belt JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1159 of 1803

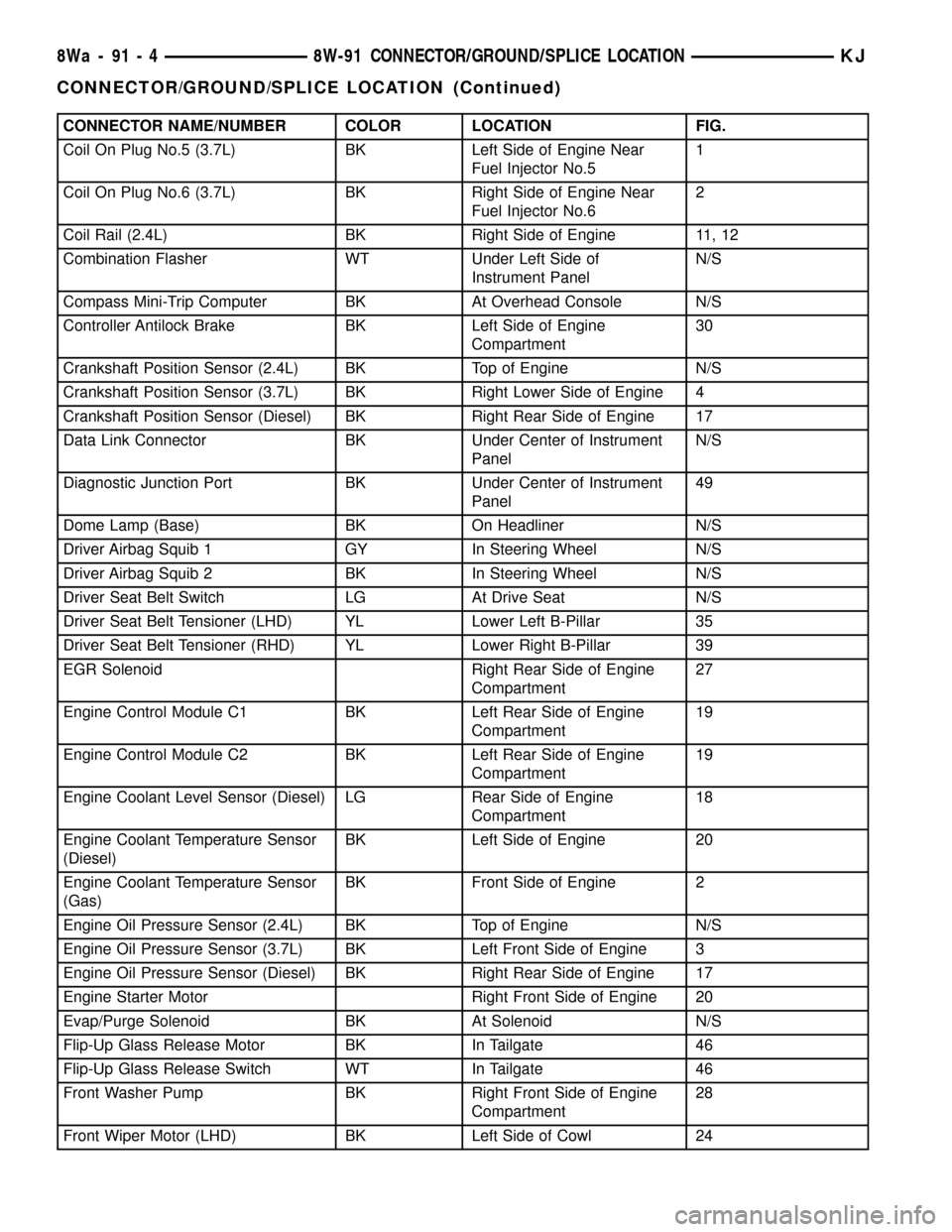

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Coil On Plug No.5 (3.7L) BK Left Side of Engine Near

Fuel Injector No.51

Coil On Plug No.6 (3.7L) BK Right Side of Engine Near

Fuel Injector No.62

Coil Rail (2.4L) BK Right Side of Engine 11, 12

Combination Flasher WT Under Left Side of

Instrument PanelN/S

Compass Mini-Trip Computer BK At Overhead Console N/S

Controller Antilock Brake BK Left Side of Engine

Compartment30

Crankshaft Position Sensor (2.4L) BK Top of Engine N/S

Crankshaft Position Sensor (3.7L) BK Right Lower Side of Engine 4

Crankshaft Position Sensor (Diesel) BK Right Rear Side of Engine 17

Data Link Connector BK Under Center of Instrument

PanelN/S

Diagnostic Junction Port BK Under Center of Instrument

Panel49

Dome Lamp (Base) BK On Headliner N/S

Driver Airbag Squib 1 GY In Steering Wheel N/S

Driver Airbag Squib 2 BK In Steering Wheel N/S

Driver Seat Belt Switch LG At Drive Seat N/S

Driver Seat Belt Tensioner (LHD) YL Lower Left B-Pillar 35

Driver Seat Belt Tensioner (RHD) YL Lower Right B-Pillar 39

EGR Solenoid Right Rear Side of Engine

Compartment27

Engine Control Module C1 BK Left Rear Side of Engine

Compartment19

Engine Control Module C2 BK Left Rear Side of Engine

Compartment19

Engine Coolant Level Sensor (Diesel) LG Rear Side of Engine

Compartment18

Engine Coolant Temperature Sensor

(Diesel)BK Left Side of Engine 20

Engine Coolant Temperature Sensor

(Gas)BK Front Side of Engine 2

Engine Oil Pressure Sensor (2.4L) BK Top of Engine N/S

Engine Oil Pressure Sensor (3.7L) BK Left Front Side of Engine 3

Engine Oil Pressure Sensor (Diesel) BK Right Rear Side of Engine 17

Engine Starter Motor Right Front Side of Engine 20

Evap/Purge Solenoid BK At Solenoid N/S

Flip-Up Glass Release Motor BK In Tailgate 46

Flip-Up Glass Release Switch WT In Tailgate 46

Front Washer Pump BK Right Front Side of Engine

Compartment28

Front Wiper Motor (LHD) BK Left Side of Cowl 24

8Wa - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONKJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1162 of 1803

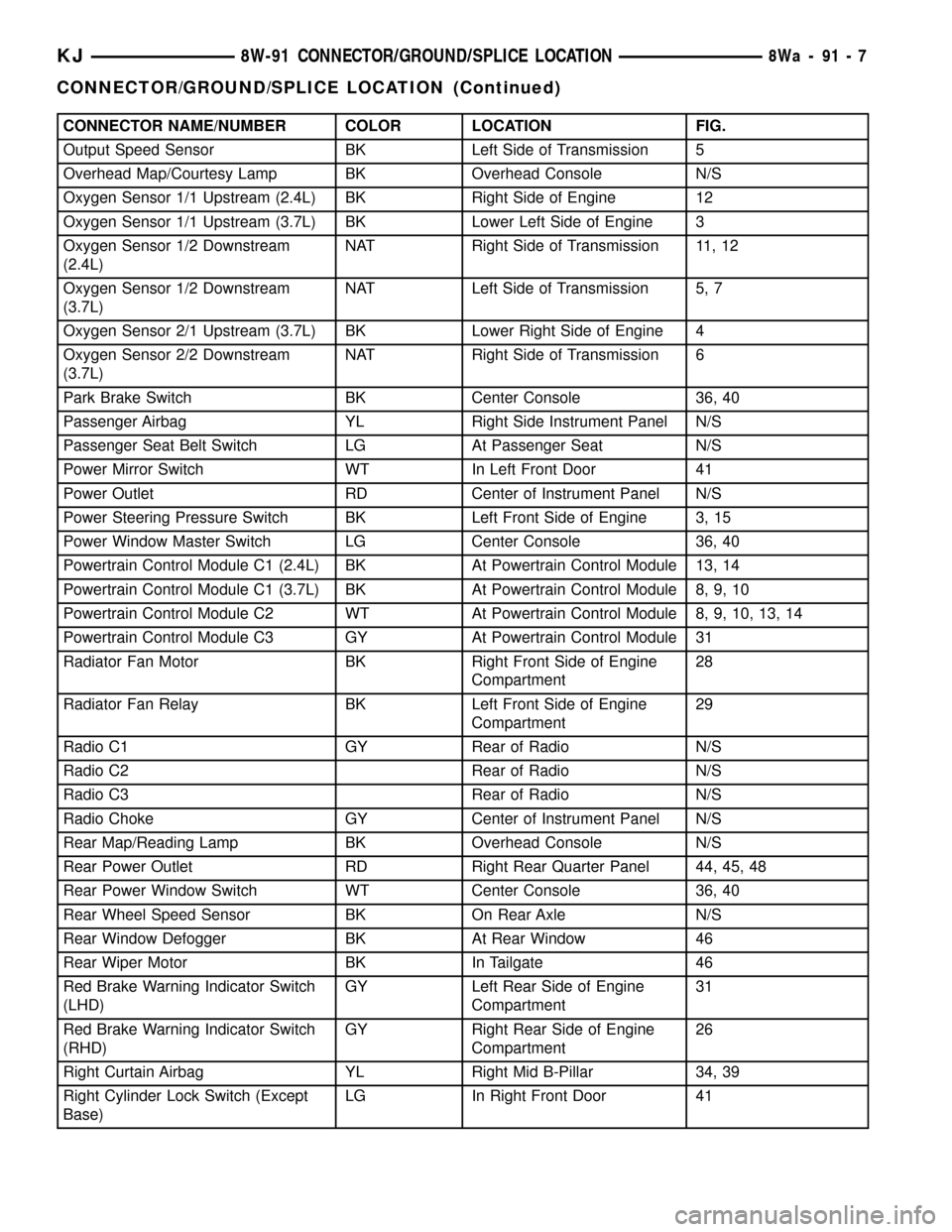

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Output Speed Sensor BK Left Side of Transmission 5

Overhead Map/Courtesy Lamp BK Overhead Console N/S

Oxygen Sensor 1/1 Upstream (2.4L) BK Right Side of Engine 12

Oxygen Sensor 1/1 Upstream (3.7L) BK Lower Left Side of Engine 3

Oxygen Sensor 1/2 Downstream

(2.4L)NAT Right Side of Transmission 11, 12

Oxygen Sensor 1/2 Downstream

(3.7L)NAT Left Side of Transmission 5, 7

Oxygen Sensor 2/1 Upstream (3.7L) BK Lower Right Side of Engine 4

Oxygen Sensor 2/2 Downstream

(3.7L)NAT Right Side of Transmission 6

Park Brake Switch BK Center Console 36, 40

Passenger Airbag YL Right Side Instrument Panel N/S

Passenger Seat Belt Switch LG At Passenger Seat N/S

Power Mirror Switch WT In Left Front Door 41

Power Outlet RD Center of Instrument Panel N/S

Power Steering Pressure Switch BK Left Front Side of Engine 3, 15

Power Window Master Switch LG Center Console 36, 40

Powertrain Control Module C1 (2.4L) BK At Powertrain Control Module 13, 14

Powertrain Control Module C1 (3.7L) BK At Powertrain Control Module 8, 9, 10

Powertrain Control Module C2 WT At Powertrain Control Module 8, 9, 10, 13, 14

Powertrain Control Module C3 GY At Powertrain Control Module 31

Radiator Fan Motor BK Right Front Side of Engine

Compartment28

Radiator Fan Relay BK Left Front Side of Engine

Compartment29

Radio C1 GY Rear of Radio N/S

Radio C2 Rear of Radio N/S

Radio C3 Rear of Radio N/S

Radio Choke GY Center of Instrument Panel N/S

Rear Map/Reading Lamp BK Overhead Console N/S

Rear Power Outlet RD Right Rear Quarter Panel 44, 45, 48

Rear Power Window Switch WT Center Console 36, 40

Rear Wheel Speed Sensor BK On Rear Axle N/S

Rear Window Defogger BK At Rear Window 46

Rear Wiper Motor BK In Tailgate 46

Red Brake Warning Indicator Switch

(LHD)GY Left Rear Side of Engine

Compartment31

Red Brake Warning Indicator Switch

(RHD)GY Right Rear Side of Engine

Compartment26

Right Curtain Airbag YL Right Mid B-Pillar 34, 39

Right Cylinder Lock Switch (Except

Base)LG In Right Front Door 41

KJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION8Wa-91-7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

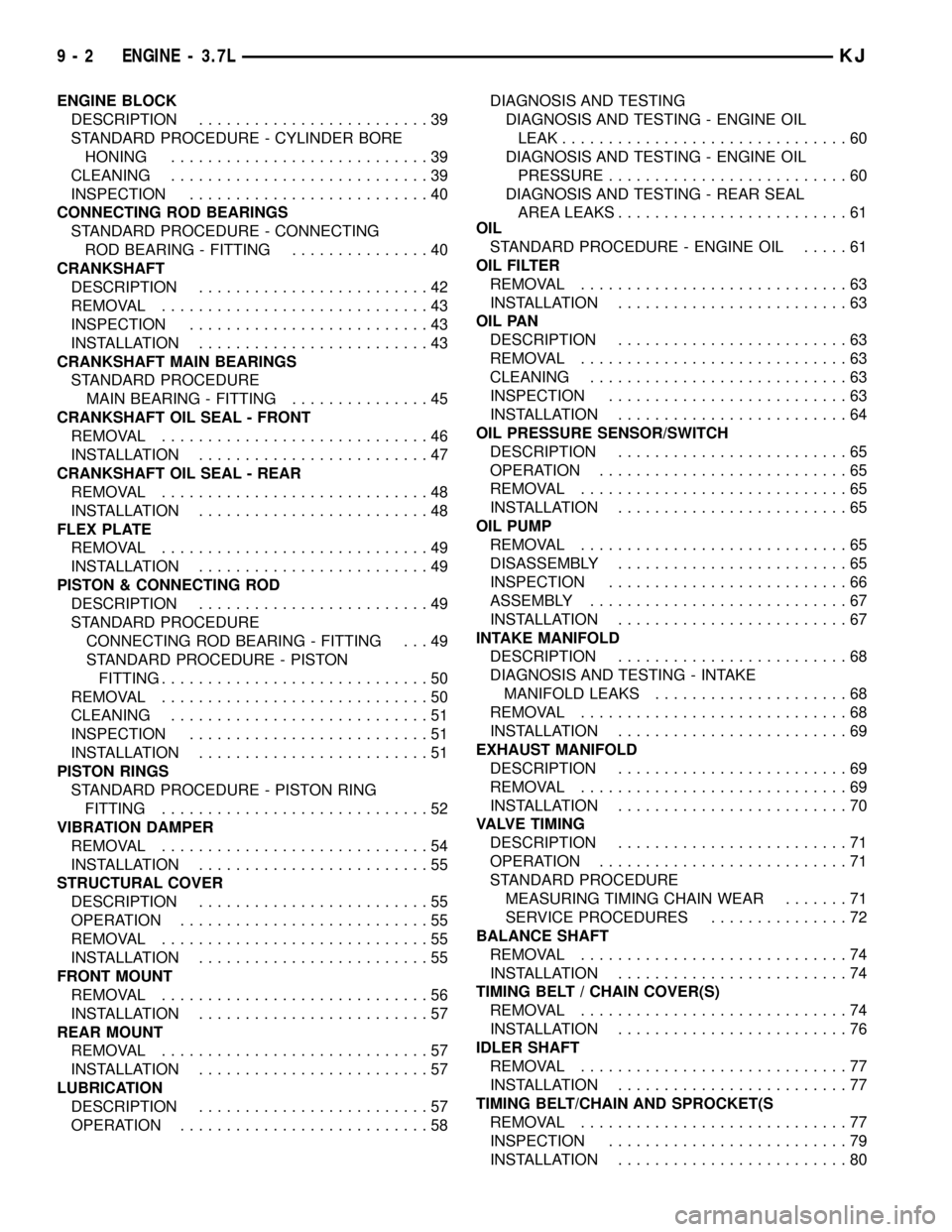

Page 1217 of 1803

ENGINE BLOCK

DESCRIPTION.........................39

STANDARD PROCEDURE - CYLINDER BORE

HONING............................39

CLEANING............................39

INSPECTION..........................40

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - CONNECTING

ROD BEARING - FITTING...............40

CRANKSHAFT

DESCRIPTION.........................42

REMOVAL.............................43

INSPECTION..........................43

INSTALLATION.........................43

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE

MAIN BEARING - FITTING...............45

CRANKSHAFT OIL SEAL - FRONT

REMOVAL.............................46

INSTALLATION.........................47

CRANKSHAFT OIL SEAL - REAR

REMOVAL.............................48

INSTALLATION.........................48

FLEX PLATE

REMOVAL.............................49

INSTALLATION.........................49

PISTON & CONNECTING ROD

DESCRIPTION.........................49

STANDARD PROCEDURE

CONNECTING ROD BEARING - FITTING . . . 49

STANDARD PROCEDURE - PISTON

FITTING.............................50

REMOVAL.............................50

CLEANING............................51

INSPECTION..........................51

INSTALLATION.........................51

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING.............................52

VIBRATION DAMPER

REMOVAL.............................54

INSTALLATION.........................55

STRUCTURAL COVER

DESCRIPTION.........................55

OPERATION...........................55

REMOVAL.............................55

INSTALLATION.........................55

FRONT MOUNT

REMOVAL.............................56

INSTALLATION.........................57

REAR MOUNT

REMOVAL.............................57

INSTALLATION.........................57

LUBRICATION

DESCRIPTION.........................57

OPERATION...........................58DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK...............................60

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE..........................60

DIAGNOSIS AND TESTING - REAR SEAL

AREA LEAKS.........................61

OIL

STANDARD PROCEDURE - ENGINE OIL.....61

OIL FILTER

REMOVAL.............................63

INSTALLATION.........................63

OIL PAN

DESCRIPTION.........................63

REMOVAL.............................63

CLEANING............................63

INSPECTION..........................63

INSTALLATION.........................64

OIL PRESSURE SENSOR/SWITCH

DESCRIPTION.........................65

OPERATION...........................65

REMOVAL.............................65

INSTALLATION.........................65

OIL PUMP

REMOVAL.............................65

DISASSEMBLY.........................65

INSPECTION..........................66

ASSEMBLY............................67

INSTALLATION.........................67

INTAKE MANIFOLD

DESCRIPTION.........................68

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS.....................68

REMOVAL.............................68

INSTALLATION.........................69

EXHAUST MANIFOLD

DESCRIPTION.........................69

REMOVAL.............................69

INSTALLATION.........................70

VALVE TIMING

DESCRIPTION.........................71

OPERATION...........................71

STANDARD PROCEDURE

MEASURING TIMING CHAIN WEAR.......71

SERVICE PROCEDURES...............72

BALANCE SHAFT

REMOVAL.............................74

INSTALLATION.........................74

TIMING BELT / CHAIN COVER(S)

REMOVAL.............................74

INSTALLATION.........................76

IDLER SHAFT

REMOVAL.............................77

INSTALLATION.........................77

TIMING BELT/CHAIN AND SPROCKET(S

REMOVAL.............................77

INSPECTION..........................79

INSTALLATION.........................80

9 - 2 ENGINE - 3.7LKJ

Page 1225 of 1803

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

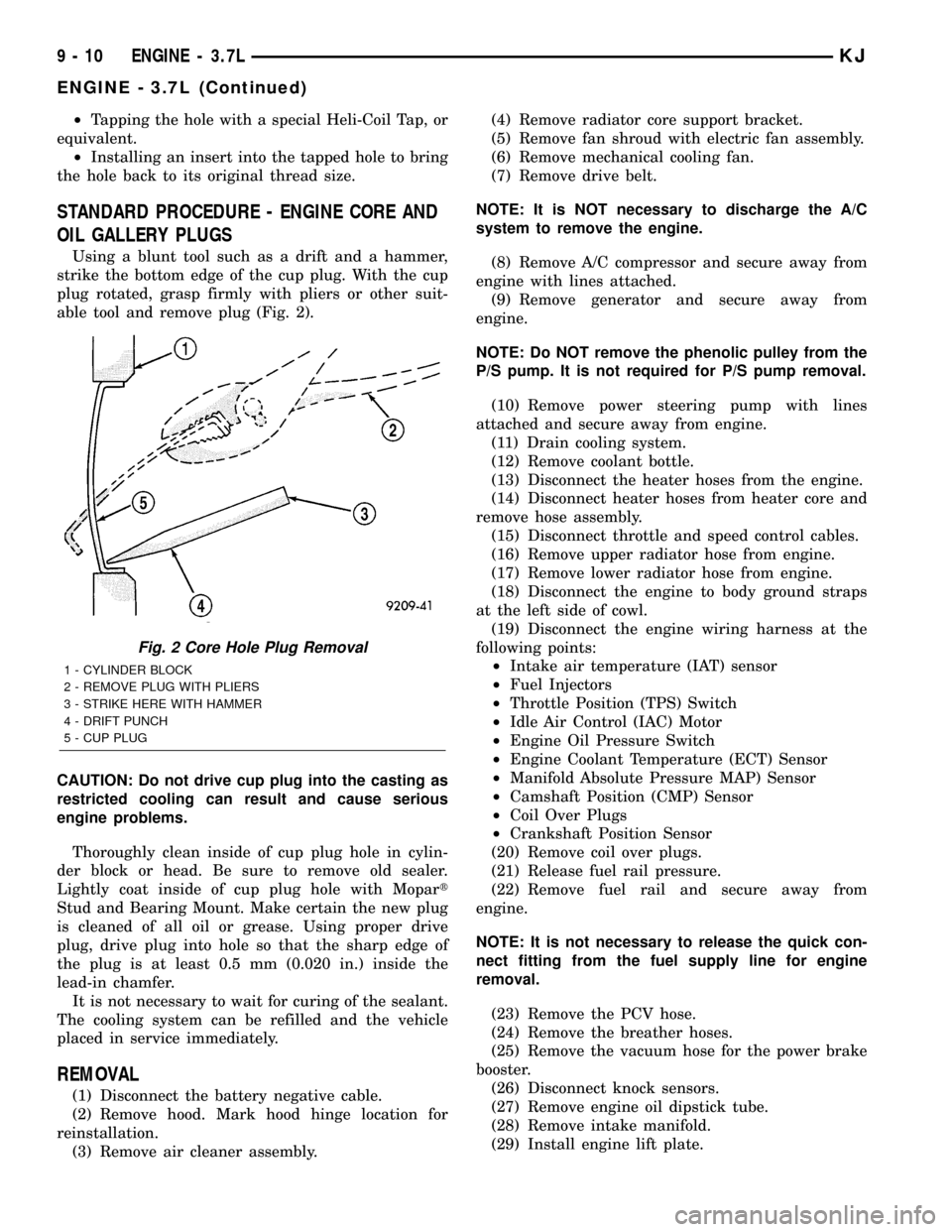

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 2).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove hood. Mark hood hinge location for

reinstallation.

(3) Remove air cleaner assembly.(4) Remove radiator core support bracket.

(5) Remove fan shroud with electric fan assembly.

(6) Remove mechanical cooling fan.

(7) Remove drive belt.

NOTE: It is NOT necessary to discharge the A/C

system to remove the engine.

(8) Remove A/C compressor and secure away from

engine with lines attached.

(9) Remove generator and secure away from

engine.

NOTE: Do NOT remove the phenolic pulley from the

P/S pump. It is not required for P/S pump removal.

(10) Remove power steering pump with lines

attached and secure away from engine.

(11) Drain cooling system.

(12) Remove coolant bottle.

(13) Disconnect the heater hoses from the engine.

(14) Disconnect heater hoses from heater core and

remove hose assembly.

(15) Disconnect throttle and speed control cables.

(16) Remove upper radiator hose from engine.

(17) Remove lower radiator hose from engine.

(18) Disconnect the engine to body ground straps

at the left side of cowl.

(19) Disconnect the engine wiring harness at the

following points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(20) Remove coil over plugs.

(21) Release fuel rail pressure.

(22) Remove fuel rail and secure away from

engine.

NOTE: It is not necessary to release the quick con-

nect fitting from the fuel supply line for engine

removal.

(23) Remove the PCV hose.

(24) Remove the breather hoses.

(25) Remove the vacuum hose for the power brake

booster.

(26) Disconnect knock sensors.

(27) Remove engine oil dipstick tube.

(28) Remove intake manifold.

(29) Install engine lift plate.

Fig. 2 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

9 - 10 ENGINE - 3.7LKJ

ENGINE - 3.7L (Continued)

Page 1226 of 1803

NOTE: Recheck bolt torque for engine lift plate

before removing engine.

(30) Secure the left and right engine wiring har-

nesses away from engine.

(31) Raise vehicle.

(32) Disconnect oxygen sensor wiring.

(33) Disconnect crankshaft postion sensor.

(34) Disconnect the engine block heater power

cable, if equipped.

(35) Disconnect the front propshaft at the front

differential and secure out of way.

NOTE: It is necessary to disconnect the front prop-

shaft for access to the starter and left side exhaust

flange.

(36) Remove the starter.

(37) Remove the ground straps from the left and

right side of the block.

(38) Disconnect the right and left exhaust pipes at

the manifolds and from the crossover, and remove

from the vehicle.

NOTE: The exhaust clamps at the manifolds cannot

be reused. New clamps must be used or leaks may

occur.

NOTE: For manual transmission vehicles, the trans-

mission must be removed from the vehicle, before

the engine can be removed. The manual transmis-

sion will contact the floorpan before the engine

clears the motor mounts, so it must be removed.

(39) Remove the structural cover.

(40) Remove torque convertor bolts, and mark

location for reassembly.

(41) Remove transmission bellhousing to engine

bolts.

(42) Loosen left and right engine mount thru bolts.

NOTE: It is not necessary to completely remove

engine mount thru bolts, for engine removal.

(43) Lower the vehicle.

(44) Support the transmission with a suitable jack.

(45) Connect a suitable engine hoist to the engine

lift plate.

(46) Remove engine from vehicle.

INSTALLATION

(1) Position the engine in the vehicle.

(2) Install both left and right side engine mounts

onto engine.

(3) Raise the vehicle.(4) Install the transmission bellhousing to engine

mounting bolts. Tighten the bolts to 41 N´m (30ft.

lbs.).

(5) Tighten the engine mount thru bolts.

(6) Install the torque convertor bolts.

(7) Connect the ground straps on the left and right

side of the engine.

(8) Install the starter.

(9) Connect the crankshaft position sensor.

(10) Install the engine block heater power cable, if

equipped.

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(11) Install the structural cover.

NOTE: New clamps must be used on exhaust man-

ifold flanges. Failure to use new clamps may result

in exhaust leaks.

(12) Install the left and right exhaust pipes.

(13) Connect the left and right oxygen sensors.

(14) Lower vehicle.

(15) Remove the engine lift plate.

(16) Connect the knock sensors.

(17) Connect the engine to body ground straps at

the left side of the cowl.

(18) Install the intake manifold.

(19) Install the engine oil dipstick tube.

(20) Install the power brake booster vacuum hose.

(21) Install the breather hoses.

(22) Install the PCV hose.

(23) Install the fuel rail.

(24) Install the coil over plugs.

(25) Connect the engine wiring harness at the fol-

lowing points:

²Intake air temperature (IAT) sensor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

²Crankshaft Position Sensor

(26) Connect lower radiator hose.

(27) Connect upper radiator hose.

(28) Connect throttle and speed control cables.

(29) Install the heater hose assembly.

(30) Install coolant recovery bottle.

(31) Install the power steering pump.

(32) Install the generator.

(33) Install the A/C compressor.

(34) Install the drive belt.

KJENGINE - 3.7L 9 - 11

ENGINE - 3.7L (Continued)

Page 1235 of 1803

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50±70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the left side

exhaust manifold.

(4) Drain the engine coolant. Refer to COOLING

SYSTEM.

(5) Lower the vehicle.

(6) Remove the intake manifold. Refer to proce-

dure in this section.

(7) Remove the cylinder head cover. Refer to proce-

dure in this section.

(8) Remove the fan shroud and fan blade assembly.

Refer to COOLING SYSTEM.

(9) Remove accessory drive belt. Refer to COOL-

ING SYSTEM.

(10) Remove the power steering pump and set

aside.

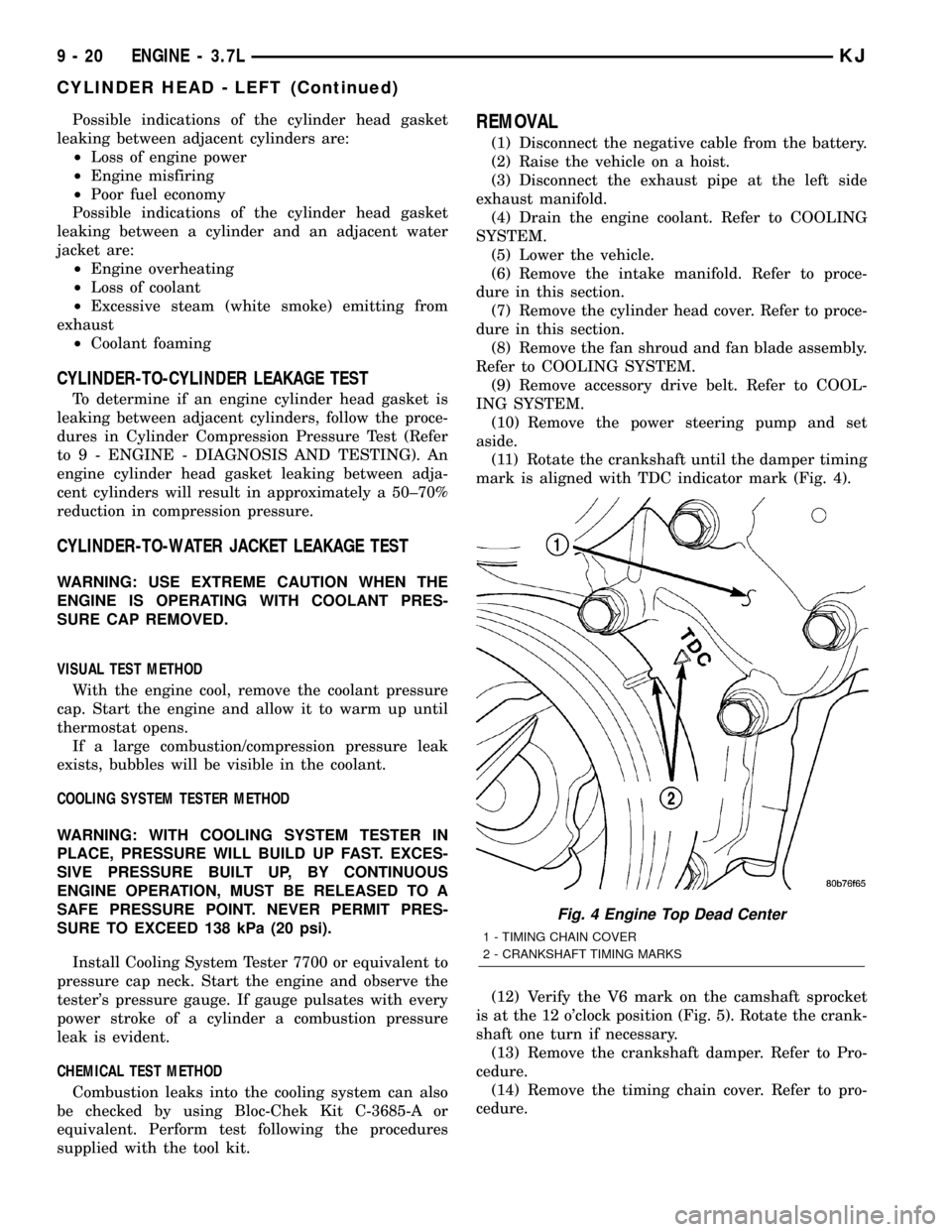

(11) Rotate the crankshaft until the damper timing

mark is aligned with TDC indicator mark (Fig. 4).

(12) Verify the V6 mark on the camshaft sprocket

is at the 12 o'clock position (Fig. 5). Rotate the crank-

shaft one turn if necessary.

(13) Remove the crankshaft damper. Refer to Pro-

cedure.

(14) Remove the timing chain cover. Refer to pro-

cedure.

Fig. 4 Engine Top Dead Center

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

9 - 20 ENGINE - 3.7LKJ

CYLINDER HEAD - LEFT (Continued)

Page 1246 of 1803

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise the vehicle on a hoist.

(3) Disconnect the exhaust pipe at the right side

exhaust manifold.

(4) Drain the engine coolant. Refer to COOLING

SYSTEM.

(5) Lower the vehicle.

(6) Remove the intake manifold. Refer to proce-

dure.

(7) Remove the cylinder head cover. Refer to proce-

dure.

(8) Remove the fan shroud. Refer to COOLING

SYSTEM.

(9) Remove oil fill housing from cylinder head.

(10) Remove accessory drive belt. Refer to COOL-

ING SYSTEM.

(11) Rotate the crankshaft until the damper timing

mark is aligned with TDC indicator mark.

(12) Verify the V6 mark on the camshaft sprocket

is at the 12 o'clock position. Rotate the crankshaft

one turn if necessary.

(13) Remove the crankshaft damper. Refer to pro-

cedure.

(14) Remove the timing chain cover. Refer to pro-

cedure.

(15) Lock the secondary timing chains to the idler

sprocket using Special Tool 8429 Timing Chain Hold-

ing Fixture.NOTE: Mark the secondary timing chain prior to

removal to aid in installation.

(16) Mark the secondary timing chain, one link on

each side of the V6 mark on the camshaft drive gear.

(17) Remove the right side secondary chain ten-

sioner. Refer to Timing Chain and Sprockets in this

section.

(18) Remove the cylinder head access plug.

(19) Remove the right side secondary chain guide.

Refer to Timing Chain and Sprockets in this section.

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason, as

the sprocket and camshaft sensor target wheel is

serviced as an assembly. If the nut was removed

retorque nut to 5 N´m (44 in. lbs.).

(20) Remove the retaining bolt and the camshaft

drive gear.

CAUTION: Do not allow the engine to rotate. severe

damage to the valve train can occur.

CAUTION: Do not overlook the four smaller bolts at

the front of the cylinder head. Do not attempt to

remove the cylinder head without removing these

four bolts.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason. A damaged target wheel

can result in a vehicle no start condition.

NOTE: The cylinder head is attached to the cylinder

block with twelve bolts.

(21) Remove the cylinder head retaining bolts.

(22) Remove the cylinder head and gasket. Discard

the gasket.

CAUTION: Do not lay the cylinder head on its gas-

ket sealing surface, do to the design of the cylinder

head gasket any distortion to the cylinder head

sealing surface may prevent the gasket from prop-

erly sealing resulting in leaks.

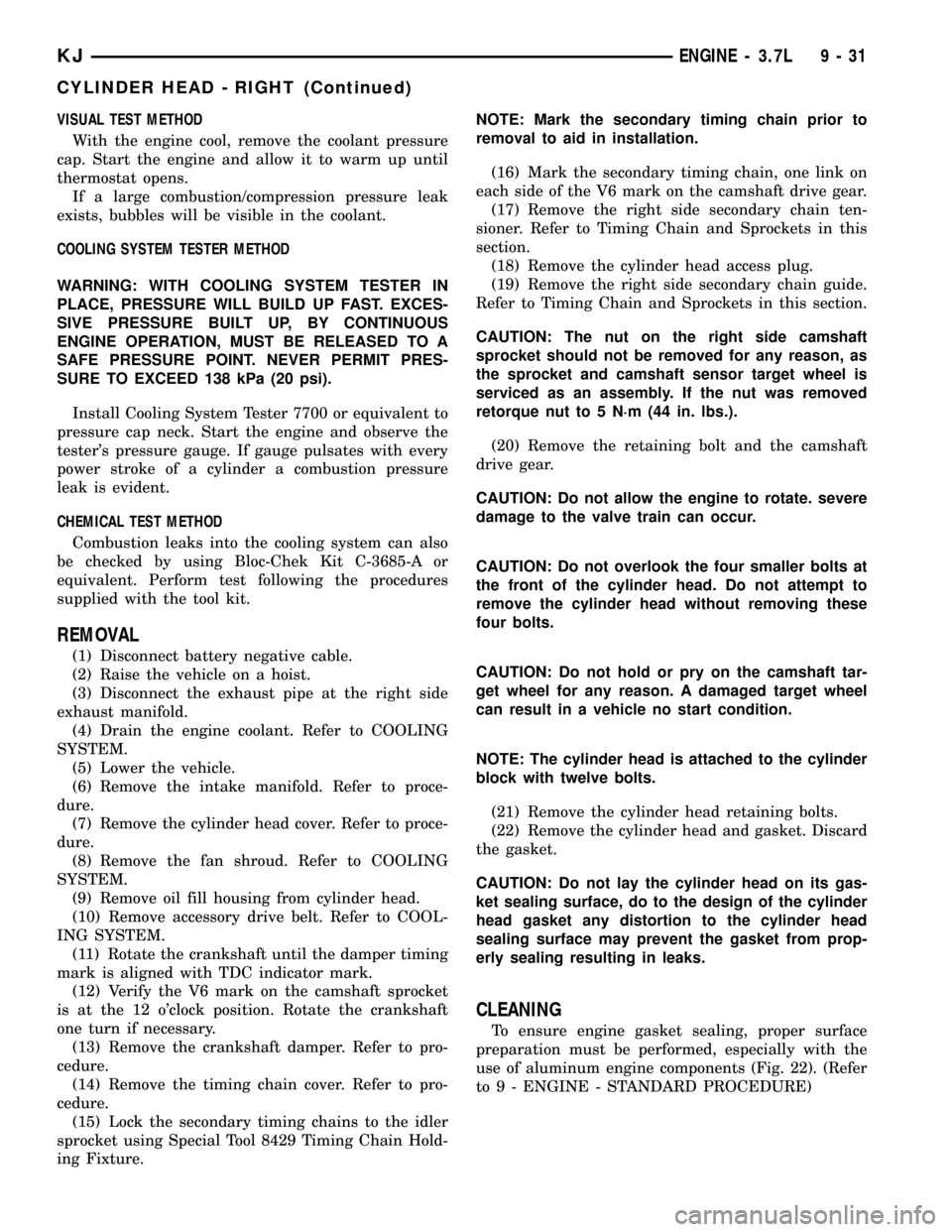

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components (Fig. 22). (Refer

to 9 - ENGINE - STANDARD PROCEDURE)

KJENGINE - 3.7L 9 - 31

CYLINDER HEAD - RIGHT (Continued)

Page 1247 of 1803

INSPECTION

(1) Inspect the cylinder head for out-of-flatness,

using a straightedge and a feeler gauge. If measure-

ments exceed 0.0508 mm (0.002 in.) replace the cyl-

inder head.

(2) Inspect the valve seats for damage. Service the

valve seats as necessary.

(3) Inspect the valve guides for wear, cracks or

looseness. If either condition exist, replace the cylin-

der head.

INSTALLATION

NOTE: The cylinder head bolts are tightened using

a torque plus angle procedure. The bolts must be

examined BEFORE reuse. If the threads are necked

down the bolts should be replaced.

Necking can be checked by holding a straight edge

against the threads. If all the threads do not contact

the scale, the bolt should be replaced.

CAUTION: When cleaning cylinder head and cylin-

der block surfaces, DO NOT use a metal scraper

because the surfaces could be cut or ground. Use

only a wooden or plastic scraper.

(1) Clean the cylinder head and cylinder block

mating surfaces.

(2) Position the new cylinder head gasket on the

locating dowels.CAUTION: When installing cylinder head, use care

not damage the tensioner arm or the guide arm.

(3) Position the cylinder head onto the cylinder

block. Make sure the cylinder head seats fully over

the locating dowels.

NOTE: The four M8 cylinder head mounting bolts

require sealant to be added to them before install-

ing. Failure to do so may cause leaks. Do not reuse

the old M8 bolts, use new M8 bolts.

(4) Lubricate the cylinder head bolt threads with

clean engine oil and install the eight M10 bolts.

(5) Coat the four M8 cylinder head bolts with

Mopar Lock and Seal Adhesivethen install the

bolts.

The cylinder head bolts are tightened using an

angle torque procedure, however, the bolts are not a

torque-to-yield design.

(6) Tighten the bolts in sequence using the follow-

ing steps and torque values:

²Step 1: Tighten bolts 1±10, 20 N´m (15 ft. lbs.).

²Step 2: Tighten bolts 1±10, 47 N´m (35 ft. lbs.).

Tighten bolts 11±14, 25 N´m (18 ft. lbs.).

²Step 3: Tighten bolts 1±10, 90 degrees. Tighten

bolts 11±14, 30 N´m (22 ft. lbs.).

CAUTION: The nut on the right side camshaft

sprocket should not be removed for any reason, as

the sprocket and camshaft sensor target wheel is

serviced as an assembly. If the nut was removed

retorque nut to 5 N´m (44 in. lbs.).

(7) Position the secondary chain onto the camshaft

drive gear, making sure one marked chain link is on

either side of the V6 mark on the gear then using

Special Tool 8428 Camshaft Wrench, position the

gear onto the camshaft.

CAUTION: Remove excess oil from camshaft

sprocket retaining bolt before reinstalling bolt. Fail-

ure to do so may cause over-torquing of bolt result-

ing in bolt failure.

(8) Install the camshaft drive gear retaining bolt.

(9) Install the right side secondary chain guide.

(10) Install the cylinder head access plug.

(11) Re-set and install the right side secondary

chain tensioner.

(12) Remove Special Tool 8429.

(13) Install the timing chain cover.

(14) Install the crankshaft damper.Tighten damper

bolt 175 N´m (130 Ft. Lbs.).

(15) Install accessory drive belt.

(16) Install the fan shroud.

(17) Install the cylinder head cover.

(18) Install the intake manifold.

Fig. 22 Proper Tool Usage For Surface Preparation

1 - PLASTIC/WOOD SCRAPER

9 - 32 ENGINE - 3.7LKJ

CYLINDER HEAD - RIGHT (Continued)

Page 1249 of 1803

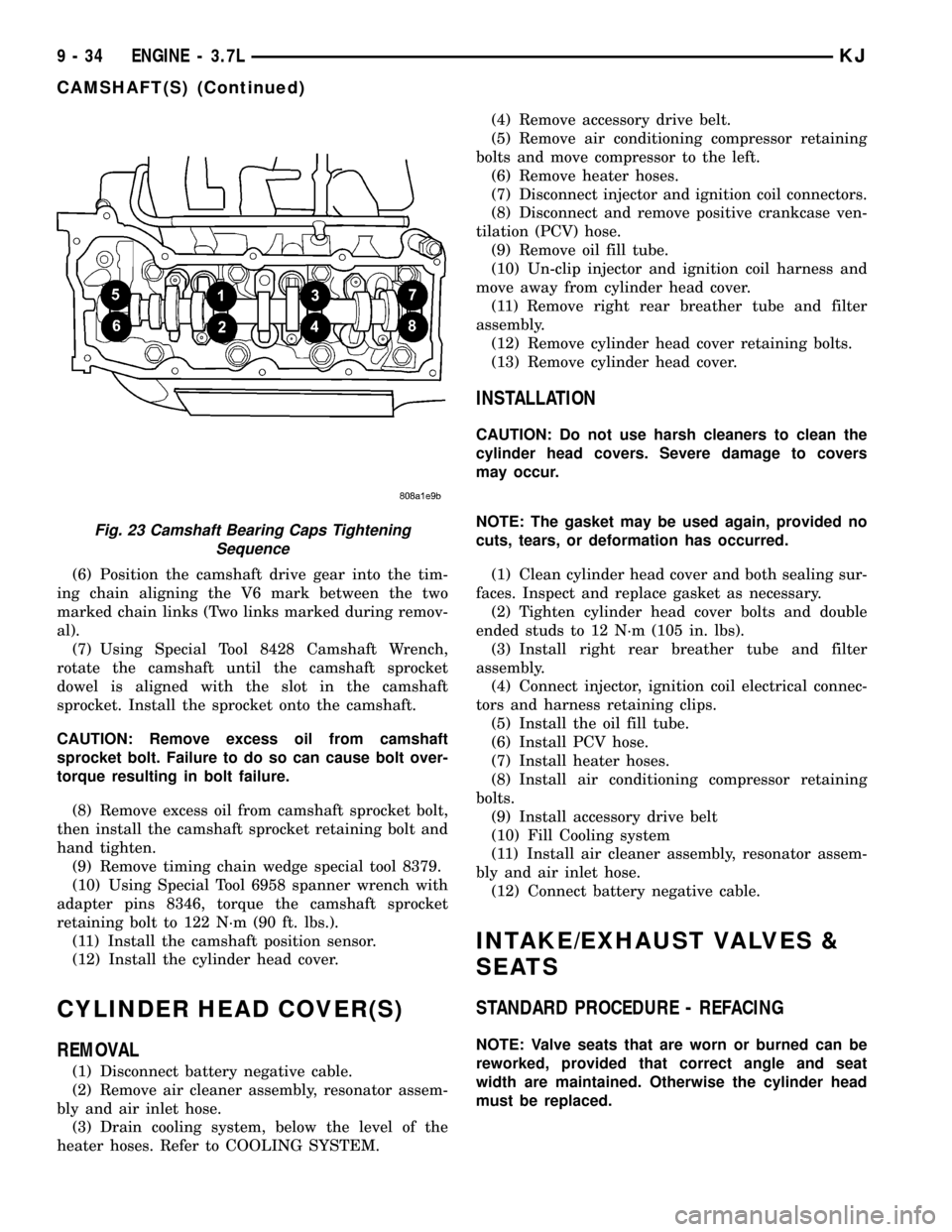

(6) Position the camshaft drive gear into the tim-

ing chain aligning the V6 mark between the two

marked chain links (Two links marked during remov-

al).

(7) Using Special Tool 8428 Camshaft Wrench,

rotate the camshaft until the camshaft sprocket

dowel is aligned with the slot in the camshaft

sprocket. Install the sprocket onto the camshaft.

CAUTION: Remove excess oil from camshaft

sprocket bolt. Failure to do so can cause bolt over-

torque resulting in bolt failure.

(8) Remove excess oil from camshaft sprocket bolt,

then install the camshaft sprocket retaining bolt and

hand tighten.

(9) Remove timing chain wedge special tool 8379.

(10) Using Special Tool 6958 spanner wrench with

adapter pins 8346, torque the camshaft sprocket

retaining bolt to 122 N´m (90 ft. lbs.).

(11) Install the camshaft position sensor.

(12) Install the cylinder head cover.

CYLINDER HEAD COVER(S)

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove air cleaner assembly, resonator assem-

bly and air inlet hose.

(3) Drain cooling system, below the level of the

heater hoses. Refer to COOLING SYSTEM.(4) Remove accessory drive belt.

(5) Remove air conditioning compressor retaining

bolts and move compressor to the left.

(6) Remove heater hoses.

(7) Disconnect injector and ignition coil connectors.

(8) Disconnect and remove positive crankcase ven-

tilation (PCV) hose.

(9) Remove oil fill tube.

(10) Un-clip injector and ignition coil harness and

move away from cylinder head cover.

(11) Remove right rear breather tube and filter

assembly.

(12) Remove cylinder head cover retaining bolts.

(13) Remove cylinder head cover.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs).

(3) Install right rear breather tube and filter

assembly.

(4) Connect injector, ignition coil electrical connec-

tors and harness retaining clips.

(5) Install the oil fill tube.

(6) Install PCV hose.

(7) Install heater hoses.

(8) Install air conditioning compressor retaining

bolts.

(9) Install accessory drive belt

(10) Fill Cooling system

(11) Install air cleaner assembly, resonator assem-

bly and air inlet hose.

(12) Connect battery negative cable.

INTAKE/EXHAUST VALVES &

SEATS

STANDARD PROCEDURE - REFACING

NOTE: Valve seats that are worn or burned can be

reworked, provided that correct angle and seat

width are maintained. Otherwise the cylinder head

must be replaced.

Fig. 23 Camshaft Bearing Caps Tightening

Sequence

9 - 34 ENGINE - 3.7LKJ

CAMSHAFT(S) (Continued)

Page 1261 of 1803

MAIN BEARING JOURNAL DIAMETER

(CRANKSHAFT REMOVED)

Remove the crankshaft from the cylinder block.

Refer to CRANKSHAFT.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper is 0.008mm (0.0004

inch.) and maximum out of round is 0.005mm (0.002

inch). Compare the measured diameter with the jour-

nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

Install the crankshaft into the cylinder block. Refer

to CRANKSHAFT.

Check crankshaft end play. Refer to CHECKING

CRANKSHAFT END PLAY.

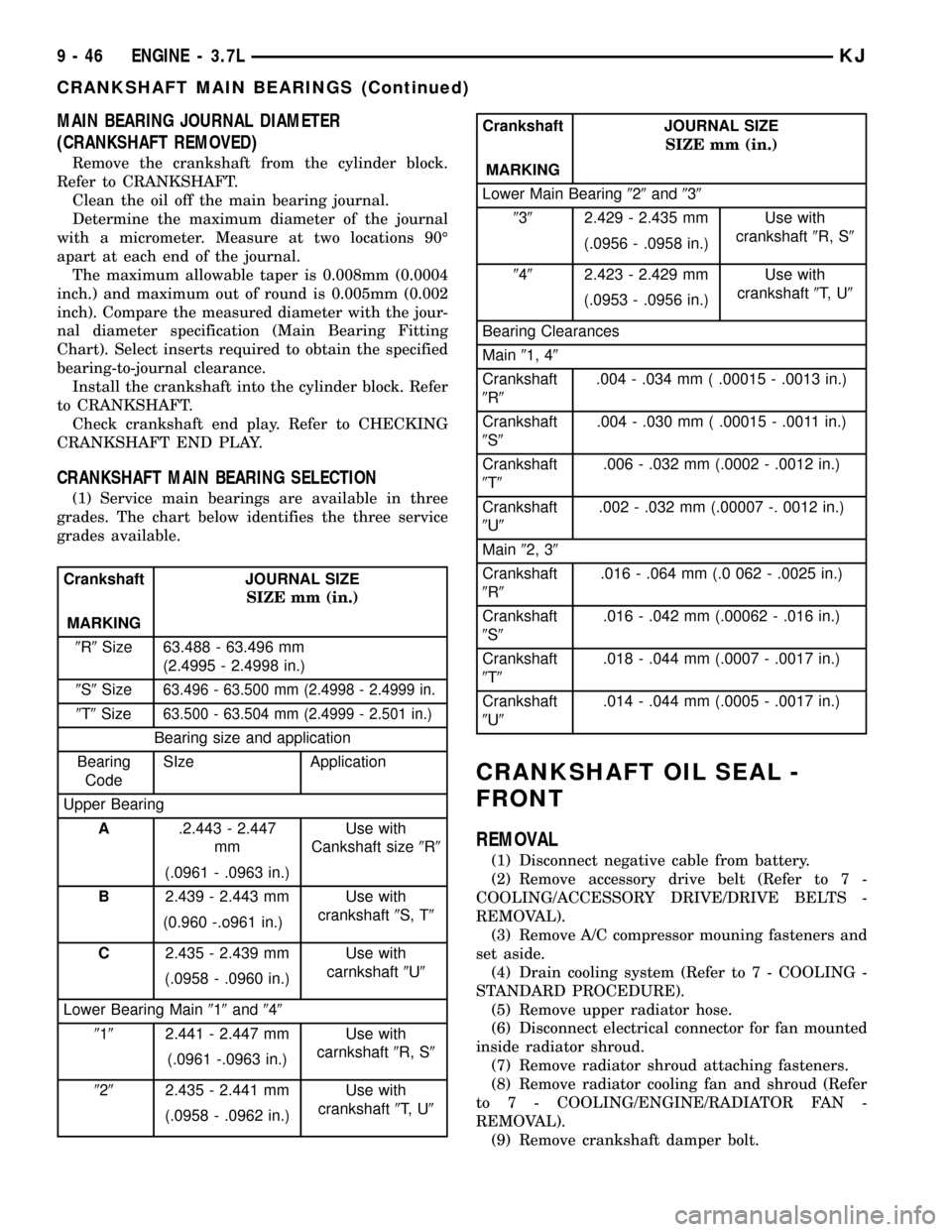

CRANKSHAFT MAIN BEARING SELECTION

(1) Service main bearings are available in three

grades. The chart below identifies the three service

grades available.

Crankshaft JOURNAL SIZE

SIZE mm (in.)

MARKING

9R9Size 63.488 - 63.496 mm

(2.4995 - 2.4998 in.)

9S9Size

63.496 - 63.500 mm (2.4998 - 2.4999 in.

9T9Size63.500 - 63.504 mm (2.4999 - 2.501 in.)

Bearing size and application

Bearing

CodeSIze Application

Upper Bearing

A.2.443 - 2.447

mmUse with

Cankshaft size9R9

(.0961 - .0963 in.)

B2.439 - 2.443 mm Use with

crankshaft9S, T9

(0.960 -.o961 in.)

C2.435 - 2.439 mm Use with

carnkshaft9U9

(.0958 - .0960 in.)

Lower Bearing Main919and949

9192.441 - 2.447 mm Use with

carnkshaft9R, S9

(.0961 -.0963 in.)

9292.435 - 2.441 mm Use with

crankshaft9T, U9

(.0958 - .0962 in.)

Crankshaft JOURNAL SIZE

SIZE mm (in.)

MARKING

Lower Main Bearing929and939

9392.429 - 2.435 mm Use with

crankshaft9R, S9

(.0956 - .0958 in.)

9492.423 - 2.429 mm Use with

crankshaft9T, U9

(.0953 - .0956 in.)

Bearing Clearances

Main91, 49

Crankshaft

9R9.004 - .034 mm ( .00015 - .0013 in.)

Crankshaft

9S9.004 - .030 mm ( .00015 - .0011 in.)

Crankshaft

9T9.006 - .032 mm (.0002 - .0012 in.)

Crankshaft

9U9.002 - .032 mm (.00007 -. 0012 in.)

Main92, 39

Crankshaft

9R9.016 - .064 mm (.0 062 - .0025 in.)

Crankshaft

9S9.016 - .042 mm (.00062 - .016 in.)

Crankshaft

9T9.018 - .044 mm (.0007 - .0017 in.)

Crankshaft

9U9.014 - .044 mm (.0005 - .0017 in.)

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(3) Remove A/C compressor mouning fasteners and

set aside.

(4) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(5) Remove upper radiator hose.

(6) Disconnect electrical connector for fan mounted

inside radiator shroud.

(7) Remove radiator shroud attaching fasteners.

(8) Remove radiator cooling fan and shroud (Refer

to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

(9) Remove crankshaft damper bolt.

9 - 46 ENGINE - 3.7LKJ

CRANKSHAFT MAIN BEARINGS (Continued)