JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 181 of 1803

INSTALLATION

(1) Install caliper to the caliper adapter.

(2) Coat the caliper mounting slide pin bolts with

silicone grease. Begin with the bolt closet to the

bleeder screws (top), Then install and tighten the

bolts to 15 N´m (11 ft. lbs.).

(3) Install the brake hose banjo bolt if removed.

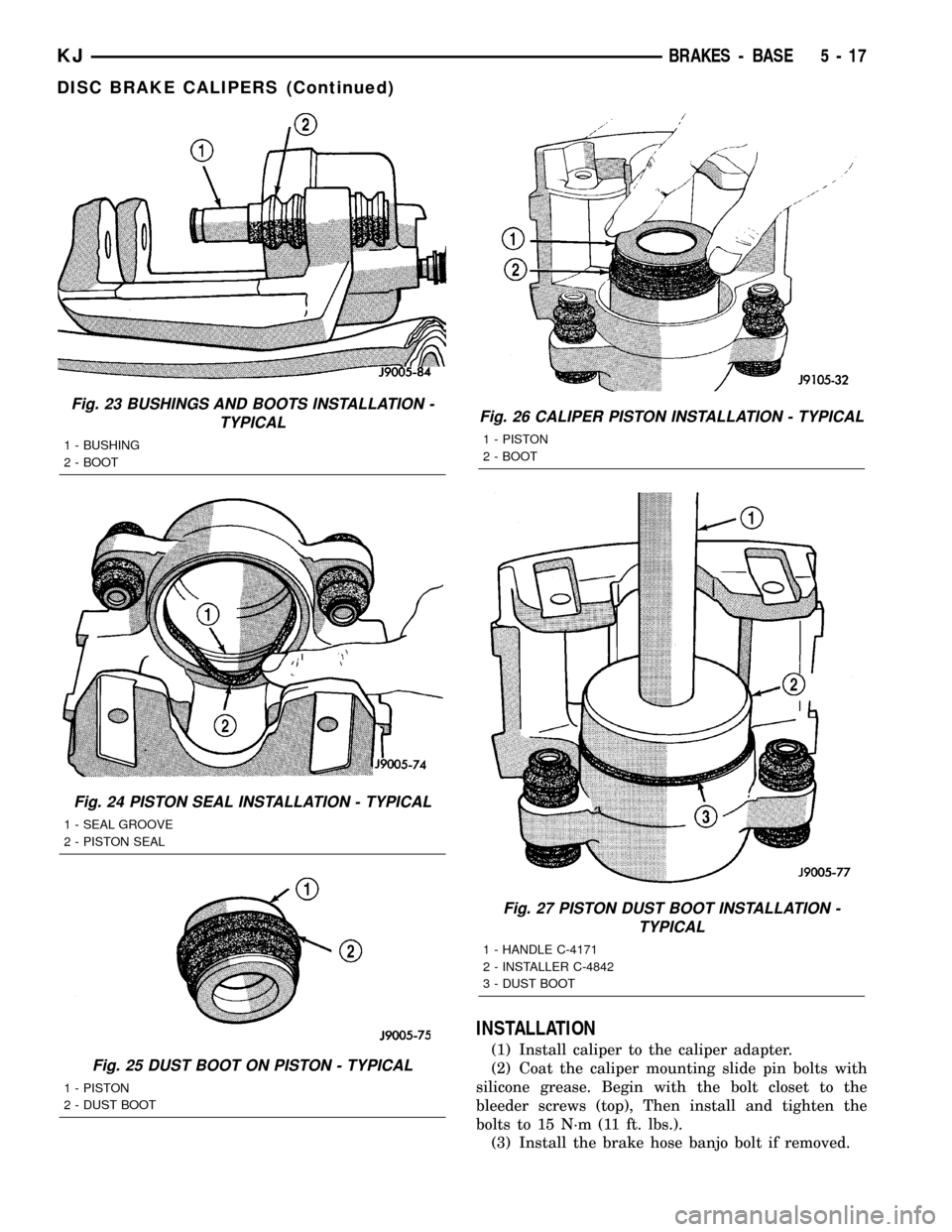

Fig. 23 BUSHINGS AND BOOTS INSTALLATION -

TYPICAL

1 - BUSHING

2 - BOOT

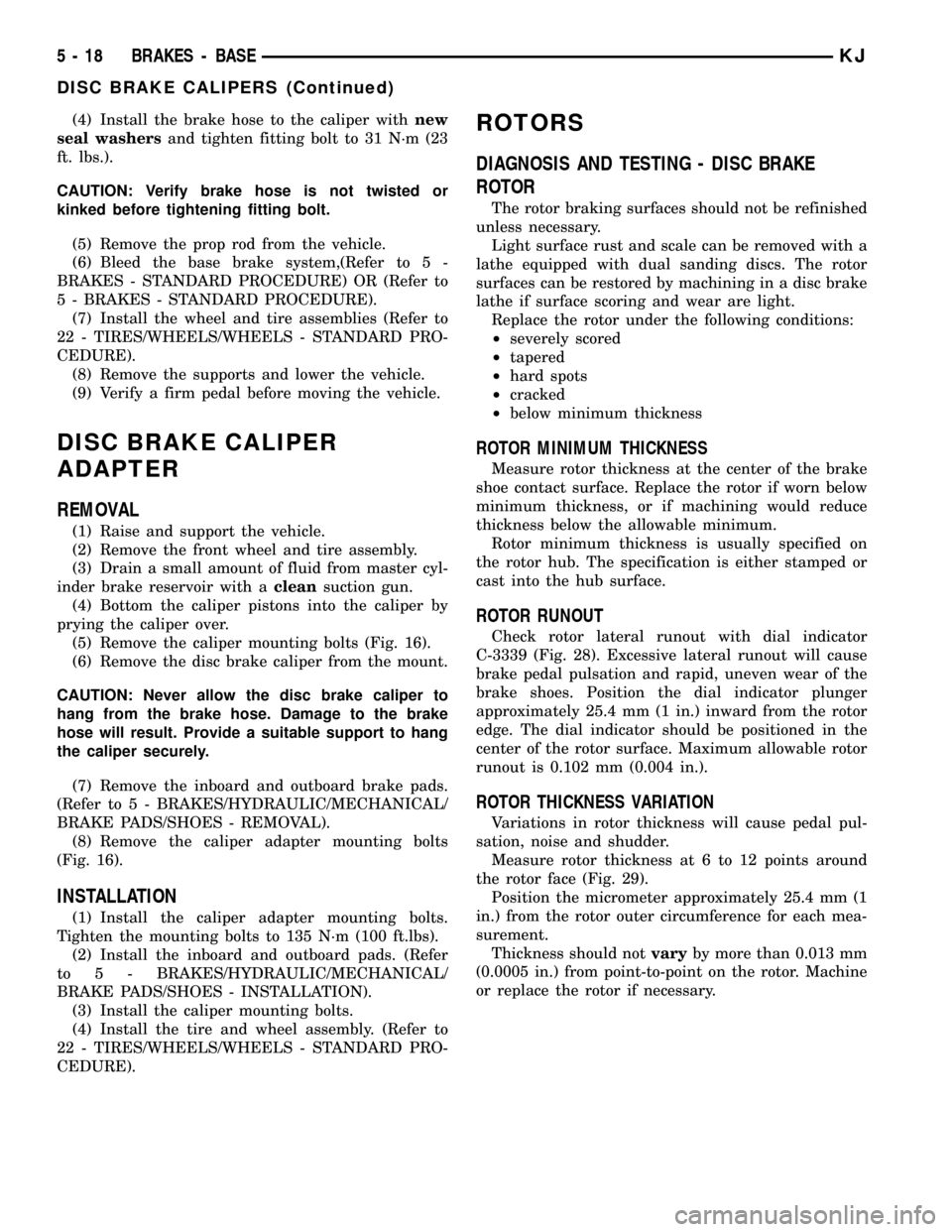

Fig. 24 PISTON SEAL INSTALLATION - TYPICAL

1 - SEAL GROOVE

2 - PISTON SEAL

Fig. 25 DUST BOOT ON PISTON - TYPICAL

1 - PISTON

2 - DUST BOOT

Fig. 26 CALIPER PISTON INSTALLATION - TYPICAL

1 - PISTON

2 - BOOT

Fig. 27 PISTON DUST BOOT INSTALLATION -

TYPICAL

1 - HANDLE C-4171

2 - INSTALLER C-4842

3 - DUST BOOT

KJBRAKES - BASE 5 - 17

DISC BRAKE CALIPERS (Continued)

Page 182 of 1803

(4) Install the brake hose to the caliper withnew

seal washersand tighten fitting bolt to 31 N´m (23

ft. lbs.).

CAUTION: Verify brake hose is not twisted or

kinked before tightening fitting bolt.

(5) Remove the prop rod from the vehicle.

(6) Bleed the base brake system,(Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(7) Install the wheel and tire assemblies (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(8) Remove the supports and lower the vehicle.

(9) Verify a firm pedal before moving the vehicle.

DISC BRAKE CALIPER

ADAPTER

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the front wheel and tire assembly.

(3) Drain a small amount of fluid from master cyl-

inder brake reservoir with acleansuction gun.

(4) Bottom the caliper pistons into the caliper by

prying the caliper over.

(5) Remove the caliper mounting bolts (Fig. 16).

(6) Remove the disc brake caliper from the mount.

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose will result. Provide a suitable support to hang

the caliper securely.

(7) Remove the inboard and outboard brake pads.

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

BRAKE PADS/SHOES - REMOVAL).

(8) Remove the caliper adapter mounting bolts

(Fig. 16).

INSTALLATION

(1) Install the caliper adapter mounting bolts.

Tighten the mounting bolts to 135 N´m (100 ft.lbs).

(2) Install the inboard and outboard pads. (Refer

to 5 - BRAKES/HYDRAULIC/MECHANICAL/

BRAKE PADS/SHOES - INSTALLATION).

(3) Install the caliper mounting bolts.

(4) Install the tire and wheel assembly. (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

ROTORS

DIAGNOSIS AND TESTING - DISC BRAKE

ROTOR

The rotor braking surfaces should not be refinished

unless necessary.

Light surface rust and scale can be removed with a

lathe equipped with dual sanding discs. The rotor

surfaces can be restored by machining in a disc brake

lathe if surface scoring and wear are light.

Replace the rotor under the following conditions:

²severely scored

²tapered

²hard spots

²cracked

²below minimum thickness

ROTOR MINIMUM THICKNESS

Measure rotor thickness at the center of the brake

shoe contact surface. Replace the rotor if worn below

minimum thickness, or if machining would reduce

thickness below the allowable minimum.

Rotor minimum thickness is usually specified on

the rotor hub. The specification is either stamped or

cast into the hub surface.

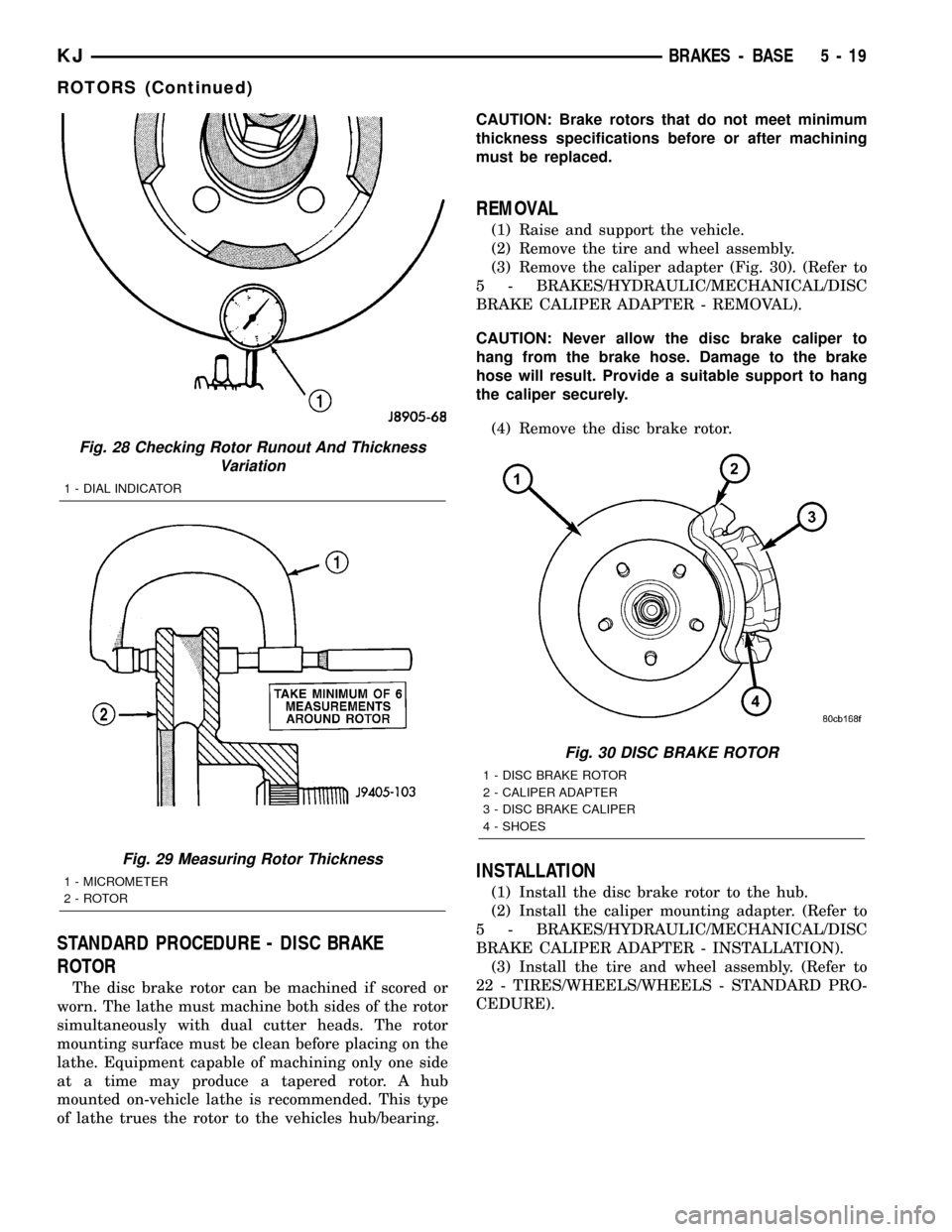

ROTOR RUNOUT

Check rotor lateral runout with dial indicator

C-3339 (Fig. 28). Excessive lateral runout will cause

brake pedal pulsation and rapid, uneven wear of the

brake shoes. Position the dial indicator plunger

approximately 25.4 mm (1 in.) inward from the rotor

edge. The dial indicator should be positioned in the

center of the rotor surface. Maximum allowable rotor

runout is 0.102 mm (0.004 in.).

ROTOR THICKNESS VARIATION

Variations in rotor thickness will cause pedal pul-

sation, noise and shudder.

Measure rotor thickness at 6 to 12 points around

the rotor face (Fig. 29).

Position the micrometer approximately 25.4 mm (1

in.) from the rotor outer circumference for each mea-

surement.

Thickness should notvaryby more than 0.013 mm

(0.0005 in.) from point-to-point on the rotor. Machine

or replace the rotor if necessary.

5 - 18 BRAKES - BASEKJ

DISC BRAKE CALIPERS (Continued)

Page 183 of 1803

STANDARD PROCEDURE - DISC BRAKE

ROTOR

The disc brake rotor can be machined if scored or

worn. The lathe must machine both sides of the rotor

simultaneously with dual cutter heads. The rotor

mounting surface must be clean before placing on the

lathe. Equipment capable of machining only one side

at a time may produce a tapered rotor. A hub

mounted on-vehicle lathe is recommended. This type

of lathe trues the rotor to the vehicles hub/bearing.CAUTION: Brake rotors that do not meet minimum

thickness specifications before or after machining

must be replaced.

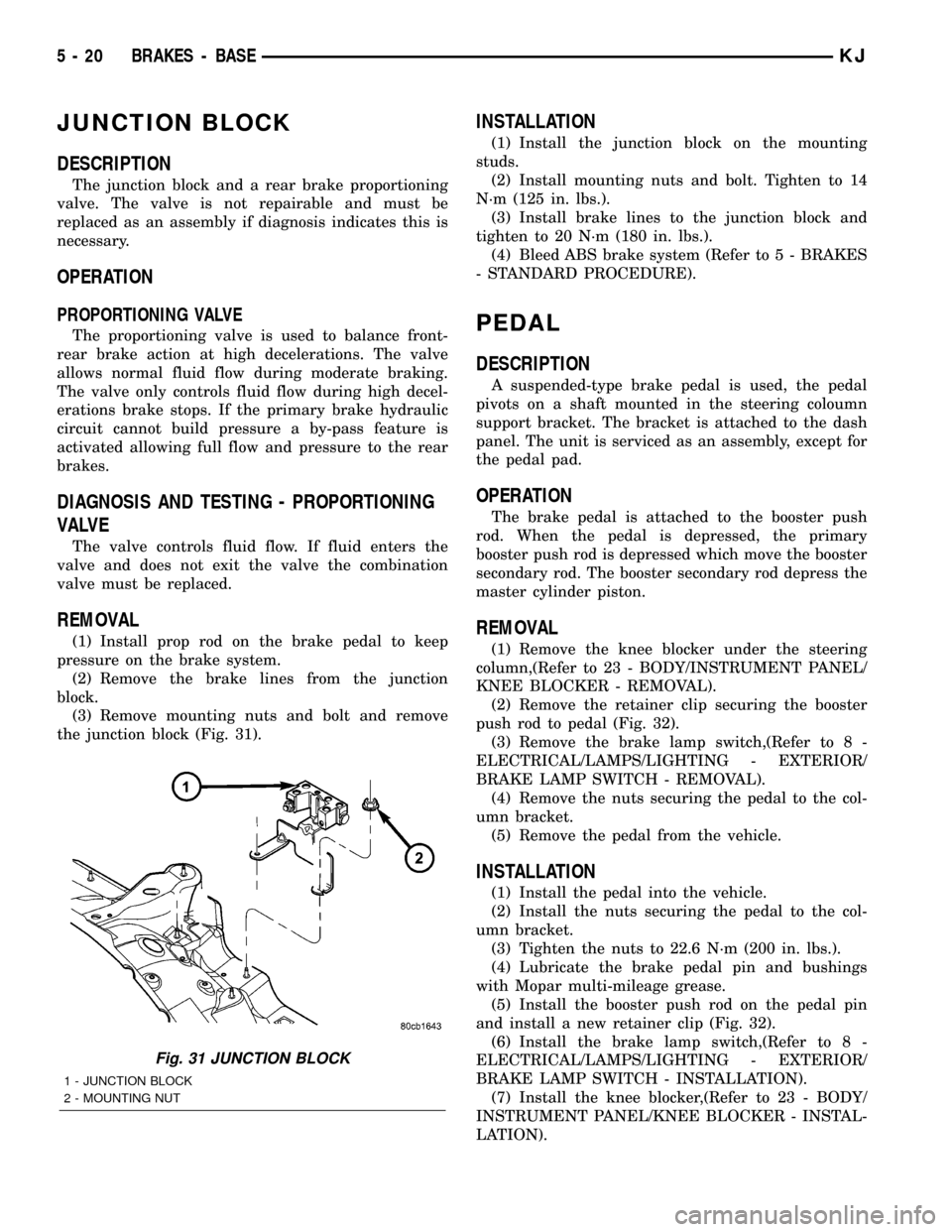

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Remove the caliper adapter (Fig. 30). (Refer to

5 - BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - REMOVAL).

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose will result. Provide a suitable support to hang

the caliper securely.

(4) Remove the disc brake rotor.

INSTALLATION

(1) Install the disc brake rotor to the hub.

(2) Install the caliper mounting adapter. (Refer to

5 - BRAKES/HYDRAULIC/MECHANICAL/DISC

BRAKE CALIPER ADAPTER - INSTALLATION).

(3) Install the tire and wheel assembly. (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

Fig. 28 Checking Rotor Runout And Thickness

Variation

1 - DIAL INDICATOR

Fig. 29 Measuring Rotor Thickness

1 - MICROMETER

2 - ROTOR

Fig. 30 DISC BRAKE ROTOR

1 - DISC BRAKE ROTOR

2 - CALIPER ADAPTER

3 - DISC BRAKE CALIPER

4 - SHOES

KJBRAKES - BASE 5 - 19

ROTORS (Continued)

Page 184 of 1803

JUNCTION BLOCK

DESCRIPTION

The junction block and a rear brake proportioning

valve. The valve is not repairable and must be

replaced as an assembly if diagnosis indicates this is

necessary.

OPERATION

PROPORTIONING VALVE

The proportioning valve is used to balance front-

rear brake action at high decelerations. The valve

allows normal fluid flow during moderate braking.

The valve only controls fluid flow during high decel-

erations brake stops. If the primary brake hydraulic

circuit cannot build pressure a by-pass feature is

activated allowing full flow and pressure to the rear

brakes.

DIAGNOSIS AND TESTING - PROPORTIONING

VALVE

The valve controls fluid flow. If fluid enters the

valve and does not exit the valve the combination

valve must be replaced.

REMOVAL

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Remove the brake lines from the junction

block.

(3) Remove mounting nuts and bolt and remove

the junction block (Fig. 31).

INSTALLATION

(1) Install the junction block on the mounting

studs.

(2) Install mounting nuts and bolt. Tighten to 14

N´m (125 in. lbs.).

(3) Install brake lines to the junction block and

tighten to 20 N´m (180 in. lbs.).

(4) Bleed ABS brake system (Refer to 5 - BRAKES

- STANDARD PROCEDURE).

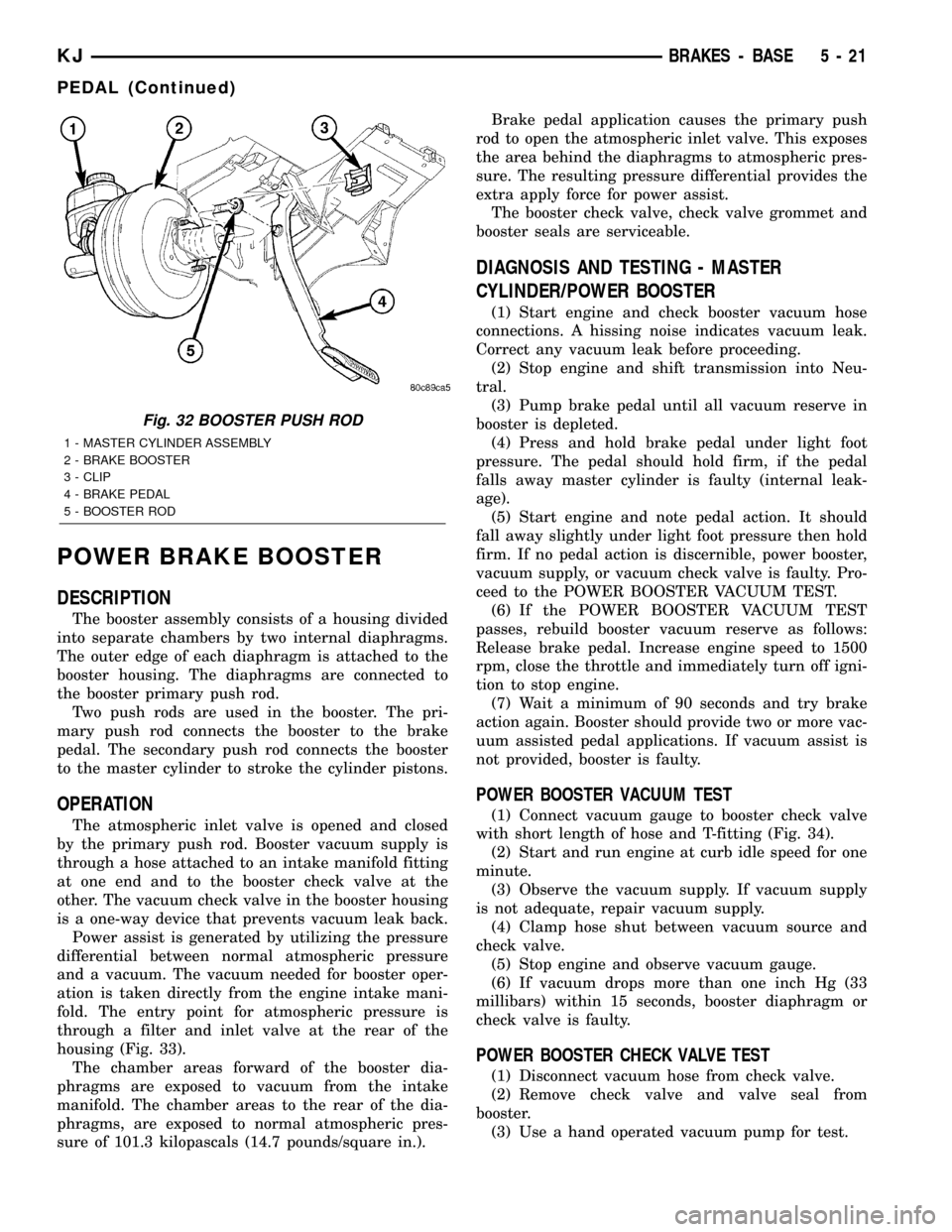

PEDAL

DESCRIPTION

A suspended-type brake pedal is used, the pedal

pivots on a shaft mounted in the steering coloumn

support bracket. The bracket is attached to the dash

panel. The unit is serviced as an assembly, except for

the pedal pad.

OPERATION

The brake pedal is attached to the booster push

rod. When the pedal is depressed, the primary

booster push rod is depressed which move the booster

secondary rod. The booster secondary rod depress the

master cylinder piston.

REMOVAL

(1) Remove the knee blocker under the steering

column,(Refer to 23 - BODY/INSTRUMENT PANEL/

KNEE BLOCKER - REMOVAL).

(2) Remove the retainer clip securing the booster

push rod to pedal (Fig. 32).

(3) Remove the brake lamp switch,(Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL).

(4) Remove the nuts securing the pedal to the col-

umn bracket.

(5) Remove the pedal from the vehicle.

INSTALLATION

(1) Install the pedal into the vehicle.

(2) Install the nuts securing the pedal to the col-

umn bracket.

(3) Tighten the nuts to 22.6 N´m (200 in. lbs.).

(4) Lubricate the brake pedal pin and bushings

with Mopar multi-mileage grease.

(5) Install the booster push rod on the pedal pin

and install a new retainer clip (Fig. 32).

(6) Install the brake lamp switch,(Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - INSTALLATION).

(7) Install the knee blocker,(Refer to 23 - BODY/

INSTRUMENT PANEL/KNEE BLOCKER - INSTAL-

LATION).

Fig. 31 JUNCTION BLOCK

1 - JUNCTION BLOCK

2 - MOUNTING NUT

5 - 20 BRAKES - BASEKJ

Page 185 of 1803

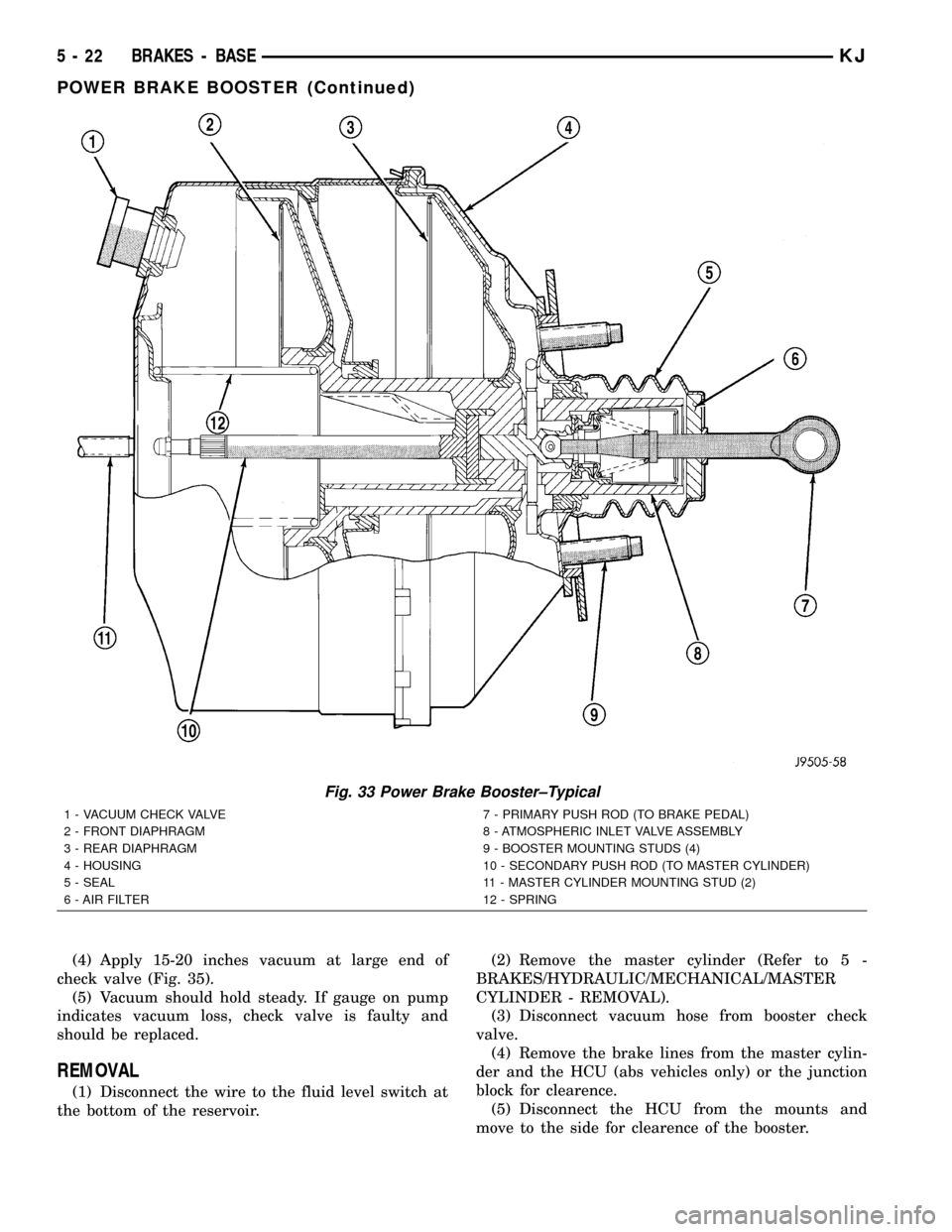

POWER BRAKE BOOSTER

DESCRIPTION

The booster assembly consists of a housing divided

into separate chambers by two internal diaphragms.

The outer edge of each diaphragm is attached to the

booster housing. The diaphragms are connected to

the booster primary push rod.

Two push rods are used in the booster. The pri-

mary push rod connects the booster to the brake

pedal. The secondary push rod connects the booster

to the master cylinder to stroke the cylinder pistons.

OPERATION

The atmospheric inlet valve is opened and closed

by the primary push rod. Booster vacuum supply is

through a hose attached to an intake manifold fitting

at one end and to the booster check valve at the

other. The vacuum check valve in the booster housing

is a one-way device that prevents vacuum leak back.

Power assist is generated by utilizing the pressure

differential between normal atmospheric pressure

and a vacuum. The vacuum needed for booster oper-

ation is taken directly from the engine intake mani-

fold. The entry point for atmospheric pressure is

through a filter and inlet valve at the rear of the

housing (Fig. 33).

The chamber areas forward of the booster dia-

phragms are exposed to vacuum from the intake

manifold. The chamber areas to the rear of the dia-

phragms, are exposed to normal atmospheric pres-

sure of 101.3 kilopascals (14.7 pounds/square in.).Brake pedal application causes the primary push

rod to open the atmospheric inlet valve. This exposes

the area behind the diaphragms to atmospheric pres-

sure. The resulting pressure differential provides the

extra apply force for power assist.

The booster check valve, check valve grommet and

booster seals are serviceable.

DIAGNOSIS AND TESTING - MASTER

CYLINDER/POWER BOOSTER

(1) Start engine and check booster vacuum hose

connections. A hissing noise indicates vacuum leak.

Correct any vacuum leak before proceeding.

(2) Stop engine and shift transmission into Neu-

tral.

(3) Pump brake pedal until all vacuum reserve in

booster is depleted.

(4) Press and hold brake pedal under light foot

pressure. The pedal should hold firm, if the pedal

falls away master cylinder is faulty (internal leak-

age).

(5) Start engine and note pedal action. It should

fall away slightly under light foot pressure then hold

firm. If no pedal action is discernible, power booster,

vacuum supply, or vacuum check valve is faulty. Pro-

ceed to the POWER BOOSTER VACUUM TEST.

(6) If the POWER BOOSTER VACUUM TEST

passes, rebuild booster vacuum reserve as follows:

Release brake pedal. Increase engine speed to 1500

rpm, close the throttle and immediately turn off igni-

tion to stop engine.

(7) Wait a minimum of 90 seconds and try brake

action again. Booster should provide two or more vac-

uum assisted pedal applications. If vacuum assist is

not provided, booster is faulty.

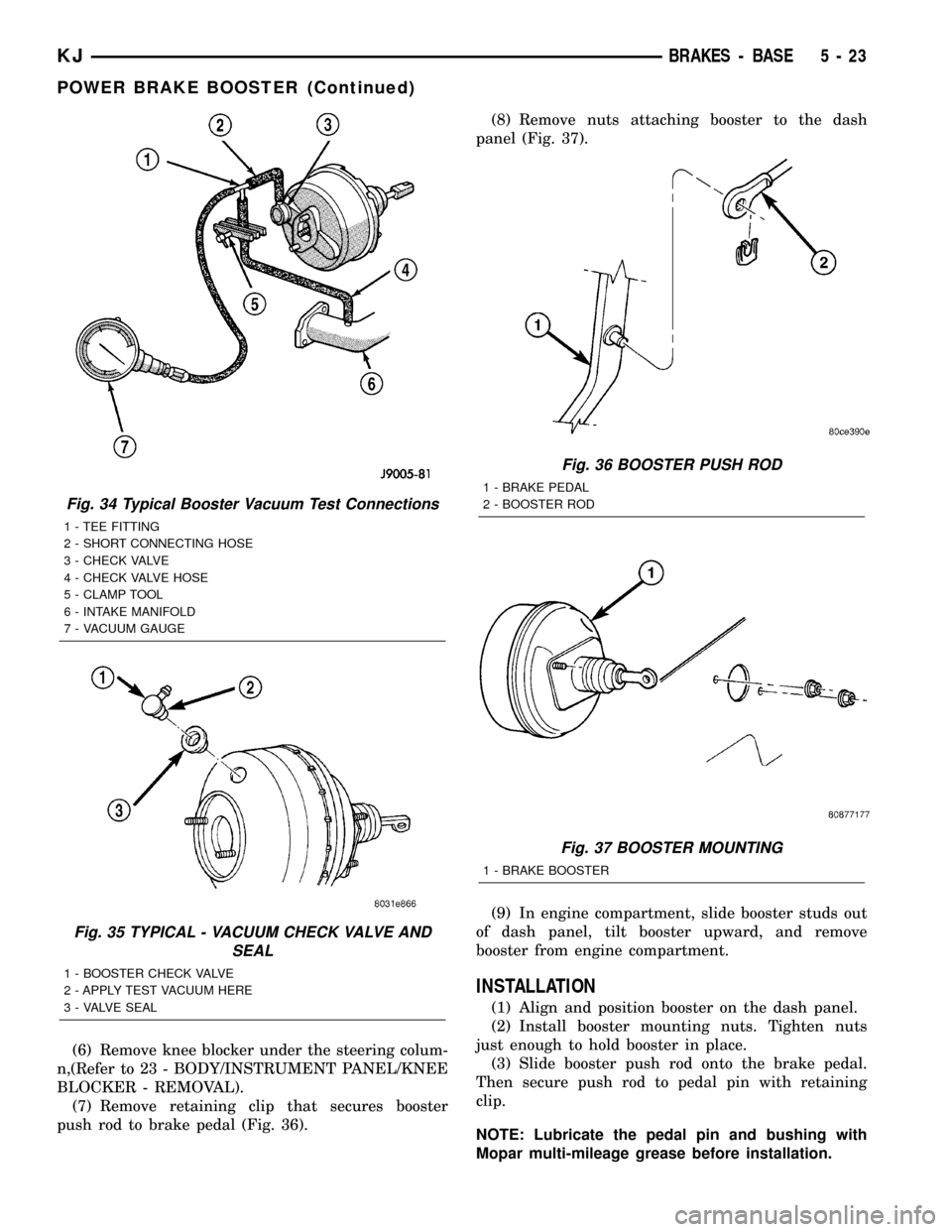

POWER BOOSTER VACUUM TEST

(1) Connect vacuum gauge to booster check valve

with short length of hose and T-fitting (Fig. 34).

(2) Start and run engine at curb idle speed for one

minute.

(3) Observe the vacuum supply. If vacuum supply

is not adequate, repair vacuum supply.

(4) Clamp hose shut between vacuum source and

check valve.

(5) Stop engine and observe vacuum gauge.

(6) If vacuum drops more than one inch Hg (33

millibars) within 15 seconds, booster diaphragm or

check valve is faulty.

POWER BOOSTER CHECK VALVE TEST

(1) Disconnect vacuum hose from check valve.

(2) Remove check valve and valve seal from

booster.

(3) Use a hand operated vacuum pump for test.

Fig. 32 BOOSTER PUSH ROD

1 - MASTER CYLINDER ASSEMBLY

2 - BRAKE BOOSTER

3 - CLIP

4 - BRAKE PEDAL

5 - BOOSTER ROD

KJBRAKES - BASE 5 - 21

PEDAL (Continued)

Page 186 of 1803

(4) Apply 15-20 inches vacuum at large end of

check valve (Fig. 35).

(5) Vacuum should hold steady. If gauge on pump

indicates vacuum loss, check valve is faulty and

should be replaced.

REMOVAL

(1) Disconnect the wire to the fluid level switch at

the bottom of the reservoir.(2) Remove the master cylinder (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/MASTER

CYLINDER - REMOVAL).

(3) Disconnect vacuum hose from booster check

valve.

(4) Remove the brake lines from the master cylin-

der and the HCU (abs vehicles only) or the junction

block for clearence.

(5) Disconnect the HCU from the mounts and

move to the side for clearence of the booster.

Fig. 33 Power Brake Booster±Typical

1 - VACUUM CHECK VALVE

2 - FRONT DIAPHRAGM

3 - REAR DIAPHRAGM

4 - HOUSING

5 - SEAL

6 - AIR FILTER7 - PRIMARY PUSH ROD (TO BRAKE PEDAL)

8 - ATMOSPHERIC INLET VALVE ASSEMBLY

9 - BOOSTER MOUNTING STUDS (4)

10 - SECONDARY PUSH ROD (TO MASTER CYLINDER)

11 - MASTER CYLINDER MOUNTING STUD (2)

12 - SPRING

5 - 22 BRAKES - BASEKJ

POWER BRAKE BOOSTER (Continued)

Page 187 of 1803

(6) Remove knee blocker under the steering colum-

n,(Refer to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(7) Remove retaining clip that secures booster

push rod to brake pedal (Fig. 36).(8) Remove nuts attaching booster to the dash

panel (Fig. 37).

(9) In engine compartment, slide booster studs out

of dash panel, tilt booster upward, and remove

booster from engine compartment.

INSTALLATION

(1) Align and position booster on the dash panel.

(2) Install booster mounting nuts. Tighten nuts

just enough to hold booster in place.

(3) Slide booster push rod onto the brake pedal.

Then secure push rod to pedal pin with retaining

clip.

NOTE: Lubricate the pedal pin and bushing with

Mopar multi-mileage grease before installation.

Fig. 34 Typical Booster Vacuum Test Connections

1 - TEE FITTING

2 - SHORT CONNECTING HOSE

3 - CHECK VALVE

4 - CHECK VALVE HOSE

5 - CLAMP TOOL

6 - INTAKE MANIFOLD

7 - VACUUM GAUGE

Fig. 35 TYPICAL - VACUUM CHECK VALVE AND

SEAL

1 - BOOSTER CHECK VALVE

2 - APPLY TEST VACUUM HERE

3 - VALVE SEAL

Fig. 36 BOOSTER PUSH ROD

1 - BRAKE PEDAL

2 - BOOSTER ROD

Fig. 37 BOOSTER MOUNTING

1 - BRAKE BOOSTER

KJBRAKES - BASE 5 - 23

POWER BRAKE BOOSTER (Continued)

Page 188 of 1803

(4) Tighten booster mounting nuts to 22.6 N´m

(200 ft. lbs.).

(5) Install the knee blocker,(Refer to 23 - BODY/

INSTRUMENT PANEL/KNEE BLOCKER - INSTAL-

LATION).

(6) If original master cylinder is being installed,

check condition of seal at rear of master cylinder.

Replace seal if cut, or torn.

(7) Clean cylinder mounting surface of brake

booster. Use shop towel wetted with brake cleaner for

this purpose. Dirt, grease, or similar materials will

prevent proper cylinder seating and could result in

vacuum leak.

(8) Align and install master cylinder on the

booster studs. Install mounting nuts and tighten to

22.6 N´m (200 in. lbs.).

(9) Connect vacuum hose to booster check valve.

(10) Remount the HCU. Tighten bracket mounting

nuts to 22.6 N´m (200 in. lbs.).

(11) Connect and secure the brake lines to HCU or

junction block and master cylinder. Start all brake

line fittings by hand to avoid cross threading.

(12) Connect the wire to fluid level switch at the

bottom of the reservoir.

(13) Fill and bleed base brake system,(Refer to 5 -

BRAKES - STANDARD PROCEDURE).

(14) Verify proper brake operation before moving

vehicle.

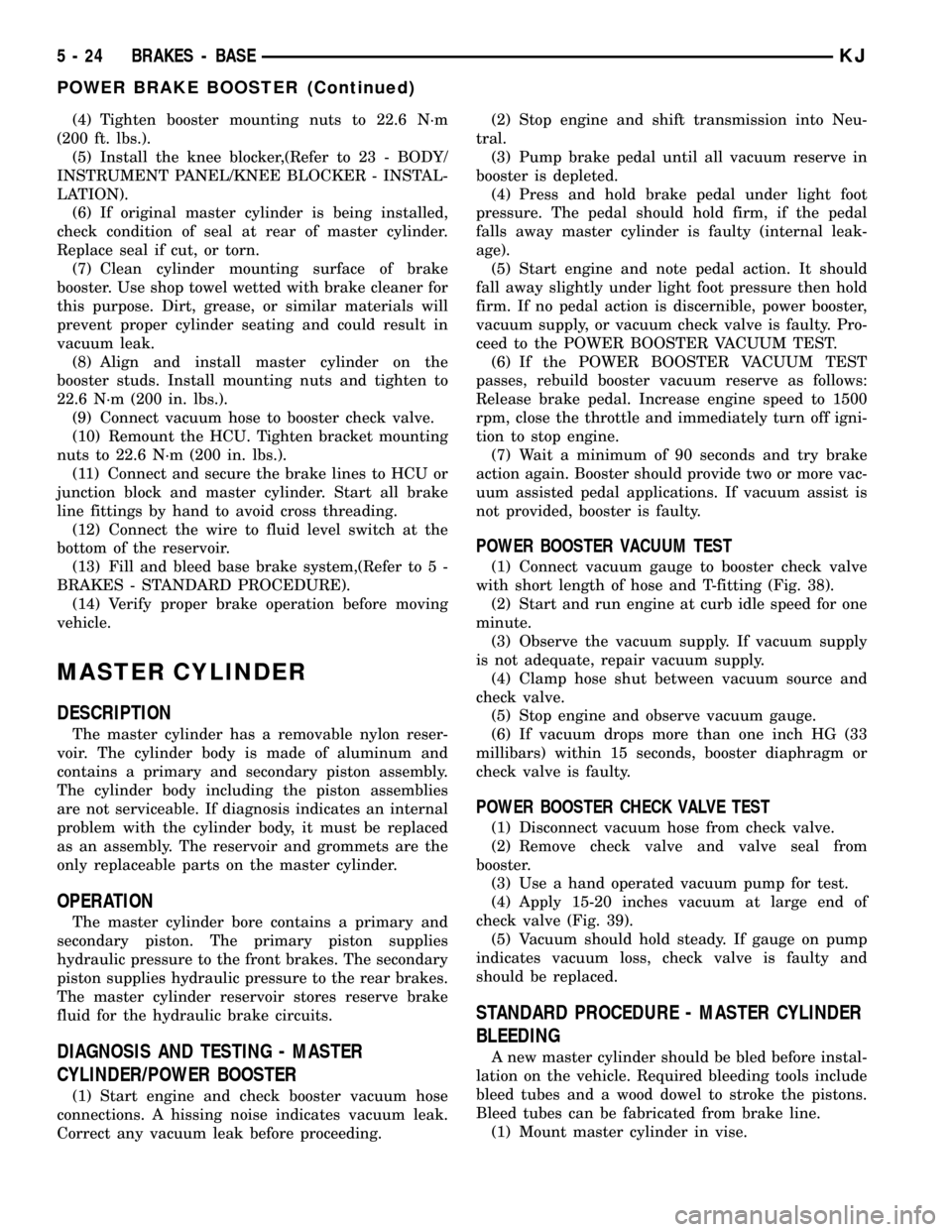

MASTER CYLINDER

DESCRIPTION

The master cylinder has a removable nylon reser-

voir. The cylinder body is made of aluminum and

contains a primary and secondary piston assembly.

The cylinder body including the piston assemblies

are not serviceable. If diagnosis indicates an internal

problem with the cylinder body, it must be replaced

as an assembly. The reservoir and grommets are the

only replaceable parts on the master cylinder.

OPERATION

The master cylinder bore contains a primary and

secondary piston. The primary piston supplies

hydraulic pressure to the front brakes. The secondary

piston supplies hydraulic pressure to the rear brakes.

The master cylinder reservoir stores reserve brake

fluid for the hydraulic brake circuits.

DIAGNOSIS AND TESTING - MASTER

CYLINDER/POWER BOOSTER

(1) Start engine and check booster vacuum hose

connections. A hissing noise indicates vacuum leak.

Correct any vacuum leak before proceeding.(2) Stop engine and shift transmission into Neu-

tral.

(3) Pump brake pedal until all vacuum reserve in

booster is depleted.

(4) Press and hold brake pedal under light foot

pressure. The pedal should hold firm, if the pedal

falls away master cylinder is faulty (internal leak-

age).

(5) Start engine and note pedal action. It should

fall away slightly under light foot pressure then hold

firm. If no pedal action is discernible, power booster,

vacuum supply, or vacuum check valve is faulty. Pro-

ceed to the POWER BOOSTER VACUUM TEST.

(6) If the POWER BOOSTER VACUUM TEST

passes, rebuild booster vacuum reserve as follows:

Release brake pedal. Increase engine speed to 1500

rpm, close the throttle and immediately turn off igni-

tion to stop engine.

(7) Wait a minimum of 90 seconds and try brake

action again. Booster should provide two or more vac-

uum assisted pedal applications. If vacuum assist is

not provided, booster is faulty.

POWER BOOSTER VACUUM TEST

(1) Connect vacuum gauge to booster check valve

with short length of hose and T-fitting (Fig. 38).

(2) Start and run engine at curb idle speed for one

minute.

(3) Observe the vacuum supply. If vacuum supply

is not adequate, repair vacuum supply.

(4) Clamp hose shut between vacuum source and

check valve.

(5) Stop engine and observe vacuum gauge.

(6) If vacuum drops more than one inch HG (33

millibars) within 15 seconds, booster diaphragm or

check valve is faulty.

POWER BOOSTER CHECK VALVE TEST

(1) Disconnect vacuum hose from check valve.

(2) Remove check valve and valve seal from

booster.

(3) Use a hand operated vacuum pump for test.

(4) Apply 15-20 inches vacuum at large end of

check valve (Fig. 39).

(5) Vacuum should hold steady. If gauge on pump

indicates vacuum loss, check valve is faulty and

should be replaced.

STANDARD PROCEDURE - MASTER CYLINDER

BLEEDING

A new master cylinder should be bled before instal-

lation on the vehicle. Required bleeding tools include

bleed tubes and a wood dowel to stroke the pistons.

Bleed tubes can be fabricated from brake line.

(1) Mount master cylinder in vise.

5 - 24 BRAKES - BASEKJ

POWER BRAKE BOOSTER (Continued)

Page 189 of 1803

(2) Attach bleed tubes to cylinder outlet ports.

Then position each tube end into reservoir (Fig. 40).

(3) Fill reservoir with fresh brake fluid.

(4) Press cylinder pistons inward with wood dowel.

Then release pistons and allow them to return underspring pressure. Continue bleeding operations until

air bubbles are no longer visible in fluid.

REMOVAL

(1) Siphon and drain the fluid from the reservoir.

(2) Remove the brake lines at the master cylinder.

(3) Disconnect the fluid level electrical connector

from the reservoir.

(4) Remove mounting nuts from the master cylin-

der.

(5) Remove master cylinder.

(6) Remove cylinder cover and drain the rest of the

fluid.

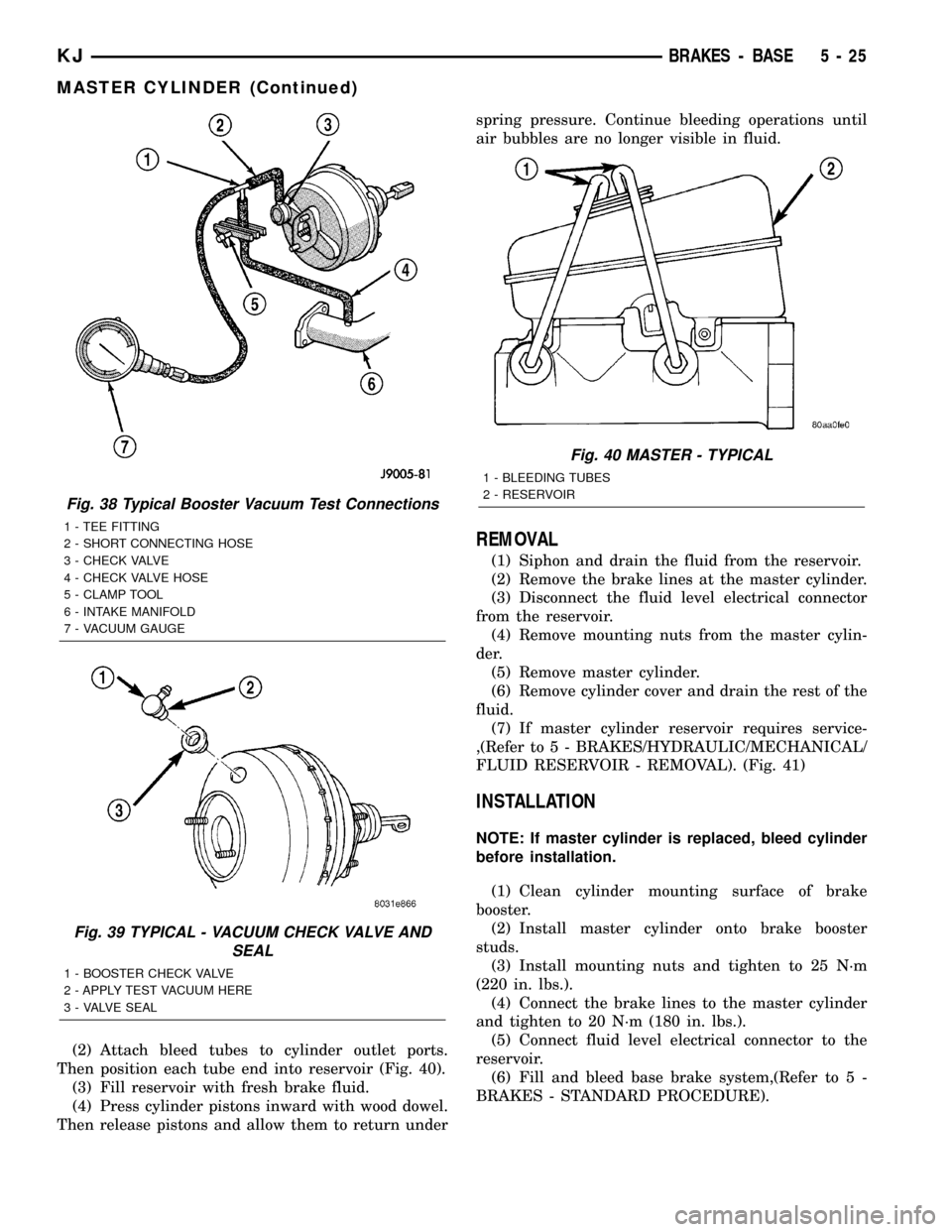

(7) If master cylinder reservoir requires service-

,(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

FLUID RESERVOIR - REMOVAL). (Fig. 41)

INSTALLATION

NOTE: If master cylinder is replaced, bleed cylinder

before installation.

(1) Clean cylinder mounting surface of brake

booster.

(2) Install master cylinder onto brake booster

studs.

(3) Install mounting nuts and tighten to 25 N´m

(220 in. lbs.).

(4) Connect the brake lines to the master cylinder

and tighten to 20 N´m (180 in. lbs.).

(5) Connect fluid level electrical connector to the

reservoir.

(6) Fill and bleed base brake system,(Refer to 5 -

BRAKES - STANDARD PROCEDURE).

Fig. 38 Typical Booster Vacuum Test Connections

1 - TEE FITTING

2 - SHORT CONNECTING HOSE

3 - CHECK VALVE

4 - CHECK VALVE HOSE

5 - CLAMP TOOL

6 - INTAKE MANIFOLD

7 - VACUUM GAUGE

Fig. 39 TYPICAL - VACUUM CHECK VALVE AND

SEAL

1 - BOOSTER CHECK VALVE

2 - APPLY TEST VACUUM HERE

3 - VALVE SEAL

Fig. 40 MASTER - TYPICAL

1 - BLEEDING TUBES

2 - RESERVOIR

KJBRAKES - BASE 5 - 25

MASTER CYLINDER (Continued)

Page 190 of 1803

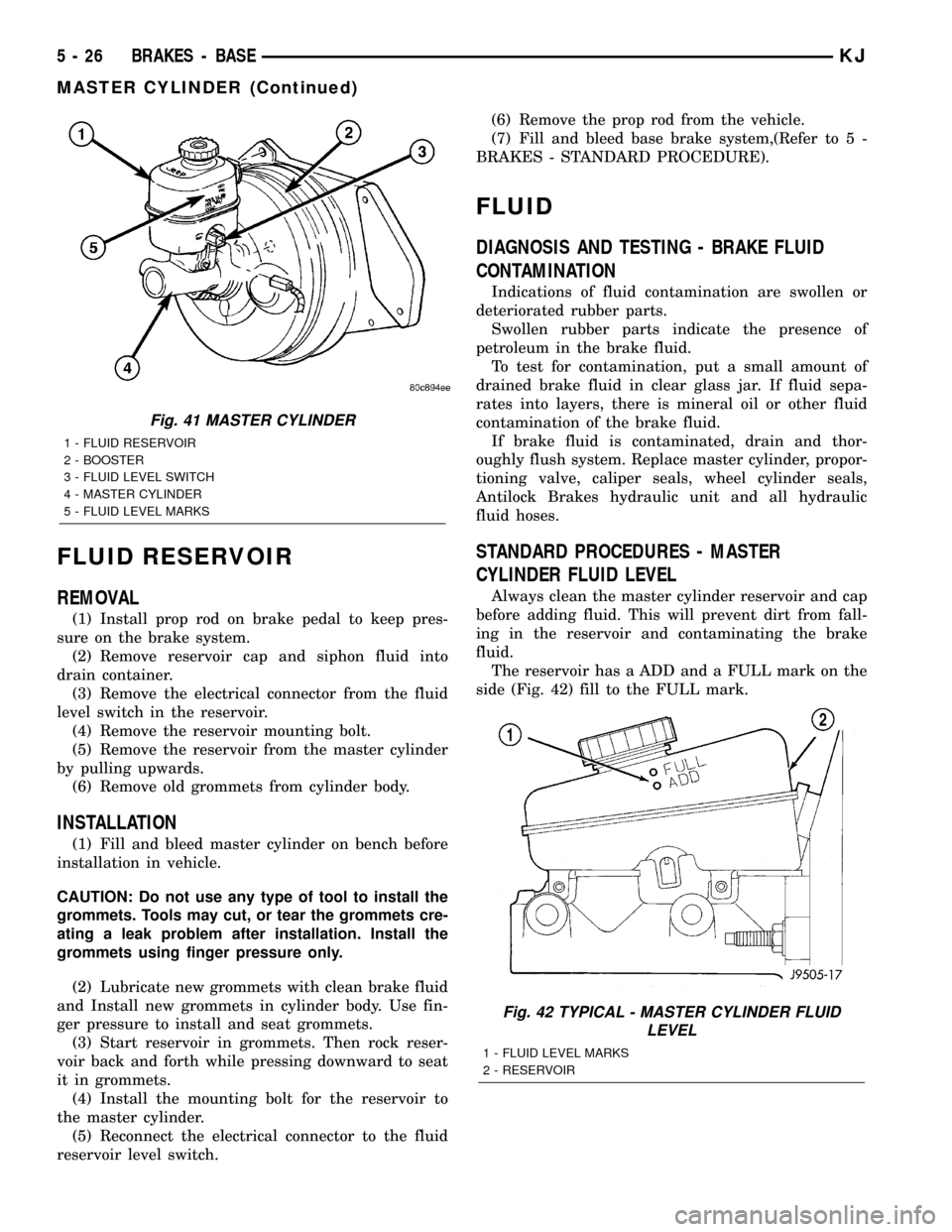

FLUID RESERVOIR

REMOVAL

(1) Install prop rod on brake pedal to keep pres-

sure on the brake system.

(2) Remove reservoir cap and siphon fluid into

drain container.

(3) Remove the electrical connector from the fluid

level switch in the reservoir.

(4) Remove the reservoir mounting bolt.

(5) Remove the reservoir from the master cylinder

by pulling upwards.

(6) Remove old grommets from cylinder body.

INSTALLATION

(1) Fill and bleed master cylinder on bench before

installation in vehicle.

CAUTION: Do not use any type of tool to install the

grommets. Tools may cut, or tear the grommets cre-

ating a leak problem after installation. Install the

grommets using finger pressure only.

(2) Lubricate new grommets with clean brake fluid

and Install new grommets in cylinder body. Use fin-

ger pressure to install and seat grommets.

(3) Start reservoir in grommets. Then rock reser-

voir back and forth while pressing downward to seat

it in grommets.

(4) Install the mounting bolt for the reservoir to

the master cylinder.

(5) Reconnect the electrical connector to the fluid

reservoir level switch.(6) Remove the prop rod from the vehicle.

(7) Fill and bleed base brake system,(Refer to 5 -

BRAKES - STANDARD PROCEDURE).

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts.

Swollen rubber parts indicate the presence of

petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder, propor-

tioning valve, caliper seals, wheel cylinder seals,

Antilock Brakes hydraulic unit and all hydraulic

fluid hoses.

STANDARD PROCEDURES - MASTER

CYLINDER FLUID LEVEL

Always clean the master cylinder reservoir and cap

before adding fluid. This will prevent dirt from fall-

ing in the reservoir and contaminating the brake

fluid.

The reservoir has a ADD and a FULL mark on the

side (Fig. 42) fill to the FULL mark.

Fig. 41 MASTER CYLINDER

1 - FLUID RESERVOIR

2 - BOOSTER

3 - FLUID LEVEL SWITCH

4 - MASTER CYLINDER

5 - FLUID LEVEL MARKS

Fig. 42 TYPICAL - MASTER CYLINDER FLUID

LEVEL

1 - FLUID LEVEL MARKS

2 - RESERVOIR

5 - 26 BRAKES - BASEKJ

MASTER CYLINDER (Continued)