relay JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 532 of 1803

move the headlamps to the selected position based

upon the voltage input received from the switch. The

headlamp leveling motors and switch have a path to

ground at all times. The headlamp leveling compo-

nents operate on battery current received through

the fused park lamp relay output circuit so that the

system will only operate when the exterior lighting is

turned on.

PARK LAMPS

The park lamps system includes the Body Control

Module (BCM), a park lamp relay installed in the

Junction Block (JB), and the exterior lighting switch

integral to the left (lighting) control stalk of the

multi-function switch. The front park lamp and side

marker or, if equipped, the front position lamp bulbs

each have a path to ground at all times through their

connections to the grille opening reinforcement wire

harness from two take outs of the headlamp and

dash wire harness with eyelet terminal connectors

that are secured by ground screws to the left inner

fender shield in the engine compartment. The rear

park lamp bulbs and license plate lamp have a path

to ground at all times through their connection to the

rear lighting wire harness from a take out of the rear

body wire harness with an eyelet terminal connector

that is secured by a ground screw to the base of the

right D-pillar behind the quarter trim panel. The

BCM controls the park lamp operation by monitoring

the exterior lighting switch inputs from the multi-

function switch, then energizing or de-energizing the

control coil of the park lamp relay. When the park

lamp relay is energized, it provides battery current

from a fused B(+) fuse in the Power Distribution

Center (PDC) through a park lamp relay output cir-

cuit and a separate fuse in the JB through a fused

park lamp relay output circuit to the appropriate

lamp bulb filaments. The BCM provides a battery

saver (load shedding) feature for the park lamps,

which will turn these lamps off if they are left on for

more than about eight minutes with the ignition

switch in the Off position.

REAR FOG LAMPS

Rear fog lamps are installed on vehicles manufac-

tured for certain markets where they are required.

The rear fog lamp system includes a premium Body

Control Module (BCM), a rear fog lamp relay

installed in the Junction Block (JB), and a rear fog

lamp switch integral to the left (lighting) control

stalk of the multi-function switch. The rear fog lamps

have a path to ground at all times through their con-

nection to the rear lighting wire harness from a take

out of the rear body wire harness with an eyelet ter-

minal connector that is secured by a ground screw to

the base of the right D-pillar behind the quarter trimpanel. The BCM controls rear fog lamp operation by

monitoring the exterior lighting switch input from

the multi-function switch, then energizing or de-ener-

gizing the rear fog lamp relay control coil; and, by

sending the appropriate electronic message to the

instrument cluster over the Programmable Commu-

nications Interface (PCI) data bus to turn the rear

fog lamp indicator on or off. When the rear fog lamp

relay is energized, it provides battery current from a

fused B(+) fuse in the JB to the rear fog lamps

through the rear fog lamp relay output circuit. The

BCM provides a battery saver (load shedding) feature

for the rear fog lamps, which will turn these lamps

off if they are left on for more than about eight min-

utes with the ignition switch in the Off position.

TURN SIGNAL LAMPS

When the left control stalk of the multi-function

switch is moved up (right turn) or down (left turn),

the turn signal system is activated causing the

selected right or left turn signal indicator, and right

or left turn signal lamps to flash on and off. When

the turn signal system is activated, the circuitry

within the turn signal switch and the hazard switch/

electronic combination flasher unit will repeatedly

energize and de-energize one of two internal relays

that switch battery current from a fused ignition

switch output (run) fuse in the Junction Block (JB) to

the right side or left side turn signal indicators and

turn signal lamps through the right or left turn sig-

nal circuits. The ElectroMechanical Instrument Clus-

ter (EMIC) chime tone generator will generate an

audible turn signal cancel warning each time the

vehicle is driven for a distance of about 3.2 kilome-

ters (about two miles) with a turn signal indicator

flashing. The EMIC uses Programmable Communica-

tions Interface (PCI) data bus distance messages

from the Powertrain Control Module (PCM) and a

hard wired input from the turn signal switch cir-

cuitry of the multi-function switch to determine when

to sound the turn signal cancel warning.

DIAGNOSIS AND TESTING - LAMPS/LIGHTING

- EXTERIOR

The hard wired circuits and components of the

exterior lighting systems may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the Body

Control Module (BCM), the ElectroMechanical

Instrument Cluster (EMIC), the Powertrain Control

Module (PCM), or the Programmable Communica-

tions Interface (PCI) data bus network. The most

reliable, efficient, and accurate means to diagnose

the BCM, the EMIC, the PCM, and the PCI data bus

network inputs and outputs related to the various

KJLAMPS8Ls-7

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 534 of 1803

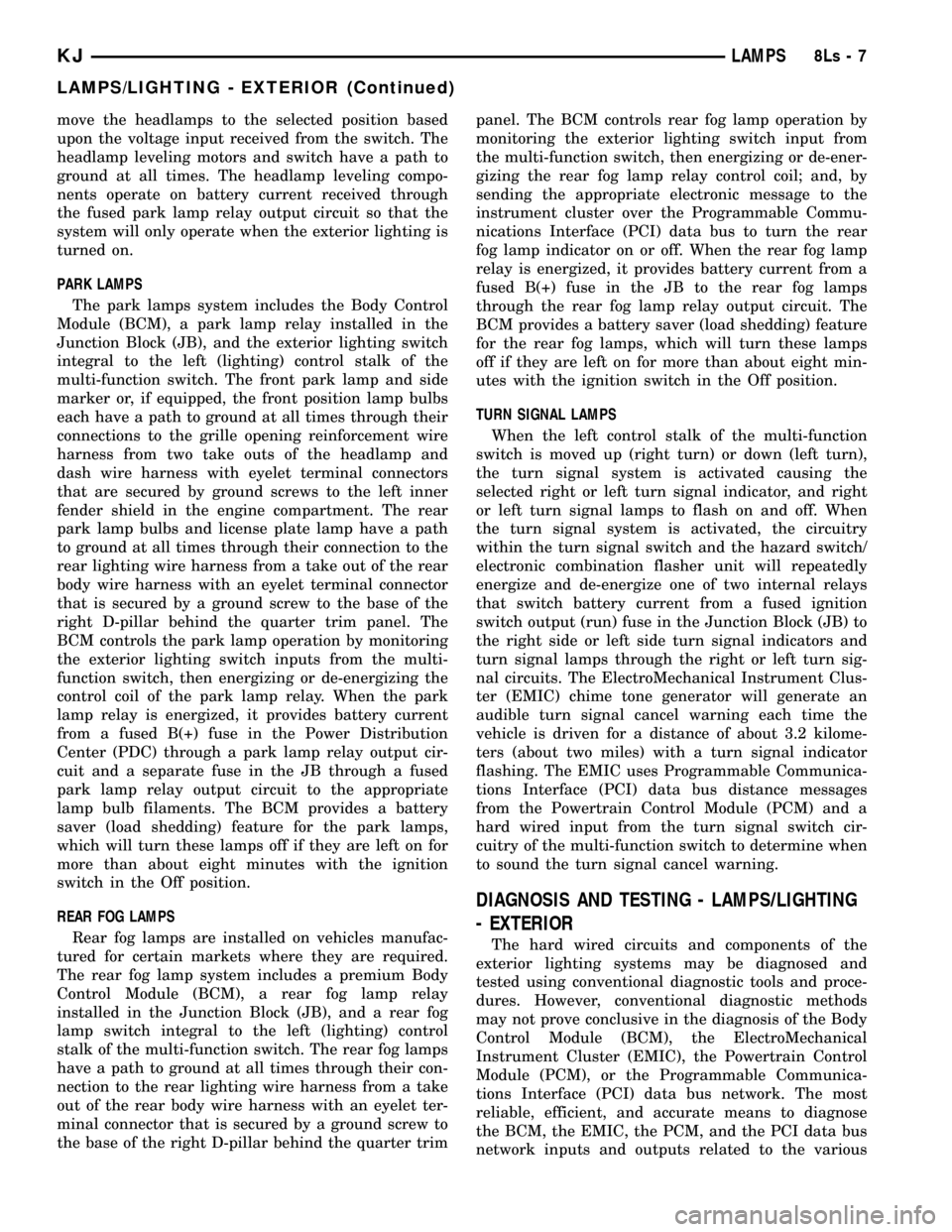

BRAKE LAMPS

CONDITION POSSIBLE CAUSES CORRECTION

BRAKE LAMP DOES NOT

ILLUMINATE1. Faulty or missing fuse. 1. Test and replace brake lamp fuse as

required.

2. Faulty or missing bulb. 2. Test and replace brake lamp bulb as

required.

3. Faulty switch. 3. Test and replace brake lamp switch as

required.

4. Faulty ground circuit. 4. Test and repair brake lamp ground circuit

as required.

5. Faulty feed circuit. 5. Test and repair open brake lamp switch

output circuit as required.

BRAKE LAMP DOES NOT

EXTINGUISH1. Faulty switch. 1. Test and replace brake lamp switch as

required.

2. Faulty feed circuit. 2. Test and repair shorted brake lamp

switch output circuit as required.

DAYTIME RUNNING LAMPS

Before performing the following tests, determine

whether the headlamp low and high beams operate.If the headlamp high and low beams are also inoper-

ative, diagnose and repair that problem before

attempting to repair the Daytime Running Lamps.

CONDITION POSSIBLE CAUSES CORRECTION

DAYTIME RUNNING

LAMPS WILL NOT

ILLUMINATE1. High beam relay installed. 1. Remove high beam relay as required.

2. Faulty or missing DRL relay. 2. Replace DRL relay with a known good

unit and check operation. Replace DRL

relay as required.

3. Incorrect BCM programming. 3. Use a DRBIIITscan tool to check and

program correct country code into BCM as

required.

4. Faulty BCM inputs or outputs. 4. Use a DRBIIITscan tool to test the BCM

inputs or outputs. Refer to the appropriate

diagnostic information.

KJLAMPS8Ls-9

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 535 of 1803

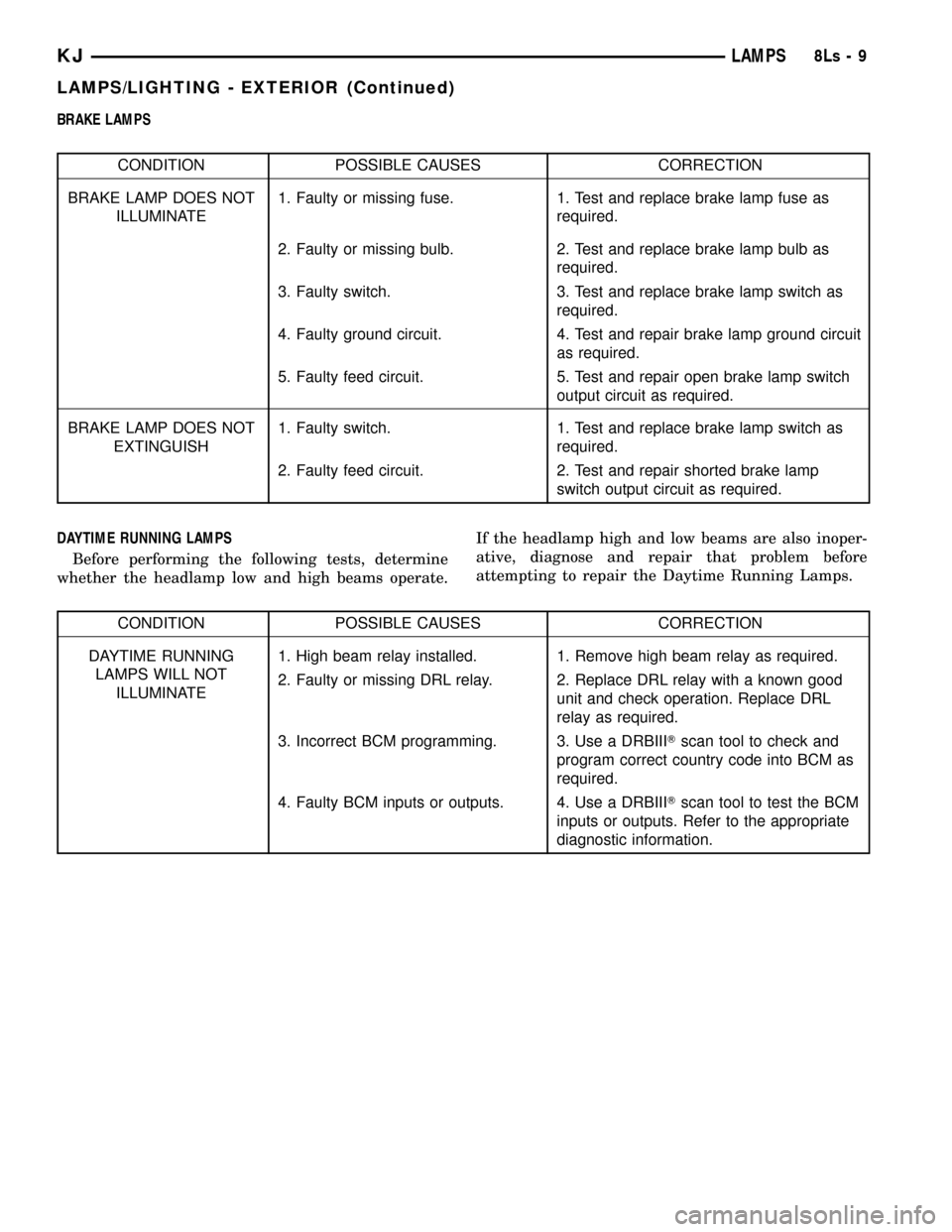

FRONT FOG LAMPS

CONDITION POSSIBLE CAUSES CORRECTION

FRONT FOG LAMP DOES

NOT ILLUMINATE1. Faulty or missing fuse. 1. Test and replace front fog lamp fuse as

required.

2. Faulty or missing bulb. 2. Test and replace front fog lamp bulb as

required.

3. Faulty or missing relay. 3. Test and replace front fog lamp relay as

required.

4. Faulty switch. 4. Test and replace multi-function switch as

required.

5. Faulty ground circuit. 5. Test and repair front fog lamp ground

circuit as required.

6. Faulty feed circuit. 6. Test and repair open front fog lamp relay

output circuit as required.

7. Faulty BCM inputs or outputs. 7. Use a DRBIIITscan tool to test the BCM

inputs and outputs. Refer to the appropriate

diagnostic information.

FRONT FOG LAMP DOES

NOT EXTINGUISH1. Faulty relay. 1. Test and replace front fog lamp relay as

required.

2. Faulty switch. 2. Test and replace multi-function switch as

required.

3. Faulty feed circuit. 3. Test and repair shorted front fog lamp

relay output circuit as required.

4. Faulty BCM inputs or outputs. 4. Use a DRBIIITscan tool to test the BCM

inputs and outputs. Refer to the appropriate

diagnostic information.

HAZARD WARNING LAMPS

Before performing the following tests, confirm

whether the left and right turn signals operate satis-

factorily. If the turn signals are inoperative or oper-ate improperly, diagnose and repair that problem

before attempting to repair the Hazard Warning

Lamps.

CONDITION POSSIBLE CAUSES CORRECTION

HAZARD WARNING

LAMPS DO NOT FLASH1. Faulty or missing fuse. 1. Test and replace hazard warning fuse as

required.

2. Faulty ground circuit. 2. Test and repair hazard switch ground

circuit as required.

3. Faulty feed circuit. 3. Test and repair open hazard switch fused

B(+) circuit as required.

4. Faulty switch/flasher. 4. Replace hazard switch/combination

flasher with a known good unit and check

operation. Replace hazard switch/

combination flasher unit if required.

8Ls - 10 LAMPSKJ

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 536 of 1803

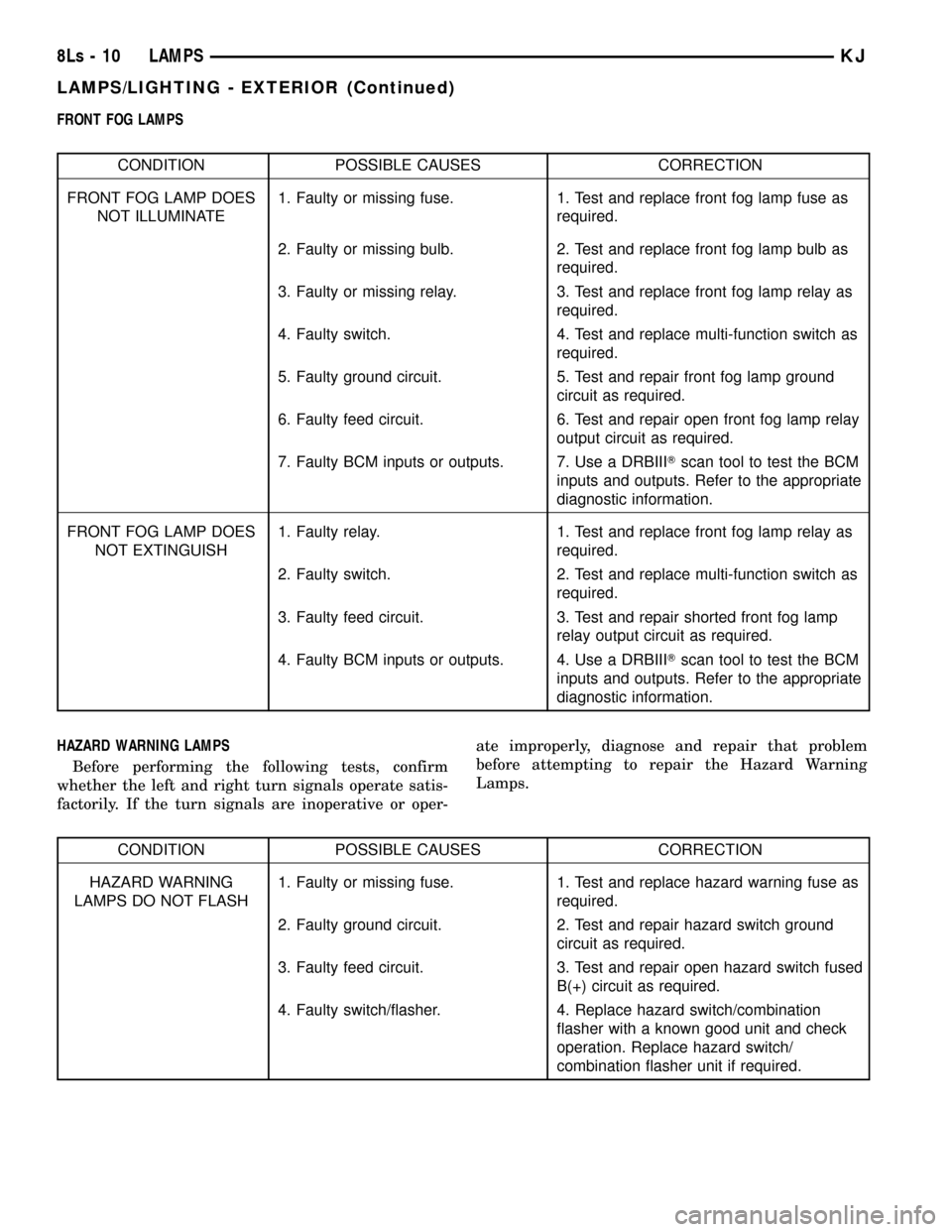

HEADLAMPS

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMP DOES NOT

ILLUMINATE1. Faulty or missing fuse. 1. Test and replace headlamp fuse as

required.

2. Faulty or missing bulb. 2. Test and replace headlamp bulb as

required.

3. Faulty or missing relay. 3. Test and replace low beam or high beam

relay as required. (Note: Vehicles with a

DRL relay do not use a high beam relay.

The DRL relay cannot be tested. Replace

DRL relay with a known good unit and

check operation. Replace DRL relay as

required.)

4. Faulty switch. 4. Test and replace multi-function switch as

required.

5. Faulty ground circuit. 5. Test and repair open headlamp ground

circuit as required.

6. Faulty feed circuit. 6. Test and repair open headlamp low

beam, high beam, or DRL relay output

circuit as required.

7. Faulty BCM inputs or outputs. 7. Use a DRBIIITscan tool to test the BCM

inputs and outputs. Refer to the appropriate

diagnostic information.

HEADLAMP DOES NOT

EXTINGUISH1. Faulty relay. 1. Test and replace low beam or high beam

relay as required. (Note: Vehicles with a

DRL relay do not use a high beam relay.

The DRL relay cannot be tested. Replace

DRL relay with a known good unit and

check operation. Replace DRL relay as

required.)

2. Faulty switch. 2. Test and replace multi-function switch as

required.

3. Faulty feed circuit. 3. Test and repair shorted headlamp low

beam, high beam, or DRL relay output

circuit as required.

4. Faulty BCM inputs or outputs. 4. Use a DRBIIITscan tool to test the BCM

inputs and outputs. Refer to the appropriate

diagnostic information.

KJLAMPS8Ls-11

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 537 of 1803

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS WILL NOT

SWITCH FROM HIGH TO

LOW BEAMS, OR FROM

LOW TO HIGH BEAMS1. Faulty relay. 1. Test and replace low beam or high beam

relay as required. (Note: Vehicles with a

DRL relay do not use a high beam relay.

The DRL relay cannot be tested. Replace

DRL relay with a known good unit and

check operation. Replace DRL relay as

required.)

2. Faulty switch. 2. Test and replace multi-function switch as

required.

3. Faulty BCM inputs or outputs. 3. Use a DRBIIITscan tool to test the BCM

inputs and outputs. Refer to the appropriate

diagnostic information.

HEADLAMP LEVELING

Before performing the following tests, confirm

whether the park lamps operate satisfactorily. If thepark lamps are inoperative, diagnose and repair that

problem before attempting to repair the Headlamp

Leveling System.

CONDITION POSSIBLE CAUSES CORRECTION

ONE LEVELING MOTOR

IS INOPERATIVE1. Faulty ground circuit. 1. Test and repair open leveling motor

ground circuit as required.

2. Faulty feed circuit. 2. Test and repair open leveling motor feed

circuit as required.

3. Faulty signal circuit. 3. Test and repair open headlamp adjust

signal circuit as required.

4. Faulty motor. 4. Test and replace headlamp leveling

motor as required.

BOTH LEVELING

MOTORS ARE

INOPERATIVE1. Faulty switch ground circuit. 1. Test and repair open leveling switch

ground circuit as required.

2. Faulty motor ground circuit. 2. Test and repair open leveling motor

ground circuit as required.

3. Faulty switch feed circuit. 3. Test and repair open leveling switch feed

circuit as required.

4. Faulty motor feed circuit. 4. Test and repair open leveling motor feed

circuit as required.

5. Faulty signal circuit. 5. Test and repair open or shorted leveling

motor signal circuit as required.

6. Faulty switch. 6. Test and replace leveling switch as

required.

7. Faulty motors. 7. Test and replace leveling motors as

required.

8Ls - 12 LAMPSKJ

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 538 of 1803

PARK LAMPS

CONDITION POSSIBLE CAUSES CORRECTION

PARK LAMP DOES NOT

ILLUMINATE1. Faulty or missing fuse. 1. Test and replace park lamp fuse as

required.

2. Faulty or missing bulb. 2. Test and replace park lamp bulb as

required.

3. Faulty or missing relay. 3. Test and replace park lamp relay as

required.

4. Faulty switch. 4. Test and replace multi-function switch as

required.

5. Faulty ground circuit. 5. Test and repair open park lamp ground

circuit as required.

6. Faulty feed circuit. 6. Test and repair open park lamp relay

output circuit as required.

7. Faulty BCM inputs or outputs. 7. Use a DRBIIITscan tool to test the BCM

inputs and outputs. Refer to the appropriate

diagnostic information.

PARK LAMP DOES NOT

EXTINGUISH1. Faulty relay. 1. Test and replace park lamp relay as

required.

2. Faulty switch. 2. Test and replace multi-function switch as

required.

3. Faulty feed circuit. 3. Test and repair shorted park lamp relay

output circuit as required.

4. Faulty BCM inputs or outputs. 4. Use a DRBIIITscan tool to test the BCM

inputs and outputs. Refer to the appropriate

diagnostic information.

REAR FOG LAMPS

CONDITION POSSIBLE CAUSES CORRECTION

REAR FOG LAMP DOES

NOT ILLUMINATE1. Faulty or missing fuse. 1. Test and replace rear fog lamp fuse as

required.

2. Faulty or missing bulb. 2. Test and replace rear fog lamp bulb as

required.

3. Faulty or missing relay. 3. Test and replace rear fog lamp relay as

required.

4. Faulty switch. 4. Test and replace multi-function switch as

required.

5. Faulty ground circuit. 5. Test and repair open rear fog lamp

ground circuit as required.

6. Faulty feed circuit. 6. Test and repair open rear fog lamp relay

output circuit as required.

7. Faulty BCM inputs or outputs. 7. Use a DRBIIITscan tool to test the BCM

inputs and outputs. Refer to the appropriate

diagnostic information.

KJLAMPS8Ls-13

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 539 of 1803

CONDITION POSSIBLE CAUSES CORRECTION

REAR FOG LAMP DOES

NOT EXTINGUISH1. Faulty relay. 1. Test and replace rear fog lamp relay as

required.

2. Faulty switch. 2. Test and replace multi-function switch as

required.

3. Faulty feed circuit. 3. Test and repair shorted rear fog lamp

relay output circuit as required.

4. Faulty BCM inputs or outputs. 4. Use a DRBIIITscan tool to test the BCM

inputs and outputs. Refer to the appropriate

diagnostic information.

TURN SIGNAL LAMPS

CONDITION POSSIBLE CAUSES CORRECTION

ONE TURN SIGNAL LAMP

DOES NOT ILLUMINATE1. Faulty or missing bulb. 1. Test and replace turn signal bulb as

required.

2. Faulty ground circuit. 2. Test and repair open ground circuit as

required.

3. Faulty feed circuit. 3. Test and repair open right or left turn

signal circuit as required.

ALL RIGHT SIDE AND/OR

ALL LEFT SIDE TURN

SIGNAL LAMPS DO NOT

FLASH1. Faulty sense circuit. 1. Test and repair open right or left turn

switch sense circuit as required.

2. Faulty switch. 2. Test and replace multi-function switch as

required.

3. Faulty flasher. 3. Replace hazard switch/combination

flasher with a known good unit and check

operation. Replace hazard switch/

combination flasher unit as required.

4. Faulty signal circuit. 4. Test and repair open right or left turn

signal circuit as required.

ALL RIGHT SIDE OR ALL

LEFT SIDE TURN

SIGNALS FLASH TOO

RAPIDLY (MORE THAN

100 FLASHES PER

MINUTE)1. Faulty or missing bulb. 1. Test and replace faulty bulb as required.

2. Faulty ground circuit. 2. Test and repair open ground circuit as

required.

3. Faulty signal circuit 3. Test and repair open right or left turn

signal circuit as required.

4. Faulty flasher. 4. Replace hazard switch/combination

flasher with a known good unit and check

operation. Replace hazard switch/

combination flasher unit as required.

8Ls - 14 LAMPSKJ

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 544 of 1803

INSTALLATION

CAUTION: Always use the correct bulb size and

type for replacement. An incorrect bulb size or type

may overheat and cause damage to the lamp, the

socket and/or the lamp wiring.

(1) Align the base of the bulb with the receptacle

in the Center High Mounted Stop Lamp (CHMSL)

unit socket.

(2) Push the bulb straight into the CHMSL unit

socket until it is firmly seated.

(3) Align the socket and bulb with the socket open-

ing on the back of CHMSL unit housing.

(4) Push the socket and bulb straight into the

CHMSL unit housing until it is firmly seated (Fig. 6).

(5) Rotate the socket on the back of the CHMSL

unit housing clockwise about 30 degrees.

(6) Reinstall the CHMSL unit onto the roof panel.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/CENTER HIGH MOUNTED STOP

LAMP UNIT - INSTALLATION).

(7) Reconnect the battery negative cable.

CENTER HIGH MOUNTED

STOP LAMP UNIT

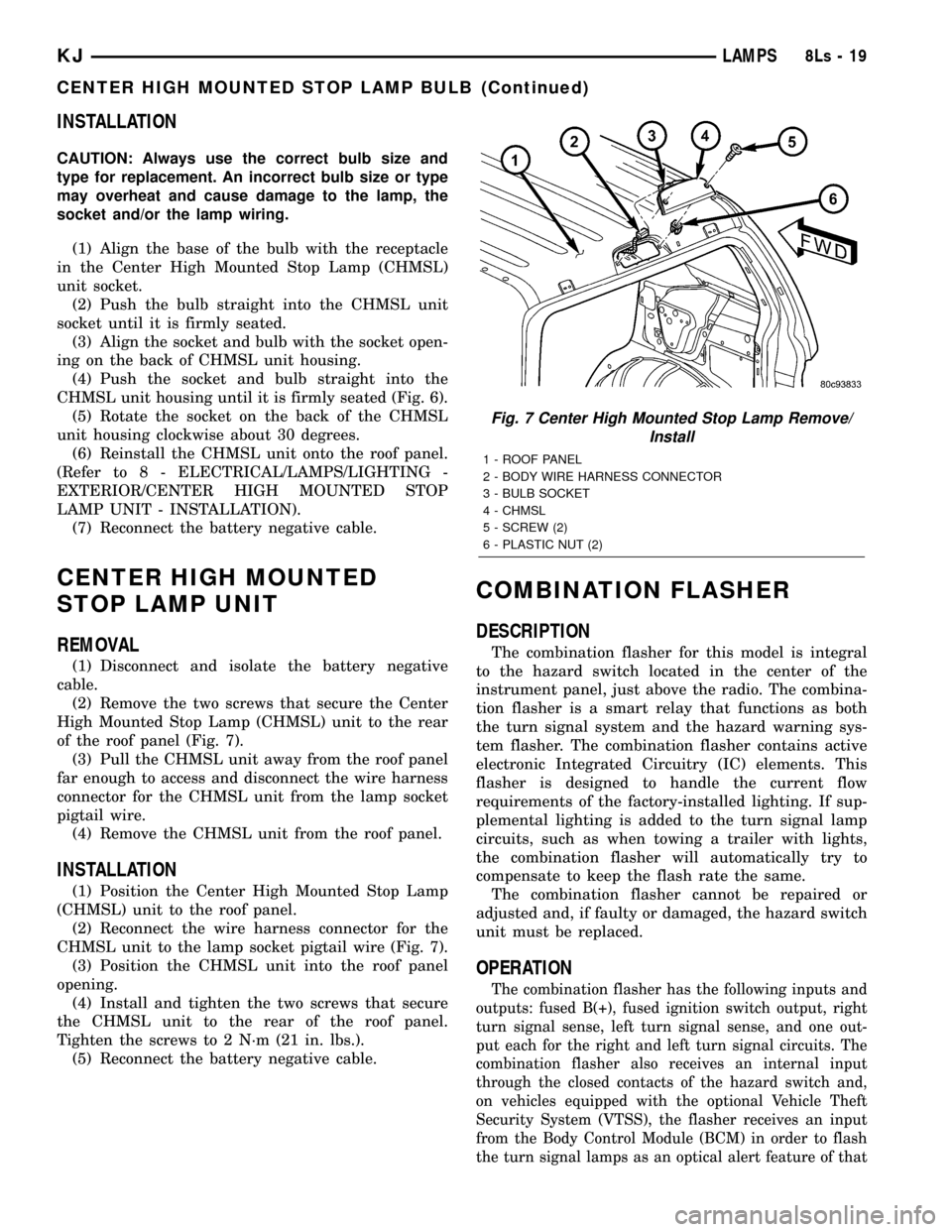

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the two screws that secure the Center

High Mounted Stop Lamp (CHMSL) unit to the rear

of the roof panel (Fig. 7).

(3) Pull the CHMSL unit away from the roof panel

far enough to access and disconnect the wire harness

connector for the CHMSL unit from the lamp socket

pigtail wire.

(4) Remove the CHMSL unit from the roof panel.

INSTALLATION

(1) Position the Center High Mounted Stop Lamp

(CHMSL) unit to the roof panel.

(2) Reconnect the wire harness connector for the

CHMSL unit to the lamp socket pigtail wire (Fig. 7).

(3) Position the CHMSL unit into the roof panel

opening.

(4) Install and tighten the two screws that secure

the CHMSL unit to the rear of the roof panel.

Tighten the screws to 2 N´m (21 in. lbs.).

(5) Reconnect the battery negative cable.

COMBINATION FLASHER

DESCRIPTION

The combination flasher for this model is integral

to the hazard switch located in the center of the

instrument panel, just above the radio. The combina-

tion flasher is a smart relay that functions as both

the turn signal system and the hazard warning sys-

tem flasher. The combination flasher contains active

electronic Integrated Circuitry (IC) elements. This

flasher is designed to handle the current flow

requirements of the factory-installed lighting. If sup-

plemental lighting is added to the turn signal lamp

circuits, such as when towing a trailer with lights,

the combination flasher will automatically try to

compensate to keep the flash rate the same.

The combination flasher cannot be repaired or

adjusted and, if faulty or damaged, the hazard switch

unit must be replaced.

OPERATION

The combination flasher has the following inputs and

outputs: fused B(+), fused ignition switch output, right

turn signal sense, left turn signal sense, and one out-

put each for the right and left turn signal circuits. The

combination flasher also receives an internal input

through the closed contacts of the hazard switch and,

on vehicles equipped with the optional Vehicle Theft

Security System (VTSS), the flasher receives an input

from the Body Control Module (BCM) in order to flash

the turn signal lamps as an optical alert feature of that

Fig. 7 Center High Mounted Stop Lamp Remove/

Install

1 - ROOF PANEL

2 - BODY WIRE HARNESS CONNECTOR

3 - BULB SOCKET

4 - CHMSL

5 - SCREW (2)

6 - PLASTIC NUT (2)

KJLAMPS8Ls-19

CENTER HIGH MOUNTED STOP LAMP BULB (Continued)

Page 545 of 1803

system. Constant battery voltage is supplied to the

flasher so that it can perform the hazard warning func-

tion, and ignition switched battery voltage is supplied

for the turn signal function. The Integrated Circuit (IC)

within the combination flasher contains the logic that

controls the flasher operation and the flash rate. The

IC receives separate sense ground inputs from the

multi-function switch for the right and left turn sig-

nals, and from the hazard switch contacts or the BCM

for the hazard warning signals. A special design feature

of the combination flasher allows it to9sense9that a

turn signal circuit or bulb is not operating, and provide

the driver an indication of the condition by flashing the

remaining bulbs in the affected circuit at a higher rate

(120 flashes-per-minute or higher). Conventional flash-

ers either continue flashing at their typical rate (heavy-

duty type), or discontinue flashing the affected circuit

entirely (standard-duty type).

Because of the active electronic elements within

the combination flasher, it cannot be tested with con-

ventional automotive electrical test equipment. If the

combination flasher is believed to be faulty, test the

turn signal and hazard warning system. Then

replace the hazard switch with a known good unit to

confirm system operation.

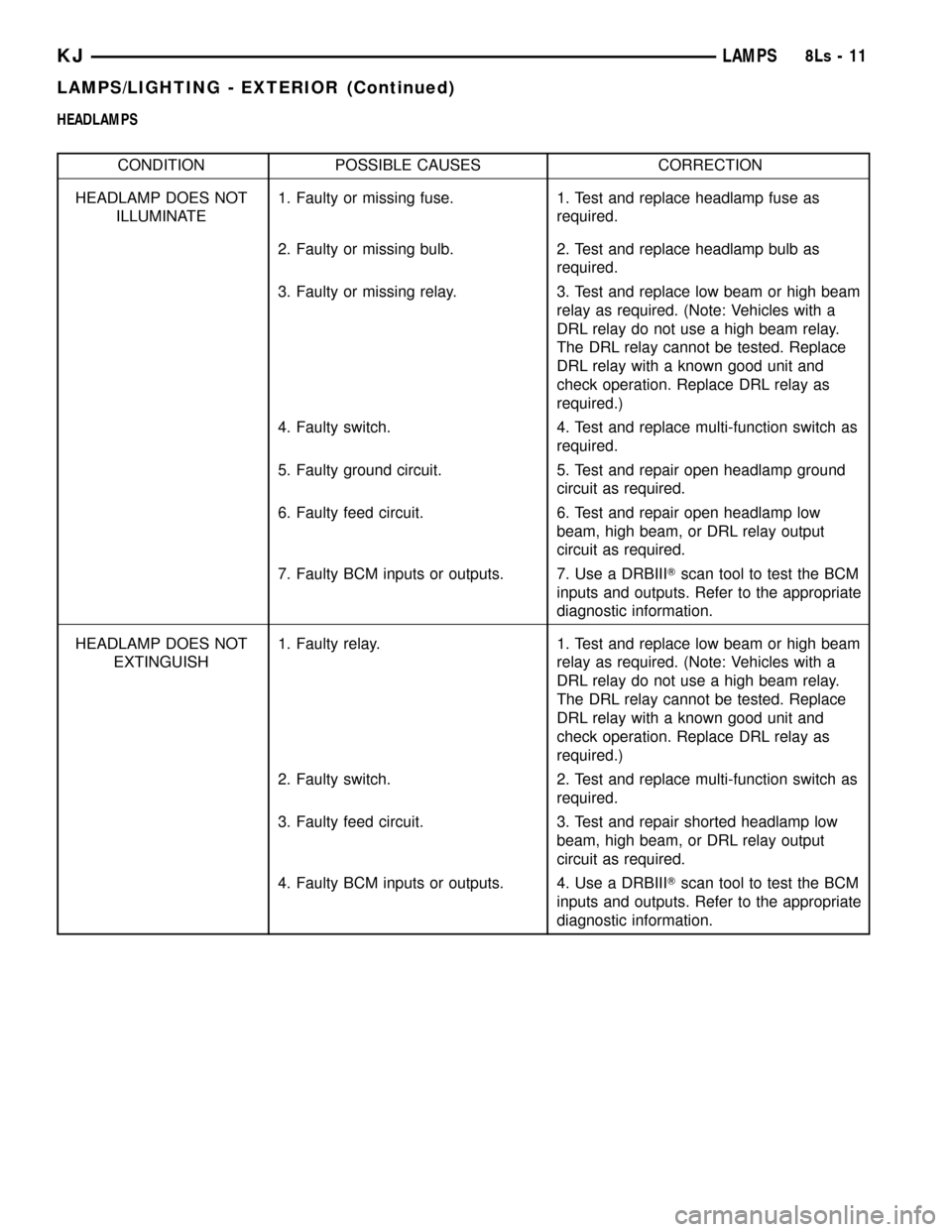

DAYTIME RUNNING LAMP

RELAY

DESCRIPTION

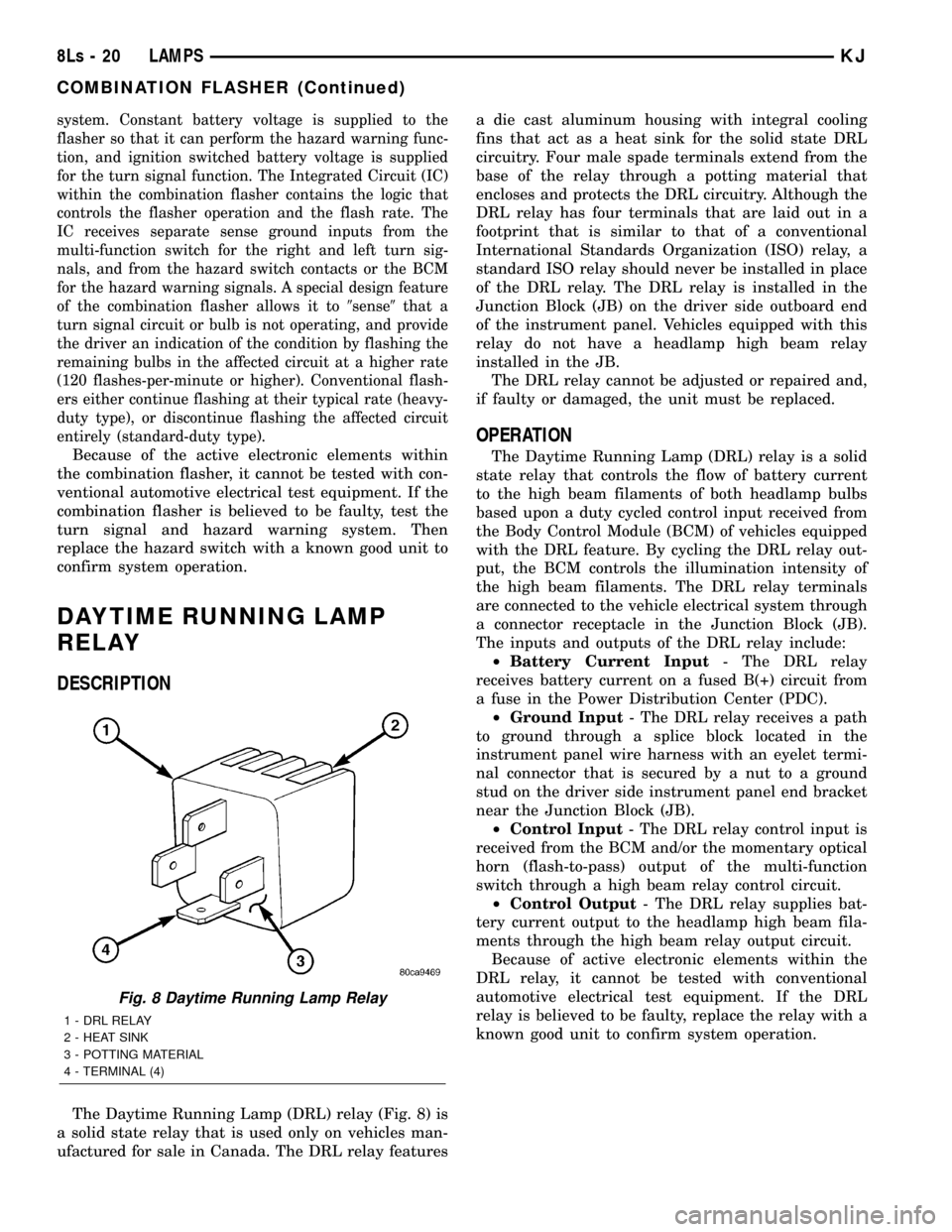

The Daytime Running Lamp (DRL) relay (Fig. 8) is

a solid state relay that is used only on vehicles man-

ufactured for sale in Canada. The DRL relay featuresa die cast aluminum housing with integral cooling

fins that act as a heat sink for the solid state DRL

circuitry. Four male spade terminals extend from the

base of the relay through a potting material that

encloses and protects the DRL circuitry. Although the

DRL relay has four terminals that are laid out in a

footprint that is similar to that of a conventional

International Standards Organization (ISO) relay, a

standard ISO relay should never be installed in place

of the DRL relay. The DRL relay is installed in the

Junction Block (JB) on the driver side outboard end

of the instrument panel. Vehicles equipped with this

relay do not have a headlamp high beam relay

installed in the JB.

The DRL relay cannot be adjusted or repaired and,

if faulty or damaged, the unit must be replaced.

OPERATION

The Daytime Running Lamp (DRL) relay is a solid

state relay that controls the flow of battery current

to the high beam filaments of both headlamp bulbs

based upon a duty cycled control input received from

the Body Control Module (BCM) of vehicles equipped

with the DRL feature. By cycling the DRL relay out-

put, the BCM controls the illumination intensity of

the high beam filaments. The DRL relay terminals

are connected to the vehicle electrical system through

a connector receptacle in the Junction Block (JB).

The inputs and outputs of the DRL relay include:

²Battery Current Input- The DRL relay

receives battery current on a fused B(+) circuit from

a fuse in the Power Distribution Center (PDC).

²Ground Input- The DRL relay receives a path

to ground through a splice block located in the

instrument panel wire harness with an eyelet termi-

nal connector that is secured by a nut to a ground

stud on the driver side instrument panel end bracket

near the Junction Block (JB).

²Control Input- The DRL relay control input is

received from the BCM and/or the momentary optical

horn (flash-to-pass) output of the multi-function

switch through a high beam relay control circuit.

²Control Output- The DRL relay supplies bat-

tery current output to the headlamp high beam fila-

ments through the high beam relay output circuit.

Because of active electronic elements within the

DRL relay, it cannot be tested with conventional

automotive electrical test equipment. If the DRL

relay is believed to be faulty, replace the relay with a

known good unit to confirm system operation.

Fig. 8 Daytime Running Lamp Relay

1 - DRL RELAY

2 - HEAT SINK

3 - POTTING MATERIAL

4 - TERMINAL (4)

8Ls - 20 LAMPSKJ

COMBINATION FLASHER (Continued)

Page 546 of 1803

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the end cap from the driver side out-

board end of the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL END CAP - REMOVAL).

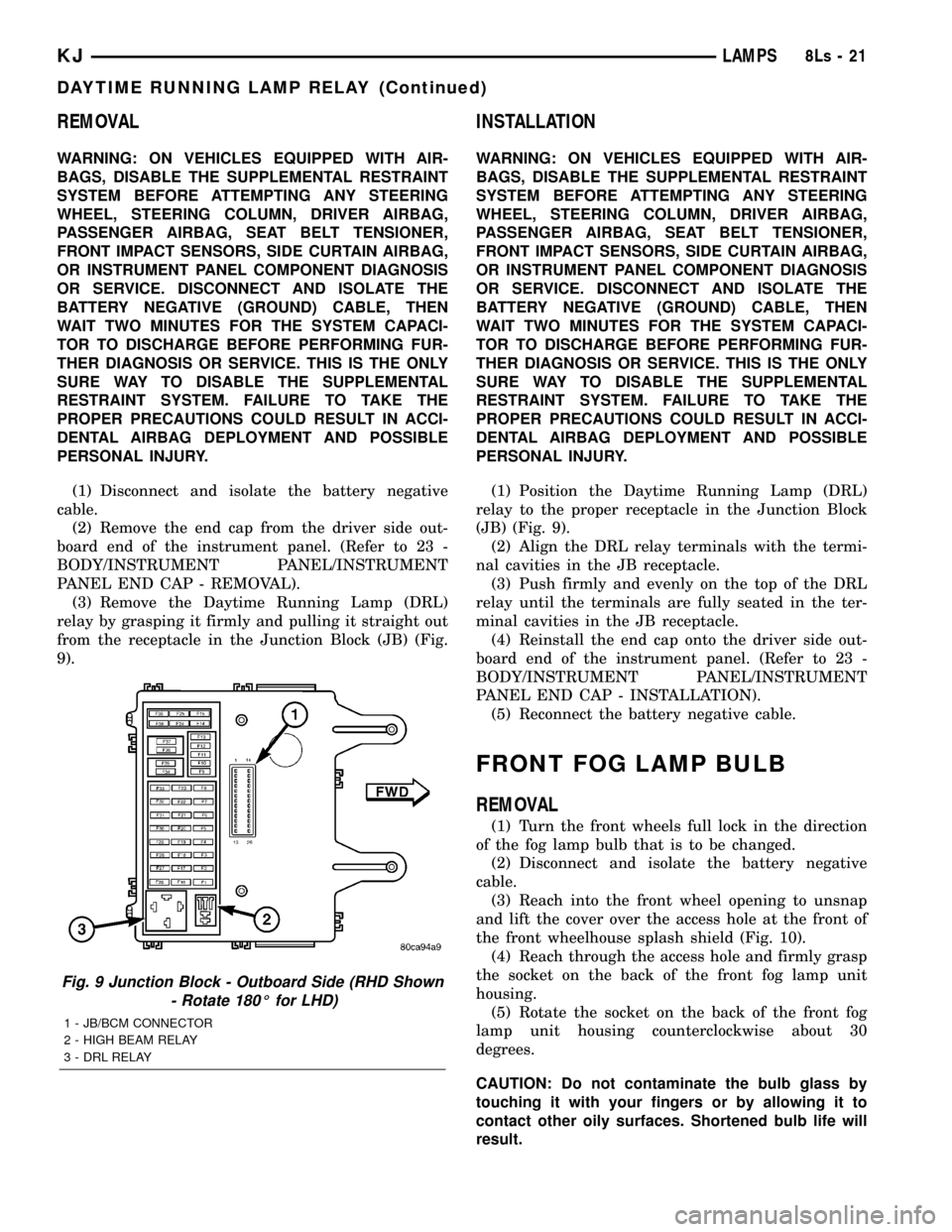

(3) Remove the Daytime Running Lamp (DRL)

relay by grasping it firmly and pulling it straight out

from the receptacle in the Junction Block (JB) (Fig.

9).

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the Daytime Running Lamp (DRL)

relay to the proper receptacle in the Junction Block

(JB) (Fig. 9).

(2) Align the DRL relay terminals with the termi-

nal cavities in the JB receptacle.

(3) Push firmly and evenly on the top of the DRL

relay until the terminals are fully seated in the ter-

minal cavities in the JB receptacle.

(4) Reinstall the end cap onto the driver side out-

board end of the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL END CAP - INSTALLATION).

(5) Reconnect the battery negative cable.

FRONT FOG LAMP BULB

REMOVAL

(1) Turn the front wheels full lock in the direction

of the fog lamp bulb that is to be changed.

(2) Disconnect and isolate the battery negative

cable.

(3) Reach into the front wheel opening to unsnap

and lift the cover over the access hole at the front of

the front wheelhouse splash shield (Fig. 10).

(4) Reach through the access hole and firmly grasp

the socket on the back of the front fog lamp unit

housing.

(5) Rotate the socket on the back of the front fog

lamp unit housing counterclockwise about 30

degrees.

CAUTION: Do not contaminate the bulb glass by

touching it with your fingers or by allowing it to

contact other oily surfaces. Shortened bulb life will

result.

Fig. 9 Junction Block - Outboard Side (RHD Shown

- Rotate 180É for LHD)

1 - JB/BCM CONNECTOR

2 - HIGH BEAM RELAY

3 - DRL RELAY

KJLAMPS8Ls-21

DAYTIME RUNNING LAMP RELAY (Continued)