part time JEEP LIBERTY 2002 KJ / 1.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1694 of 1803

used to charge the refrigerant system with R-134a

refrigerant. Refer to the operating instructions sup-

plied by the equipment manufacturer for proper care

and use of this equipment.

SPECIFICATIONS - CHARGE CAPACITY

The R-134a refrigerant system charge capacity for

this vehicle is 0.737 kilograms (1.63 pounds).

A/C COMPRESSOR

DESCRIPTION

DESCRIPTION

The air conditioning system uses a Sanden

PXF-18, reciprocating swash plate-type compressor

on all models. This compressor has a fixed displace-

ment of 180 cubic centimeters (10.984 cubic inches),

and has both the suction and discharge ports located

on the cylinder head. A label identifying the use of

R-134a refrigerant is located on the compressor.

DESCRIPTION - HIGH PRESSURE RELIEF

VALVE

A high pressure relief valve is located on the com-

pressor cylinder head, which is on the rear of the

compressor. This mechanical valve is designed to

vent refrigerant from the system to protect against

damage to the compressor and other system compo-

nents, caused by condenser air flow restriction or an

overcharge of refrigerant.

OPERATION

OPERATION

The compressor is driven by the engine through an

electric clutch, drive rotor and belt arrangement. The

compressor is lubricated by refrigerant oil that is cir-

culated throughout the refrigerant system with the

refrigerant.

The compressor draws in low-pressure refrigerant

vapor from the evaporator through its suction port. It

then compresses the refrigerant into a high-pressure,

high-temperature refrigerant vapor, which is then

pumped to the condenser through the compressor dis-

charge port.

The compressor cannot be repaired. If faulty or

damaged, the entire compressor assembly must be

replaced. The compressor clutch, pulley and clutch

coil are available for service.

OPERATION - HIGH PRESSURE RELIEF VALVE

The high pressure relief valve vents the system

when a discharge pressure of 3445 to 4135 kPa (500

to 600 psi) or above is reached. The valve closes

when a minimum discharge pressure of 2756 kPa

(400 psi) is reached.

The high pressure relief valve vents only enough

refrigerant to reduce the system pressure, and then

re-seats itself. The majority of the refrigerant is con-

served in the system. If the valve vents refrigerant, it

does not mean that the valve is faulty.

The high pressure relief valve is a factory-cali-

brated unit. The valve cannot be adjusted or

repaired, and must not be removed or otherwise dis-

turbed. The valve is only serviced as a part of the

compressor assembly.

DIAGNOSIS AND TESTING - A/C COMPRESSOR

NOISE

When investigating an air conditioning related

noise, you must first know the conditions under

which the noise occurs. These conditions include:

weather, vehicle speed, transmission in gear or neu-

tral, engine speed, engine temperature, and any

other special conditions. Noises that develop during

air conditioning operation can often be misleading.

For example: What sounds like a failed front bearing

or connecting rod, may be caused by loose bolts, nuts,

mounting brackets, or a loose compressor clutch

assembly.

Drive belts are speed sensitive. At different engine

speeds and depending upon belt tension, belts can

develop noises that are mistaken for a compressor

noise. Improper belt tension can cause a misleading

noise when the compressor clutch is engaged, which

may not occur when the compressor clutch is disen-

gaged. Check the serpentine drive belt condition and

tension as described in Cooling before beginning this

procedure.

(1) Select a quiet area for testing. Duplicate the

complaint conditions as much as possible. Switch the

compressor on and off several times to clearly iden-

tify the compressor noise. Listen to the compressor

while the clutch is engaged and disengaged. Probe

the compressor with an engine stethoscope or a long

screwdriver with the handle held to your ear to bet-

ter localize the source of the noise.

(2) Loosen all of the compressor mounting hard-

ware and retighten. Tighten the compressor clutch

mounting nut. Be certain that the clutch coil is

mounted securely to the compressor, and that the

clutch plate and rotor are properly aligned and have

the correct air gap. (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS/A/C COMPRESSOR

CLUTCH - INSTALLATION)

24 - 42 PLUMBINGKJ

PLUMBING (Continued)

Page 1708 of 1803

DESCRIPTION - STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. Connect

the DRB scan tool to the data link connector and

access the state display screen. Then access either

State Display Inputs and Outputs or State Display

Sensors.

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly. Connect the DRB scan tool to the data link

connector and access the Actuators screen.

DESCRIPTION - DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

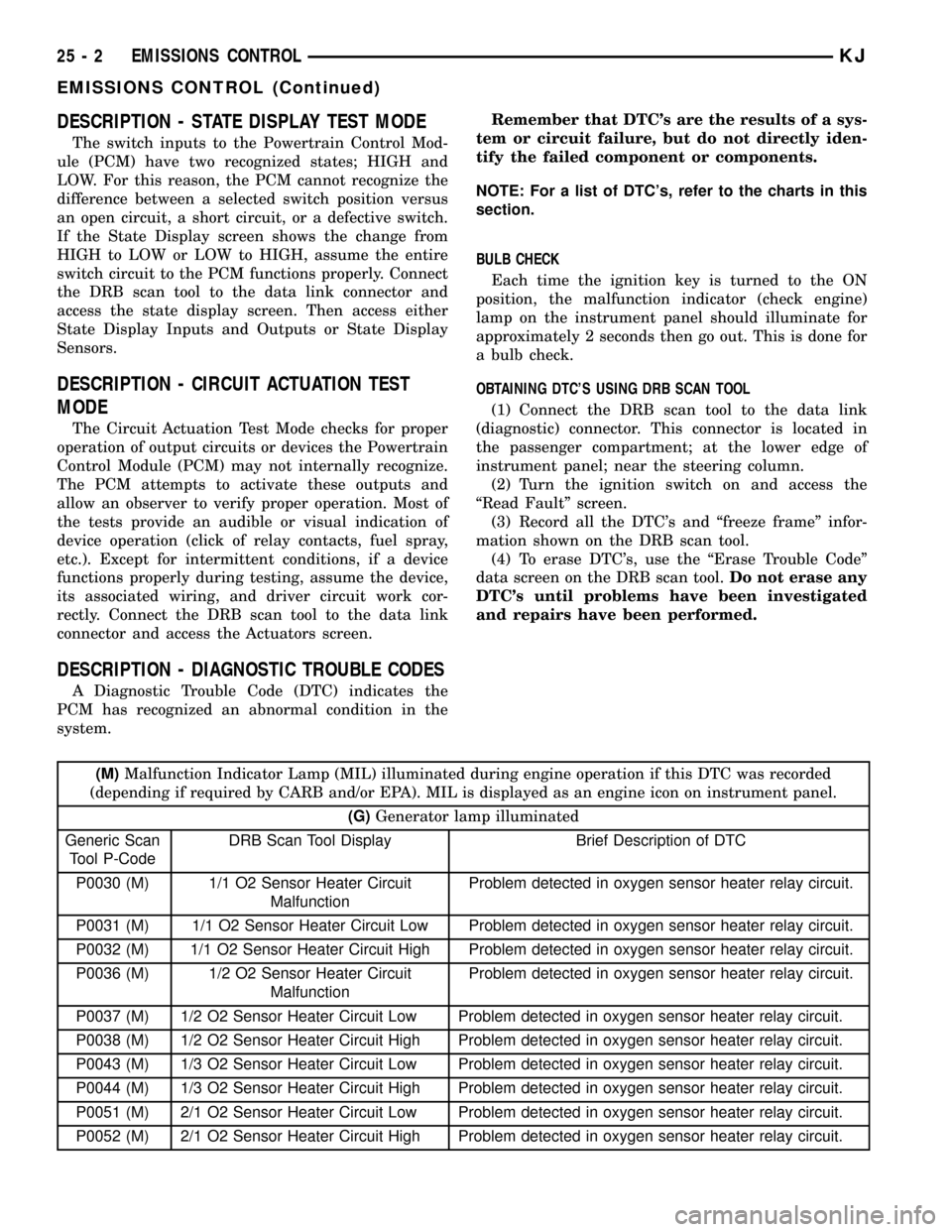

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0030 (M) 1/1 O2 Sensor Heater Circuit

MalfunctionProblem detected in oxygen sensor heater relay circuit.

P0031 (M) 1/1 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0032 (M) 1/1 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0036 (M) 1/2 O2 Sensor Heater Circuit

MalfunctionProblem detected in oxygen sensor heater relay circuit.

P0037 (M) 1/2 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0038 (M) 1/2 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0043 (M) 1/3 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0044 (M) 1/3 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0051 (M) 2/1 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0052 (M) 2/1 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

25 - 2 EMISSIONS CONTROLKJ

EMISSIONS CONTROL (Continued)

Page 1725 of 1803

Normal vehicle miles or engine misfire can cause a

catalyst to decay. This can increase vehicle emissions

and deteriorate engine performance, driveability and

fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S's sensor strategy is based on the fact that

as a catalyst deteriorates, its oxygen storage capacity

and its efficiency are both reduced. By monitoring

the oxygen storage capacity of a catalyst, its effi-

ciency can be indirectly calculated. The upstream

O2S is used to detect the amount of oxygen in the

exhaust gas before the gas enters the catalytic con-

verter. The PCM calculates the A/F mixture from the

output of the O2S. A low voltage indicates high oxy-

gen content (lean mixture). A high voltage indicates a

low content of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstream O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For a

totally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL will be illu-

minated.

DESCRIPTION - TRIP DEFINITION

The term ªTripº has different meanings depending

on what the circumstances are. If the MIL (Malfunc-

tion Indicator Lamp) is OFF, a Trip is defined as

when the Oxygen Sensor Monitor and the Catalyst

Monitor have been completed in the same drive cycle.

When any Emission DTC is set, the MIL on the

dash is turned ON. When the MIL is ON, it takes 3good trips to turn the MIL OFF. In this case, it

depends on what type of DTC is set to know what a

ªTripº is.

For the Fuel Monitor or Mis-Fire Monitor (contin-

uous monitor), the vehicle must be operated in the

ªSimilar Condition Windowº for a specified amount of

time to be considered a Good Trip.

If a Non-Contiuous OBDII Monitor fails twice in a

row and turns ON the MIL, re-running that monitor

which previously failed, on the next start-up and

passing the monitor, is considered to be a Good Trip.

These will include the following:

²Oxygen Sensor

²Catalyst Monitor

²Purge Flow Monitor

²Leak Detection Pump Monitor (if equipped)

²EGR Monitor (if equipped)

²Oxygen Sensor Heater Monitor

If any other Emission DTC is set (not an OBDII

Monitor), a Good Trip is considered to be when the

Oxygen Sensor Monitor and Catalyst Monitor have

been completed; or 2 Minutes of engine run time if

the Oxygen Sensor Monitor or Catalyst Monitor have

been stopped from running.

It can take up to 2 Failures in a row to turn on the

MIL. After the MIL is ON, it takes 3 Good Trips to

turn the MIL OFF. After the MIL is OFF, the PCM

will self-erase the DTC after 40 Warm-up cycles. A

Warm-up cycle is counted when the ECT (Engine

Coolant Temperature Sensor) has crossed 160ÉF and

has risen by at least 40ÉF since the engine has been

started.

DESCRIPTION - COMPONENT MONITORS

There are several components that will affect vehi-

cle emissions if they malfunction. If one of these com-

ponents malfunctions the Malfunction Indicator

Lamp (MIL) will illuminate.

Some of the component monitors are checking for

proper operation of the part. Electrically operated

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of a

greater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum if

the TPS indicates a small throttle opening.

All open/short circuit checks or any component that

has an associated limp in will set a fault after 1 trip

with the malfunction present. Components without

KJEMISSIONS CONTROL 25 - 19

EMISSIONS CONTROL (Continued)

Page 1733 of 1803

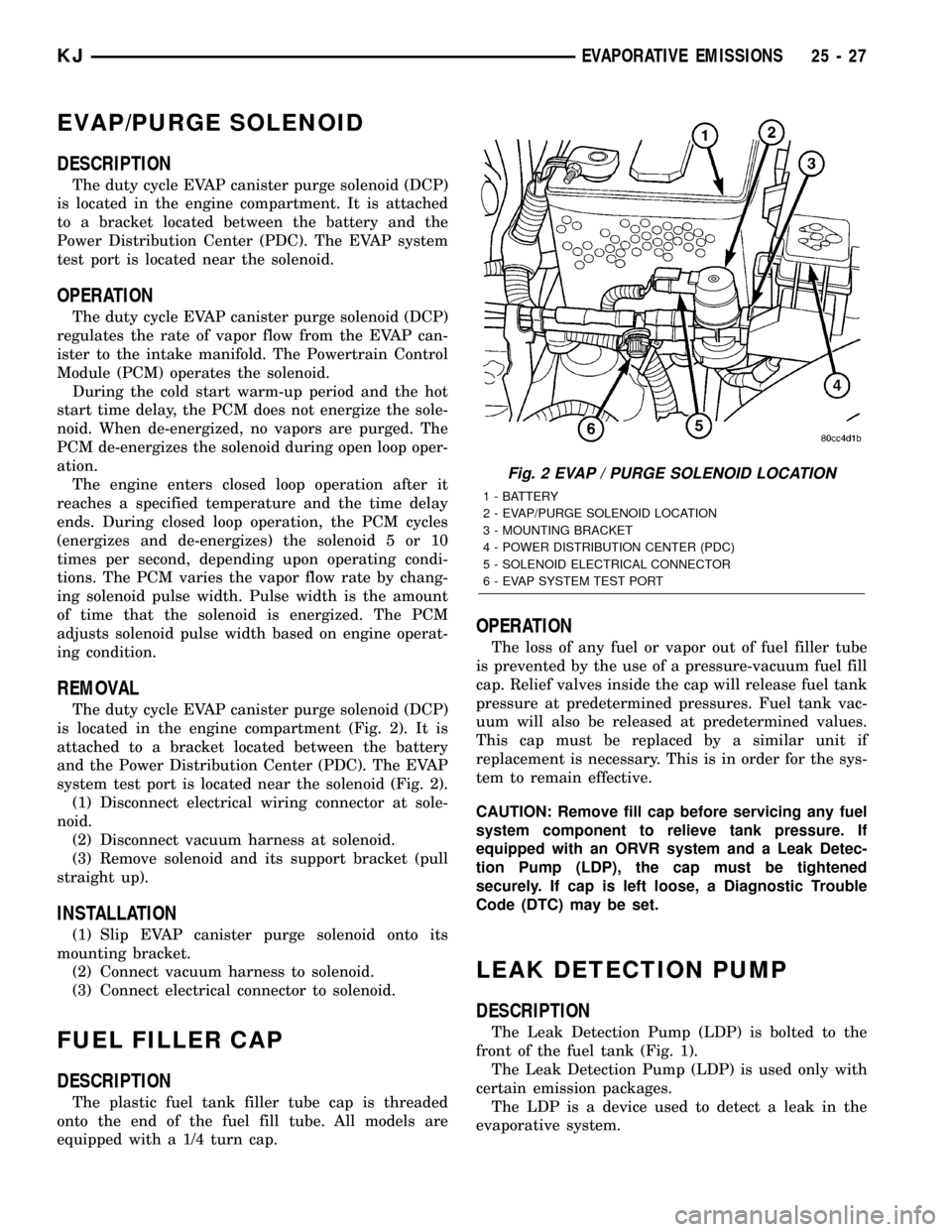

EVAP/PURGE SOLENOID

DESCRIPTION

The duty cycle EVAP canister purge solenoid (DCP)

is located in the engine compartment. It is attached

to a bracket located between the battery and the

Power Distribution Center (PDC). The EVAP system

test port is located near the solenoid.

OPERATION

The duty cycle EVAP canister purge solenoid (DCP)

regulates the rate of vapor flow from the EVAP can-

ister to the intake manifold. The Powertrain Control

Module (PCM) operates the solenoid.

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged. The

PCM de-energizes the solenoid during open loop oper-

ation.

The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM cycles

(energizes and de-energizes) the solenoid 5 or 10

times per second, depending upon operating condi-

tions. The PCM varies the vapor flow rate by chang-

ing solenoid pulse width. Pulse width is the amount

of time that the solenoid is energized. The PCM

adjusts solenoid pulse width based on engine operat-

ing condition.

REMOVAL

The duty cycle EVAP canister purge solenoid (DCP)

is located in the engine compartment (Fig. 2). It is

attached to a bracket located between the battery

and the Power Distribution Center (PDC). The EVAP

system test port is located near the solenoid (Fig. 2).

(1) Disconnect electrical wiring connector at sole-

noid.

(2) Disconnect vacuum harness at solenoid.

(3) Remove solenoid and its support bracket (pull

straight up).

INSTALLATION

(1) Slip EVAP canister purge solenoid onto its

mounting bracket.

(2) Connect vacuum harness to solenoid.

(3) Connect electrical connector to solenoid.

FUEL FILLER CAP

DESCRIPTION

The plastic fuel tank filler tube cap is threaded

onto the end of the fuel fill tube. All models are

equipped with a 1/4 turn cap.

OPERATION

The loss of any fuel or vapor out of fuel filler tube

is prevented by the use of a pressure-vacuum fuel fill

cap. Relief valves inside the cap will release fuel tank

pressure at predetermined pressures. Fuel tank vac-

uum will also be released at predetermined values.

This cap must be replaced by a similar unit if

replacement is necessary. This is in order for the sys-

tem to remain effective.

CAUTION: Remove fill cap before servicing any fuel

system component to relieve tank pressure. If

equipped with an ORVR system and a Leak Detec-

tion Pump (LDP), the cap must be tightened

securely. If cap is left loose, a Diagnostic Trouble

Code (DTC) may be set.

LEAK DETECTION PUMP

DESCRIPTION

The Leak Detection Pump (LDP) is bolted to the

front of the fuel tank (Fig. 1).

The Leak Detection Pump (LDP) is used only with

certain emission packages.

The LDP is a device used to detect a leak in the

evaporative system.

Fig. 2 EVAP / PURGE SOLENOID LOCATION

1 - BATTERY

2 - EVAP/PURGE SOLENOID LOCATION

3 - MOUNTING BRACKET

4 - POWER DISTRIBUTION CENTER (PDC)

5 - SOLENOID ELECTRICAL CONNECTOR

6 - EVAP SYSTEM TEST PORT

KJEVAPORATIVE EMISSIONS 25 - 27

Page 1752 of 1803

HVAC CONTROL ASSEMBLY WINDOW

DEFOGGER FUNCTION - DIAGNOSIS

AND TESTING, REAR..................8G-9

HVAC HOUSING - ASSEMBLY...........24-34

HVAC HOUSING - DISASSEMBLY........24-34

HVAC HOUSING - INSTALLATION........24-34

HVAC HOUSING - REMOVAL............24-33

HYDRAULIC LASH ADJUSTER -

DIAGNOSIS AND TESTING..........9-19,9-30

HYDRAULIC PRESSURE TEST -

DIAGNOSIS AND TESTING.............21-79

HYDRAULIC SCHEMATICS, SCHEMATICS

AND DIAGRAMS....................21-100

HYDROMETER TEST - STANDARD

PROCEDURE........................8F-11

IDENTIFICATION - DESCRIPTION,

FASTENER.........................Intro.-1

IDENTIFICATION AND INFORMATION -

DESCRIPTION, SECTION.............8W-01-6

IDENTIFICATION NUMBER -

DESCRIPTION, VEHICLE..............Intro.-8

IDLE AIR CONTROL MOTOR -

DESCRIPTION.......................14-35

IDLE AIR CONTROL MOTOR -

INSTALLATION.......................14-36

IDLE AIR CONTROL MOTOR -

OPERATION.........................14-35

IDLE AIR CONTROL MOTOR - REMOVAL . . 14-36

IDLER SHAFT - INSTALLATION...........9-77

IDLER SHAFT - REMOVAL...............9-77

IGNITION CIRCUIT SENSE -

DESCRIPTION.........................8E-13

IGNITION CIRCUIT SENSE - OPERATION . . 8E-15

IGNITION COIL - DESCRIPTION...........8I-9

IGNITION COIL - INSTALLATION.........8I-10

IGNITION COIL - OPERATION.............8I-9

IGNITION COIL - REMOVAL.............8I-10

IGNITION COIL CAPACITOR -

DESCRIPTION........................8I-16

IGNITION COIL CAPACITOR -

INSTALLATION.......................8I-16

IGNITION COIL CAPACITOR - OPERATION . . 8I-16

IGNITION COIL CAPACITOR - REMOVAL . . . 8I-16

IGNITION COIL RESISTANCE, 2.4L.........8I-2

IGNITION COIL RESISTANCE, 3.7L V-6.....8I-3

IGNITION CONTROL - DESCRIPTION.......8I-1

IGNITION CONTROL - OPERATION.........8I-1

IGNITION SWITCH - DESCRIPTION........19-8

IGNITION SWITCH - DESCRIPTION,

KEY-IN.............................19-10

IGNITION SWITCH - DIAGNOSIS AND

TESTING............................19-8

IGNITION SWITCH - DIAGNOSIS AND

TESTING, KEY-IN.....................19-10

IGNITION SWITCH INSTALLATION,

INSTALLATION........................19-9

IGNITION SWITCH REMOVAL, REMOVAL . . . 19-9

IGNITION SYSTEM - TORQUE............8I-3

IGNITION TIMING - SPECIFICATIONS......8I-2

IGNITION-OFF DRAW TEST - STANDARD

PROCEDURE........................8F-14

ILLUMINATION BULB - INSTALLATION,

COMPASS MINI-TRIP

.................8L-75

ILLUMINATION BULB - INSTALLATION,

HEATER-A/C CONTROL

................8L-78

ILLUMINATION BULB - INSTALLATION,

TRANSMISSION RANGE INDICATOR

......8L-83

ILLUMINATION BULB - REMOVAL,

COMPASS MINI-TRIP

.................8L-74

ILLUMINATION BULB - REMOVAL,

HEATER-A/C CONTROL

................8L-78

ILLUMINATION BULB - REMOVAL,

TRANSMISSION RANGE INDICATOR

......8L-82

IMMOBILIZER MODULE - DESCRIPTION,

SENTRY KEY

........................8E-15

IMMOBILIZER MODULE - INSTALLATION,

SENTRY KEY

........................8E-18

IMMOBILIZER MODULE - OPERATION,

SENTRY KEY

........................8E-16

IMMOBILIZER MODULE - REMOVAL,

SENTRY KEY

........................8E-17

IMPACT AIRBAG CONTROL MODULE -

DESCRIPTION, SIDE

..................8O-43

IMPACT AIRBAG CONTROL MODULE -

INSTALLATION, SIDE

.................8O-45

IMPACT AIRBAG CONTROL MODULE -

OPERATION, SIDE

....................8O-43IMPACT AIRBAG CONTROL MODULE -

REMOVAL, SIDE.....................8O-44

IMPACT SENSOR - DESCRIPTION,

FRONT.............................8O-21

IMPACT SENSOR - INSTALLATION,

FRONT.............................8O-22

IMPACT SENSOR - OPERATION, FRONT . . . 8O-21

IMPACT SENSOR - REMOVAL, FRONT....8O-22

INCORRECT FLUID LEVEL - DIAGNOSIS

AND TESTING, EFFECTS OF............21-125

INDICATOR - DESCRIPTION, ABS........8J-11

INDICATOR - DESCRIPTION, AIRBAG.....8J-12

INDICATOR - DESCRIPTION, BRAKE/

PARK BRAKE........................8J-13

INDICATOR - DESCRIPTION, CHARGING . . . 8J-15

INDICATOR - DESCRIPTION, COOLANT

LOW...............................8J-15

INDICATOR - DESCRIPTION, CRUISE.....8J-16

INDICATOR - DESCRIPTION, DOOR AJAR . . 8J-17

INDICATOR - DESCRIPTION, FOUR LOW

MODE.............................8J-29

INDICATOR - DESCRIPTION, FRONT FOG

LAMP..............................8J-19

INDICATOR - DESCRIPTION, FULL TIME . . . 8J-29

INDICATOR - DESCRIPTION, GATE AJAR . . 8J-20

INDICATOR - DESCRIPTION, GLASS

AJAR..............................8J-21

INDICATOR - DESCRIPTION, HIGH BEAM . . 8J-22

INDICATOR - DESCRIPTION, LOW FUEL . . . 8J-22

INDICATOR - DESCRIPTION, LOW OIL

PRESSURE..........................8J-23

INDICATOR - DESCRIPTION, OVERDRIVE

OFF ...............................8J-26

INDICATOR - DESCRIPTION, PART TIME . . 8J-29

INDICATOR - DESCRIPTION, REAR FOG

LAMP..............................8J-27

INDICATOR - DESCRIPTION, SEATBELT . . . 8J-27

INDICATOR - DESCRIPTION, SECURITY . . . 8J-28

INDICATOR - DESCRIPTION, SKIS........8J-31

INDICATOR - DESCRIPTION, TRANS

TEMP..............................8J-33

INDICATOR - DESCRIPTION, TURN

SIGNAL............................8J-34

INDICATOR - DESCRIPTION, WAIT-TO-

START .............................8J-35

INDICATOR - DESCRIPTION, WASHER

FLUID..............................8J-35

INDICATOR - DESCRIPTION, WATER-IN-

FUEL..............................8J-37

INDICATOR - DIAGNOSIS AND TESTING,

BRAKE.............................8J-14

INDICATOR - DIAGNOSIS AND TESTING,

WASHER FLUID......................8J-36

INDICATOR - OPERATION, ABS..........8J-11

INDICATOR - OPERATION, AIRBAG.......8J-12

INDICATOR - OPERATION, BRAKE/PARK

BRAKE.............................8J-13

INDICATOR - OPERATION, CHARGING....8J-15

INDICATOR - OPERATION, COOLANT

LOW...............................8J-16

INDICATOR - OPERATION, CRUISE.......8J-17

INDICATOR - OPERATION, DOOR AJAR . . . 8J-17

INDICATOR - OPERATION, FOUR LOW

MODE.............................8J-30

INDICATOR - OPERATION, FRONT FOG

LAMP..............................8J-19

INDICATOR - OPERATION, FULL TIME....8J-30

INDICATOR - OPERATION, GATE AJAR....8J-20

INDICATOR - OPERATION, GLASS AJAR . . . 8J-21

INDICATOR - OPERATION, HIGH BEAM

....8J-22

INDICATOR - OPERATION, LOW FUEL

.....8J-22

INDICATOR - OPERATION, LOW OIL

PRESSURE

..........................8J-23

INDICATOR - OPERATION, OVERDRIVE

OFF

...............................8J-26

INDICATOR - OPERATION, PART TIME

....8J-29

INDICATOR - OPERATION, REAR FOG

LAMP

..............................8J-27

INDICATOR - OPERATION, SEATBELT

.....8J-28

INDICATOR - OPERATION, SECURITY

.....8J-28

INDICATOR - OPERATION, SKIS

.........8J-31

INDICATOR - OPERATION, TRANS TEMP

. . 8J-34

INDICATOR - OPERATION, TURN SIGNAL

. . 8J-34

INDICATOR - OPERATION, WAIT-TO-

START

.............................8J-35

INDICATOR - OPERATION, WASHER

FLUID

..............................8J-36INDICATOR - OPERATION, WATER-IN-

FUEL..............................8J-37

INDICATOR ILLUMINATION BULB -

INSTALLATION, TRANSMISSION

RANGE.............................8L-83

INDICATOR ILLUMINATION BULB -

REMOVAL, TRANSMISSION RANGE......8L-82

INDICATOR LAMP (MIL) - DESCRIPTION,

MALFUNCTION.......................8J-24

INDICATOR LAMP (MIL) - OPERATION,

MALFUNCTION.......................8J-24

INDICATOR TEST - STANDARD

PROCEDURE, BUILT-IN................8F-10

INDICATORS - DIAGNOSIS AND

TESTING, TREAD WEAR................22-8

INFLATION - DIAGNOSIS AND TESTING,

TIRE................................22-7

INITIAL OPERATION - STANDARD

PROCEDURE, POWER STEERING

PUMP.............................19-18

INITIALIZATION - STANDARD

PROCEDURE, SKIS....................8Q-8

INJECTION - DESCRIPTION, FUEL........14-29

INJECTOR - DESCRIPTION, FUEL........14-33

INJECTOR - DIAGNOSIS AND TESTING,

FUEL..............................14-33

INJECTOR - OPERATION, FUEL..........14-33

INLET FILTER - INSTALLATION..........14-28

INLET FILTER - REMOVAL..............14-28

INPUT - OPERATION, ASD SENSE - PCM . . . 8I-4

INPUT CLUTCH ASSEMBLY - ASSEMBLY . 21-138

INPUT CLUTCH ASSEMBLY -

DESCRIPTION......................21-133

INPUT CLUTCH ASSEMBLY -

DISASSEMBLY......................21-135

INPUT CLUTCH ASSEMBLY - OPERATION . 21-135

INPUT SPEED SENSOR - DESCRIPTION . . 21-143

INPUT SPEED SENSOR - INSTALLATION . 21-143

INPUT SPEED SENSOR - OPERATION....21-143

INPUT SPEED SENSOR - REMOVAL.....21-143

INSTRUMENT CLUSTER - ASSEMBLY.....8J-10

INSTRUMENT CLUSTER - DESCRIPTION . . . 8J-2

INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING........................8J-7

INSTRUMENT CLUSTER - DISASSEMBLY . . . 8J-9

INSTRUMENT CLUSTER - INSTALLATION . . 8J-11

INSTRUMENT CLUSTER - OPERATION.....8J-4

INSTRUMENT CLUSTER - REMOVAL......8J-9

INSTRUMENT PANEL ANTENNA CABLE -

INSTALLATION.......................8A-8

INSTRUMENT PANEL ANTENNA CABLE -

REMOVAL...........................8A-7

INSTRUMENT PANEL ASSEMBLY -

INSTALLATION......................23-151

INSTRUMENT PANEL ASSEMBLY -

REMOVAL.........................23-149

INSTRUMENT PANEL CENTER BEZEL -

INSTALLATION......................23-154

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL.........................23-154

INSTRUMENT PANEL DRIVER SIDE

BEZELS - INSTALLATION..............23-154

INSTRUMENT PANEL DRIVER SIDE

BEZELS - REMOVAL.................23-153

INSTRUMENT PANEL END CAP -

INSTALLATION

......................23-153

INSTRUMENT PANEL END CAP -

REMOVAL

.........................23-153

INSTRUMENT PANEL PASSENGER SIDE

BEZEL - INSTALLATION

...............23-154

INSTRUMENT PANEL PASSENGER SIDE

BEZEL - REMOVAL

..................23-154

INSTRUMENT PANEL TOP COVER -

INSTALLATION

......................23-153

INSTRUMENT PANEL TOP COVER -

REMOVAL

.........................23-152

INTAKE AIR TEMPERATURE SENSOR -

DESCRIPTION

.......................14-36

INTAKE AIR TEMPERATURE SENSOR -

INSTALLATION

.......................14-38

INTAKE AIR TEMPERATURE SENSOR -

OPERATION

.........................14-36

INTAKE AIR TEMPERATURE SENSOR -

REMOVAL

..........................14-37

INTAKE MANIFOLD - DESCRIPTION

.......9-68

INTAKE MANIFOLD - INSTALLATION

.......9-69

INTAKE MANIFOLD - REMOVAL

..........9-68

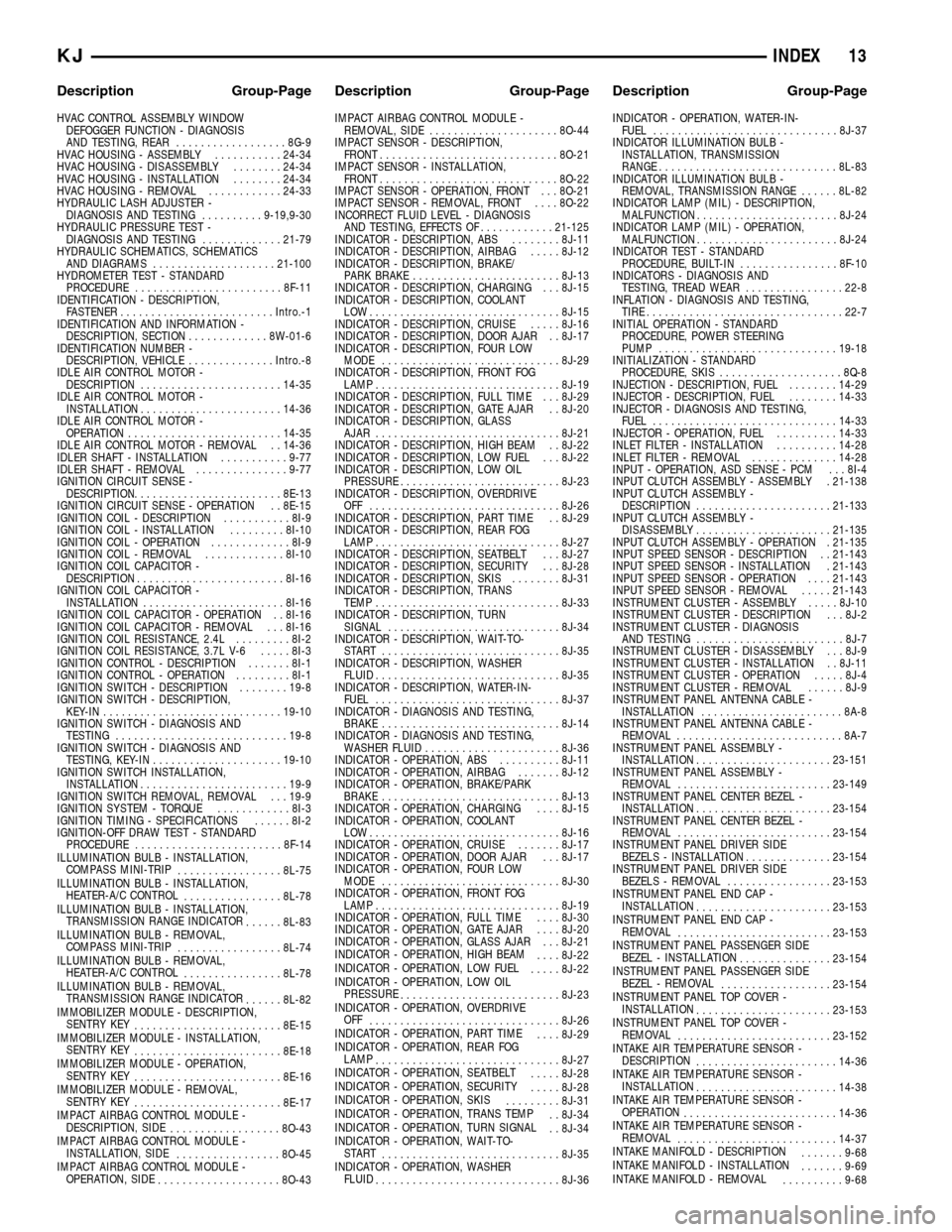

KJINDEX 13

Description Group-Page Description Group-Page Description Group-Page

Page 1757 of 1803

OPERATION - DESCRIPTION, MODES OF . . 8E-11

OPERATION - DIAGNOSIS AND TESTING,

AIR CHECKING TRANSMISSION

CLUTCH............................21-80

ORDER, 2.4L 4-CYLINDER - ENGINE

FIRING..............................8I-2

ORDER, 3.7L V-6 - ENGINE FIRING........8I-2

ORIFICE TUBE - DESCRIPTION, A/C......24-50

ORIFICE TUBE - INSTALLATION, A/C......24-50

ORIFICE TUBE - OPERATION, A/C........24-50

ORIFICE TUBE - REMOVAL, A/C.........24-50

ORVR - DESCRIPTION.................25-29

ORVR - OPERATION..................25-29

OUT - ADJUSTMENT, LOCK..............5-30

OUTBOARD SEAT BELT & RETRACTOR -

INSTALLATION, REAR.................8O-34

OUTBOARD SEAT BELT & RETRACTOR -

REMOVAL, REAR....................8O-33

OUTER BELT MOLDING - INSTALLATION,

FRONT DOOR......................23-186

OUTER BELT MOLDING - INSTALLATION,

REAR DOOR.......................23-186

OUTER BELT MOLDING - REMOVAL,

FRONT DOOR......................23-186

OUTER BELT MOLDING - REMOVAL,

REAR DOOR.......................23-186

OUTER TIE ROD END REMOVAL TOOL,

SPECIAL TOOLS.....................19-15

OUTLET - DESCRIPTION, CIGAR

LIGHTER.........................8W-97-2

OUTLET - DESCRIPTION, POWER......8W-97-11

OUTLET - DIAGNOSIS AND TESTING,

CIGAR LIGHTER...................8W-97-2

OUTLET - DIAGNOSIS AND TESTING,

POWER.........................8W-97-11

OUTLET - INSTALLATION, POWER....8W-97-13

OUTLET - OPERATION, CIGAR LIGHTER . 8W-97-2

OUTLET - OPERATION, POWER......8W-97-11

OUTLET - REMOVAL, POWER........8W-97-12

OUTLET BARRELS - INSTALLATION,

PANEL.............................24-29

OUTLET BARRELS - REMOVAL, PANEL . . . 24-29

OUTLETS - DESCRIPTION, DEMISTER....24-29

OUTPUT - DESCRIPTION, PCM...........8I-4

OUTPUT - OPERATION, PCM............14-33

OUTPUT - OPERATION, PCM.............8I-4

OUTPUT SHAFT SEAL - INSTALLATION,

FRONT......................21-208,21-246

OUTPUT SHAFT SEAL - INSTALLATION,

REAR.............................21-212

OUTPUT SHAFT SEAL - REMOVAL,

FRONT......................21-208,21-246

OUTPUT SHAFT SEAL - REMOVAL, REAR . 21-210

OUTPUT SPEED SENSOR - DESCRIPTION . 21-152

OUTPUT SPEED SENSOR -

INSTALLATION......................21-152

OUTPUT SPEED SENSOR - OPERATION . . 21-152

OUTPUT SPEED SENSOR - REMOVAL . . . 21-152

OVERDRIVE OFF INDICATOR -

DESCRIPTION.......................8J-26

OVERDRIVE OFF INDICATOR -

OPERATION.........................8J-26

OVERDRIVE SWITCH - DESCRIPTION....21-153

OVERDRIVE SWITCH - OPERATION.....21-153

OVERHEAD CONSOLE - DESCRIPTION....8M-1

OVERHEAD CONSOLE - OPERATION......8M-2

OVERHEAD CONSOLE, REMOVAL........8M-4

OVERRIDE RELAY - DESCRIPTION,

CLUTCH SWITCH......................6-10

OVERRIDE RELAY - INSTALLATION,

CLUTCH SWITCH......................6-10

OVERRIDE RELAY - OPERATION,

CLUTCH SWITCH......................6-10

OVERRIDE RELAY - REMOVAL, CLUTCH

SWITCH.............................6-10

OXYGEN SENSOR - DESCRIPTION.......14-40

OXYGEN SENSOR - INSTALLATION.......14-43

OXYGEN SENSOR - OPERATION.........14-40

OXYGEN SENSOR - REMOVAL..........14-41

PADS - INSTALLATION, FRONT BRAKE.....5-11

PADS - REMOVAL, FRONT BRAKE........5-11

PAINT CODE - DESCRIPTION..........23-162

PAINT CODES - SPECIFICATIONS.......23-162

PAINT TOUCH-UP - DESCRIPTION

......23-163

PAN - CLEANING, OIL

..................9-63

PAN - DESCRIPTION, OIL

...............9-63

PAN - INSPECTION, OIL

................9-63

PAN - INSTALLATION, OIL

...............9-64PAN - REMOVAL, OIL..................9-63

PANEL - DESCRIPTION, LATCH - ACCESS . 23-139

PANEL - INSTALLATION, GLASS........23-178

PANEL - INSTALLATION, LATCH -

ACCESS...........................23-139

PANEL - INSTALLATION, QUARTER TRIM . 23-159

PANEL - INSTALLATION, TRIM . . . 23-126,23-132,

23-138

PANEL - REMOVAL, GLASS............23-178

PANEL - REMOVAL, LATCH - ACCESS . . . 23-139

PANEL - REMOVAL, QUARTER TRIM....23-159

PANEL - REMOVAL, TRIM . 23-125,23-132,23-138

PANEL ADJUSTMENT, ADJUSTMENTS -

SUNROOF GLASS...................23-178

PANEL ANTENNA CABLE -

INSTALLATION, INSTRUMENT............8A-8

PANEL ANTENNA CABLE - REMOVAL,

INSTRUMENT........................8A-7

PANEL ASSEMBLY - INSTALLATION,

INSTRUMENT......................23-151

PANEL ASSEMBLY - REMOVAL,

INSTRUMENT......................23-149

PANEL CENTER BEZEL - INSTALLATION,

INSTRUMENT......................23-154

PANEL CENTER BEZEL - REMOVAL,

INSTRUMENT......................23-154

PANEL DOOR - INSTALLATION..........24-36

PANEL DOOR ACTUATOR -

INSTALLATION.......................24-25

PANEL DOOR ACTUATOR - REMOVAL....24-24

PANEL DRIVER SIDE BEZELS -

INSTALLATION, INSTRUMENT..........23-154

PANEL DRIVER SIDE BEZELS -

REMOVAL, INSTRUMENT.............23-153

PANEL END CAP - INSTALLATION,

INSTRUMENT......................23-153

PANEL END CAP - REMOVAL,

INSTRUMENT......................23-153

PANEL OUTLET BARRELS -

INSTALLATION.......................24-29

PANEL OUTLET BARRELS - REMOVAL....24-29

PANEL PASSENGER SIDE BEZEL -

INSTALLATION, INSTRUMENT..........23-154

PANEL PASSENGER SIDE BEZEL -

REMOVAL, INSTRUMENT.............23-154

PANEL SEAL - INSTALLATION, GLASS . . . 23-178

PANEL SEAL - REMOVAL, GLASS.......23-178

PANEL TOP COVER - INSTALLATION,

INSTRUMENT......................23-153

PANEL TOP COVER - REMOVAL,

INSTRUMENT......................23-152

PARK - INTERLOCK CABLE -

INSTALLATION......................21-153

PARK - INTERLOCK CABLE - REMOVAL . . 21-153

PARK LAMP RELAY - DESCRIPTION......8L-54

PARK LAMP RELAY - DIAGNOSIS AND

TESTING...........................8L-55

PARK LAMP RELAY - INSTALLATION.....8L-56

PARK LAMP RELAY - OPERATION.......8L-54

PARK LAMP RELAY - REMOVAL.........8L-55

PARK RAMP - INSTALLATION, WIPER

ARM ..............................8R-43

PARK RAMP - REMOVAL, WIPER ARM . . . 8R-43

PARKING BRAKE - DESCRIPTION.........5-29

PARKING BRAKE - OPERATION...........5-29

PARK-INTERLOCK CABLE -

ADJUSTMENTS.....................21-154

PART TIME INDICATOR - DESCRIPTION . . . 8J-29

PART TIME INDICATOR - OPERATION.....8J-29

PASSENGER AIRBAG - DESCRIPTION....8O-27

PASSENGER AIRBAG - INSTALLATION....8O-29

PASSENGER AIRBAG - OPERATION......8O-27

PASSENGER AIRBAG - REMOVAL........8O-28

PASSENGER AIRBAG DOOR -

INSTALLATION......................8O-30

PASSENGER AIRBAG DOOR - REMOVAL . . 8O-29

PASSENGER AIRBAG MOUNTING

BRACKET - INSTALLATION.............8O-31

PASSENGER AIRBAG MOUNTING

BRACKET - REMOVAL

.................8O-31

PASSENGER SEAT HEATER SWITCH -

DESCRIPTION

.......................8G-14

PASSENGER SEAT HEATER SWITCH -

INSTALLATION

......................8G-15

PASSENGER SEAT HEATER SWITCH -

OPERATION

.........................8G-14

PASSENGER SEAT HEATER SWITCH -

REMOVAL

..........................8G-15PASSENGER SIDE BEZEL -

INSTALLATION, INSTRUMENT PANEL....23-154

PASSENGER SIDE BEZEL - REMOVAL,

INSTRUMENT PANEL.................23-154

PATTERNS - DIAGNOSIS AND TESTING,

TIRE WEAR..........................22-8

PCM - DESCRIPTION..................8E-11

PCM - OPERATION...................8E-14

PCM INPUT - OPERATION, ASD SENSE.....8I-4

PCM OUTPUT - DESCRIPTION............8I-4

PCM OUTPUT - OPERATION............14-33

PCM OUTPUT - OPERATION.............8I-4

PCM/SKIM PROGRAMMING - STANDARD

PROCEDURE.........................8E-1

PCV VALVE - DESCRIPTION............25-29

PCV VALVE - DIAGNOSIS AND TESTING . . . 25-31

PCV VALVE - INSTALLATION............25-32

PCV VALVE - OPERATION..............25-31

PCV VALVE - REMOVAL...............25-32

PEDAL - DESCRIPTION.................5-20

PEDAL - INSTALLATION................5-20

PEDAL - INSTALLATION, ACCELERATOR . . . 14-30

PEDAL - INSTALLATION, CLUTCH.........6-10

PEDAL - OPERATION...................5-20

PEDAL - REMOVAL....................5-20

PEDAL - REMOVAL, ACCELERATOR......14-29

PEDAL - REMOVAL, CLUTCH............6-10

PEDAL POSITION SWITCH -

DESCRIPTION, CLUTCH.................6-11

PEDAL POSITION SWITCH - DIAGNOSIS

AND TESTING, CLUTCH.................6-11

PEDAL POSITION SWITCH - OPERATION,

CLUTCH.............................6-11

PERFORMANCE - DIAGNOSIS AND

TESTING, A/C........................24-2

PERFORMANCE - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS............9-4

PERFORMANCE - DIAGNOSIS AND

TESTING, HEATER.....................24-6

PILOT BEARING - INSTALLATION..........6-8

PILOT BEARING - REMOVAL..............6-8

PINION GEAR/RING GEAR -

INSTALLATION........................3-46

PINION GEAR/RING GEAR - REMOVAL.....3-44

PINION GEAR/RING GEAR/TONE RING -

INSTALLATION...................3-112,3-82

PINION GEAR/RING GEAR/TONE RING -

REMOVAL......................3-110,3-79

PINION SEAL - INSTALLATION . . 3-103,3-39,3-68

PINION SEAL - REMOVAL......3-102,3-38,3-68

PIPE - INSTALLATION, CROSS-OVER......11-3

PIPE - REMOVAL, CROSS-OVER..........11-3

PISTON & CONNECTING ROD -

DESCRIPTION........................9-49

PISTON FITTING - STANDARD

PROCEDURE.........................9-50

PISTON RING FITTING - STANDARD

PROCEDURE.........................9-52

PISTONS - DESCRIPTION.............21-155

PISTONS - OPERATION...............21-155

PLANETARY GEARTRAIN - ASSEMBLY . . . 21-160

PLANETARY GEARTRAIN - CLEANING....21-159

PLANETARY GEARTRAIN - DESCRIPTION . 21-157

PLANETARY GEARTRAIN -

DISASSEMBLY......................21-159

PLANETARY GEARTRAIN - INSPECTION . . 21-159

PLANETARY GEARTRAIN - OPERATION . . 21-157

PLATE - INSTALLATION, DOOR SILL

SCUFF............................23-157

PLATE - INSTALLATION, FLEX............9-49

PLATE - INSTALLATION, FRONT SKID......13-6

PLATE - INSTALLATION, FUEL TANK

SKID...............................13-9

PLATE - INSTALLATION, REAR DOOR

SCUFF............................23-160

PLATE - INSTALLATION, TRANSFER

CASE SKID..........................13-7

PLATE - REMOVAL, DOOR SILL SCUFF . . . 23-157

PLATE - REMOVAL, FLEX...............9-49

PLATE - REMOVAL, FRONT SKID.........13-6

PLATE - REMOVAL, FUEL TANK SKID

......13-9

PLATE - REMOVAL, REAR DOOR SCUFF

. . 23-160

PLATE - REMOVAL, TRANSFER CASE

SKID

...............................13-7

PLATE LAMP BULB - INSTALLATION,

LICENSE

...........................8L-45

PLATE LAMP BULB - REMOVAL,

LICENSE

...........................8L-44

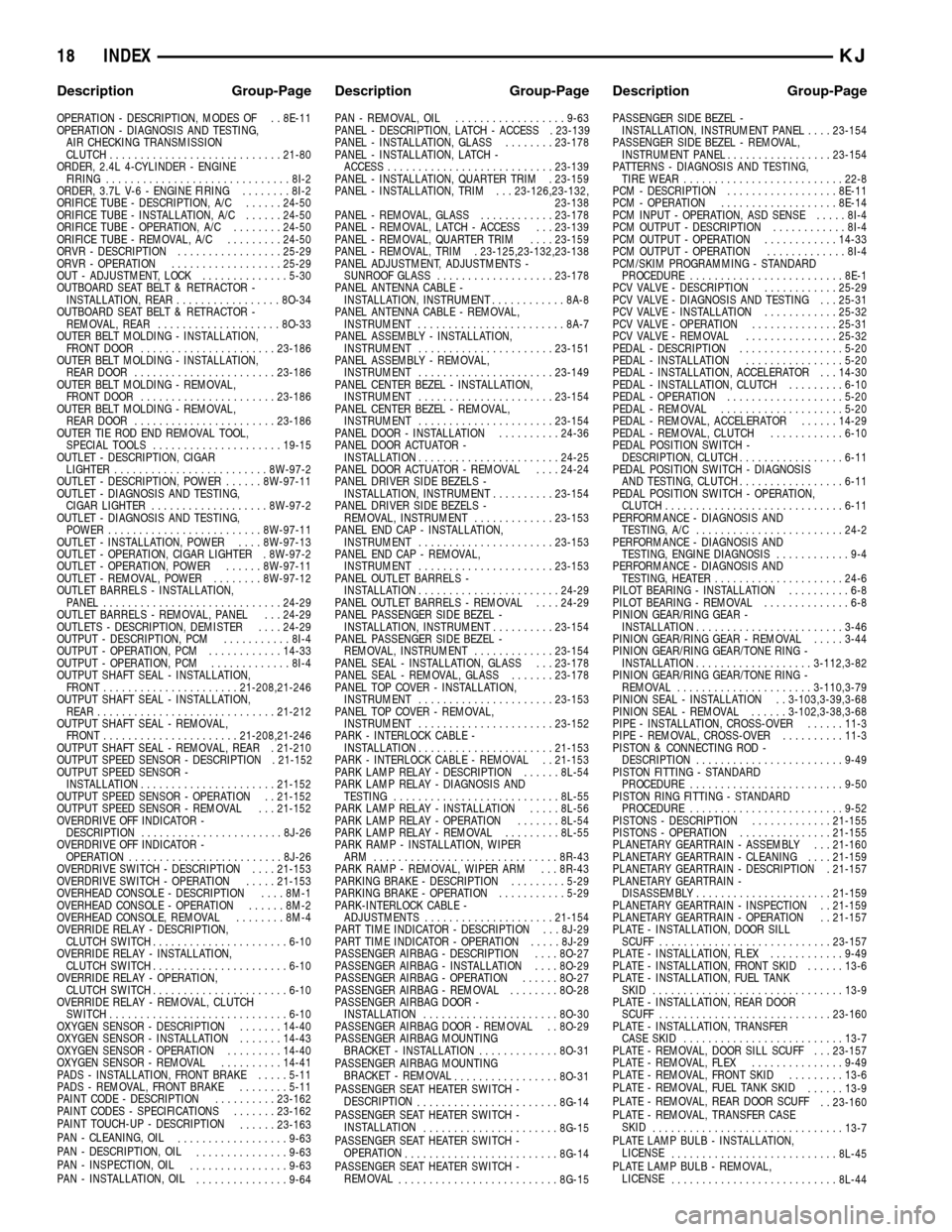

18 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1766 of 1803

TANK - REMOVAL, FUEL...............14-25

TANK CHECK VALVE - DESCRIPTION,

FUEL..............................14-28

TANK CHECK VALVE - INSTALLATION,

FUEL..............................14-28

TANK CHECK VALVE - OPERATION, FUEL . . 14-28

TANK CHECK VALVE - REMOVAL, FUEL . . . 14-28

TANK SKID PLATE - INSTALLATION,

FUEL...............................13-9

TANK SKID PLATE - REMOVAL, FUEL......13-9

TASK MANAGER - DESCRIPTION........25-17

TASK MANAGER - OPERATION..........25-21

TCM QUICK LEARN - STANDARD

PROCEDURE........................8E-21

TEMP INDICATOR - DESCRIPTION,

TRANS.............................8J-33

TEMP INDICATOR - OPERATION, TRANS . . 8J-34

TEMP SENSOR - DESCRIPTION,

AMBIENT...........................8M-9

TEMP SENSOR - OPERATION, AMBIENT . . . 8M-9

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE............................8J-18

TEMPERATURE GAUGE - OPERATION,

ENGINE............................8J-18

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY...........................8F-24

TEMPERATURE SENSOR - DESCRIPTION,

ENGINE COOLANT.....................7-19

TEMPERATURE SENSOR - DESCRIPTION,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION.....................21-170

TEMPERATURE SENSOR - DIAGNOSIS

AND TESTING, AMBIENT...............8M-9

TEMPERATURE SENSOR -

INSTALLATION, BATTERY..............8F-24

TEMPERATURE SENSOR -

INSTALLATION, ENGINE COOLANT........7-21

TEMPERATURE SENSOR -

INSTALLATION, INTAKE AIR............14-38

TEMPERATURE SENSOR - OPERATION,

BATTERY...........................8F-24

TEMPERATURE SENSOR - OPERATION,

ENGINE COOLANT.....................7-20

TEMPERATURE SENSOR - OPERATION,

INTAKE AIR .........................14-36

TEMPERATURE SENSOR - OPERATION,

TRANSMISSION.....................21-170

TEMPERATURE SENSOR - REMOVAL,

BATTERY...........................8F-24

TEMPERATURE SENSOR - REMOVAL,

ENGINE COOLANT.....................7-20

TEMPERATURE SENSOR - REMOVAL,

INTAKE AIR .........................14-37

TEMPERATURE SENSOR CIRCUIT -

DIAGNOSIS AND TESTING, AMBIENT.....8M-9

TENSIONER - DESCRIPTION, SEAT BELT . . 8O-36

TENSIONER - OPERATION, SEAT BELT....8O-36

TERMINAL - INSTALLATION.........8W-01-14

TERMINAL - REMOVAL.............8W-01-14

TEST - DIAGNOSIS AND TESTING, FUEL

PRESSURE LEAK DOWN................14-3

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP AMPERAGE....................14-16

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP CAPACITY.....................14-15

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP PRESSURE....................14-15

TEST - DIAGNOSIS AND TESTING,

HYDRAULIC PRESSURE...............21-79

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-2

TEST - STANDARD PROCEDURE,

BUILT-IN INDICATOR..................8F-10

TEST - STANDARD PROCEDURE,

HYDROMETER.......................8F-11

TEST - STANDARD PROCEDURE,

IGNITION-OFF DRAW..................8F-14

TEST - STANDARD PROCEDURE, LOAD . . . 8F-12

TEST - STANDARD PROCEDURE,

OPEN-CIRCUIT VOLTAGE

...............8F-12

TEST - STANDARD PROCEDURE,

VERIFICATION

........................8O-8

TEST MODE - DESCRIPTION, CIRCUIT

ACTUATION

..........................25-2

TEST MODE - DESCRIPTION, STATE

DISPLAY

............................25-2

TESTER - STANDARD PROCEDURE,

USING MIDTRONICS ELECTRICAL

.......8F-15TETHER ANCHOR - DESCRIPTION, CHILD . 8O-13

TETHER ANCHOR - OPERATION, CHILD . . . 8O-13

THEFT SECURITY - DESCRIPTION,

VEHICLE............................8Q-1

THEFT SECURITY - OPERATION, VEHICLE . . 8Q-3

THEFT SECURITY SYSTEM - DIAGNOSIS

AND TESTING, VEHICLE................8Q-6

THERMAL GUARD - DESCRIPTION.......8F-20

THERMAL GUARD - INSTALLATION......8F-20

THERMAL GUARD - OPERATION.........8F-20

THERMAL GUARD - REMOVAL..........8F-20

THERMOSTAT - DIAGNOSIS AND

TESTING............................7-21

THERMOSTAT - OPERATION, ENGINE

COOLANT............................7-21

THREAD REPAIR - STANDARD

PROCEDURE, ALUMINUM..............21-81

THREADED HOLE REPAIR -

DESCRIPTION......................Intro.-4

THREADS - STANDARD PROCEDURE,

REPAIR DAMAGED OR WORN............9-9

THROTTLE BODY - DESCRIPTION........14-43

THROTTLE BODY - INSTALLATION.......14-44

THROTTLE BODY - OPERATION.........14-43

THROTTLE BODY - REMOVAL...........14-43

THROTTLE CONTROL CABLE -

INSTALLATION.......................14-46

THROTTLE CONTROL CABLE - REMOVAL . . 14-45

THROTTLE POSITION SENSOR -

DESCRIPTION.........................14-47

THROTTLE POSITION SENSOR -

INSTALLATION.......................14-48

THROTTLE POSITION SENSOR -

OPERATION.........................14-47

THROTTLE POSITION SENSOR -

REMOVAL..........................14-47

TIE ROD END - INSTALLATION..........19-16

TIE ROD END - REMOVAL..............19-16

TIE ROD END REMOVAL TOOL, SPECIAL

TOOLS - OUTER.....................19-15

TIME INDICATOR - DESCRIPTION, FULL . . . 8J-29

TIME INDICATOR - DESCRIPTION, PART . . 8J-29

TIME INDICATOR - OPERATION, FULL....8J-30

TIME INDICATOR - OPERATION, PART....8J-29

TIMING - DESCRIPTION, VALVE..........9-71

TIMING - OPERATION, VALVE............9-71

TIMING - SPECIFICATIONS, IGNITION......8I-2

TIMING BELT / CHAIN COVER(S) -

INSTALLATION........................9-76

TIMING BELT / CHAIN COVER(S) -

REMOVAL...........................9-74

TIMING CHAIN WEAR, STANDARD

PROCEDURE - MEASURING.............9-71

TIRE - INSTALLATION, SPARE...........22-9

TIRE - REMOVAL, SPARE...............22-8

TIRE INFLATION - DIAGNOSIS AND

TESTING............................22-7

TIRE NOISE OR VIBRATION - DIAGNOSIS

AND TESTING........................22-8

TIRE ROTATION - STANDARD

PROCEDURE.........................22-2

TIRE &TEMPORARY - DESCRIPTION,

SPARE..............................22-6

TIRE WEAR PATTERNS - DIAGNOSIS

AND TESTING........................22-8

TIRES - DESCRIPTION.................22-6

TIRES - DESCRIPTION, RADIAL-PLY.......22-6

TIRES - DESCRIPTION, REPLACEMENT....22-7

TIRES AND WHEEL RUNOUT -

DIAGNOSIS AND TESTING..............22-1

TO GROUND - STANDARD PROCEDURE,

TESTING FOR A SHORT.............8W-01-9

TO GROUND ON FUSES POWERING

SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT . . 8W-01-9

TO USE WIRING DIAGRAMS -

DESCRIPTION, HOW................8W-01-1

TOE ADJUSTMENT - STANDARD

PROCEDURE..........................2-5

TOE ADJUSTMENT - STANDARD

PROCEDURE, CAMBER, CASTER..........2-5

TOOL, SPECIAL TOOLS - OUTER TIE

ROD END REMOVAL..................19-15

TOOLS - 3.7L ENGINE, SPECIAL

..........9-15

TOOLS - 8 1/4 AXLE, SPECIAL

...........3-98

TOOLS - BASE BRAKES, SPECIAL

.........5-7

TOOLS - BODY, SPECIAL

................23-5

TOOLS - COOLING, SPECIAL

.............7-14TOOLS - FRONT AXLE, SPECIAL..........3-34

TOOLS - FRONT SUSPENSION, SPECIAL....2-8

TOOLS - FUEL SYSTEM, SPECIAL........14-6

TOOLS - OUTER TIE ROD END REMOVAL

TOOL, SPECIAL......................19-15

TOOLS - POWER DISTRIBUTION

SYSTEMS, SPECIAL................8W-97-2

TOOLS - POWER STEERING PUMP,

SPECIAL...........................19-20

TOOLS - REAR AXLE, SPECIAL...........3-63

TOOLS - RFE TRANSMISSION, SPECIAL . . 21-120

TOOLS - STEERING COLUMN, SPECIAL....19-8

TOOLS - WIRING/TERMINAL, SPECIAL . 8W-01-10

TOOLS, BATTERY SYSTEM - SPECIAL.....8F-7

TOOLS, SPECIFICATIONS - SPECIAL....3-12,3-6

TOOLS, SPECIFICATIONS - SPECIAL......8F-24

TOP COVER - INSTALLATION,

INSTRUMENT PANEL.................23-153

TOP COVER - REMOVAL, INSTRUMENT

PANEL............................23-152

TORQUE - SPECIFICATIONS.............13-6

TORQUE CHART, SPECIFICATIONS . . 19-15,19-19,

19-8

TORQUE CHART, SPECIFICATIONS.....2-17,2-8

TORQUE CONVERTER - DESCRIPTION . . . 21-162

TORQUE CONVERTER - INSTALLATION . . . 21-167

TORQUE CONVERTER - OPERATION.....21-166

TORQUE CONVERTER - REMOVAL......21-167

TORQUE, EXCEPT DIESEL..............8F-23

TORQUE, GAS POWERED..............8F-38

TORQUE, IGNITION SYSTEM.............8I-3

TORQUE REFERENCES - DESCRIPTION . . Intro.-7

TORQUE, SPECIFICATIONS...............5-7

TORQUE, SPECIFICATIONS..............7-13

TORQUE, SPECIFICATIONS.............25-26

TORQUE, SPECIFICATIONS..............9-12

TORQUE, SPECIFICATIONS..............14-5

TORQUE, SPEED CONTROL.............8P-2

TOUCH-UP - DESCRIPTION, PAINT......23-163

TOW CONNECTOR - INSTALLATION,

TRAILER...........................8L-61

TOW CONNECTOR - REMOVAL, TRAILER . . 8L-61

TOW HOOK - INSTALLATION, FRONT......13-8

TOW HOOK - INSTALLATION, REAR.......13-8

TOW HOOK - REMOVAL, FRONT..........13-8

TOW HOOK - REMOVAL, REAR...........13-8

TOW RELAY - DESCRIPTION, TRAILER....8L-61

TOW RELAY - DIAGNOSIS AND TESTING,

TRAILER...........................8L-62

TOW RELAY - INSTALLATION, TRAILER . . . 8L-64

TOW RELAY - OPERATION, TRAILER.....8L-62

TOW RELAY - REMOVAL, TRAILER.......8L-63

TOW WIRING - DESCRIPTION, TRAILER . . 8L-64

TOWING - STANDARD PROCEDURE........0-6

TRACK - DESCRIPTION, SEAT..........8N-15

TRACK - DIAGNOSIS AND TESTING,

SEAT ..............................8N-16

TRACK - INSTALLATION, SEAT.........23-168

TRACK - INSTALLATION, SEAT..........8N-16

TRACK - OPERATION, SEAT............8N-15

TRACK - REMOVAL, SEAT.............23-168

TRACK - REMOVAL, SEAT..............8N-16

TRAC-LOK - ASSEMBLY, DIFFERENTIAL . . . 3-109,

3-77

TRAC-LOK - CLEANING, DIFFERENTIAL . . . 3-109,

3-77

TRAC-LOK - DISASSEMBLY,

DIFFERENTIAL...................3-107,3-75

TRAC-LOK - INSPECTION, DIFFERENTIAL . 3-109,

3-77

TRAC-LOKT- DIAGNOSIS AND TESTING . . 3-106,

3-74

TRAILER HITCH - INSTALLATION.........13-9

TRAILER HITCH - REMOVAL.............13-9

TRAILER TOW CONNECTOR -

INSTALLATION.......................8L-61

TRAILER TOW CONNECTOR - REMOVAL . . 8L-61

TRAILER TOW RELAY - DESCRIPTION....8L-61

TRAILER TOW RELAY - DIAGNOSIS AND

TESTING...........................8L-62

TRAILER TOW RELAY - INSTALLATION . . . 8L-64

TRAILER TOW RELAY - OPERATION......8L-62

TRAILER TOW RELAY - REMOVAL

.......8L-63

TRAILER TOW WIRING - DESCRIPTION

. . . 8L-64

TRANS COOLER - DESCRIPTION

.........7-32

TRANS TEMP INDICATOR -

DESCRIPTION

.......................8J-33

TRANS TEMP INDICATOR - OPERATION

. . . 8J-34

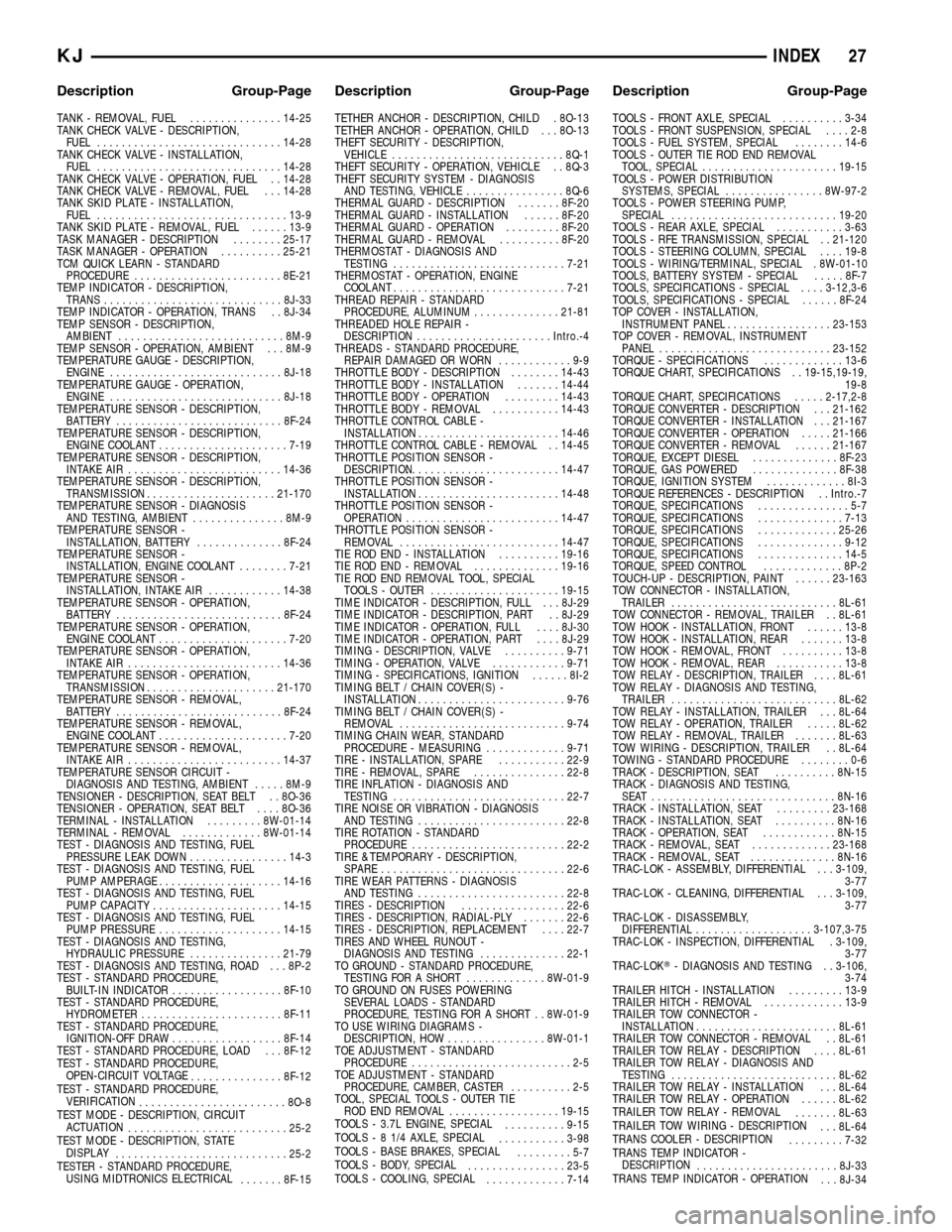

KJINDEX 27

Description Group-Page Description Group-Page Description Group-Page

Page 1784 of 1803

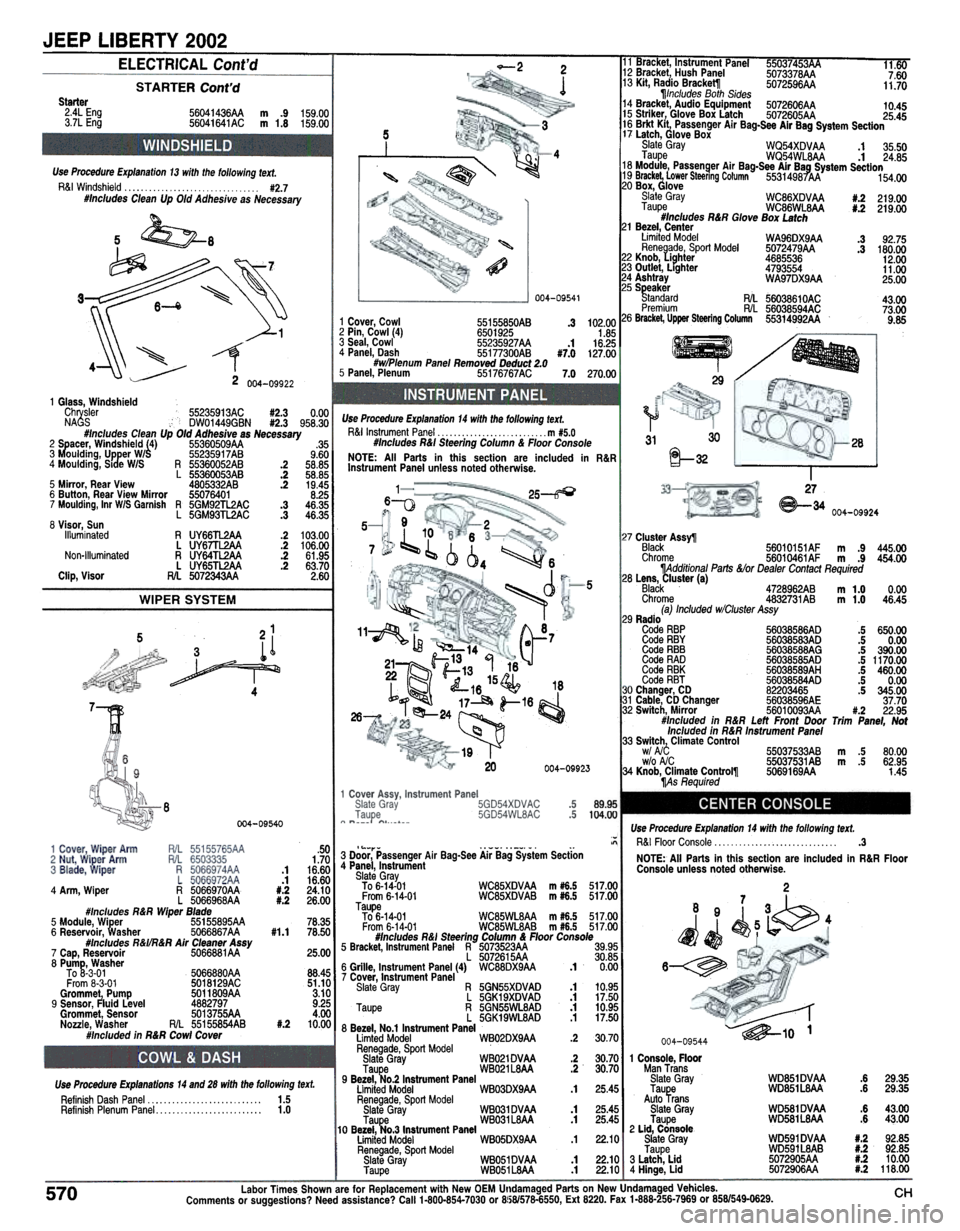

Starter2.4L Eng3.7L Eng

STARTER Cont'd

56041436M m .9 159.0056041641AC m 1.8 159.0035 I-

r~..:::---~ ~;i:i~:~'"

4~

Use Procedure Explanation 13 with the following tex!.R&IWindshield ...#2.7#Includes Clean Up Old Adhesive as Necessary

5 ~8

~~~~ -,

S-(::~:~~::~~:::::::~ ,,~(" p-~~ ~

\\\

f,

~

'~

):1

004-09541

1 Cover, Cowl 55155850AB.3 102.002 Pin, Cowl (4) 6501925 1.853 Seal, Cowl 55235927AA.1 16.254 Panel, Dash 55177300AB #7.0 127.00#W/Plenum Panel Removed Deduct 2.05 Panel, Plenum 55176767AC 7.0 270.00

\\\

4~1'"~

JEEP LIBERTY 2002

ELECTRICALCont'd2211 racket, Instrument anel9- 12 Bracket, Hush Panel 78 7.60

113 Kit, Radio Bracke~ 5072596M 11.701]lncludes Both Sides14 Bracket, Audio Equipment 5072606M 10.4515 Striker} Glove Box Latch 5072605M 25.4516 Brk! KI!t Passenger Air Bag-See Air Bag System Section11 Latch, ulove BoxSlate Gray WQ54XDVM.1 35.50Taupe WQ54WL8AA.1 24.8518 Module, PassenQer Air Bag-See Air Bag System Section19 Bracket, Lower Steeling Column 5531498TAA 154.0020 Box, GloveSlate Gray WC86XDVAA #.2 219.00Taupe WC86WL8AA #.2 219.00#Includes R&R Glove Box Latch21 Bezel, CenterLimited Model WA96DX9AA.3 92.75Renegade, Sport Model 5072479AA .3 180.0022 Knob, Li9hter 4685536 12.0023 Outlet, Lighter 4793554 11.0024 Ashtray WA97DX9AA 25.0025 SpeakerStandard AiL 56038610AC 43.00Premium AiL 56038594AC 73.0026 Bracket, UpperSt~ring Column 55314992AA 9.85

~/-

~313028

r:l-32I27

8-34 004-09924

2

7

5WIPER SYSTEM

213 I!

""""",~~~~-~~~4

5

~,..~6

,--d

~ :: 1

11~~~ ~ 19 ~14 .7

21~h13 4 1822 r:13 IIII ~ L16 15~ 18!Jj,j17~ 'j;--16 ~-" ~24 ~ ~

1~20 004-09923

7lf26--

?7 Cluster Ass~Black 56010151AF m .9 445.00Chrome 56010461AF m .9 454.00llAdditional Palts &/or Dealer Contact Required28 Lens, Cluster (a)Black 4728962AB m 1.0 0.00Chrome 4832731AB m 1.0 46.45la) Included wlCluster Assy29 RadioCode RBP 56038586AD.5 650.00Code RBY 56038583AD.5 0.00Code RBB 56038588AG.5 390.00Code RAD 56038585AD.5 1170.00Code RBK 56038589AH.5 460.00Code RBT 56038584AD.5 0.0030 Changer, CD 82203465 .5 345.00131 Cable, CD Changer 56038596AE 37.7032 Switch, Mirror 56010093AA #.2 22.95#Included in R&R Left Front Door Trim Panel, NotIncluded in R&R Instrument Panel33 Switch;, Climate ControlI wi Nv 55037533AB m .5 80.00wlo NC 55037531AB m .5 62.95134 Knob, Climate Controlll 5069169AA 1.451]As Required

8004-09540

on

6--<:~

#1.1

,-"-;:;;;;;;::~4~10 1

WD851DVAAWD851LSAA

WD581DVAAWD581L8AA

WD591DVAAWD591L8AB5072905AA5072906AA

.6 29.35.6 29.35

.6 43.00.6 43.00

#.2 92.85#.2 92.85#.2 10.00#.2 118.00

Use Procedure Explanations 14 and 28 with the following text.Refinish Dash Panel 1.5Refinish Plenum Panel 1.0

Labor Times Shown are for Replacement with New OEM Undamaged Parts on New Undamaged Vehicles.Comments or suggestions? Need assistance? Call 1.800-854-7030 or 8!;8/578-6550, Ext 8220. Fax 1-888-256-7969 or 858/549-0629.570CH

' 2 004-09922

1 Glass, WindshieldChrysler 55235913AC #2.3 0.00 ...NAGS c DW01449GBN #2.3 958.30 Use Procedure Explanation 14 with the following text.#Includes Clean Up Otd Adhesive as Necessary R&llnstrument Panel.. m #5.02 Spacer, Windshield /4) 55360509AA .35 #tncludes R&I Steering Column & Floor Console3 Mould!ng. Upper W/$ 55235917AB 9.60 NOTE: All Parts in this section are included in R&R4 Moulding. Side WIS R 55360052AB .2 58.85 Instrument Panel unless noted otherwiseL 55360053AB .2 58.85 .

5 Mirror, Rear View 4805332AB .2 19.45 16 Button, Rear View Mirror 55076401 8.25 25-{!:Q7 Moulding, Inr W/S Garnish R 5GM92TL2AC .3 46.35 6-0L 5GM93TL2AC .3 46.3598 Visor, Sun 5Illuminated R UY66TL2AA .2 103.00 I 10 6L UY67TL2AA .2 106.00 ~Non-Illuminated R UY64TL2AA .2 61.95 ~ 6 1L UY65TL2AA .2 63.70 ()\4Clip, Visor R/L 5072343AA 2.60

4 Arm, Wiper R 5666970AAL 5066968AA#Includes R&R Wiper Blade5 Module, Wiper 55155895AA6 Reservoir, Washer 5066867AA#Includes R&I/R&R Air Cleaner Assy7 Cap, Reservoir 5066881AA8 Pump, WasherTo 8-3-01 5066880AAFrom 8-3-01 5018129ACGrommet Pump 5011809AA9 Sensor, Fluid Level 4882797Grommet, Sensor 5013755AANozzle, Washer AiL 55155854AB#Included in R&R Cowl Cover

Use Procedure Explanation 14 with the following text.R&IFloorConsole .3

NOTE: All Parts in this section are included in R&R FloorConsole unless noted otherwise.

2

~~~~~~

,~-.- ,-,..1'70 3 Door, Passenger Air Bag-See Air Bag System Section1 16'60 4 Panel, Instrument.116'60Slate Gray..To 6-14-01 WC85XDVAA m #6.5 517.00#.2 24.10 From 6-14-01 WC85XDVAB m#6.5 517.00#.2 26.00 Taupe

To 6-14-01 WC85WL8AA m #6.5 517,0078,35 From 6-14-01 WC85WL8AB m #6.5 517,0078.50 #Includes R&I Steering Column & Floor Console25005 Bracket, Instrument Panel R 5073523AA 39.95, L 5072615AA 30,8588 45 6 Grille, Instrument Panel (4) WC88DX9AA .1 0,00.7 Cover, Instrument Panel531.1100Slate Gray R 5GN55XDVAD .1 10,95, L 5GK19XDVAD .1 17,5094,2005 Taupe R 5GN55WL8AD .1 10.95, L 5GK19WL8AD .1 17,50#.2 10,00 8 Bezel, No.1 Instrument PanelLimted Model WB02DX9AA.2 30,70 004-09544Renegade, Sport ModelSlate Gray WB021DVAA.2 30.70 1 Console, FloorTaupe WB021L8AA.2 30,70 Man Trans9 Bezel, No.2 Instrument Panel Slate GrayLimited Model WB03DX9AA.1 25,45 TaupeRenegade, Sport Model Auto TransSlate Gray WB031DVAA.1 25.45 Slate GrayTaupe WB031 L8AA .1 25.45 Taupe10 Bezel, No.3 Instrument Panel 2 Lid, ConsoleLimited Model WB05DX9AA.1 22.10 Slate Grayi Renegade, Sport Model TaupeISlate Gray WB051DVAA.1 22.10 3 Latch, LidTaupe WB051l8AA.1 22.10 4 Hinge, Lid

Page 1786 of 1803

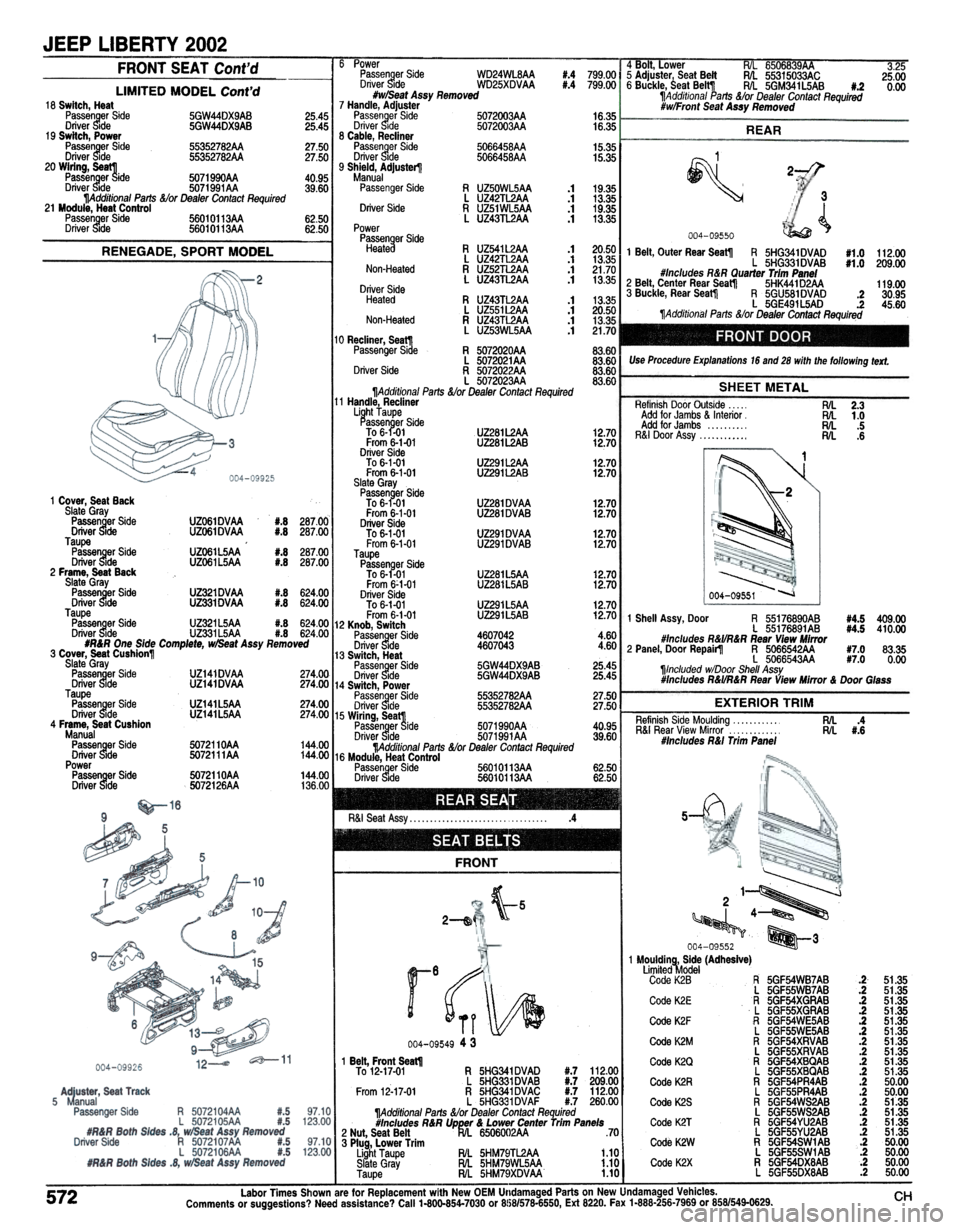

JEEP LIBERTY 2002

FRONT SEAT Cont'd25.000.00#.4 799.00 I 5 Adjuster;. Seat Belt R/L 55315033AC#.4 799.00 6 Buckle, :oeat Belt11 R/L 5GM341L5AB '.2lIAdditional Parls &/or Deater Contact Required#w/Front Seat ASBY RemovedLIMITED MODEL Cont'd18 Switch, HeatPassenger Side 5GW44DX9ABDriver Side 5GW44DX9AB19 Switch, PowerPassen.Qer Side 55352782AADriver Side 55352782AA20 WIring, Seet1lPassenger Side 5O71990AADriver Side 5071991AA11Additional Parts &/or Dealer Contact Required21 Module, Heat ControlPassenger Side 56010113AADriver Side 56010113AA

25.4525.45

27.5027.50

40.9539.60

REAR

1

~2~

t'ower -

Passenger Side WD24WL8AADriver Side WD25XDVAA#WISest Assy Removed7 Handle, AdjusterPassenjjer Side 5072003AADriver Side 5072003AA8 Cable, ReclinerPassenjjer Side 5066458AADriver Side 5066458AA9 Shield, Adjuster1jManualPassenger Side R UZ50WL5AA .1L UZ42TL2AA .1Driver Side R UZ51WL5AA .1L UZ43TL2AA .1PowerPassenger SideHeateiJ R UZ541L2AAL UZ42TL2AANon-Heated R UZ52TL2AAL UZ43TL2AADriver SideHeated R UZ43TL2AAL UZ551L2AANon-Heated R UZ43TL2AAL UZ53WL5AA10 Recliner, Seal11Passenger Side R 5072020AAL 5072021AADriver Side R 5072022AAL 5072023AA1]Additional Paris &lor Dealer Contact Required11 Handle, ReclinerLight TaupePassenger SideTo 6-1-01 UZ281L2AAFrom 6-1-01 UZ281L2ABDriver SideTo 6-1-01 UZ291L2AAFrom 6-1-01 UZ291L2ABSlate GrayPassenger SideTo 6-1-01 UZ281DVAAFrom 6-1-01 UZ281 DVABDriver SideTo 6-1-01 UZ291 DVAAFrom 6-1-01 UZ291 DVABTaupePassenger SideTo 6-1-01 UZ281L5AAFrom 6'1-01 UZ281L5ABDriver SideTo 6-1-01 UZ291L5AAFrom 6-1-01 UZ291L5AB12 Knob, SwitchPassenjjer Side 4607042Driver Side 460704313 Switch, HeatPassenger Side 5GW44DX9ABDriver Side 5GW44DX9AB14 Switch, PowerPassenjjer Side 55352782AADriver Side 55352782AA15 Wiring, Seal11! Passenger Side 5071990AAIDriver Side 5071991AA1]Additional Paris &lor Dealer Contact Required16 Module, Heat Control! PassenSJer Side 56010113AADriver Side 56010113AA

16.3516.35

15.3515.35

19.3513.3519.3513.35~62.5062.50

RENEGADE, SPORT MODEL.1.1.1.1.1.1.1.1

3

~004-09550 ~20.50 1 Belt, Outer Rear Seat1] R 5HG341DVAD #1.0 112.0013.35 L 5HG331DVAB #1.0 209.0021.70 #Includes R&R Quarter Trim Panel13.35 2 Belt, Center Rear Seat1] 5HK441D2AA 119.003 Buckle, Rear Seat1] R 5GU581DVAD .2 30.9513.35 L 5GE491L5AD .2 45.6020.50 ~Additional Parts &/or Dealer Contact Required

83.60 I Use Procedure Explanations 16 and 28 with the following text.83.6083.60SHEET METAL

Refinish Door Outside. ...Add for Jambs & InteriorAddforJambs R&I Door Assy .""""'"

AIL 2.3AIL 1.0AIL .5AIL .612.7012.70

12.7012.70

1

""-l

12.7012.70

12.7012.70

#.8 28700#.8 287.00I#.8 287.00I#.8 287.0012.12:

12:12:

4.'4.'

25.25.

27.27.

40;39.'

~~004-09551

1 Cover, Seat BackSlate GrayPassenJjer Side UZ061DVAADriver Side UZ061DVAATaupePassenger Side UZ061L5AADriver Side UZ061L5AA2 Frame, Seat BackSlate GrayPassenger Side UZ321DVAA #.8 624.00Driver Side UZ331DVAA #.8 624.00TaupePassenJjer Side UZ321L5AA #.B 624.00Driver Side UZ331 L5AA #.B 624.00#R&R One Side Complete, wlSeat Assy Removed3 Cover, Seat CushionllSlate GrayPassenJjer Side UZ141DVAA 274.00Driver Side UZ141DVAA 274.00TaupePassenJjer Side UZ141L5AA 274.00Driver Side UZ141L5AA 274.004 Freme, Seat CushionManualPassenJjer Side 5O72110AA 144.00Driver Side 5O72111AA 144.00PowerPassenger Side 5O72110AA 144.00Driver S'tde 5O72126AA

~

1 Shell Assy, Door R 55176890AB #4.5 409.00L 55176891AB #4.5 410.00"ncludes R&UR&R Resr VIew Mirror2 Panel, Door Repair11 R 5066542AA #7.0 83.35L 5066543AA #7.0 0.001]lncluded wlDoor Shell Assy"ncludes R&UR&R Resr View MI"or & Door Glsss

EXTERIOR TRIM

R/L .4AiL #.6Refinish Side Moulding R&IRearViewMirror #Includes R&I Trim Panel

62.50!62.50

5-f1R&I Seal~Y:-: ;.,...~:::.:.:::::;;:.4

FRONT

1~~~~~~~~~~-, ~2

~~4~004-09552 --31 Moulding, Side (Adhesive)Limited ModelCode K2B I

Code K2E 1

Code K2F I

Code K2M

Code K2Q

Code K2R

Code K2S

Code K2T

Code K2W

Code K2X

\-52-t\)~

8/

i ~ TI\V6I

004-0954943

1 Belt, Front Seat1JTo 12-17-01 R 5HG341DVAD #.7 112.00L 5HG331DVAB #.7 209.00From 12-17-01 R 5HG341DVAC #.7 112.00L 5HG331DVAF #.7 260,00llAdditional Palts &lor Dealer Contact Required#Includes R&R Up~r & Lower Center Trim Panels2 Nut, Seat Belt R/L 6506002AA ,3 Plug, Lower TrimLight Taupe AiL 5HM79TL2AASlate Gray R/L 5HM79WL5AATaupe AiL 5HM79XDVAA

F 5GF54WB7ABL 5GF55WB7ABR 5GF54XGRABL 5GF55XGRABR 5GF54WE5ABL 5GF55WE5ABR 5GF54XRVABL 5GF55XRVABR 5GF54XBQABL 5GF55XBQABR 5GF54PR4ABL 5GF55PR4ABR 5GF54WS2ABL 5GF55WS2ABR 5GF54YU2ABL 5GF55YU2ABR 5GF54SW1ABL 5GF55SW1ABR 5GF54DX8ABL 5GF55DX8AB

.2 51.35.2 51.35.2 51.35.2 51.35.2 51.35.2 51.35.2 51.35.2 51.35.2 51.35.2 51.35.2 50.00.2 50.00.2 5f35.2 51.35.2 51.35.2 51.35.2 50.00.2 50.00..2 50.00.2 50.00

70

1.101.10

I1.10

Labor Times Shown are for Replacement with New OEM Undamaged Parts on New Undamaged Vehicles.Comments or suggestions? Need assistance? Call 1-800-854-7030 or 8~;8/578-6550, Ext 8220. Fax 1-888-256-7969 or 858/549-0629.572CH

7070

707060

604545

50501

95601

Page 1788 of 1803

![JEEP LIBERTY 2002 KJ / 1.G Owners Manual JEEP LIBERTY 2002

4M"anuaIWindows R 55360036AA #.3 66.70L 55360027AA #.3 66.70#WlDoor Glass RemovedPower Windows1! R 55360034AA #.3 46.35L 55360035AA #.3 46.351]Additional Paris &/or Dealer Colltact JEEP LIBERTY 2002 KJ / 1.G Owners Manual JEEP LIBERTY 2002

4M"anuaIWindows R 55360036AA #.3 66.70L 55360027AA #.3 66.70#WlDoor Glass RemovedPower Windows1! R 55360034AA #.3 46.35L 55360035AA #.3 46.351]Additional Paris &/or Dealer Colltact](/img/16/7176/w960_7176-1787.png)

JEEP LIBERTY 2002

4'M"anuaIWindows R 55360036AA #.3 66.70L 55360027AA #.3 66.70#WlDoor Glass RemovedPower Windows1! R 55360034AA #.3 46.35L 55360035AA #.3 46.351]Additional Paris &/or Dealer Col'ltact RequiredMotor, Window Ail N.A #.3 0.00#R&R One Side Complete, w/D'~or Glass RemovedHandle, Window R/L FW80WI_5 6.95

~5

~

REAR DOOR Cont'd

Refinish UpperHinge-~~ .Refinish Lower Hinge R&I Outside Handle Assy #/ncludes R&I Trim PanelR/L .3R/L .3AiL #.5

2

1

11

..PUse Procedure Explanations 17 and 28 with the following tex/.3004-09564~

SHEET METAL121 Console, Overheadw/Sunroofw/o SunroofModule, Consolew/Garage Door Opener2 Lamp, Consolew/Sunroof Switchw/o Sunroof Switch3 Lens, LampI 4 Wiring Console5 Bulb, 'Console (2)Switch, SunroofSwitch, Reading Lamp

WA951L2AA5O14271AA

4760145BF

WA901L2AAPB83TL2AB55196755AA4760644LOOOO1925GM78TL2AA4685445

.4 00.45.4 189.00

315.00

.3 66.35.3 78.20.1 6.50.3 20.85.1 1.9575.105.00

3.5

1.0~7

e-d r

10~

9-d

Refinish RoofOulside Add 10 R&R Roof Panel

To Drill for & Install Luggage Rack5

~12 3

~"

3

ROOF LUGGAGE RACK

4004-09561R&I Luggage RackAssy .5R&R Luggage Rack Complete (Includes R&I) 8

NOTE: All Parts in this section are included in R&R LuggageRack Complete unless noted otherwise.

#.3 5O.35l#.3 45:75-#.3 81.75 1 Panel Roof#.3 81.75 w/Sunroof 55176995AB #16.5 215.00.2 875 wlo Sunroof 55176994AB #15.5 155.002.75 #Does Not Inc/l~de R&R Quslter Glass2'95 2 Panel, Front Header 55177022AA 1.0 22.952.95 3 Bow, No.1 Roof15.70 wlo Sunroof 553602E:1AA 1.0 18.102:85 4 Bow, No.2 Roof 5517699:~AA 1.0 18.101AA 1.0 18.102.8510.00 EXTERIOR TRIM~

I ~-

T ~;:../ 4~~b -8 11--dJ'~~:;;f~~::::::=~- 3 6

12 '

004-09559

1 Latch, DoorManual Locks R 55177046ABL 55177047ABPower Locks R 55177044ABL 55177045AB#Wrrrim Panel Removed2 Striker, Latch AiL 4780607AA3 Spacer, Striker AiL 45202894 Rod, Inside Lock R 5072360AAL 5O72361AACover, Latch AiL 5014395AA5 Rod, Inside Handle R 5072356AAL 5072357AA6 Rod, Lock Knob R 55360464AAL 55360465AA7 Handle, Outside R 55360334AB #.2 36.00 IL 55360335AB #.2 36.00#Wrrrim Panel Removed8 Hinge, Upper AiL 55177030AA #.2 26.259 Hinge, Lower AiL 55177030AA #.2 26.25#W/Door & Upper Center Trim Panel Removed10 Check, Door AiL 55177036AB #.2 26.50#Wrrrim Panel Removed11 Seal, Lower Door AiL 55235930AA .2 9.0012 Weatherstrip, Door1] AiL 5GU15WL5AA .6 57.201]Addilional Paris &/or Dealer Contact Required

"--"~~~~-~,'" -~$ --.""",," _,,;-r-:>"'-~,,--'"~~ -s:",,- -~-'"",," 6"",-""~-/-. '- /,'--=, I'

1

'"'.."

.4 90.25

13.1013.1012.4512.45

#.3 59.50#.3 59.50

0.000.00

0.000.00

.8 409.00

#.3 59.50

#.3 59.50

GLASS & PARTS1 Moulding, Roofw/Roof~ack

wiD Roof Rack

.5.5.5.5

54.2054.2066.20166.20

1-{12

R 553601i'4AAL 553601i'5AAR 553601i'6AAL 553601i7AA

9

p

R&I Headliner.2.8v

,~,17=~'7~

t'...'"004-09932 ""',Ii;-

1 Rail, Luggage Rack AIL 55360419ABCover, luggage RackFront R 55360424AAL 55360425AA3 Rear R 55360426AAIL 55360427AA4 Rail, Luggage Rack CrossFront 55360526AARear 55156586AA#R&R Both .4I 5 Cap, Screw Cover (2iSidelAIL 55156591AA6 Cap, Cross Rail End (2JSide Ail 55156597AA7 Cover, Cross RailFront SJA18ZSPAARear SJA19ZSPAA8 Carrier Assy, CargoRenegade Model 5HZ66ZSPAB9 Rail, Front Cross~Renegade Model 55360526AB10 Rail, Rear Cross1\Renegade Model 55156586AB~fncfuded w/Cargo Carrier Assy#R&R Both.411 Isolator, Cargo Carrierw/Sunroof

WiD Sunroof

3

2, ,

~

6

R 55156592ABL 55156593ABR 55156594ABL 55156595AB

9.709.709.709.70.J/004-09563

LIGHT BAR004-09930

1 Glass, Rear DoorChrysler-Tinted R 55360378ABL 55360379ABNAGSGreen R/L DDO9986-7GTYPrivacy R/L DD10064-3YPY2 Glass/Channel, GlassChrysler-TintedGreen R 55235876ABL 55235877ABPrivacy R 55360172ABL 55360173ABNAGSGreen R/L DVO9993-4GTNPrivacy R/L DV10Q65-6YPY#W/Door Glass Removed3 Weatherstrip, Frt Pillar R/L 55235860AA4 Weatherstrip, Outer Belt R 55235872AAL 55235873AA5 Weatherstrip, Inner Belt R 55235886ABL 55235887AB

1.0 195.001.0 210.00

1.0 403.651.0 411.85

2

3~45

~~6

004-09933

1 Cover, Light Bar2 lamPILight Bar (4)3 Bulb 4l4 Cover, ens5 Bar, Support6 Harness, Light Bar

5HZO1ZSPAB52112063ABLOOO90065HZO7RXFAB5083967 AA52112062AA

1 Headliner1l Iw/Sunroolw/Side Air Bag OY911 L2AA 2.8 627.00'wlo Side Air Bag UY731L2AA 2.8 800.00wlo Sunroofw/Side Air Bag UY87TL2AA 2.8 627.00wlo Side Air Bag' UY71TL2AA 2.8 735.001]Additional Parts &/or Dealer Contact Required2 Handle, Grab R UY681L2AA .1 0.00L UY691L2AA .1 0.00#.3 139.00'Lamp, Cargo 5FT10TL2 43.50#.3 139.00 Lens, ~argo Lamp. 55196755AA 6.50#.3 145.00 Moulding, Rear Intenor#.3 145.00 Slate Gray 5GP80WL5AC 11.50Taupe 5GP80XDVAC 11.50#.3 0.00 Clip, Mldg Retainer (!9) 6506311 AA .45#.3 737.10

.2 13.95.2 24.751R&I Overhead Console .2.2 24.7520.25 NOTE: All Parts in this section are included in R&R Overhead20.25 Console unless noted otherwise.

Labor Times Shown are for Replacement with New OEM Undamaged Parts on New Undamaged Vehicles.Comments or suggestions? Need assistance? Call 1-800-854-7030 or 8581578-6550, Ext 8220. Fax 1-888-256-7969 or 8581549-0629.574

165.00143.0010.000.00160.0040.35

2,