tow JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1441 of 1803

INSTALLATION

The ignition key must be in the key cylinder for

cylinder installation.

(1) Install the lock cylinder into the housing using

care to align the end of the lock cylinder with the

ignition switch.

(2) Push the lock cylinder in until it clicks.

(3) Rotate the key to the lock position.

(4) install the halo ring around the lock cylinder

housing.

(5) Install the R.K.E. module.

(6) Install the lower shroud cover.

INTERMEDIATE SHAFT

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove knee blocker cover and knee blocker,

(Refer to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(3) Lock the steering wheel with the tires in the

straight ahead position.

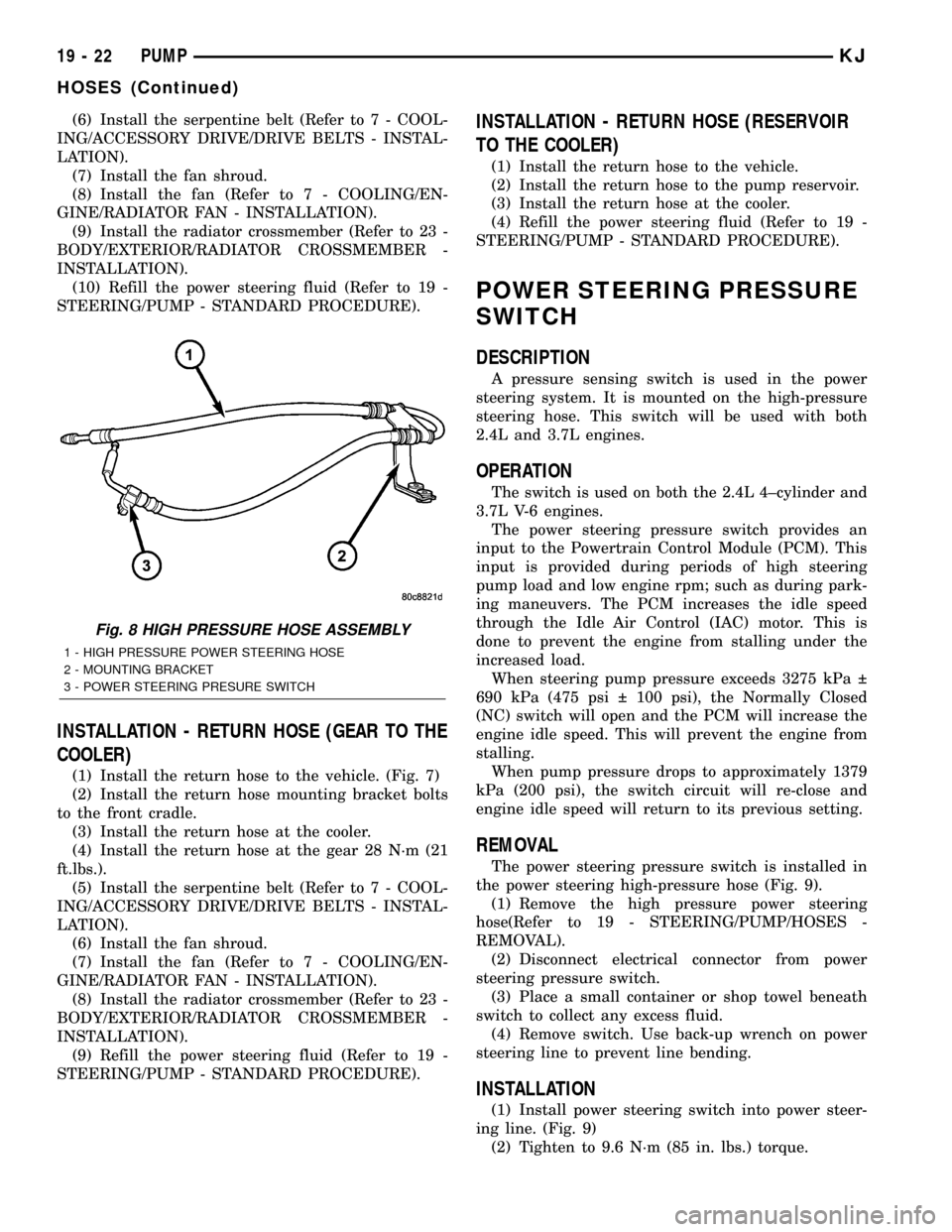

(4) Remove the lower column pinch bolt (Fig. 12).

(5) Lower the steering coupler shaft from the col-

umn.

(6) Remove the intermediate shaft seal by pushing

in the four tangs securing it to the panel (Fig. 12).

(7) Remove the center support bearing bracket

from the mount on the shock tower.

(8) Remove the lower coupler pinch bolt at the

steering gear (Fig. 12).

(9) Remove the coupler at the steering gear (Fig.

12).(10) Remove the intermediate shaft from the vehi-

cle (Fig. 12).

(11) Remove the center support bracket from the

steering shaft (if replacing the intermediate shaft).

INSTALLATION

(1) Install the center support bracket to the steer-

ing shaft (if removed).

(2) Install the intermediate shaft to the vehicle

(Fig. 12).

(3) Install the coupler at the steering gear (Fig.

12).

(4) Install the lower coupler pinch bolt at the

steering gear and tighten the bolt to 49 N´m (36 ft.

lbs.) (Fig. 12).

(5) Install the center support bearing bracket to

the mounting holes on the shock tower.

(6) Install the intermediate shaft seal by pushing

it in securing the four tangs to the panel (Fig. 12).

(7) Install the steering coupler shaft to the column.

(8) Install the lower column pinch bolt and tighten

the bolt to 49 N´m (36 ft. lbs.) (Fig. 12).

(9) Unlock the steering wheel.

(10) Install the knee blocker cover and knee

blocker (Refer to 23 - BODY/INSTRUMENT PANEL/

KNEE BLOCKER - INSTALLATION).

(11) Reconnect the negative battery cable.

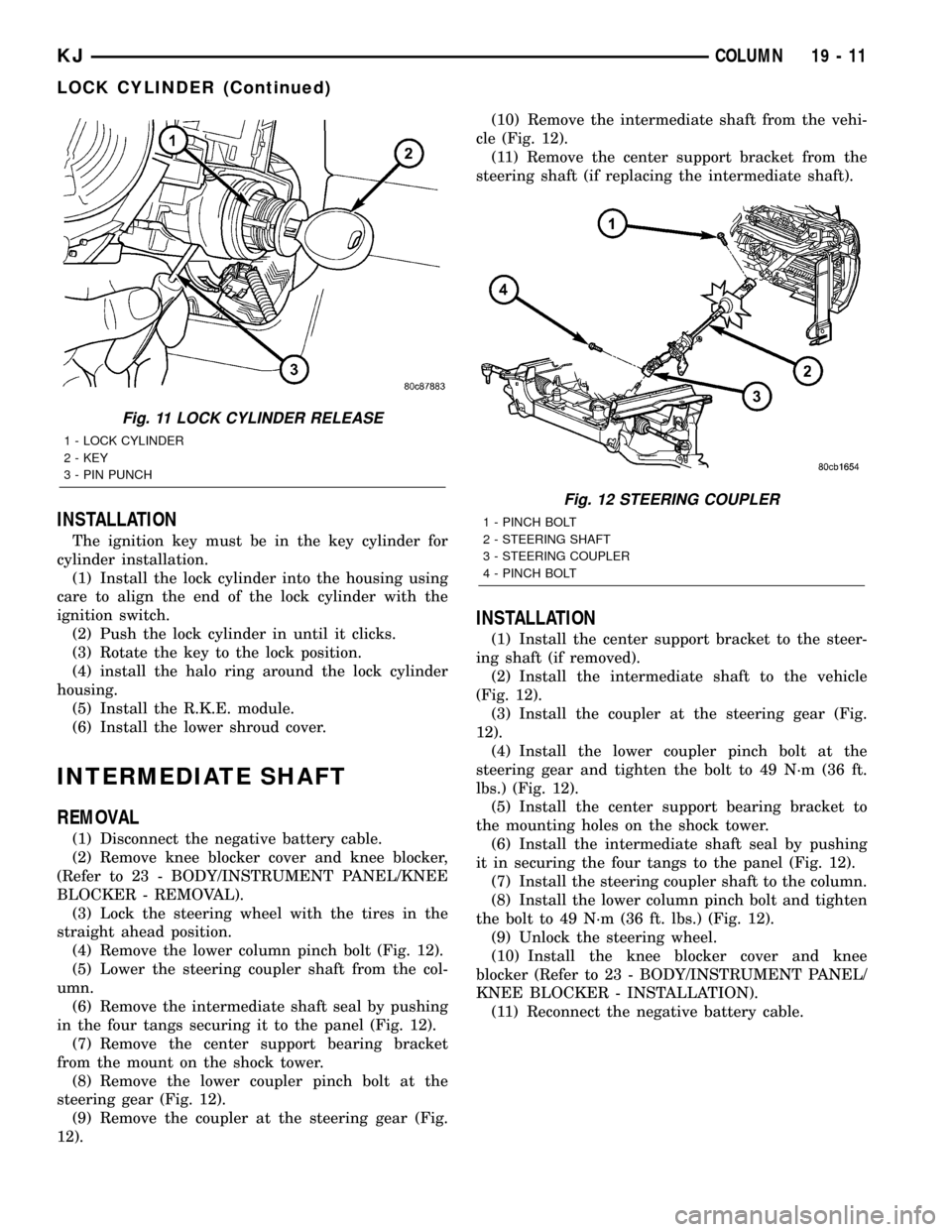

Fig. 11 LOCK CYLINDER RELEASE

1 - LOCK CYLINDER

2 - KEY

3 - PIN PUNCH

Fig. 12 STEERING COUPLER

1 - PINCH BOLT

2 - STEERING SHAFT

3 - STEERING COUPLER

4 - PINCH BOLT

KJCOLUMN 19 - 11

LOCK CYLINDER (Continued)

Page 1452 of 1803

(6) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(7) Install the fan shroud.

(8) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(9) Install the radiator crossmember (Refer to 23 -

BODY/EXTERIOR/RADIATOR CROSSMEMBER -

INSTALLATION).

(10) Refill the power steering fluid (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

INSTALLATION - RETURN HOSE (GEAR TO THE

COOLER)

(1) Install the return hose to the vehicle. (Fig. 7)

(2) Install the return hose mounting bracket bolts

to the front cradle.

(3) Install the return hose at the cooler.

(4) Install the return hose at the gear 28 N´m (21

ft.lbs.).

(5) Install the serpentine belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(6) Install the fan shroud.

(7) Install the fan (Refer to 7 - COOLING/EN-

GINE/RADIATOR FAN - INSTALLATION).

(8) Install the radiator crossmember (Refer to 23 -

BODY/EXTERIOR/RADIATOR CROSSMEMBER -

INSTALLATION).

(9) Refill the power steering fluid (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

INSTALLATION - RETURN HOSE (RESERVOIR

TO THE COOLER)

(1) Install the return hose to the vehicle.

(2) Install the return hose to the pump reservoir.

(3) Install the return hose at the cooler.

(4) Refill the power steering fluid (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE).

POWER STEERING PRESSURE

SWITCH

DESCRIPTION

A pressure sensing switch is used in the power

steering system. It is mounted on the high-pressure

steering hose. This switch will be used with both

2.4L and 3.7L engines.

OPERATION

The switch is used on both the 2.4L 4±cylinder and

3.7L V-6 engines.

The power steering pressure switch provides an

input to the Powertrain Control Module (PCM). This

input is provided during periods of high steering

pump load and low engine rpm; such as during park-

ing maneuvers. The PCM increases the idle speed

through the Idle Air Control (IAC) motor. This is

done to prevent the engine from stalling under the

increased load.

When steering pump pressure exceeds 3275 kPa

690 kPa (475 psi 100 psi), the Normally Closed

(NC) switch will open and the PCM will increase the

engine idle speed. This will prevent the engine from

stalling.

When pump pressure drops to approximately 1379

kPa (200 psi), the switch circuit will re-close and

engine idle speed will return to its previous setting.

REMOVAL

The power steering pressure switch is installed in

the power steering high-pressure hose (Fig. 9).

(1) Remove the high pressure power steering

hose(Refer to 19 - STEERING/PUMP/HOSES -

REMOVAL).

(2) Disconnect electrical connector from power

steering pressure switch.

(3) Place a small container or shop towel beneath

switch to collect any excess fluid.

(4) Remove switch. Use back-up wrench on power

steering line to prevent line bending.

INSTALLATION

(1) Install power steering switch into power steer-

ing line. (Fig. 9)

(2) Tighten to 9.6 N´m (85 in. lbs.) torque.

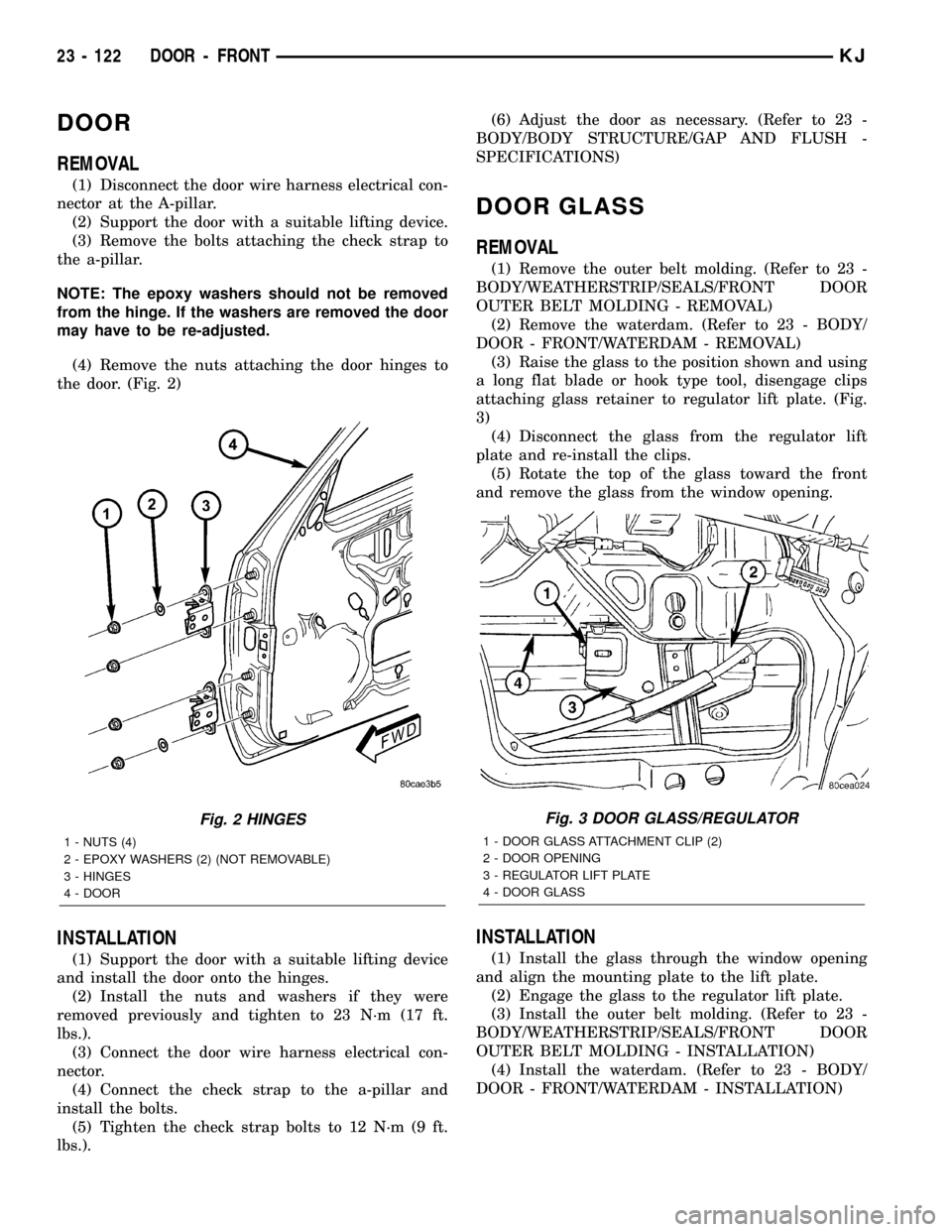

Fig. 8 HIGH PRESSURE HOSE ASSEMBLY

1 - HIGH PRESSURE POWER STEERING HOSE

2 - MOUNTING BRACKET

3 - POWER STEERING PRESURE SWITCH

19 - 22 PUMPKJ

HOSES (Continued)

Page 1587 of 1803

DOOR

REMOVAL

(1) Disconnect the door wire harness electrical con-

nector at the A-pillar.

(2) Support the door with a suitable lifting device.

(3) Remove the bolts attaching the check strap to

the a-pillar.

NOTE: The epoxy washers should not be removed

from the hinge. If the washers are removed the door

may have to be re-adjusted.

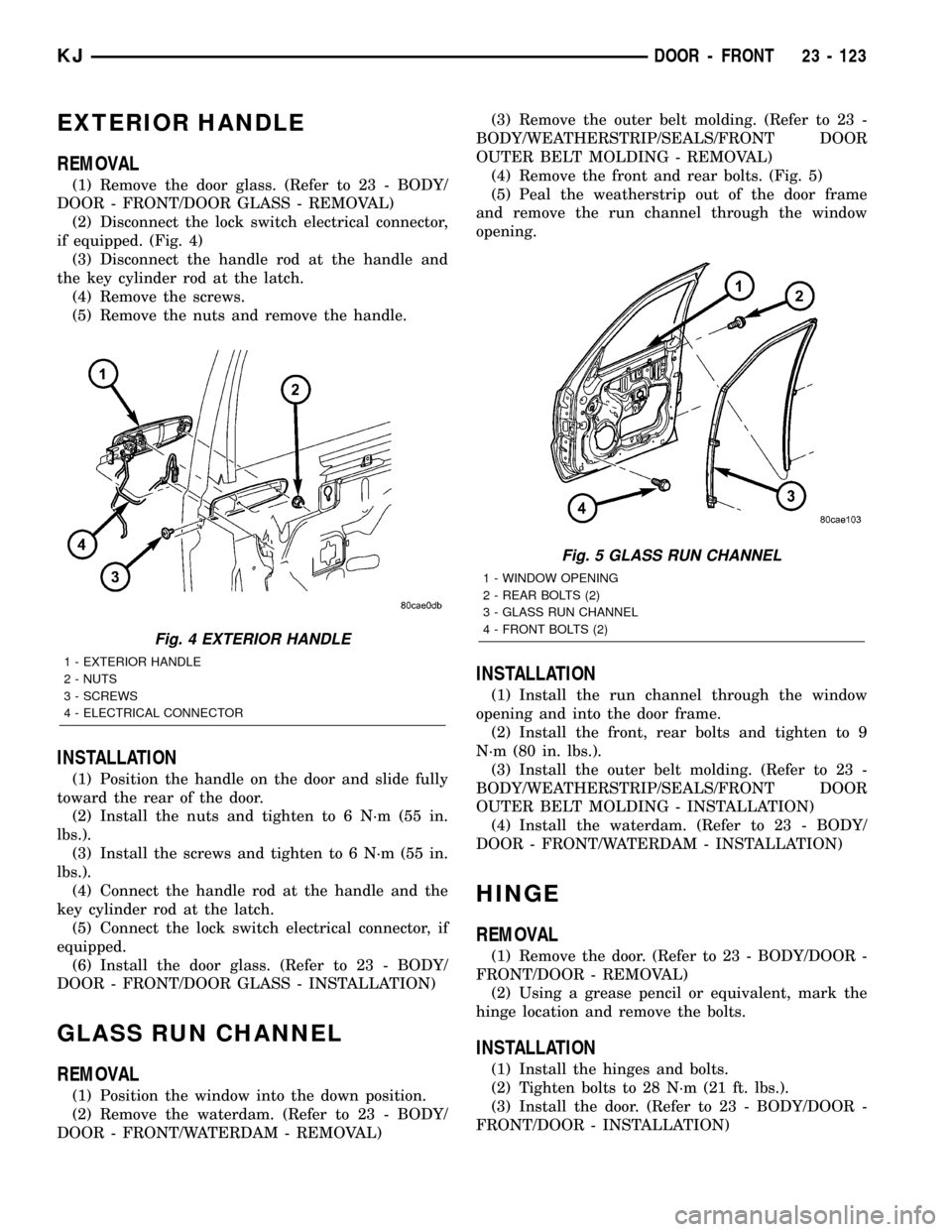

(4) Remove the nuts attaching the door hinges to

the door. (Fig. 2)

INSTALLATION

(1) Support the door with a suitable lifting device

and install the door onto the hinges.

(2) Install the nuts and washers if they were

removed previously and tighten to 23 N´m (17 ft.

lbs.).

(3) Connect the door wire harness electrical con-

nector.

(4) Connect the check strap to the a-pillar and

install the bolts.

(5) Tighten the check strap bolts to 12 N´m (9 ft.

lbs.).(6) Adjust the door as necessary. (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

DOOR GLASS

REMOVAL

(1) Remove the outer belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

OUTER BELT MOLDING - REMOVAL)

(2) Remove the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - REMOVAL)

(3) Raise the glass to the position shown and using

a long flat blade or hook type tool, disengage clips

attaching glass retainer to regulator lift plate. (Fig.

3)

(4) Disconnect the glass from the regulator lift

plate and re-install the clips.

(5) Rotate the top of the glass toward the front

and remove the glass from the window opening.

INSTALLATION

(1) Install the glass through the window opening

and align the mounting plate to the lift plate.

(2) Engage the glass to the regulator lift plate.

(3) Install the outer belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

OUTER BELT MOLDING - INSTALLATION)

(4) Install the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION)

Fig. 2 HINGES

1 - NUTS (4)

2 - EPOXY WASHERS (2) (NOT REMOVABLE)

3 - HINGES

4 - DOOR

Fig. 3 DOOR GLASS/REGULATOR

1 - DOOR GLASS ATTACHMENT CLIP (2)

2 - DOOR OPENING

3 - REGULATOR LIFT PLATE

4 - DOOR GLASS

23 - 122 DOOR - FRONTKJ

Page 1588 of 1803

EXTERIOR HANDLE

REMOVAL

(1) Remove the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - REMOVAL)

(2) Disconnect the lock switch electrical connector,

if equipped. (Fig. 4)

(3) Disconnect the handle rod at the handle and

the key cylinder rod at the latch.

(4) Remove the screws.

(5) Remove the nuts and remove the handle.

INSTALLATION

(1) Position the handle on the door and slide fully

toward the rear of the door.

(2) Install the nuts and tighten to 6 N´m (55 in.

lbs.).

(3) Install the screws and tighten to 6 N´m (55 in.

lbs.).

(4) Connect the handle rod at the handle and the

key cylinder rod at the latch.

(5) Connect the lock switch electrical connector, if

equipped.

(6) Install the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - INSTALLATION)

GLASS RUN CHANNEL

REMOVAL

(1) Position the window into the down position.

(2) Remove the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - REMOVAL)(3) Remove the outer belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

OUTER BELT MOLDING - REMOVAL)

(4) Remove the front and rear bolts. (Fig. 5)

(5) Peal the weatherstrip out of the door frame

and remove the run channel through the window

opening.

INSTALLATION

(1) Install the run channel through the window

opening and into the door frame.

(2) Install the front, rear bolts and tighten to 9

N´m (80 in. lbs.).

(3) Install the outer belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FRONT DOOR

OUTER BELT MOLDING - INSTALLATION)

(4) Install the waterdam. (Refer to 23 - BODY/

DOOR - FRONT/WATERDAM - INSTALLATION)

HINGE

REMOVAL

(1) Remove the door. (Refer to 23 - BODY/DOOR -

FRONT/DOOR - REMOVAL)

(2) Using a grease pencil or equivalent, mark the

hinge location and remove the bolts.

INSTALLATION

(1) Install the hinges and bolts.

(2) Tighten bolts to 28 N´m (21 ft. lbs.).

(3) Install the door. (Refer to 23 - BODY/DOOR -

FRONT/DOOR - INSTALLATION)

Fig. 4 EXTERIOR HANDLE

1 - EXTERIOR HANDLE

2 - NUTS

3 - SCREWS

4 - ELECTRICAL CONNECTOR

Fig. 5 GLASS RUN CHANNEL

1 - WINDOW OPENING

2 - REAR BOLTS (2)

3 - GLASS RUN CHANNEL

4 - FRONT BOLTS (2)

KJDOOR - FRONT 23 - 123

Page 1594 of 1803

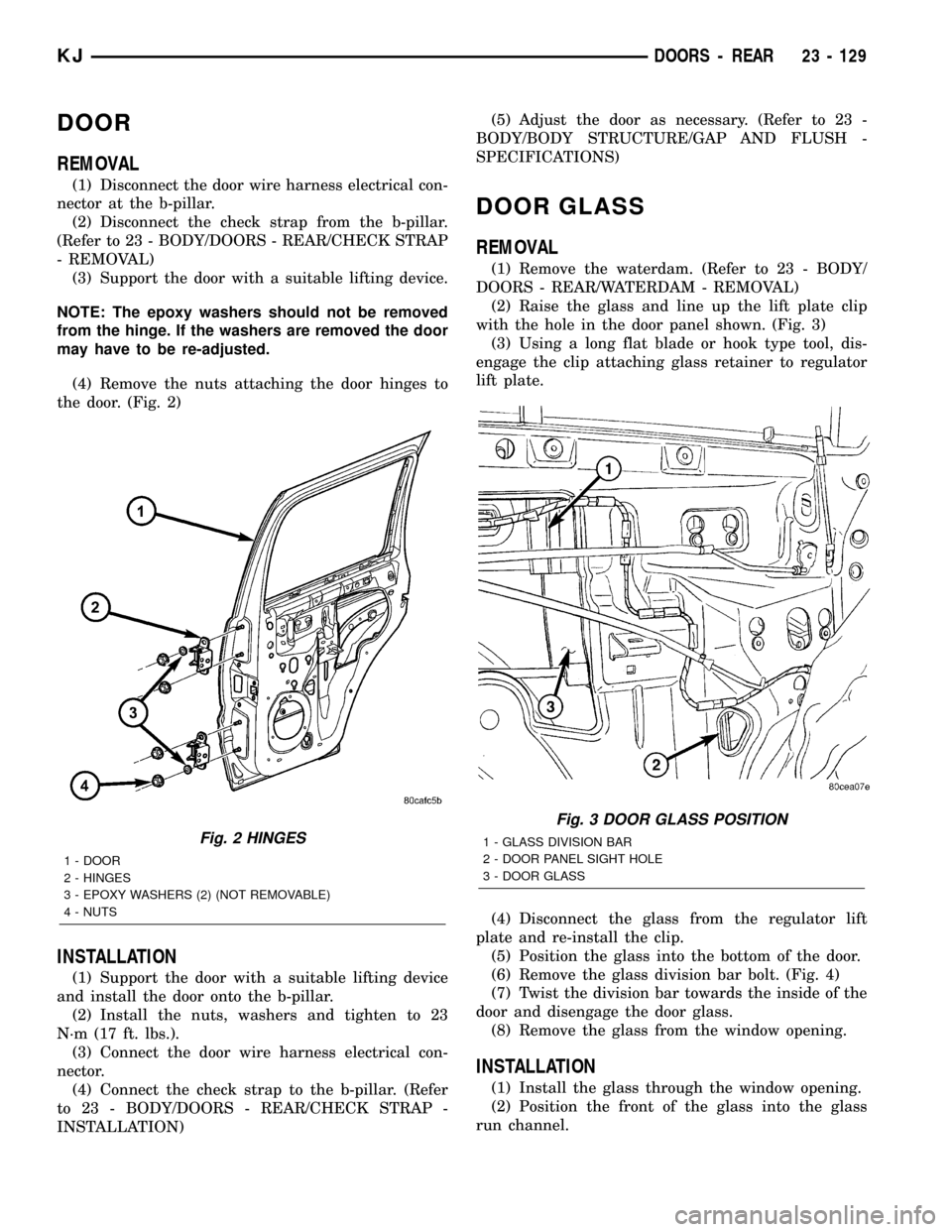

DOOR

REMOVAL

(1) Disconnect the door wire harness electrical con-

nector at the b-pillar.

(2) Disconnect the check strap from the b-pillar.

(Refer to 23 - BODY/DOORS - REAR/CHECK STRAP

- REMOVAL)

(3) Support the door with a suitable lifting device.

NOTE: The epoxy washers should not be removed

from the hinge. If the washers are removed the door

may have to be re-adjusted.

(4) Remove the nuts attaching the door hinges to

the door. (Fig. 2)

INSTALLATION

(1) Support the door with a suitable lifting device

and install the door onto the b-pillar.

(2) Install the nuts, washers and tighten to 23

N´m (17 ft. lbs.).

(3) Connect the door wire harness electrical con-

nector.

(4) Connect the check strap to the b-pillar. (Refer

to 23 - BODY/DOORS - REAR/CHECK STRAP -

INSTALLATION)(5) Adjust the door as necessary. (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

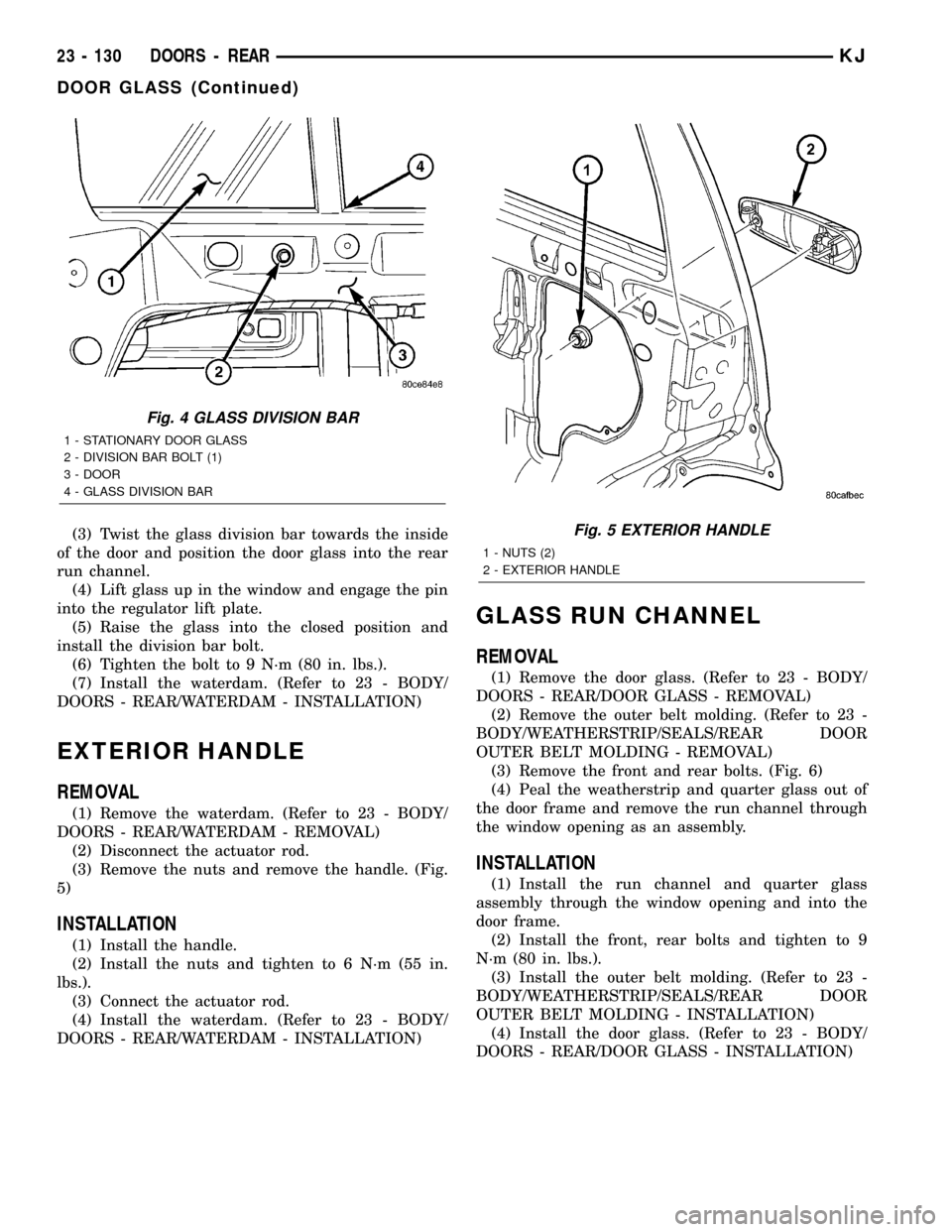

DOOR GLASS

REMOVAL

(1) Remove the waterdam. (Refer to 23 - BODY/

DOORS - REAR/WATERDAM - REMOVAL)

(2) Raise the glass and line up the lift plate clip

with the hole in the door panel shown. (Fig. 3)

(3) Using a long flat blade or hook type tool, dis-

engage the clip attaching glass retainer to regulator

lift plate.

(4) Disconnect the glass from the regulator lift

plate and re-install the clip.

(5) Position the glass into the bottom of the door.

(6) Remove the glass division bar bolt. (Fig. 4)

(7) Twist the division bar towards the inside of the

door and disengage the door glass.

(8) Remove the glass from the window opening.

INSTALLATION

(1) Install the glass through the window opening.

(2) Position the front of the glass into the glass

run channel.

Fig. 2 HINGES

1 - DOOR

2 - HINGES

3 - EPOXY WASHERS (2) (NOT REMOVABLE)

4 - NUTS

Fig. 3 DOOR GLASS POSITION

1 - GLASS DIVISION BAR

2 - DOOR PANEL SIGHT HOLE

3 - DOOR GLASS

KJDOORS - REAR 23 - 129

Page 1595 of 1803

(3) Twist the glass division bar towards the inside

of the door and position the door glass into the rear

run channel.

(4) Lift glass up in the window and engage the pin

into the regulator lift plate.

(5) Raise the glass into the closed position and

install the division bar bolt.

(6) Tighten the bolt to 9 N´m (80 in. lbs.).

(7) Install the waterdam. (Refer to 23 - BODY/

DOORS - REAR/WATERDAM - INSTALLATION)

EXTERIOR HANDLE

REMOVAL

(1) Remove the waterdam. (Refer to 23 - BODY/

DOORS - REAR/WATERDAM - REMOVAL)

(2) Disconnect the actuator rod.

(3) Remove the nuts and remove the handle. (Fig.

5)

INSTALLATION

(1) Install the handle.

(2) Install the nuts and tighten to 6 N´m (55 in.

lbs.).

(3) Connect the actuator rod.

(4) Install the waterdam. (Refer to 23 - BODY/

DOORS - REAR/WATERDAM - INSTALLATION)

GLASS RUN CHANNEL

REMOVAL

(1) Remove the door glass. (Refer to 23 - BODY/

DOORS - REAR/DOOR GLASS - REMOVAL)

(2) Remove the outer belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/REAR DOOR

OUTER BELT MOLDING - REMOVAL)

(3) Remove the front and rear bolts. (Fig. 6)

(4) Peal the weatherstrip and quarter glass out of

the door frame and remove the run channel through

the window opening as an assembly.

INSTALLATION

(1) Install the run channel and quarter glass

assembly through the window opening and into the

door frame.

(2) Install the front, rear bolts and tighten to 9

N´m (80 in. lbs.).

(3) Install the outer belt molding. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/REAR DOOR

OUTER BELT MOLDING - INSTALLATION)

(4) Install the door glass. (Refer to 23 - BODY/

DOORS - REAR/DOOR GLASS - INSTALLATION)

Fig. 4 GLASS DIVISION BAR

1 - STATIONARY DOOR GLASS

2 - DIVISION BAR BOLT (1)

3 - DOOR

4 - GLASS DIVISION BAR

Fig. 5 EXTERIOR HANDLE

1 - NUTS (2)

2 - EXTERIOR HANDLE

23 - 130 DOORS - REARKJ

DOOR GLASS (Continued)

Page 1626 of 1803

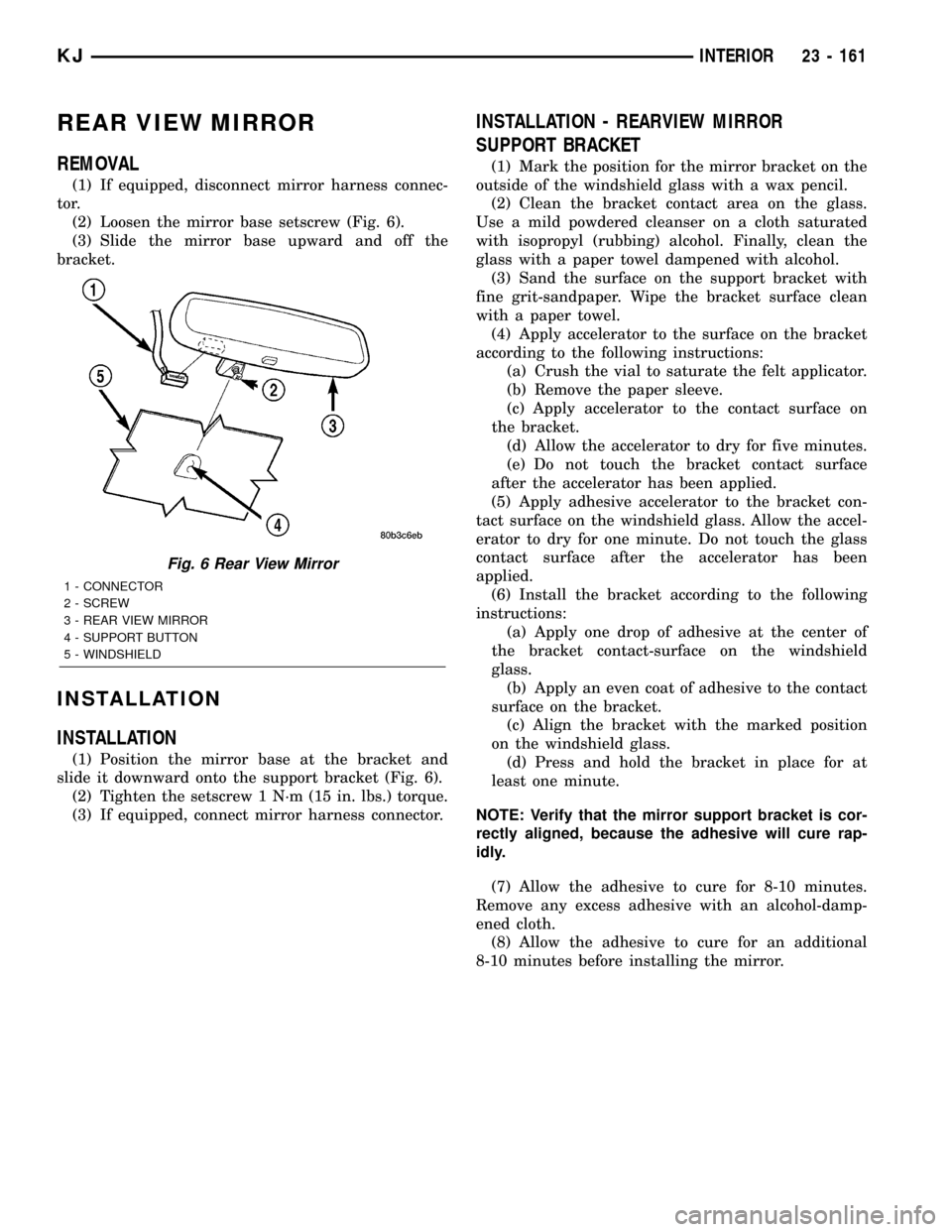

REAR VIEW MIRROR

REMOVAL

(1) If equipped, disconnect mirror harness connec-

tor.

(2) Loosen the mirror base setscrew (Fig. 6).

(3) Slide the mirror base upward and off the

bracket.

INSTALLATION

INSTALLATION

(1) Position the mirror base at the bracket and

slide it downward onto the support bracket (Fig. 6).

(2) Tighten the setscrew 1 N´m (15 in. lbs.) torque.

(3) If equipped, connect mirror harness connector.

INSTALLATION - REARVIEW MIRROR

SUPPORT BRACKET

(1) Mark the position for the mirror bracket on the

outside of the windshield glass with a wax pencil.

(2) Clean the bracket contact area on the glass.

Use a mild powdered cleanser on a cloth saturated

with isopropyl (rubbing) alcohol. Finally, clean the

glass with a paper towel dampened with alcohol.

(3) Sand the surface on the support bracket with

fine grit-sandpaper. Wipe the bracket surface clean

with a paper towel.

(4) Apply accelerator to the surface on the bracket

according to the following instructions:

(a) Crush the vial to saturate the felt applicator.

(b) Remove the paper sleeve.

(c) Apply accelerator to the contact surface on

the bracket.

(d) Allow the accelerator to dry for five minutes.

(e) Do not touch the bracket contact surface

after the accelerator has been applied.

(5) Apply adhesive accelerator to the bracket con-

tact surface on the windshield glass. Allow the accel-

erator to dry for one minute. Do not touch the glass

contact surface after the accelerator has been

applied.

(6) Install the bracket according to the following

instructions:

(a) Apply one drop of adhesive at the center of

the bracket contact-surface on the windshield

glass.

(b) Apply an even coat of adhesive to the contact

surface on the bracket.

(c) Align the bracket with the marked position

on the windshield glass.

(d) Press and hold the bracket in place for at

least one minute.

NOTE: Verify that the mirror support bracket is cor-

rectly aligned, because the adhesive will cure rap-

idly.

(7) Allow the adhesive to cure for 8-10 minutes.

Remove any excess adhesive with an alcohol-damp-

ened cloth.

(8) Allow the adhesive to cure for an additional

8-10 minutes before installing the mirror.

Fig. 6 Rear View Mirror

1 - CONNECTOR

2 - SCREW

3 - REAR VIEW MIRROR

4 - SUPPORT BUTTON

5 - WINDSHIELD

KJINTERIOR 23 - 161

Page 1737 of 1803

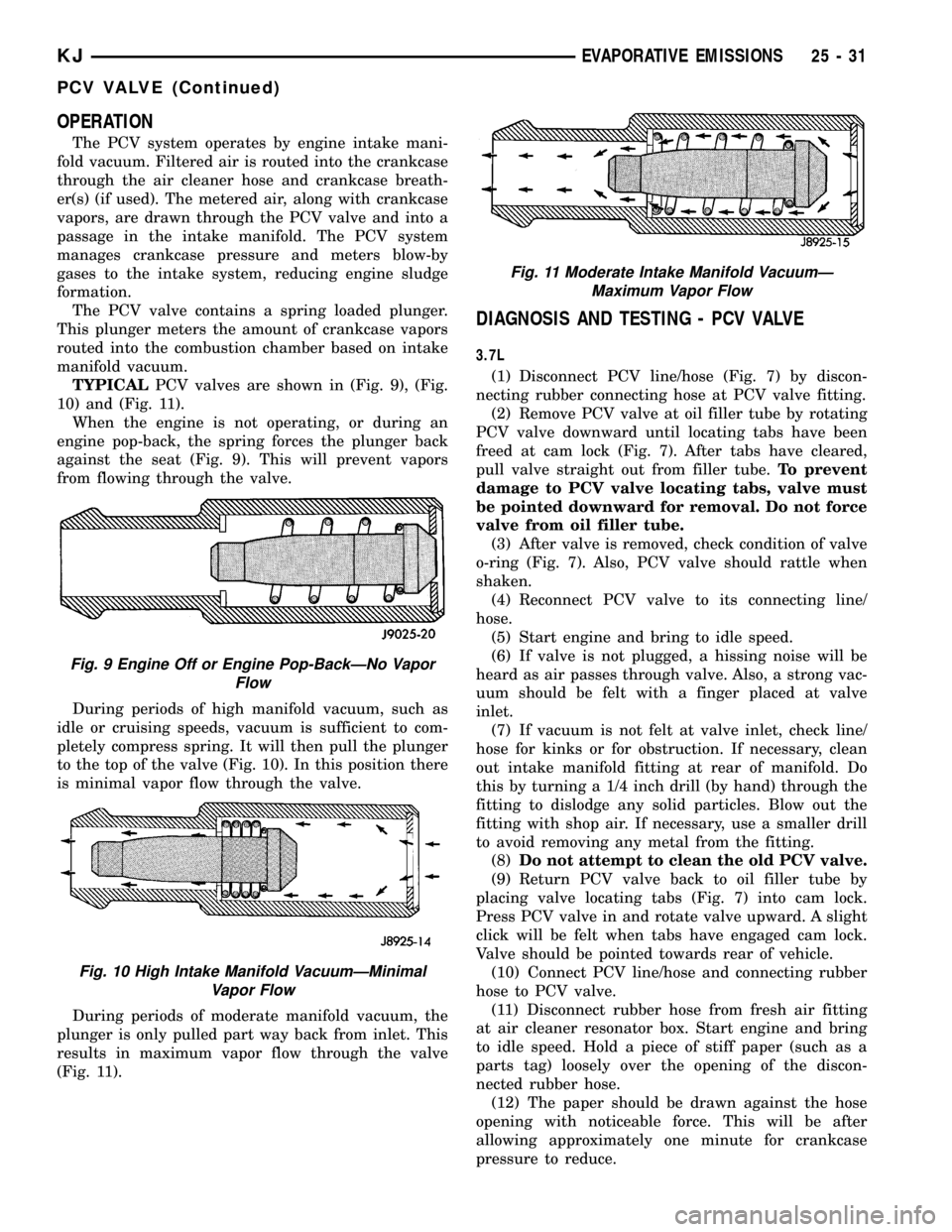

OPERATION

The PCV system operates by engine intake mani-

fold vacuum. Filtered air is routed into the crankcase

through the air cleaner hose and crankcase breath-

er(s) (if used). The metered air, along with crankcase

vapors, are drawn through the PCV valve and into a

passage in the intake manifold. The PCV system

manages crankcase pressure and meters blow-by

gases to the intake system, reducing engine sludge

formation.

The PCV valve contains a spring loaded plunger.

This plunger meters the amount of crankcase vapors

routed into the combustion chamber based on intake

manifold vacuum.

TYPICALPCV valves are shown in (Fig. 9), (Fig.

10) and (Fig. 11).

When the engine is not operating, or during an

engine pop-back, the spring forces the plunger back

against the seat (Fig. 9). This will prevent vapors

from flowing through the valve.

During periods of high manifold vacuum, such as

idle or cruising speeds, vacuum is sufficient to com-

pletely compress spring. It will then pull the plunger

to the top of the valve (Fig. 10). In this position there

is minimal vapor flow through the valve.

During periods of moderate manifold vacuum, the

plunger is only pulled part way back from inlet. This

results in maximum vapor flow through the valve

(Fig. 11).

DIAGNOSIS AND TESTING - PCV VALVE

3.7L

(1) Disconnect PCV line/hose (Fig. 7) by discon-

necting rubber connecting hose at PCV valve fitting.

(2) Remove PCV valve at oil filler tube by rotating

PCV valve downward until locating tabs have been

freed at cam lock (Fig. 7). After tabs have cleared,

pull valve straight out from filler tube.To prevent

damage to PCV valve locating tabs, valve must

be pointed downward for removal. Do not force

valve from oil filler tube.

(3) After valve is removed, check condition of valve

o-ring (Fig. 7). Also, PCV valve should rattle when

shaken.

(4) Reconnect PCV valve to its connecting line/

hose.

(5) Start engine and bring to idle speed.

(6) If valve is not plugged, a hissing noise will be

heard as air passes through valve. Also, a strong vac-

uum should be felt with a finger placed at valve

inlet.

(7) If vacuum is not felt at valve inlet, check line/

hose for kinks or for obstruction. If necessary, clean

out intake manifold fitting at rear of manifold. Do

this by turning a 1/4 inch drill (by hand) through the

fitting to dislodge any solid particles. Blow out the

fitting with shop air. If necessary, use a smaller drill

to avoid removing any metal from the fitting.

(8)Do not attempt to clean the old PCV valve.

(9) Return PCV valve back to oil filler tube by

placing valve locating tabs (Fig. 7) into cam lock.

Press PCV valve in and rotate valve upward. A slight

click will be felt when tabs have engaged cam lock.

Valve should be pointed towards rear of vehicle.

(10) Connect PCV line/hose and connecting rubber

hose to PCV valve.

(11) Disconnect rubber hose from fresh air fitting

at air cleaner resonator box. Start engine and bring

to idle speed. Hold a piece of stiff paper (such as a

parts tag) loosely over the opening of the discon-

nected rubber hose.

(12) The paper should be drawn against the hose

opening with noticeable force. This will be after

allowing approximately one minute for crankcase

pressure to reduce.

Fig. 9 Engine Off or Engine Pop-BackÐNo Vapor

Flow

Fig. 10 High Intake Manifold VacuumÐMinimal

Vapor Flow

Fig. 11 Moderate Intake Manifold VacuumÐ

Maximum Vapor Flow

KJEVAPORATIVE EMISSIONS 25 - 31

PCV VALVE (Continued)

Page 1738 of 1803

(13) If vacuum is not present, disconnect each PCV

system hose at top of each crankcase breather (Fig.

8). Check for obstructions or restrictions.

(14) If vacuum is still not present, remove each

PCV system crankcase breather (Fig. 8) from each

cylinder head. Check for obstructions or restrictions.

If plugged, replace breather. Tighten breather to 12

N´m (106 in. lbs.) torque. Do not attempt to clean

breather

(15) If vacuum is still not present, disconnect each

PCV system hose at each fitting and check for

obstructions or restrictions.

REMOVAL

2.4L

The PCV valve is attached to the left/front side of

the valve cover (Fig. 5). It is secured with 1 bolt. An

o-ring is used to seal valve to valve cover (Fig. 6).

(1) Remove hose from valve (Fig. 5). Check condi-

tion of hose.

(2) Remove 1 bolt.

(3) Remove PCV valve from valve cover.

(4) Check condition of valve o-ring.

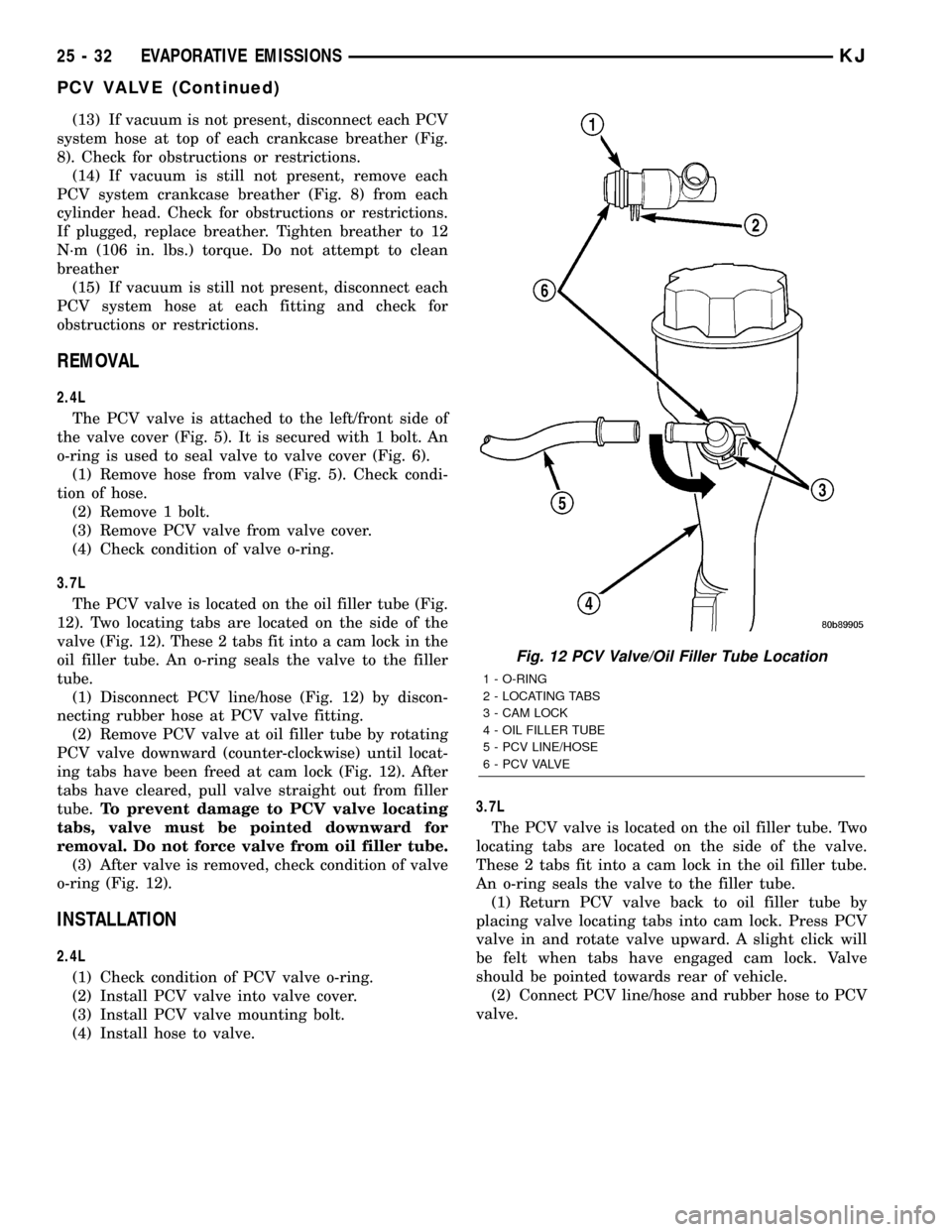

3.7L

The PCV valve is located on the oil filler tube (Fig.

12). Two locating tabs are located on the side of the

valve (Fig. 12). These 2 tabs fit into a cam lock in the

oil filler tube. An o-ring seals the valve to the filler

tube.

(1) Disconnect PCV line/hose (Fig. 12) by discon-

necting rubber hose at PCV valve fitting.

(2) Remove PCV valve at oil filler tube by rotating

PCV valve downward (counter-clockwise) until locat-

ing tabs have been freed at cam lock (Fig. 12). After

tabs have cleared, pull valve straight out from filler

tube.To prevent damage to PCV valve locating

tabs, valve must be pointed downward for

removal. Do not force valve from oil filler tube.

(3) After valve is removed, check condition of valve

o-ring (Fig. 12).

INSTALLATION

2.4L

(1) Check condition of PCV valve o-ring.

(2) Install PCV valve into valve cover.

(3) Install PCV valve mounting bolt.

(4) Install hose to valve.3.7L

The PCV valve is located on the oil filler tube. Two

locating tabs are located on the side of the valve.

These 2 tabs fit into a cam lock in the oil filler tube.

An o-ring seals the valve to the filler tube.

(1) Return PCV valve back to oil filler tube by

placing valve locating tabs into cam lock. Press PCV

valve in and rotate valve upward. A slight click will

be felt when tabs have engaged cam lock. Valve

should be pointed towards rear of vehicle.

(2) Connect PCV line/hose and rubber hose to PCV

valve.

Fig. 12 PCV Valve/Oil Filler Tube Location

1 - O-RING

2 - LOCATING TABS

3 - CAM LOCK

4 - OIL FILLER TUBE

5 - PCV LINE/HOSE

6 - P C V VA LV E

25 - 32 EVAPORATIVE EMISSIONSKJ

PCV VALVE (Continued)

Page 1745 of 1803

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-2

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-2

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING..............8M-6

COMPASS MINI-TRIP ILLUMINATION

BULB - INSTALLATION................8L-75

COMPASS MINI-TRIP ILLUMINATION

BULB - REMOVAL....................8L-74

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-3

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-4

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION.......................8M-8

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-5

COMPASS/MINI-TRIP COMPUTER -

REMOVAL...........................8M-7

COMPRESSION PRESSURE - DIAGNOSIS

AND TESTING, CYLINDER................9-8

COMPRESSOR CLUTCH - INSPECTION,

A/C................................24-14

COMPRESSOR CLUTCH - INSTALLATION,

A/C................................24-14

COMPRESSOR CLUTCH - REMOVAL, A/C . . 24-13

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE, A/C...........24-12

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING, A/C..........24-12

COMPRESSOR CLUTCH RELAY -

DESCRIPTION, A/C...................24-15

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING.............24-15

COMPRESSOR CLUTCH RELAY -

INSTALLATION, A/C...................24-16

COMPRESSOR CLUTCH RELAY -

OPERATION, A/C.....................24-15

COMPRESSOR CLUTCH RELAY -

REMOVAL, A/C......................24-16

COMPRESSOR NOISE - DIAGNOSIS AND

TESTING, A/C.......................24-42

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP..........................8M-4

COMPUTER - DIAGNOSIS AND TESTING,

COMPASS MINI-TRIP..................8M-6

COMPUTER - INSTALLATION, COMPASS/

MINI-TRIP..........................8M-8

COMPUTER - OPERATION, COMPASS/

MINI-TRIP..........................8M-5

COMPUTER - REMOVAL, COMPASS/

MINI-TRIP..........................8M-7

CONDENSER - DESCRIPTION, A/C.......24-45

CONDENSER - INSTALLATION, A/C.......24-46

CONDENSER - OPERATION, A/C.........24-45

CONDENSER - REMOVAL, A/C..........24-45

CONDITIONER - DESCRIPTION, HEATER

AND AIR ............................24-1

CONDITIONER - OPERATION, HEATER

AND AIR ............................24-2

CONDITIONS - DIAGNOSIS AND

TESTING, SPARK PLUG................8I-13

CONNECT FITTING - DESCRIPTION,

QUICK.............................14-10

CONNECTING ROD - DESCRIPTION,

PISTON.............................9-49

CONNECTING ROD BEARING - FITTING -

STANDARD PROCEDURE................9-40

CONNECTING ROD BEARING, FITTING.....9-49

CONNECTOR - DESCRIPTION, DATA LINK . 8E-10

CONNECTOR - INSTALLATION

.......8W-01-11

CONNECTOR - INSTALLATION, TRAILER

TOW

..............................8L-61

CONNECTOR - OPERATION, DATA LINK

. . . 8E-10

CONNECTOR - REMOVAL

...........8W-01-11

CONNECTOR - REMOVAL, TRAILER TOW

. . 8L-61

CONNECTOR, GROUND AND SPLICE

INFORMATION - DESCRIPTION

........8W-01-7

CONNECTOR/GROUND/SPLICE LOCATION

- DESCRIPTION

....................8W-91-1

CONSOLE - DESCRIPTION, OVERHEAD

....8M-1

CONSOLE - INSTALLATION, FLOOR

.....23-158

CONSOLE - OPERATION, OVERHEAD

......8M-2

CONSOLE - REMOVAL, FLOOR

.........23-158

CONSOLE DUCT - INSTALLATION, FLOOR

. 24-31

CONSOLE DUCT - REMOVAL, FLOOR

.....24-31CONSOLE LID LATCH - INSTALLATION,

FLOOR............................23-158

CONSOLE LID LATCH - REMOVAL,

FLOOR............................23-158

CONSOLE, REMOVAL - OVERHEAD.......8M-4

CONTAINER - DESCRIPTION, COOLANT

RECOVERY PRESS....................7-19

CONTAINER - OPERATION, COOLANT

RECOVERY PRESS....................7-19

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID................5-26

CONTAMINATION - DIAGNOSIS AND

TESTING, FLUID....................21-125

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-9

CONTROL - DESCRIPTION, A/C HEATER . . . 24-16

CONTROL - DESCRIPTION, IGNITION......8I-1

CONTROL - DESCRIPTION, SPEED........8P-1

CONTROL - INSTALLATION, A/C HEATER . . 24-17

CONTROL - OPERATION, IGNITION........8I-1

CONTROL - OPERATION, SPEED..........8P-1

CONTROL - REMOVAL, A/C HEATER......24-17

CONTROL - TORQUE, SPEED............8P-2

CONTROL ARM - DESCRIPTION, LOWER . . . 2-21

CONTROL ARM - INSTALLATION, LOWER . . 2-10,

2-21

CONTROL ARM - INSTALLATION, UPPER . . . 2-21

CONTROL ARM - OPERATION, LOWER.....2-21

CONTROL ARM - REMOVAL, LOWER . . 2-10,2-21

CONTROL ARM - REMOVAL, UPPER......2-20

CONTROL ASSEMBLY WINDOW

DEFOGGER FUNCTION - DIAGNOSIS

AND TESTING, REAR HVAC.............8G-9

CONTROL CABLE - INSTALLATION,

THROTTLE..........................14-46

CONTROL CABLE - REMOVAL,

THROTTLE..........................14-45

CONTROL ILLUMINATION BULB -

INSTALLATION, HEATER-A/C............8L-78

CONTROL ILLUMINATION BULB -

REMOVAL, HEATER-A/C...............8L-78

CONTROL INFORMATION (VECI) LABEL -

DESCRIPTION, VEHICLE EMISSION.....Intro.-8

CONTROL MODULE - DESCRIPTION,

AIRBAG.............................8O-9

CONTROL MODULE - DESCRIPTION,

BODY...............................8E-2

CONTROL MODULE - DESCRIPTION,

SIDE IMPACT AIRBAG.................8O-43

CONTROL MODULE - DESCRIPTION,

TRANSMISSION......................8E-18

CONTROL MODULE - DIAGNOSIS AND

TESTING, BODY.......................8E-7

CONTROL MODULE - INSTALLATION....23-183

CONTROL MODULE - INSTALLATION,

AIRBAG............................8O-12

CONTROL MODULE - INSTALLATION,

BODY...............................8E-7

CONTROL MODULE - INSTALLATION,

SIDE IMPACT AIRBAG.................8O-45

CONTROL MODULE - OPERATION,

AIRBAG............................8O-10

CONTROL MODULE - OPERATION, BODY . . . 8E-5

CONTROL MODULE - OPERATION, SIDE

IMPACT AIRBAG.....................8O-43

CONTROL MODULE - OPERATION,

TRANSMISSION......................8E-18

CONTROL MODULE - REMOVAL........23-183

CONTROL MODULE - REMOVAL, AIRBAG . 8O-11

CONTROL MODULE - REMOVAL, BODY....8E-7

CONTROL MODULE - REMOVAL, SIDE

IMPACT AIRBAG.....................8O-44

CONTROL MOTOR - DESCRIPTION, IDLE

AIR ...............................14-35

CONTROL MOTOR - INSTALLATION, IDLE

AIR ...............................14-36

CONTROL MOTOR - OPERATION, IDLE

AIR ...............................14-35

CONTROL MOTOR - REMOVAL, IDLE AIR . . 14-36

CONTROL RELAY - DESCRIPTION,

TRANSMISSION.....................21-168

CONTROL RELAY - OPERATION,

TRANSMISSION

.....................21-168

CONTROL SWITCH - DESCRIPTION

.....23-184

CONTROL SWITCH - DIAGNOSIS AND

TESTING

..........................23-184

CONTROL SWITCH - INSTALLATION

.....23-184

CONTROL SWITCH - OPERATION

.......23-184CONTROL SWITCH - REMOVAL........23-184

CONTROL SYSTEM - DESCRIPTION,

EMISSION...........................25-1

CONTROL SYSTEM - DESCRIPTION,

EVAPORATION.......................25-24

CONTROLLER ANTILOCK BRAKE -

INSTALLATION.......................8E-10

CONTROLLER ANTILOCK BRAKE -

REMOVAL..........................8E-10

CONVERTER - DESCRIPTION, CATALYTIC . . . 11-2

CONVERTER - DESCRIPTION, TORQUE . . . 21-162

CONVERTER - INSPECTION, CATALYTIC....11-3

CONVERTER - INSTALLATION, CATALYTIC . . 11-3

CONVERTER - INSTALLATION, TORQUE . . 21-167

CONVERTER - OPERATION, TORQUE....21-166

CONVERTER - REMOVAL, CATALYTIC......11-2

CONVERTER - REMOVAL, TORQUE......21-167

CONVERTER HOUSING FLUID LEAK -

DIAGNOSIS AND TESTING.............21-80

COOLANT - DESCRIPTION, ENGINE........0-3

COOLANT LOW INDICATOR -

DESCRIPTION.......................8J-15

COOLANT LOW INDICATOR - OPERATION . 8J-16

COOLANT RECOVERY PRESS

CONTAINER - DESCRIPTION.............7-19

COOLANT RECOVERY PRESS

CONTAINER - OPERATION...............7-19

COOLANT TEMPERATURE SENSOR -

DESCRIPTION, ENGINE.................7-19

COOLANT TEMPERATURE SENSOR -

INSTALLATION, ENGINE................7-21

COOLANT TEMPERATURE SENSOR -

OPERATION, ENGINE...................7-20

COOLANT TEMPERATURE SENSOR -

REMOVAL, ENGINE....................7-20

COOLANT THERMOSTAT - OPERATION,

ENGINE.............................7-21

COOLER - DESCRIPTION, FLUID.........19-20

COOLER - DESCRIPTION, TRANS.........7-32

COOLER - INSTALLATION, FLUID........19-20

COOLER - OPERATION, FLUID..........19-20

COOLER - REMOVAL, FLUID............19-20

COOLING, SPECIAL TOOLS..............7-14

COOLING SYSTEM - OPERATION..........7-2

COOLING SYSTEM - REVERSE

FLUSHING - STANDARD PROCEDURE.....7-12

COOLING SYSTEM 3.7L ENGINE -

DESCRIPTION.........................7-1

COOLING SYSTEM 3.7L ENGINE -

STANDARD PROCEDURE, DRAINING......7-12

COOLING SYSTEM 3.7L ENGINE -

STANDARD PROCEDURE, REFILLING......7-12

COOLING SYSTEM DIAGNOSIS CHART -

DIAGNOSIS AND TESTING...............7-6

COOLING SYSTEM LEAKS - DIAGNOSIS

AND TESTING.........................7-4

COOLING SYSTEM REQUIREMENTS -

DESCRIPTION........................24-1

COOLING SYSTEM ROUTING 3.7L

ENGINE - DESCRIPTION.................7-2

CORE - DESCRIPTION, HEATER.........24-52

CORE - INSTALLATION, HEATER.........24-53

CORE - OPERATION, HEATER...........24-52

CORE - REMOVAL, HEATER............24-52

CORE AND OIL GALLERY PLUGS -

STANDARD PROCEDURE, ENGINE........9-10

COURTESY LAMP BULB - INSTALLATION . . 8L-76

COURTESY LAMP BULB - REMOVAL.....8L-75

COURTESY LAMP REPLACEMENT -

STANDARD PROCEDURE...............8M-2

COURTESY LAMP UNIT - INSTALLATION . . 8L-77

COURTESY LAMP UNIT - REMOVAL......8L-76

COVER - DESCRIPTION, STRUCTURAL.....9-55

COVER - FRONT - INSTALLATION, SEAT

BACK.............................23-167

COVER - FRONT - INSTALLATION, SEAT

CUSHION..........................23-167

COVER - FRONT - REMOVAL, SEAT BACK . 23-166

COVER - FRONT - REMOVAL, SEAT

CUSHION..........................23-167

COVER - INSTALLATION, COWL TRIM . . . 23-157

COVER - INSTALLATION, INSTRUMENT

PANEL TOP

........................23-153

COVER - INSTALLATION, STRUCTURAL

....9-55

COVER - OPERATION, STRUCTURAL

......9-55

COVER - REAR - INSTALLATION, SEAT

BACK

.............................23-169

COVER - REAR - REMOVAL, SEAT BACK

. 23-169

6 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page