JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 171 of 1803

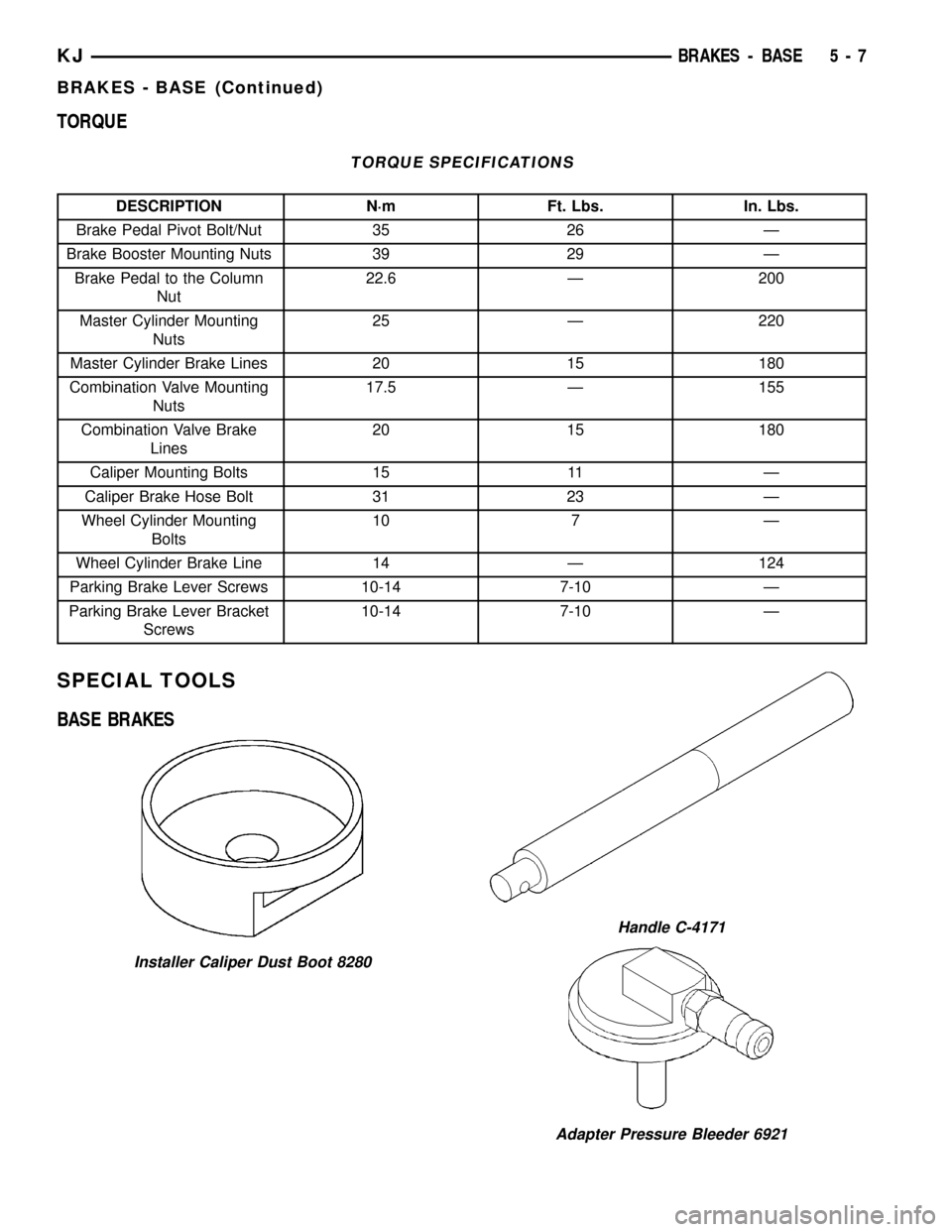

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Brake Pedal Pivot Bolt/Nut 35 26 Ð

Brake Booster Mounting Nuts 39 29 Ð

Brake Pedal to the Column

Nut22.6 Ð 200

Master Cylinder Mounting

Nuts25 Ð 220

Master Cylinder Brake Lines 20 15 180

Combination Valve Mounting

Nuts17.5 Ð 155

Combination Valve Brake

Lines20 15 180

Caliper Mounting Bolts 15 11 Ð

Caliper Brake Hose Bolt 31 23 Ð

Wheel Cylinder Mounting

Bolts10 7 Ð

Wheel Cylinder Brake Line 14 Ð 124

Parking Brake Lever Screws 10-14 7-10 Ð

Parking Brake Lever Bracket

Screws10-14 7-10 Ð

SPECIAL TOOLS

BASE BRAKES

Installer Caliper Dust Boot 8280

Handle C-4171

Adapter Pressure Bleeder 6921

KJBRAKES - BASE 5 - 7

BRAKES - BASE (Continued)

Page 172 of 1803

BRAKE LINES

DESCRIPTION

Flexible rubber hose is used at both front brakes

and at the rear axle junction block. Double walled

steel tubing is used to connect the master cylinder to

the major hydraulic braking components and then to

the flexible rubber hoses. Double inverted style and

ISO style flares are used on the brake lines.

DIAGNOSIS AND TESTING - BRAKE LINE AND

HOSES

Flexible rubber hose is used at both front brakes

and at the rear axle junction block. Inspect the hoses

whenever the brake system is serviced, at every

engine oil change, or whenever the vehicle is in for

service.

Inspect the hoses for surface cracking, scuffing, or

worn spots. Replace any brake hose immediately if

the fabric casing of the hose is exposed due to cracks

or abrasions.

Also check brake hose installation. Faulty installa-

tion can result in kinked, twisted hoses, or contact

with the wheels and tires or other chassis compo-

nents. All of these conditions can lead to scuffing,

cracking and eventual failure.

The steel brake lines should be inspected periodi-

cally for evidence of corrosion, twists, kinks, leaks, or

other damage. Heavily corroded lines will eventually

rust through causing leaks. In any case, corroded or

damaged brake lines should be replaced.

Factory replacement brake lines and hoses are rec-

ommended to ensure quality, correct length and supe-

rior fatigue life. Care should be taken to make sure

that brake line and hose mating surfaces are clean

and free from nicks and burrs. Also remember that

right and left brake hoses are not interchangeable.

Use new copper seal washers at all caliper connec-

tions. Be sure brake line connections are properly

made (not cross threaded) and tightened to recom-

mended torque.

STANDARD PROCEDURE

STANDARD PROCEDURE - DOUBLE INVERTED

FLARING

A preformed metal brake tube is recommended and

preferred for all repairs. However, double-wall steel

tube can be used for emergency repair when factory

replacement parts are not readily available.

Special bending tools are needed to avoid kinking

or twisting of metal brake tubes. Special flaring tools

are needed to make a double inverted flare or ISO

flare.(1) Cut off damaged tube with Tubing Cutter.

(2) Ream cut edges of tubing to ensure proper

flare.

(3) Install replacement tube nut on the tube.

(4) Insert tube in flaring tool.

(5) Place gauge form over the end of the tube.

(6) Push tubing through flaring tool jaws until

tube contacts recessed notch in gauge that matches

tube diameter.

(7) Tighten the tool bar on the tube

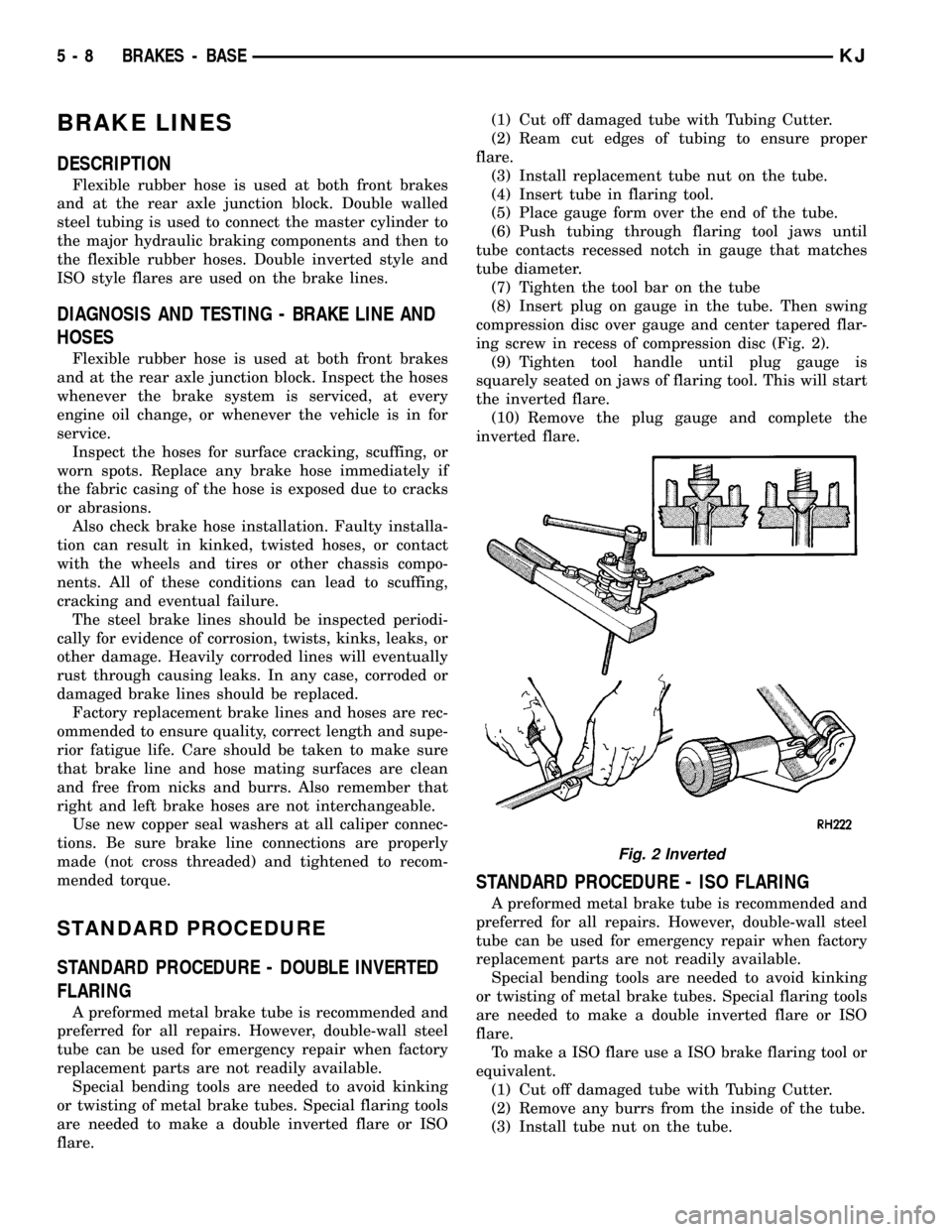

(8) Insert plug on gauge in the tube. Then swing

compression disc over gauge and center tapered flar-

ing screw in recess of compression disc (Fig. 2).

(9) Tighten tool handle until plug gauge is

squarely seated on jaws of flaring tool. This will start

the inverted flare.

(10) Remove the plug gauge and complete the

inverted flare.

STANDARD PROCEDURE - ISO FLARING

A preformed metal brake tube is recommended and

preferred for all repairs. However, double-wall steel

tube can be used for emergency repair when factory

replacement parts are not readily available.

Special bending tools are needed to avoid kinking

or twisting of metal brake tubes. Special flaring tools

are needed to make a double inverted flare or ISO

flare.

To make a ISO flare use a ISO brake flaring tool or

equivalent.

(1) Cut off damaged tube with Tubing Cutter.

(2) Remove any burrs from the inside of the tube.

(3) Install tube nut on the tube.

Fig. 2 Inverted

5 - 8 BRAKES - BASEKJ

Page 173 of 1803

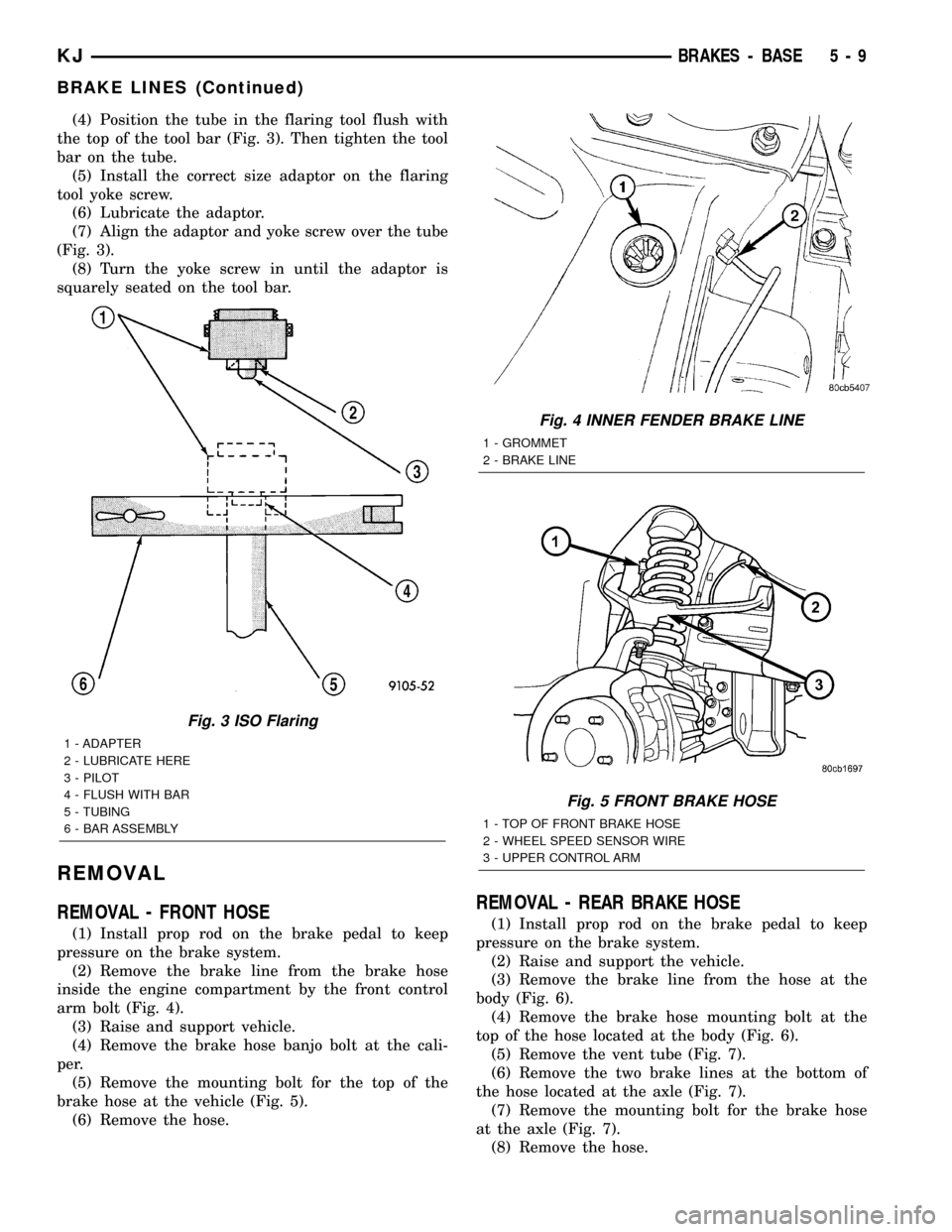

(4) Position the tube in the flaring tool flush with

the top of the tool bar (Fig. 3). Then tighten the tool

bar on the tube.

(5) Install the correct size adaptor on the flaring

tool yoke screw.

(6) Lubricate the adaptor.

(7) Align the adaptor and yoke screw over the tube

(Fig. 3).

(8) Turn the yoke screw in until the adaptor is

squarely seated on the tool bar.

REMOVAL

REMOVAL - FRONT HOSE

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

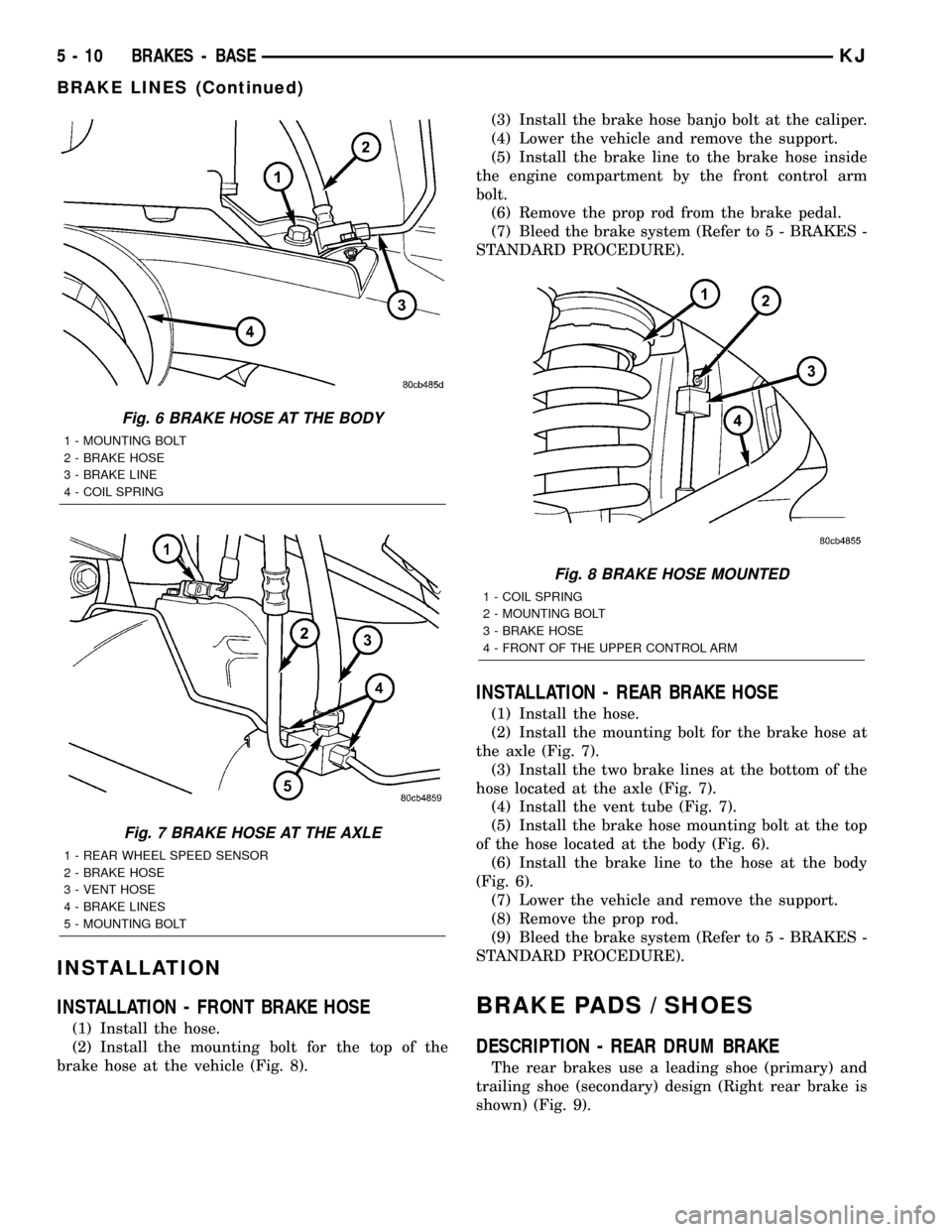

(2) Remove the brake line from the brake hose

inside the engine compartment by the front control

arm bolt (Fig. 4).

(3) Raise and support vehicle.

(4) Remove the brake hose banjo bolt at the cali-

per.

(5) Remove the mounting bolt for the top of the

brake hose at the vehicle (Fig. 5).

(6) Remove the hose.

REMOVAL - REAR BRAKE HOSE

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support the vehicle.

(3) Remove the brake line from the hose at the

body (Fig. 6).

(4) Remove the brake hose mounting bolt at the

top of the hose located at the body (Fig. 6).

(5) Remove the vent tube (Fig. 7).

(6) Remove the two brake lines at the bottom of

the hose located at the axle (Fig. 7).

(7) Remove the mounting bolt for the brake hose

at the axle (Fig. 7).

(8) Remove the hose.

Fig. 3 ISO Flaring

1 - ADAPTER

2 - LUBRICATE HERE

3 - PILOT

4 - FLUSH WITH BAR

5 - TUBING

6 - BAR ASSEMBLY

Fig. 4 INNER FENDER BRAKE LINE

1 - GROMMET

2 - BRAKE LINE

Fig. 5 FRONT BRAKE HOSE

1 - TOP OF FRONT BRAKE HOSE

2 - WHEEL SPEED SENSOR WIRE

3 - UPPER CONTROL ARM

KJBRAKES - BASE 5 - 9

BRAKE LINES (Continued)

Page 174 of 1803

INSTALLATION

INSTALLATION - FRONT BRAKE HOSE

(1) Install the hose.

(2) Install the mounting bolt for the top of the

brake hose at the vehicle (Fig. 8).(3) Install the brake hose banjo bolt at the caliper.

(4) Lower the vehicle and remove the support.

(5) Install the brake line to the brake hose inside

the engine compartment by the front control arm

bolt.

(6) Remove the prop rod from the brake pedal.

(7) Bleed the brake system (Refer to 5 - BRAKES -

STANDARD PROCEDURE).

INSTALLATION - REAR BRAKE HOSE

(1) Install the hose.

(2) Install the mounting bolt for the brake hose at

the axle (Fig. 7).

(3) Install the two brake lines at the bottom of the

hose located at the axle (Fig. 7).

(4) Install the vent tube (Fig. 7).

(5) Install the brake hose mounting bolt at the top

of the hose located at the body (Fig. 6).

(6) Install the brake line to the hose at the body

(Fig. 6).

(7) Lower the vehicle and remove the support.

(8) Remove the prop rod.

(9) Bleed the brake system (Refer to 5 - BRAKES -

STANDARD PROCEDURE).

BRAKE PADS / SHOES

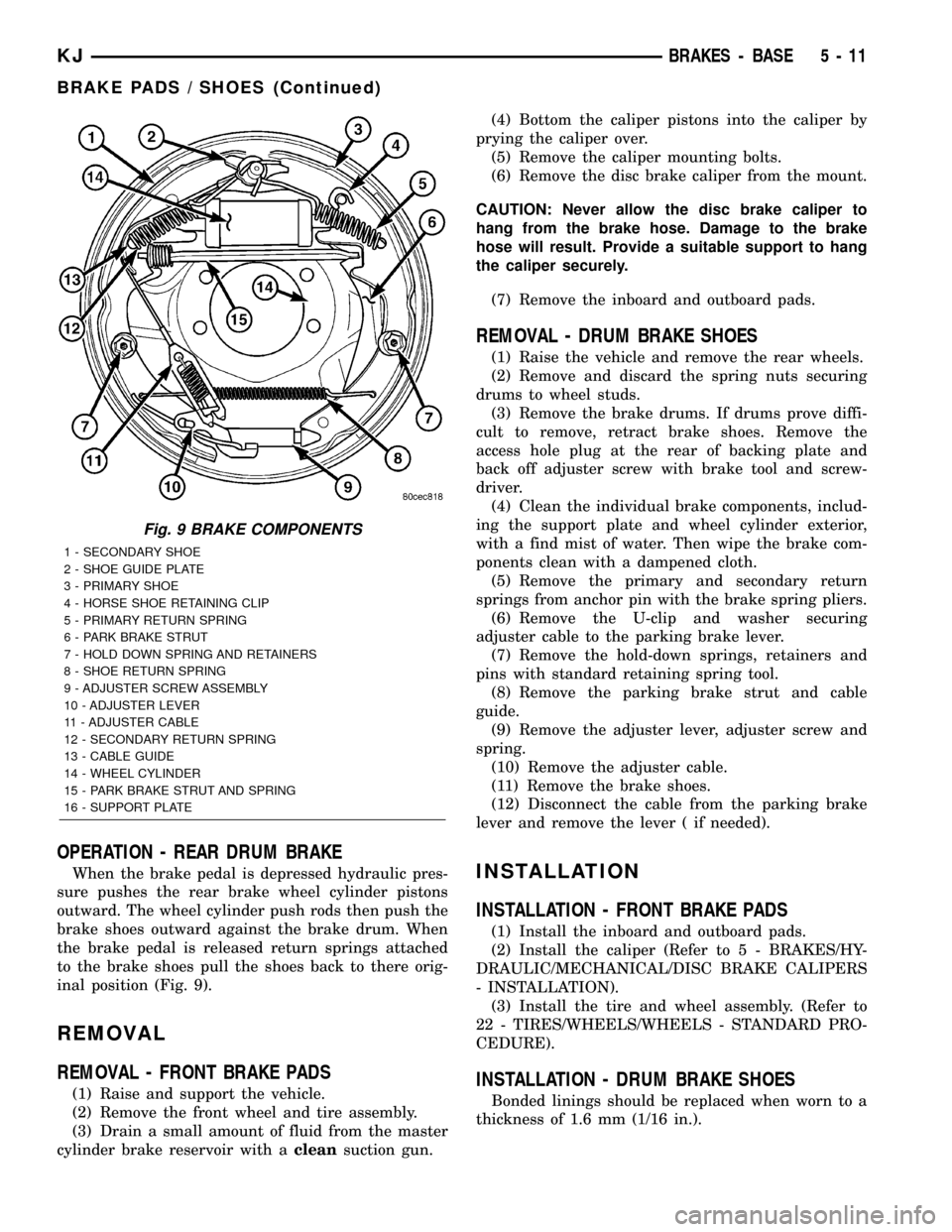

DESCRIPTION - REAR DRUM BRAKE

The rear brakes use a leading shoe (primary) and

trailing shoe (secondary) design (Right rear brake is

shown) (Fig. 9).

Fig. 6 BRAKE HOSE AT THE BODY

1 - MOUNTING BOLT

2 - BRAKE HOSE

3 - BRAKE LINE

4 - COIL SPRING

Fig. 7 BRAKE HOSE AT THE AXLE

1 - REAR WHEEL SPEED SENSOR

2 - BRAKE HOSE

3 - VENT HOSE

4 - BRAKE LINES

5 - MOUNTING BOLT

Fig. 8 BRAKE HOSE MOUNTED

1 - COIL SPRING

2 - MOUNTING BOLT

3 - BRAKE HOSE

4 - FRONT OF THE UPPER CONTROL ARM

5 - 10 BRAKES - BASEKJ

BRAKE LINES (Continued)

Page 175 of 1803

OPERATION - REAR DRUM BRAKE

When the brake pedal is depressed hydraulic pres-

sure pushes the rear brake wheel cylinder pistons

outward. The wheel cylinder push rods then push the

brake shoes outward against the brake drum. When

the brake pedal is released return springs attached

to the brake shoes pull the shoes back to there orig-

inal position (Fig. 9).

REMOVAL

REMOVAL - FRONT BRAKE PADS

(1) Raise and support the vehicle.

(2) Remove the front wheel and tire assembly.

(3) Drain a small amount of fluid from the master

cylinder brake reservoir with acleansuction gun.(4) Bottom the caliper pistons into the caliper by

prying the caliper over.

(5) Remove the caliper mounting bolts.

(6) Remove the disc brake caliper from the mount.

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose will result. Provide a suitable support to hang

the caliper securely.

(7) Remove the inboard and outboard pads.

REMOVAL - DRUM BRAKE SHOES

(1) Raise the vehicle and remove the rear wheels.

(2) Remove and discard the spring nuts securing

drums to wheel studs.

(3) Remove the brake drums. If drums prove diffi-

cult to remove, retract brake shoes. Remove the

access hole plug at the rear of backing plate and

back off adjuster screw with brake tool and screw-

driver.

(4) Clean the individual brake components, includ-

ing the support plate and wheel cylinder exterior,

with a find mist of water. Then wipe the brake com-

ponents clean with a dampened cloth.

(5) Remove the primary and secondary return

springs from anchor pin with the brake spring pliers.

(6) Remove the U-clip and washer securing

adjuster cable to the parking brake lever.

(7) Remove the hold-down springs, retainers and

pins with standard retaining spring tool.

(8) Remove the parking brake strut and cable

guide.

(9) Remove the adjuster lever, adjuster screw and

spring.

(10) Remove the adjuster cable.

(11) Remove the brake shoes.

(12) Disconnect the cable from the parking brake

lever and remove the lever ( if needed).

INSTALLATION

INSTALLATION - FRONT BRAKE PADS

(1) Install the inboard and outboard pads.

(2) Install the caliper (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DISC BRAKE CALIPERS

- INSTALLATION).

(3) Install the tire and wheel assembly. (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

INSTALLATION - DRUM BRAKE SHOES

Bonded linings should be replaced when worn to a

thickness of 1.6 mm (1/16 in.).

Fig. 9 BRAKE COMPONENTS

1 - SECONDARY SHOE

2 - SHOE GUIDE PLATE

3 - PRIMARY SHOE

4 - HORSE SHOE RETAINING CLIP

5 - PRIMARY RETURN SPRING

6 - PARK BRAKE STRUT

7 - HOLD DOWN SPRING AND RETAINERS

8 - SHOE RETURN SPRING

9 - ADJUSTER SCREW ASSEMBLY

10 - ADJUSTER LEVER

11 - ADJUSTER CABLE

12 - SECONDARY RETURN SPRING

13 - CABLE GUIDE

14 - WHEEL CYLINDER

15 - PARK BRAKE STRUT AND SPRING

16 - SUPPORT PLATE

KJBRAKES - BASE 5 - 11

BRAKE PADS / SHOES (Continued)

Page 176 of 1803

Examine the lining contact pattern to determine if

the shoes are bent or the drum is tapered. The lining

should exhibit contact across its entire width. Shoes

exhibiting contact only on one side should be

replaced and the drum checked for runout or taper.

Inspect the adjuster screw assembly. Replace the

assembly if the star wheel or threads are damaged,

or the components are severely rusted or corroded.

Discard the brake springs and retainer components

if worn, distorted or collapsed. Also replace the

springs if a brake drag condition had occurred. Over-

heating will distort and weaken the springs.

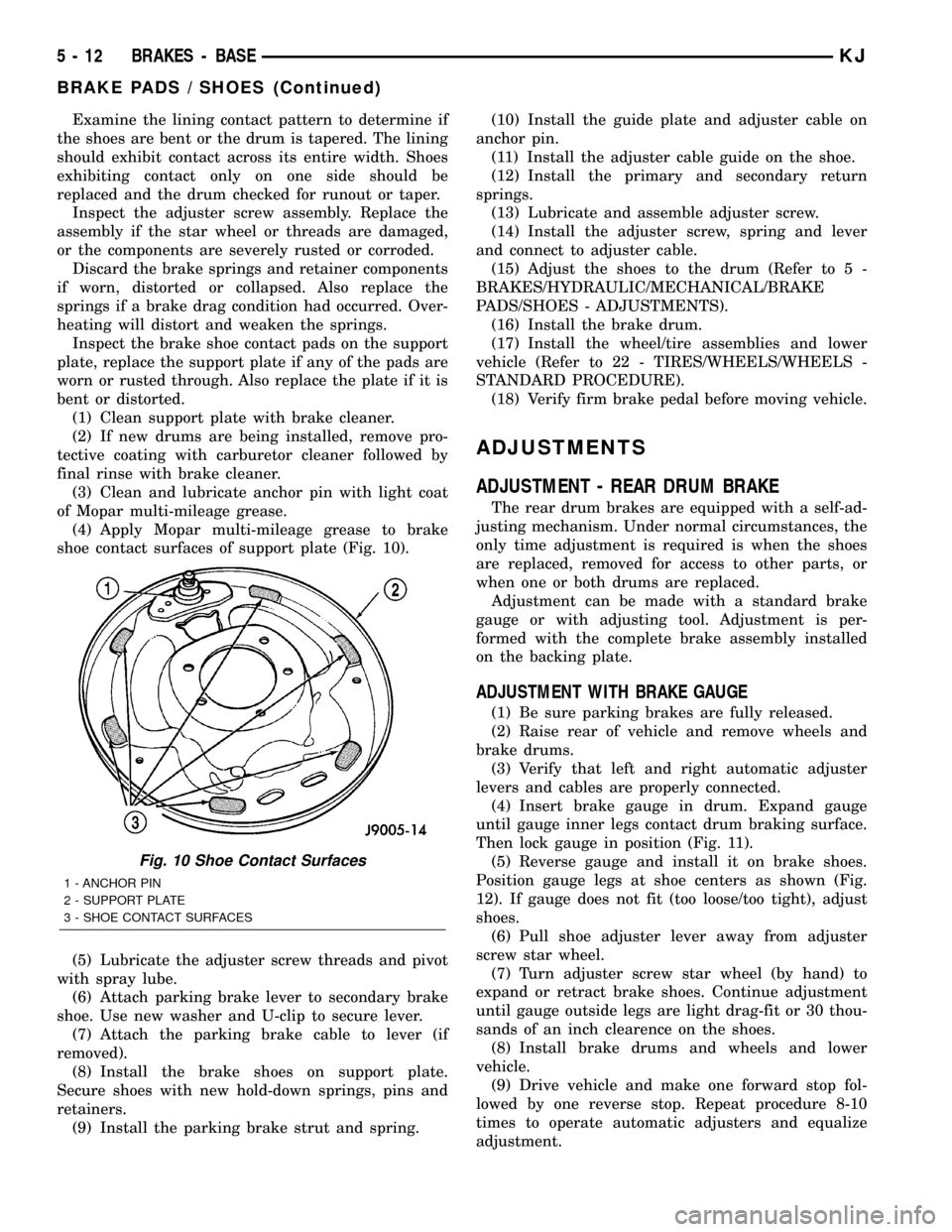

Inspect the brake shoe contact pads on the support

plate, replace the support plate if any of the pads are

worn or rusted through. Also replace the plate if it is

bent or distorted.

(1) Clean support plate with brake cleaner.

(2) If new drums are being installed, remove pro-

tective coating with carburetor cleaner followed by

final rinse with brake cleaner.

(3) Clean and lubricate anchor pin with light coat

of Mopar multi-mileage grease.

(4) Apply Mopar multi-mileage grease to brake

shoe contact surfaces of support plate (Fig. 10).

(5) Lubricate the adjuster screw threads and pivot

with spray lube.

(6) Attach parking brake lever to secondary brake

shoe. Use new washer and U-clip to secure lever.

(7) Attach the parking brake cable to lever (if

removed).

(8) Install the brake shoes on support plate.

Secure shoes with new hold-down springs, pins and

retainers.

(9) Install the parking brake strut and spring.(10) Install the guide plate and adjuster cable on

anchor pin.

(11) Install the adjuster cable guide on the shoe.

(12) Install the primary and secondary return

springs.

(13) Lubricate and assemble adjuster screw.

(14) Install the adjuster screw, spring and lever

and connect to adjuster cable.

(15) Adjust the shoes to the drum (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/BRAKE

PADS/SHOES - ADJUSTMENTS).

(16) Install the brake drum.

(17) Install the wheel/tire assemblies and lower

vehicle (Refer to 22 - TIRES/WHEELS/WHEELS -

STANDARD PROCEDURE).

(18) Verify firm brake pedal before moving vehicle.

ADJUSTMENTS

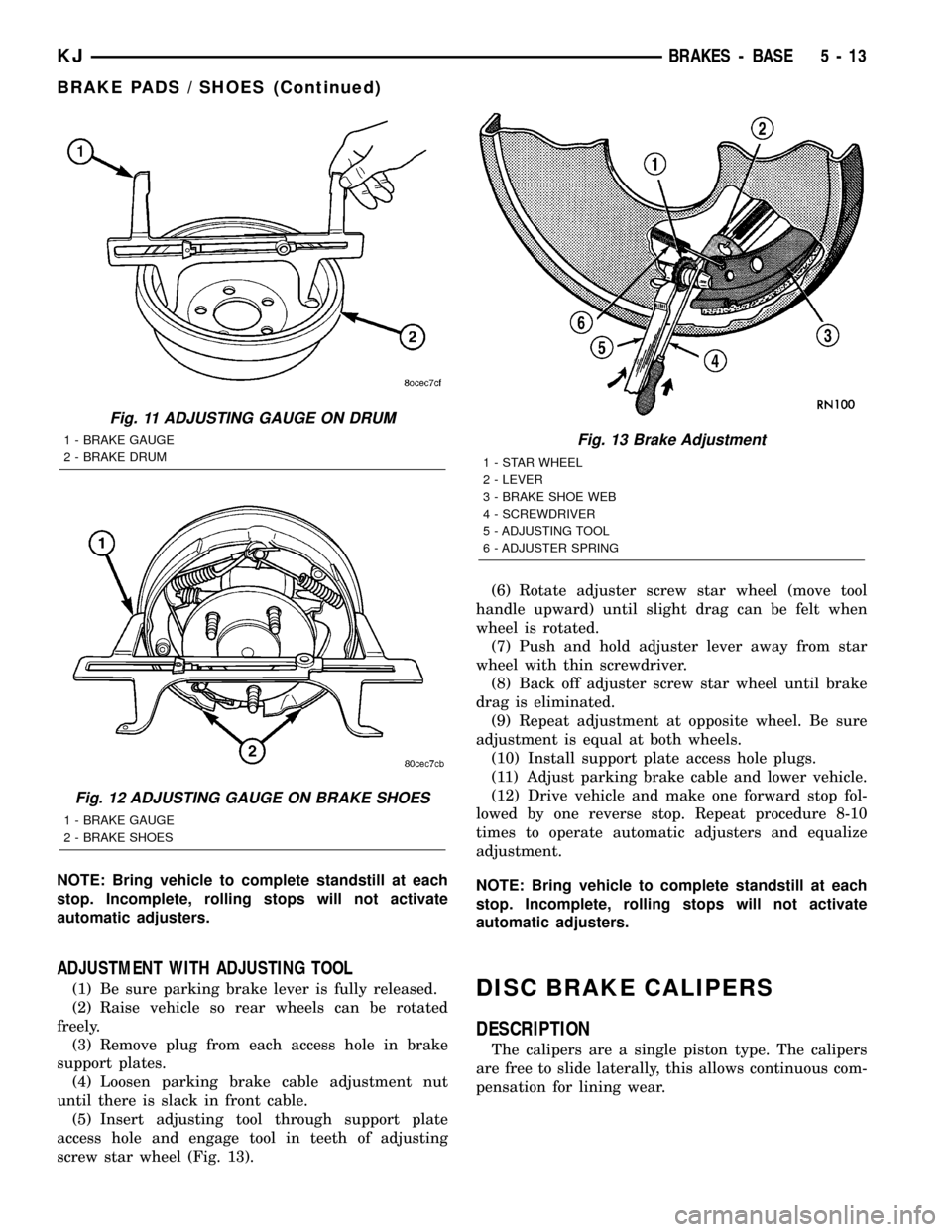

ADJUSTMENT - REAR DRUM BRAKE

The rear drum brakes are equipped with a self-ad-

justing mechanism. Under normal circumstances, the

only time adjustment is required is when the shoes

are replaced, removed for access to other parts, or

when one or both drums are replaced.

Adjustment can be made with a standard brake

gauge or with adjusting tool. Adjustment is per-

formed with the complete brake assembly installed

on the backing plate.

ADJUSTMENT WITH BRAKE GAUGE

(1) Be sure parking brakes are fully released.

(2) Raise rear of vehicle and remove wheels and

brake drums.

(3) Verify that left and right automatic adjuster

levers and cables are properly connected.

(4) Insert brake gauge in drum. Expand gauge

until gauge inner legs contact drum braking surface.

Then lock gauge in position (Fig. 11).

(5) Reverse gauge and install it on brake shoes.

Position gauge legs at shoe centers as shown (Fig.

12). If gauge does not fit (too loose/too tight), adjust

shoes.

(6) Pull shoe adjuster lever away from adjuster

screw star wheel.

(7) Turn adjuster screw star wheel (by hand) to

expand or retract brake shoes. Continue adjustment

until gauge outside legs are light drag-fit or 30 thou-

sands of an inch clearence on the shoes.

(8) Install brake drums and wheels and lower

vehicle.

(9) Drive vehicle and make one forward stop fol-

lowed by one reverse stop. Repeat procedure 8-10

times to operate automatic adjusters and equalize

adjustment.

Fig. 10 Shoe Contact Surfaces

1 - ANCHOR PIN

2 - SUPPORT PLATE

3 - SHOE CONTACT SURFACES

5 - 12 BRAKES - BASEKJ

BRAKE PADS / SHOES (Continued)

Page 177 of 1803

NOTE: Bring vehicle to complete standstill at each

stop. Incomplete, rolling stops will not activate

automatic adjusters.

ADJUSTMENT WITH ADJUSTING TOOL

(1) Be sure parking brake lever is fully released.

(2) Raise vehicle so rear wheels can be rotated

freely.

(3) Remove plug from each access hole in brake

support plates.

(4) Loosen parking brake cable adjustment nut

until there is slack in front cable.

(5) Insert adjusting tool through support plate

access hole and engage tool in teeth of adjusting

screw star wheel (Fig. 13).(6) Rotate adjuster screw star wheel (move tool

handle upward) until slight drag can be felt when

wheel is rotated.

(7) Push and hold adjuster lever away from star

wheel with thin screwdriver.

(8) Back off adjuster screw star wheel until brake

drag is eliminated.

(9) Repeat adjustment at opposite wheel. Be sure

adjustment is equal at both wheels.

(10) Install support plate access hole plugs.

(11) Adjust parking brake cable and lower vehicle.

(12) Drive vehicle and make one forward stop fol-

lowed by one reverse stop. Repeat procedure 8-10

times to operate automatic adjusters and equalize

adjustment.

NOTE: Bring vehicle to complete standstill at each

stop. Incomplete, rolling stops will not activate

automatic adjusters.DISC BRAKE CALIPERS

DESCRIPTION

The calipers are a single piston type. The calipers

are free to slide laterally, this allows continuous com-

pensation for lining wear.

Fig. 11 ADJUSTING GAUGE ON DRUM

1 - BRAKE GAUGE

2 - BRAKE DRUM

Fig. 12 ADJUSTING GAUGE ON BRAKE SHOES

1 - BRAKE GAUGE

2 - BRAKE SHOES

Fig. 13 Brake Adjustment

1 - STAR WHEEL

2 - LEVER

3 - BRAKE SHOE WEB

4 - SCREWDRIVER

5 - ADJUSTING TOOL

6 - ADJUSTER SPRING

KJBRAKES - BASE 5 - 13

BRAKE PADS / SHOES (Continued)

Page 178 of 1803

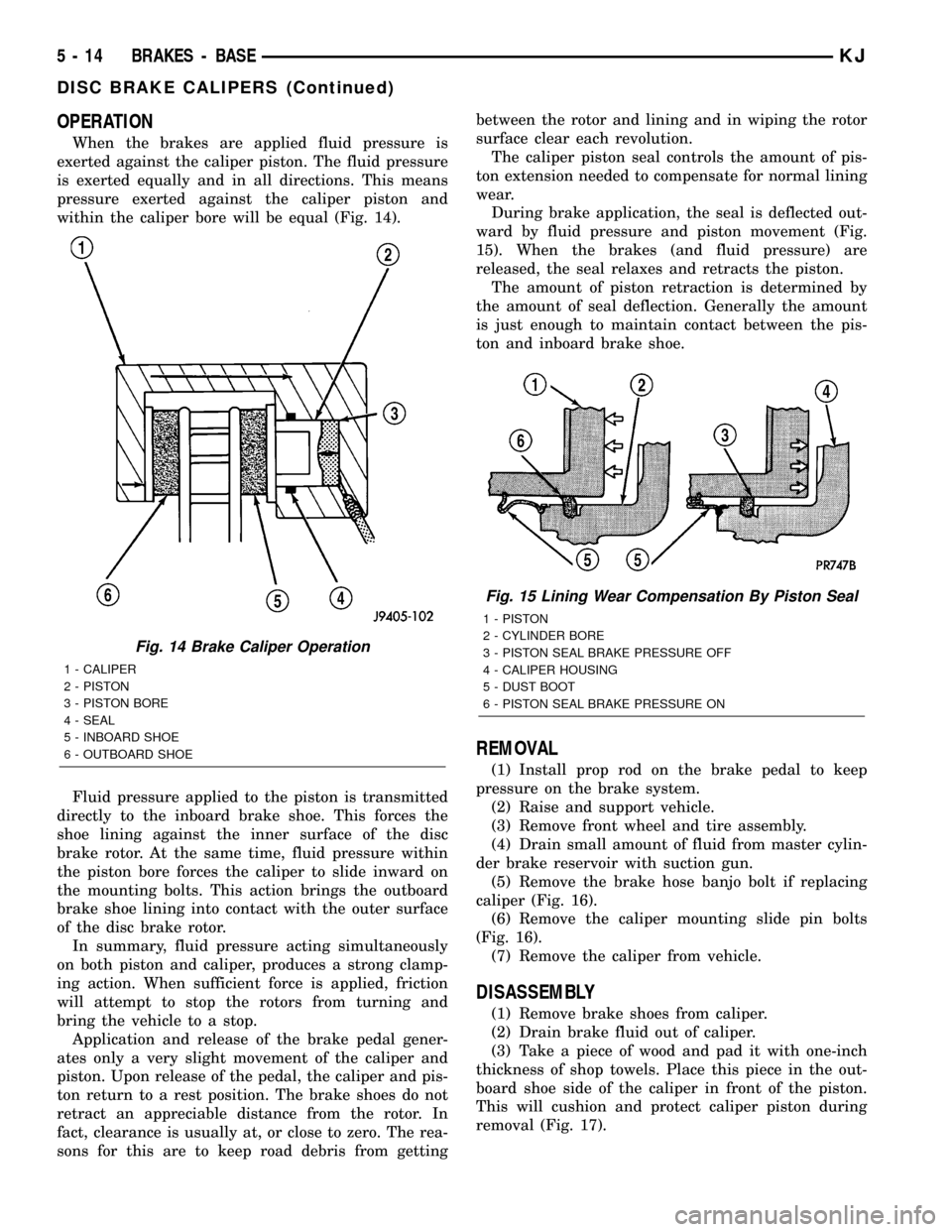

OPERATION

When the brakes are applied fluid pressure is

exerted against the caliper piston. The fluid pressure

is exerted equally and in all directions. This means

pressure exerted against the caliper piston and

within the caliper bore will be equal (Fig. 14).

Fluid pressure applied to the piston is transmitted

directly to the inboard brake shoe. This forces the

shoe lining against the inner surface of the disc

brake rotor. At the same time, fluid pressure within

the piston bore forces the caliper to slide inward on

the mounting bolts. This action brings the outboard

brake shoe lining into contact with the outer surface

of the disc brake rotor.

In summary, fluid pressure acting simultaneously

on both piston and caliper, produces a strong clamp-

ing action. When sufficient force is applied, friction

will attempt to stop the rotors from turning and

bring the vehicle to a stop.

Application and release of the brake pedal gener-

ates only a very slight movement of the caliper and

piston. Upon release of the pedal, the caliper and pis-

ton return to a rest position. The brake shoes do not

retract an appreciable distance from the rotor. In

fact, clearance is usually at, or close to zero. The rea-

sons for this are to keep road debris from gettingbetween the rotor and lining and in wiping the rotor

surface clear each revolution.

The caliper piston seal controls the amount of pis-

ton extension needed to compensate for normal lining

wear.

During brake application, the seal is deflected out-

ward by fluid pressure and piston movement (Fig.

15). When the brakes (and fluid pressure) are

released, the seal relaxes and retracts the piston.

The amount of piston retraction is determined by

the amount of seal deflection. Generally the amount

is just enough to maintain contact between the pis-

ton and inboard brake shoe.

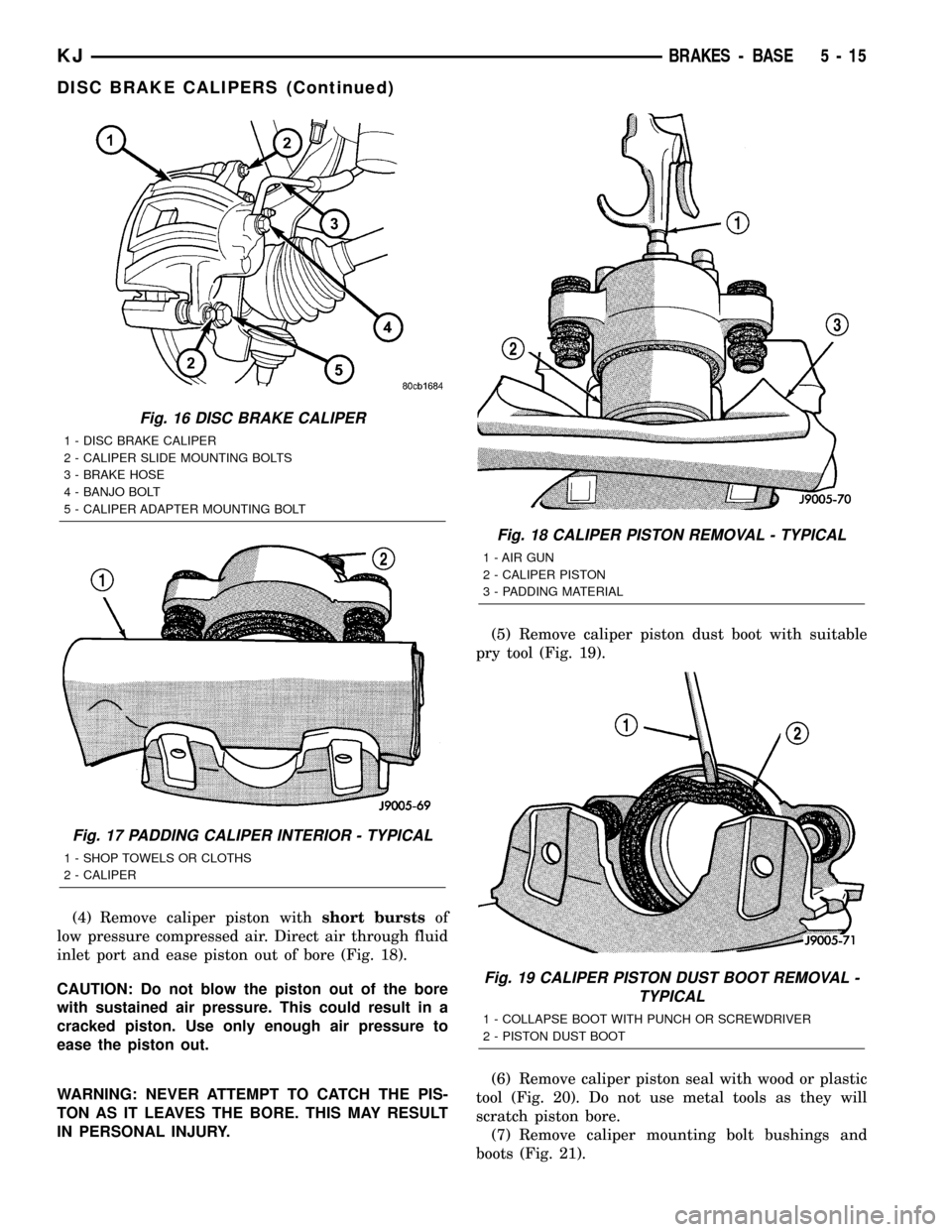

REMOVAL

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support vehicle.

(3) Remove front wheel and tire assembly.

(4) Drain small amount of fluid from master cylin-

der brake reservoir with suction gun.

(5) Remove the brake hose banjo bolt if replacing

caliper (Fig. 16).

(6) Remove the caliper mounting slide pin bolts

(Fig. 16).

(7) Remove the caliper from vehicle.

DISASSEMBLY

(1) Remove brake shoes from caliper.

(2) Drain brake fluid out of caliper.

(3) Take a piece of wood and pad it with one-inch

thickness of shop towels. Place this piece in the out-

board shoe side of the caliper in front of the piston.

This will cushion and protect caliper piston during

removal (Fig. 17).

Fig. 14 Brake Caliper Operation

1 - CALIPER

2 - PISTON

3 - PISTON BORE

4 - SEAL

5 - INBOARD SHOE

6 - OUTBOARD SHOE

Fig. 15 Lining Wear Compensation By Piston Seal

1 - PISTON

2 - CYLINDER BORE

3 - PISTON SEAL BRAKE PRESSURE OFF

4 - CALIPER HOUSING

5 - DUST BOOT

6 - PISTON SEAL BRAKE PRESSURE ON

5 - 14 BRAKES - BASEKJ

DISC BRAKE CALIPERS (Continued)

Page 179 of 1803

(4) Remove caliper piston withshort burstsof

low pressure compressed air. Direct air through fluid

inlet port and ease piston out of bore (Fig. 18).

CAUTION: Do not blow the piston out of the bore

with sustained air pressure. This could result in a

cracked piston. Use only enough air pressure to

ease the piston out.

WARNING: NEVER ATTEMPT TO CATCH THE PIS-

TON AS IT LEAVES THE BORE. THIS MAY RESULT

IN PERSONAL INJURY.(5) Remove caliper piston dust boot with suitable

pry tool (Fig. 19).

(6) Remove caliper piston seal with wood or plastic

tool (Fig. 20). Do not use metal tools as they will

scratch piston bore.

(7) Remove caliper mounting bolt bushings and

boots (Fig. 21).

Fig. 16 DISC BRAKE CALIPER

1 - DISC BRAKE CALIPER

2 - CALIPER SLIDE MOUNTING BOLTS

3 - BRAKE HOSE

4 - BANJO BOLT

5 - CALIPER ADAPTER MOUNTING BOLT

Fig. 17 PADDING CALIPER INTERIOR - TYPICAL

1 - SHOP TOWELS OR CLOTHS

2 - CALIPER

Fig. 18 CALIPER PISTON REMOVAL - TYPICAL

1 - AIR GUN

2 - CALIPER PISTON

3 - PADDING MATERIAL

Fig. 19 CALIPER PISTON DUST BOOT REMOVAL -

TYPICAL

1 - COLLAPSE BOOT WITH PUNCH OR SCREWDRIVER

2 - PISTON DUST BOOT

KJBRAKES - BASE 5 - 15

DISC BRAKE CALIPERS (Continued)

Page 180 of 1803

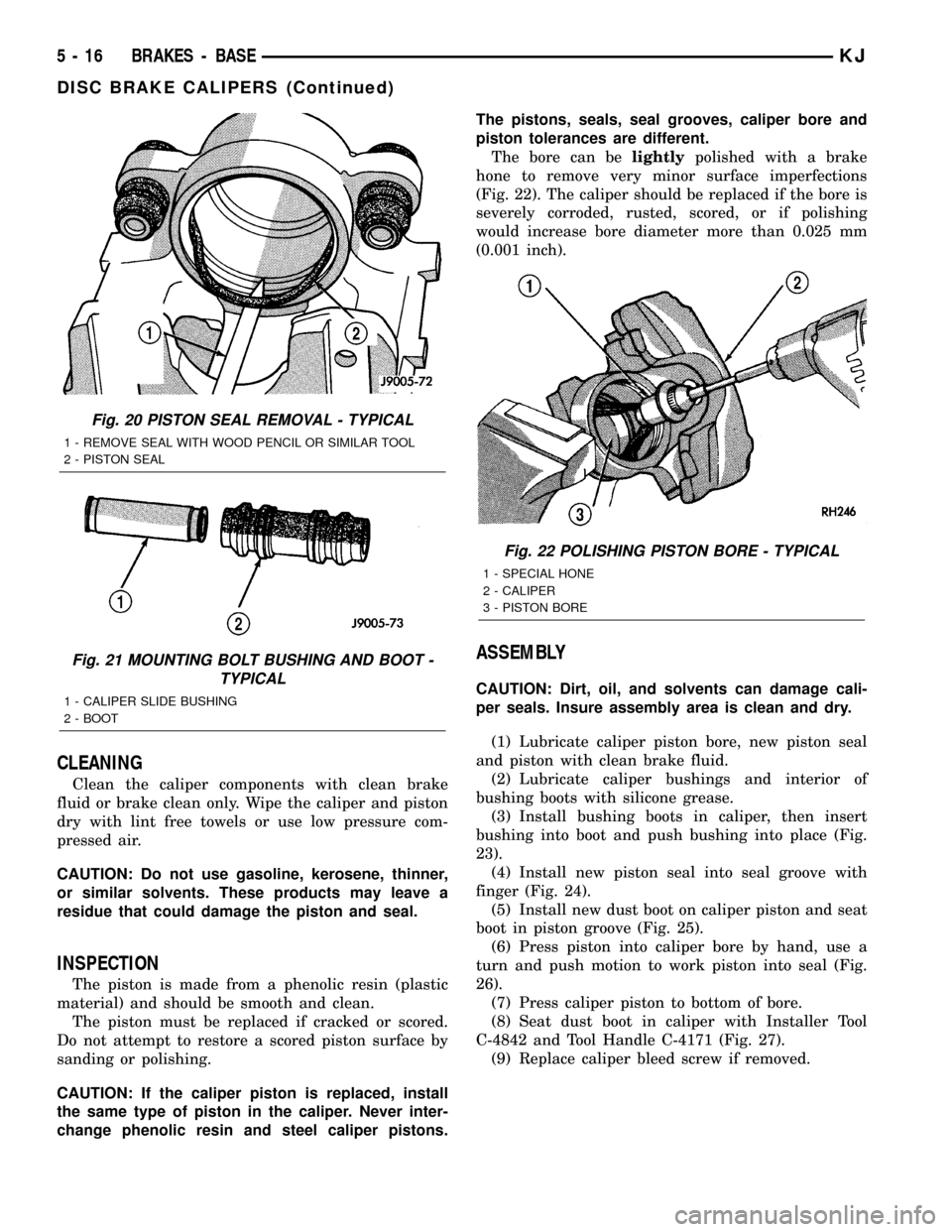

CLEANING

Clean the caliper components with clean brake

fluid or brake clean only. Wipe the caliper and piston

dry with lint free towels or use low pressure com-

pressed air.

CAUTION: Do not use gasoline, kerosene, thinner,

or similar solvents. These products may leave a

residue that could damage the piston and seal.

INSPECTION

The piston is made from a phenolic resin (plastic

material) and should be smooth and clean.

The piston must be replaced if cracked or scored.

Do not attempt to restore a scored piston surface by

sanding or polishing.

CAUTION: If the caliper piston is replaced, install

the same type of piston in the caliper. Never inter-

change phenolic resin and steel caliper pistons.The pistons, seals, seal grooves, caliper bore and

piston tolerances are different.

The bore can belightlypolished with a brake

hone to remove very minor surface imperfections

(Fig. 22). The caliper should be replaced if the bore is

severely corroded, rusted, scored, or if polishing

would increase bore diameter more than 0.025 mm

(0.001 inch).

ASSEMBLY

CAUTION: Dirt, oil, and solvents can damage cali-

per seals. Insure assembly area is clean and dry.

(1) Lubricate caliper piston bore, new piston seal

and piston with clean brake fluid.

(2) Lubricate caliper bushings and interior of

bushing boots with silicone grease.

(3) Install bushing boots in caliper, then insert

bushing into boot and push bushing into place (Fig.

23).

(4) Install new piston seal into seal groove with

finger (Fig. 24).

(5) Install new dust boot on caliper piston and seat

boot in piston groove (Fig. 25).

(6) Press piston into caliper bore by hand, use a

turn and push motion to work piston into seal (Fig.

26).

(7) Press caliper piston to bottom of bore.

(8) Seat dust boot in caliper with Installer Tool

C-4842 and Tool Handle C-4171 (Fig. 27).

(9) Replace caliper bleed screw if removed.

Fig. 20 PISTON SEAL REMOVAL - TYPICAL

1 - REMOVE SEAL WITH WOOD PENCIL OR SIMILAR TOOL

2 - PISTON SEAL

Fig. 21 MOUNTING BOLT BUSHING AND BOOT -

TYPICAL

1 - CALIPER SLIDE BUSHING

2 - BOOT

Fig. 22 POLISHING PISTON BORE - TYPICAL

1 - SPECIAL HONE

2 - CALIPER

3 - PISTON BORE

5 - 16 BRAKES - BASEKJ

DISC BRAKE CALIPERS (Continued)