body JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 580 of 1803

The park lamp relay can be diagnosed using con-

ventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - PARK LAMP

RELAY

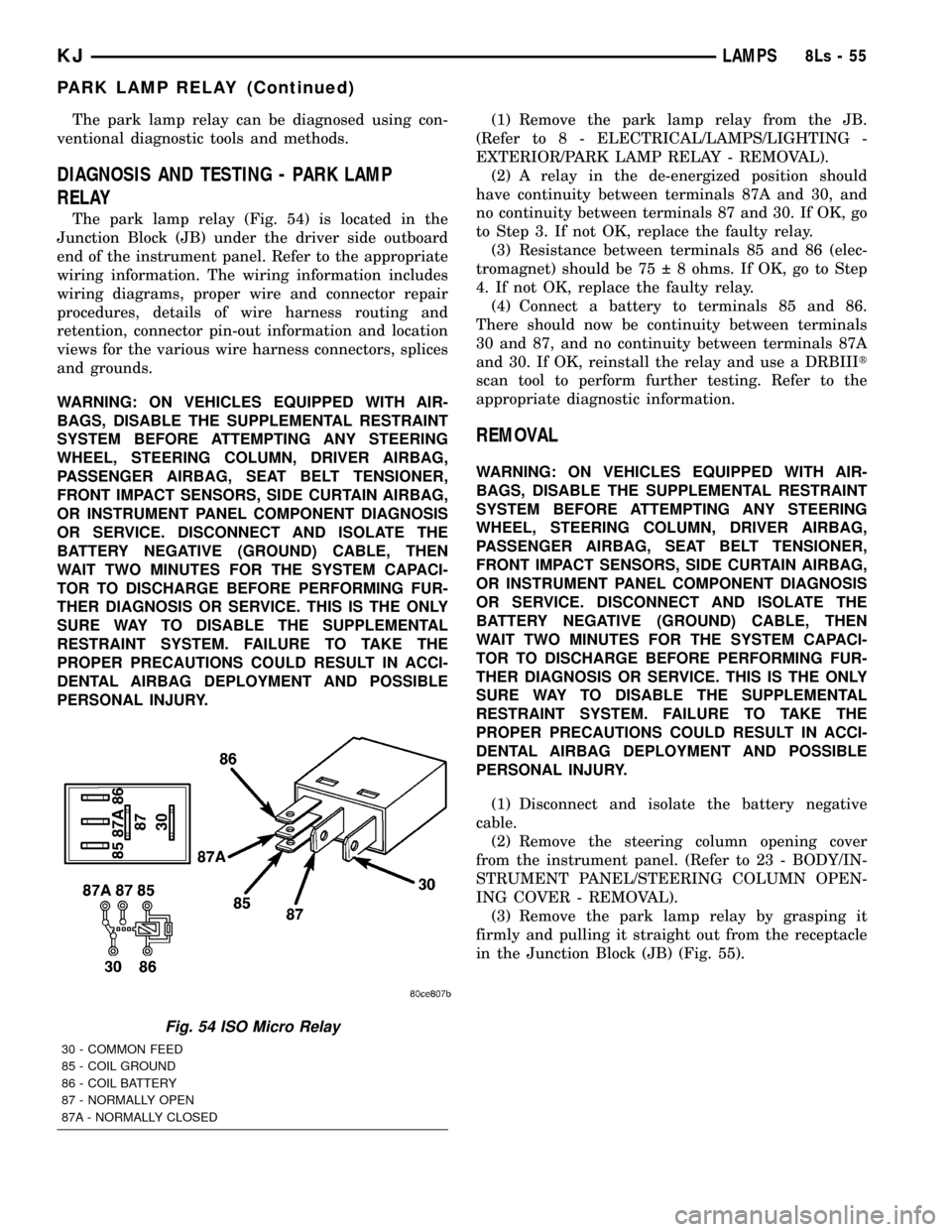

The park lamp relay (Fig. 54) is located in the

Junction Block (JB) under the driver side outboard

end of the instrument panel. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.(1) Remove the park lamp relay from the JB.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/PARK LAMP RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

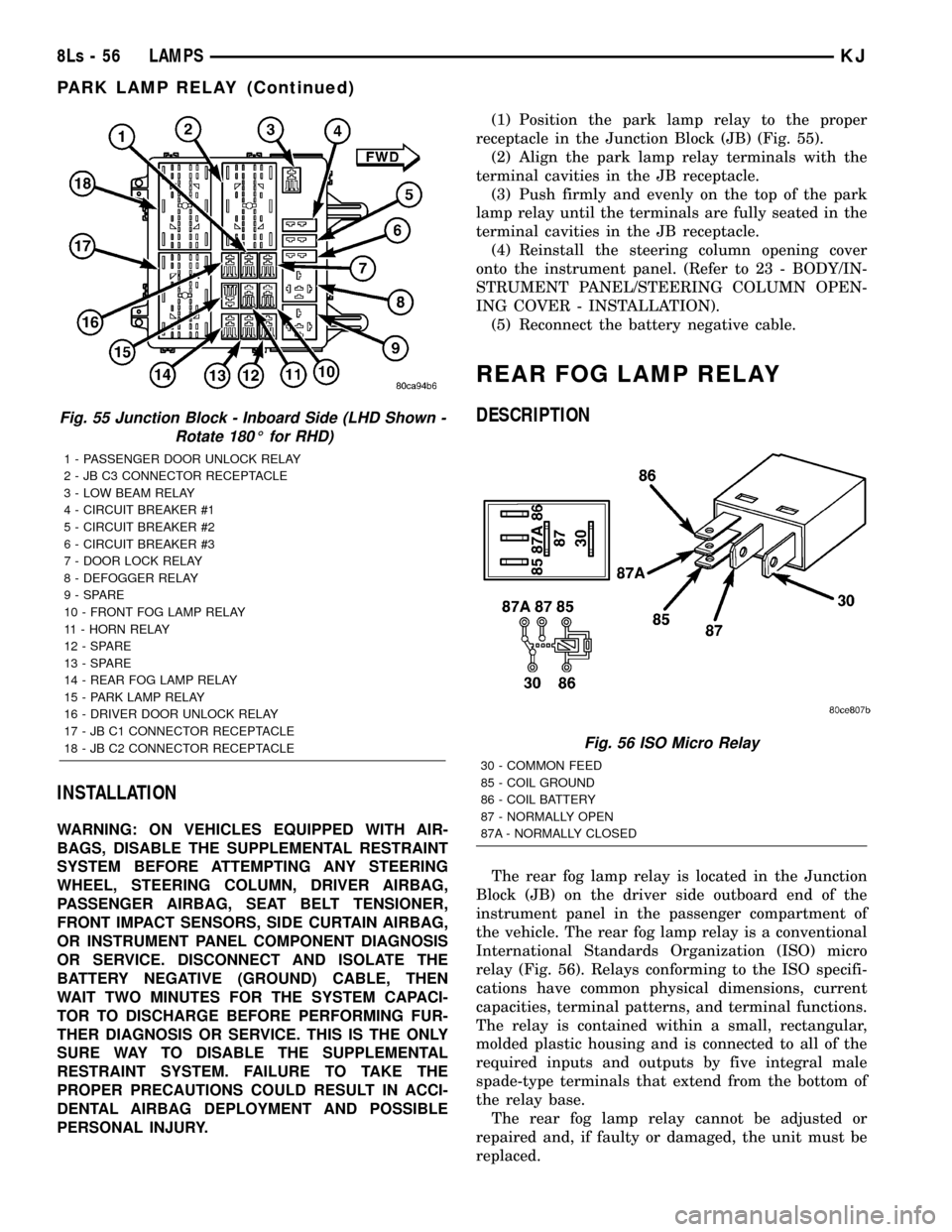

(3) Remove the park lamp relay by grasping it

firmly and pulling it straight out from the receptacle

in the Junction Block (JB) (Fig. 55).

Fig. 54 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJLAMPS8Ls-55

PARK LAMP RELAY (Continued)

Page 581 of 1803

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.(1) Position the park lamp relay to the proper

receptacle in the Junction Block (JB) (Fig. 55).

(2) Align the park lamp relay terminals with the

terminal cavities in the JB receptacle.

(3) Push firmly and evenly on the top of the park

lamp relay until the terminals are fully seated in the

terminal cavities in the JB receptacle.

(4) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(5) Reconnect the battery negative cable.

REAR FOG LAMP RELAY

DESCRIPTION

The rear fog lamp relay is located in the Junction

Block (JB) on the driver side outboard end of the

instrument panel in the passenger compartment of

the vehicle. The rear fog lamp relay is a conventional

International Standards Organization (ISO) micro

relay (Fig. 56). Relays conforming to the ISO specifi-

cations have common physical dimensions, current

capacities, terminal patterns, and terminal functions.

The relay is contained within a small, rectangular,

molded plastic housing and is connected to all of the

required inputs and outputs by five integral male

spade-type terminals that extend from the bottom of

the relay base.

The rear fog lamp relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

Fig. 55 Junction Block - Inboard Side (LHD Shown -

Rotate 180É for RHD)

1 - PASSENGER DOOR UNLOCK RELAY

2 - JB C3 CONNECTOR RECEPTACLE

3 - LOW BEAM RELAY

4 - CIRCUIT BREAKER #1

5 - CIRCUIT BREAKER #2

6 - CIRCUIT BREAKER #3

7 - DOOR LOCK RELAY

8 - DEFOGGER RELAY

9-SPARE

10 - FRONT FOG LAMP RELAY

11 - HORN RELAY

12 - SPARE

13 - SPARE

14 - REAR FOG LAMP RELAY

15 - PARK LAMP RELAY

16 - DRIVER DOOR UNLOCK RELAY

17 - JB C1 CONNECTOR RECEPTACLE

18 - JB C2 CONNECTOR RECEPTACLE

Fig. 56 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

8Ls - 56 LAMPSKJ

PARK LAMP RELAY (Continued)

Page 582 of 1803

OPERATION

The rear fog lamp relay is an electromechanical

switch that uses a low current input from the Body

Control Module (BCM) to control a high current out-

put to the rear fog lamps. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The rear fog lamp relay terminals are connected to

the vehicle electrical system through a connector

receptacle in the Junction Block (JB). The inputs and

outputs of the rear fog lamp relay include:

²Common Feed Terminal- The common feed

terminal (30) receives battery current at all times

from a fuse in the JB through a fused B(+) circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the pre-

mium Body Control Module (BCM) through a rear

fog lamp relay control circuit. The BCM controls rear

fog lamp operation by controlling a ground path

through this circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a fuse in the JB through a fused B(+) circuit.

²Normally Open Terminal- The normally open

terminal (87) is connected to the rear fog lamps

through a rear fog lamp relay output circuit and pro-

vides battery current to the rear fog lamps whenever

the relay is energized.

²Normally Closed Terminal- The normally

closed terminal (87A) is not connected in this appli-

cation.

The rear fog lamp relay can be diagnosed using

conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - REAR FOG LAMP

RELAY

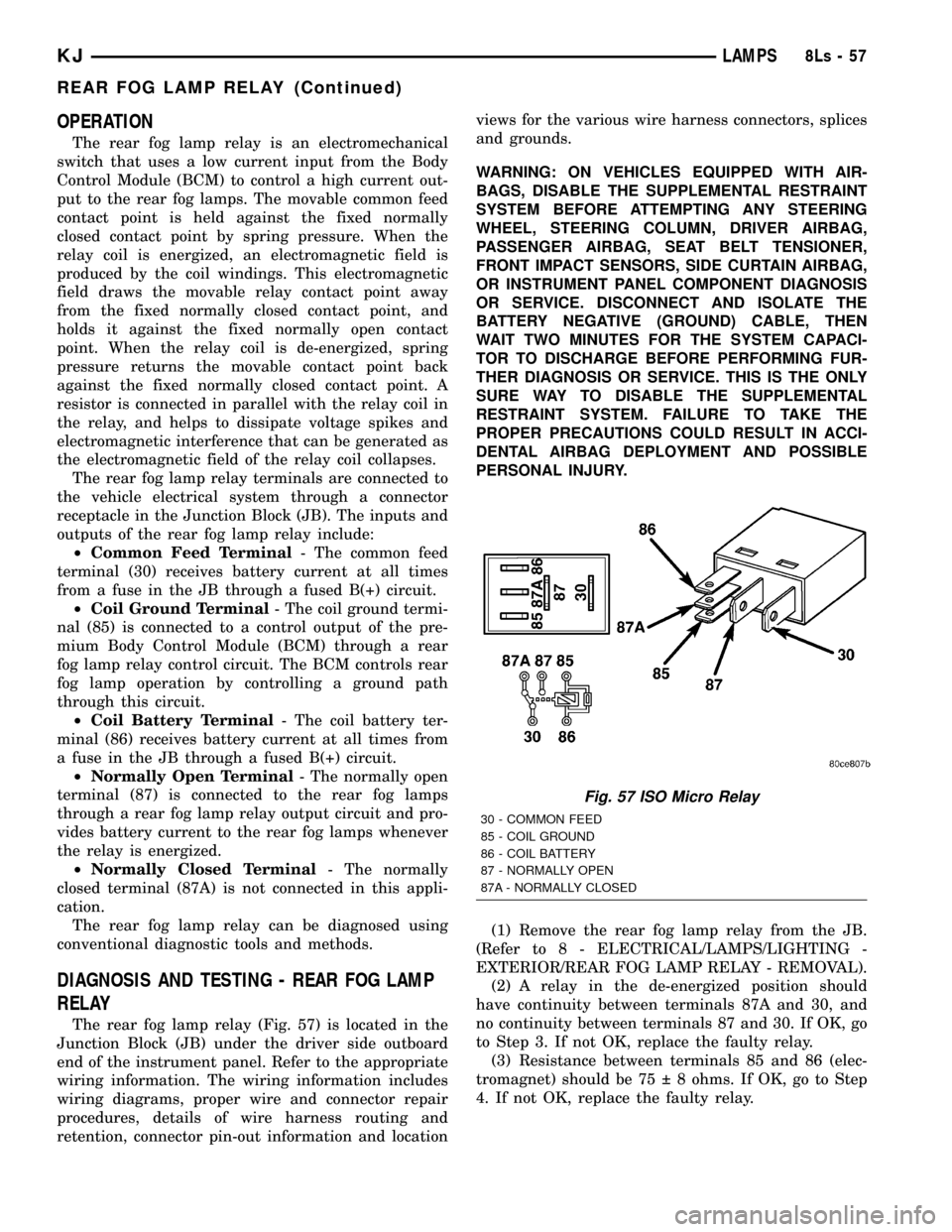

The rear fog lamp relay (Fig. 57) is located in the

Junction Block (JB) under the driver side outboard

end of the instrument panel. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and locationviews for the various wire harness connectors, splices

and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Remove the rear fog lamp relay from the JB.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/REAR FOG LAMP RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

Fig. 57 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJLAMPS8Ls-57

REAR FOG LAMP RELAY (Continued)

Page 583 of 1803

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

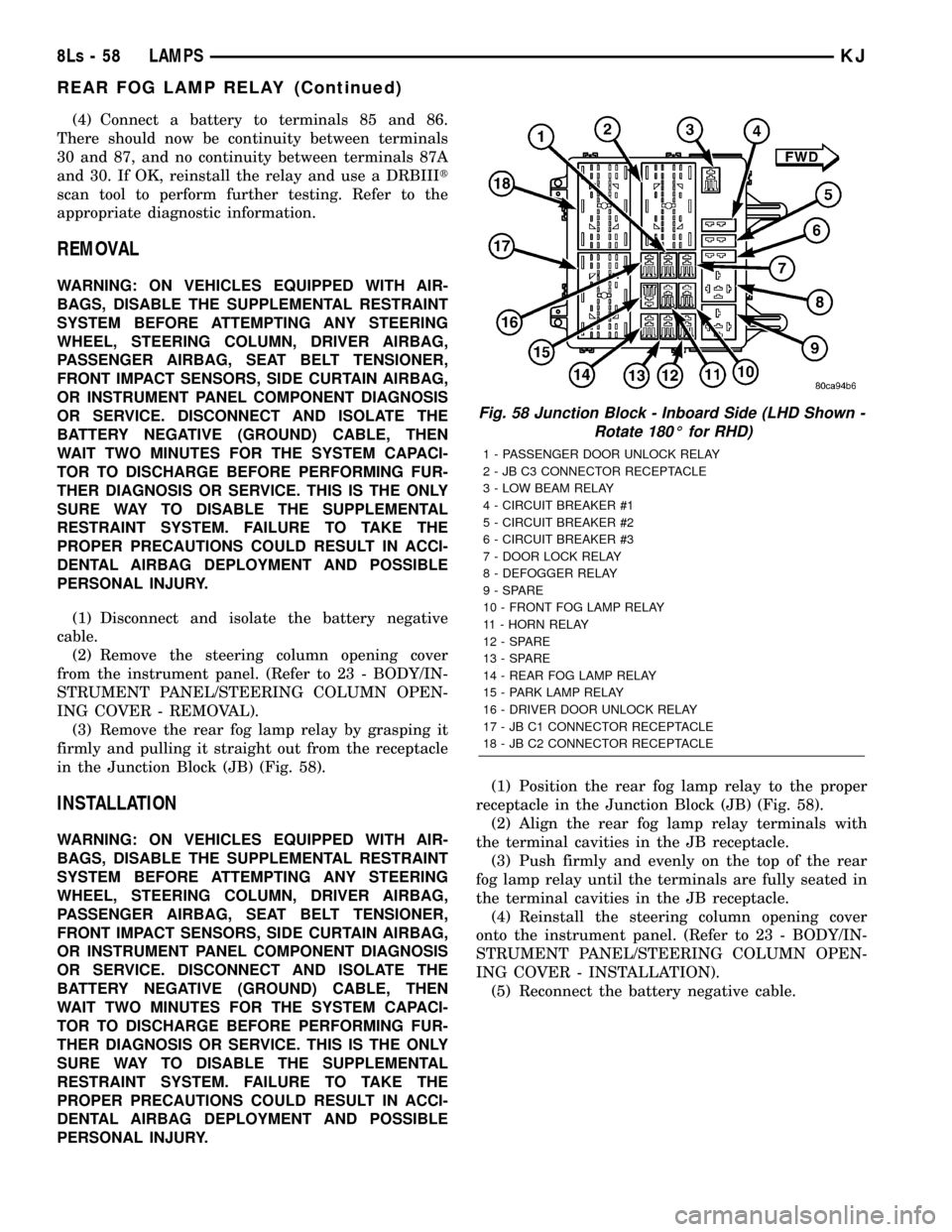

(3) Remove the rear fog lamp relay by grasping it

firmly and pulling it straight out from the receptacle

in the Junction Block (JB) (Fig. 58).

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.(1) Position the rear fog lamp relay to the proper

receptacle in the Junction Block (JB) (Fig. 58).

(2) Align the rear fog lamp relay terminals with

the terminal cavities in the JB receptacle.

(3) Push firmly and evenly on the top of the rear

fog lamp relay until the terminals are fully seated in

the terminal cavities in the JB receptacle.

(4) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(5) Reconnect the battery negative cable.

Fig. 58 Junction Block - Inboard Side (LHD Shown -

Rotate 180É for RHD)

1 - PASSENGER DOOR UNLOCK RELAY

2 - JB C3 CONNECTOR RECEPTACLE

3 - LOW BEAM RELAY

4 - CIRCUIT BREAKER #1

5 - CIRCUIT BREAKER #2

6 - CIRCUIT BREAKER #3

7 - DOOR LOCK RELAY

8 - DEFOGGER RELAY

9-SPARE

10 - FRONT FOG LAMP RELAY

11 - HORN RELAY

12 - SPARE

13 - SPARE

14 - REAR FOG LAMP RELAY

15 - PARK LAMP RELAY

16 - DRIVER DOOR UNLOCK RELAY

17 - JB C1 CONNECTOR RECEPTACLE

18 - JB C2 CONNECTOR RECEPTACLE

8Ls - 58 LAMPSKJ

REAR FOG LAMP RELAY (Continued)

Page 586 of 1803

REPEATER LAMP UNIT

REMOVAL

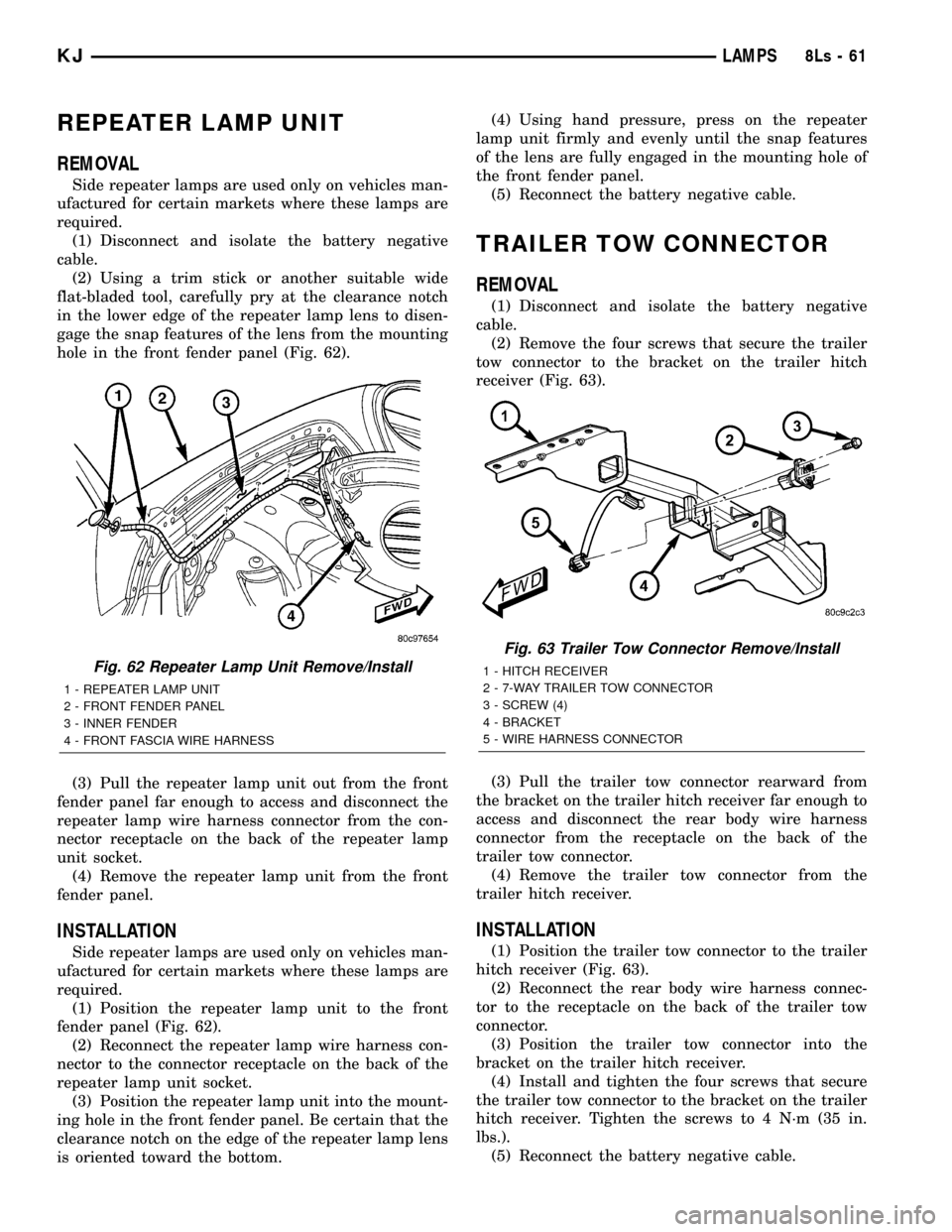

Side repeater lamps are used only on vehicles man-

ufactured for certain markets where these lamps are

required.

(1) Disconnect and isolate the battery negative

cable.

(2) Using a trim stick or another suitable wide

flat-bladed tool, carefully pry at the clearance notch

in the lower edge of the repeater lamp lens to disen-

gage the snap features of the lens from the mounting

hole in the front fender panel (Fig. 62).

(3) Pull the repeater lamp unit out from the front

fender panel far enough to access and disconnect the

repeater lamp wire harness connector from the con-

nector receptacle on the back of the repeater lamp

unit socket.

(4) Remove the repeater lamp unit from the front

fender panel.

INSTALLATION

Side repeater lamps are used only on vehicles man-

ufactured for certain markets where these lamps are

required.

(1) Position the repeater lamp unit to the front

fender panel (Fig. 62).

(2) Reconnect the repeater lamp wire harness con-

nector to the connector receptacle on the back of the

repeater lamp unit socket.

(3) Position the repeater lamp unit into the mount-

ing hole in the front fender panel. Be certain that the

clearance notch on the edge of the repeater lamp lens

is oriented toward the bottom.(4) Using hand pressure, press on the repeater

lamp unit firmly and evenly until the snap features

of the lens are fully engaged in the mounting hole of

the front fender panel.

(5) Reconnect the battery negative cable.

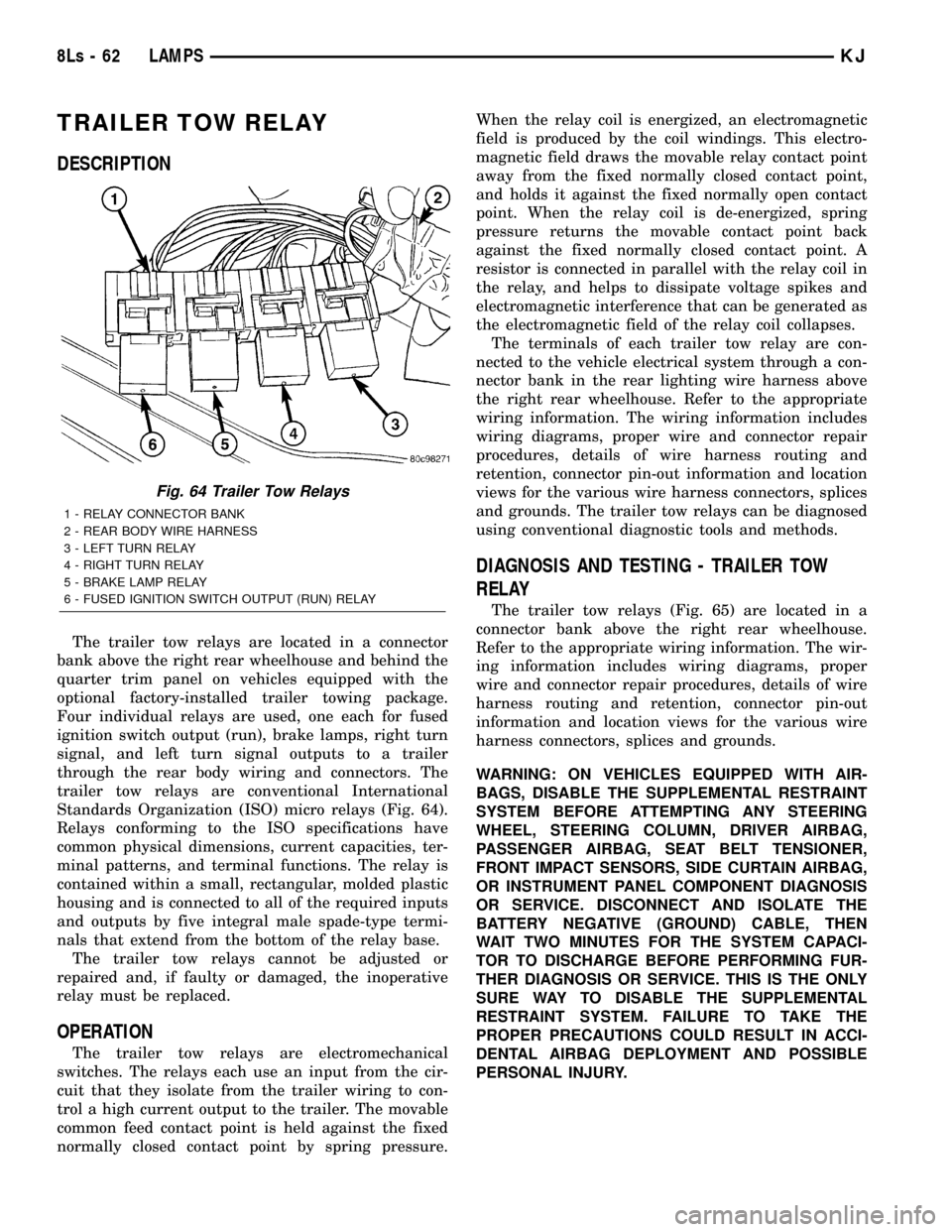

TRAILER TOW CONNECTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the four screws that secure the trailer

tow connector to the bracket on the trailer hitch

receiver (Fig. 63).

(3) Pull the trailer tow connector rearward from

the bracket on the trailer hitch receiver far enough to

access and disconnect the rear body wire harness

connector from the receptacle on the back of the

trailer tow connector.

(4) Remove the trailer tow connector from the

trailer hitch receiver.

INSTALLATION

(1) Position the trailer tow connector to the trailer

hitch receiver (Fig. 63).

(2) Reconnect the rear body wire harness connec-

tor to the receptacle on the back of the trailer tow

connector.

(3) Position the trailer tow connector into the

bracket on the trailer hitch receiver.

(4) Install and tighten the four screws that secure

the trailer tow connector to the bracket on the trailer

hitch receiver. Tighten the screws to 4 N´m (35 in.

lbs.).

(5) Reconnect the battery negative cable.

Fig. 62 Repeater Lamp Unit Remove/Install

1 - REPEATER LAMP UNIT

2 - FRONT FENDER PANEL

3 - INNER FENDER

4 - FRONT FASCIA WIRE HARNESS

Fig. 63 Trailer Tow Connector Remove/Install

1 - HITCH RECEIVER

2 - 7-WAY TRAILER TOW CONNECTOR

3 - SCREW (4)

4 - BRACKET

5 - WIRE HARNESS CONNECTOR

KJLAMPS8Ls-61

Page 587 of 1803

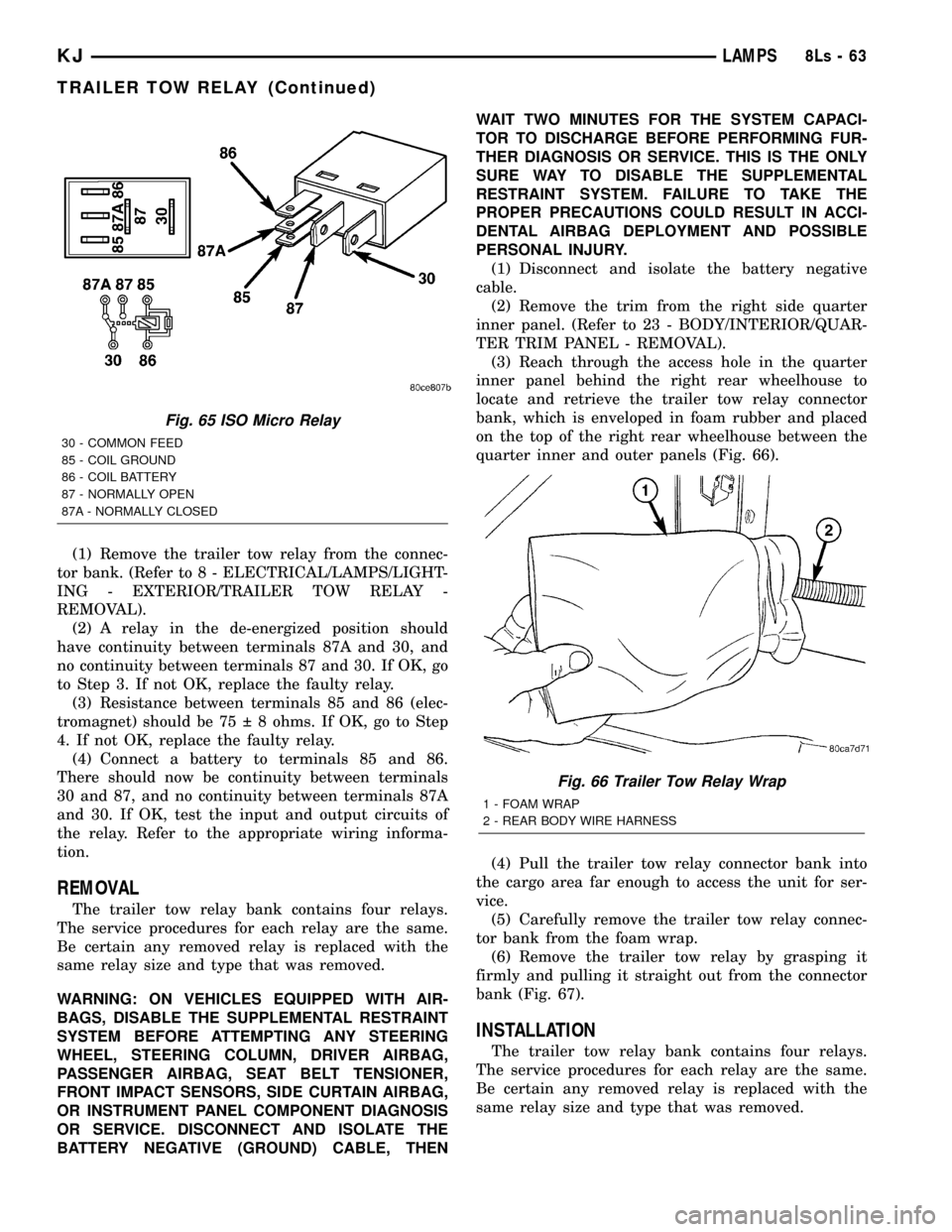

TRAILER TOW RELAY

DESCRIPTION

The trailer tow relays are located in a connector

bank above the right rear wheelhouse and behind the

quarter trim panel on vehicles equipped with the

optional factory-installed trailer towing package.

Four individual relays are used, one each for fused

ignition switch output (run), brake lamps, right turn

signal, and left turn signal outputs to a trailer

through the rear body wiring and connectors. The

trailer tow relays are conventional International

Standards Organization (ISO) micro relays (Fig. 64).

Relays conforming to the ISO specifications have

common physical dimensions, current capacities, ter-

minal patterns, and terminal functions. The relay is

contained within a small, rectangular, molded plastic

housing and is connected to all of the required inputs

and outputs by five integral male spade-type termi-

nals that extend from the bottom of the relay base.

The trailer tow relays cannot be adjusted or

repaired and, if faulty or damaged, the inoperative

relay must be replaced.

OPERATION

The trailer tow relays are electromechanical

switches. The relays each use an input from the cir-

cuit that they isolate from the trailer wiring to con-

trol a high current output to the trailer. The movable

common feed contact point is held against the fixed

normally closed contact point by spring pressure.When the relay coil is energized, an electromagnetic

field is produced by the coil windings. This electro-

magnetic field draws the movable relay contact point

away from the fixed normally closed contact point,

and holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The terminals of each trailer tow relay are con-

nected to the vehicle electrical system through a con-

nector bank in the rear lighting wire harness above

the right rear wheelhouse. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds. The trailer tow relays can be diagnosed

using conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - TRAILER TOW

RELAY

The trailer tow relays (Fig. 65) are located in a

connector bank above the right rear wheelhouse.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

Fig. 64 Trailer Tow Relays

1 - RELAY CONNECTOR BANK

2 - REAR BODY WIRE HARNESS

3 - LEFT TURN RELAY

4 - RIGHT TURN RELAY

5 - BRAKE LAMP RELAY

6 - FUSED IGNITION SWITCH OUTPUT (RUN) RELAY

8Ls - 62 LAMPSKJ

Page 588 of 1803

(1) Remove the trailer tow relay from the connec-

tor bank. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/TRAILER TOW RELAY -

REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, test the input and output circuits of

the relay. Refer to the appropriate wiring informa-

tion.

REMOVAL

The trailer tow relay bank contains four relays.

The service procedures for each relay are the same.

Be certain any removed relay is replaced with the

same relay size and type that was removed.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THENWAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim from the right side quarter

inner panel. (Refer to 23 - BODY/INTERIOR/QUAR-

TER TRIM PANEL - REMOVAL).

(3) Reach through the access hole in the quarter

inner panel behind the right rear wheelhouse to

locate and retrieve the trailer tow relay connector

bank, which is enveloped in foam rubber and placed

on the top of the right rear wheelhouse between the

quarter inner and outer panels (Fig. 66).

(4) Pull the trailer tow relay connector bank into

the cargo area far enough to access the unit for ser-

vice.

(5) Carefully remove the trailer tow relay connec-

tor bank from the foam wrap.

(6) Remove the trailer tow relay by grasping it

firmly and pulling it straight out from the connector

bank (Fig. 67).

INSTALLATION

The trailer tow relay bank contains four relays.

The service procedures for each relay are the same.

Be certain any removed relay is replaced with the

same relay size and type that was removed.

Fig. 65 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

Fig. 66 Trailer Tow Relay Wrap

1 - FOAM WRAP

2 - REAR BODY WIRE HARNESS

KJLAMPS8Ls-63

TRAILER TOW RELAY (Continued)

Page 589 of 1803

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the trailer tow relay to the proper con-

nector in the connector bank (Fig. 67).

(2) Align the trailer tow relay terminals with the

terminal cavities in the connector.

(3) Push firmly and evenly on the top of the trailer

tow relay until the terminals are fully seated in the

terminal cavities in the connector.

(4) Carefully restore the foam wrap around the

trailer tow relay connector bank (Fig. 66).

(5) Reach through the access hole in the quarter

inner panel behind the right rear wheelhouse to

place the trailer tow relay connector bank on the top

of the right rear wheelhouse between the quarter

inner and outer panels.(6) Reinstall the trim onto the right side quarter

inner panel. (Refer to 23 - BODY/INTERIOR/QUAR-

TER TRIM PANEL - INSTALLATION).

(7) Reconnect the battery negative cable.

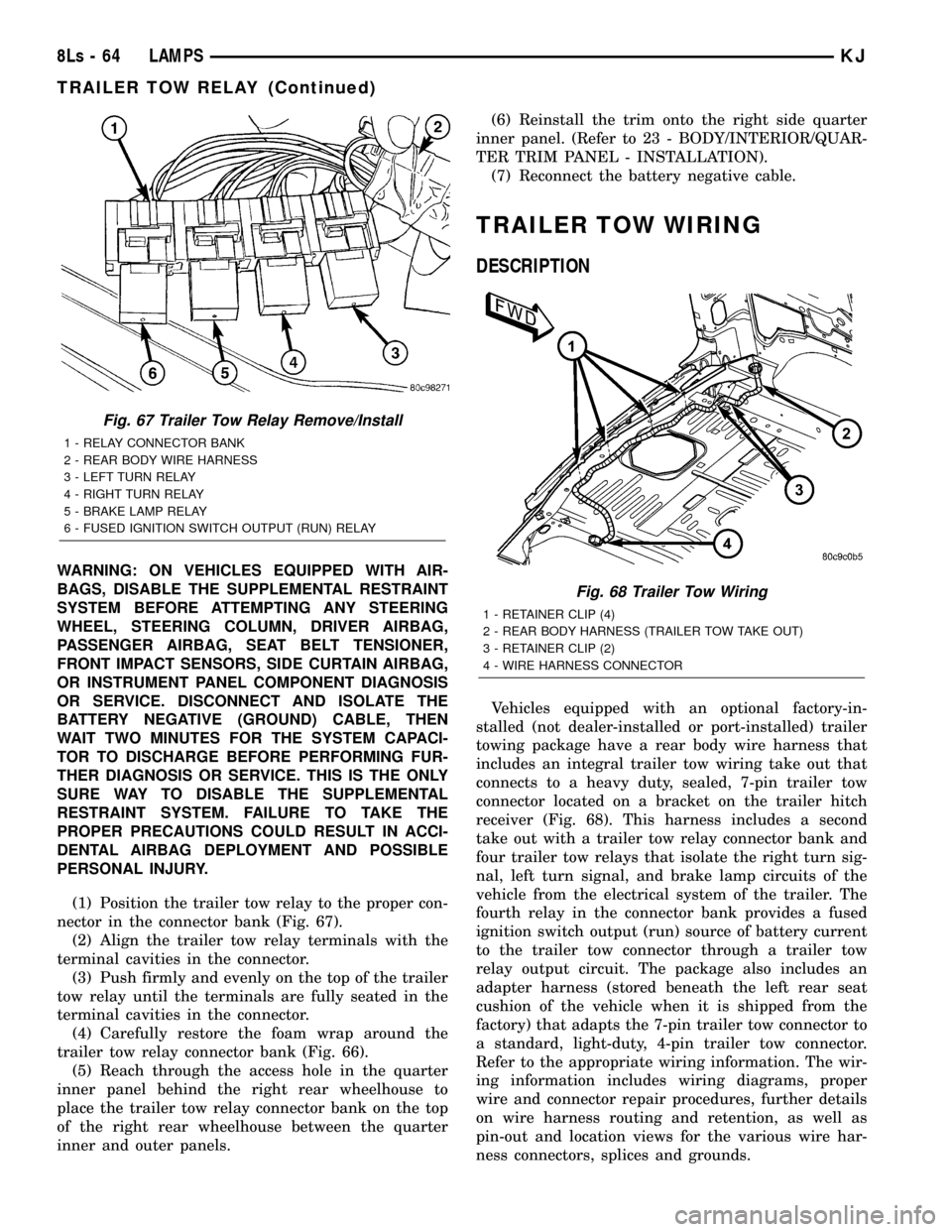

TRAILER TOW WIRING

DESCRIPTION

Vehicles equipped with an optional factory-in-

stalled (not dealer-installed or port-installed) trailer

towing package have a rear body wire harness that

includes an integral trailer tow wiring take out that

connects to a heavy duty, sealed, 7-pin trailer tow

connector located on a bracket on the trailer hitch

receiver (Fig. 68). This harness includes a second

take out with a trailer tow relay connector bank and

four trailer tow relays that isolate the right turn sig-

nal, left turn signal, and brake lamp circuits of the

vehicle from the electrical system of the trailer. The

fourth relay in the connector bank provides a fused

ignition switch output (run) source of battery current

to the trailer tow connector through a trailer tow

relay output circuit. The package also includes an

adapter harness (stored beneath the left rear seat

cushion of the vehicle when it is shipped from the

factory) that adapts the 7-pin trailer tow connector to

a standard, light-duty, 4-pin trailer tow connector.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

Fig. 67 Trailer Tow Relay Remove/Install

1 - RELAY CONNECTOR BANK

2 - REAR BODY WIRE HARNESS

3 - LEFT TURN RELAY

4 - RIGHT TURN RELAY

5 - BRAKE LAMP RELAY

6 - FUSED IGNITION SWITCH OUTPUT (RUN) RELAY

Fig. 68 Trailer Tow Wiring

1 - RETAINER CLIP (4)

2 - REAR BODY HARNESS (TRAILER TOW TAKE OUT)

3 - RETAINER CLIP (2)

4 - WIRE HARNESS CONNECTOR

8Ls - 64 LAMPSKJ

TRAILER TOW RELAY (Continued)

Page 598 of 1803

The CMTC may also be integrated with the Uni-

versal Transmitter. If so, your CMTC module will

have three buttons centered together between the

outer four buttons. Below the three buttons are cor-

responding dots to indicate which button you are

using.

The Compass Mini-Trip Computer includes the fol-

lowing display options:

²Compass and thermometer- provides the out-

side temperature and one of eight compass readings

to indicate the direction the vehicle is facing.

²Average fuel economy- shows the average

fuel economy since the last trip computer reset.

²Distance to empty- shows the estimated dis-

tance that can be travelled with the fuel remaining

in the fuel tank. This estimated distance is computed

using the average miles-per-gallon from the last 30

gallons of fuel used.

²Instant fuel economy- shows the present fuel

economy based upon the current vehicle distance and

fuel used information.

²Trip odometer- shows the distance travelled

since the last trip computer reset.

²Elapsed time- shows the accumulated igni-

tion-on time since the last trip computer reset.

²Blank screen- the CMTC compass/thermome-

ter/trip computer VFD is turned off.

If the vehicle is equipped with the optional Univer-

sal Transmitter transceiver, the CMTC will also dis-

play messages and an icon indicating when the

Universal Transmitter is being trained, which of the

three transmitter buttons is transmitting, and when

the transceiver is cleared.

Data input for all CMTC functions, including VFD

dimming level, is received through PCI data bus

messages. The CMTC module uses its internal pro-

gramming and all of its data inputs to calculate and

display the requested data. If the data displayed is

incorrect, perform the self-diagnostic tests as

described in this group. If these tests prove inconclu-

sive, the use of a DRBIIItscan tool and the proper

Diagnostic Procedures manual are recommended for

further testing of the CMTC module and the PCI

data bus.

The CMTC module cannot be repaired, and is

available for service only as a unit. This unit

includes the push button switches and the plastic

module and display lens. If any of these components

is faulty or damaged, the complete CMTC module

must be replaced. The incandescent bulbs used for

CMTC push button back-lighting are available for

service replacement.

DESCRIPTION - COMPASS

While in the compass/thermometer mode, the com-

pass will display the direction in which the vehicle ispointed using the eight major compass headings

(Examples: north is N, northeast is NE). The self-cal-

ibrating compass unit requires no adjusting in nor-

mal use. The only calibration that may prove

necessary is to drive the vehicle in three complete

circles at 5 to 8 kilometers-per-hour (3 to 5 miles-per-

hour), on level ground, in not less than forty-eight

seconds. This will reorient the compass unit to its

vehicle.

The compass unit also will compensate for magne-

tism the body of the vehicle may acquire during nor-

mal use. However, avoid placing anything magnetic

directly on the roof of the vehicle. Magnetic mounts

for an antenna, a repair order hat, or a funeral pro-

cession flag can exceed the compensating ability of

the compass unit if placed on the roof panel. Mag-

netic bit drivers used on the fasteners that hold the

overhead console assembly to the roof header can

also affect compass operation. If the vehicle roof

should become magnetized, the demagnetizing and

calibration procedures found in this group may be

required to restore proper compass operation.

DESCRIPTION - THERMOMETER

The thermometer displays the outside ambient

temperature in whole degrees. The temperature dis-

play can be toggled from Fahrenheit to Celsius by

using the U.S./Metric button. The displayed temper-

ature is not an instant reading of conditions, but an

average temperature. It may take the thermometer

display several minutes to respond to a major tem-

perature change, such as driving out of a heated

garage into winter temperatures.

When the ignition switch is turned to the Off posi-

tion, the last displayed temperature reading stays in

the Body Control Module (BCM) unit memory. When

the ignition switch is turned to the On position

again, the CMTC will display the memory tempera-

ture for one minute; then update the display to the

current average temperature reading within five

minutes.

The thermometer function is supported by an

ambient temperature sensor. The sensor is mounted

outside the passenger compartment near the front

and center of the vehicle, and is hard wired to the

Body Control Module (BCM). The BCM sends tem-

perature status messages to the CMTC module over

the PCI data bus network. The ambient temperature

sensor is available as a separate service item, refer to

additional information later in this section.

OPERATION

The compass mini-trip computer operates when the

ignition is in the ON position. The VFD will display

the last display before ignition was turned OFF. The

four outer buttons operate:

KJMESSAGE SYSTEMS 8M - 5

COMPASS/MINI-TRIP COMPUTER (Continued)

Page 599 of 1803

²STEP

²C/T - Compass/Temperature

²US/M - English/Metric

²RESET

1. STEP BUTTON

Pressing the STEP button selects one of the follow-

ing 6 displays:

²Average fuel economy

²Distance to empty

²Instantaneous fuel economy

²Trip odometer

²Elapsed time

²Blank Screen

2. C/T (COMPASS/TEMPERATURE)

BUTTON

Pressing the C/T button selects the Compass/Tem-

perature display.

3. US/M (ENGLISH/METRIC

MEASUREMENT) BUTTON

Pressing the US/M button switches the display

units between English and Metric readings.

4. RESET BUTTON

Pressing the RESET button resets the function on

the display, provided that function can be reset. The

functions which can be reset are Average fuel econ-

omy, Trip odometer and Elapsed time.

Global ResetThis feature allows all three dis-

plays (Average fuel economy, Trip odometer and

Elapsed time) to be reset easily, by pressing the

RESET button twice within three seconds with any

of the screens in display. This eliminates the need to

reset each display individually.

The RESET button is also used to set the variance

and/or calibrate the compass. Refer to the Variance

Procedure and Calibration Procedure in this section.

For more information on the features, control func-

tions and setting procedures for the CMTC module,

see the owner's manual in the vehicle glove box.

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER

The following diagnostic procedure can be used if

the compass mini-trip computer is not operational in

any way. If the problem is specific to a individual

CMTC display, go to the appropriate display title

noted below and diagnose using the information pro-

vided on how these displays are generated.

(1) Remove the overhead console from the head-

liner (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

(2) Using a ohmmeter, check the ground circuit

cavity of the compass mini-trip computer electricalconnector for proper continuity to ground. Continuity

should be present, If OK go to Step 3, If not OK

repair the open or shorted ground circuit as required.

NOTE: Connect the negative battery cable before

proceeding.

(3) Using a voltmeter, check the fused (B+) circuit

cavity of the compass mini-trip computer electrical

connector for 12v. Voltage should be present, If OK go

to Step 4, If not OK repair the open or shorted fused

(B+) circuit as required.

(4) Using a voltmeter, check the fused ignition

switch output circuit cavity of the compass mini-trip

computer electrical connector for 12v with Key ON.

Voltage should be present, If OK, replace the inoper-

ative CMTC module, If not OK repair the open or

shorted fused ignition switch output circuit as

required.

TEMPERATURE

The compass mini-trip computer receives Program-

mable Communications Interface bus (PCI bus) mes-

sages from the Body Control Module (BCM) for all

displayed information except the compass display. If

a dash (-) is displayed, the compass mini-trip com-

puter is not receiving a PCI bus message from the

BCM. To check out the PCI bus line and the BCM,

use the DRB llltscan tool and proper Body Diagnos-

tic Procedure Manual.

If the compass mini-trip computer displays a tem-

perature more than 54É C (130É F), check for a short

circuit between the temperature sensor and the

BCM.

If the compass mini-trip computer displays a tem-

perature less than -40É C (-67É F), check for an open

circuit between the temperature sensor and the

BCM.

AVERAGE FUEL ECONOMY

The compass mini-trip computer receives average

fuel economy information from the BCM over the PCI

bus line. If the compass mini-trip computer displays

-.- instead of an average fuel economy value, it is not

receiving a PCI bus message for the average fuel

economy from the BCM. To check out the PCI bus

line and the BCM use the DRB llltscan tool and

proper Body Diagnostic Procedure Manual.

DISTANCE TO EMPTY

The compass mini-trip computer receives distance

to empty information from the BCM over the PCI bus

line. If compass mini-trip computer displays a dash

(-) instead of a distance to empty value, it is not

receiving a PCI bus message for the distance to

empty from the BCM. To check out the PCI bus line

8M - 6 MESSAGE SYSTEMSKJ

COMPASS/MINI-TRIP COMPUTER (Continued)