ECU JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 46 of 1803

LOWER BALL JOINT

REMOVAL

(1) Remove the tire and wheel assembly.

(2) Remove the brake caliper and rotor (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

REMOVAL).

(3) Disconnect the tie rod from the steering

knuckle (Refer to 19 - STEERING/LINKAGE/TIE

ROD END - REMOVAL).

(4) Remove the steering knuckle (Refer to 2 - SUS-

PENSION/FRONT/KNUCKLE - REMOVAL).

(5) Move the halfshaft to the side and support the

halfshaft out of the way (If Equipped).

NOTE: Extreme pressure lubrication must be used

on the threaded portions of the tool. This will

increase the longevity of the tool and insure proper

operation during the removal and installation pro-

cess.

(6) Secure the steering knuckle in a vise.

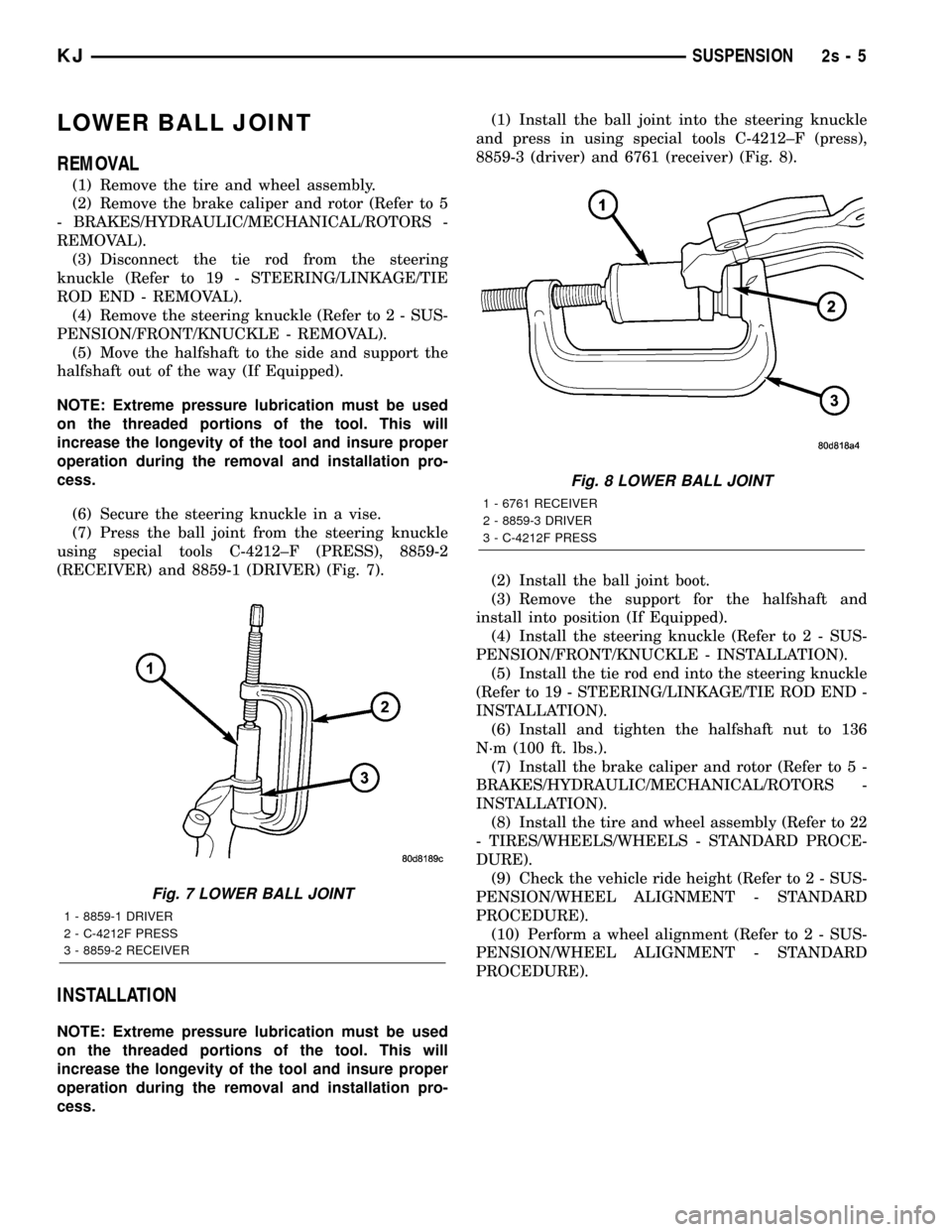

(7) Press the ball joint from the steering knuckle

using special tools C-4212±F (PRESS), 8859-2

(RECEIVER) and 8859-1 (DRIVER) (Fig. 7).

INSTALLATION

NOTE: Extreme pressure lubrication must be used

on the threaded portions of the tool. This will

increase the longevity of the tool and insure proper

operation during the removal and installation pro-

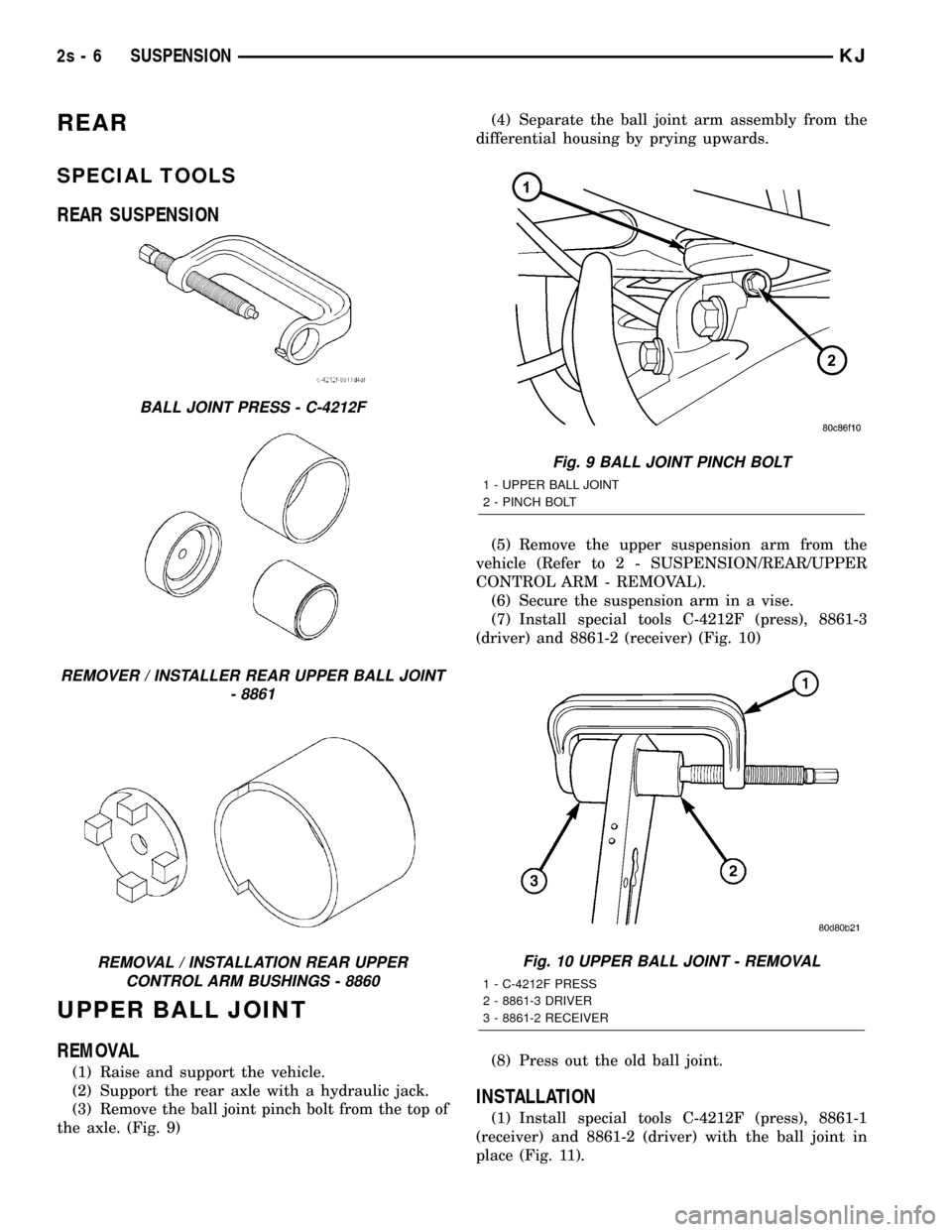

cess.(1) Install the ball joint into the steering knuckle

and press in using special tools C-4212±F (press),

8859-3 (driver) and 6761 (receiver) (Fig. 8).

(2) Install the ball joint boot.

(3) Remove the support for the halfshaft and

install into position (If Equipped).

(4) Install the steering knuckle (Refer to 2 - SUS-

PENSION/FRONT/KNUCKLE - INSTALLATION).

(5) Install the tie rod end into the steering knuckle

(Refer to 19 - STEERING/LINKAGE/TIE ROD END -

INSTALLATION).

(6) Install and tighten the halfshaft nut to 136

N´m (100 ft. lbs.).

(7) Install the brake caliper and rotor (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ROTORS -

INSTALLATION).

(8) Install the tire and wheel assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(9) Check the vehicle ride height (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

(10) Perform a wheel alignment (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE).

Fig. 7 LOWER BALL JOINT

1 - 8859-1 DRIVER

2 - C-4212F PRESS

3 - 8859-2 RECEIVER

Fig. 8 LOWER BALL JOINT

1 - 6761 RECEIVER

2 - 8859-3 DRIVER

3 - C-4212F PRESS

KJSUSPENSION 2s - 5

Page 47 of 1803

REAR

SPECIAL TOOLS

REAR SUSPENSION

UPPER BALL JOINT

REMOVAL

(1) Raise and support the vehicle.

(2) Support the rear axle with a hydraulic jack.

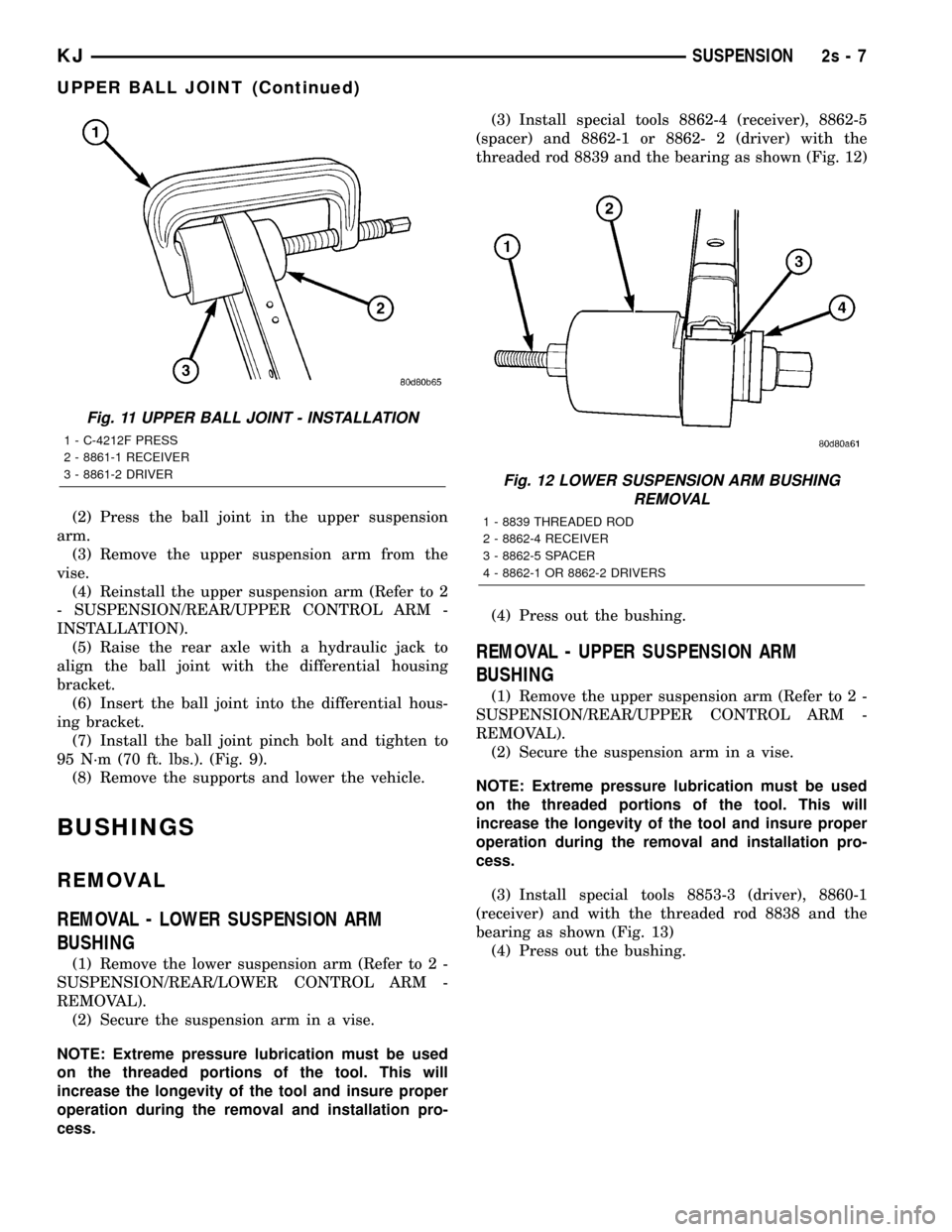

(3) Remove the ball joint pinch bolt from the top of

the axle. (Fig. 9)(4) Separate the ball joint arm assembly from the

differential housing by prying upwards.

(5) Remove the upper suspension arm from the

vehicle (Refer to 2 - SUSPENSION/REAR/UPPER

CONTROL ARM - REMOVAL).

(6) Secure the suspension arm in a vise.

(7) Install special tools C-4212F (press), 8861-3

(driver) and 8861-2 (receiver) (Fig. 10)

(8) Press out the old ball joint.

INSTALLATION

(1) Install special tools C-4212F (press), 8861-1

(receiver) and 8861-2 (driver) with the ball joint in

place (Fig. 11).

BALL JOINT PRESS - C-4212F

REMOVER / INSTALLER REAR UPPER BALL JOINT

- 8861

REMOVAL / INSTALLATION REAR UPPER

CONTROL ARM BUSHINGS - 8860

Fig. 9 BALL JOINT PINCH BOLT

1 - UPPER BALL JOINT

2 - PINCH BOLT

Fig. 10 UPPER BALL JOINT - REMOVAL

1 - C-4212F PRESS

2 - 8861-3 DRIVER

3 - 8861-2 RECEIVER

2s - 6 SUSPENSIONKJ

Page 48 of 1803

(2) Press the ball joint in the upper suspension

arm.

(3) Remove the upper suspension arm from the

vise.

(4) Reinstall the upper suspension arm (Refer to 2

- SUSPENSION/REAR/UPPER CONTROL ARM -

INSTALLATION).

(5) Raise the rear axle with a hydraulic jack to

align the ball joint with the differential housing

bracket.

(6) Insert the ball joint into the differential hous-

ing bracket.

(7) Install the ball joint pinch bolt and tighten to

95 N´m (70 ft. lbs.). (Fig. 9).

(8) Remove the supports and lower the vehicle.

BUSHINGS

REMOVAL

REMOVAL - LOWER SUSPENSION ARM

BUSHING

(1) Remove the lower suspension arm (Refer to 2 -

SUSPENSION/REAR/LOWER CONTROL ARM -

REMOVAL).

(2) Secure the suspension arm in a vise.

NOTE: Extreme pressure lubrication must be used

on the threaded portions of the tool. This will

increase the longevity of the tool and insure proper

operation during the removal and installation pro-

cess.(3) Install special tools 8862-4 (receiver), 8862-5

(spacer) and 8862-1 or 8862- 2 (driver) with the

threaded rod 8839 and the bearing as shown (Fig. 12)

(4) Press out the bushing.

REMOVAL - UPPER SUSPENSION ARM

BUSHING

(1) Remove the upper suspension arm (Refer to 2 -

SUSPENSION/REAR/UPPER CONTROL ARM -

REMOVAL).

(2) Secure the suspension arm in a vise.

NOTE: Extreme pressure lubrication must be used

on the threaded portions of the tool. This will

increase the longevity of the tool and insure proper

operation during the removal and installation pro-

cess.

(3) Install special tools 8853-3 (driver), 8860-1

(receiver) and with the threaded rod 8838 and the

bearing as shown (Fig. 13)

(4) Press out the bushing.

Fig. 11 UPPER BALL JOINT - INSTALLATION

1 - C-4212F PRESS

2 - 8861-1 RECEIVER

3 - 8861-2 DRIVER

Fig. 12 LOWER SUSPENSION ARM BUSHING

REMOVAL

1 - 8839 THREADED ROD

2 - 8862-4 RECEIVER

3 - 8862-5 SPACER

4 - 8862-1 OR 8862-2 DRIVERS

KJSUSPENSION 2s - 7

UPPER BALL JOINT (Continued)

Page 64 of 1803

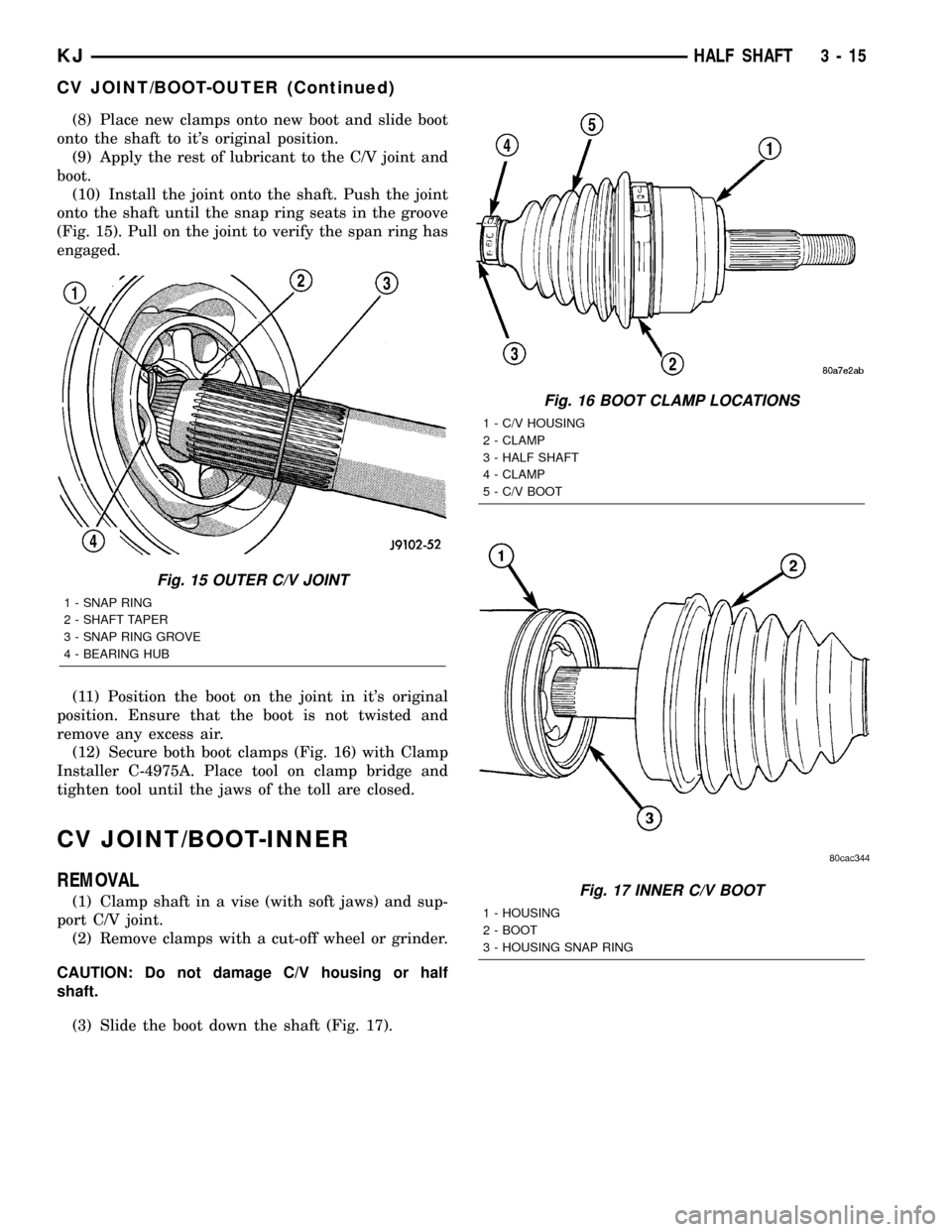

(8) Place new clamps onto new boot and slide boot

onto the shaft to it's original position.

(9) Apply the rest of lubricant to the C/V joint and

boot.

(10) Install the joint onto the shaft. Push the joint

onto the shaft until the snap ring seats in the groove

(Fig. 15). Pull on the joint to verify the span ring has

engaged.

(11) Position the boot on the joint in it's original

position. Ensure that the boot is not twisted and

remove any excess air.

(12) Secure both boot clamps (Fig. 16) with Clamp

Installer C-4975A. Place tool on clamp bridge and

tighten tool until the jaws of the toll are closed.

CV JOINT/BOOT-INNER

REMOVAL

(1) Clamp shaft in a vise (with soft jaws) and sup-

port C/V joint.

(2) Remove clamps with a cut-off wheel or grinder.

CAUTION: Do not damage C/V housing or half

shaft.

(3) Slide the boot down the shaft (Fig. 17).

Fig. 15 OUTER C/V JOINT

1 - SNAP RING

2 - SHAFT TAPER

3 - SNAP RING GROVE

4 - BEARING HUB

Fig. 16 BOOT CLAMP LOCATIONS

1 - C/V HOUSING

2 - CLAMP

3 - HALF SHAFT

4 - CLAMP

5 - C/V BOOT

Fig. 17 INNER C/V BOOT

1 - HOUSING

2 - BOOT

3 - HOUSING SNAP RING

KJHALF SHAFT 3 - 15

CV JOINT/BOOT-OUTER (Continued)

Page 67 of 1803

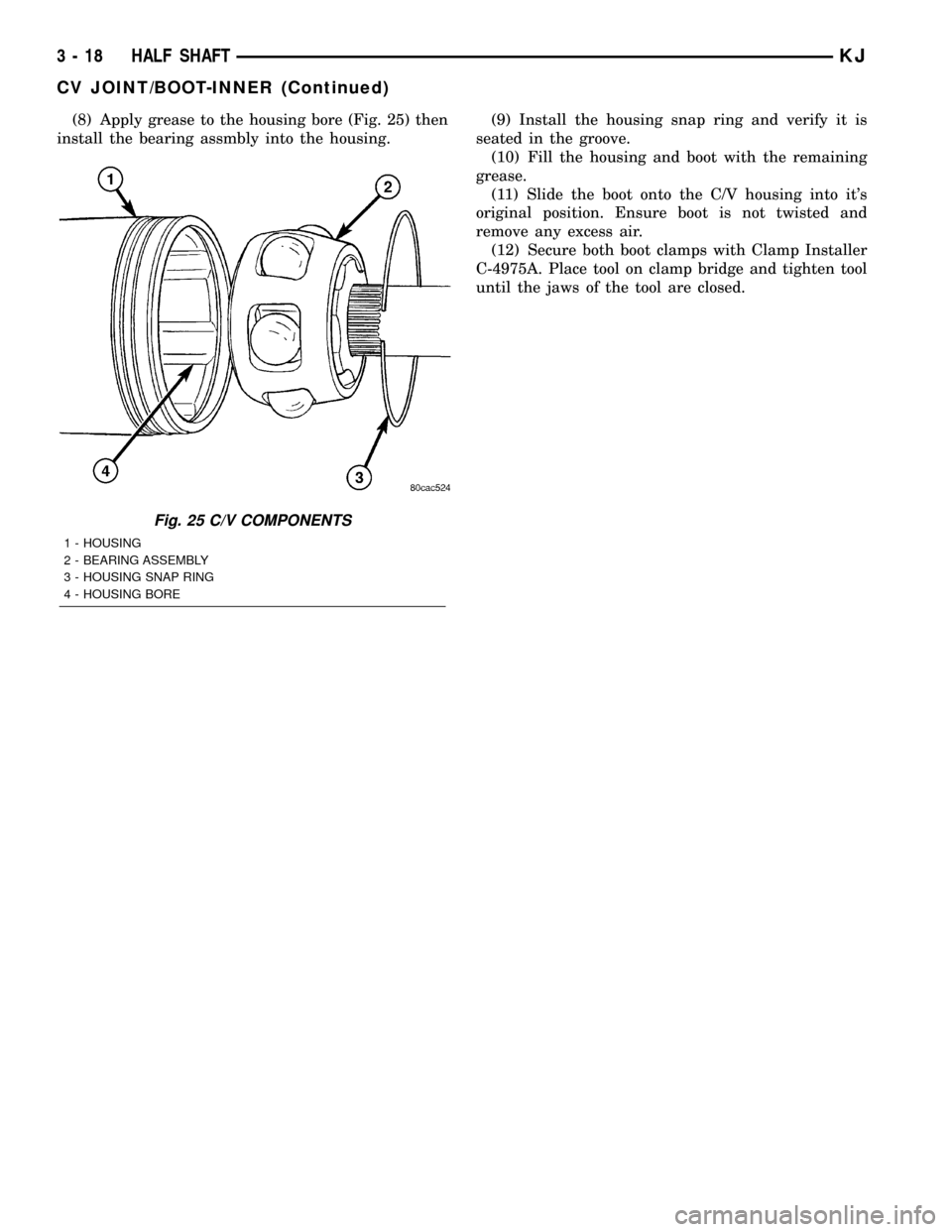

(8) Apply grease to the housing bore (Fig. 25) then

install the bearing assmbly into the housing.(9) Install the housing snap ring and verify it is

seated in the groove.

(10) Fill the housing and boot with the remaining

grease.

(11) Slide the boot onto the C/V housing into it's

original position. Ensure boot is not twisted and

remove any excess air.

(12) Secure both boot clamps with Clamp Installer

C-4975A. Place tool on clamp bridge and tighten tool

until the jaws of the tool are closed.

Fig. 25 C/V COMPONENTS

1 - HOUSING

2 - BEARING ASSEMBLY

3 - HOUSING SNAP RING

4 - HOUSING BORE

3 - 18 HALF SHAFTKJ

CV JOINT/BOOT-INNER (Continued)

Page 76 of 1803

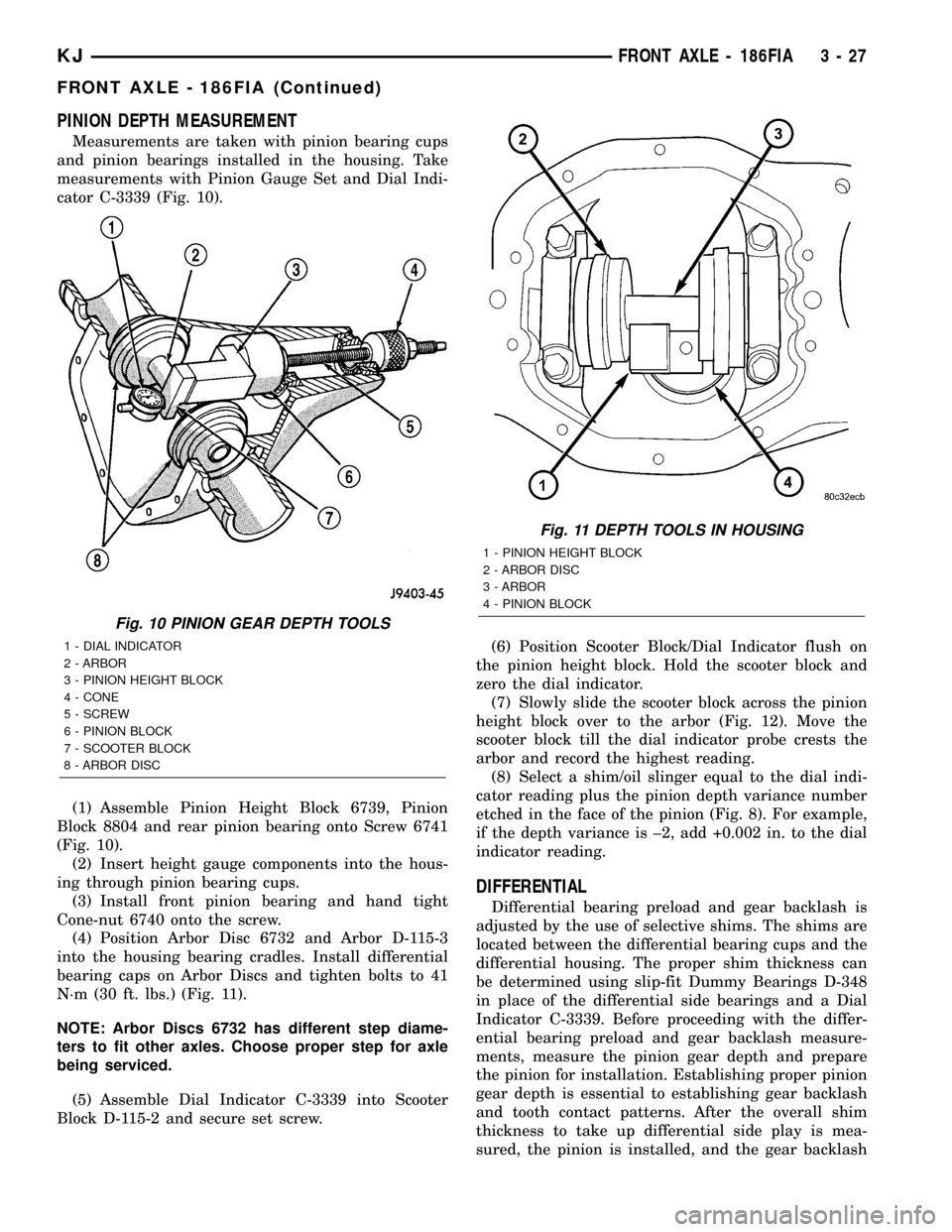

PINION DEPTH MEASUREMENT

Measurements are taken with pinion bearing cups

and pinion bearings installed in the housing. Take

measurements with Pinion Gauge Set and Dial Indi-

cator C-3339 (Fig. 10).

(1) Assemble Pinion Height Block 6739, Pinion

Block 8804 and rear pinion bearing onto Screw 6741

(Fig. 10).

(2) Insert height gauge components into the hous-

ing through pinion bearing cups.

(3) Install front pinion bearing and hand tight

Cone-nut 6740 onto the screw.

(4) Position Arbor Disc 6732 and Arbor D-115-3

into the housing bearing cradles. Install differential

bearing caps on Arbor Discs and tighten bolts to 41

N´m (30 ft. lbs.) (Fig. 11).

NOTE: Arbor Discs 6732 has different step diame-

ters to fit other axles. Choose proper step for axle

being serviced.

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.(6) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold the scooter block and

zero the dial indicator.

(7) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 12). Move the

scooter block till the dial indicator probe crests the

arbor and record the highest reading.

(8) Select a shim/oil slinger equal to the dial indi-

cator reading plus the pinion depth variance number

etched in the face of the pinion (Fig. 8). For example,

if the depth variance is ±2, add +0.002 in. to the dial

indicator reading.

DIFFERENTIAL

Differential bearing preload and gear backlash is

adjusted by the use of selective shims. The shims are

located between the differential bearing cups and the

differential housing. The proper shim thickness can

be determined using slip-fit Dummy Bearings D-348

in place of the differential side bearings and a Dial

Indicator C-3339. Before proceeding with the differ-

ential bearing preload and gear backlash measure-

ments, measure the pinion gear depth and prepare

the pinion for installation. Establishing proper pinion

gear depth is essential to establishing gear backlash

and tooth contact patterns. After the overall shim

thickness to take up differential side play is mea-

sured, the pinion is installed, and the gear backlash

Fig. 10 PINION GEAR DEPTH TOOLS

1 - DIAL INDICATOR

2 - ARBOR

3 - PINION HEIGHT BLOCK

4 - CONE

5 - SCREW

6 - PINION BLOCK

7 - SCOOTER BLOCK

8 - ARBOR DISC

Fig. 11 DEPTH TOOLS IN HOUSING

1 - PINION HEIGHT BLOCK

2 - ARBOR DISC

3 - ARBOR

4 - PINION BLOCK

KJFRONT AXLE - 186FIA 3 - 27

FRONT AXLE - 186FIA (Continued)

Page 103 of 1803

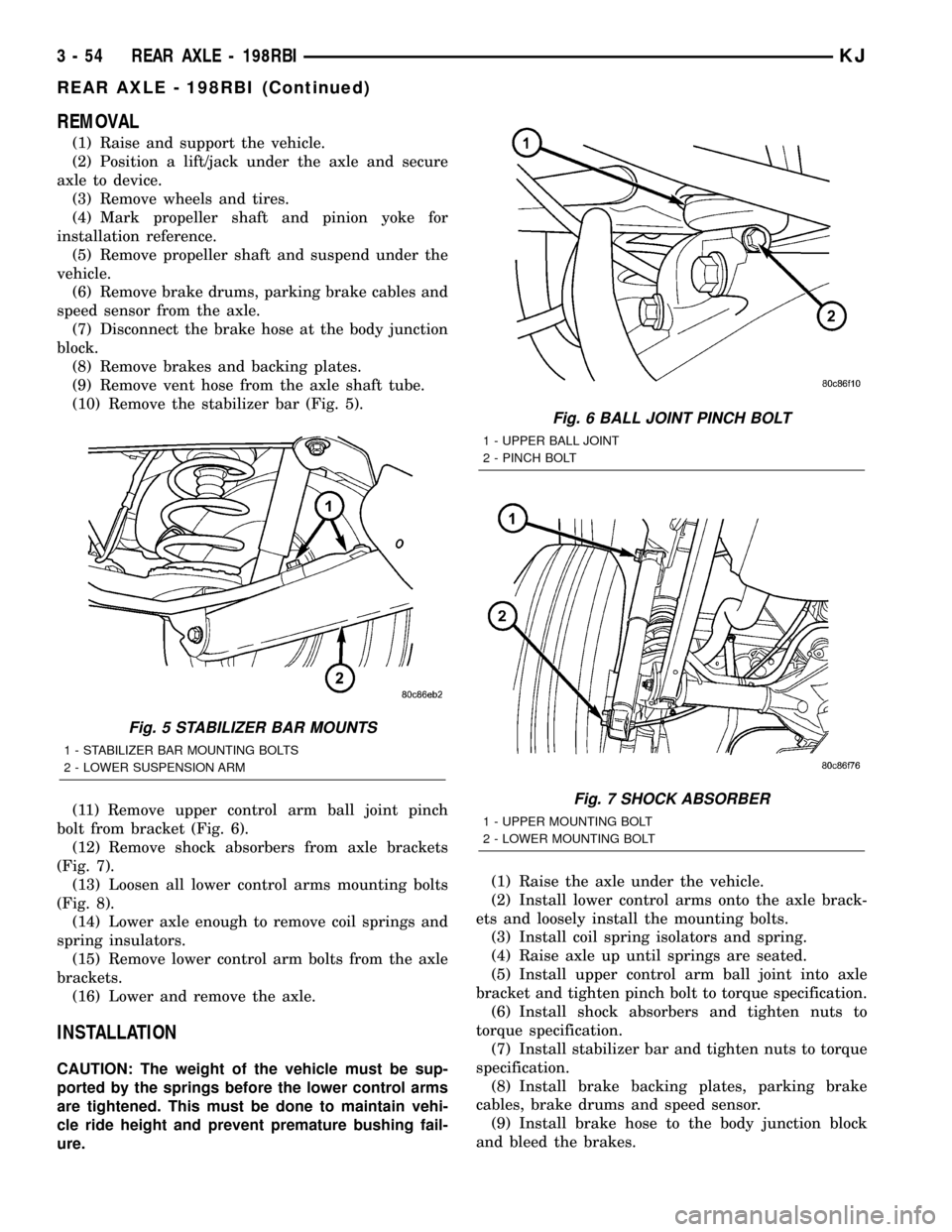

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lift/jack under the axle and secure

axle to device.

(3) Remove wheels and tires.

(4) Mark propeller shaft and pinion yoke for

installation reference.

(5) Remove propeller shaft and suspend under the

vehicle.

(6) Remove brake drums, parking brake cables and

speed sensor from the axle.

(7) Disconnect the brake hose at the body junction

block.

(8) Remove brakes and backing plates.

(9) Remove vent hose from the axle shaft tube.

(10) Remove the stabilizer bar (Fig. 5).

(11) Remove upper control arm ball joint pinch

bolt from bracket (Fig. 6).

(12) Remove shock absorbers from axle brackets

(Fig. 7).

(13) Loosen all lower control arms mounting bolts

(Fig. 8).

(14) Lower axle enough to remove coil springs and

spring insulators.

(15) Remove lower control arm bolts from the axle

brackets.

(16) Lower and remove the axle.

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before the lower control arms

are tightened. This must be done to maintain vehi-

cle ride height and prevent premature bushing fail-

ure.(1) Raise the axle under the vehicle.

(2) Install lower control arms onto the axle brack-

ets and loosely install the mounting bolts.

(3) Install coil spring isolators and spring.

(4) Raise axle up until springs are seated.

(5) Install upper control arm ball joint into axle

bracket and tighten pinch bolt to torque specification.

(6) Install shock absorbers and tighten nuts to

torque specification.

(7) Install stabilizer bar and tighten nuts to torque

specification.

(8) Install brake backing plates, parking brake

cables, brake drums and speed sensor.

(9) Install brake hose to the body junction block

and bleed the brakes.

Fig. 5 STABILIZER BAR MOUNTS

1 - STABILIZER BAR MOUNTING BOLTS

2 - LOWER SUSPENSION ARM

Fig. 6 BALL JOINT PINCH BOLT

1 - UPPER BALL JOINT

2 - PINCH BOLT

Fig. 7 SHOCK ABSORBER

1 - UPPER MOUNTING BOLT

2 - LOWER MOUNTING BOLT

3 - 54 REAR AXLE - 198RBIKJ

REAR AXLE - 198RBI (Continued)

Page 106 of 1803

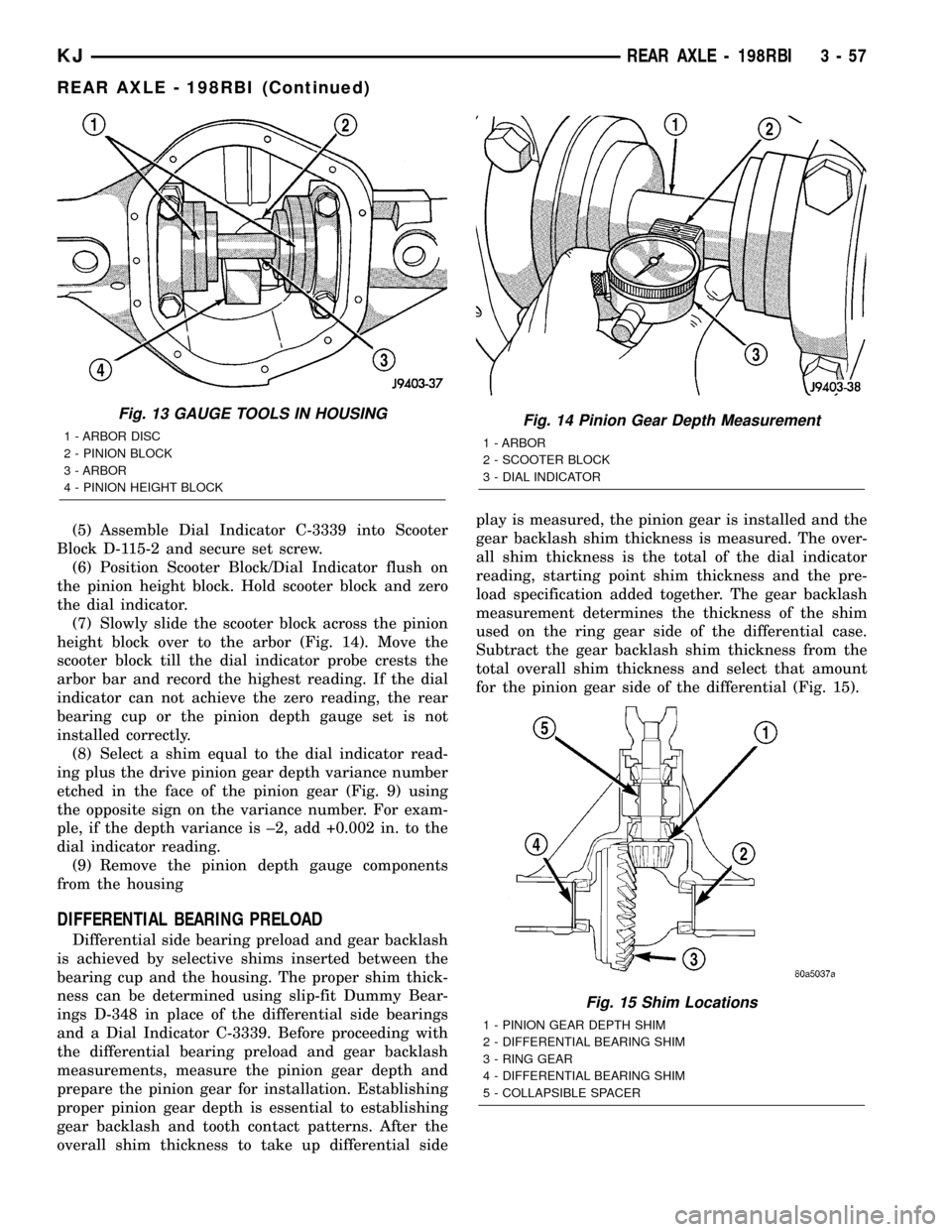

(5) Assemble Dial Indicator C-3339 into Scooter

Block D-115-2 and secure set screw.

(6) Position Scooter Block/Dial Indicator flush on

the pinion height block. Hold scooter block and zero

the dial indicator.

(7) Slowly slide the scooter block across the pinion

height block over to the arbor (Fig. 14). Move the

scooter block till the dial indicator probe crests the

arbor bar and record the highest reading. If the dial

indicator can not achieve the zero reading, the rear

bearing cup or the pinion depth gauge set is not

installed correctly.

(8) Select a shim equal to the dial indicator read-

ing plus the drive pinion gear depth variance number

etched in the face of the pinion gear (Fig. 9) using

the opposite sign on the variance number. For exam-

ple, if the depth variance is ±2, add +0.002 in. to the

dial indicator reading.

(9) Remove the pinion depth gauge components

from the housing

DIFFERENTIAL BEARING PRELOAD

Differential side bearing preload and gear backlash

is achieved by selective shims inserted between the

bearing cup and the housing. The proper shim thick-

ness can be determined using slip-fit Dummy Bear-

ings D-348 in place of the differential side bearings

and a Dial Indicator C-3339. Before proceeding with

the differential bearing preload and gear backlash

measurements, measure the pinion gear depth and

prepare the pinion gear for installation. Establishing

proper pinion gear depth is essential to establishing

gear backlash and tooth contact patterns. After the

overall shim thickness to take up differential sideplay is measured, the pinion gear is installed and the

gear backlash shim thickness is measured. The over-

all shim thickness is the total of the dial indicator

reading, starting point shim thickness and the pre-

load specification added together. The gear backlash

measurement determines the thickness of the shim

used on the ring gear side of the differential case.

Subtract the gear backlash shim thickness from the

total overall shim thickness and select that amount

for the pinion gear side of the differential (Fig. 15).

Fig. 13 GAUGE TOOLS IN HOUSING

1 - ARBOR DISC

2 - PINION BLOCK

3 - ARBOR

4 - PINION HEIGHT BLOCKFig. 14 Pinion Gear Depth Measurement

1 - ARBOR

2 - SCOOTER BLOCK

3 - DIAL INDICATOR

Fig. 15 Shim Locations

1 - PINION GEAR DEPTH SHIM

2 - DIFFERENTIAL BEARING SHIM

3 - RING GEAR

4 - DIFFERENTIAL BEARING SHIM

5 - COLLAPSIBLE SPACER

KJREAR AXLE - 198RBI 3 - 57

REAR AXLE - 198RBI (Continued)

Page 126 of 1803

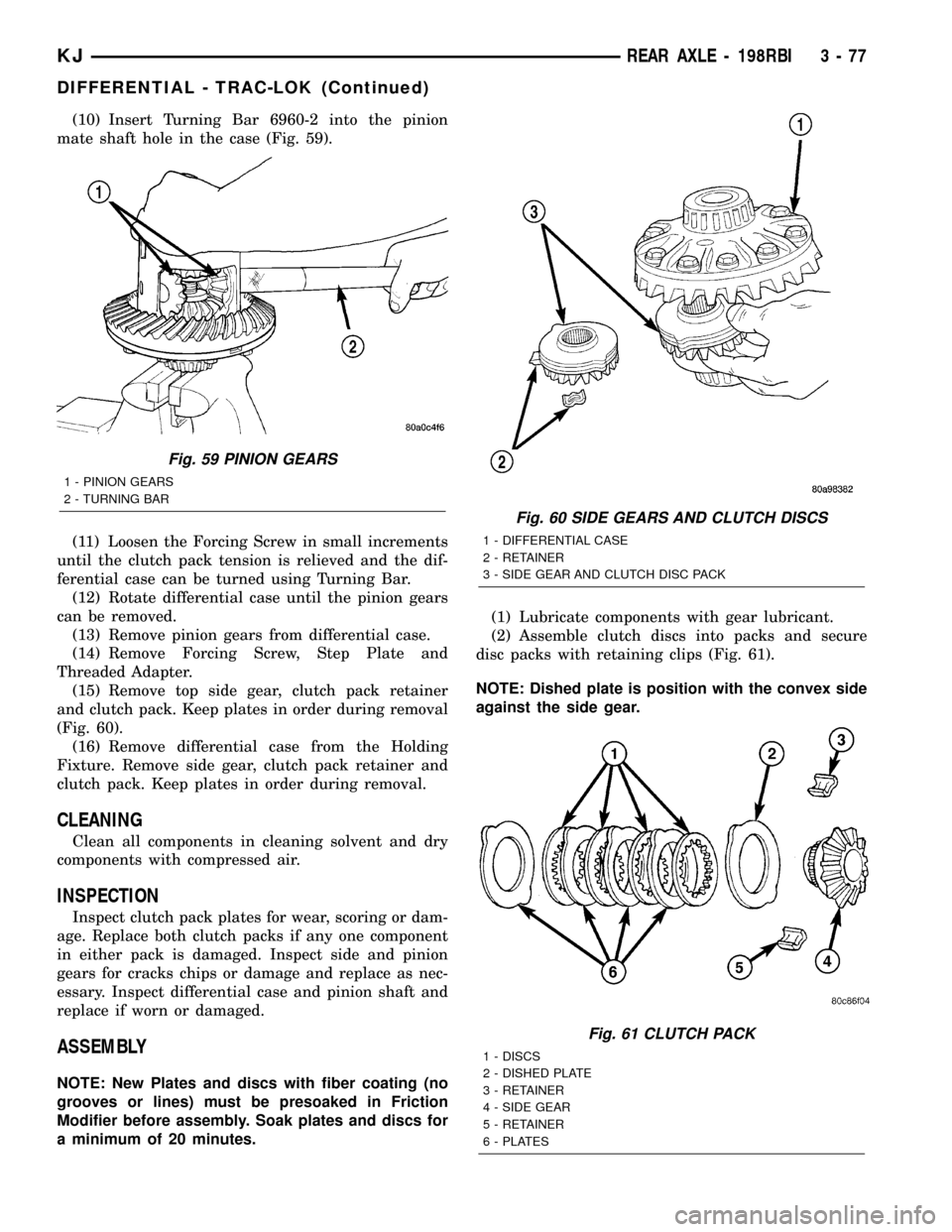

(10) Insert Turning Bar 6960-2 into the pinion

mate shaft hole in the case (Fig. 59).

(11) Loosen the Forcing Screw in small increments

until the clutch pack tension is relieved and the dif-

ferential case can be turned using Turning Bar.

(12) Rotate differential case until the pinion gears

can be removed.

(13) Remove pinion gears from differential case.

(14) Remove Forcing Screw, Step Plate and

Threaded Adapter.

(15) Remove top side gear, clutch pack retainer

and clutch pack. Keep plates in order during removal

(Fig. 60).

(16) Remove differential case from the Holding

Fixture. Remove side gear, clutch pack retainer and

clutch pack. Keep plates in order during removal.

CLEANING

Clean all components in cleaning solvent and dry

components with compressed air.

INSPECTION

Inspect clutch pack plates for wear, scoring or dam-

age. Replace both clutch packs if any one component

in either pack is damaged. Inspect side and pinion

gears for cracks chips or damage and replace as nec-

essary. Inspect differential case and pinion shaft and

replace if worn or damaged.

ASSEMBLY

NOTE: New Plates and discs with fiber coating (no

grooves or lines) must be presoaked in Friction

Modifier before assembly. Soak plates and discs for

a minimum of 20 minutes.(1) Lubricate components with gear lubricant.

(2) Assemble clutch discs into packs and secure

disc packs with retaining clips (Fig. 61).

NOTE: Dished plate is position with the convex side

against the side gear.

Fig. 59 PINION GEARS

1 - PINION GEARS

2 - TURNING BAR

Fig. 60 SIDE GEARS AND CLUTCH DISCS

1 - DIFFERENTIAL CASE

2 - RETAINER

3 - SIDE GEAR AND CLUTCH DISC PACK

Fig. 61 CLUTCH PACK

1 - DISCS

2 - DISHED PLATE

3 - RETAINER

4 - SIDE GEAR

5 - RETAINER

6 - PLATES

KJREAR AXLE - 198RBI 3 - 77

DIFFERENTIAL - TRAC-LOK (Continued)

Page 140 of 1803

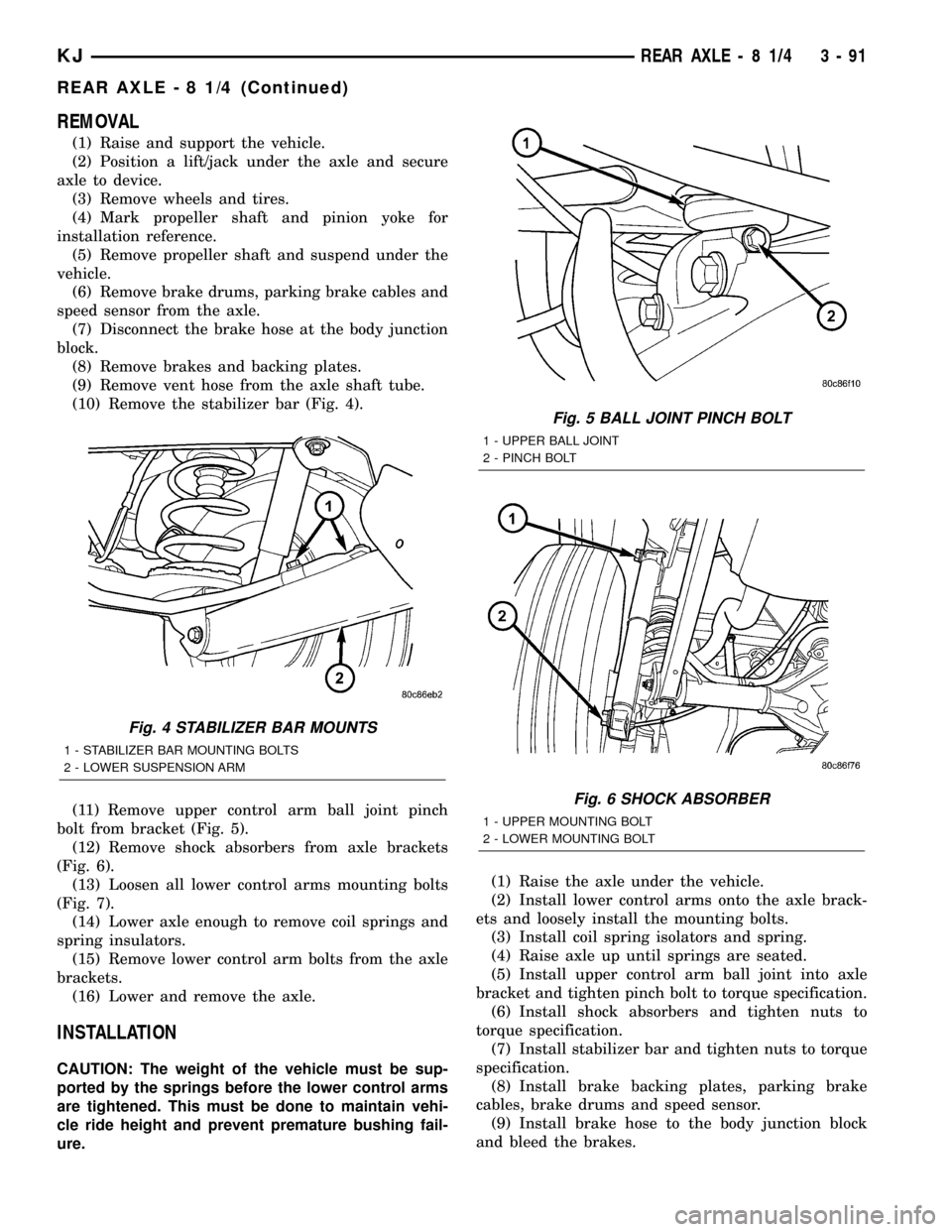

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lift/jack under the axle and secure

axle to device.

(3) Remove wheels and tires.

(4) Mark propeller shaft and pinion yoke for

installation reference.

(5) Remove propeller shaft and suspend under the

vehicle.

(6) Remove brake drums, parking brake cables and

speed sensor from the axle.

(7) Disconnect the brake hose at the body junction

block.

(8) Remove brakes and backing plates.

(9) Remove vent hose from the axle shaft tube.

(10) Remove the stabilizer bar (Fig. 4).

(11) Remove upper control arm ball joint pinch

bolt from bracket (Fig. 5).

(12) Remove shock absorbers from axle brackets

(Fig. 6).

(13) Loosen all lower control arms mounting bolts

(Fig. 7).

(14) Lower axle enough to remove coil springs and

spring insulators.

(15) Remove lower control arm bolts from the axle

brackets.

(16) Lower and remove the axle.

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before the lower control arms

are tightened. This must be done to maintain vehi-

cle ride height and prevent premature bushing fail-

ure.(1) Raise the axle under the vehicle.

(2) Install lower control arms onto the axle brack-

ets and loosely install the mounting bolts.

(3) Install coil spring isolators and spring.

(4) Raise axle up until springs are seated.

(5) Install upper control arm ball joint into axle

bracket and tighten pinch bolt to torque specification.

(6) Install shock absorbers and tighten nuts to

torque specification.

(7) Install stabilizer bar and tighten nuts to torque

specification.

(8) Install brake backing plates, parking brake

cables, brake drums and speed sensor.

(9) Install brake hose to the body junction block

and bleed the brakes.

Fig. 4 STABILIZER BAR MOUNTS

1 - STABILIZER BAR MOUNTING BOLTS

2 - LOWER SUSPENSION ARM

Fig. 5 BALL JOINT PINCH BOLT

1 - UPPER BALL JOINT

2 - PINCH BOLT

Fig. 6 SHOCK ABSORBER

1 - UPPER MOUNTING BOLT

2 - LOWER MOUNTING BOLT

KJREAR AXLE - 8 1/4 3 - 91

REAR AXLE - 8 1/4 (Continued)