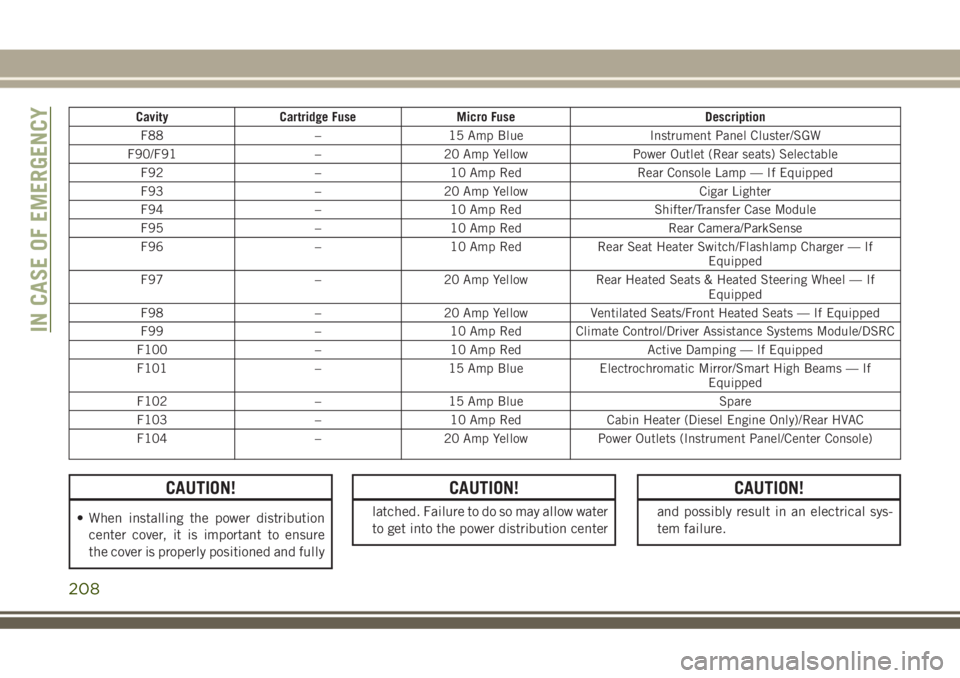

Cavity Cartridge Fuse Micro Fuse Description

F88 – 15 Amp Blue Instrument Panel Cluster/SGW

F90/F91 – 20 Amp Yellow Power Outlet (Rear seats) Selectable

F92 – 10 Amp Red Rear Console Lamp — If Equipped

F93 – 20 Amp Yellow Cigar Lighter

F94 – 10 Amp Red Shifter/Transfer Case Module

F95 – 10 Amp Red Rear Camera/ParkSense

F96 – 10 Amp Red Rear Seat Heater Switch/Flashlamp Charger — If

Equipped

F97 – 20 Amp Yellow Rear Heated Seats & Heated Steering Wheel — If

Equipped

F98 – 20 Amp Yellow Ventilated Seats/Front Heated Seats — If Equipped

F99 – 10 Amp Red Climate Control/Driver Assistance Systems Module/DSRC

F100 – 10 Amp Red Active Damping — If Equipped

F101 – 15 Amp Blue Electrochromatic Mirror/Smart High Beams — If

Equipped

F102 – 15 Amp Blue Spare

F103 – 10 Amp Red Cabin Heater (Diesel Engine Only)/Rear HVAC

F104 – 20 Amp Yellow Power Outlets (Instrument Panel/Center Console)

CAUTION!

• When installing the power distribution

center cover, it is important to ensure

the cover is properly positioned and fully

CAUTION!

latched. Failure to do so may allow water

to get into the power distribution center

CAUTION!

and possibly result in an electrical sys-

tem failure.

IN CASE OF EMERGENCY

208

Page 212 of 368

Preparations For Jacking

CAUTION!

Always lift or jack the vehicle from the

correct jacking points. Failure to follow

this information could cause damage to

the vehicle or underbody components.

NOTE:

To assist with changing a spare tire, the air

suspension system (if equipped) has a fea-

ture which allows the automatic leveling to

be disabled.

1. Park the vehicle on a firm, level surface.

Avoid ice or slippery surfaces.

WARNING!

Do not attempt to change a tire on the side

of the vehicle closest to moving traffic,

pull far enough off the road to avoid being

hit when operating the jack or changing

the wheel.

2. Turn on the Hazard Warning flasher.

3. Apply the parking brake.4. Place the gear selector into PARK.

5. Turn the ignition OFF.

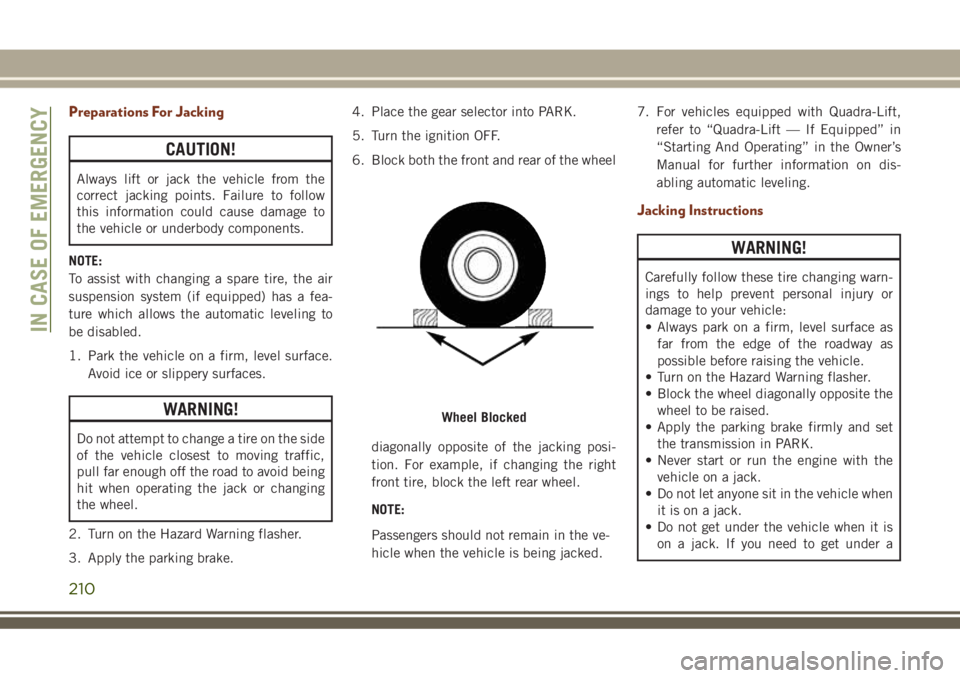

6. Block both the front and rear of the wheel

diagonally opposite of the jacking posi-

tion. For example, if changing the right

front tire, block the left rear wheel.

NOTE:

Passengers should not remain in the ve-

hicle when the vehicle is being jacked.7. For vehicles equipped with Quadra-Lift,

refer to “Quadra-Lift — If Equipped” in

“Starting And Operating” in the Owner’s

Manual for further information on dis-

abling automatic leveling.

Jacking Instructions

WARNING!

Carefully follow these tire changing warn-

ings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as

far from the edge of the roadway as

possible before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the

wheel to be raised.

• Apply the parking brake firmly and set

the transmission in PARK.

• Never start or run the engine with the

vehicle on a jack.

• Do not let anyone sit in the vehicle when

it is on a jack.

• Do not get under the vehicle when it is

on a jack. If you need to get under a

Wheel Blocked

IN CASE OF EMERGENCY

210

Page 219 of 368

Jack Usage Precautions

To complete the Use and Maintenance Hand-

book to which this supplement is attached,

given below are some instructions on the

proper use of the jack.

WARNING!

When using the crank, make sure it turns

freely without the risk of scraping hands

against the ground.

Even the moving parts of the jack, the

“worm screw” and joints can cause inju-

ries: avoid contact with them. Clean it

thoroughly if dirtied with grease.

CAUTION!

The jack is a tool designed exclusively for

changing a wheel, in case of a puncture or

damage to a tire of the vehicle on which it

is fitted or on vehicles of the same model.

Any other use, e.g. to jack up other vehicle

CAUTION!

models or different things, is strictly pro-

hibited. Never use it to carry out mainte-

nance or repairs under the vehicle or to

change summer/winter wheels and vice

versa. Never go under the raised vehicle. If

any work under the vehicle is necessary,

contact an authorized dealer. Incorrect

placing of the jack can cause the vehicle to

drop: use it only in the positions indicated.

Do not use the jack for loads higher than

that specified on the label. Never start the

engine with vehicle raised. If the vehicle is

raised more than necessary, everything

can become more unstable, with the risk of

the vehicle dropping violently. Therefore

raise the vehicle only as much as neces-

sary for the wheel/spare.

Maintenance

• Make sure grime does not build up on the

“worm screw.”

• Keep the “worm screw” lubricated.• Never modify the jack.

Conditions Of Non-Use:

• Temperatures below −40°C.

• On sandy or muddy ground.

• On uneven ground.

• On steep roads.

• In extreme weather conditions: thunder-

storms, typhoons, hurricanes, blizzards,

storms, etc.

JUMP STARTING

If your vehicle has a discharged battery it can

be jump started using a set of jumper cables

and a battery in another vehicle or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly so

please follow the procedures in this section

carefully.

217