chime JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 408 of 1803

gauge readings during normal operation that are con-

sistent with customer expectations. However, when

abnormal conditions exist such as high coolant tem-

perature, the algorithm can drive the gauge pointer

to an extreme position and the microprocessor can

sound a chime through the on-board chime tone gen-

erator to provide distinct visual and audible indica-

tions of a problem to the vehicle operator. The

instrument cluster circuitry may also perform chime

service for other electronic modules in the vehicle

based upon electronic chime tone request messages

received over the PCI data bus to provide the vehicle

operator with an audible alert to supplement a visual

indication. One such alert is a door ajar warning

chime, which the EMIC provides by monitoring PCI

bus messages from the Body Control Module (BCM).

The EMIC circuitry operates on battery current

received through a fused B(+) fuse in the Junction

Block (JB) on a non-switched fused B(+) circuit, and

on battery current received through a fused ignition

switch output (run-start) fuse in the JB on a fused

ignition switch output (run-start) circuit. This

arrangement allows the EMIC to provide some fea-

tures regardless of the ignition switch position, while

other features will operate only with the ignition

switch in the On or Start positions. The EMIC

receives a ground input from the BCM as a wake-up

signal in order to provide the ignition-off features.

The EMIC circuitry is grounded through a ground

circuit and take out of the instrument panel wire

harness with an eyelet terminal connector that is

secured by a nut to a ground stud located on the left

instrument panel end bracket.

The EMIC also has a self-diagnostic actuator test

capability, which will test each of the PCI bus mes-

sage-controlled functions of the cluster by lighting

the appropriate indicators (except the airbag indica-

tor), sweeping the gauge needles to several calibra-

tion points across the gauge faces, and stepping the

odometer display sequentially from all ones through

all nines. (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). See the

owner's manual in the vehicle glove box for more

information on the features, use and operation of the

EMIC.

GAUGES All gauges receive battery current

through the EMIC circuitry when the ignition switch

is in the On or Start positions. With the ignition

switch in the Off position battery current is not sup-

plied to any gauges, and the EMIC circuitry is pro-

grammed to move all of the gauge needles back to

the low end of their respective scales. Therefore, the

gauges do not accurately indicate any vehicle condi-

tion unless the ignition switch is in the On or Start

positions. All of the EMIC gauges, except the odome-

ter, are air core magnetic units. Two fixed electro-magnetic coils are located within each gauge. These

coils are wrapped at right angles to each other

around a movable permanent magnet. The movable

magnet is suspended within the coils on one end of a

pivot shaft, while the gauge needle is attached to the

other end of the shaft. One of the coils has a fixed

current flowing through it to maintain a constant

magnetic field strength. Current flow through the

second coil changes, which causes changes in its

magnetic field strength. The current flowing through

the second coil is changed by the EMIC circuitry in

response to messages received over the PCI data bus.

The gauge needle moves as the movable permanent

magnet aligns itself to the changing magnetic fields

created around it by the electromagnets.

The gauges are diagnosed using the EMIC self-di-

agnostic actuator test. (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). Proper testing of the PCI data bus and

the electronic data bus message inputs to the EMIC

that control each gauge require the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation. Specific operation details for each gauge may

be found elsewhere in this service information.

VACUUM-FLUORESCENT DISPLAY The Vacu-

um-Fluorescent Display (VFD) module is soldered to

the EMIC circuit board. The display is active when

the driver door is opened with the ignition switch in

the Off or Accessory positions (Rental Car mode), and

with the ignition switch in the On or Start positions.

The VFD is inactive when the ignition switch is in

the Off or Accessory positions and the driver door is

closed. The illumination intensity of the VFD is con-

trolled by the EMIC circuitry based upon electronic

dimming level messages received from the BCM over

the PCI data bus, and is synchronized with the illu-

mination intensity of other VFDs in the vehicle. The

BCM provides dimming level messages based upon

internal programming and inputs it receives from the

control knob and control ring on the left (lighting)

control stalk of the multi-function switch on the

steering column.

The VFD has several display capabilities including

odometer, trip odometer, and warning messages

whenever the appropriate conditions exist. The VFD

warning messages include:

²ªdoorº- indicating a door is ajar.

²ªgateº- indicating the tailgate is ajar.

²ªglassº- indicating the tailgate glass is ajar.

²ªlowashº- indicating that the washer fluid

level is low.

²ªno busº- indicating there is no PCI data bus

communication detected.

An odometer/trip odometer switch on the EMIC cir-

cuit board is used to control the display modes. This

switch is actuated manually by depressing the odom-

KJINSTRUMENT CLUSTER 8J - 5

INSTRUMENT CLUSTER (Continued)

Page 410 of 1803

fused panel lamps dimmer switch signal circuit. The

cluster illumination lamps are grounded at all times.

In addition, the control ring on the left (lighting)

control stalk of the multi-function switch has a

Parade Mode position to provide a parade mode. The

BCM monitors the request for this mode from the

multi-function switch, then sends an electronic dim-

ming level message to the EMIC over the PCI data

bus to illuminate all VFDs in the vehicle at full

intensity for easier visibility when driving in daylight

with the exterior lighting turned On.

The hard wired cluster illumination lamp circuits

may be diagnosed using conventional diagnostic

methods. However, proper testing of the PWM output

of the EMIC and the electronic dimming level mes-

sages sent by the BCM over the PCI data bus

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

CHIME WARNING SERVICE The EMIC is pro-

grammed to provide chime service when certain indi-

cators are illuminated. When the programmed

conditions are met, the EMIC generates an electronic

chime tone through its integral chime tone generator.

In addition, the EMIC is programmed to provide

chime service for other electronic modules in the

vehicle when it receives the proper electronic chime

request messages over the PCI data bus. Upon

receiving the proper chime request message, the

EMIC activates the integral chime tone generator to

provide the audible chime tone to the vehicle opera-

tor. (Refer to 8 - ELECTRICAL/CHIME/BUZZER -

OPERATION). Proper testing of the EMIC and the

PCI data bus chime request message functions

requires the use of a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER

If all of the instrument cluster gauges and/or indi-

cators are inoperative, refer to PRELIMINARY

DIAGNOSIS . If an individual gauge or Programma-

ble Communications Interface (PCI) data bus mes-

sage-controlled indicator is inoperative, refer to

ACTUATOR TEST . If an individual hard wired indi-

cator is inoperative, refer to the diagnosis and testing

information for that specific indicator. If the instru-

ment cluster chime service is inoperative, refer to

CHIME SERVICE DIAGNOSIS . If the instrument

cluster illumination lighting is inoperative, refer to

CLUSTER ILLUMINATION DIAGNOSIS . Refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.NOTE: Certain indicators in this instrument cluster

are automatically configured. This feature allows

those indicators to be activated for compatibility

with certain optional equipment. If the problem

being diagnosed involves illumination of the ABS

indicator, the airbag indicator, or the SKIS indicator

when the vehicle does not have this equipment, a

DRBIIITscan tool must be used to disable the erro-

neous indicator(s). Refer to the appropriate diag-

nostic information.

PRELIMINARY DIAGNOSIS

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse (Fuse 34 - 15

ampere) in the Junction Block (JB). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

(Fuse 34 - 15 ampere) in the JB. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit between

the JB and the Power Distribution Center (PDC) as

required.

(3) Disconnect and isolate the battery negative

cable. Remove the instrument cluster. Reconnect the

battery negative cable. Check for battery voltage at

the fused B(+) circuit cavity of the instrument panel

wire harness connector for the instrument cluster. If

OK, go to Step 4. If not OK, repair the open fused

B(+) circuit between the instrument cluster and the

JB as required.

(4) Check the fused ignition switch output (run-

start) fuse (Fuse 13 - 10 ampere) in the JB. If OK, go

to Step 5. If not OK, repair the shorted circuit or

component as required and replace the faulty fuse.

(5) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run-start) fuse (Fuse 13 - 10 ampere) in the

JB. If OK, go to Step 6. If not OK, repair the open

KJINSTRUMENT CLUSTER 8J - 7

INSTRUMENT CLUSTER (Continued)

Page 411 of 1803

fused ignition switch output (run-start) circuit

between the JB and the ignition switch as required.

(6) With the ignition switch still in the On posi-

tion, check for battery voltage at the fused ignition

switch output (run-start) circuit cavity of the instru-

ment panel wire harness connector for the instru-

ment cluster. If OK, go to Step 7. If not OK, repair

the open fused ignition switch output circuit (run-

start) between the instrument cluster and the JB as

required.

(7) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Check for continuity between the ground circuit cav-

ity of the instrument panel wire harness connector

for the instrument cluster and a good ground. There

should be continuity. If OK, refer to ACTUATOR

TEST . If not OK, repair the open ground circuit

between the instrument cluster and ground (G202) as

required.

ACTUATOR TEST

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

The instrument cluster actuator test will put the

instrument cluster into its self-diagnostic mode. In

this mode the instrument cluster can perform a self-

diagnostic test that will confirm that the instrument

cluster circuitry, the gauges, the PCI data bus mes-

sage controlled indicator lamps, and the chime tone

generator are capable of operating as designed. Dur-

ing the actuator test the instrument cluster circuitry

will sound the chime tone generator, position each of

the gauge needles at various specified calibration

points, illuminate each of the segments in the Vacu-um-Fluorescent Display (VFD), and turn all of the

PCI data bus message-controlled indicators on and

off again.

Successful completion of the actuator test will con-

firm that the instrument cluster is operational. How-

ever, there may still be a problem with the PCI data

bus, the Powertrain Control Module (PCM), the Air-

bag Control Module (ACM), the Sentry Key Immobi-

lizer Module (SKIM), or the inputs to one of these

electronic control modules. Use a DRBIIItscan tool

to diagnose these components. Refer to the appropri-

ate diagnostic information.

(1) Begin the test with the ignition switch in the

Off position.

(2) Depress the odometer/trip odometer switch but-

ton.

(3) While still holding the odometer/trip odometer

switch button depressed, turn the ignition switch to

the On position, but do not start the engine.

(4) Release the odometer/trip odometer switch but-

ton.

(5) The instrument cluster will automatically

begin the actuator test sequence, as follows:

(a) The cluster will turn on, then off again each

of the PCI data bus message controlled indicators

to confirm the functionality of the indicator and

the cluster control circuitry:

(b) The cluster will sweep the needles for each of

the gauges to several calibration points in sequence

to confirm the functionality of the gauge and the

cluster control circuitry:

(c) The cluster will sequentially step the odome-

ter/trip odometer VFD display from all ones

( 111111 )through all nines (999999) to confirm the

functionality of all VFD segments and their control

circuitry, then display the software version number.

(d) The cluster will generate five (5) chime tones

to confirm the functionality of the chime tone gen-

erator and the chime control circuitry.

(6) The actuator test is now completed. The instru-

ment cluster will automatically exit the self-diagnos-

tic mode and return to normal operation at the

completion of the test, if the ignition switch is turned

to the Off position during the test, or if an engine

rpm message indicating that the engine is running is

received from the PCM over the PCI data bus during

the test.

(7) Go back to Step 1 to repeat the test, if

required.

8J - 8 INSTRUMENT CLUSTERKJ

INSTRUMENT CLUSTER (Continued)

Page 412 of 1803

CHIME SERVICE DIAGNOSIS

The most reliable, efficient, and accurate means to

diagnose the Chime Service function of the instru-

ment cluster requires the use of a DRBIIItscan tool.

Refer to the appropriate diagnostic information.

CLUSTER ILLUMINATION DIAGNOSIS

If the problem being diagnosed is a single inopera-

tive illumination lamp, be certain that the bulb and

bulb holder unit are properly installed in the instru-

ment cluster electronic circuit board. If no installa-

tion problems are found replace the faulty bulb and

bulb holder unit. If all of the cluster illumination

lamps are inoperative, the most reliable, efficient,

and accurate means to diagnose the cluster illumina-

tion function of the instrument cluster requires the

use of a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

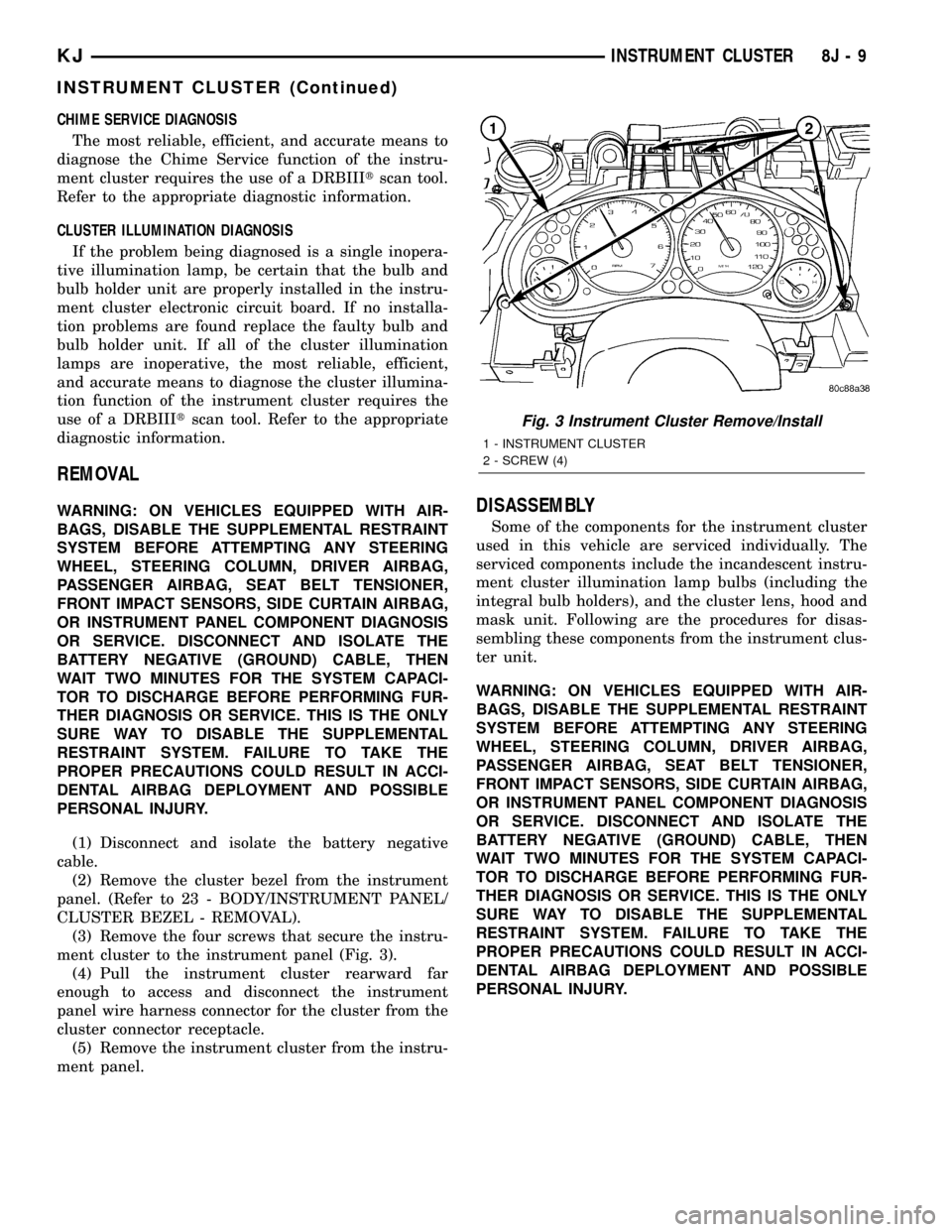

(2) Remove the cluster bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(3) Remove the four screws that secure the instru-

ment cluster to the instrument panel (Fig. 3).

(4) Pull the instrument cluster rearward far

enough to access and disconnect the instrument

panel wire harness connector for the cluster from the

cluster connector receptacle.

(5) Remove the instrument cluster from the instru-

ment panel.DISASSEMBLY

Some of the components for the instrument cluster

used in this vehicle are serviced individually. The

serviced components include the incandescent instru-

ment cluster illumination lamp bulbs (including the

integral bulb holders), and the cluster lens, hood and

mask unit. Following are the procedures for disas-

sembling these components from the instrument clus-

ter unit.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

Fig. 3 Instrument Cluster Remove/Install

1 - INSTRUMENT CLUSTER

2 - SCREW (4)

KJINSTRUMENT CLUSTER 8J - 9

INSTRUMENT CLUSTER (Continued)

Page 448 of 1803

leveling switch is a resistor multiplexed unit that

provides one of four voltage outputs to the headlamp

leveling motors. The headlamp leveling motors will

move the headlamps to the selected position based

upon the voltage input received from the switch. The

headlamp leveling motors and switch have a path to

ground at all times. The headlamp leveling compo-

nents operate on battery current received through

the fused park lamp relay output circuit so that the

system will only operate when the exterior lighting is

turned on.

PARK LAMPS

The park lamps system includes the Body Control

Module (BCM), a park lamp relay installed in the

Junction Block (JB), and the exterior lighting switch

integral to the left (lighting) control stalk of the

multi-function switch. The front park lamp and side

marker or, if equipped, the front position lamp bulbs

each have a path to ground at all times through their

connections to the grille opening reinforcement wire

harness from two take outs of the headlamp and

dash wire harness with eyelet terminal connectors

that are secured by ground screws to the left inner

fender shield in the engine compartment. The rear

park lamp bulbs and license plate lamp have a path

to ground at all times through their connection to the

rear lighting wire harness from a take out of the rear

body wire harness with an eyelet terminal connector

that is secured by a ground screw to the base of the

right D-pillar behind the quarter trim panel. The

BCM controls the park lamp operation by monitoring

the exterior lighting switch inputs from the multi-

function switch, then energizing or de-energizing the

control coil of the park lamp relay. When the park

lamp relay is energized, it provides battery current

from a fused B(+) fuse in the Power Distribution

Center (PDC) through a park lamp relay output cir-

cuit and a separate fuse in the JB through a fused

park lamp relay output circuit to the appropriate

lamp bulb filaments. The BCM provides a battery

saver (load shedding) feature for the park lamps,

which will turn these lamps off if they are left on for

more than about eight minutes with the ignition

switch in the Off position.

REAR FOG LAMPS

Rear fog lamps are installed on vehicles manufac-

tured for certain markets where they are required.

The rear fog lamp system includes a premium Body

Control Module (BCM), a rear fog lamp relay

installed in the Junction Block (JB), and a rear fog

lamp switch integral to the left (lighting) control

stalk of the multi-function switch. The rear fog lamps

have a path to ground at all times through their con-

nection to the rear lighting wire harness from a takeout of the rear body wire harness with an eyelet ter-

minal connector that is secured by a ground screw to

the base of the right D-pillar behind the quarter trim

panel. The BCM controls rear fog lamp operation by

monitoring the exterior lighting switch input from

the multi-function switch, then energizing or de-ener-

gizing the rear fog lamp relay control coil; and, by

sending the appropriate electronic message to the

instrument cluster over the Programmable Commu-

nications Interface (PCI) data bus to turn the rear

fog lamp indicator on or off. When the rear fog lamp

relay is energized, it provides battery current from a

fused B(+) fuse in the JB to the rear fog lamps

through the rear fog lamp relay output circuit. The

BCM provides a battery saver (load shedding) feature

for the rear fog lamps, which will turn these lamps

off if they are left on for more than about eight min-

utes with the ignition switch in the Off position.

TURN SIGNAL LAMPS

When the left control stalk of the multi-function

switch is moved up (right turn) or down (left turn),

the turn signal system is activated causing the

selected right or left turn signal indicator, and right

or left turn signal lamps to flash on and off. When

the turn signal system is activated, the circuitry

within the turn signal switch and the hazard switch/

electronic combination flasher unit will repeatedly

energize and de-energize one of two internal relays

that switch battery current from a fused ignition

switch output (run) fuse in the Junction Block (JB) to

the right side or left side turn signal indicators and

turn signal lamps through the right or left turn sig-

nal circuits. The ElectroMechanical Instrument Clus-

ter (EMIC) chime tone generator will generate an

audible turn signal cancel warning each time the

vehicle is driven for a distance of about 3.2 kilome-

ters (about two miles) with a turn signal indicator

flashing. The EMIC uses Programmable Communica-

tions Interface (PCI) data bus distance messages

from the Powertrain Control Module (PCM) and a

hard wired input from the turn signal switch cir-

cuitry of the multi-function switch to determine when

to sound the turn signal cancel warning.

DIAGNOSIS AND TESTING - LAMPS/LIGHTING

- EXTERIOR

The hard wired circuits and components of the

exterior lighting systems may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the Body

Control Module (BCM), the ElectroMechanical

Instrument Cluster (EMIC), the Powertrain Control

Module (PCM), or the Programmable Communica-

tions Interface (PCI) data bus network. The most

KJLAMPS/LIGHTING - EXTERIOR 8L - 7

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 532 of 1803

move the headlamps to the selected position based

upon the voltage input received from the switch. The

headlamp leveling motors and switch have a path to

ground at all times. The headlamp leveling compo-

nents operate on battery current received through

the fused park lamp relay output circuit so that the

system will only operate when the exterior lighting is

turned on.

PARK LAMPS

The park lamps system includes the Body Control

Module (BCM), a park lamp relay installed in the

Junction Block (JB), and the exterior lighting switch

integral to the left (lighting) control stalk of the

multi-function switch. The front park lamp and side

marker or, if equipped, the front position lamp bulbs

each have a path to ground at all times through their

connections to the grille opening reinforcement wire

harness from two take outs of the headlamp and

dash wire harness with eyelet terminal connectors

that are secured by ground screws to the left inner

fender shield in the engine compartment. The rear

park lamp bulbs and license plate lamp have a path

to ground at all times through their connection to the

rear lighting wire harness from a take out of the rear

body wire harness with an eyelet terminal connector

that is secured by a ground screw to the base of the

right D-pillar behind the quarter trim panel. The

BCM controls the park lamp operation by monitoring

the exterior lighting switch inputs from the multi-

function switch, then energizing or de-energizing the

control coil of the park lamp relay. When the park

lamp relay is energized, it provides battery current

from a fused B(+) fuse in the Power Distribution

Center (PDC) through a park lamp relay output cir-

cuit and a separate fuse in the JB through a fused

park lamp relay output circuit to the appropriate

lamp bulb filaments. The BCM provides a battery

saver (load shedding) feature for the park lamps,

which will turn these lamps off if they are left on for

more than about eight minutes with the ignition

switch in the Off position.

REAR FOG LAMPS

Rear fog lamps are installed on vehicles manufac-

tured for certain markets where they are required.

The rear fog lamp system includes a premium Body

Control Module (BCM), a rear fog lamp relay

installed in the Junction Block (JB), and a rear fog

lamp switch integral to the left (lighting) control

stalk of the multi-function switch. The rear fog lamps

have a path to ground at all times through their con-

nection to the rear lighting wire harness from a take

out of the rear body wire harness with an eyelet ter-

minal connector that is secured by a ground screw to

the base of the right D-pillar behind the quarter trimpanel. The BCM controls rear fog lamp operation by

monitoring the exterior lighting switch input from

the multi-function switch, then energizing or de-ener-

gizing the rear fog lamp relay control coil; and, by

sending the appropriate electronic message to the

instrument cluster over the Programmable Commu-

nications Interface (PCI) data bus to turn the rear

fog lamp indicator on or off. When the rear fog lamp

relay is energized, it provides battery current from a

fused B(+) fuse in the JB to the rear fog lamps

through the rear fog lamp relay output circuit. The

BCM provides a battery saver (load shedding) feature

for the rear fog lamps, which will turn these lamps

off if they are left on for more than about eight min-

utes with the ignition switch in the Off position.

TURN SIGNAL LAMPS

When the left control stalk of the multi-function

switch is moved up (right turn) or down (left turn),

the turn signal system is activated causing the

selected right or left turn signal indicator, and right

or left turn signal lamps to flash on and off. When

the turn signal system is activated, the circuitry

within the turn signal switch and the hazard switch/

electronic combination flasher unit will repeatedly

energize and de-energize one of two internal relays

that switch battery current from a fused ignition

switch output (run) fuse in the Junction Block (JB) to

the right side or left side turn signal indicators and

turn signal lamps through the right or left turn sig-

nal circuits. The ElectroMechanical Instrument Clus-

ter (EMIC) chime tone generator will generate an

audible turn signal cancel warning each time the

vehicle is driven for a distance of about 3.2 kilome-

ters (about two miles) with a turn signal indicator

flashing. The EMIC uses Programmable Communica-

tions Interface (PCI) data bus distance messages

from the Powertrain Control Module (PCM) and a

hard wired input from the turn signal switch cir-

cuitry of the multi-function switch to determine when

to sound the turn signal cancel warning.

DIAGNOSIS AND TESTING - LAMPS/LIGHTING

- EXTERIOR

The hard wired circuits and components of the

exterior lighting systems may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the Body

Control Module (BCM), the ElectroMechanical

Instrument Cluster (EMIC), the Powertrain Control

Module (PCM), or the Programmable Communica-

tions Interface (PCI) data bus network. The most

reliable, efficient, and accurate means to diagnose

the BCM, the EMIC, the PCM, and the PCI data bus

network inputs and outputs related to the various

KJLAMPS8Ls-7

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 612 of 1803

Press and hold the transmitter UNLOCK button

for four to ten seconds. While pressing the UNLOCK

button in, press the LOCK button. Release both but-

tons.

This will toggle between Driver door first and

Unlock all doors function.

STANDARD PROCEDURE - RKE TRANSMITTER

PROGRAMING

New Remote Keyless Entry (RKE) transmitters can

be programed using the DRBIIItscan tool and the

proper Diagnostic Procedures manual. The DRBIIIt

scan tool can provide confirmation that the PCI data

bus is functional, and that all of the electronic mod-

ules are sending and receiving the proper messages

on the PCI data bus.

The following procedure can be used as long as one

functioning transmitter is available:

(1) Using the original transmitter, press the

UNLOCK button for 4 to 10 seconds.

(2) Without releasing the UNLOCK button, press

the PANIC button (within the 4 to 10 second inter-

val).

(3) Release both buttons.

(4) Press LOCK and UNLOCK simultaneously on

the original transmitter.

(5) Release both buttons.

(6) Press any button on the ORIGINAL transmit-

ter. A chime tone from the instrument cluster will

confirm the programming of the ORIGINAL trans-

mitter.

(7) On NEW transmitter, press LOCK and

UNLOCK simultaneously.

(8) Release both buttons.

(9) Press any button on the NEW transmitter. A

chime tone from the instrument cluster will confirm

the programming of the NEW transmitter.

(10) Up to four transmitters can be programed for

one vehicle.

SPECIFICATIONS - REMOTE KEYLESS ENTRY

TRANSMITTER

RANGE

Normal operation range is up to a distance of 3 to

7 meters (10 to 23 ft.) of the vehicle. Range may be

better or worse depending on the environment

around the vehicle.

TAILGATE CYLINDER LOCK

SWITCH

DESCRIPTION

The tailgate cylinder lock switch is integral to the

key lock cylinder inside the tailgate. The tailgate cyl-

inder lock switch is a normally-open momentary

switch that is hard wired directly to the Body Con-

trol Module (BCM), and closes a path to ground

through an internal resistor when the lock cylinder is

rotated to the unlock or lock position.

The tailgate cylinder lock switch cannot be

adjusted or repaired.

OPERATION

The tailgate cylinder lock switch is actuated when

the key is inserted in the lock cylinder and turned to

the unlock or lock position. The tailgate cylinder lock

switch closes a path to ground through an internal

resistor for the Body Control Module (BCM) when

the tailgate key lock cylinder is in the lock or unlock

position, and opens the ground path when the lock

cylinder is in the neutral position. The BCM reads

the switch status, then sends the proper switch sta-

tus messages to other electronic modules over the

Programmable Communications Interface (PCI) data

bus network. The tailgate cylinder lock switch unlock

status message is used by the BCM as an input for

Vehicle Theft Security System (VTSS) operation and

to tell the BCM to lock or unlock the tailgate. There

is no mechanical linkage between the tailgate key

cylinder and the latches.

DIAGNOSIS AND TESTING - TAILGATE

CYLINDER LOCK SWITCH

(1) Disconnect and isolate the battery negative

cable.

(2) Remove tailgate trim panel (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL).

(3) Disconnect tailgate cylinder lock switch har-

ness connector.

(4) Using a ohmmeter, test for resistances as

shown in the Tailgate Cylinder Lock Switch Table.

KJPOWER LOCKS 8N - 9

REMOTE KEYLESS ENTRY TRANSMITTER (Continued)

Page 689 of 1803

continuity. If OK, go to Step 6. If not OK, repair the

open ground circuit(s) to ground (G202) as required.

(6) Reconnect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

instrument panel wire harness connector for the

SKIM. If OK, go to Step 7. If not OK, repair the open

fused B(+) circuit between the SKIM and the JB as

required.

(7) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run-start) circuit cavity of the instrument

panel wire harness connector for the SKIM. If OK,

use a DRBIIItscan tool to complete the diagnosis of

the SKIS. Refer to the appropriate diagnostic infor-

mation. If not OK, repair the open fused ignition

switch output (run-start) circuit between the SKIM

and the JB as required.

SKIS INDICATOR FLASHES UPON IGNITION ªONº OR

LIGHTS SOLID FOLLOWING BULB TEST

A SKIS indicator that flashes following the ignition

switch being turned to the On position indicates that

an invalid key has been detected, or that a key-re-

lated fault has been set. A SKIS indicator that lights

solid following a successful bulb test indicates that

the SKIM has detected a system malfunction or that

the SKIS is inoperative. In either case, fault informa-

tion will be stored in the SKIM memory. For retrieval

of this fault information and further diagnosis of the

SKIS, the PCI data bus, the SKIM electronic mes-

sage outputs to the instrument cluster that control

the SKIS indicator and chime, or the electronic mes-

sage inputs and outputs between the SKIM and the

Powertrain Control Module (PCM) that control

engine operation, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information. Fol-

lowing are preliminary troubleshooting guidelines to

be followed during diagnosis using a DRBIIItscan

tool:

(1) Using the DRBIIItscan tool, read and record

the faults as they exist in the SKIM when you first

begin your diagnosis of the vehicle. It is important to

document these faults because the SKIM does not

differentiate between historical faults (those that

have occurred in the past) and active faults (those

that are currently present). If this problem turns out

to be an intermittent condition, this information may

become invaluable to your diagnosis.

(2) Using the DRBIIItscan tool, erase all of the

faults from the SKIM.

(3) Cycle the ignition switch to the Off position,

then back to the On position.

(4) Using the DRBIIItscan tool, read any faults

that are now present in the SKIM. These are the

active faults.(5) Using this active fault information, refer to the

proper procedure in the appropriate diagnostic infor-

mation for the specific additional diagnostic steps.

STANDARD PROCEDURE

STANDARD PROCEDURE - SKIS

INITIALIZATION

The Sentry Key Immobilizer System (SKIS) must

be initialized following a Sentry Key Immobilizer

Module (SKIM) replacement. SKIS initialization

requires the use of a DRBIIItscan tool. Initialization

will also require that you have access to the unique

four-digit PIN code that was assigned to the original

SKIM. The PIN codemustbe used to enter the

Secured Access Mode in the SKIM. This PIN number

may be obtained from the vehicle owner, from the

original vehicle invoice, or from the DaimlerChrysler

Customer Center. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES - STANDARD PRO-

CEDURE - PCM/SKIM PROGRAMMING).

NOTE: If a Powertrain Control Module (PCM) is

replaced on a vehicle equipped with the Sentry Key

Immobilizer System (SKIS), the unique Secret Key

data must be transferred from the Sentry Key

Immobilizer Module (SKIM) to the new PCM using

the PCM replacement procedure. This procedure

also requires the use of a DRBIIITscan tool and the

unique four-digit PIN code to enter the Secured

Access Mode in the SKIM. Refer to the appropriate

diagnostic information for the proper PCM replace-

ment procedures.

STANDARD PROCEDURE - SENTRY KEY

TRANSPONDER PROGRAMMING

All Sentry Keys included with the vehicle are pre-

programmed to work with the Sentry Key Immobi-

lizer System (SKIS) when it is shipped from the

factory. The Sentry Key Immobilizer Module (SKIM)

can be programmed to recognize up to a total of eight

Sentry Keys. When programming a blank Sentry Key

transponder, the key must first be cut to match the

ignition switch lock cylinder in the vehicle for which

it will be used. Once the additional or new key has

been cut, the SKIM must be programmed to recog-

nize it as a valid key. There are two possible methods

to program the SKIM to recognize a new or addi-

tional valid key, the Secured Access Method and the

Customer Learn Method. Following are the details of

these two programming methods.

8Q - 8 VEHICLE THEFT SECURITYKJ

VEHICLE THEFT SECURITY (Continued)

Page 690 of 1803

SECURED ACCESS METHOD

The Secured Access method applies to all vehicles.

This method requires the use of a DRBIIItscan tool.

This method will also require that you have access to

the unique four-digit PIN code that was assigned to

the original SKIM. The PIN codemustbe used to

enter the Secured Access Mode in the SKIM. This

PIN number may be obtained from the vehicle owner,

from the original vehicle invoice, or from the

DaimlerChrysler Customer Center. Refer to the

appropriate diagnostic information for the proper

Secured Access method programming procedures.

CUSTOMER LEARN METHOD

The Customer Learn feature is only available on

domestic vehicles, or those vehicles which have a

U.S. country code designator. This programming

method also requires access to at least two valid Sen-

try Keys. If two valid Sentry Keys are not available,

or if the vehicle does not have a U.S. country code

designator, the Secured Access Methodmustbe used

to program new or additional valid keys to the SKIM.

The Customer Learn programming method proce-

dures are as follows:

(1) Obtain the blank Sentry Key(s) that are to be

programmed as valid keys for the vehicle. Cut the

blank key(s) to match the ignition switch lock cylin-

der mechanical key codes.

(2) Insert one of the two valid Sentry Keys into the

ignition switch and turn the ignition switch to the

On position.

(3) After the ignition switch has been in the On

position for longer than three seconds, but no more

than fifteen seconds, cycle the ignition switch back to

the Off position. Replace the first valid Sentry Key in

the ignition switch lock cylinder with the second

valid Sentry Key and turn the ignition switch back to

the On position. The second valid Sentry Key must

be inserted in the lock cylinder within fifteen seconds

of removing the first valid key.

(4) About ten seconds after the completion of Step

3, the SKIS indicator in the instrument cluster will

start to flash and a single audible chime tone will

sound to indicate that the system has entered the

Customer Learn programming mode.

(5) Within sixty seconds of entering the Customer

Learn programming mode, turn the ignition switch to

the Off position, replace the valid Sentry Key with a

blank Sentry Key transponder, and turn the ignition

switch back to the On position.

(6)

About ten seconds after the completion of Step 5,

a single audible chime tone will sound and the SKIS

indicator will stop flashing, stay on solid for three sec-

onds, then turn off to indicate that the blank Sentry

Key has been successfully programmed. The SKIS will

immediately exit the Customer Learn programmingmode and the vehicle may now be started using the

newly programmed valid Sentry Key.

Each of these steps must be repeated and com-

pleted in their entirety for each additional Sentry

Key that is to be programmed. If the above steps are

not completed in the given sequence, or within the

allotted time, the SKIS will exit the Customer Learn

programming mode and the programming will be

unsuccessful. The SKIS will also automatically exit

the Customer Learn programming mode if it sees a

non-blank Sentry Key transponder when it should

see a blank, if it has already programmed eight (8)

valid Sentry Keys, or if the ignition switch is turned

to the Off position for more than about fifty seconds.

NOTE: If an attempt is made to start the vehicle

while in the Customer Learn mode (SKIS indicator

flashing), the SKIS will respond as though the vehi-

cle were being started with an invalid key. In other

words, the engine will stall after about two seconds

of operation. No faults will be set.

NOTE: Once a Sentry Key has been programmed as

a valid key to a vehicle, it cannot be programmed

as a valid key for use on any other vehicle.

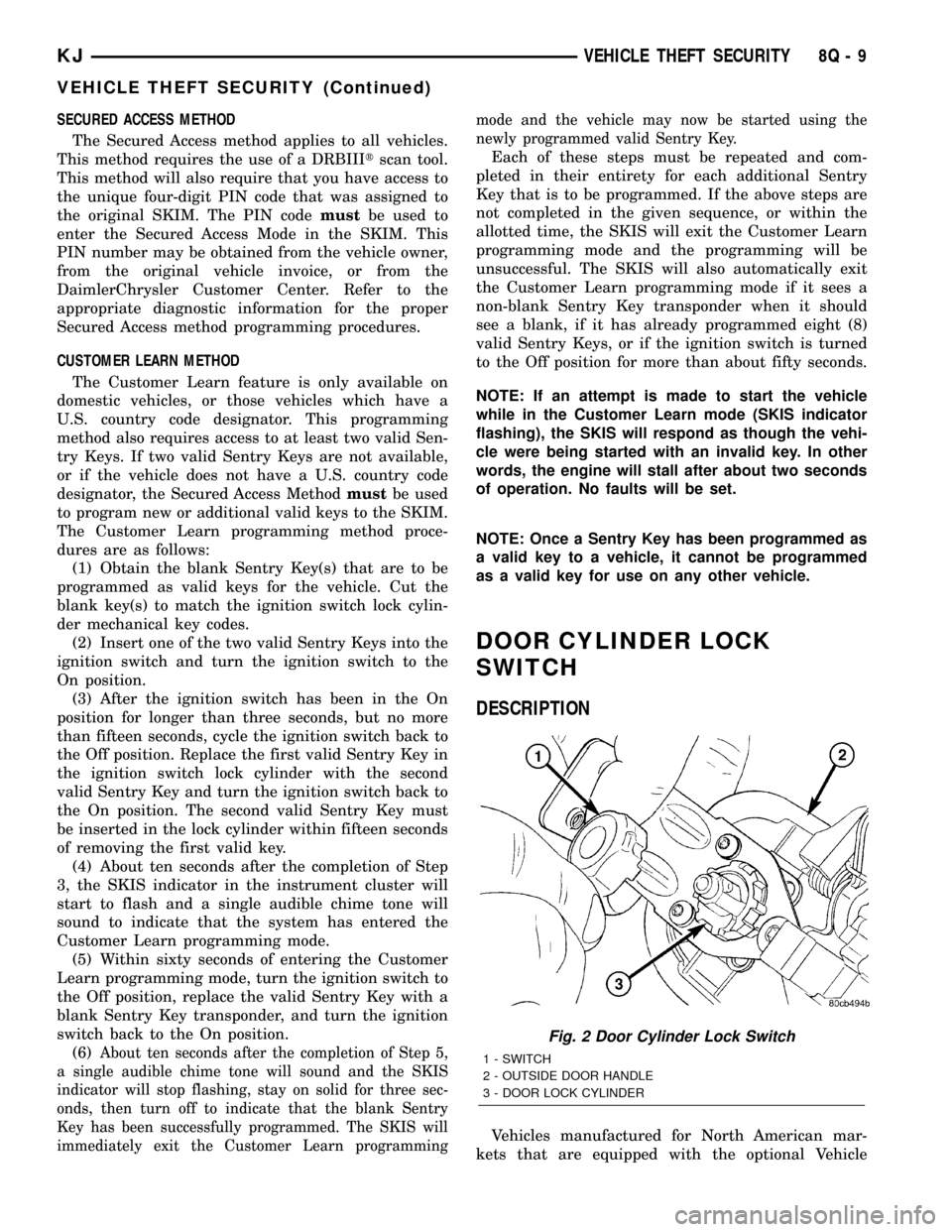

DOOR CYLINDER LOCK

SWITCH

DESCRIPTION

Vehicles manufactured for North American mar-

kets that are equipped with the optional Vehicle

Fig. 2 Door Cylinder Lock Switch

1 - SWITCH

2 - OUTSIDE DOOR HANDLE

3 - DOOR LOCK CYLINDER

KJVEHICLE THEFT SECURITY 8Q - 9

VEHICLE THEFT SECURITY (Continued)

Page 718 of 1803

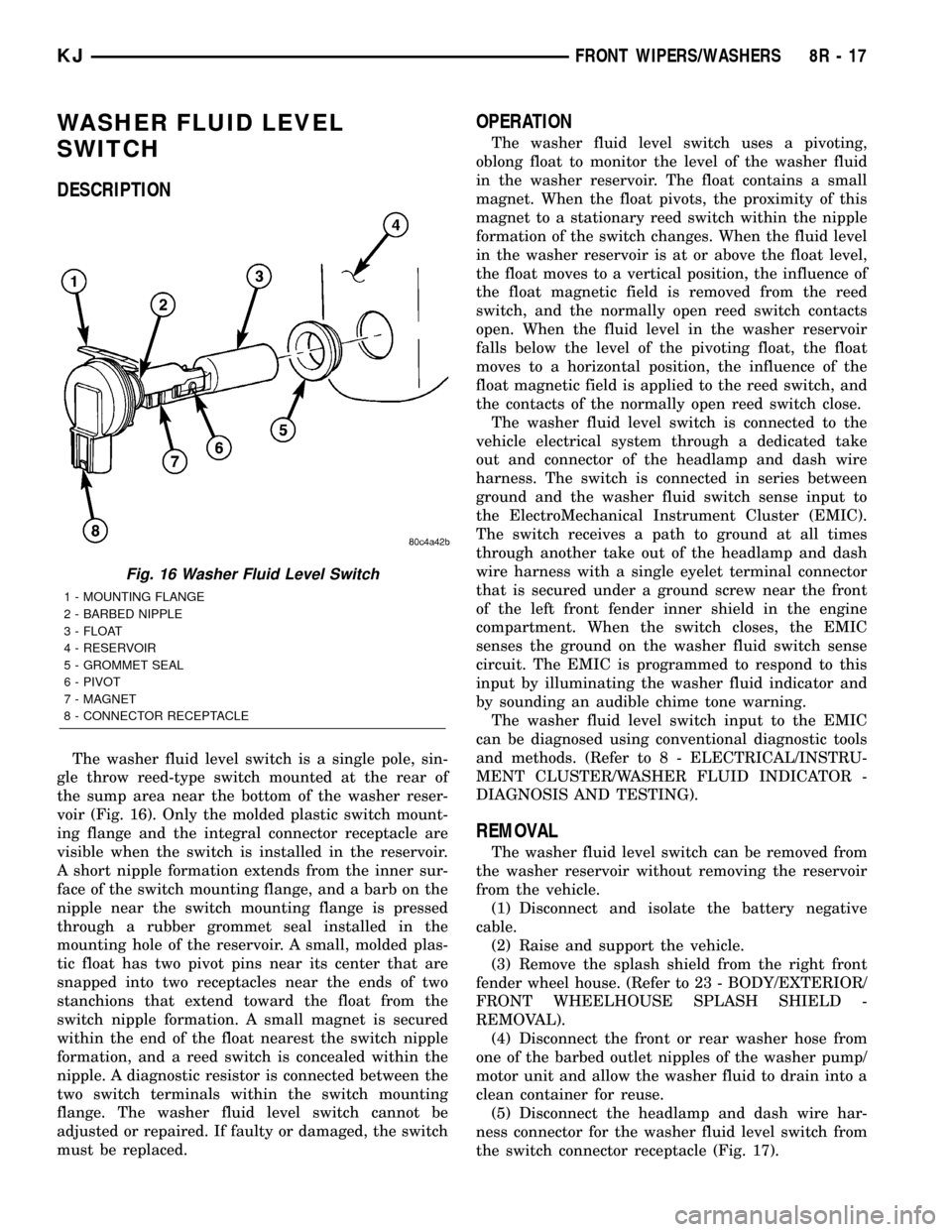

WASHER FLUID LEVEL

SWITCH

DESCRIPTION

The washer fluid level switch is a single pole, sin-

gle throw reed-type switch mounted at the rear of

the sump area near the bottom of the washer reser-

voir (Fig. 16). Only the molded plastic switch mount-

ing flange and the integral connector receptacle are

visible when the switch is installed in the reservoir.

A short nipple formation extends from the inner sur-

face of the switch mounting flange, and a barb on the

nipple near the switch mounting flange is pressed

through a rubber grommet seal installed in the

mounting hole of the reservoir. A small, molded plas-

tic float has two pivot pins near its center that are

snapped into two receptacles near the ends of two

stanchions that extend toward the float from the

switch nipple formation. A small magnet is secured

within the end of the float nearest the switch nipple

formation, and a reed switch is concealed within the

nipple. A diagnostic resistor is connected between the

two switch terminals within the switch mounting

flange. The washer fluid level switch cannot be

adjusted or repaired. If faulty or damaged, the switch

must be replaced.

OPERATION

The washer fluid level switch uses a pivoting,

oblong float to monitor the level of the washer fluid

in the washer reservoir. The float contains a small

magnet. When the float pivots, the proximity of this

magnet to a stationary reed switch within the nipple

formation of the switch changes. When the fluid level

in the washer reservoir is at or above the float level,

the float moves to a vertical position, the influence of

the float magnetic field is removed from the reed

switch, and the normally open reed switch contacts

open. When the fluid level in the washer reservoir

falls below the level of the pivoting float, the float

moves to a horizontal position, the influence of the

float magnetic field is applied to the reed switch, and

the contacts of the normally open reed switch close.

The washer fluid level switch is connected to the

vehicle electrical system through a dedicated take

out and connector of the headlamp and dash wire

harness. The switch is connected in series between

ground and the washer fluid switch sense input to

the ElectroMechanical Instrument Cluster (EMIC).

The switch receives a path to ground at all times

through another take out of the headlamp and dash

wire harness with a single eyelet terminal connector

that is secured under a ground screw near the front

of the left front fender inner shield in the engine

compartment. When the switch closes, the EMIC

senses the ground on the washer fluid switch sense

circuit. The EMIC is programmed to respond to this

input by illuminating the washer fluid indicator and

by sounding an audible chime tone warning.

The washer fluid level switch input to the EMIC

can be diagnosed using conventional diagnostic tools

and methods. (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER/WASHER FLUID INDICATOR -

DIAGNOSIS AND TESTING).

REMOVAL

The washer fluid level switch can be removed from

the washer reservoir without removing the reservoir

from the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Raise and support the vehicle.

(3) Remove the splash shield from the right front

fender wheel house. (Refer to 23 - BODY/EXTERIOR/

FRONT WHEELHOUSE SPLASH SHIELD -

REMOVAL).

(4) Disconnect the front or rear washer hose from

one of the barbed outlet nipples of the washer pump/

motor unit and allow the washer fluid to drain into a

clean container for reuse.

(5) Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the switch connector receptacle (Fig. 17).

Fig. 16 Washer Fluid Level Switch

1 - MOUNTING FLANGE

2 - BARBED NIPPLE

3 - FLOAT

4 - RESERVOIR

5 - GROMMET SEAL

6 - PIVOT

7 - MAGNET

8 - CONNECTOR RECEPTACLE

KJFRONT WIPERS/WASHERS 8R - 17