compression ratio JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1316 of 1803

AIR CLEANER ELEMENT

REMOVAL - 2.4L

Housing removal is not necessary for element (fil-

ter) replacement.

(1) Disconnect air intake duct at side of element

cover.

(2) Pry up 2 spring clips from front of housing

cover (spring clips retain cover to housing).

(3) Release housing cover from locating tabs

located on rear of housing, and remove cover.

(4) Remove air cleaner element (filter) from hous-

ing.

(5) Clean inside of housing before replacing ele-

ment.

INSTALLATION - 2.4L

(1) Install element into housing.

(2) Position housing cover into housing locating

tabs.

(3) Pry up spring clips and lock cover to housing.

(4) Connect air intake duct.

If any air filter, air resonator, air intake tubes or

air filter housing clamps had been loosened or

removed, tighten them to 5 N´m (40 in. lbs.) torque.

CYLINDER HEAD

DESCRIPTION

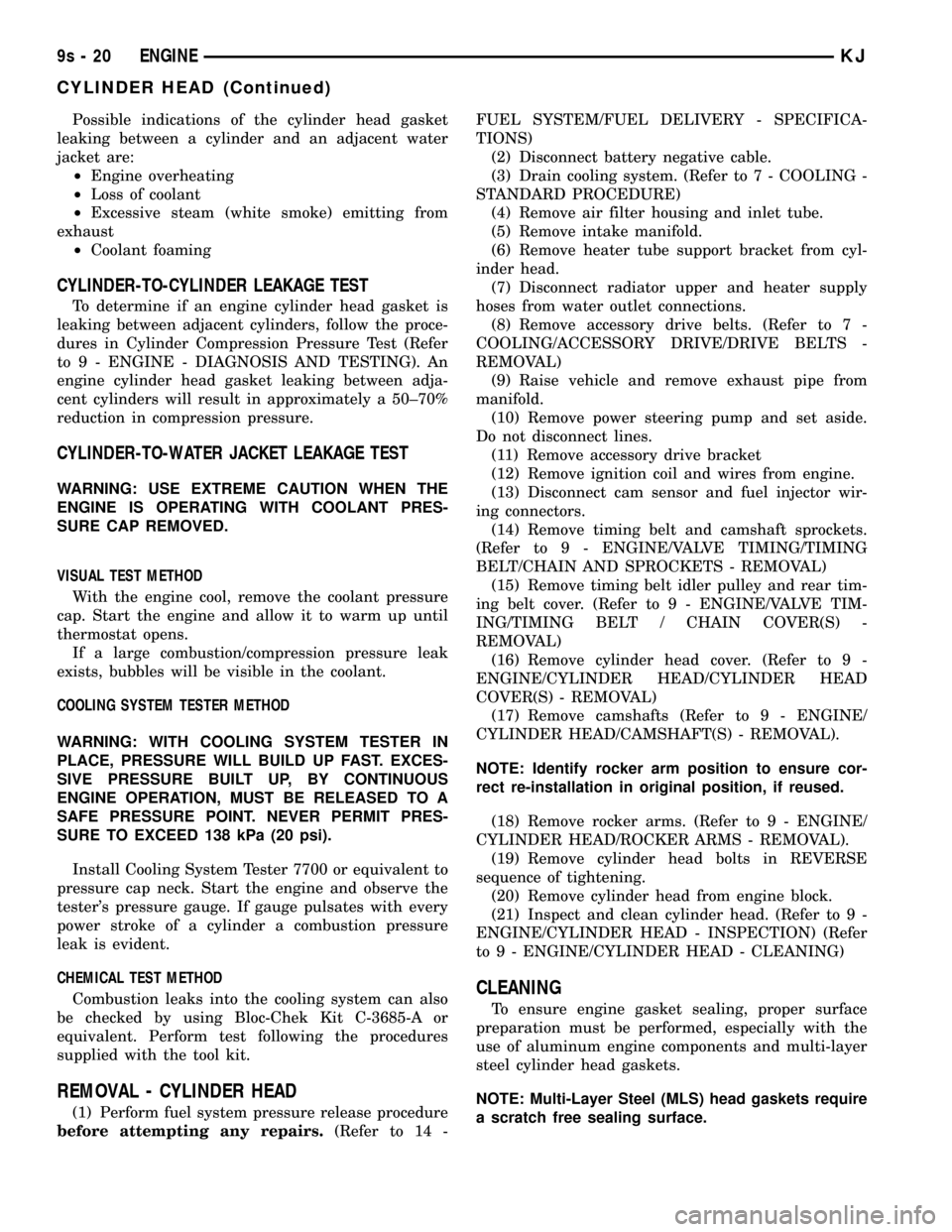

The cross flow designed, aluminum cylinder head

contains dual over-head camshafts with four valves

per cylinder (Fig. 5). The valves are arrange in two

in-line banks. The intake valves face toward the left

side of the vehicle. The exhaust valves face the right

side. The cylinder head incorporates powdered metalvalve guides and seats. The cylinder head is sealed to

the block using a multi-layer steel head gasket and

retaining bolts.

Integral oil galleries providing lubrication passages

to the hydraulic lash adjusters, camshafts, and valve

mechanisms.

OPERATION

The cylinder head closes the combustion chamber,

allowing the pistons to compress the fuel/air mixture

for ignition. The valves are actuated by the lobe pro-

files on the camshaft to open and close at specified

duration to either allow clean air in the combustion

chamber or the exhaust gases out; depending on the

stroke of the engine.

DIAGNOSIS AND TESTING - CYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Combustion Leak Tester C-3685-A

Cylinder Compression Pressure Adaptor 8116

Fig. 5 Cylinder Head and Camshafts

CAM PLUG - NOT SHOWN

1 - CAMSHAFT BEARING CAPS

2 - PLUG

3 - CAMSHAFT

4 - CYLINDER HEAD

5 - CAMSHAFT OIL SEAL

KJENGINE9s-19

ENGINE - 2.4L (Continued)

Page 1317 of 1803

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test (Refer

to 9 - ENGINE - DIAGNOSIS AND TESTING). An

engine cylinder head gasket leaking between adja-

cent cylinders will result in approximately a 50±70%

reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.

COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

REMOVAL - CYLINDER HEAD

(1) Perform fuel system pressure release procedure

before attempting any repairs.(Refer to 14 -FUEL SYSTEM/FUEL DELIVERY - SPECIFICA-

TIONS)

(2) Disconnect battery negative cable.

(3) Drain cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(4) Remove air filter housing and inlet tube.

(5) Remove intake manifold.

(6) Remove heater tube support bracket from cyl-

inder head.

(7) Disconnect radiator upper and heater supply

hoses from water outlet connections.

(8) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(9) Raise vehicle and remove exhaust pipe from

manifold.

(10) Remove power steering pump and set aside.

Do not disconnect lines.

(11) Remove accessory drive bracket

(12) Remove ignition coil and wires from engine.

(13) Disconnect cam sensor and fuel injector wir-

ing connectors.

(14) Remove timing belt and camshaft sprockets.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT/CHAIN AND SPROCKETS - REMOVAL)

(15) Remove timing belt idler pulley and rear tim-

ing belt cover. (Refer to 9 - ENGINE/VALVE TIM-

ING/TIMING BELT / CHAIN COVER(S) -

REMOVAL)

(16) Remove cylinder head cover. (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL)

(17) Remove camshafts (Refer to 9 - ENGINE/

CYLINDER HEAD/CAMSHAFT(S) - REMOVAL).

NOTE: Identify rocker arm position to ensure cor-

rect re-installation in original position, if reused.

(18) Remove rocker arms. (Refer to 9 - ENGINE/

CYLINDER HEAD/ROCKER ARMS - REMOVAL).

(19) Remove cylinder head bolts in REVERSE

sequence of tightening.

(20) Remove cylinder head from engine block.

(21) Inspect and clean cylinder head. (Refer to 9 -

ENGINE/CYLINDER HEAD - INSPECTION) (Refer

to 9 - ENGINE/CYLINDER HEAD - CLEANING)

CLEANING

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

9s - 20 ENGINEKJ

CYLINDER HEAD (Continued)

Page 1338 of 1803

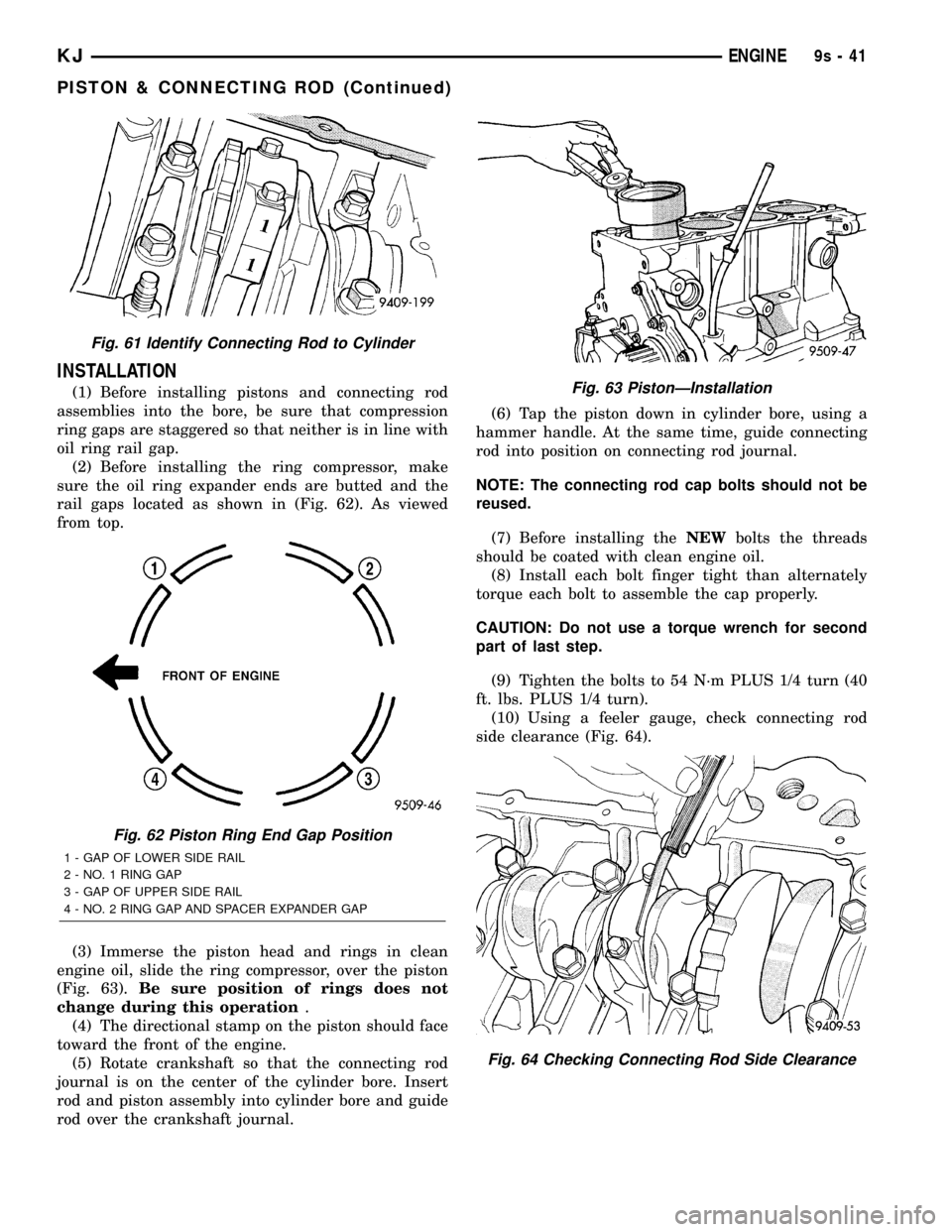

INSTALLATION

(1) Before installing pistons and connecting rod

assemblies into the bore, be sure that compression

ring gaps are staggered so that neither is in line with

oil ring rail gap.

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 62). As viewed

from top.

(3) Immerse the piston head and rings in clean

engine oil, slide the ring compressor, over the piston

(Fig. 63).Be sure position of rings does not

change during this operation.

(4) The directional stamp on the piston should face

toward the front of the engine.

(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insert

rod and piston assembly into cylinder bore and guide

rod over the crankshaft journal.(6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

NOTE: The connecting rod cap bolts should not be

reused.

(7) Before installing theNEWbolts the threads

should be coated with clean engine oil.

(8) Install each bolt finger tight than alternately

torque each bolt to assemble the cap properly.

CAUTION: Do not use a torque wrench for second

part of last step.

(9) Tighten the bolts to 54 N´m PLUS 1/4 turn (40

ft. lbs. PLUS 1/4 turn).

(10) Using a feeler gauge, check connecting rod

side clearance (Fig. 64).

Fig. 61 Identify Connecting Rod to Cylinder

Fig. 62 Piston Ring End Gap Position

1 - GAP OF LOWER SIDE RAIL

2 - NO. 1 RING GAP

3 - GAP OF UPPER SIDE RAIL

4 - NO. 2 RING GAP AND SPACER EXPANDER GAP

Fig. 63 PistonÐInstallation

Fig. 64 Checking Connecting Rod Side Clearance

KJENGINE9s-41

PISTON & CONNECTING ROD (Continued)

Page 1745 of 1803

COMPASS CALIBRATION - STANDARD

PROCEDURE.........................8M-2

COMPASS DEMAGNETIZING -

STANDARD PROCEDURE...............8M-2

COMPASS MINI-TRIP COMPUTER -

DIAGNOSIS AND TESTING..............8M-6

COMPASS MINI-TRIP ILLUMINATION

BULB - INSTALLATION................8L-75

COMPASS MINI-TRIP ILLUMINATION

BULB - REMOVAL....................8L-74

COMPASS VARIATION ADJUSTMENT -

STANDARD PROCEDURE...............8M-3

COMPASS/MINI-TRIP COMPUTER -

DESCRIPTION........................8M-4

COMPASS/MINI-TRIP COMPUTER -

INSTALLATION.......................8M-8

COMPASS/MINI-TRIP COMPUTER -

OPERATION.........................8M-5

COMPASS/MINI-TRIP COMPUTER -

REMOVAL...........................8M-7

COMPRESSION PRESSURE - DIAGNOSIS

AND TESTING, CYLINDER................9-8

COMPRESSOR CLUTCH - INSPECTION,

A/C................................24-14

COMPRESSOR CLUTCH - INSTALLATION,

A/C................................24-14

COMPRESSOR CLUTCH - REMOVAL, A/C . . 24-13

COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE, A/C...........24-12

COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING, A/C..........24-12

COMPRESSOR CLUTCH RELAY -

DESCRIPTION, A/C...................24-15

COMPRESSOR CLUTCH RELAY -

DIAGNOSIS AND TESTING.............24-15

COMPRESSOR CLUTCH RELAY -

INSTALLATION, A/C...................24-16

COMPRESSOR CLUTCH RELAY -

OPERATION, A/C.....................24-15

COMPRESSOR CLUTCH RELAY -

REMOVAL, A/C......................24-16

COMPRESSOR NOISE - DIAGNOSIS AND

TESTING, A/C.......................24-42

COMPUTER - DESCRIPTION, COMPASS/

MINI-TRIP..........................8M-4

COMPUTER - DIAGNOSIS AND TESTING,

COMPASS MINI-TRIP..................8M-6

COMPUTER - INSTALLATION, COMPASS/

MINI-TRIP..........................8M-8

COMPUTER - OPERATION, COMPASS/

MINI-TRIP..........................8M-5

COMPUTER - REMOVAL, COMPASS/

MINI-TRIP..........................8M-7

CONDENSER - DESCRIPTION, A/C.......24-45

CONDENSER - INSTALLATION, A/C.......24-46

CONDENSER - OPERATION, A/C.........24-45

CONDENSER - REMOVAL, A/C..........24-45

CONDITIONER - DESCRIPTION, HEATER

AND AIR ............................24-1

CONDITIONER - OPERATION, HEATER

AND AIR ............................24-2

CONDITIONS - DIAGNOSIS AND

TESTING, SPARK PLUG................8I-13

CONNECT FITTING - DESCRIPTION,

QUICK.............................14-10

CONNECTING ROD - DESCRIPTION,

PISTON.............................9-49

CONNECTING ROD BEARING - FITTING -

STANDARD PROCEDURE................9-40

CONNECTING ROD BEARING, FITTING.....9-49

CONNECTOR - DESCRIPTION, DATA LINK . 8E-10

CONNECTOR - INSTALLATION

.......8W-01-11

CONNECTOR - INSTALLATION, TRAILER

TOW

..............................8L-61

CONNECTOR - OPERATION, DATA LINK

. . . 8E-10

CONNECTOR - REMOVAL

...........8W-01-11

CONNECTOR - REMOVAL, TRAILER TOW

. . 8L-61

CONNECTOR, GROUND AND SPLICE

INFORMATION - DESCRIPTION

........8W-01-7

CONNECTOR/GROUND/SPLICE LOCATION

- DESCRIPTION

....................8W-91-1

CONSOLE - DESCRIPTION, OVERHEAD

....8M-1

CONSOLE - INSTALLATION, FLOOR

.....23-158

CONSOLE - OPERATION, OVERHEAD

......8M-2

CONSOLE - REMOVAL, FLOOR

.........23-158

CONSOLE DUCT - INSTALLATION, FLOOR

. 24-31

CONSOLE DUCT - REMOVAL, FLOOR

.....24-31CONSOLE LID LATCH - INSTALLATION,

FLOOR............................23-158

CONSOLE LID LATCH - REMOVAL,

FLOOR............................23-158

CONSOLE, REMOVAL - OVERHEAD.......8M-4

CONTAINER - DESCRIPTION, COOLANT

RECOVERY PRESS....................7-19

CONTAINER - OPERATION, COOLANT

RECOVERY PRESS....................7-19

CONTAMINATION - DIAGNOSIS AND

TESTING, BRAKE FLUID................5-26

CONTAMINATION - DIAGNOSIS AND

TESTING, FLUID....................21-125

CONTINUITY - STANDARD PROCEDURE,

TESTING.........................8W-01-9

CONTROL - DESCRIPTION, A/C HEATER . . . 24-16

CONTROL - DESCRIPTION, IGNITION......8I-1

CONTROL - DESCRIPTION, SPEED........8P-1

CONTROL - INSTALLATION, A/C HEATER . . 24-17

CONTROL - OPERATION, IGNITION........8I-1

CONTROL - OPERATION, SPEED..........8P-1

CONTROL - REMOVAL, A/C HEATER......24-17

CONTROL - TORQUE, SPEED............8P-2

CONTROL ARM - DESCRIPTION, LOWER . . . 2-21

CONTROL ARM - INSTALLATION, LOWER . . 2-10,

2-21

CONTROL ARM - INSTALLATION, UPPER . . . 2-21

CONTROL ARM - OPERATION, LOWER.....2-21

CONTROL ARM - REMOVAL, LOWER . . 2-10,2-21

CONTROL ARM - REMOVAL, UPPER......2-20

CONTROL ASSEMBLY WINDOW

DEFOGGER FUNCTION - DIAGNOSIS

AND TESTING, REAR HVAC.............8G-9

CONTROL CABLE - INSTALLATION,

THROTTLE..........................14-46

CONTROL CABLE - REMOVAL,

THROTTLE..........................14-45

CONTROL ILLUMINATION BULB -

INSTALLATION, HEATER-A/C............8L-78

CONTROL ILLUMINATION BULB -

REMOVAL, HEATER-A/C...............8L-78

CONTROL INFORMATION (VECI) LABEL -

DESCRIPTION, VEHICLE EMISSION.....Intro.-8

CONTROL MODULE - DESCRIPTION,

AIRBAG.............................8O-9

CONTROL MODULE - DESCRIPTION,

BODY...............................8E-2

CONTROL MODULE - DESCRIPTION,

SIDE IMPACT AIRBAG.................8O-43

CONTROL MODULE - DESCRIPTION,

TRANSMISSION......................8E-18

CONTROL MODULE - DIAGNOSIS AND

TESTING, BODY.......................8E-7

CONTROL MODULE - INSTALLATION....23-183

CONTROL MODULE - INSTALLATION,

AIRBAG............................8O-12

CONTROL MODULE - INSTALLATION,

BODY...............................8E-7

CONTROL MODULE - INSTALLATION,

SIDE IMPACT AIRBAG.................8O-45

CONTROL MODULE - OPERATION,

AIRBAG............................8O-10

CONTROL MODULE - OPERATION, BODY . . . 8E-5

CONTROL MODULE - OPERATION, SIDE

IMPACT AIRBAG.....................8O-43

CONTROL MODULE - OPERATION,

TRANSMISSION......................8E-18

CONTROL MODULE - REMOVAL........23-183

CONTROL MODULE - REMOVAL, AIRBAG . 8O-11

CONTROL MODULE - REMOVAL, BODY....8E-7

CONTROL MODULE - REMOVAL, SIDE

IMPACT AIRBAG.....................8O-44

CONTROL MOTOR - DESCRIPTION, IDLE

AIR ...............................14-35

CONTROL MOTOR - INSTALLATION, IDLE

AIR ...............................14-36

CONTROL MOTOR - OPERATION, IDLE

AIR ...............................14-35

CONTROL MOTOR - REMOVAL, IDLE AIR . . 14-36

CONTROL RELAY - DESCRIPTION,

TRANSMISSION.....................21-168

CONTROL RELAY - OPERATION,

TRANSMISSION

.....................21-168

CONTROL SWITCH - DESCRIPTION

.....23-184

CONTROL SWITCH - DIAGNOSIS AND

TESTING

..........................23-184

CONTROL SWITCH - INSTALLATION

.....23-184

CONTROL SWITCH - OPERATION

.......23-184CONTROL SWITCH - REMOVAL........23-184

CONTROL SYSTEM - DESCRIPTION,

EMISSION...........................25-1

CONTROL SYSTEM - DESCRIPTION,

EVAPORATION.......................25-24

CONTROLLER ANTILOCK BRAKE -

INSTALLATION.......................8E-10

CONTROLLER ANTILOCK BRAKE -

REMOVAL..........................8E-10

CONVERTER - DESCRIPTION, CATALYTIC . . . 11-2

CONVERTER - DESCRIPTION, TORQUE . . . 21-162

CONVERTER - INSPECTION, CATALYTIC....11-3

CONVERTER - INSTALLATION, CATALYTIC . . 11-3

CONVERTER - INSTALLATION, TORQUE . . 21-167

CONVERTER - OPERATION, TORQUE....21-166

CONVERTER - REMOVAL, CATALYTIC......11-2

CONVERTER - REMOVAL, TORQUE......21-167

CONVERTER HOUSING FLUID LEAK -

DIAGNOSIS AND TESTING.............21-80

COOLANT - DESCRIPTION, ENGINE........0-3

COOLANT LOW INDICATOR -

DESCRIPTION.......................8J-15

COOLANT LOW INDICATOR - OPERATION . 8J-16

COOLANT RECOVERY PRESS

CONTAINER - DESCRIPTION.............7-19

COOLANT RECOVERY PRESS

CONTAINER - OPERATION...............7-19

COOLANT TEMPERATURE SENSOR -

DESCRIPTION, ENGINE.................7-19

COOLANT TEMPERATURE SENSOR -

INSTALLATION, ENGINE................7-21

COOLANT TEMPERATURE SENSOR -

OPERATION, ENGINE...................7-20

COOLANT TEMPERATURE SENSOR -

REMOVAL, ENGINE....................7-20

COOLANT THERMOSTAT - OPERATION,

ENGINE.............................7-21

COOLER - DESCRIPTION, FLUID.........19-20

COOLER - DESCRIPTION, TRANS.........7-32

COOLER - INSTALLATION, FLUID........19-20

COOLER - OPERATION, FLUID..........19-20

COOLER - REMOVAL, FLUID............19-20

COOLING, SPECIAL TOOLS..............7-14

COOLING SYSTEM - OPERATION..........7-2

COOLING SYSTEM - REVERSE

FLUSHING - STANDARD PROCEDURE.....7-12

COOLING SYSTEM 3.7L ENGINE -

DESCRIPTION.........................7-1

COOLING SYSTEM 3.7L ENGINE -

STANDARD PROCEDURE, DRAINING......7-12

COOLING SYSTEM 3.7L ENGINE -

STANDARD PROCEDURE, REFILLING......7-12

COOLING SYSTEM DIAGNOSIS CHART -

DIAGNOSIS AND TESTING...............7-6

COOLING SYSTEM LEAKS - DIAGNOSIS

AND TESTING.........................7-4

COOLING SYSTEM REQUIREMENTS -

DESCRIPTION........................24-1

COOLING SYSTEM ROUTING 3.7L

ENGINE - DESCRIPTION.................7-2

CORE - DESCRIPTION, HEATER.........24-52

CORE - INSTALLATION, HEATER.........24-53

CORE - OPERATION, HEATER...........24-52

CORE - REMOVAL, HEATER............24-52

CORE AND OIL GALLERY PLUGS -

STANDARD PROCEDURE, ENGINE........9-10

COURTESY LAMP BULB - INSTALLATION . . 8L-76

COURTESY LAMP BULB - REMOVAL.....8L-75

COURTESY LAMP REPLACEMENT -

STANDARD PROCEDURE...............8M-2

COURTESY LAMP UNIT - INSTALLATION . . 8L-77

COURTESY LAMP UNIT - REMOVAL......8L-76

COVER - DESCRIPTION, STRUCTURAL.....9-55

COVER - FRONT - INSTALLATION, SEAT

BACK.............................23-167

COVER - FRONT - INSTALLATION, SEAT

CUSHION..........................23-167

COVER - FRONT - REMOVAL, SEAT BACK . 23-166

COVER - FRONT - REMOVAL, SEAT

CUSHION..........................23-167

COVER - INSTALLATION, COWL TRIM . . . 23-157

COVER - INSTALLATION, INSTRUMENT

PANEL TOP

........................23-153

COVER - INSTALLATION, STRUCTURAL

....9-55

COVER - OPERATION, STRUCTURAL

......9-55

COVER - REAR - INSTALLATION, SEAT

BACK

.............................23-169

COVER - REAR - REMOVAL, SEAT BACK

. 23-169

6 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1746 of 1803

COVER - REMOVAL, COWL TRIM.......23-157

COVER - REMOVAL, INSTRUMENT

PANEL TOP........................23-152

COVER - REMOVAL, STRUCTURAL........9-55

COVER(S) - DESCRIPTION, CYLINDER

HEAD...............................9-25

COVER(S) - INSTALLATION, CYLINDER

HEAD...........................9-26,9-34

COVER(S) - INSTALLATION, TIMING

BELT / CHAIN........................9-76

COVER(S) - REMOVAL, CYLINDER HEAD . . 9-25,

9-34

COVER(S) - REMOVAL, TIMING BELT /

CHAIN..............................9-74

COWL GRILLE - INSTALLATION........23-140

COWL GRILLE - REMOVAL............23-140

COWL TRIM COVER - INSTALLATION....23-157

COWL TRIM COVER - REMOVAL.......23-157

COWL WEATHERSTRIP - INSTALLATION . 23-185

COWL WEATHERSTRIP - REMOVAL.....23-185

COWL/PLENUM SEAL - INSTALLATION . . . 23-187

COWL/PLENUM SEAL - REMOVAL......23-187

COWL/PLENUM WINDOW BAFFLE SEAL -

INSTALLATION......................23-187

COWL/PLENUM WINDOW BAFFLE SEAL -

REMOVAL.........................23-187

CRADLE CROSSMEMBER -

INSTALLATION, ENGINE................13-6

CRADLE CROSSMEMBER - REMOVAL,

ENGINE.............................13-6

CRANKSHAFT - DESCRIPTION...........9-42

CRANKSHAFT - INSPECTION.............9-43

CRANKSHAFT - INSTALLATION...........9-43

CRANKSHAFT - REMOVAL..............9-43

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION........................9-47

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL...........................9-46

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION........................9-48

CRANKSHAFT OIL SEAL - REAR -

REMOVAL...........................9-48

CRANKSHAFT POSITION SENSOR -

DESCRIPTION.......................14-30

CRANKSHAFT POSITION SENSOR -

INSTALLATION.......................14-32

CRANKSHAFT POSITION SENSOR -

OPERATION.........................14-31

CRANKSHAFT POSITION SENSOR -

REMOVAL..........................14-31

CROSSMEMBER - INSTALLATION,

ENGINE CRADLE......................13-6

CROSSMEMBER - INSTALLATION,

RADIATOR.........................23-146

CROSSMEMBER - INSTALLATION, REAR . . . 13-7

CROSSMEMBER - REMOVAL, ENGINE

CRADLE.............................13-6

CROSSMEMBER - REMOVAL, RADIATOR . 23-146

CROSSMEMBER - REMOVAL, REAR.......13-7

CROSS-OVER PIPE - INSTALLATION.......11-3

CROSS-OVER PIPE - REMOVAL..........11-3

CRUISE INDICATOR - DESCRIPTION......8J-16

CRUISE INDICATOR - OPERATION.......8J-17

CURTAIN AIRBAG - DESCRIPTION, SIDE . . 8O-38

CURTAIN AIRBAG - INSTALLATION, SIDE . . 8O-41

CURTAIN AIRBAG - OPERATION, SIDE....8O-39

CURTAIN AIRBAG - REMOVAL, SIDE.....8O-40

CUSHION - FRONT - INSTALLATION,

SEAT .............................23-167

CUSHION - FRONT - INSTALLATION,

SEAT BACK........................23-167

CUSHION - FRONT - REMOVAL, SEAT . . . 23-167

CUSHION - FRONT - REMOVAL, SEAT

BACK.............................23-167

CUSHION - REAR - INSTALLATION, SEAT . 23-171

CUSHION - REAR - INSTALLATION, SEAT

BACK.............................23-170

CUSHION - REAR - REMOVAL, SEAT....23-171

CUSHION - REAR - REMOVAL, SEAT

BACK

.............................23-170

CUSHION COVER - FRONT -

INSTALLATION, SEAT

.................23-167

CUSHION COVER - FRONT - REMOVAL,

SEAT

.............................23-167

CUSHION SIDE SHIELDS -

INSTALLATION, SEAT

.................23-167

CUSHION SIDE SHIELDS - REMOVAL,

SEAT

.............................23-167CUSTOMER PREFERENCES - STANDARD

PROCEDURE, RKE TRANSMITTER........8N-8

CV JOINT/BOOT-INNER - INSTALLATION . . . 3-17

CV JOINT/BOOT-INNER - REMOVAL.......3-15

CV JOINT/BOOT-OUTER - INSTALLATION . . . 3-13

CV JOINT/BOOT-OUTER - REMOVAL.......3-12

CYLINDER - DESCRIPTION, MASTER......5-24

CYLINDER - INSPECTION, MASTER........6-9

CYLINDER - INSTALLATION, FLIP-UP

GLASS SUPPORT...................23-139

CYLINDER - INSTALLATION, LOCK......23-125,

23-138

CYLINDER - INSTALLATION, LOCK.......19-11

CYLINDER - INSTALLATION, MASTER.....5-25

CYLINDER - INSTALLATION, SUPPORT . . . 23-120

CYLINDER - OPERATION, MASTER........5-24

CYLINDER - REMOVAL, FLIP-UP GLASS

SUPPORT.........................23-139

CYLINDER - REMOVAL, LOCK....23-125,23-137

CYLINDER - REMOVAL, LOCK...........19-10

CYLINDER - REMOVAL, MASTER.........5-25

CYLINDER - REMOVAL, SUPPORT......23-120

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER.................5-24

CYLINDER BORE HONING - STANDARD

PROCEDURE.........................9-39

CYLINDER COMBUSTION PRESSURE

LEAKAGE - DIAGNOSIS AND TESTING......9-8

CYLINDER COMPRESSION PRESSURE -

DIAGNOSIS AND TESTING...............9-8

CYLINDER FLUID LEVEL - STANDARD

PROCEDURES, MASTER................5-26

CYLINDER HEAD - DESCRIPTION.........9-30

CYLINDER HEAD COVER(S) -

DESCRIPTION........................9-25

CYLINDER HEAD COVER(S) -

INSTALLATION....................9-26,9-34

CYLINDER HEAD COVER(S) - REMOVAL . . . 9-25,

9-34

CYLINDER HEAD GASKET - DIAGNOSIS

AND TESTING....................9-19,9-30

CYLINDER LOCK SWITCH -

DESCRIPTION, DOOR..................8Q-9

CYLINDER LOCK SWITCH -

DESCRIPTION, TAILGATE...............8N-9

CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, DOOR.................8Q-10

CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, TAILGATE...............8N-9

CYLINDER LOCK SWITCH -

INSTALLATION, DOOR.................8Q-10

CYLINDER LOCK SWITCH -

INSTALLATION, TAILGATE..............8N-10

CYLINDER LOCK SWITCH - OPERATION,

DOOR.............................8Q-10

CYLINDER LOCK SWITCH - OPERATION,

TAILGATE...........................8N-9

CYLINDER LOCK SWITCH - REMOVAL,

DOOR.............................8Q-10

CYLINDER LOCK SWITCH - REMOVAL,

TAILGATE..........................8N-10

CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING, MASTER . . 5-21,5-24

CYLINDERS - ASSEMBLY, WHEEL.........5-29

CYLINDERS - CLEANING, WHEEL.........5-28

CYLINDERS - DISASSEMBLY, WHEEL......5-28

CYLINDERS - INSPECTION, WHEEL.......5-29

CYLINDERS - INSTALLATION, WHEEL

.....5-29

CYLINDERS - REMOVAL, WHEEL

.........5-28

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE, REPAIR

.........9-9

DAMPER - INSTALLATION, VIBRATION

.....9-55

DAMPER - REMOVAL, VIBRATION

........9-54

DATA LINK CONNECTOR - DESCRIPTION

. . 8E-10

DATA LINK CONNECTOR - OPERATION

....8E-10

DAYTIME RUNNING LAMP RELAY -

DESCRIPTION

.......................8L-20

DAYTIME RUNNING LAMP RELAY -

INSTALLATION

.......................8L-21

DAYTIME RUNNING LAMP RELAY -

OPERATION

.........................8L-20

DAYTIME RUNNING LAMP RELAY -

REMOVAL

..........................8L-21

DECOUPLER - DIAGNOSIS AND

TESTING, GENERATOR

................8F-27

DECOUPLER PULLEY - DESCRIPTION,

GENERATOR

........................8F-26DECOUPLER PULLEY - INSTALLATION,

GENERATOR........................8F-30

DECOUPLER PULLEY - OPERATION,

GENERATOR........................8F-27

DECOUPLER PULLEY - REMOVAL,

GENERATOR........................8F-27

DEFINITION - DESCRIPTION, TRIP.......25-19

DEFLECTOR - INSTALLATION, WIND.....23-180

DEFLECTOR - REMOVAL, WIND........23-180

DEFOGGER - DESCRIPTION, REAR

WINDOW............................8G-3

DEFOGGER - OPERATION, REAR

WINDOW............................8G-3

DEFOGGER FUNCTION - DIAGNOSIS AND

TESTING, REAR HVAC CONTROL

ASSEMBLY WINDOW..................8G-9

DEFOGGER GRID - DESCRIPTION, REAR

WINDOW............................8G-5

DEFOGGER GRID - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-5

DEFOGGER GRID - OPERATION, REAR

WINDOW............................8G-5

DEFOGGER RELAY - DESCRIPTION,

REAR WINDOW.......................8G-6

DEFOGGER RELAY - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-6

DEFOGGER RELAY - INSTALLATION,

REAR WINDOW.......................8G-7

DEFOGGER RELAY - OPERATION, REAR

WINDOW............................8G-6

DEFOGGER RELAY - REMOVAL, REAR

WINDOW............................8G-7

DEFOGGER SWITCH - DESCRIPTION,

REAR WINDOW.......................8G-8

DEFOGGER SWITCH - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-8

DEFOGGER SWITCH - OPERATION, REAR

WINDOW............................8G-8

DEFOGGER SYSTEM - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-4

DEFROST DOO - INSTALLATION, FLOOR . . 24-37

DEFROST DOOR - REMOVAL...........24-35

DEFROST DOOR - REMOVAL, FLOOR.....24-36

DEFROST DOOR ACTUATOR -

INSTALLATION, FLOOR................24-25

DEFROST DOOR ACTUATOR - REMOVAL,

FLOOR.............................24-24

DEFROST DUCT/DEMISTER ADAPTOR -

REMOVAL..........................24-32

DEFROST/DEMISTER DUCT -

INSTALLATION.......................24-32

DELIVERY - DESCRIPTION, FUEL.........14-2

DELIVERY - OPERATION, FUEL...........14-3

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS...............8M-2

DEMISTER OUTLETS - DESCRIPTION.....24-29

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL RESTRAINT............8O-6

DETECTION PUMP - DESCRIPTION, LEAK . 25-27

DETECTION PUMP - INSTALLATION,

LEAK..............................25-28

DETECTION PUMP - OPERATION, LEAK . . . 25-28

DETECTION PUMP - REMOVAL, LEAK....25-28

DEVICES - STANDARD PROCEDURE,

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE........................8W-01-8

DIAGNOSIS CHART - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-6

DIAGNOSIS, DIAGNOSIS AND TESTING -

WATER DRAINAGE AND WIND NOISE . . . 23-176

DIAGNOSTIC PROCEDURES, DIAGNOSIS

AND TESTING......................23-176

DIAGNOSTIC TROUBLE CODES -

DESCRIPTION........................25-2

DIAGNOSTICS (OBD) - DIAGNOSIS AND

TESTING, ON-BOARD...................7-3

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING......................8W-01-1

DIAGRAMS - HYDRAULIC SCHEMATICS,

SCHEMATICS.......................21-100

DIESEL - TORQUE, EXCEPT.............8F-23

DIFFERENTIAL - ASSEMBLY

........3-105,3-41

DIFFERENTIAL - DISASSEMBLY

.....3-105,3-41

DIFFERENTIAL - INSTALLATION

. 3-105,3-42,3-73

DIFFERENTIAL - REMOVAL

.....3-104,3-40,3-71

DIFFERENTIAL - TRAC-LOK - ASSEMBLY

. . 3-109,

3-77

KJINDEX 7

Description Group-Page Description Group-Page Description Group-Page

Page 1758 of 1803

PLATE LAMP UNIT - INSTALLATION,

LICENSE...........................8L-46

PLATE LAMP UNIT - REMOVAL, LICENSE . . 8L-45

PLATES - INSTALLATION, EXTERIOR

NAME............................23-141

PLATES - REMOVAL, EXTERIOR NAME . . . 23-140

PLUG - CLEANING SPARK PLUGS,

SPARK .............................8I-15

PLUG - DESCRIPTION, SPARK...........8I-12

PLUG - INSTALLATION, SPARK..........8I-15

PLUG - OPERATION, SPARK............8I-12

PLUG - REMOVAL, SPARK..............8I-15

PLUG CABLE RESISTANCE, 2.4L - SPARK . . . 8I-3

PLUG CONDITIONS - DIAGNOSIS AND

TESTING, SPARK.....................8I-13

PLUGS - STANDARD PROCEDURE,

ENGINE CORE AND OIL GALLERY........9-10

PLUGS, SPARK PLUG - CLEANING

SPARK .............................8I-15

PLUGS, SPECIFICATIONS - SPARK........8I-3

POLISHING - DESCRIPTION, FINESSE

SANDING/BUFFING..................23-163

PORT - DESCRIPTION, REFRIGERANT

SYSTEM SERVICE.....................24-2

PORT - OPERATION, REFRIGERANT

SYSTEM SERVICE.....................24-2

POSITION LAMP BULB - INSTALLATION,

FRONT.............................8L-28

POSITION LAMP BULB - REMOVAL,

FRONT.............................8L-28

POSITION SENSOR - DESCRIPTION . 21-209,21-247

POSITION SENSOR - DESCRIPTION,

CRANKSHAFT.......................14-30

POSITION SENSOR - DESCRIPTION,

THROTTLE..........................14-47

POSITION SENSOR - INSTALLATION....21-210,

21-247

POSITION SENSOR - INSTALLATION,

CRANKSHAFT.......................14-32

POSITION SENSOR - INSTALLATION,

THROTTLE..........................14-48

POSITION SENSOR - OPERATION . 21-209,21-247

POSITION SENSOR - OPERATION,

CRANKSHAFT.......................14-31

POSITION SENSOR - OPERATION,

THROTTLE..........................14-47

POSITION SENSOR - REMOVAL . . 21-210,21-247

POSITION SENSOR - REMOVAL,

CRANKSHAFT.......................14-31

POSITION SENSOR - REMOVAL,

THROTTLE..........................14-47

POSITION SWITCH - DESCRIPTION,

CLUTCH PEDAL.......................6-11

POSITION SWITCH - DIAGNOSIS AND

TESTING, CLUTCH PEDAL...............6-11

POSITION SWITCH - OPERATION,

CLUTCH PEDAL.......................6-11

POTENTIAL - STANDARD PROCEDURE,

TESTING OF VOLTAGE..............8W-01-9

POWER BRAKE BOOSTER -

DESCRIPTION........................5-21

POWER BRAKE BOOSTER -

INSTALLATION........................5-23

POWER BRAKE BOOSTER - OPERATION . . . 5-21

POWER BRAKE BOOSTER - REMOVAL.....5-22

POWER DISTRIBUTION - DESCRIPTION . 8W-97-1

POWER DISTRIBUTION - OPERATION . . 8W-97-1

POWER DISTRIBUTION CENTER -

DESCRIPTION.....................8W-97-6

POWER DISTRIBUTION CENTER -

OPERATION.......................8W-97-7

POWER DISTRIBUTION CENTER -

REMOVAL........................8W-97-7

POWER DISTRIBUTION CENTER

ASSEMBLY, ASSEMBLY.............8W-97-10

POWER DISTRIBUTION CENTER

DISASSEMBLY, DISASSEMBLY........8W-97-7

POWER DISTRIBUTION SYSTEMS,

SPECIAL TOOLS...................8W-97-2

POWER GROUNDS - DESCRIPTION......8E-13

POWER LOCKS - DESCRIPTION

..........8N-1

POWER LOCKS - DIAGNOSIS AND

TESTING

............................8N-3

POWER LOCKS - OPERATION

............8N-3

POWER MIRROR SWITCH - DIAGNOSIS

AND TESTING

.......................8N-12

POWER MIRROR SWITCH -

INSTALLATION

......................8N-13POWER MIRROR SWITCH - REMOVAL . . . 8N-13

POWER MIRRORS - DESCRIPTION......8N-11

POWER MIRRORS - DIAGNOSIS AND

TESTING...........................8N-11

POWER MIRRORS - OPERATION........8N-11

POWER OUTLET - DESCRIPTION.....8W-97-11

POWER OUTLET - DIAGNOSIS AND

TESTING........................8W-97-11

POWER OUTLET - INSTALLATION....8W-97-13

POWER OUTLET - OPERATION.......8W-97-11

POWER OUTLET - REMOVAL........8W-97-12

POWER SEAT SWITCH - DESCRIPTION,

LEFT..............................8N-16

POWER SEAT SWITCH - DESCRIPTION,

RIGHT.............................8N-19

POWER SEAT SWITCH - DIAGNOSIS

AND TESTING, LEFT..................8N-17

POWER SEAT SWITCH - DIAGNOSIS

AND TESTING, RIGHT.................8N-19

POWER SEAT SWITCH - INSTALLATION,

LEFT..............................8N-18

POWER SEAT SWITCH - INSTALLATION,

RIGHT.............................8N-20

POWER SEAT SWITCH - OPERATION,

LEFT..............................8N-17

POWER SEAT SWITCH - OPERATION,

RIGHT.............................8N-19

POWER SEAT SWITCH - REMOVAL, LEFT . 8N-18

POWER SEAT SWITCH - REMOVAL,

RIGHT.............................8N-20

POWER SEATS - DESCRIPTION...........8N-14

POWER SEATS - DIAGNOSIS AND

TESTING...........................8N-15

POWER SEATS - OPERATION...........8N-15

POWER STEERING FLOW AND

PRESSURE - DIAGNOSIS AND

TESTING............................19-3

POWER STEERING PRESSURE SWITCH -

DESCRIPTION.......................19-22

POWER STEERING PRESSURE SWITCH -

INSTALLATION.......................19-22

POWER STEERING PRESSURE SWITCH -

OPERATION.........................19-22

POWER STEERING PRESSURE SWITCH -

REMOVAL..........................19-22

POWER STEERING PUMP - INITIAL

OPERATION - STANDARD PROCEDURE . . . 19-18

POWER STEERING PUMP, SPECIAL

TOOLS.............................19-20

POWER STEERING SYSTEM -

DIAGNOSIS AND TESTING..............19-1

POWER WINDOWS - DESCRIPTION......8N-21

POWER WINDOWS - DIAGNOSIS AND

TESTING...........................8N-21

POWER WINDOWS - OPERATION........8N-21

POWERED - STARTER MOTOR, GAS......8F-39

POWERED - TORQUE, GAS.............8F-38

POWERING SEVERAL LOADS -

STANDARD PROCEDURE, TESTING

FOR A SHORT TO GROUND ON FUSES . 8W-01-9

PRECAUTIONS - CAUTION,

REFRIGERANT HOSES/LINES/TUBES

......24-40

PRECAUTIONS - OPERATION, SERVICE

....19-5

PRECAUTIONS AND WARNINGS,

WARNING - SAFETY

...................23-1

PRECAUTIONS, WARNING -

WINDSHIELD SAFETY

................23-173

PREFERENCES - STANDARD

PROCEDURE, RKE TRANSMITTER

CUSTOMER

..........................8N-8

PRELIMINARY - DIAGNOSIS AND

TESTING

...........................21-78

PRELIMINARY CHECKS - DIAGNOSIS

AND TESTING

.........................7-3

PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET

SURFACE

.............................9-9

PRESS CONTAINER - DESCRIPTION,

COOLANT RECOVERY

..................7-19

PRESS CONTAINER - OPERATION,

COOLANT RECOVERY

..................7-19

PRESSURE - DIAGNOSIS AND TESTING,

CYLINDER COMPRESSION

...............9-8

PRESSURE - DIAGNOSIS AND TESTING,

ENGINE OIL

..........................9-60

PRESSURE - DIAGNOSIS AND TESTING,

POWER STEERING FLOW

...............19-3PRESSURE BLEEDING - STANDARD

PROCEDURE..........................5-5

PRESSURE CAP - CLEANING, RADIATOR . . . 7-25

PRESSURE CAP - DESCRIPTION,

RADIATOR...........................7-25

PRESSURE CAP - DIAGNOSIS AND

TESTING, RADIATOR...................7-25

PRESSURE CAP - INSPECTION,

RADIATOR...........................7-25

PRESSURE CAP - OPERATION,

RADIATOR...........................7-25

PRESSURE HOSE - INSTALLATION.......19-21

PRESSURE HOSE - REMOVAL..........19-21

PRESSURE INDICATOR - DESCRIPTION,

LOW OIL ...........................8J-23

PRESSURE INDICATOR - OPERATION,

LOW OIL ...........................8J-23

PRESSURE LEAK DOWN TEST -

DIAGNOSIS AND TESTING, FUEL.........14-3

PRESSURE LEAKAGE - DIAGNOSIS AND

TESTING, CYLINDER COMBUSTION........9-8

PRESSURE (LP) SENSOR -

DESCRIPTION, LINE.................21-144

PRESSURE (LP) SENSOR -

INSTALLATION, LINE.................21-144

PRESSURE (LP) SENSOR - OPERATION,

LINE..............................21-144

PRESSURE (LP) SENSOR - REMOVAL,

LINE..............................21-144

PRESSURE REGULATOR - DESCRIPTION,

FUEL..............................14-13

PRESSURE REGULATOR -

INSTALLATION, FUEL...................14-14

PRESSURE REGULATOR - OPERATION,

FUEL..............................14-14

PRESSURE REGULATOR - REMOVAL,

FUEL..............................14-14

PRESSURE RELEASE - STANDARD

PROCEDURE, FUEL SYSTEM.............14-4

PRESSURE RELIEF VALVE -

DESCRIPTION, HIGH..................24-42

PRESSURE RELIEF VALVE - OPERATION,

HIGH..............................24-42

PRESSURE SENSOR/SWITCH -

DESCRIPTION, OIL....................9-65

PRESSURE SENSOR/SWITCH -

INSTALLATION, OIL....................9-65

PRESSURE SENSOR/SWITCH -

OPERATION, OIL......................9-65

PRESSURE SENSOR/SWITCH -

REMOVAL, OIL.......................9-65

PRESSURE, SPECIFICATIONS - FUEL

SYSTEM............................14-5

PRESSURE SWITCH - DESCRIPTION, A/C

HIGH..............................24-17

PRESSURE SWITCH - DESCRIPTION, A/C

LOW ..............................24-18

PRESSURE SWITCH - DESCRIPTION,

POWER STEERING...................19-22

PRESSURE SWITCH - DIAGNOSIS AND

TESTING, A/C HIGH...................24-18

PRESSURE SWITCH - DIAGNOSIS AND

TESTING, A/C LOW

...................24-19

PRESSURE SWITCH - INSTALLATION,

A/C HIGH

...........................24-18

PRESSURE SWITCH - INSTALLATION,

A/C LOW

...........................24-19

PRESSURE SWITCH - INSTALLATION,

POWER STEERING

...................19-22

PRESSURE SWITCH - OPERATION, A/C

HIGH

..............................24-18

PRESSURE SWITCH - OPERATION, A/C

LOW

..............................24-18

PRESSURE SWITCH - OPERATION,

POWER STEERING

...................19-22

PRESSURE SWITCH - REMOVAL, A/C

HIGH

..............................24-18

PRESSURE SWITCH - REMOVAL, A/C

LOW

..............................24-19

PRESSURE SWITCH - REMOVAL,

POWER STEERING

...................19-22

PRESSURE TEST - DIAGNOSIS AND

TESTING, FUEL PUMP

.................14-15

PRESSURE TEST - DIAGNOSIS AND

TESTING, HYDRAULIC

.................21-79

PRIMARY WEATHERSTRIP -

INSTALLATION, DOOR

................23-185

KJINDEX 19

Description Group-Page Description Group-Page Description Group-Page

Page 1770 of 1803

ADJUSTER (TAPPET) NOISE DIAGNOSIS

- DIAGNOSIS AND TESTING, LASH........9-28

ADJUSTMENT, FRONT FOG LAMP UNIT . . . 8L-25

ADJUSTMENT, HEADLAMP UNIT.........8L-42

AIMING - STANDARD PROCEDURE,

LAMP BAR..........................8L-65

ARM BUSHING - INSTALLATION, LOWER

CONTROL............................2-3

ARM BUSHING - INSTALLATION, LOWER

SUSPENSION..........................2-8

ARM BUSHING - INSTALLATION, UPPER

SUSPENSION..........................2-8

ARM BUSHING - REMOVAL, LOWER

CONTROL............................2-2

ARM BUSHING - REMOVAL, LOWER

SUSPENSION..........................2-7

ARM BUSHING - REMOVAL, UPPER

SUSPENSION..........................2-7

ARM BUSHINGS - INSTALLATION,

UPPER CONTROL......................2-4

ARM BUSHINGS - REMOVAL, UPPER

CONTROL............................2-3

ARMS - INSPECTION, ROCKER...........9-30

ARMS - INSTALLATION, ROCKER.........9-30

ARMS - REMOVAL, ROCKER.............9-29

ASSEMBLY - INSTALLATION, ENGINE......9-12

ASSEMBLY - REMOVAL, ENGINE.........9-12

ASSEMBLY, OIL PUMP.................9-50

BACKUP LAMP SWITCH - DESCRIPTION . . 8L-15

BACKUP LAMP SWITCH - DIAGNOSIS

AND TESTING.........................8L-15

BACKUP LAMP SWITCH - OPERATION....8L-15

BALANCE SHAFT - DESCRIPTION.........9-59

BALANCE SHAFT - OPERATION...........9-59

BALANCE SHAFT - REMOVAL............9-60

BALANCE SHAFT CARRIER -

INSTALLATION........................9-64

BALANCE SHAFT CARRIER - REMOVAL....9-64

BALANCE SHAFT CHAIN - INSTALLATION . . . 9-64

BALANCE SHAFT CHAIN - REMOVAL......9-64

BALANCE SHAFT TIMING, INSTALLATION . . . 9-61

BALL JOINT - INSTALLATION, LOWER......2-5

BALL JOINT - INSTALLATION, UPPER......2-6

BALL JOINT - REMOVAL, LOWER..........2-5

BALL JOINT - REMOVAL, UPPER..........2-6

BAR - DESCRIPTION, LAMP............8L-65

BAR - DIAGNOSIS AND TESTING, LAMP . . 8L-65

BAR - INSTALLATION, LAMP............8L-66

BAR - OPERATION, LAMP..............8L-65

BAR - REMOVAL, LAMP...............8L-65

BAR AIMING - STANDARD PROCEDURE,

LAMP..............................8L-65

BAR SWITCH - DESCRIPTION, LAMP.....8L-67

BAR SWITCH - INSTALLATION, LAMP....8L-67

BAR SWITCH - REMOVAL, LAMP........8L-67

BEAM RELAY - DESCRIPTION,

HEADLAMP HIGH....................8L-33

BEAM RELAY - DESCRIPTION,

HEADLAMP LOW.....................8L-39

BEAM RELAY - DIAGNOSIS AND

TESTING, HEADLAMP HIGH............8L-34

BEAM RELAY - DIAGNOSIS AND

TESTING, HEADLAMP LOW.............8L-40

BEAM RELAY - INSTALLATION,

HEADLAMP HIGH

....................8L-35

BEAM RELAY - INSTALLATION,

HEADLAMP LOW

.....................8L-41

BEAM RELAY - OPERATION, HEADLAMP

HIGH

..............................8L-33

BEAM RELAY - OPERATION, HEADLAMP

LOW

..............................8L-39

BEAM RELAY - REMOVAL, HEADLAMP

HIGH

..............................8L-34

BEAM RELAY - REMOVAL, HEADLAMP

LOW

..............................8L-40

BEARING - FITTING - STANDARD

PROCEDURE, MAIN

....................9-35

BEARING CLEARANCE USING

PLASTIGAGE - STANDARD

PROCEDURE, MEASURING

..............9-11

BELT - INSTALLATION, TIMING

...........9-56

BELT - REMOVAL, TIMING

..............9-55

BELT COVER(S) - INSTALLATION,

TIMING

.............................9-53

BELT COVER(S) - REMOVAL, TIMING

......9-53

BELT DIAGNOSIS - DIAGNOSIS AND

TESTING, SERPENTINE DRIVE

...........7-15BELT TENSIONER & PULLEY -

INSTALLATION, TIMING.................9-59

BELT TENSIONER & PULLEY -

REMOVAL, TIMING....................9-59

BLOCK - DESCRIPTION, ENGINE..........9-30

BLOCK HEATER - 2.4L - DESCRIPTION,

ENGINE.............................7-20

BLOCK HEATER - 2.4L - OPERATION,

ENGINE.............................7-20

BORE FITTING - STANDARD

PROCEDURE, PISTON TO CYLINDER......9-30

BORE HONING - STANDARD

PROCEDURE, CYLINDER................9-31

BRACKET BUSHING - INSTALLATION,

CLEVIS..............................2-4

BRACKET BUSHING - REMOVAL, CLEVIS....2-2

BRAKE LAMP SWITCH - DESCRIPTION . . . 8L-16

BRAKE LAMP SWITCH - DIAGNOSIS

AND TESTING.......................8L-17

BRAKE LAMP SWITCH - INSTALLATION . . . 8L-18

BRAKE LAMP SWITCH - OPERATION.....8L-16

BRAKE LAMP SWITCH - REMOVAL......8L-17

BULB - INSTALLATION, CENTER HIGH

MOUNTED STOP LAMP................8L-19

BULB - INSTALLATION, FRONT FOG

LAMP..............................8L-22

BULB - INSTALLATION, FRONT LAMP....8L-27

BULB - INSTALLATION, FRONT POSITION

LAMP..............................8L-28

BULB - INSTALLATION, HEADLAMP......8L-32

BULB - INSTALLATION, LICENSE PLATE

LAMP..............................8L-45

BULB - INSTALLATION, REAR LAMP.....8L-59

BULB - INSTALLATION, REPEATER LAMP . . 8L-60

BULB - REMOVAL, CENTER HIGH

MOUNTED STOP LAMP................8L-18

BULB - REMOVAL, FRONT FOG LAMP....8L-21

BULB - REMOVAL, FRONT LAMP........8L-27

BULB - REMOVAL, FRONT POSITION

LAMP..............................8L-28

BULB - REMOVAL, HEADLAMP..........8L-30

BULB - REMOVAL, LICENSE PLATE

LAMP..............................8L-44

BULB - REMOVAL, REAR LAMP.........8L-59

BULB - REMOVAL, REPEATER LAMP.....8L-60

BUSHING - INSTALLATION, CLEVIS

BRACKET.............................2-4

BUSHING - INSTALLATION, LOWER

CONTROL ARM........................2-3

BUSHING - INSTALLATION, LOWER

SUSPENSION ARM.....................2-8

BUSHING - INSTALLATION, UPPER

SUSPENSION ARM.....................2-8

BUSHING - REMOVAL, CLEVIS BRACKET....2-2

BUSHING - REMOVAL, LOWER CONTROL

ARM ................................2-2

BUSHING - REMOVAL, LOWER

SUSPENSION ARM.....................2-7

BUSHING - REMOVAL, UPPER

SUSPENSION ARM.....................2-7

BUSHINGS - INSTALLATION, UPPER

CONTROL ARM........................2-4

BUSHINGS - REMOVAL, UPPER

CONTROL ARM........................2-3

CAMSHAFT END-PLAY - STANDARD

PROCEDURE.........................9-23

CAMSHAFT OIL SEAL(S) - INSTALLATION . . 9-22

CAMSHAFT OIL SEAL(S) - REMOVAL......9-22

CAMSHAFT(S) - CLEANING..............9-24

CAMSHAFT(S) - DESCRIPTION...........9-23

CAMSHAFT(S) - INSPECTION............9-25

CAMSHAFT(S) - INSTALLATION..........9-25

CAMSHAFT(S) - OPERATION.............9-23

CAMSHAFT(S) - REMOVAL..............9-24

CAP - CLEANING, RADIATOR PRESSURE . . . 7-25

CAP - DESCRIPTION, RADIATOR

PRESSURE..........................7-25

CAP - DIAGNOSIS AND TESTING,

RADIATOR PRESSURE.................7-25

CAP - INSPECTION, RADIATOR

PRESSURE..........................7-25

CAP - OPERATION, RADIATOR

PRESSURE

..........................7-25

CARRIER - INSTALLATION, BALANCE

SHAFT

..............................9-64

CARRIER - REMOVAL, BALANCE SHAFT

....9-64

CATALYTIC CONVERTER - DESCRIPTION

. . . 11-2

CATALYTIC CONVERTER - INSPECTION

....11-3CATALYTIC CONVERTER - INSTALLATION . . . 11-3

CATALYTIC CONVERTER - REMOVAL......11-2

CENTER HIGH MOUNTED STOP LAMP

BULB - INSTALLATION................8L-19

CENTER HIGH MOUNTED STOP LAMP

BULB - REMOVAL....................8L-18

CENTER HIGH MOUNTED STOP LAMP

UNIT - INSTALLATION.................8L-19

CENTER HIGH MOUNTED STOP LAMP

UNIT - REMOVAL....................8L-19

CHAIN - INSTALLATION, BALANCE

SHAFT..............................9-64

CHAIN - REMOVAL, BALANCE SHAFT......9-64

CHANGE - STANDARD PROCEDURE,

ENGINE OIL AND FILTER................9-47

CHART - DIAGNOSIS AND TESTING,

COOLING SYSTEM DIAGNOSIS............7-5

CHECK, STANDARD PROCEDURE -

ENGINE OIL LEVEL....................9-47

CHECKING - DIAGNOSIS AND TESTING,

ENGINE OIL PRESSURE................9-46

CHECKS - DIAGNOSIS AND TESTING,

PRELIMINARY.........................7-2

CLAMPS - DESCRIPTION, HOSE...........7-1

CLAMPS - OPERATION, HOSE.............7-2

CLEANING, CAMSHAFT(S)...............9-24

CLEANING, CYLINDER HEAD.............9-20

CLEANING, CYLINDER HEAD COVER......9-26

CLEANING, EXHAUST MANIFOLD.........9-53

CLEANING, INTAKE/EXHAUST VALVES &

SEATS................................9-27

CLEANING, OIL PUMP..................9-49

CLEANING, RADIATOR.................7-24

CLEANING, RADIATOR PRESSURE CAP....7-25

CLEANING, REMOVAL..................9-55

CLEANING, STANDARD PROCEDURE......9-31

CLEARANCE USING PLASTIGAGE -

STANDARD PROCEDURE, MEASURING

BEARING............................9-11

CLEVIS BRACKET BUSHING -

INSTALLATION.........................2-4

CLEVIS BRACKET BUSHING - REMOVAL....2-2

COLLAR - INSTALLATION, STRUCTURAL . . . 9-44

COLLAR - REMOVAL, STRUCTURAL.......9-44

COMBINATION FLASHER - DESCRIPTION . . 8L-19

COMBINATION FLASHER - OPERATION . . . 8L-19

COMBUSTION PRESSURE LEAKAGE

TEST - DIAGNOSIS AND TESTING,

CYLINDER............................9-3

COMPRESSION PRESSURE TEST -

DIAGNOSIS AND TESTING, CYLINDER......9-3

CONNECTING ROD - DESCRIPTION,

PISTON.............................9-40

CONNECTING ROD - INSTALLATION,

PISTON.............................9-41

CONNECTING ROD - OPERATION,

PISTON.............................9-40

CONNECTING ROD - REMOVAL, PISTON . . . 9-40

CONNECTING ROD, FITTING.............9-32

CONNECTOR - INSTALLATION, TRAILER

TOW ..............................8L-61

CONNECTOR - REMOVAL, TRAILER TOW . . 8L-61

CONTAINER - DESCRIPTION, COOLANT

RECOVERY PRESS....................7-20

CONTAINER - OPERATION, COOLANT

RECOVERY PRESS....................7-20

CONTROL ARM BUSHING -

INSTALLATION, LOWER.................2-3

CONTROL ARM BUSHING - REMOVAL,

LOWER..............................2-2

CONTROL ARM BUSHINGS -

INSTALLATION, UPPER..................2-4

CONTROL ARM BUSHINGS - REMOVAL,

UPPER...............................2-3

CONVERTER - DESCRIPTION, CATALYTIC . . . 11-2

CONVERTER - INSPECTION, CATALYTIC....11-3

CONVERTER - INSTALLATION, CATALYTIC . . 11-3

CONVERTER - REMOVAL, CATALYTIC......11-2

COOLANT - DESCRIPTION, ENGINE.......7-19

COOLANT - DESCRIPTION, HOAT

.........7-18

COOLANT RECOVERY PRESS

CONTAINER - DESCRIPTION

.............7-20

COOLANT RECOVERY PRESS

CONTAINER - OPERATION

...............7-20

COOLANT TEMPERATURE SENSOR -

DESCRIPTION, ENGINE

.................7-21

COOLANT TEMPERATURE SENSOR -

INSTALLATION, ENGINE

................7-22

KJINDEX 1

Description Group-Page Description Group-Page Description Group-Page

Page 1771 of 1803

COOLANT TEMPERATURE SENSOR -

OPERATION, ENGINE...................7-21

COOLANT TEMPERATURE SENSOR -

REMOVAL, ENGINE....................7-21

COOLER - DESCRIPTION, TRANS.........7-30

COOLERS AND TUBES - STANDARD

PROCEDURE, FLUSHING................7-30

COOLING, SPECIAL TOOLS..............7-13

COOLING SYSTEM - OPERATION..........7-2

COOLING SYSTEM - REVERSE

FLUSHING - STANDARD PROCEDURE.....7-12

COOLING SYSTEM - STANDARD

PROCEDURE, DRAINING................7-11

COOLING SYSTEM - STANDARD

PROCEDURE, REFILLING................7-11

COOLING SYSTEM 2.4L ENGINE -

DESCRIPTION.........................7-1

COOLING SYSTEM DIAGNOSIS CHART -

DIAGNOSIS AND TESTING...............7-5

COOLING SYSTEM LEAKS - DIAGNOSIS

AND TESTING.........................7-2

CORE AND OIL GALLERY PLUGS -

STANDARD PROCEDURE, ENGINE.........9-9

COVER - CLEANING, CYLINDER HEAD.....9-26

COVER - INSPECTION, CYLINDER HEAD . . . 9-26

COVER - INSTALLATION, CYLINDER

HEAD...............................9-26

COVER - REMOVAL, CYLINDER HEAD.....9-26

COVER(S) - INSTALLATION, TIMING

BELT ...............................9-53

COVER(S) - REMOVAL, TIMING BELT......9-53

CRANKSHAFT - DESCRIPTION...........9-32

CRANKSHAFT - INSPECTION.............9-34

CRANKSHAFT - INSTALLATION...........9-34

CRANKSHAFT - OPERATION.............9-33

CRANKSHAFT - REMOVAL..............9-33

CRANKSHAFT END PLAY - STANDARD

PROCEDURE.........................9-33

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION........................9-37

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL...........................9-37

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION........................9-39

CRANKSHAFT OIL SEAL - REAR -

REMOVAL...........................9-38

CRANKSHAFT SPROCKET -

INSTALLATION........................9-56

CRANKSHAFT SPROCKET - REMOVAL.....9-55

CROSS-OVER PIPE - INSTALLATION.......11-4

CROSS-OVER PIPE - REMOVAL..........11-4

CYLINDER BORE FITTING - STANDARD

PROCEDURE, PISTON TO...............9-30

CYLINDER BORE HONING - STANDARD

PROCEDURE.........................9-31

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST - DIAGNOSIS AND

TESTING.............................9-3

CYLINDER COMPRESSION PRESSURE

TEST - DIAGNOSIS AND TESTING.........9-3

CYLINDER HEAD - CLEANING............9-20

CYLINDER HEAD - DESCRIPTION.........9-19

CYLINDER HEAD - INSPECTION..........9-21

CYLINDER HEAD - INSTALLATION........9-21

CYLINDER HEAD - OPERATION...........9-19

CYLINDER HEAD - REMOVAL............9-20

CYLINDER HEAD COVER - CLEANING......9-26

CYLINDER HEAD COVER - INSPECTION....9-26

CYLINDER HEAD COVER -

INSTALLATION

........................9-26

CYLINDER HEAD COVER - REMOVAL

......9-26

CYLINDER HEAD GASKET - DIAGNOSIS

AND TESTING

........................9-19

CYLINDER HEAD OFF - INSTALLATION

.....9-28

CYLINDER HEAD OFF - REMOVAL

........9-27

CYLINDER HEAD ON - INSTALLATION

.....9-28

CYLINDER HEAD ON - REMOVAL

.........9-27

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE, REPAIR OF

.......9-9

DAMPER - INSTALLATION, VIBRATION

.....9-43

DAMPER - REMOVAL, VIBRATION

........9-43

DAYTIME RUNNING LAMP RELAY -

DESCRIPTION

.......................8L-20

DAYTIME RUNNING LAMP RELAY -

INSTALLATION

.......................8L-21

DAYTIME RUNNING LAMP RELAY -

OPERATION

.........................8L-20DAYTIME RUNNING LAMP RELAY -

REMOVAL..........................8L-21

DESCRIPTION - OPERATION.............7-20

DESCRIPTION, BACKUP LAMP SWITCH . . . 8L-15

DESCRIPTION, BALANCE SHAFT..........9-59

DESCRIPTION, BRAKE LAMP SWITCH....8L-16

DESCRIPTION, CAMSHAFT(S)............9-23

DESCRIPTION, CATALYTIC CONVERTER....11-2

DESCRIPTION, COMBINATION FLASHER . . . 8L-19

DESCRIPTION, COOLANT RECOVERY

PRESS CONTAINER....................7-20

DESCRIPTION, COOLING SYSTEM 2.4L

ENGINE..............................7-1

DESCRIPTION, CRANKSHAFT............9-32

DESCRIPTION, CYLINDER HEAD..........9-19

DESCRIPTION, DAYTIME RUNNING

LAMP RELAY........................8L-20

DESCRIPTION, ENGINE - 2.4L.............9-3

DESCRIPTION, ENGINE BLOCK...........9-30

DESCRIPTION, ENGINE BLOCK HEATER -

2.4L................................7-20

DESCRIPTION, ENGINE COOLANT.........7-19

DESCRIPTION, ENGINE COOLANT

TEMPERATURE SENSOR................7-21

DESCRIPTION, ENGINE MOUNTING.......9-44

DESCRIPTION, EXHAUST MANIFOLD......9-53

DESCRIPTION, EXHAUST SYSTEM........11-1

DESCRIPTION, FRONT FOG LAMP RELAY . . 8L-22

DESCRIPTION, HAZARD SWITCH........8L-28

DESCRIPTION, HEADLAMP HIGH BEAM

RELAY.............................8L-33

DESCRIPTION, HEADLAMP LEVELING

MOTOR............................8L-35

DESCRIPTION, HEADLAMP LEVELING

SWITCH............................8L-37

DESCRIPTION, HEADLAMP LOW BEAM

RELAY.............................8L-39

DESCRIPTION, HEAT SHIELDS...........11-4

DESCRIPTION, HOAT COOLANT..........7-18

DESCRIPTION, HOSE CLAMPS............7-1

DESCRIPTION, INTAKE MANIFOLD........9-51

DESCRIPTION, INTAKE/EXHAUST VALVES

& SEATS ............................9-27

DESCRIPTION, LAMP BAR.............8L-65

DESCRIPTION, LAMP BAR SWITCH......8L-67

DESCRIPTION, LAMPS/LIGHTING -

EXTERIOR...........................8L-2

DESCRIPTION, LUBRICATION............9-46

DESCRIPTION, MUFFLER...............11-4

DESCRIPTION, MULTI-FUNCTION

SWITCH............................8L-46

DESCRIPTION, OIL FILTER..............9-47

DESCRIPTION, OIL PRESSURE

SENSOR/SWITCH.....................9-48

DESCRIPTION, PARK LAMP RELAY.......8L-54

DESCRIPTION, PISTON & CONNECTING

ROD................................9-40

DESCRIPTION, RADIATOR...............7-22

DESCRIPTION, RADIATOR FAN -

ELECTRIC...........................7-26

DESCRIPTION, RADIATOR PRESSURE

CAP ................................7-25

DESCRIPTION, REAR FOG LAMP RELAY . . . 8L-56

DESCRIPTION, TRAILER TOW RELAY.....8L-62

DESCRIPTION, TRAILER TOW WIRING....8L-64

DESCRIPTION, TRANS COOLER..........7-30

DESCRIPTION, WATER PUMP - 2.4L......7-27

DIAGNOSIS - DIAGNOSIS AND TESTING,

LASH ADJUSTER (TAPPET) NOISE........9-28

DIAGNOSIS - DIAGNOSIS AND TESTING,

SERPENTINE DRIVE BELT...............7-15

DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING, ENGINE........9-5

DIAGNOSIS AND TESTING, BACKUP

LAMP SWITCH......................8L-15

DIAGNOSIS AND TESTING, BRAKE LAMP

SWITCH............................8L-17

DIAGNOSIS AND TESTING, COOLING

SYSTEM DIAGNOSIS CHART

..............7-5

DIAGNOSIS AND TESTING, COOLING

SYSTEM LEAKS

........................7-2

DIAGNOSIS AND TESTING, CYLINDER

COMBUSTION PRESSURE LEAKAGE

TEST

................................9-3

DIAGNOSIS AND TESTING, CYLINDER

COMPRESSION PRESSURE TEST

..........9-3

DIAGNOSIS AND TESTING, CYLINDER

HEAD GASKET

........................9-19DIAGNOSIS AND TESTING, ENGINE........9-5

DIAGNOSIS AND TESTING, ENGINE

DIAGNOSIS - PERFORMANCE.............9-5

DIAGNOSIS AND TESTING, ENGINE

MECHANICAL.........................9-7

DIAGNOSIS AND TESTING, ENGINE OIL

LEAK INSPECTION......................9-4

DIAGNOSIS AND TESTING, ENGINE OIL

PRESSURE CHECKING.................9-46

DIAGNOSIS AND TESTING, EXHAUST

SYSTEM............................11-2

DIAGNOSIS AND TESTING, FRONT FOG

LAMP RELAY........................8L-23

DIAGNOSIS AND TESTING, HEADLAMP

HIGH BEAM RELAY...................8L-34

DIAGNOSIS AND TESTING, HEADLAMP

LEVELING SWITCH...................8L-37

DIAGNOSIS AND TESTING, HEADLAMP

LOW BEAM RELAY...................8L-40

DIAGNOSIS AND TESTING, INTAKE

MANIFOLD LEAKS.....................9-51

DIAGNOSIS AND TESTING, LAMP BAR....8L-65

DIAGNOSIS AND TESTING, LAMPS/

LIGHTING - EXTERIOR.................8L-7

DIAGNOSIS AND TESTING, LASH

ADJUSTER (TAPPET) NOISE

DIAGNOSIS..........................9-28

DIAGNOSIS AND TESTING, MULTI-

FUNCTION SWITCH...................8L-50

DIAGNOSIS AND TESTING, ON-BOARD

DIAGNOSTICS (OBD)....................7-2

DIAGNOSIS AND TESTING, PARK LAMP

RELAY.............................8L-55

DIAGNOSIS AND TESTING,

PRELIMINARY CHECKS..................7-2

DIAGNOSIS AND TESTING, RADIATOR

PRESSURE CAP.......................7-25

DIAGNOSIS AND TESTING, REAR FOG

LAMP RELAY........................8L-57

DIAGNOSIS AND TESTING, SERPENTINE

DRIVE BELT DIAGNOSIS................7-15

DIAGNOSIS AND TESTING, TRAILER

TOW RELAY.........................8L-62

DIAGNOSIS CHART - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-5

DIAGNOSTICS (OBD) - DIAGNOSIS AND

TESTING, ON-BOARD...................7-2

DISASSEMBLY, OIL PUMP...............9-49

DRAINING COOLING SYSTEM -

STANDARD PROCEDURE................7-11

DRIVE BELT DIAGNOSIS - DIAGNOSIS

AND TESTING, SERPENTINE.............7-15

ELECTRIC - DESCRIPTION, RADIATOR

FAN ................................7-26

ELECTRIC - INSTALLATION, RADIATOR

FAN ................................7-27

ELECTRIC - OPERATION, RADIATOR FAN . . . 7-26

ELECTRIC - REMOVAL, RADIATOR FAN....7-26

END PLAY - STANDARD PROCEDURE,

CRANKSHAFT........................9-33

END-PLAY - STANDARD PROCEDURE,

CAMSHAFT..........................9-23

ENGINE - 2.4L - DESCRIPTION............9-3

ENGINE - DESCRIPTION, COOLING

SYSTEM 2.4L.........................7-1

ENGINE - DIAGNOSIS AND TESTING.......9-5

ENGINE - INSTALLATION, 2.4L . . 7-14,7-17,7-22,

7-28

ENGINE - REMOVAL, 2.4L . . . 7-14,7-16,7-22,7-27

ENGINE - SPECIFICATIONS, 2.4L.........9-13

ENGINE - STANDARD PROCEDURE,

HYDROSTATIC LOCKED..................9-9

ENGINE ASSEMBLY - INSTALLATION......9-12

ENGINE ASSEMBLY - REMOVAL..........9-12

ENGINE BLOCK - DESCRIPTION..........9-30

ENGINE BLOCK HEATER - 2.4L -

DESCRIPTION........................7-20

ENGINE BLOCK HEATER - 2.4L -

OPERATION..........................7-20

ENGINE COOLANT - DESCRIPTION

........7-19

ENGINE COOLANT TEMPERATURE

SENSOR - DESCRIPTION

...............7-21

ENGINE COOLANT TEMPERATURE

SENSOR - INSTALLATION

...............7-22

ENGINE COOLANT TEMPERATURE

SENSOR - OPERATION

.................7-21

ENGINE COOLANT TEMPERATURE

SENSOR - REMOVAL

...................7-21

2 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1774 of 1803

MANIFOLD LEAKS - DIAGNOSIS AND

TESTING, INTAKE.....................9-51

MEASURING BEARING CLEARANCE

USING PLASTIGAGE - STANDARD

PROCEDURE.........................9-11

MECHANICAL - DIAGNOSIS AND

TESTING, ENGINE......................9-7

MOTOR - DESCRIPTION, HEADLAMP

LEVELING..........................8L-35

MOTOR - INSTALLATION, HEADLAMP

LEVELING..........................8L-36

MOTOR - OPERATION, HEADLAMP

LEVELING..........................8L-36

MOTOR - REMOVAL, HEADLAMP

LEVELING..........................8L-36

MOUNT - INSTALLATION, FRONT.........9-44

MOUNT - INSTALLATION, REAR..........9-45

MOUNT - REMOVAL, FRONT.............9-44

MOUNT - REMOVAL, REAR..............9-45

MOUNTED STOP LAMP BULB -

INSTALLATION, CENTER HIGH..........8L-19

MOUNTED STOP LAMP BULB -

REMOVAL, CENTER HIGH..............8L-18

MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER HIGH..........8L-19

MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER HIGH..............8L-19

MOUNTING - DESCRIPTION, ENGINE......9-44

MUFFLER - DESCRIPTION...............11-4

MUFFLER - INSTALLATION..............11-5

MUFFLER - REMOVAL..................11-4

MULTI-FUNCTION SWITCH -

DESCRIPTION.......................8L-46

MULTI-FUNCTION SWITCH - DIAGNOSIS

AND TESTING.......................8L-50

MULTI-FUNCTION SWITCH -

INSTALLATION.......................8L-53

MULTI-FUNCTION SWITCH - OPERATION . . 8L-48

MULTI-FUNCTION SWITCH - REMOVAL . . . 8L-53

NOISE DIAGNOSIS - DIAGNOSIS AND

TESTING, LASH ADJUSTER (TAPPET)......9-28

OFF - INSTALLATION, CYLINDER HEAD....9-28

OFF - REMOVAL, CYLINDER HEAD........9-27

OIL AND FILTER CHANGE - STANDARD

PROCEDURE, ENGINE..................9-47

OIL FILTER - DESCRIPTION.............9-47

OIL FILTER - INSTALLATION.............9-47

OIL FILTER - REMOVAL.................9-47

OIL GALLERY PLUGS - STANDARD

PROCEDURE, ENGINE CORE..............9-9

OIL LEAK INSPECTION - DIAGNOSIS

AND TESTING, ENGINE..................9-4

OIL LEVEL CHECK, STANDARD

PROCEDURE - ENGINE.................9-47

OIL PAN - INSTALLATION...............9-48

OIL PAN - REMOVAL...................9-48

OIL PRESSURE CHECKING - DIAGNOSIS

AND TESTING, ENGINE.................9-46

OIL PRESSURE SENSOR/SWITCH -

DESCRIPTION........................9-48

OIL PRESSURE SENSOR/SWITCH -

OPERATION..........................9-48

OIL PUMP - ASSEMBLY................9-50

OIL PUMP - CLEANING.................9-49

OIL PUMP - DISASSEMBLY.............9-49

OIL PUMP - INSPECTION...............9-50

OIL PUMP - INSTALLATION.............9-50

OIL PUMP - REMOVAL.................9-49

OIL SEAL - FRONT - INSTALLATION,

CRANKSHAFT........................9-37

OIL SEAL - FRONT - REMOVAL,

CRANKSHAFT........................9-37

OIL SEAL - REAR - INSTALLATION,

CRANKSHAFT........................9-39

OIL SEAL - REAR - REMOVAL,

CRANKSHAFT........................9-38

OIL SEAL(S) - INSTALLATION,

CAMSHAFT..........................9-22

OIL SEAL(S) - REMOVAL, CAMSHAFT.....9-22

ON-BOARD DIAGNOSTICS (OBD) -

DIAGNOSIS AND TESTING...............7-2

OPERATION, BACKUP LAMP SWITCH.....8L-15

OPERATION, BALANCE SHAFT

...........9-59

OPERATION, BRAKE LAMP SWITCH

......8L-16

OPERATION, CAMSHAFT(S)

.............9-23

OPERATION, COMBINATION FLASHER

....8L-19

OPERATION, COOLANT RECOVERY

PRESS CONTAINER

....................7-20OPERATION, COOLING SYSTEM...........7-2

OPERATION, CRANKSHAFT..............9-33

OPERATION, CYLINDER HEAD...........9-19

OPERATION, DAYTIME RUNNING LAMP

RELAY.............................8L-20

OPERATION, DESCRIPTION..............7-20

OPERATION, ENGINE BLOCK HEATER -

2.4L................................7-20

OPERATION, ENGINE COOLANT

TEMPERATURE SENSOR................7-21

OPERATION, EXHAUST MANIFOLD........9-53

OPERATION, FRONT FOG LAMP RELAY . . . 8L-22

OPERATION, HAZARD SWITCH..........8L-29

OPERATION, HEADLAMP HIGH BEAM

RELAY.............................8L-33

OPERATION, HEADLAMP LEVELING

MOTOR............................8L-36

OPERATION, HEADLAMP LEVELING

SWITCH............................8L-37

OPERATION, HEADLAMP LOW BEAM

RELAY.............................8L-39

OPERATION, HOSE CLAMPS..............7-2

OPERATION, INTAKE MANIFOLD..........9-51

OPERATION, LAMP BAR...............8L-65

OPERATION, LAMPS/LIGHTING -

EXTERIOR...........................8L-5

OPERATION, LUBRICATION..............9-46

OPERATION, MULTI-FUNCTION SWITCH . . . 8L-48

OPERATION, OIL PRESSURE SENSOR/

SWITCH..............................9-48

OPERATION, PARK LAMP RELAY........8L-54

OPERATION, PISTON & CONNECTING

ROD................................9-40

OPERATION, RADIATOR FAN - ELECTRIC . . . 7-26

OPERATION, RADIATOR PRESSURE CAP . . . 7-25

OPERATION, REAR FOG LAMP RELAY....8L-57

OPERATION, TRAILER TOW RELAY.......8L-62

OPERATION, WATER PUMP - 2.4L........7-27

PAN - INSTALLATION, OIL...............9-48

PAN - REMOVAL, OIL..................9-48

PARK LAMP RELAY - DESCRIPTION......8L-54

PARK LAMP RELAY - DIAGNOSIS AND

TESTING...........................8L-55

PARK LAMP RELAY - INSTALLATION.....8L-56

PARK LAMP RELAY - OPERATION.......8L-54

PARK LAMP RELAY - REMOVAL.........8L-55

PERFORMANCE - DIAGNOSIS AND

TESTING, ENGINE DIAGNOSIS............9-5

PIPE - INSTALLATION, CROSS-OVER......11-4

PIPE - REMOVAL, CROSS-OVER..........11-4

PISTON & CONNECTING ROD -

DESCRIPTION........................9-40

PISTON & CONNECTING ROD -

INSTALLATION........................9-41

PISTON & CONNECTING ROD -

OPERATION..........................9-40

PISTON & CONNECTING ROD -

REMOVAL...........................9-40

PISTON RING, FITTING.................9-42

PISTON TO CYLINDER BORE FITTING -

STANDARD PROCEDURE................9-30

PLASTIGAGE - STANDARD PROCEDURE,

MEASURING BEARING CLEARANCE

USING..............................9-11

PLATE LAMP BULB - INSTALLATION,

LICENSE...........................8L-45

PLATE LAMP BULB - REMOVAL,

LICENSE...........................8L-44

PLATE LAMP UNIT - INSTALLATION,

LICENSE...........................8L-46

PLATE LAMP UNIT - REMOVAL, LICENSE . . 8L-45

PLAY - STANDARD PROCEDURE,

CRANKSHAFT END....................9-33

PLUGS - STANDARD PROCEDURE,

ENGINE CORE AND OIL GALLERY.........9-9

POSITION LAMP BULB - INSTALLATION,

FRONT.............................8L-28

POSITION LAMP BULB - REMOVAL,

FRONT

.............................8L-28

PRELIMINARY CHECKS - DIAGNOSIS

AND TESTING

.........................7-2

PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET

SURFACE

............................9-11

PRESS CONTAINER - DESCRIPTION,

COOLANT RECOVERY

..................7-20

PRESS CONTAINER - OPERATION,

COOLANT RECOVERY

..................7-20PRESSURE CAP - CLEANING, RADIATOR . . . 7-25

PRESSURE CAP - DESCRIPTION,

RADIATOR...........................7-25

PRESSURE CAP - DIAGNOSIS AND

TESTING, RADIATOR...................7-25

PRESSURE CAP - INSPECTION,

RADIATOR...........................7-25

PRESSURE CAP - OPERATION,

RADIATOR...........................7-25

PRESSURE CHECKING - DIAGNOSIS AND

TESTING, ENGINE OIL..................9-46

PRESSURE LEAKAGE TEST - DIAGNOSIS

AND TESTING, CYLINDER

COMBUSTION.........................9-3

PRESSURE SENSOR/SWITCH -

DESCRIPTION, OIL....................9-48

PRESSURE SENSOR/SWITCH -

OPERATION, OIL......................9-48

PRESSURE TEST - DIAGNOSIS AND

TESTING, CYLINDER COMPRESSION.......9-3

PULLEY - INSTALLATION, TIMING BELT

TENSIONER..........................9-59

PULLEY - REMOVAL, TIMING BELT

TENSIONER..........................9-59

PUMP - 2.4L - DESCRIPTION, WATER.....7-27

PUMP - 2.4L - INSPECTION, WATER......7-28

PUMP - 2.4L - OPERATION, WATER.......7-27

PUMP - ASSEMBLY, OIL................9-50

PUMP - CLEANING, OIL................9-49

PUMP - DISASSEMBLY, OIL.............9-49

PUMP - INSPECTION, OIL...............9-50

PUMP - INSTALLATION, OIL.............9-50

PUMP - REMOVAL, OIL.................9-49

RADIATOR - CLEANING.................7-24

RADIATOR - DESCRIPTION..............7-22

RADIATOR - INSPECTION...............7-24

RADIATOR - INSTALLATION.............7-24

RADIATOR - REMOVAL.................7-22

RADIATOR FAN - ELECTRIC -

DESCRIPTION........................7-26

RADIATOR FAN - ELECTRIC -

INSTALLATION........................7-27

RADIATOR FAN - ELECTRIC -

OPERATION..........................7-26

RADIATOR FAN - ELECTRIC - REMOVAL . . . 7-26

RADIATOR PRESSURE CAP - CLEANING . . . 7-25

RADIATOR PRESSURE CAP -

DESCRIPTION........................7-25

RADIATOR PRESSURE CAP - DIAGNOSIS

AND TESTING........................7-25

RADIATOR PRESSURE CAP -

INSPECTION.........................7-25

RADIATOR PRESSURE CAP - OPERATION . . 7-25

REAR - INSTALLATION, CRANKSHAFT

OIL SEAL............................9-39

REAR - REMOVAL, CRANKSHAFT OIL

SEAL...............................9-38

REAR FOG LAMP RELAY - DESCRIPTION . . 8L-56

REAR FOG LAMP RELAY - DIAGNOSIS

AND TESTING.......................8L-57

REAR FOG LAMP RELAY -

INSTALLATION.......................8L-58

REAR FOG LAMP RELAY - OPERATION . . . 8L-57

REAR FOG LAMP RELAY - REMOVAL.....8L-58

REAR LAMP BULB - INSTALLATION......8L-59

REAR LAMP BULB - REMOVAL..........8L-59

REAR LAMP UNIT - INSTALLATION......8L-60

REAR LAMP UNIT - REMOVAL..........8L-59

REAR MOUNT - INSTALLATION..........9-45

REAR MOUNT - REMOVAL..............9-45

REAR SUSPENSION, SPECIAL TOOLS......2-6

RECOVERY PRESS CONTAINER -

DESCRIPTION, COOLANT...............7-20

RECOVERY PRESS CONTAINER -

OPERATION, COOLANT.................7-20

REFILLING COOLING SYSTEM -

STANDARD PROCEDURE................7-11

RELAY - DESCRIPTION, DAYTIME

RUNNING LAMP.....................8L-20

RELAY - DESCRIPTION, FRONT FOG

LAMP..............................8L-22

RELAY - DESCRIPTION, HEADLAMP

HIGH BEAM

.........................8L-33

RELAY - DESCRIPTION, HEADLAMP LOW

BEAM

..............................8L-39

RELAY - DESCRIPTION, PARK LAMP

.....8L-54

RELAY - DESCRIPTION, REAR FOG LAMP

. 8L-56

RELAY - DESCRIPTION, TRAILER TOW

....8L-62

KJINDEX 5

Description Group-Page Description Group-Page Description Group-Page

Page 1776 of 1803

STOP LAMP BULB - INSTALLATION,

CENTER HIGH MOUNTED..............8L-19

STOP LAMP BULB - REMOVAL, CENTER

HIGH MOUNTED.....................8L-18

STOP LAMP UNIT - INSTALLATION,

CENTER HIGH MOUNTED..............8L-19

STOP LAMP UNIT - REMOVAL, CENTER

HIGH MOUNTED.....................8L-19

STRUCTURAL COLLAR - INSTALLATION....9-44

STRUCTURAL COLLAR - REMOVAL.......9-44

SURFACE PREPARATION - STANDARD

PROCEDURE, ENGINE GASKET...........9-11

SUSPENSION ARM BUSHING -

INSTALLATION, LOWER.................2-8

SUSPENSION ARM BUSHING -

INSTALLATION, UPPER..................2-8

SUSPENSION ARM BUSHING -

REMOVAL, LOWER.....................2-7

SUSPENSION ARM BUSHING -

REMOVAL, UPPER......................2-7

SUSPENSION, SPECIAL TOOLS - FRONT....2-1

SUSPENSION, SPECIAL TOOLS - REAR.....2-6

SWITCH - DESCRIPTION, BACKUP LAMP . . 8L-15

SWITCH - DESCRIPTION, BRAKE LAMP . . . 8L-16

SWITCH - DESCRIPTION, HAZARD.......8L-28

SWITCH - DESCRIPTION, HEADLAMP

LEVELING..........................8L-37

SWITCH - DESCRIPTION, LAMP BAR.....8L-67

SWITCH - DESCRIPTION, MULTI-