torque JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 2 of 1803

FOREWORD

This manual is designed as a supplement to be used along with the 2002 Liberty service manual,

81-370-02060. It includes information related to the 2.4L gas engine installed in this vehicle by

DaimlerChrysler Corporation. For diagnosis or service procedures relating to other components or systems,

refer to the 2002 Liberty Service Manual.

The information contained in this service manual has been prepared for the professional automotive tech-

nician involved in daily repair operations. Information describing the operation and use of standard and

optional equipment is included in the Owner's Manual provided with the vehicle.

Information in this manual is divided into groups. These groups contain description, operation, diagnosis,

testing, adjustments, removal, installation, disassembly, and assembly procedures for the systems and compo-

nents. To assist in locating a group title page, use the Group Tab Locator on the following page. The solid bar

after the group title is aligned to a solid tab on the first page of each group. The first page of the group has

a contents section that lists major topics within the group. If you are not sure which Group contains the infor-

mation you need, look up the Component/System in the alphabetical index located in the rear of this manual.

A Service Manual Comment form is included at the rear of this manual. Use the form to provide

DaimlerChrysler Corporation with your comments and suggestions.

Tightening torques are provided as a specific value throughout this manual. This value represents the

midpoint of the acceptable engineering torque range for a given fastener application. These torque values are

intended for use in service assembly and installation procedures using the correct OEM fasteners. When

replacing fasteners, always use the same type (part number) fastener as removed.

DaimlerChrysler Corporation reserves the right to change testing procedures, specifications, diagnosis,

repair methods, or vehicle wiring at any time without prior notice or incurring obligation.

Page 4 of 1803

INTRODUCTION

TABLE OF CONTENTS

page page

FASTENER IDENTIFICATION

DESCRIPTION..........................1

FASTENER USAGE

DESCRIPTION

DESCRIPTION........................4

DESCRIPTION........................4

THREADED HOLE REPAIR

DESCRIPTION..........................4

INTERNATIONAL SYMBOLS

DESCRIPTION..........................4

METRIC SYSTEM

DESCRIPTION..........................5TORQUE REFERENCES

DESCRIPTION..........................7

VEHICLE EMISSION CONTROL INFORMATION

(VECI) LABEL

DESCRIPTION..........................8

VEHICLE IDENTIFICATION NUMBER

DESCRIPTION..........................8

VEHICLE SAFETY CERTIFICATION LABEL

DESCRIPTION..........................9

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of linemarks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts (Fig. 1) and (Fig. 2).

KJINTRODUCTION 1

Page 7 of 1803

FASTENER USAGE

DESCRIPTION

DESCRIPTION

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and torque references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

DESCRIPTION

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

THREADED HOLE REPAIR

DESCRIPTION

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

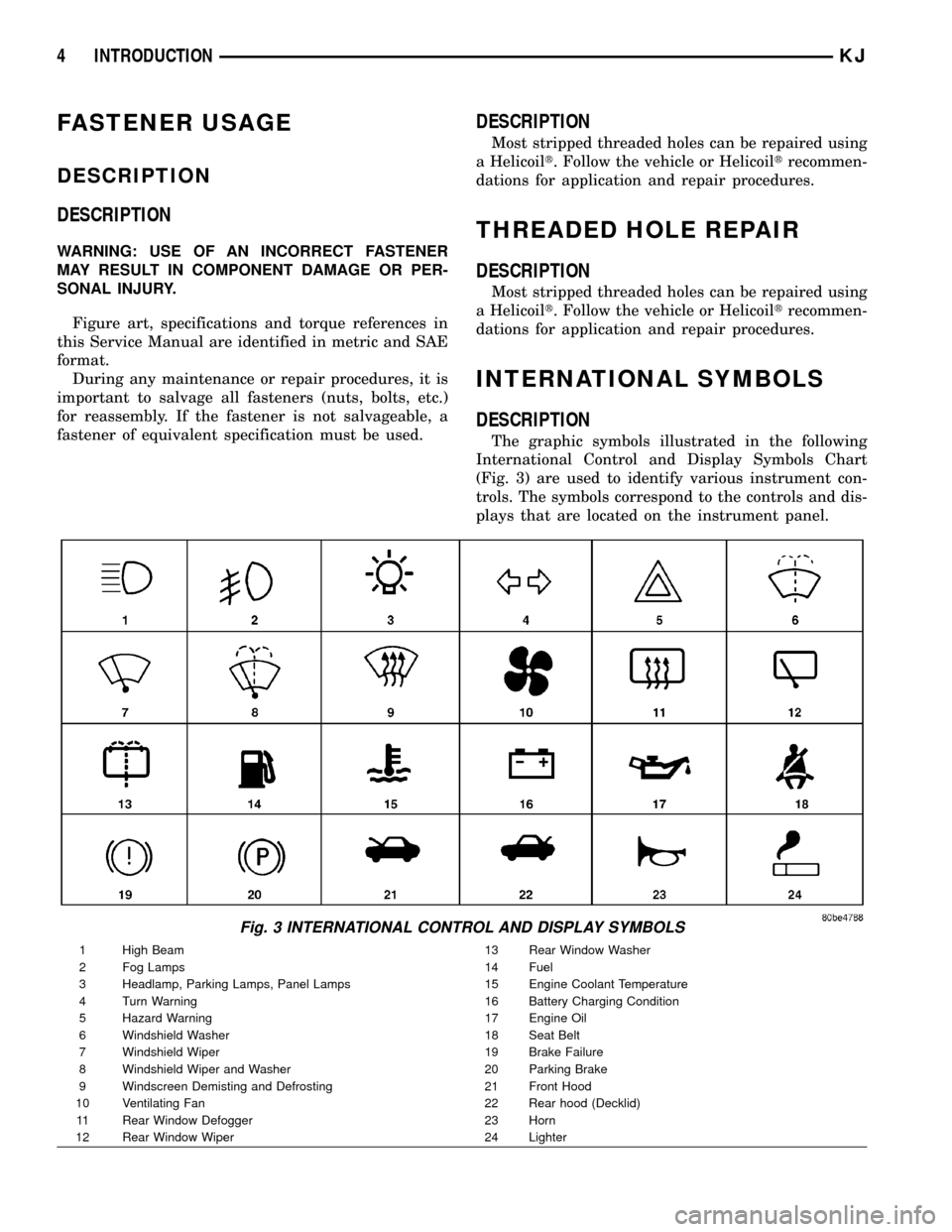

INTERNATIONAL SYMBOLS

DESCRIPTION

The graphic symbols illustrated in the following

International Control and Display Symbols Chart

(Fig. 3) are used to identify various instrument con-

trols. The symbols correspond to the controls and dis-

plays that are located on the instrument panel.

Fig. 3 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

4 INTRODUCTIONKJ

Page 8 of 1803

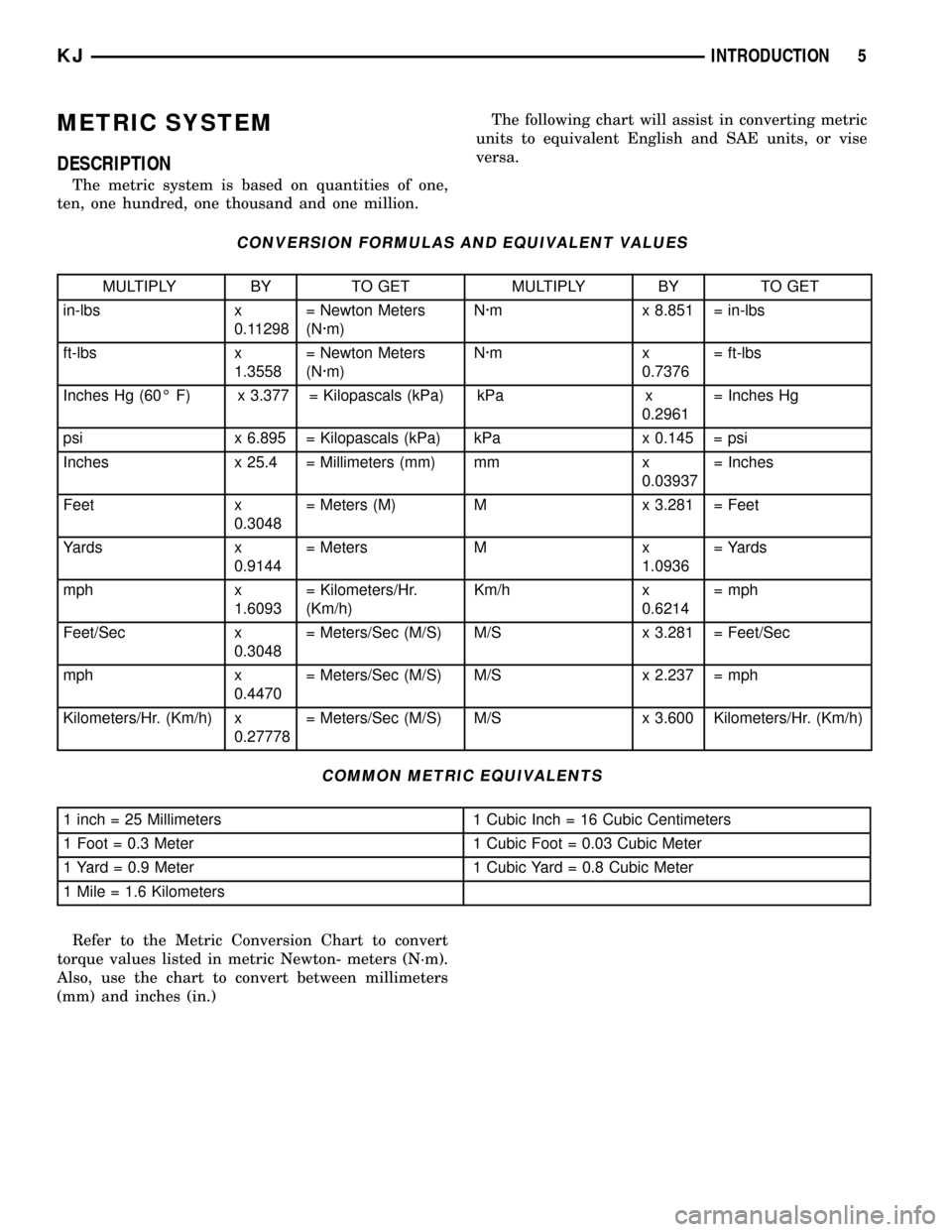

METRIC SYSTEM

DESCRIPTION

The metric system is based on quantities of one,

ten, one hundred, one thousand and one million.The following chart will assist in converting metric

units to equivalent English and SAE units, or vise

versa.

CONVERSION FORMULAS AND EQUIVALENT VALUES

MULTIPLY BY TO GET MULTIPLY BY TO GET

in-lbs x

0.11298= Newton Meters

(N´m)N´m x 8.851 = in-lbs

ft-lbs x

1.3558= Newton Meters

(N´m)N´m x

0.7376= ft-lbs

Inches Hg (60É F) x 3.377 = Kilopascals (kPa) kPa x

0.2961= Inches Hg

psi x 6.895 = Kilopascals (kPa) kPa x 0.145 = psi

Inches x 25.4 = Millimeters (mm) mm x

0.03937= Inches

Feet x

0.3048= Meters (M) M x 3.281 = Feet

Yards x

0.9144= Meters M x

1.0936= Yards

mph x

1.6093= Kilometers/Hr.

(Km/h)Km/h x

0.6214= mph

Feet/Sec x

0.3048= Meters/Sec (M/S) M/S x 3.281 = Feet/Sec

mph x

0.4470= Meters/Sec (M/S) M/S x 2.237 = mph

Kilometers/Hr. (Km/h) x

0.27778= Meters/Sec (M/S) M/S x 3.600 Kilometers/Hr. (Km/h)

COMMON METRIC EQUIVALENTS

1 inch = 25 Millimeters 1 Cubic Inch = 16 Cubic Centimeters

1 Foot = 0.3 Meter 1 Cubic Foot = 0.03 Cubic Meter

1 Yard = 0.9 Meter 1 Cubic Yard = 0.8 Cubic Meter

1 Mile = 1.6 Kilometers

Refer to the Metric Conversion Chart to convert

torque values listed in metric Newton- meters (N´m).

Also, use the chart to convert between millimeters

(mm) and inches (in.)

KJINTRODUCTION 5

Page 10 of 1803

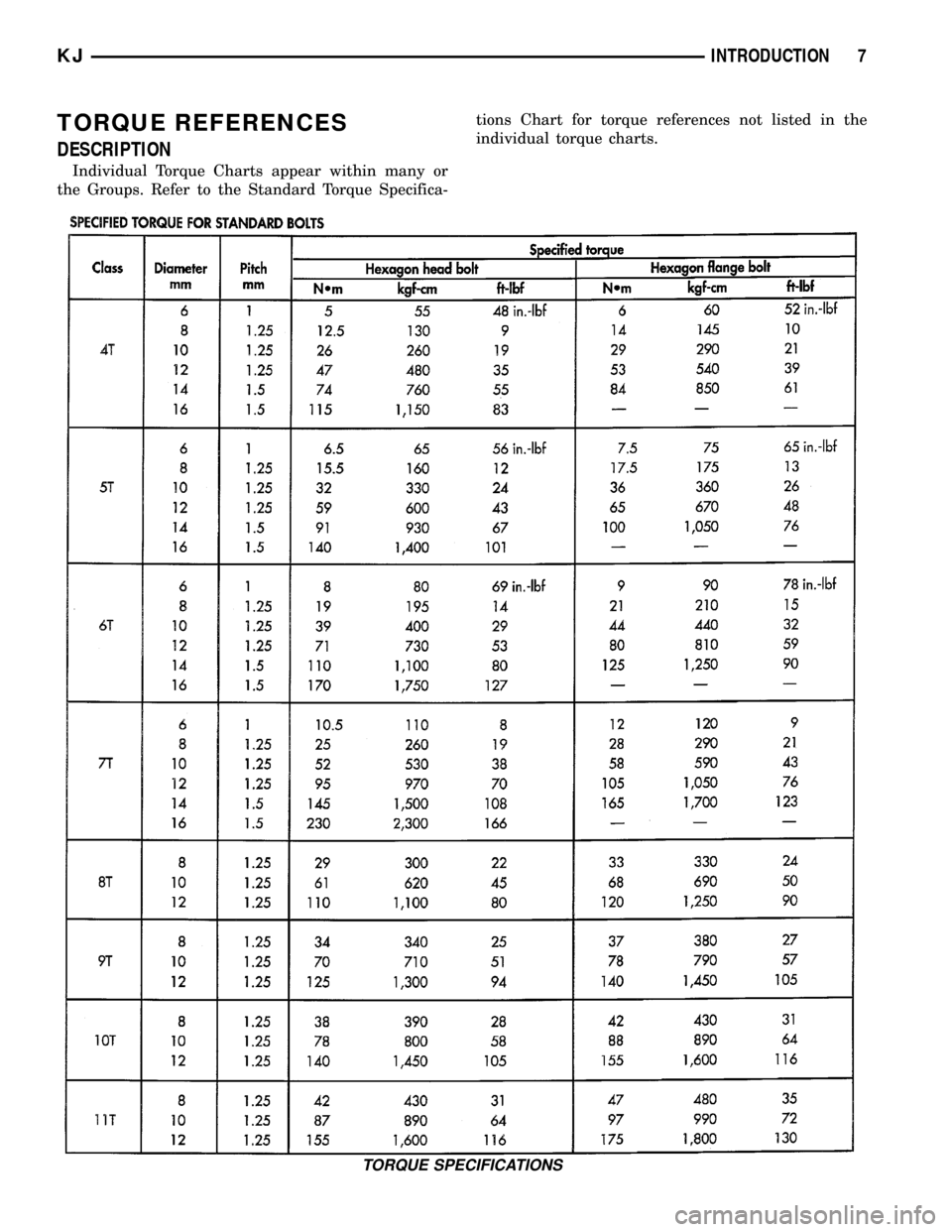

TORQUE REFERENCES

DESCRIPTION

Individual Torque Charts appear within many or

the Groups. Refer to the Standard Torque Specifica-tions Chart for torque references not listed in the

individual torque charts.

TORQUE SPECIFICATIONS

KJINTRODUCTION 7

Page 25 of 1803

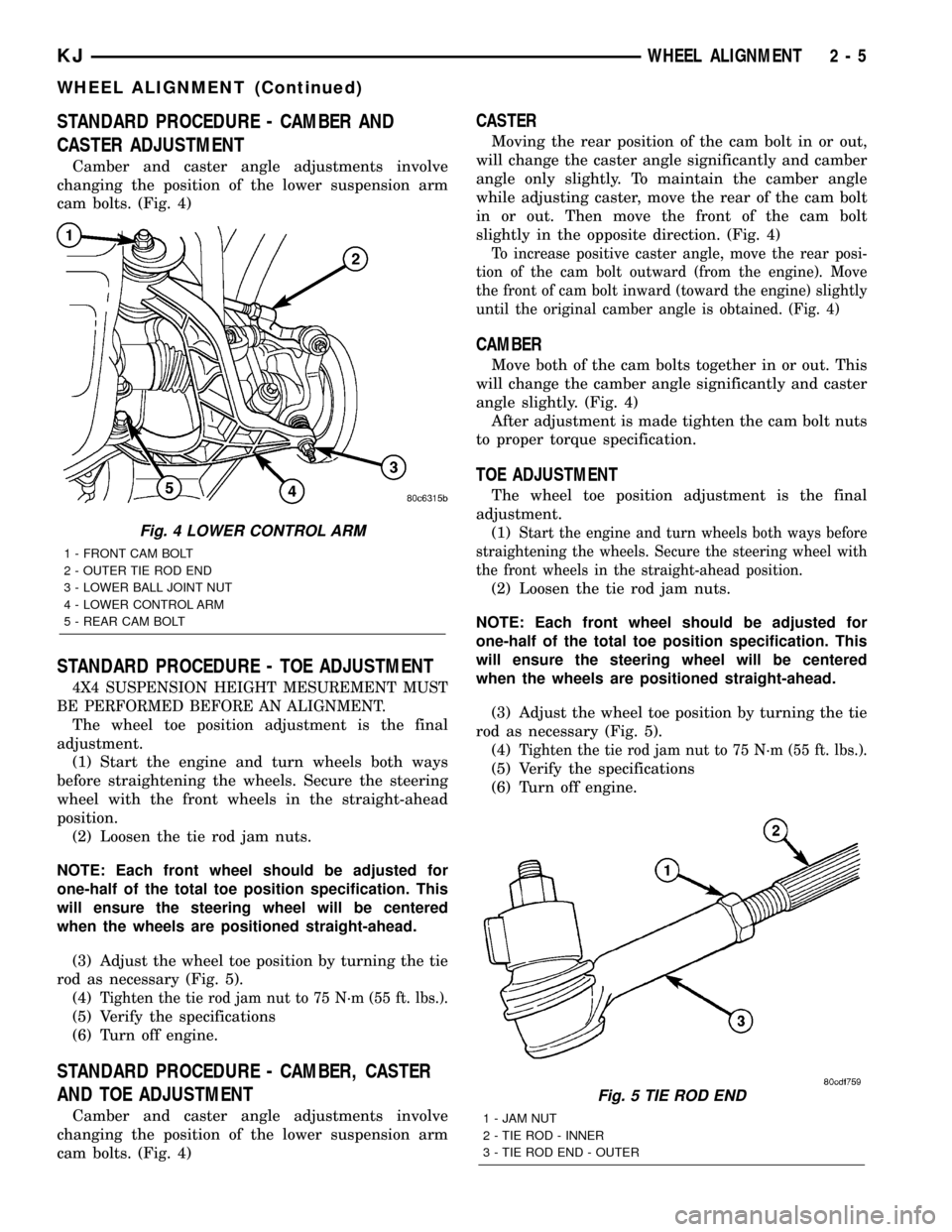

STANDARD PROCEDURE - CAMBER AND

CASTER ADJUSTMENT

Camber and caster angle adjustments involve

changing the position of the lower suspension arm

cam bolts. (Fig. 4)

STANDARD PROCEDURE - TOE ADJUSTMENT

4X4 SUSPENSION HEIGHT MESUREMENT MUST

BE PERFORMED BEFORE AN ALIGNMENT.

The wheel toe position adjustment is the final

adjustment.

(1) Start the engine and turn wheels both ways

before straightening the wheels. Secure the steering

wheel with the front wheels in the straight-ahead

position.

(2) Loosen the tie rod jam nuts.

NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the tie

rod as necessary (Fig. 5).

(4)

Tighten the tie rod jam nut to 75 N´m (55 ft. lbs.).

(5) Verify the specifications

(6) Turn off engine.

STANDARD PROCEDURE - CAMBER, CASTER

AND TOE ADJUSTMENT

Camber and caster angle adjustments involve

changing the position of the lower suspension arm

cam bolts. (Fig. 4)

CASTER

Moving the rear position of the cam bolt in or out,

will change the caster angle significantly and camber

angle only slightly. To maintain the camber angle

while adjusting caster, move the rear of the cam bolt

in or out. Then move the front of the cam bolt

slightly in the opposite direction. (Fig. 4)

To increase positive caster angle, move the rear posi-

tion of the cam bolt outward (from the engine). Move

the front of cam bolt inward (toward the engine) slightly

until the original camber angle is obtained. (Fig. 4)

CAMBER

Move both of the cam bolts together in or out. This

will change the camber angle significantly and caster

angle slightly. (Fig. 4)

After adjustment is made tighten the cam bolt nuts

to proper torque specification.

TOE ADJUSTMENT

The wheel toe position adjustment is the final

adjustment.

(1)

Start the engine and turn wheels both ways before

straightening the wheels. Secure the steering wheel with

the front wheels in the straight-ahead position.

(2) Loosen the tie rod jam nuts.

NOTE: Each front wheel should be adjusted for

one-half of the total toe position specification. This

will ensure the steering wheel will be centered

when the wheels are positioned straight-ahead.

(3) Adjust the wheel toe position by turning the tie

rod as necessary (Fig. 5).

(4)

Tighten the tie rod jam nut to 75 N´m (55 ft. lbs.).

(5) Verify the specifications

(6) Turn off engine.

Fig. 5 TIE ROD END

1 - JAM NUT

2 - TIE ROD - INNER

3 - TIE ROD END - OUTER

Fig. 4 LOWER CONTROL ARM

1 - FRONT CAM BOLT

2 - OUTER TIE ROD END

3 - LOWER BALL JOINT NUT

4 - LOWER CONTROL ARM

5 - REAR CAM BOLT

KJWHEEL ALIGNMENT 2 - 5

WHEEL ALIGNMENT (Continued)

Page 27 of 1803

FRONT

TABLE OF CONTENTS

page page

FRONT

DESCRIPTION..........................7

WARNING.............................7

SPECIFICATIONS

TORQUE CHART......................8

SPECIAL TOOLS

FRONT SUSPENSION...................8

BUSHINGS

REMOVAL - STABILIZER BAR BUSHINGS.....9

INSTALLATION - STABILIZER BAR BUSHINGS . . 9

HUB / BEARING

REMOVAL.............................9

INSTALLATION..........................9

KNUCKLE

REMOVAL.............................9

INSTALLATION..........................9

LOWER BALL JOINT

DIAGNOSIS AND TESTING - LOWER BALL

JOINT..............................10

LOWER CONTROL ARM

REMOVAL.............................10

INSTALLATION.........................10

SHOCK

REMOVAL

REMOVAL - LEFT SIDE.................11REMOVAL - RIGHT SIDE................11

INSTALLATION

INSTALLATION - LEFT SIDE.............12

INSTALLATION - RIGHT SIDE............12

SPRING

REMOVAL.............................13

INSTALLATION.........................13

CLEVIS BRACKET

REMOVAL.............................13

INSTALLATION.........................13

STABILIZER BAR

REMOVAL.............................14

INSTALLATION.........................14

STABILIZER LINK

REMOVAL.............................14

INSTALLATION.........................14

UPPER CONTROL ARM

REMOVAL

REMOVAL - RIGHT SIDE................14

REMOVAL - LEFT SIDE.................15

INSTALLATION

INSTALLATION - RIGHT SIDE............15

INSTALLATION - LEFT SIDE.............15

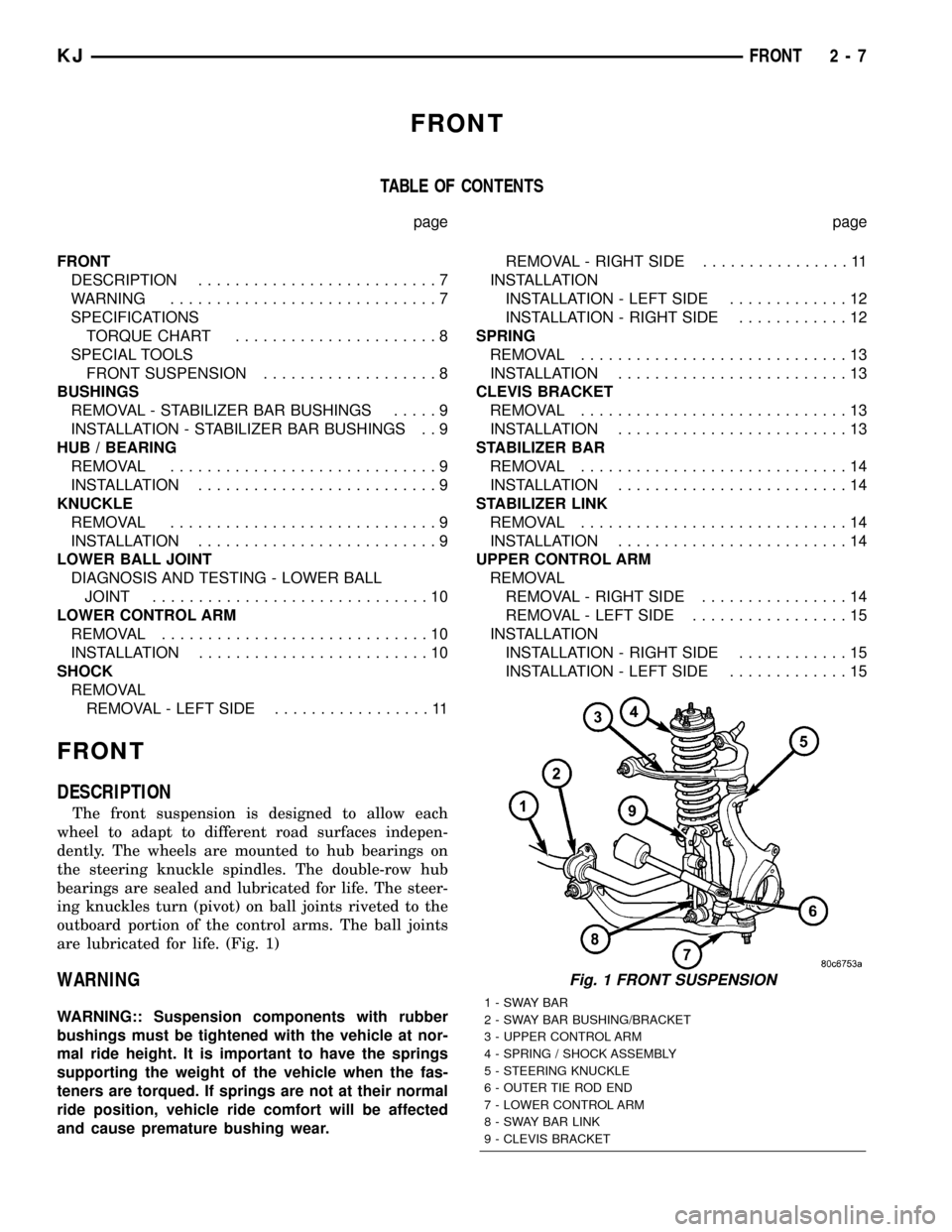

FRONT

DESCRIPTION

The front suspension is designed to allow each

wheel to adapt to different road surfaces indepen-

dently. The wheels are mounted to hub bearings on

the steering knuckle spindles. The double-row hub

bearings are sealed and lubricated for life. The steer-

ing knuckles turn (pivot) on ball joints riveted to the

outboard portion of the control arms. The ball joints

are lubricated for life. (Fig. 1)

WARNING

WARNING:: Suspension components with rubber

bushings must be tightened with the vehicle at nor-

mal ride height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort will be affected

and cause premature bushing wear.

Fig. 1 FRONT SUSPENSION

1-SWAYBAR

2 - SWAY BAR BUSHING/BRACKET

3 - UPPER CONTROL ARM

4 - SPRING / SHOCK ASSEMBLY

5 - STEERING KNUCKLE

6 - OUTER TIE ROD END

7 - LOWER CONTROL ARM

8 - SWAY BAR LINK

9 - CLEVIS BRACKET

KJFRONT 2 - 7

Page 28 of 1803

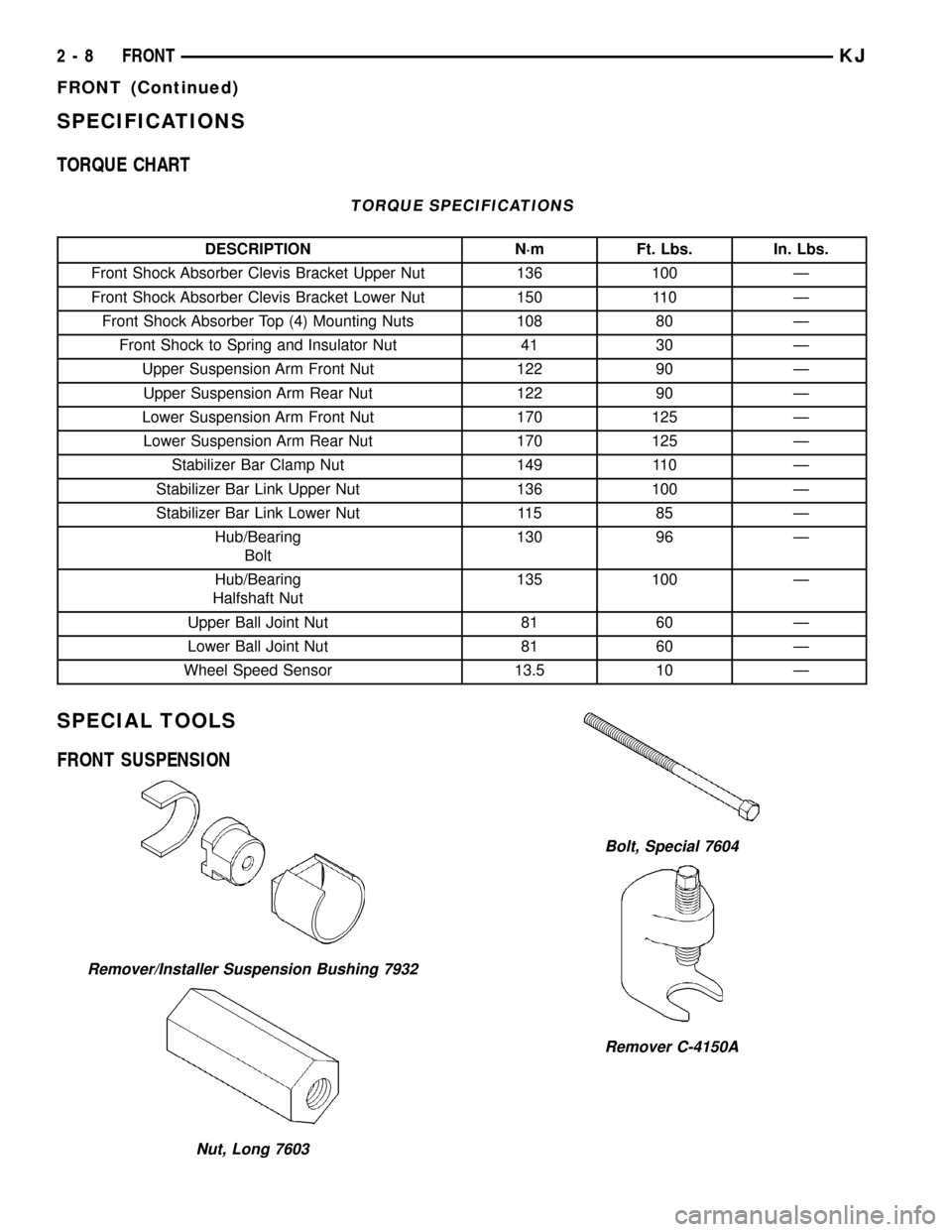

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Front Shock Absorber Clevis Bracket Upper Nut 136 100 Ð

Front Shock Absorber Clevis Bracket Lower Nut 150 110 Ð

Front Shock Absorber Top (4) Mounting Nuts 108 80 Ð

Front Shock to Spring and Insulator Nut 41 30 Ð

Upper Suspension Arm Front Nut 122 90 Ð

Upper Suspension Arm Rear Nut 122 90 Ð

Lower Suspension Arm Front Nut 170 125 Ð

Lower Suspension Arm Rear Nut 170 125 Ð

Stabilizer Bar Clamp Nut 149 110 Ð

Stabilizer Bar Link Upper Nut 136 100 Ð

Stabilizer Bar Link Lower Nut 115 85 Ð

Hub/Bearing

Bolt130 96 Ð

Hub/Bearing

Halfshaft Nut135 100 Ð

Upper Ball Joint Nut 81 60 Ð

Lower Ball Joint Nut 81 60 Ð

Wheel Speed Sensor 13.5 10 Ð

SPECIAL TOOLS

FRONT SUSPENSION

Remover/Installer Suspension Bushing 7932

Nut, Long 7603

Bolt, Special 7604

Remover C-4150A

2 - 8 FRONTKJ

FRONT (Continued)

Page 36 of 1803

REAR

TABLE OF CONTENTS

page page

REAR

DESCRIPTION.........................16

WARNING.............................16

DIAGNOSIS AND TESTING - REAR

SUSPENSION........................17

SPECIFICATIONS

TORQUE CHART......................17

SHOCK

REMOVAL.............................18

INSTALLATION.........................18

SPRING

REMOVAL.............................18

INSTALLATION.........................18

JOUNCE BUMPER

REMOVAL.............................19

INSTALLATION.........................19

STABILIZER BAR

REMOVAL.............................19INSTALLATION.........................19

UPPER BALL JOINT

REMOVAL.............................20

INSTALLATION.........................20

UPPER CONTROL ARM

DESCRIPTION - UPPER SUSPENSION ARM,

BUSHINGS, AND BALL JOINT............20

OPERATION - UPPER SUSPENSION ARM,

BUSHINGS, AND BALL JOINT............20

REMOVAL.............................20

INSTALLATION.........................21

LOWER CONTROL ARM

DESCRIPTION.........................21

OPERATION...........................21

REMOVAL.............................21

INSTALLATION.........................21

REAR

DESCRIPTION

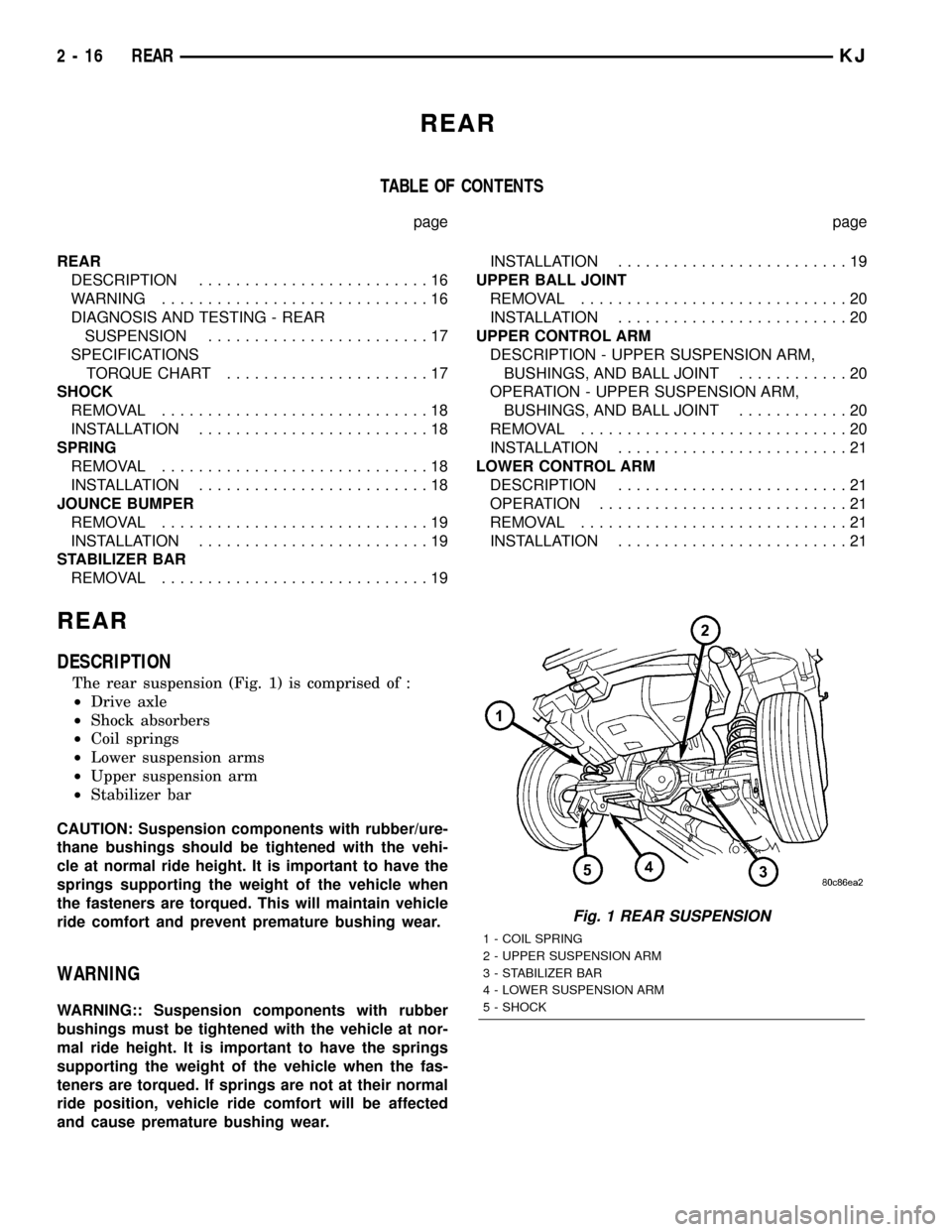

The rear suspension (Fig. 1) is comprised of :

²Drive axle

²Shock absorbers

²Coil springs

²Lower suspension arms

²Upper suspension arm

²Stabilizer bar

CAUTION: Suspension components with rubber/ure-

thane bushings should be tightened with the vehi-

cle at normal ride height. It is important to have the

springs supporting the weight of the vehicle when

the fasteners are torqued. This will maintain vehicle

ride comfort and prevent premature bushing wear.

WARNING

WARNING:: Suspension components with rubber

bushings must be tightened with the vehicle at nor-

mal ride height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort will be affected

and cause premature bushing wear.

Fig. 1 REAR SUSPENSION

1 - COIL SPRING

2 - UPPER SUSPENSION ARM

3 - STABILIZER BAR

4 - LOWER SUSPENSION ARM

5 - SHOCK

2 - 16 REARKJ

Page 37 of 1803

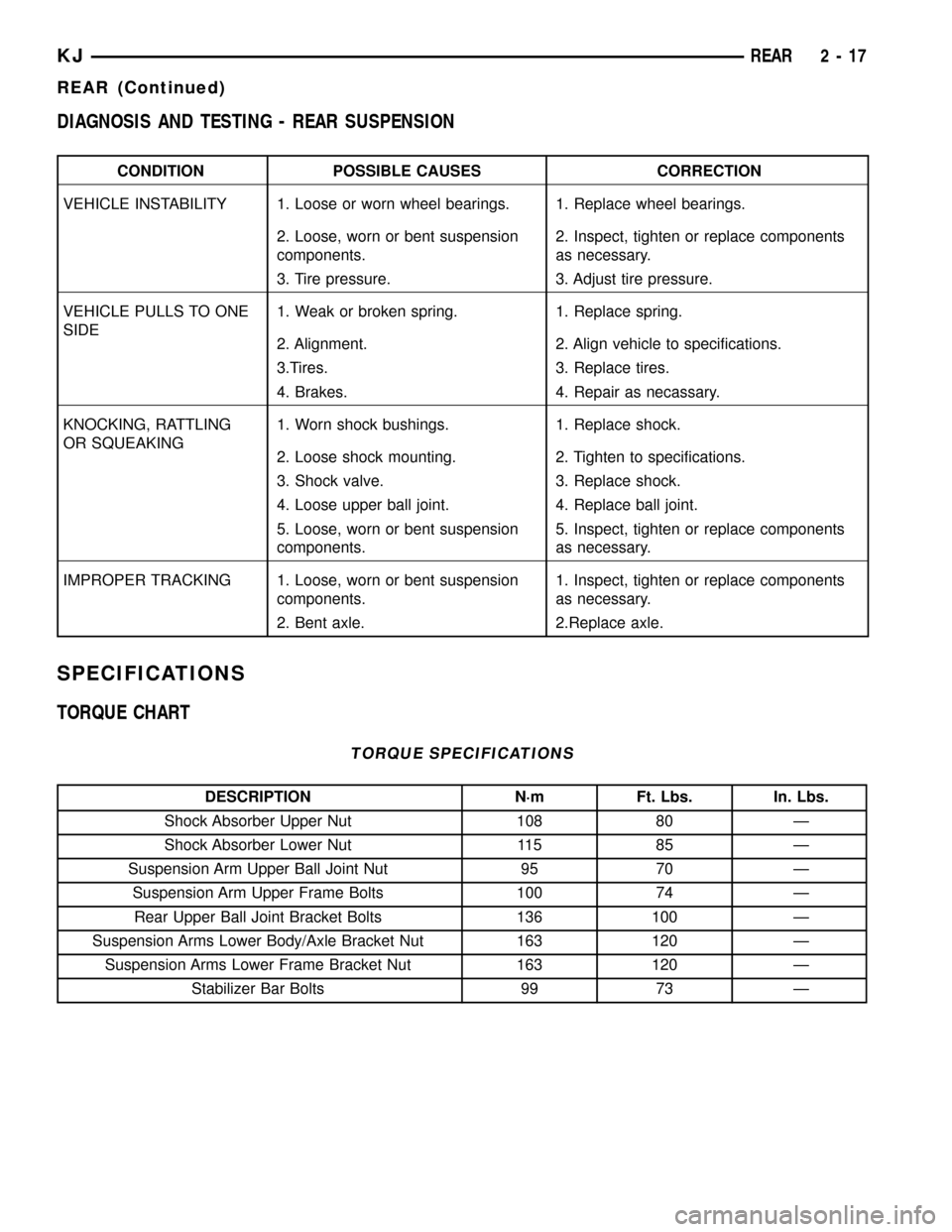

DIAGNOSIS AND TESTING - REAR SUSPENSION

CONDITION POSSIBLE CAUSES CORRECTION

VEHICLE INSTABILITY 1. Loose or worn wheel bearings. 1. Replace wheel bearings.

2. Loose, worn or bent suspension

components.2. Inspect, tighten or replace components

as necessary.

3. Tire pressure. 3. Adjust tire pressure.

VEHICLE PULLS TO ONE

SIDE1. Weak or broken spring. 1. Replace spring.

2. Alignment. 2. Align vehicle to specifications.

3.Tires. 3. Replace tires.

4. Brakes. 4. Repair as necassary.

KNOCKING, RATTLING

OR SQUEAKING1. Worn shock bushings. 1. Replace shock.

2. Loose shock mounting. 2. Tighten to specifications.

3. Shock valve. 3. Replace shock.

4. Loose upper ball joint. 4. Replace ball joint.

5. Loose, worn or bent suspension

components.5. Inspect, tighten or replace components

as necessary.

IMPROPER TRACKING 1. Loose, worn or bent suspension

components.1. Inspect, tighten or replace components

as necessary.

2. Bent axle. 2.Replace axle.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Shock Absorber Upper Nut 108 80 Ð

Shock Absorber Lower Nut 115 85 Ð

Suspension Arm Upper Ball Joint Nut 95 70 Ð

Suspension Arm Upper Frame Bolts 100 74 Ð

Rear Upper Ball Joint Bracket Bolts 136 100 Ð

Suspension Arms Lower Body/Axle Bracket Nut 163 120 Ð

Suspension Arms Lower Frame Bracket Nut 163 120 Ð

Stabilizer Bar Bolts 99 73 Ð

KJREAR 2 - 17

REAR (Continued)