engine JEEP GRAND CHEROKEE LIMITED 2019 Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2019, Model line: GRAND CHEROKEE LIMITED, Model: JEEP GRAND CHEROKEE LIMITED 2019Pages: 626, PDF Size: 3.77 MB

Page 451 of 626

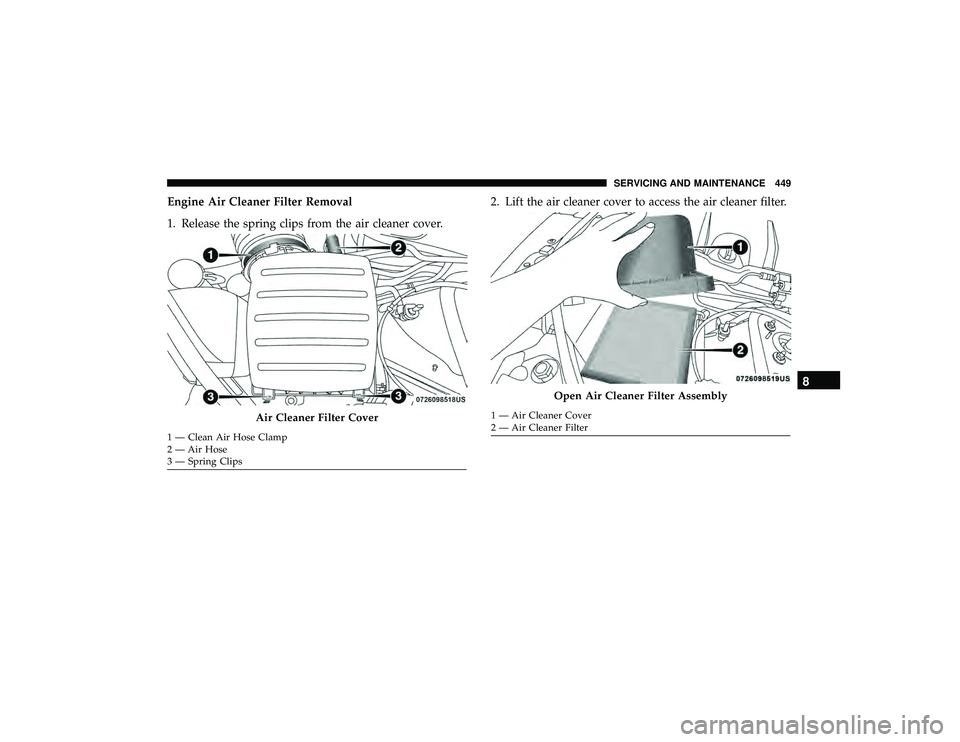

Engine Air Cleaner Filter Removal

1. Release the spring clips from the air cleaner cover.2. Lift the air cleaner cover to access the air cleaner filter.

Page 452 of 626

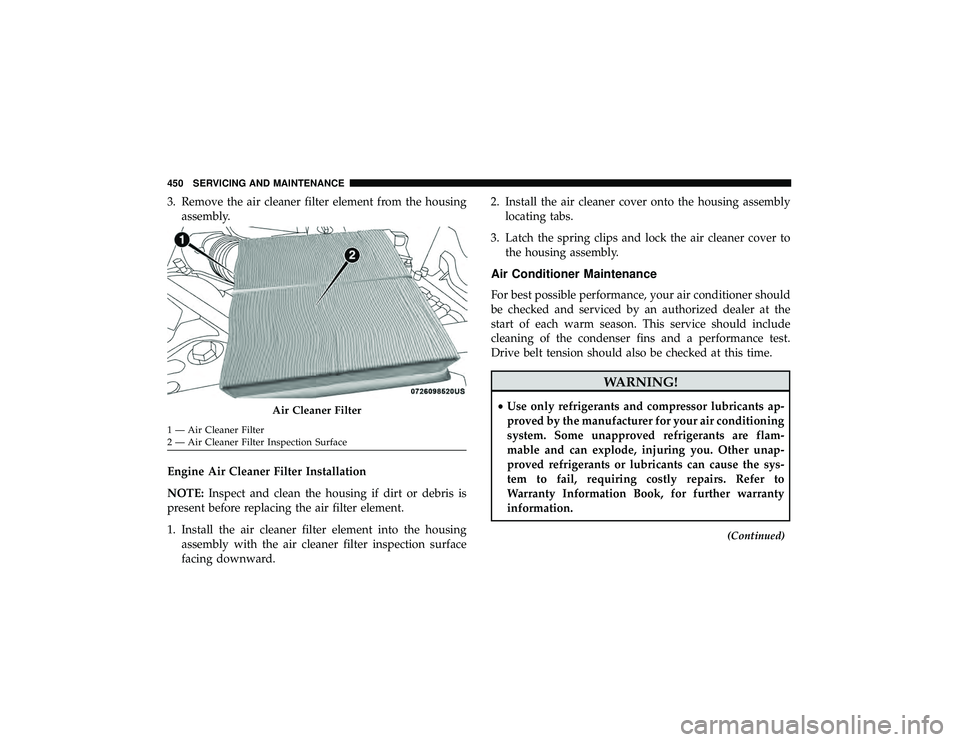

3. Remove the air cleaner filter element from the housingassembly.

Engine Air Cleaner Filter Installation

NOTE: Inspect and clean the housing if dirt or debris is

present before replacing the air filter element.

1. Install the air cleaner filter element into the housing assembly with the air cleaner filter inspection surface

facing downward. 2. Install the air cleaner cover onto the housing assembly

locating tabs.

3. Latch the spring clips and lock the air cleaner cover to the housing assembly.

Air Conditioner Maintenance

For best possible performance, your air conditioner should

be checked and serviced by an authorized dealer at the

start of each warm season. This service should include

cleaning of the condenser fins and a performance test.

Drive belt tension should also be checked at this time.

Page 458 of 626

The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as Mopar Lock

Cylinder Lubricant directly into the lock cylinder.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild nonabrasive cleaner. This will remove accumulations

of salt or road film.

Operation of the wipers on dry glass for long periods may

cause deterioration of the wiper blades. Always use washer

fluid when using the wipers to remove salt or dirt from a

dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depending

on geographical area and frequency of use. Poor perfor-

mance of blades may be present with chattering, marks,

water lines or wet spots. If any of these conditions are

present, clean the wiper blades or replace as necessary. The wiper blades and wiper arms should be inspected

periodically, not just when wiper performance problems

are experienced. This inspection should include the follow-

ing points:

•

Wear or uneven edges

• Foreign material

• Hardening or cracking

• Deformation or fatigue

If a wiper blade or wiper arm is damaged, replace the

affected wiper arm or blade with a new unit. Do not

attempt to repair a wiper arm or blade that is damaged.

Front Wiper Blade Removal/Installation

CAUTION!

Do not allow the wiper arm to spring back against the

glass without the wiper blade in place or the glass may

be damaged.

456 SERVICING AND MAINTENANCE

Page 462 of 626

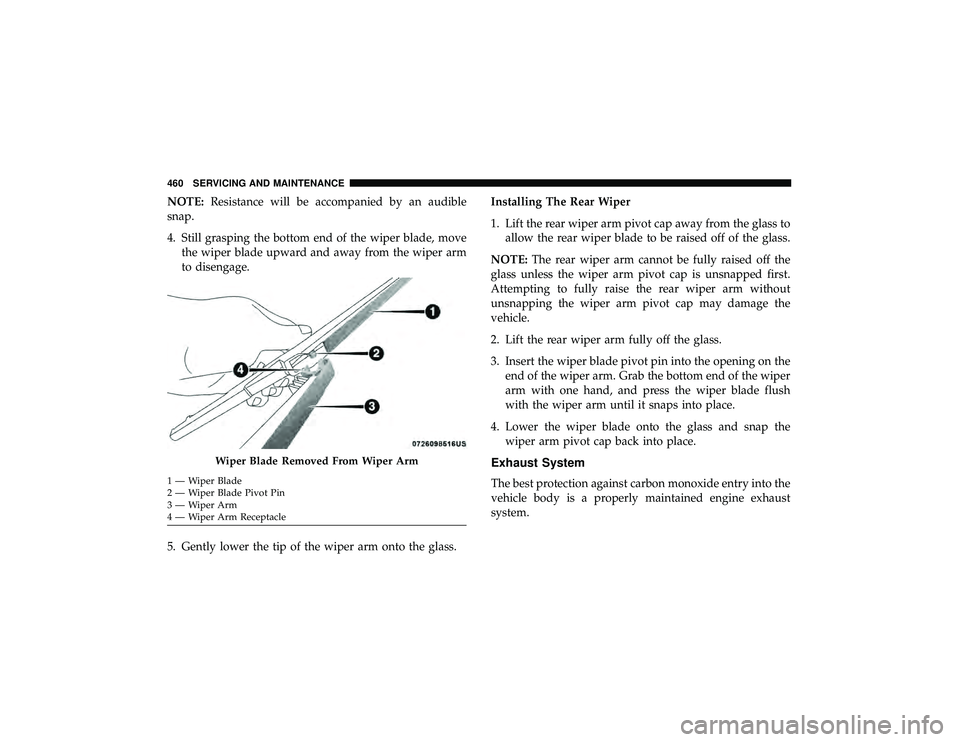

NOTE:Resistance will be accompanied by an audible

snap.

4. Still grasping the bottom end of the wiper blade, move the wiper blade upward and away from the wiper arm

to disengage.

5. Gently lower the tip of the wiper arm onto the glass. Installing The Rear Wiper

1. Lift the rear wiper arm pivot cap away from the glass to

allow the rear wiper blade to be raised off of the glass.

NOTE: The rear wiper arm cannot be fully raised off the

glass unless the wiper arm pivot cap is unsnapped first.

Attempting to fully raise the rear wiper arm without

unsnapping the wiper arm pivot cap may damage the

vehicle.

2. Lift the rear wiper arm fully off the glass.

3. Insert the wiper blade pivot pin into the opening on the end of the wiper arm. Grab the bottom end of the wiper

arm with one hand, and press the wiper blade flush

with the wiper arm until it snaps into place.

4. Lower the wiper blade onto the glass and snap the wiper arm pivot cap back into place.

Exhaust System

The best protection against carbon monoxide entry into the

vehicle body is a properly maintained engine exhaust

system.

Page 463 of 626

If you notice a change in the sound of the exhaust system;

or if the exhaust fumes can be detected inside the vehicle;

or when the underside or rear of the vehicle is damaged;

have an authorized technician inspect the complete ex-

haust system and adjacent body areas for broken, dam-

aged, deteriorated, or mispositioned parts. Open seams or

loose connections could permit exhaust fumes to seep into

the passenger compartment. In addition, have the exhaust

system inspected each time the vehicle is raised for lubri-

cation or oil change. Replace as required.CAUTION!

•The catalytic converter requires the use of unleaded

fuel only. Leaded gasoline will destroy the effective-

ness of the catalyst as an emissions control device

and may seriously reduce engine performance and

cause serious damage to the engine.

• Damage to the catalytic converter can result if your

vehicle is not kept in proper operating condition. In

the event of engine malfunction, particularly involv-

ing engine misfire or other apparent loss of perfor-

mance, have your vehicle serviced promptly. Contin-

ued operation of your vehicle with a severe

malfunction could cause the converter to overheat,

resulting in possible damage to the converter and

vehicle.

Under normal operating conditions, the catalytic converter

will not require maintenance. However, it is important to

keep the engine properly tuned to assure proper catalyst

operation and prevent possible catalyst damage.

NOTE: Intentional tampering with emissions control sys-

tems can result in civil penalties being assessed against

you.

8

SERVICING AND MAINTENANCE 461

Page 464 of 626

In unusual situations involving grossly malfunctioning

engine operation, a scorching odor may suggest severe and

abnormal catalyst overheating. If this occurs, stop the

vehicle, turn off the engine and allow it to cool. Service,

including a tune-up to manufacturer’s specifications,

should be obtained immediately.

To minimize the possibility of catalytic converter damage:

•Do not interrupt the ignition when the transmission is in

gear and the vehicle is in motion.

• Do not try to start the vehicle by pushing or towing the

vehicle.

• Do not idle the engine with any ignition components

disconnected or removed, such as when diagnostic

testing, or for prolonged periods during very rough idle

or malfunctioning operating conditions.

Cooling System

Page 465 of 626

Check the engine cooling system hoses for brittle rubber,

cracking, tears, cuts, and tightness of the connection at the

coolant recovery bottle and radiator. Inspect the entire

system for leaks. DO NOT REMOVE THE COOLANT

PRESSURE CAP WHEN THE COOLING SYSTEM IS HOT.

Cooling System — Drain, Flush And Refill

NOTE:Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly could lead to

severe internal engine damage. If any coolant is needed to

be added to the system please contact an authorized dealer.

If the engine coolant (antifreeze) is dirty or contains visible

sediment, have an authorized dealer clean and flush with

OAT coolant (antifreeze) (conforming to MS.90032).

Refer to the “Maintenance Plan” in this section for the

proper maintenance intervals.

Selection Of Coolant

Refer to “Fluids And Lubricants” in “Technical Specifica-

tions” for further information. NOTE:

•

Mixing of engine coolant (antifreeze) other than speci-

fied Organic Additive Technology (OAT) engine coolant

(antifreeze), may result in engine damage and may

decrease corrosion protection. Organic Additive Tech-

nology (OAT) engine coolant is different and should not

be mixed with Hybrid Organic Additive Technology

(HOAT) engine coolant (antifreeze) or any “globally

compatible” coolant (antifreeze). If a non-OAT engine

coolant (antifreeze) is introduced into the cooling system

in an emergency, the cooling system will need to be

drained, flushed, and refilled with fresh OAT coolant

(conforming to MS.90032), by an authorized dealer as

soon as possible.

• Do not use water alone or alcohol-based engine coolant

(antifreeze) products. Do not use additional rust inhibi-

tors or antirust products, as they may not be compatible

with the radiator engine coolant and may plug the

radiator.

• This vehicle has not been designed for use with propyl-

ene glycol-based engine coolant (antifreeze). Use of

propylene glycolbased engine coolant (antifreeze) is not

recommended.

8

SERVICING AND MAINTENANCE 463

Page 466 of 626

•Some vehicles require special tools to add coolant prop-

erly. Failure to fill these systems properly could lead to

severe internal engine damage. If any coolant is needed

to be added to the system please contact an authorized

dealer.

Adding Coolant

Your vehicle has been built with an improved engine

coolant (OAT coolant conforming to MS.90032) that allows

extended maintenance intervals. This engine coolant (anti-

freeze) can be used up to ten years or 150,000 miles

(240,000 km) before replacement. To prevent reducing this

extended maintenance period, it is important that you use

the same engine coolant (OAT coolant conforming to

MS.90032) throughout the life of your vehicle.

Please review these recommendations for using Organic

Additive Technology (OAT) engine coolant (antifreeze)

that meets the requirements of FCA Material Standard

MS.90032. When adding engine coolant (antifreeze):

•We recommend using Mopar Antifreeze/Coolant 10

Year/150,000 Mile (240,000 km) Formula OAT (Organic

Additive Technology) that meets the requirements of

FCA Material Standard MS.90032. •

Mix a minimum solution of 50% OAT engine coolant

that meets the requirements of FCA Material Standard

MS.90032 and distilled water. Use higher concentrations

(not to exceed 70%) if temperatures below �34°F (�37°C)

are anticipated. Please contact an authorized dealer for

assistance.

• Use only high purity water such as distilled or deionized

water when mixing the water/engine coolant (anti-

freeze) solution. The use of lower quality water will

reduce the amount of corrosion protection in the engine

cooling system.

NOTE:

• It is the owner’s responsibility to maintain the proper

level of protection against freezing according to the

temperatures occurring in the area where the vehicle is

operated.

• Some vehicles require special tools to add coolant prop-

erly. Failure to fill these systems properly could lead to

severe internal engine damage. If any coolant is needed

to be added to the system, please contact a local autho-

rized dealer.

464 SERVICING AND MAINTENANCE

Page 467 of 626

•Mixing engine coolant (antifreeze) types is not recom-

mended and can result in cooling system damage. If

HOAT and OAT coolant are mixed in an emergency,

have a authorized dealer drain, flush, and refill with

OAT coolant (conforming to MS.90032) as soon as pos-

sible.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of engine

coolant (antifreeze), and to ensure that engine coolant

(antifreeze) will return to the radiator from the coolant

expansion bottle/recovery tank if so equipped.

The cap should be inspected and cleaned if there is any

accumulation of foreign material on the sealing surfaces.

Page 468 of 626

The radiator normally remains completely full, so there is

no need to remove the radiator/coolant pressure cap

unless checking for engine coolant (antifreeze) freeze point

or replacing coolant. Advise your service attendant of this.

As long as the engine operating temperature is satisfactory,

the coolant bottle need only be checked once a month.

When additional engine coolant (antifreeze) is needed to

maintain the proper level, only OAT coolant that meets the

requirements of FCA Material Standard MS.90032 should

be added to the coolant bottle. Do not overfill.

Points To Remember

NOTE:When the vehicle is stopped after a few miles/

kilometers of operation, you may observe vapor coming

from the front of the engine compartment. This is normally

a result of moisture from rain, snow, or high humidity

accumulating on the radiator and being vaporized when

the thermostat opens, allowing hot engine coolant (anti-

freeze) to enter the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

• Do not overfill the coolant expansion bottle. •

Check the coolant freeze point in the radiator and in the

coolant expansion bottle. If engine coolant (antifreeze)

needs to be added, the contents of the coolant expansion

bottle must also be protected against freezing.

• If frequent engine coolant (antifreeze) additions are

required, the cooling system should be pressure tested

for leaks.

• Maintain engine coolant (antifreeze) concentration at a

minimum of 50% OAT coolant (conforming to

MS.90032) and distilled water for proper corrosion pro-

tection of your engine which contains aluminum com-

ponents.

• Make sure that the coolant expansion bottle overflow

hoses are not kinked or obstructed.

• Keep the front of the radiator clean. If your vehicle is

equipped with air conditioning, keep the front of the

condenser clean.

• Do not change the thermostat for Summer or Winter

operation. If replacement is ever necessary, install ONLY

the correct type thermostat. Other designs may result in

unsatisfactory engine coolant (antifreeze) performance,

poor gas mileage, and increased emissions.

466 SERVICING AND MAINTENANCE