warning light JEEP GRAND CHEROKEE 2020 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2020, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2020Pages: 378, PDF Size: 6.88 MB

Page 191 of 378

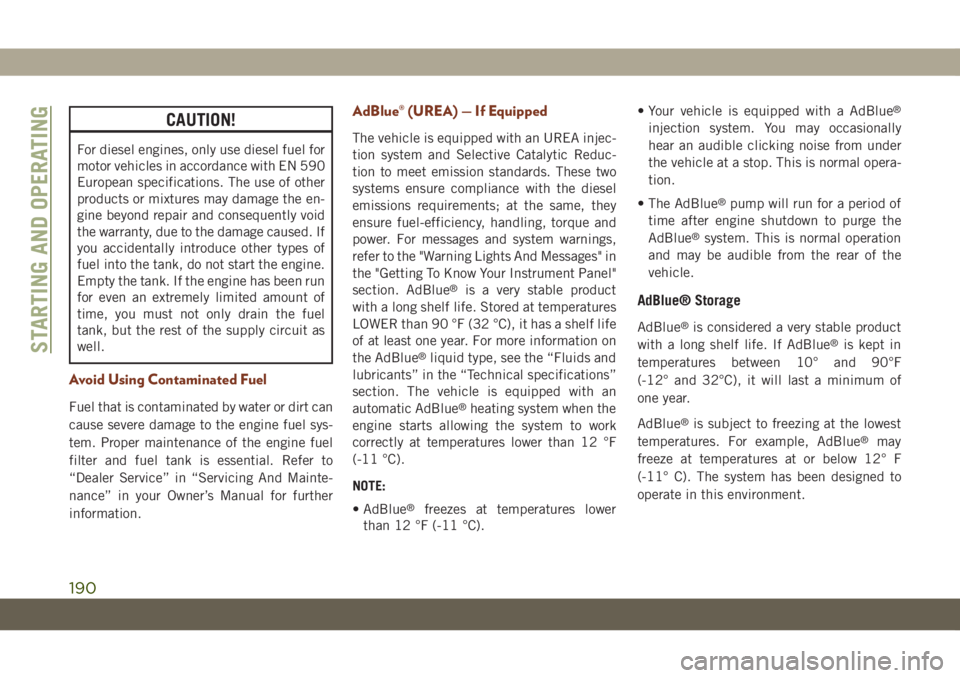

2. Insert funnel into same filler pipe opening

as the fuel nozzle.NOTE:

Ensure funnel is inserted fully to hold

flapper door open.

3. Pour fuel into funnel opening.

4. Remove funnel from filler pipe, clean off

prior to putting back in the spare tire kit.

WARNING!

• Never have any smoking materials lit in

or near the vehicle when the fuel door is

open or the tank is being filled.

• Never add fuel when the engine is run-

ning. This is in violation of most coun-

tries regulations and may cause the

“Malfunction Indicator Light” to turn

on.

• Do not apply any object/cap to the end of

the filler which is not provided for the

car. The use of non-compliant objects/

plugs could cause a pressure increase

inside the tank, resulting in dangerous

situations.

• A fire may result if fuel is pumped into a

portable container that is inside of a

vehicle. You could be burned. Always

place fuel containers on the ground

while filling.

CAUTION!

To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

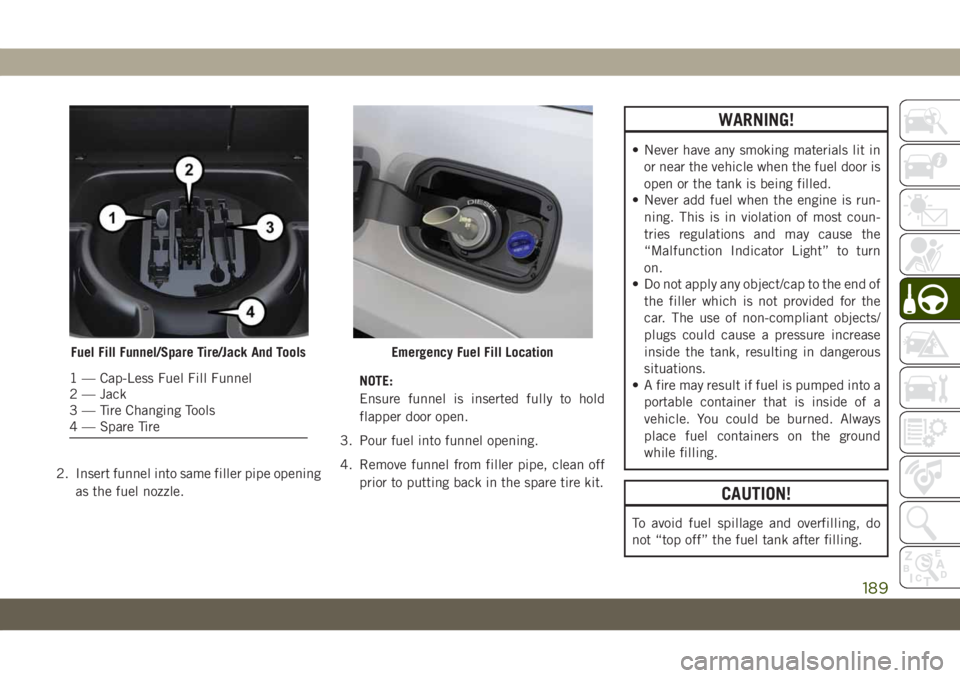

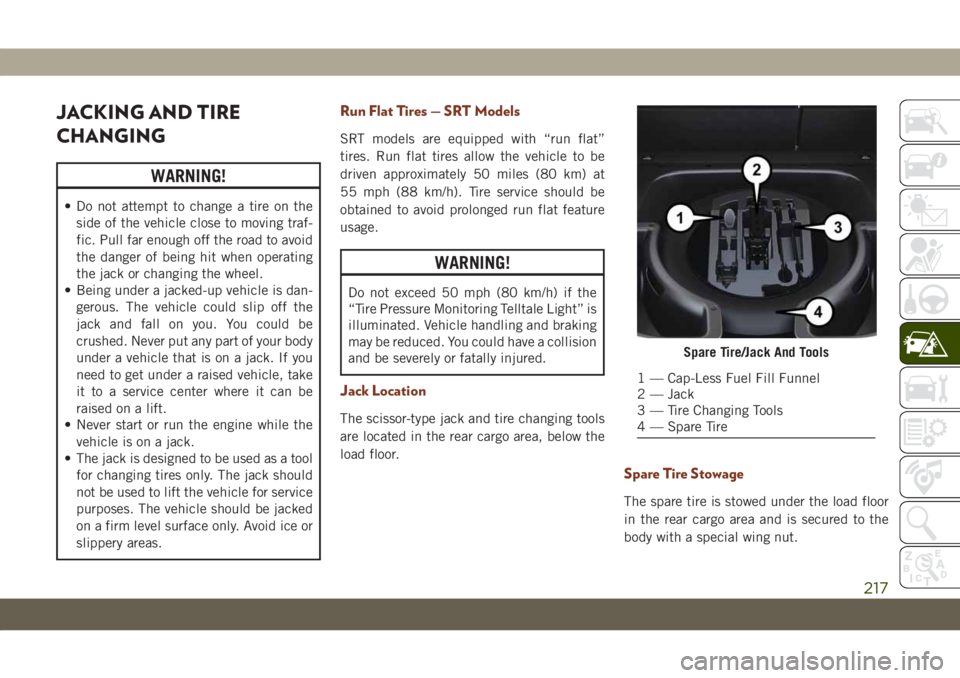

Fuel Fill Funnel/Spare Tire/Jack And Tools

1 — Cap-Less Fuel Fill Funnel

2 — Jack

3 — Tire Changing Tools

4 — Spare Tire

Emergency Fuel Fill Location

189

Page 192 of 378

CAUTION!

For diesel engines, only use diesel fuel for

motor vehicles in accordance with EN 590

European specifications. The use of other

products or mixtures may damage the en-

gine beyond repair and consequently void

the warranty, due to the damage caused. If

you accidentally introduce other types of

fuel into the tank, do not start the engine.

Empty the tank. If the engine has been run

for even an extremely limited amount of

time, you must not only drain the fuel

tank, but the rest of the supply circuit as

well.

Avoid Using Contaminated Fuel

Fuel that is contaminated by water or dirt can

cause severe damage to the engine fuel sys-

tem. Proper maintenance of the engine fuel

filter and fuel tank is essential. Refer to

“Dealer Service” in “Servicing And Mainte-

nance” in your Owner’s Manual for further

information.

AdBlue® (UREA) — If Equipped

The vehicle is equipped with an UREA injec-

tion system and Selective Catalytic Reduc-

tion to meet emission standards. These two

systems ensure compliance with the diesel

emissions requirements; at the same, they

ensure fuel-efficiency, handling, torque and

power. For messages and system warnings,

refer to the "Warning Lights And Messages" in

the "Getting To Know Your Instrument Panel"

section. AdBlue

®is a very stable product

with a long shelf life. Stored at temperatures

LOWER than 90 °F (32 °C), it has a shelf life

of at least one year. For more information on

the AdBlue

®liquid type, see the “Fluids and

lubricants” in the “Technical specifications”

section. The vehicle is equipped with an

automatic AdBlue

®heating system when the

engine starts allowing the system to work

correctly at temperatures lower than 12 °F

(-11 °C).

NOTE:

• AdBlue

®freezes at temperatures lower

than 12 °F (-11 °C).• Your vehicle is equipped with a AdBlue

®

injection system. You may occasionally

hear an audible clicking noise from under

the vehicle at a stop. This is normal opera-

tion.

• The AdBlue

®pump will run for a period of

time after engine shutdown to purge the

AdBlue

®system. This is normal operation

and may be audible from the rear of the

vehicle.

AdBlue® Storage

AdBlue®is considered a very stable product

with a long shelf life. If AdBlue®is kept in

temperatures between 10° and 90°F

(-12° and 32°C), it will last a minimum of

one year.

AdBlue

®is subject to freezing at the lowest

temperatures. For example, AdBlue®may

freeze at temperatures at or below 12° F

(-11° C). The system has been designed to

operate in this environment.

STARTING AND OPERATING

190

Page 193 of 378

NOTE:

When working with AdBlue®, it is important

to know that:

• Any containers or parts that come into con-

tact with AdBlue

®must be AdBlue®com-

patible (plastic or stainless steel). Copper,

brass, aluminum, iron or non-stainless

steel should be avoided as they are subject

to corrosion by AdBlue

®.

• If AdBlue

®is spilled, it should be wiped up

completely.

Adding AdBlue®

Preliminary Conditions

AdBlue

®freezes at temperatures lower than

12° F (-11° C). If the car stands for a long

time at this temperature refilling could be

difficult. For this reason, it is advised to park

the vehicle in a garage and/or heated environ-

ment and wait for the urea to return to liquid

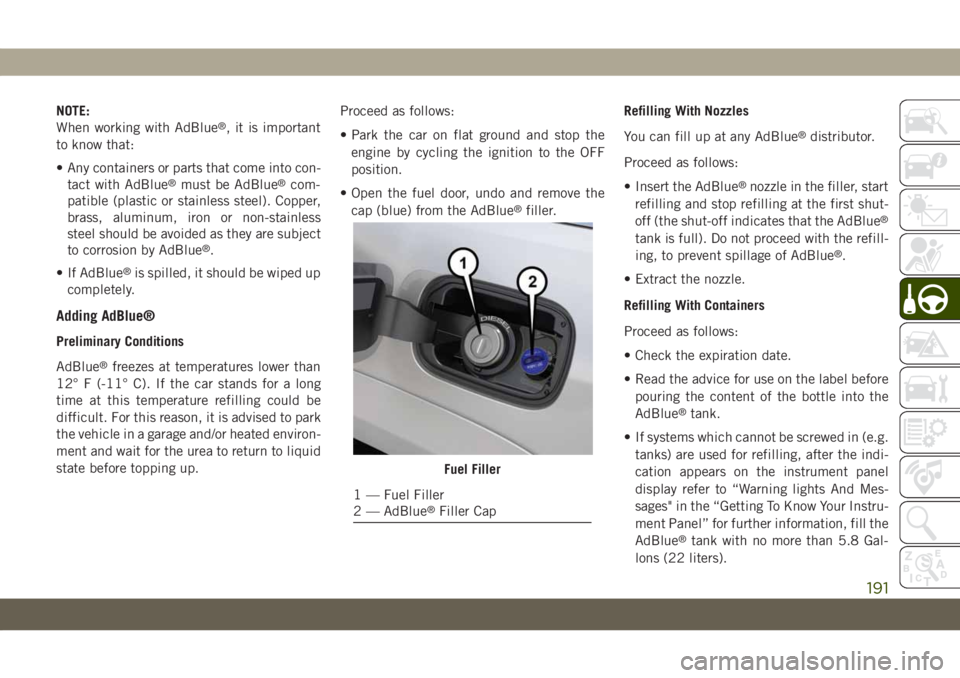

state before topping up.Proceed as follows:

• Park the car on flat ground and stop the

engine by cycling the ignition to the OFF

position.

• Open the fuel door, undo and remove the

cap (blue) from the AdBlue

®filler.Refilling With Nozzles

You can fill up at any AdBlue

®distributor.

Proceed as follows:

• Insert the AdBlue

®nozzle in the filler, start

refilling and stop refilling at the first shut-

off (the shut-off indicates that the AdBlue

®

tank is full). Do not proceed with the refill-

ing, to prevent spillage of AdBlue®.

• Extract the nozzle.

Refilling With Containers

Proceed as follows:

• Check the expiration date.

• Read the advice for use on the label before

pouring the content of the bottle into the

AdBlue

®tank.

• If systems which cannot be screwed in (e.g.

tanks) are used for refilling, after the indi-

cation appears on the instrument panel

display refer to “Warning lights And Mes-

sages" in the “Getting To Know Your Instru-

ment Panel” for further information, fill the

AdBlue

®tank with no more than 5.8 Gal-

lons (22 liters).

Fuel Filler

1 — Fuel Filler

2 — AdBlue®Filler Cap

191

Page 194 of 378

• If containers which can be screwed to the

filler are used, the reservoir is full when the

AdBlue

®level in the container stops pour-

ing out. Do not proceed further.

CAUTION!

To avoid fuel spillage and overfilling, do

not “top off” the fuel tank after filling.

Operations After Refilling

Proceed as follows:

• Fit the cap back on the AdBlue

®filler by

turning it clockwise and screwing it com-

pletely.

• Cycle the ignition to RUN (it is not neces-

sary to start the engine).

• Wait for the indication on the instrument

panel to switch off before moving the car.

The indication may stay on for a few sec-

onds to approximately half a minute. If the

engine is started and the car is moved, the

indication will remain on for longer. This

will not compromise engine operation.• If the AdBlue

®was topped up when the

tank was empty, wait for 2 minutes before

starting the engine.

NOTE:

• If AdBlue

®is spilled out of the filler neck,

clean up well the area and proceed to filling

up again. If the liquid crystallizes, elimi-

nate it with a sponge and warm water.

• DO NOT EXCEED THE MAXIMUM LEVEL:

this could cause damage to the reservoir.

AdBlue

®freezes at under 12° F (-11° C).

Although the system is designed to operate

below the freezing point of the AdBlue

®,it

is advisable not to fill the tank beyond the

maximum level because if the AdBlue

®

freezes the system can be damaged. Follow

the instructions in this section.

• If the AdBlue

®is spilled on painted sur-

faces or aluminium, immediately clean the

area with water and use absorbent material

to collect the fluid that has been spilled on

the ground.

• Do not try to start the engine if AdBlue

®

was accidentally added to the diesel fuel

tank, this can result in serious engine dam-

age, contact an authorized dealer.• Do not add additives or other fluids to

AdBlue

®, doing so could damage the

system.

• The use of non-conforming or degraded

AdBlue

®may lead to indications appearing

on the instrument panel display refer to

“Warning Lights And Messages" in the

“Getting To Know Your Instrument Panel”

for further information.

• Never pour AdBlue

®into another con-

tainer: it could be contaminated.

• If the AdBlue

®runs out, see refer to “Warn-

ing Lights And Messages" in the “Getting To

Know Your Instrument Panel” for further

information to continue using the car

normally.

TRAILER TOWING

Trailer Towing Weights (Maximum Trailer

Weight Ratings) — Non SRT

The following chart provides the maximum

trailer weight ratings towable for your given

drivetrain.

STARTING AND OPERATING

192

Page 219 of 378

JACKING AND TIRE

CHANGING

WARNING!

• Do not attempt to change a tire on the

side of the vehicle close to moving traf-

fic. Pull far enough off the road to avoid

the danger of being hit when operating

the jack or changing the wheel.

• Being under a jacked-up vehicle is dan-

gerous. The vehicle could slip off the

jack and fall on you. You could be

crushed. Never put any part of your body

under a vehicle that is on a jack. If you

need to get under a raised vehicle, take

it to a service center where it can be

raised on a lift.

• Never start or run the engine while the

vehicle is on a jack.

• The jack is designed to be used as a tool

for changing tires only. The jack should

not be used to lift the vehicle for service

purposes. The vehicle should be jacked

on a firm level surface only. Avoid ice or

slippery areas.

Run Flat Tires — SRT Models

SRT models are equipped with “run flat”

tires. Run flat tires allow the vehicle to be

driven approximately 50 miles (80 km) at

55 mph (88 km/h). Tire service should be

obtained to avoid prolonged run flat feature

usage.

WARNING!

Do not exceed 50 mph (80 km/h) if the

“Tire Pressure Monitoring Telltale Light” is

illuminated. Vehicle handling and braking

may be reduced. You could have a collision

and be severely or fatally injured.

Jack Location

The scissor-type jack and tire changing tools

are located in the rear cargo area, below the

load floor.

Spare Tire Stowage

The spare tire is stowed under the load floor

in the rear cargo area and is secured to the

body with a special wing nut.

Spare Tire/Jack And Tools

1 — Cap-Less Fuel Fill Funnel

2 — Jack

3 — Tire Changing Tools

4 — Spare Tire

217

Page 223 of 378

WARNING!

Raising the vehicle higher than necessary

can make the vehicle less stable. It could

slip off the jack and hurt someone near it.

Raise the vehicle only enough to remove

the tire.

7. Remove the lug nuts and wheel.

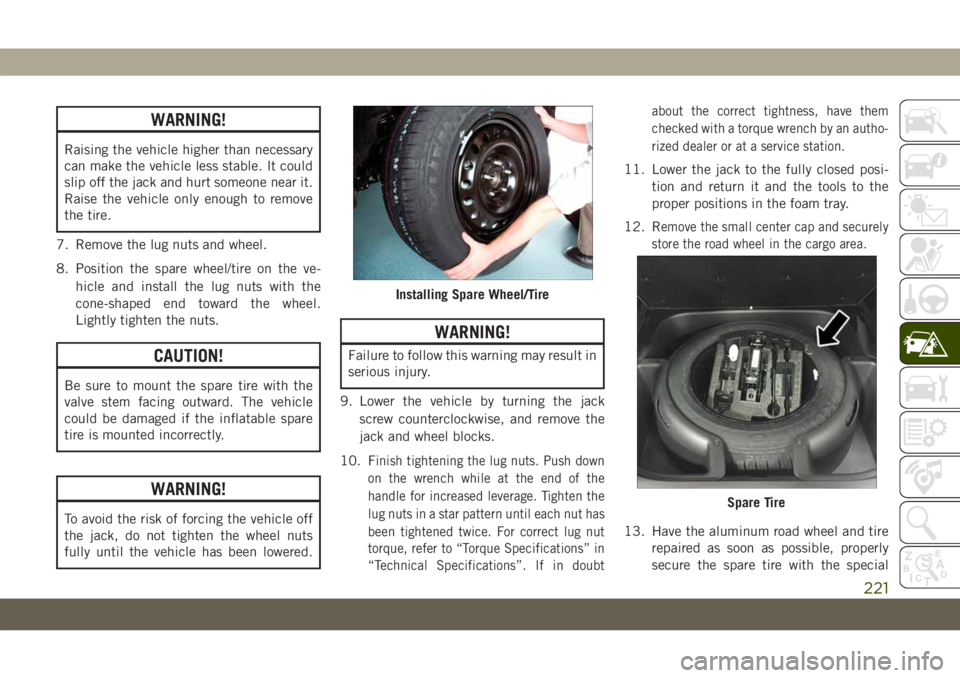

8. Position the spare wheel/tire on the ve-

hicle and install the lug nuts with the

cone-shaped end toward the wheel.

Lightly tighten the nuts.

CAUTION!

Be sure to mount the spare tire with the

valve stem facing outward. The vehicle

could be damaged if the inflatable spare

tire is mounted incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

WARNING!

Failure to follow this warning may result in

serious injury.

9. Lower the vehicle by turning the jack

screw counterclockwise, and remove the

jack and wheel blocks.

10. F

inish tightening the lug nuts. Push down

on the wrench while at the end of the

handle for increased leverage. Tighten the

lug nuts in a star pattern until each nut has

been tightened twice. For correct lug nut

torque, refer to “Torque Specifications” in

“Technical Specifications”. If in doubtabout the correct tightness, have them

checked with a torque wrench by an autho-

rized dealer or at a service station.

11. Lower the jack to the fully closed posi-

tion and return it and the tools to the

proper positions in the foam tray.

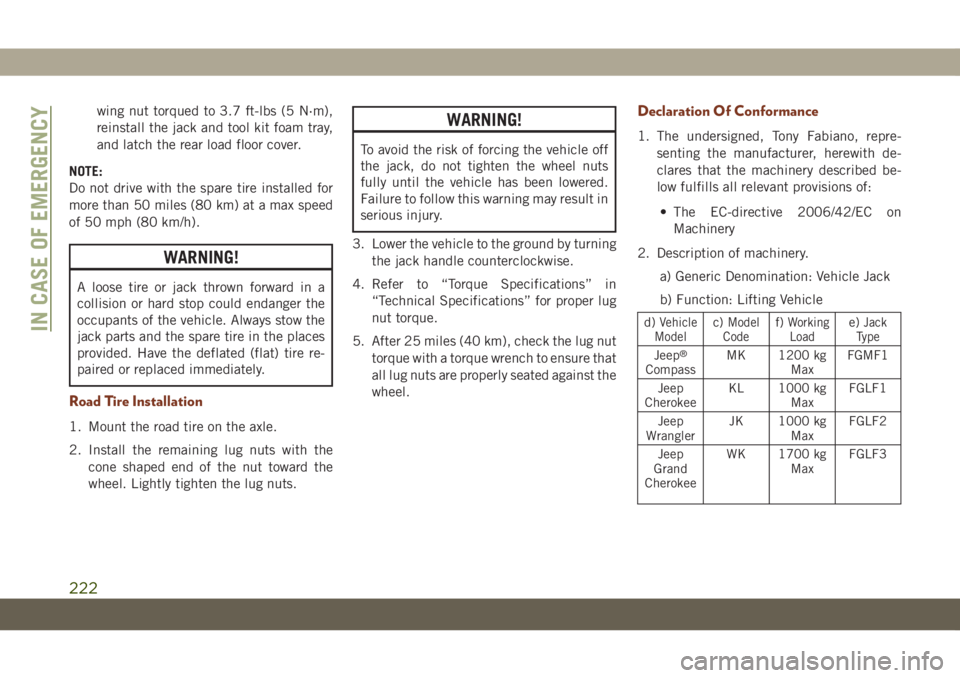

12. R

emove the small center cap and securely

store the road wheel in the cargo area.

13. Have the aluminum road wheel and tire

repaired as soon as possible, properly

secure the spare tire with the special

Installing Spare Wheel/Tire

Spare Tire

221

Page 224 of 378

wing nut torqued to 3.7 ft-lbs (5 N·m),

reinstall the jack and tool kit foam tray,

and latch the rear load floor cover.

NOTE:

Do not drive with the spare tire installed for

more than 50 miles (80 km) at a max speed

of 50 mph (80 km/h).

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

jack parts and the spare tire in the places

provided. Have the deflated (flat) tire re-

paired or replaced immediately.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the

cone shaped end of the nut toward the

wheel. Lightly tighten the lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off

the jack, do not tighten the wheel nuts

fully until the vehicle has been lowered.

Failure to follow this warning may result in

serious injury.

3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Refer to “Torque Specifications” in

“Technical Specifications” for proper lug

nut torque.

5. After 25 miles (40 km), check the lug nut

torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

Declaration Of Conformance

1. The undersigned, Tony Fabiano, repre-

senting the manufacturer, herewith de-

clares that the machinery described be-

low fulfills all relevant provisions of:

• The EC-directive 2006/42/EC on

Machinery

2. Description of machinery.

a) Generic Denomination: Vehicle Jack

b) Function: Lifting Vehicle

d)Vehicle

Modelc)Model

Codef)Working

Loade)Jack

Type

Jeep®

CompassMK 1200 kg

MaxFGMF1

Jeep

CherokeeKL 1000 kg

MaxFGLF1

Jeep

WranglerJK 1000 kg

MaxFGLF2

Jeep

Grand

CherokeeWK 1700 kg

MaxFGLF3

IN CASE OF EMERGENCY

222

Page 249 of 378

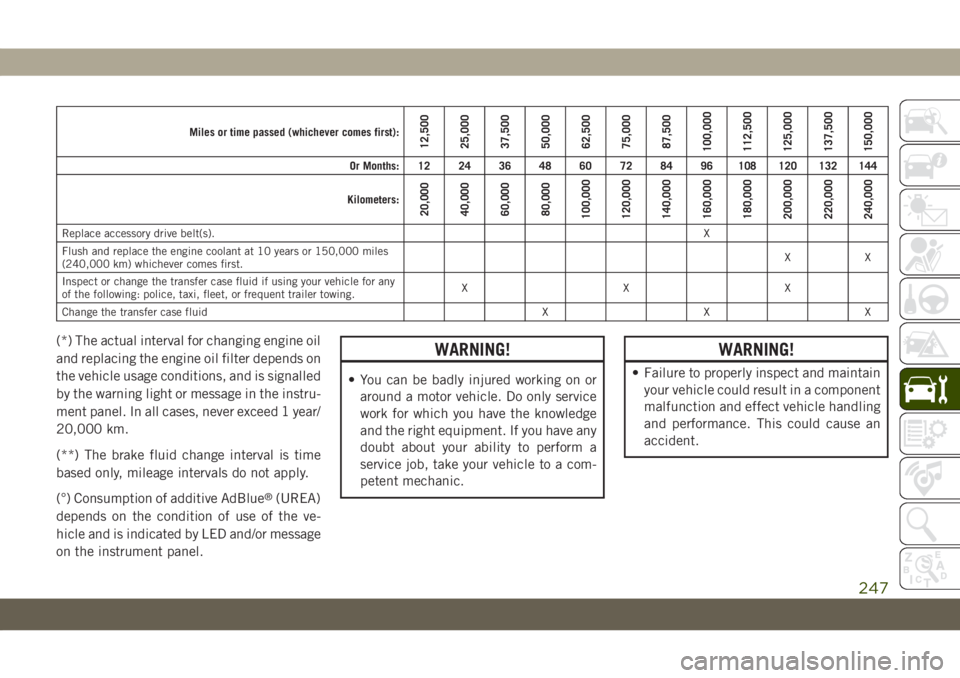

Miles or time passed (whichever comes first):12,500

25,000

37,500

50,000

62,500

75,000

87,500

100,000

112,500

125,000

137,500

150,000

Or Months: 12 24 36 48 60 72 84 96 108 120 132 144

Kilometers:

20,000

40,000

60,000

80,000

100,000

120,000

140,000

160,000

180,000

200,000

220,000

240,000

Replace accessory drive belt(s).X

Flush and replace the engine coolant at 10 years or 150,000 miles

(240,000 km) whichever comes first.XX

Inspect or change the transfer case fluid if using your vehicle for any

of the following: police, taxi, fleet, or frequent trailer towing.XXX

Change the transfer case fluid X X X

(*) The actual interval for changing engine oil

and replacing the engine oil filter depends on

the vehicle usage conditions, and is signalled

by the warning light or message in the instru-

ment panel. In all cases, never exceed 1 year/

20,000 km.

(**) The brake fluid change interval is time

based only, mileage intervals do not apply.

(°) Consumption of additive AdBlue

®(UREA)

depends on the condition of use of the ve-

hicle and is indicated by LED and/or message

on the instrument panel.

WARNING!

• You can be badly injured working on or

around a motor vehicle. Do only service

work for which you have the knowledge

and the right equipment. If you have any

doubt about your ability to perform a

service job, take your vehicle to a com-

petent mechanic.

WARNING!

• Failure to properly inspect and maintain

your vehicle could result in a component

malfunction and effect vehicle handling

and performance. This could cause an

accident.

247

Page 256 of 378

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil

level readings. Add oil only when the level on

the dipstick is below the “MIN” mark. The

total capacity from the MIN mark to the MAX

mark is 1 qt (1 L).

CAUTION!

Overfilling or underfilling the crankcase

will cause oil aeration or loss of oil pres-

sure. This could damage your engine.

NOTE:

It is possible for your oil level to be slightly

higher than a previous check. This would be

due to diesel fuel that may temporarily be in

the crankcase due to operation of the diesel

particulate filter regeneration strategy. This

fuel will evaporate out under normal opera-

tion.

Never operate the engine with oil level below

the “MIN” mark or above the upper “MAX”

mark.

WARNING!

• Never smoke while working in the engine

compartment: gas and inflammable va-

pors may be present, with the risk of fire.

• Be very careful when working in the

engine compartment when the engine is

hot: you may get burned. Do not get too

close to the radiator cooling fan: the

electric fan may start; danger of injury.

Scarves, ties and other loose clothing

might be pulled by moving parts.

CAUTION!

• Be careful not to confuse the various

types of fluids while topping up: they are

not compatible with each other! Topping

up with an unsuitable fluid could se-

verely damage your car.

• The oil level must never exceed the MAX

mark.

• Always top up using engine oil of the

same specifications as that already in

the engine.

CAUTION!

• If the engine oil is being topped up, wait

for the engine to cool down before loos-

ening the filler cap, particularly for ve-

hicles with aluminium cap (if

equipped). WARNING: risk of burns!

• Overfilling or underfilling the crankcase

will cause aeration or loss of oil pres-

sure. This could damage your engine.

Adding Washer Fluid

The instrument cluster display will indicate

when the washer fluid level is low. When the

sensor detects a low fluid level, the wind-

shield will light on the vehicle graphic outline

and the “WASHER FLUID LOW” message

will be displayed.

The fluid reservoir for the windshield washers

and the rear window washer is shared. The

fluid reservoir is located in the engine com-

partment, be sure to check the fluid level at

regular intervals. Fill the reservoir with wind-

shield washer solvent only (not radiator anti-

freeze). When refilling the washer fluid reser-

voir, take some washer fluid and apply it to a

cloth or towel and wipe clean the wiper

SERVICING AND MAINTENANCE

254

Page 257 of 378

blades, this will help blade performance. To

prevent freeze-up of your windshield washer

system in cold weather, select a solution or

mixture that meets or exceeds the tempera-

ture range of your climate. This rating infor-

mation can be found on most washer fluid

containers.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite

and burn you. Care must be exercised

when filling or working around the washer

solution.

CAUTION!

Do not travel with the windshield washer

fluid reservoir empty: the windshield

washer is essential for improving visibility.

Brake System

In order to assure brake system performance,

all brake system components should be in-

spected periodically. Refer to the “Mainte-

nance Plan” in this section for the proper

maintenance intervals.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your

foot resting or riding on the brake pedal

can result in abnormally high brake tem-

peratures, excessive lining wear, and pos-

sible brake damage. You would not have

your full braking capacity in an emergency.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should

be checked whenever the vehicle is serviced,

or immediately if the brake system warning

light is on. If necessary, add fluid to bring

level within the designated marks on the side

of the reservoir of the brake master cylinder.

Be sure to clean the top of the master cylin-

der area before removing cap. With disc

brakes, fluid level can be expected to fall asthe brake pads wear. Brake fluid level should

be checked when pads are replaced. If the

brake fluid is abnormally low, check the sys-

tem for leaks.

Refer to “Fluids And Lubricants” in “Techni-

cal Specifications” for further information.

WARNING!

• Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri-

cants” in “Technical Specifications” for

further information. Using the wrong

type of brake fluid can severely damage

your brake system and/or impair its per-

formance. The proper type of brake fluid

for your vehicle is also identified on the

original factory installed hydraulic mas-

ter cylinder reservoir.

• To avoid contamination from foreign

matter or moisture, use only new brake

fluid or fluid that has been in a tightly

closed container. Keep the master cylin-

der reservoir cap secured at all times.

Brake fluid in a open container absorbs

moisture from the air resulting in a lower

255