cruise JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 311 of 1803

²The fuel pump is energized through the fuel

pump relay by the PCM. The fuel pump will operate

for approximately three seconds unless the engine is

operating or the starter motor is engaged.

²The O2S sensor heater element is energized via

the ASD or O2S heater relay. The O2S sensor input

is not used by the PCM to calibrate air-fuel ratio dur-

ing this mode of operation.

ENGINE START-UP MODE

This is an Open Loop mode. The following actions

occur when the starter motor is engaged.

The PCM receives inputs from:

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

The PCM monitors the crankshaft position sensor.

If the PCM does not receive a crankshaft position

sensor signal within 3 seconds of cranking the

engine, it will shut down the fuel injection system.

The fuel pump is activated by the PCM through

the fuel pump relay.

Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.

The PCM determines the proper ignition timing

according to input received from the crankshaft posi-

tion sensor.

ENGINE WARM-UP MODE

This is an Open Loop mode. During engine warm-

up, the PCM receives inputs from:

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

Based on these inputs the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.²The PCM adjusts engine idle speed through the

idle air control (IAC) motor and adjusts ignition tim-

ing.

²The PCM operates the A/C compressor clutch

through the A/C compressor clutch relay. This is done

if A/C has been selected by the vehicle operator and

specified pressures are met at the high and low±pres-

sure A/C switches. Refer to Heating and Air Condi-

tioning for additional information.

²When engine has reached operating tempera-

ture, the PCM will begin monitoring O2S sensor

input. The system will then leave the warm-up mode

and go into closed loop operation.

IDLE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At idle speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Battery voltage

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen sensors

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

injection sequence and injector pulse width by turn-

ing the ground circuit to each individual injector on

and off.

²The PCM monitors the O2S sensor input and

adjusts air-fuel ratio by varying injector pulse width.

It also adjusts engine idle speed through the idle air

control (IAC) motor.

²The PCM adjusts ignition timing by increasing

and decreasing spark advance.

²The PCM operates the A/C compressor clutch

through the A/C compressor clutch relay. This is done

if A/C has been selected by the vehicle operator and

specified pressures are met at the high and low±pres-

sure A/C switches. Refer to Heating and Air Condi-

tioning for additional information.

CRUISE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At cruising speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

8E - 12 ELECTRONIC CONTROL MODULESKJ

POWERTRAIN CONTROL MODULE (Continued)

Page 339 of 1803

negative jumper posts. Select TESTING AT JUMPER

POST when connecting to that location.

(3) Connect the tester to the battery or jumper

posts, the red clamp to positive (+) and the black

clamp to negative (±).

NOTE: Multiple batteries connected in parallel must

have the ground cable disconnected to perform a

battery test. Failure to disconnect may result in

false battery test readings.

NOTE: When testing the battery in a PT Cruiser,

always test at the battery terminals

(4) Using the ARROW key selectinoroutof vehi-

cle testing and press ENTER to make a selection.

(5) If not selected, choose the Cold Cranking Amp

(CCA) battery rating. Or select the appropriate bat-

tery rating for your area (see menu). The tester will

then run its self programmed test of the battery and

display the results. Refer to the test result table

noted below.

CAUTION: If REPLACE BATTERY is the result of the

test, this may mean a poor connection between the

vehicle's cables and battery exists. After discon-

necting the vehicle's battery cables from the bat-

tery, retest the battery using the OUT-OF-VEHICLE

test before replacing.

(6) While viewing the battery test result, press the

CODE button and the tester will prompt you for the

last 4 digits of the VIN. Use the UP/DOWN arrow

buttons to scroll to the correct character; then press

ENTER to select and move to the next digit. Then

press the ENTER button to view the SERVICE

CODE. Pressing the CODE button a second time will

return you to the test results.

BATTERY TEST RESULTS

GOOD BATTERY Return to service

GOOD - RECHARGE Fully charge battery and

return to service

CHARGE & RETEST Fully charge battery and

retest battery

REPLACE BATTERY Replace the battery and

retest complete system

BAD-CELL REPLACE Replace the battery and

retest complete system

NOTE: The SERVICE CODE is required on every

warranty claim submitted for battery replacement.

REMOVAL

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Loosen the battery negative cable terminal

clamp pinch-bolt hex nut.

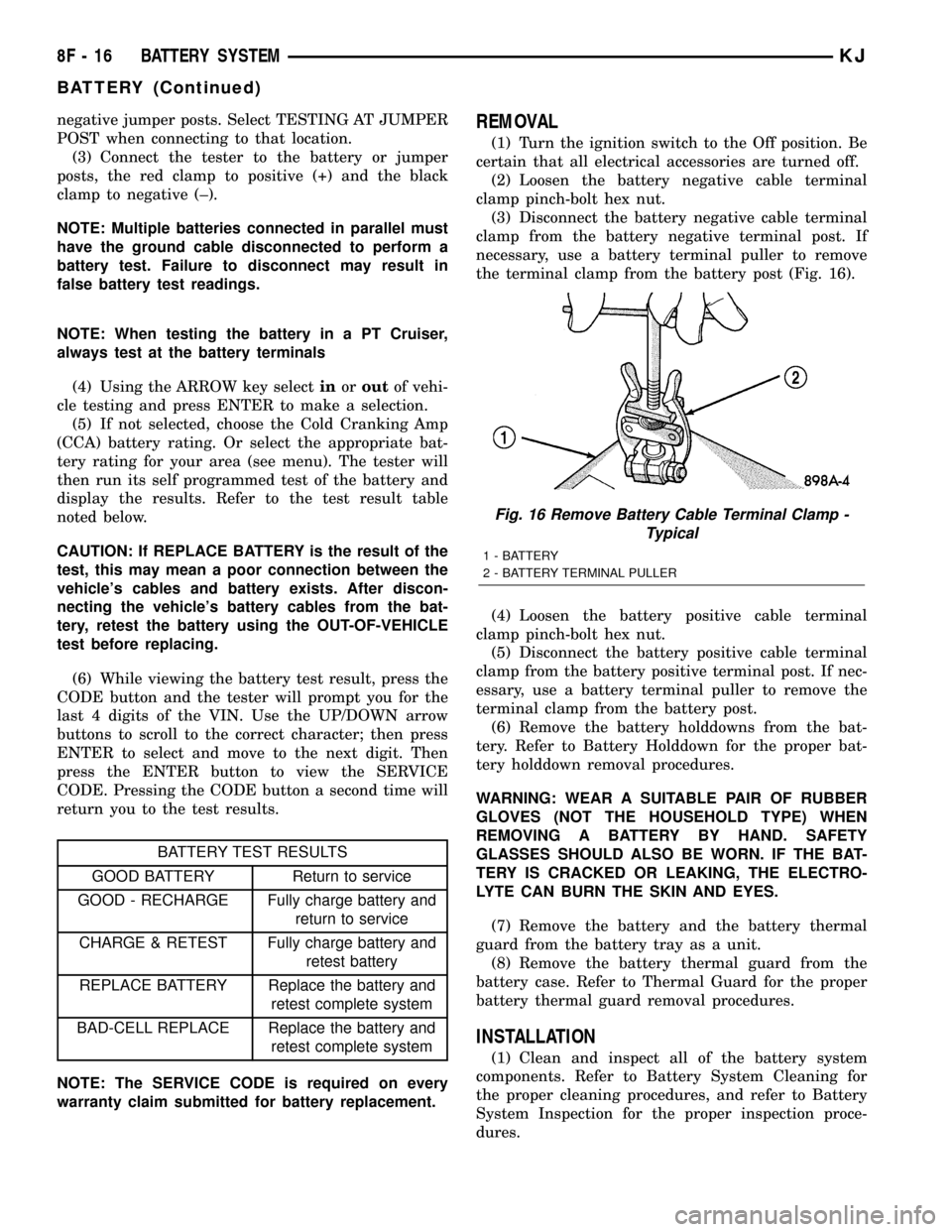

(3) Disconnect the battery negative cable terminal

clamp from the battery negative terminal post. If

necessary, use a battery terminal puller to remove

the terminal clamp from the battery post (Fig. 16).

(4) Loosen the battery positive cable terminal

clamp pinch-bolt hex nut.

(5) Disconnect the battery positive cable terminal

clamp from the battery positive terminal post. If nec-

essary, use a battery terminal puller to remove the

terminal clamp from the battery post.

(6) Remove the battery holddowns from the bat-

tery. Refer to Battery Holddown for the proper bat-

tery holddown removal procedures.

WARNING: WEAR A SUITABLE PAIR OF RUBBER

GLOVES (NOT THE HOUSEHOLD TYPE) WHEN

REMOVING A BATTERY BY HAND. SAFETY

GLASSES SHOULD ALSO BE WORN. IF THE BAT-

TERY IS CRACKED OR LEAKING, THE ELECTRO-

LYTE CAN BURN THE SKIN AND EYES.

(7) Remove the battery and the battery thermal

guard from the battery tray as a unit.

(8) Remove the battery thermal guard from the

battery case. Refer to Thermal Guard for the proper

battery thermal guard removal procedures.

INSTALLATION

(1) Clean and inspect all of the battery system

components. Refer to Battery System Cleaning for

the proper cleaning procedures, and refer to Battery

System Inspection for the proper inspection proce-

dures.

Fig. 16 Remove Battery Cable Terminal Clamp -

Typical

1 - BATTERY

2 - BATTERY TERMINAL PULLER

8F - 16 BATTERY SYSTEMKJ

BATTERY (Continued)

Page 404 of 1803

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................2

OPERATION............................4

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER............................7

REMOVAL.............................9

DISASSEMBLY..........................9

ASSEMBLY............................10

INSTALLATION.........................11

ABS INDICATOR

DESCRIPTION.........................11

OPERATION...........................11

AIRBAG INDICATOR

DESCRIPTION.........................12

OPERATION...........................12

BRAKE/PARK BRAKE INDICATOR

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING - BRAKE

INDICATOR..........................14

CHARGING INDICATOR

DESCRIPTION.........................15

OPERATION...........................15

COOLANT LOW INDICATOR

DESCRIPTION.........................15

OPERATION...........................16

CRUISE INDICATOR

DESCRIPTION.........................16

OPERATION...........................17

DOOR AJAR INDICATOR

DESCRIPTION.........................17

OPERATION...........................17

ENGINE TEMPERATURE GAUGE

DESCRIPTION.........................18

OPERATION...........................18

FRONT FOG LAMP INDICATOR

DESCRIPTION.........................19

OPERATION...........................19

FUEL GAUGE

DESCRIPTION.........................19

OPERATION...........................20

GATE AJAR INDICATOR

DESCRIPTION.........................20

OPERATION...........................20

GLASS AJAR INDICATOR

DESCRIPTION.........................21

OPERATION...........................21

HIGH BEAM INDICATOR

DESCRIPTION.........................22OPERATION...........................22

LOW FUEL INDICATOR

DESCRIPTION.........................22

OPERATION...........................22

LOW OIL PRESSURE INDICATOR

DESCRIPTION.........................23

OPERATION...........................23

MALFUNCTION INDICATOR LAMP (MIL)

DESCRIPTION.........................24

OPERATION...........................24

ODOMETER

DESCRIPTION.........................25

OPERATION...........................25

OVERDRIVE OFF INDICATOR

DESCRIPTION.........................26

OPERATION...........................26

REAR FOG LAMP INDICATOR

DESCRIPTION.........................27

OPERATION...........................27

SEATBELT INDICATOR

DESCRIPTION.........................27

OPERATION...........................28

SECURITY INDICATOR

DESCRIPTION.........................28

OPERATION...........................28

SHIFT INDICATOR (TRANSFER CASE)

DESCRIPTION

DESCRIPTION - PART TIME INDICATOR....29

DESCRIPTION - FULL TIME INDICATOR....29

DESCRIPTION - FOUR LOW MODE

INDICATOR..........................29

OPERATION

OPERATION - PART TIME INDICATOR.....29

OPERATION - FULL TIME INDICATOR.....30

OPERATION - FOUR LOW MODE

INDICATOR..........................30

SKIS INDICATOR

DESCRIPTION.........................31

OPERATION...........................31

SPEEDOMETER

DESCRIPTION.........................32

OPERATION...........................32

TACHOMETER

DESCRIPTION.........................33

OPERATION...........................33

TRANS TEMP INDICATOR

DESCRIPTION.........................33

OPERATION...........................34

KJINSTRUMENT CLUSTER 8J - 1

Page 406 of 1803

perform its many functions. The EMIC module incor-

porates a blue-green digital Vacuum Fluorescent Dis-

play (VFD) for displaying odometer and trip

odometer information, as well as several warning

messages and certain diagnostic information. In addi-

tion to instrumentation and indicators, the EMIC has

the hardware and software needed to provide the fol-

lowing features:

²Chime Warning Service- A chime tone gener-

ator on the EMIC electronic circuit board provides

audible alerts to the vehicle operator and eliminates

the need for a separate chime module. (Refer to 8 -

ELECTRICAL/CHIME WARNING SYSTEM -

DESCRIPTION).

²Panel Lamps Dimming Service- The EMIC

provides a hard wired 12-volt Pulse-Width Modulated

(PWM) output that synchronizes the dimming level

of the radio display, gear selector indicator, heater-air

conditioner control, and all other dimmable lighting

on the panel lamps dimmer circuit with that of the

cluster illumination lamps and VFD.

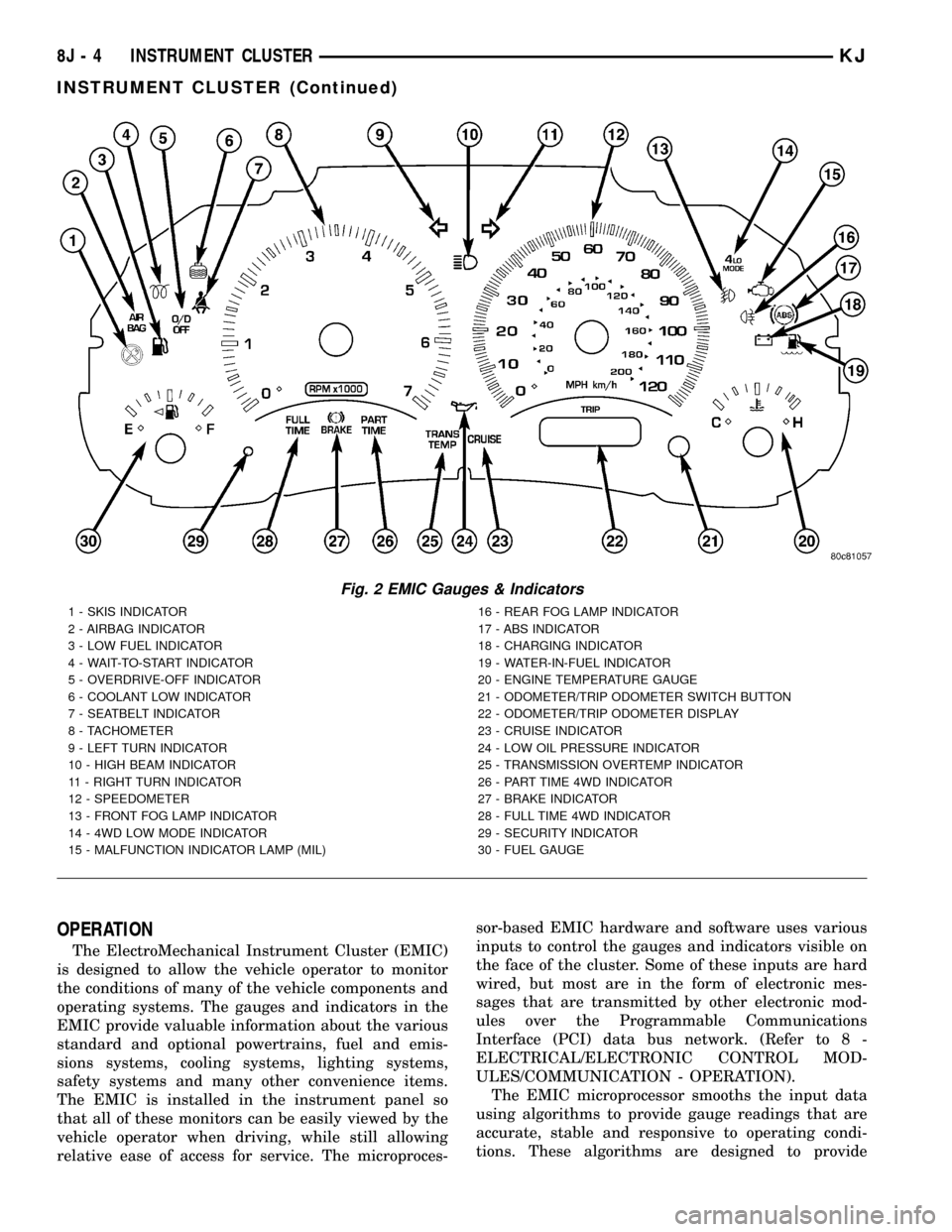

The EMIC houses four analog gauges and has pro-

visions for up to twenty-four indicators (Fig. 2). The

EMIC includes the following analog gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Speedometer

²Tachometer

Some of the EMIC indicators are automatically

configured when the EMIC is connected to the vehi-

cle electrical system for compatibility with certain

optional equipment or equipment required for regula-

tory purposes in certain markets. While each EMIC

may have provisions for indicators to support every

available option, the configurable indicators will not

be functional in a vehicle that does not have the

equipment that an indicator supports. The EMIC

includes provisions for the following indicators (Fig.

2):

²Airbag Indicator (with Airbag System only)

²Antilock Brake System (ABS) Indicator

(with ABS only)

²Brake Indicator

²Charging Indicator

²Coolant Low Indicator (with Diesel Engine

only)

²Cruise Indicator (with Speed Control Sys-

tem only)

²Four-Wheel Drive Full Time Indicator (with

Selec-Trac Transfer Case only)

²Four-Wheel Drive Low Mode Indicator

²Four-Wheel Drive Part Time Indicator

²Front Fog Lamp Indicator (with Front Fog

Lamps only)

²High Beam Indicator

²Low Fuel Indicator²Low Oil Pressure Indicator

²Malfunction Indicator Lamp (MIL)

²Overdrive-Off Indicator (with Automatic

Transmission only)

²Rear Fog Lamp Indicator (with Rear Fog

Lamps only)

²Seatbelt Indicator

²Security Indicator (with Vehicle Theft

Security System only)

²Sentry Key Immobilizer System (SKIS)

Indicator (with SKIS only)

²Transmission Overtemp Indicator (with

Automatic Transmission only)

²Turn Signal (Right and Left) Indicators

²Wait-To-Start Indicator (with Diesel Engine

only)

²Water-In-Fuel Indicator (with Diesel Engine

only)

Each indicator in the EMIC is illuminated by a

dedicated Light Emitting Diode (LED) that is sol-

dered onto the EMIC electronic circuit board. The

LEDs are not available for service replacement and,

if damaged or faulty, the entire EMIC must be

replaced. Cluster illumination is accomplished by

dimmable incandescent back lighting, which illumi-

nates the gauges for visibility when the exterior

lighting is turned on. Each of the incandescent bulbs

is secured by an integral bulb holder to the electronic

circuit board from the back of the cluster housing.

The incandescent bulb/bulb holder units are available

for service replacement.

Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the EMIC through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

The EMIC modules for this model are serviced only

as complete units. The EMIC module cannot be

adjusted or repaired. If a gauge, an LED indicator,

the VFD, the electronic circuit board, the circuit

board hardware, the cluster overlay, or the EMIC

housing are damaged or faulty, the entire EMIC mod-

ule must be replaced. The cluster lens, hood and

mask unit and the individual incandescent lamp

bulbs with holders are available for service replace-

ment.

KJINSTRUMENT CLUSTER 8J - 3

INSTRUMENT CLUSTER (Continued)

Page 407 of 1803

OPERATION

The ElectroMechanical Instrument Cluster (EMIC)

is designed to allow the vehicle operator to monitor

the conditions of many of the vehicle components and

operating systems. The gauges and indicators in the

EMIC provide valuable information about the various

standard and optional powertrains, fuel and emis-

sions systems, cooling systems, lighting systems,

safety systems and many other convenience items.

The EMIC is installed in the instrument panel so

that all of these monitors can be easily viewed by the

vehicle operator when driving, while still allowing

relative ease of access for service. The microproces-sor-based EMIC hardware and software uses various

inputs to control the gauges and indicators visible on

the face of the cluster. Some of these inputs are hard

wired, but most are in the form of electronic mes-

sages that are transmitted by other electronic mod-

ules over the Programmable Communications

Interface (PCI) data bus network. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/COMMUNICATION - OPERATION).

The EMIC microprocessor smooths the input data

using algorithms to provide gauge readings that are

accurate, stable and responsive to operating condi-

tions. These algorithms are designed to provide

Fig. 2 EMIC Gauges & Indicators

1 - SKIS INDICATOR 16 - REAR FOG LAMP INDICATOR

2 - AIRBAG INDICATOR 17 - ABS INDICATOR

3 - LOW FUEL INDICATOR 18 - CHARGING INDICATOR

4 - WAIT-TO-START INDICATOR 19 - WATER-IN-FUEL INDICATOR

5 - OVERDRIVE-OFF INDICATOR 20 - ENGINE TEMPERATURE GAUGE

6 - COOLANT LOW INDICATOR 21 - ODOMETER/TRIP ODOMETER SWITCH BUTTON

7 - SEATBELT INDICATOR 22 - ODOMETER/TRIP ODOMETER DISPLAY

8 - TACHOMETER 23 - CRUISE INDICATOR

9 - LEFT TURN INDICATOR 24 - LOW OIL PRESSURE INDICATOR

10 - HIGH BEAM INDICATOR 25 - TRANSMISSION OVERTEMP INDICATOR

11 - RIGHT TURN INDICATOR 26 - PART TIME 4WD INDICATOR

12 - SPEEDOMETER 27 - BRAKE INDICATOR

13 - FRONT FOG LAMP INDICATOR 28 - FULL TIME 4WD INDICATOR

14 - 4WD LOW MODE INDICATOR 29 - SECURITY INDICATOR

15 - MALFUNCTION INDICATOR LAMP (MIL) 30 - FUEL GAUGE

8J - 4 INSTRUMENT CLUSTERKJ

INSTRUMENT CLUSTER (Continued)

Page 419 of 1803

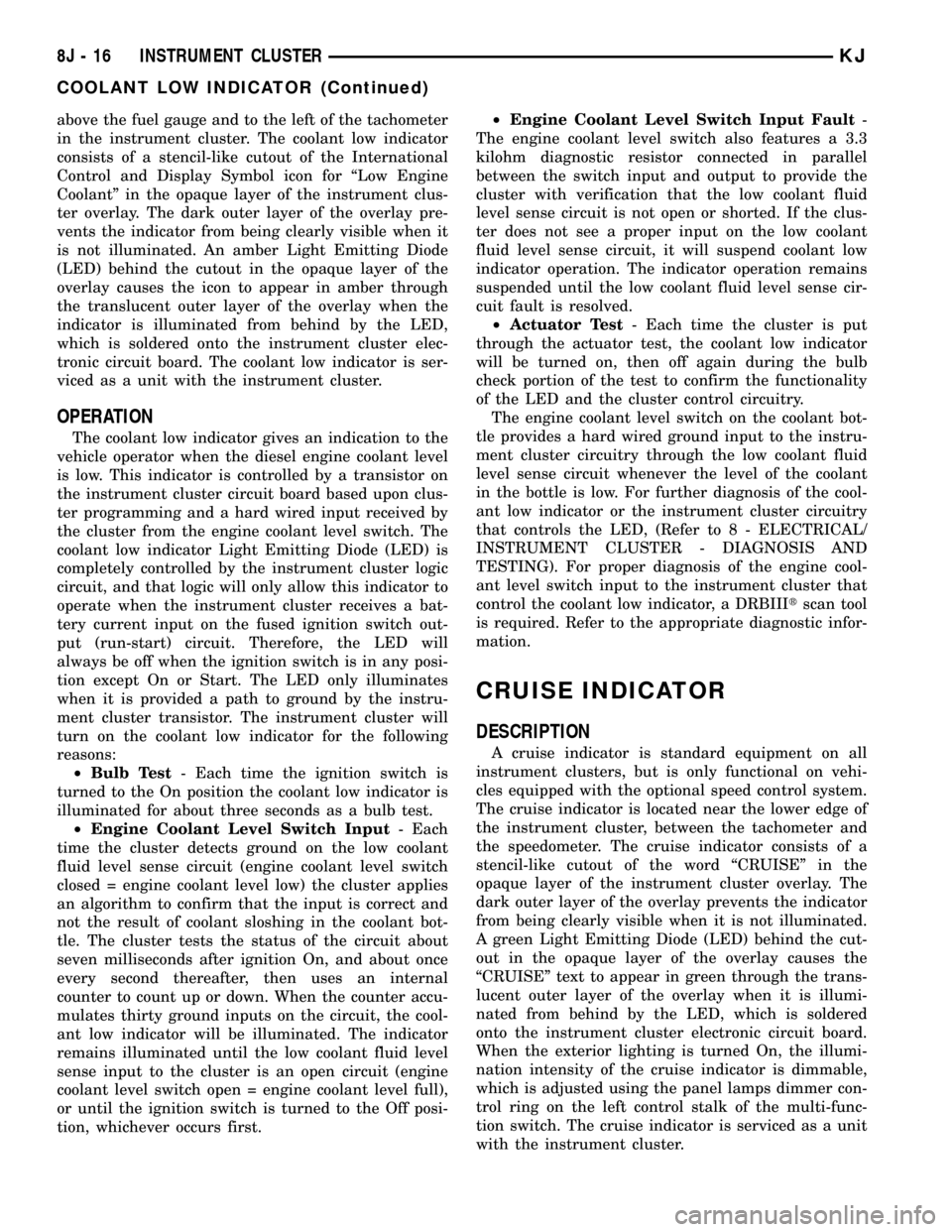

above the fuel gauge and to the left of the tachometer

in the instrument cluster. The coolant low indicator

consists of a stencil-like cutout of the International

Control and Display Symbol icon for ªLow Engine

Coolantº in the opaque layer of the instrument clus-

ter overlay. The dark outer layer of the overlay pre-

vents the indicator from being clearly visible when it

is not illuminated. An amber Light Emitting Diode

(LED) behind the cutout in the opaque layer of the

overlay causes the icon to appear in amber through

the translucent outer layer of the overlay when the

indicator is illuminated from behind by the LED,

which is soldered onto the instrument cluster elec-

tronic circuit board. The coolant low indicator is ser-

viced as a unit with the instrument cluster.

OPERATION

The coolant low indicator gives an indication to the

vehicle operator when the diesel engine coolant level

is low. This indicator is controlled by a transistor on

the instrument cluster circuit board based upon clus-

ter programming and a hard wired input received by

the cluster from the engine coolant level switch. The

coolant low indicator Light Emitting Diode (LED) is

completely controlled by the instrument cluster logic

circuit, and that logic will only allow this indicator to

operate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the LED will

always be off when the ignition switch is in any posi-

tion except On or Start. The LED only illuminates

when it is provided a path to ground by the instru-

ment cluster transistor. The instrument cluster will

turn on the coolant low indicator for the following

reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the coolant low indicator is

illuminated for about three seconds as a bulb test.

²Engine Coolant Level Switch Input- Each

time the cluster detects ground on the low coolant

fluid level sense circuit (engine coolant level switch

closed = engine coolant level low) the cluster applies

an algorithm to confirm that the input is correct and

not the result of coolant sloshing in the coolant bot-

tle. The cluster tests the status of the circuit about

seven milliseconds after ignition On, and about once

every second thereafter, then uses an internal

counter to count up or down. When the counter accu-

mulates thirty ground inputs on the circuit, the cool-

ant low indicator will be illuminated. The indicator

remains illuminated until the low coolant fluid level

sense input to the cluster is an open circuit (engine

coolant level switch open = engine coolant level full),

or until the ignition switch is turned to the Off posi-

tion, whichever occurs first.²Engine Coolant Level Switch Input Fault-

The engine coolant level switch also features a 3.3

kilohm diagnostic resistor connected in parallel

between the switch input and output to provide the

cluster with verification that the low coolant fluid

level sense circuit is not open or shorted. If the clus-

ter does not see a proper input on the low coolant

fluid level sense circuit, it will suspend coolant low

indicator operation. The indicator operation remains

suspended until the low coolant fluid level sense cir-

cuit fault is resolved.

²Actuator Test- Each time the cluster is put

through the actuator test, the coolant low indicator

will be turned on, then off again during the bulb

check portion of the test to confirm the functionality

of the LED and the cluster control circuitry.

The engine coolant level switch on the coolant bot-

tle provides a hard wired ground input to the instru-

ment cluster circuitry through the low coolant fluid

level sense circuit whenever the level of the coolant

in the bottle is low. For further diagnosis of the cool-

ant low indicator or the instrument cluster circuitry

that controls the LED, (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the engine cool-

ant level switch input to the instrument cluster that

control the coolant low indicator, a DRBIIItscan tool

is required. Refer to the appropriate diagnostic infor-

mation.

CRUISE INDICATOR

DESCRIPTION

A cruise indicator is standard equipment on all

instrument clusters, but is only functional on vehi-

cles equipped with the optional speed control system.

The cruise indicator is located near the lower edge of

the instrument cluster, between the tachometer and

the speedometer. The cruise indicator consists of a

stencil-like cutout of the word ªCRUISEº in the

opaque layer of the instrument cluster overlay. The

dark outer layer of the overlay prevents the indicator

from being clearly visible when it is not illuminated.

A green Light Emitting Diode (LED) behind the cut-

out in the opaque layer of the overlay causes the

ªCRUISEº text to appear in green through the trans-

lucent outer layer of the overlay when it is illumi-

nated from behind by the LED, which is soldered

onto the instrument cluster electronic circuit board.

When the exterior lighting is turned On, the illumi-

nation intensity of the cruise indicator is dimmable,

which is adjusted using the panel lamps dimmer con-

trol ring on the left control stalk of the multi-func-

tion switch. The cruise indicator is serviced as a unit

with the instrument cluster.

8J - 16 INSTRUMENT CLUSTERKJ

COOLANT LOW INDICATOR (Continued)

Page 420 of 1803

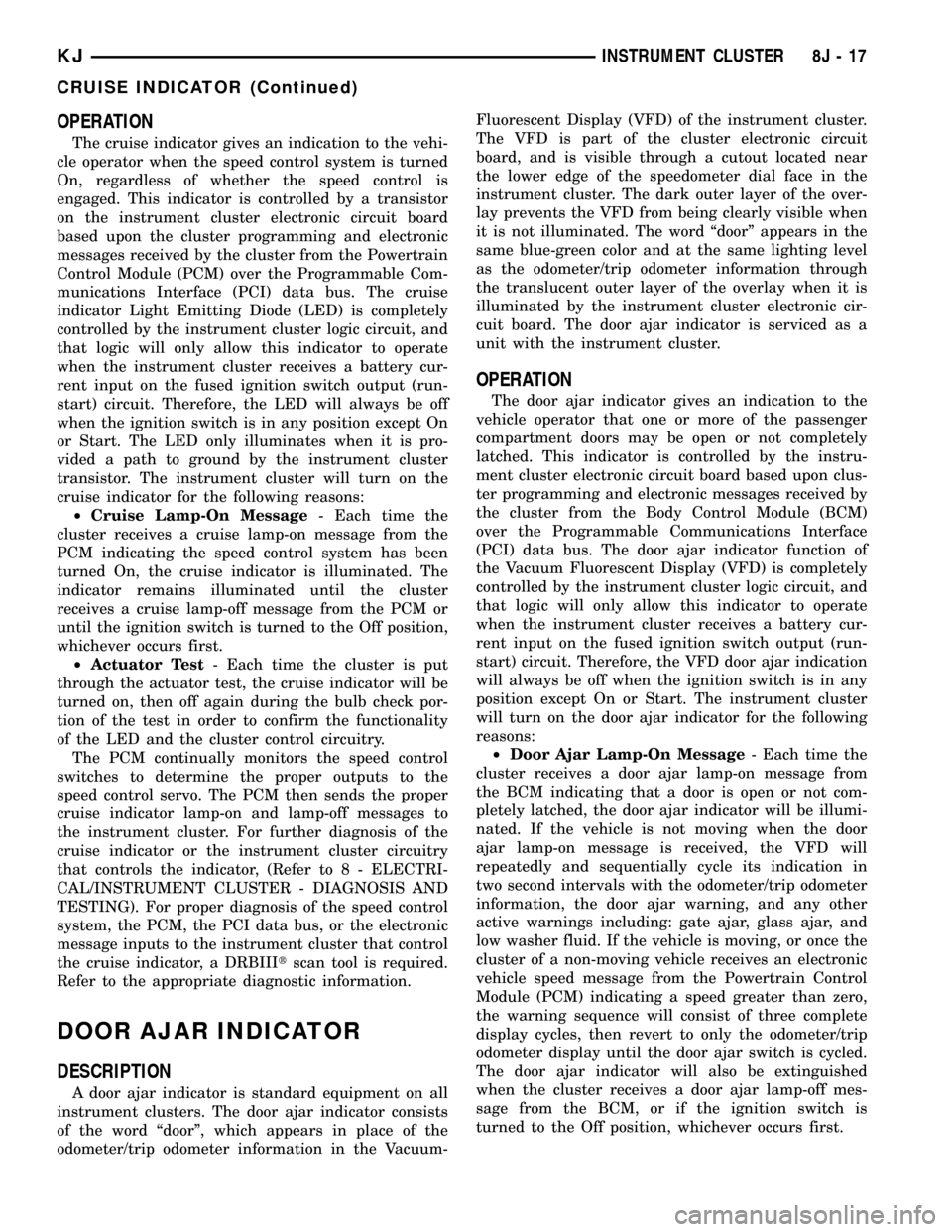

OPERATION

The cruise indicator gives an indication to the vehi-

cle operator when the speed control system is turned

On, regardless of whether the speed control is

engaged. This indicator is controlled by a transistor

on the instrument cluster electronic circuit board

based upon the cluster programming and electronic

messages received by the cluster from the Powertrain

Control Module (PCM) over the Programmable Com-

munications Interface (PCI) data bus. The cruise

indicator Light Emitting Diode (LED) is completely

controlled by the instrument cluster logic circuit, and

that logic will only allow this indicator to operate

when the instrument cluster receives a battery cur-

rent input on the fused ignition switch output (run-

start) circuit. Therefore, the LED will always be off

when the ignition switch is in any position except On

or Start. The LED only illuminates when it is pro-

vided a path to ground by the instrument cluster

transistor. The instrument cluster will turn on the

cruise indicator for the following reasons:

²Cruise Lamp-On Message- Each time the

cluster receives a cruise lamp-on message from the

PCM indicating the speed control system has been

turned On, the cruise indicator is illuminated. The

indicator remains illuminated until the cluster

receives a cruise lamp-off message from the PCM or

until the ignition switch is turned to the Off position,

whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the cruise indicator will be

turned on, then off again during the bulb check por-

tion of the test in order to confirm the functionality

of the LED and the cluster control circuitry.

The PCM continually monitors the speed control

switches to determine the proper outputs to the

speed control servo. The PCM then sends the proper

cruise indicator lamp-on and lamp-off messages to

the instrument cluster. For further diagnosis of the

cruise indicator or the instrument cluster circuitry

that controls the indicator, (Refer to 8 - ELECTRI-

CAL/INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING). For proper diagnosis of the speed control

system, the PCM, the PCI data bus, or the electronic

message inputs to the instrument cluster that control

the cruise indicator, a DRBIIItscan tool is required.

Refer to the appropriate diagnostic information.

DOOR AJAR INDICATOR

DESCRIPTION

A door ajar indicator is standard equipment on all

instrument clusters. The door ajar indicator consists

of the word ªdoorº, which appears in place of the

odometer/trip odometer information in the Vacuum-Fluorescent Display (VFD) of the instrument cluster.

The VFD is part of the cluster electronic circuit

board, and is visible through a cutout located near

the lower edge of the speedometer dial face in the

instrument cluster. The dark outer layer of the over-

lay prevents the VFD from being clearly visible when

it is not illuminated. The word ªdoorº appears in the

same blue-green color and at the same lighting level

as the odometer/trip odometer information through

the translucent outer layer of the overlay when it is

illuminated by the instrument cluster electronic cir-

cuit board. The door ajar indicator is serviced as a

unit with the instrument cluster.

OPERATION

The door ajar indicator gives an indication to the

vehicle operator that one or more of the passenger

compartment doors may be open or not completely

latched. This indicator is controlled by the instru-

ment cluster electronic circuit board based upon clus-

ter programming and electronic messages received by

the cluster from the Body Control Module (BCM)

over the Programmable Communications Interface

(PCI) data bus. The door ajar indicator function of

the Vacuum Fluorescent Display (VFD) is completely

controlled by the instrument cluster logic circuit, and

that logic will only allow this indicator to operate

when the instrument cluster receives a battery cur-

rent input on the fused ignition switch output (run-

start) circuit. Therefore, the VFD door ajar indication

will always be off when the ignition switch is in any

position except On or Start. The instrument cluster

will turn on the door ajar indicator for the following

reasons:

²Door Ajar Lamp-On Message- Each time the

cluster receives a door ajar lamp-on message from

the BCM indicating that a door is open or not com-

pletely latched, the door ajar indicator will be illumi-

nated. If the vehicle is not moving when the door

ajar lamp-on message is received, the VFD will

repeatedly and sequentially cycle its indication in

two second intervals with the odometer/trip odometer

information, the door ajar warning, and any other

active warnings including: gate ajar, glass ajar, and

low washer fluid. If the vehicle is moving, or once the

cluster of a non-moving vehicle receives an electronic

vehicle speed message from the Powertrain Control

Module (PCM) indicating a speed greater than zero,

the warning sequence will consist of three complete

display cycles, then revert to only the odometer/trip

odometer display until the door ajar switch is cycled.

The door ajar indicator will also be extinguished

when the cluster receives a door ajar lamp-off mes-

sage from the BCM, or if the ignition switch is

turned to the Off position, whichever occurs first.

KJINSTRUMENT CLUSTER 8J - 17

CRUISE INDICATOR (Continued)

Page 675 of 1803

A ªtap downº feature is used to decelerate without

disengaging the speed control system. To decelerate

from an existing recorded target speed, momentarily

depress the COAST switch. For each switch activa-

tion, speed will be lowered approximately 1 mph.

OVERSHOOT/UNDERSHOOT

If the vehicle operator repeatedly presses and

releases the SET button with their foot off of the

accelerator (referred to as a ªlift foot setº), the vehicle

may accelerate and exceed the desired set speed by

up to 5 mph (8 km/h). It may also decelerate to less

than the desired set speed, before finally achieving

the desired set speed.

The Speed Control System has an adaptive strat-

egy that compensates for vehicle-to-vehicle variations

in speed control cable lengths. When the speed con-

trol is set with the vehicle operators foot off of the

accelerator pedal, the speed control thinks there is

excessive speed control cable slack and adapts

accordingly. If the ªlift foot setsº are continually used,

a speed control overshoot/undershoot condition will

develop.

To ªunlearnº the overshoot/undershoot condition,

the vehicle operator has to press and release the set

button while maintaining the desired set speed using

the accelerator pedal (not decelerating or accelerat-

ing), and then turning the cruise control switch to

the OFF position (or press the CANCEL button if

equipped) after waiting 10 seconds. This procedure

must be performed approximately 10±15 times to

completely unlearn the overshoot/undershoot condi-

tion.

DIAGNOSIS AND TESTING - ROAD TEST

Perform a vehicle road test to verify reports of

speed control system malfunction. The road testshould include attention to the speedometer. Speed-

ometer operation should be smooth and without flut-

ter at all speeds.

Flutter in the speedometer indicates a problem

which might cause surging in the speed control sys-

tem. The cause of any speedometer problems should

be corrected before proceeding. Refer to Group 8J,

Instrument Cluster for speedometer diagnosis.

If a road test verifies a system problem and the

speedometer operates properly, check for:

²A Diagnostic Trouble Code (DTC). If a DTC

exists, conduct tests per the Powertrain Diagnostic

Procedures service manual.

²A misadjusted brake (stop) lamp switch. This

could also cause an intermittent problem.

²Loose, damaged or corroded electrical connec-

tions at the servo. Corrosion should be removed from

electrical terminals and a light coating of Mopar

MultiPurpose Grease, or equivalent, applied.

²Leaking vacuum reservoir.

²Loose or leaking vacuum hoses or connections.

²Defective one-way vacuum check valve.

²Secure attachment of both ends of the speed con-

trol servo cable.

²Smooth operation of throttle linkage and throttle

body air valve.

²Failed speed control servo. Do the servo vacuum

test.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals or seals. If

these components are damaged, intermittent or

complete system failure may occur.

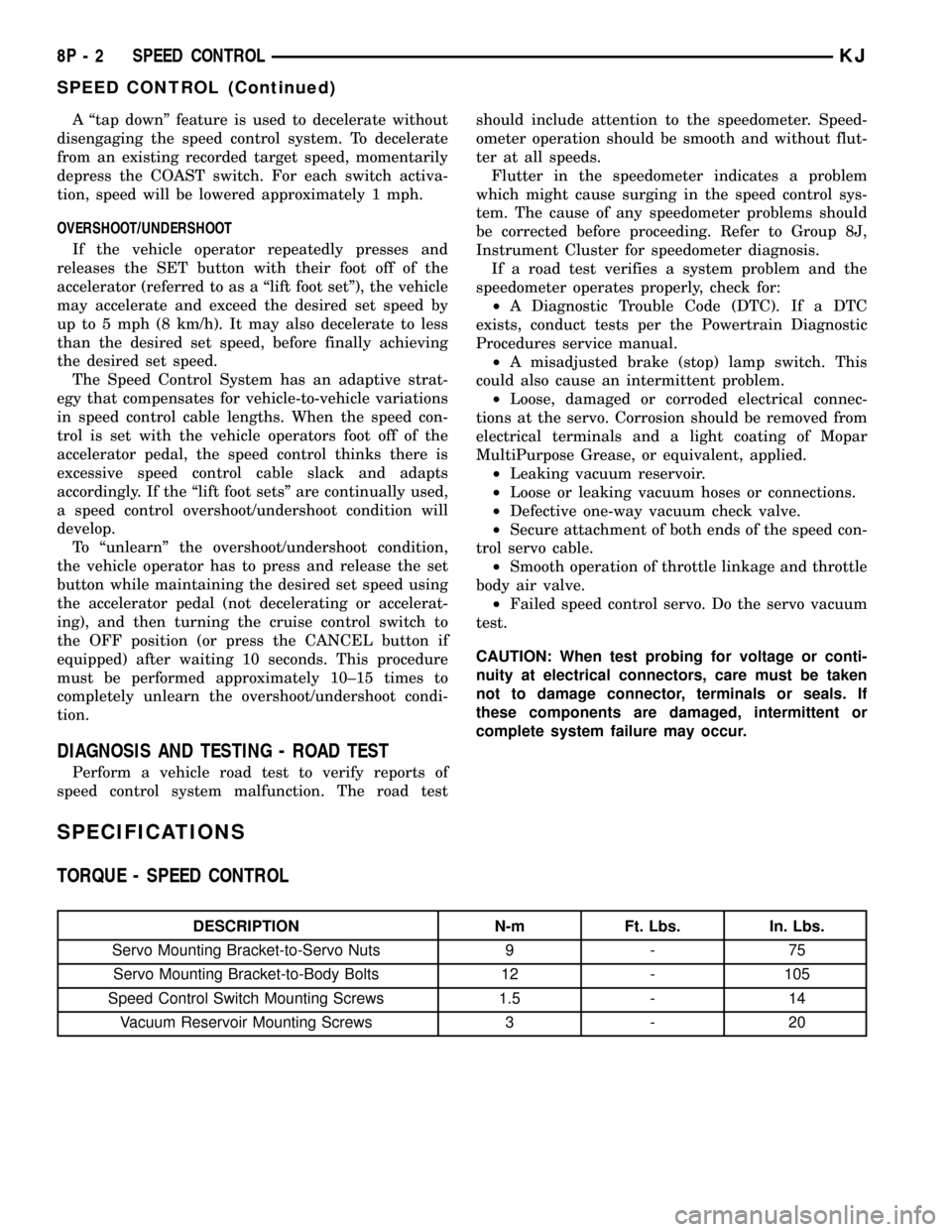

SPECIFICATIONS

TORQUE - SPEED CONTROL

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Servo Mounting Bracket-to-Servo Nuts 9 - 75

Servo Mounting Bracket-to-Body Bolts 12 - 105

Speed Control Switch Mounting Screws 1.5 - 14

Vacuum Reservoir Mounting Screws 3 - 20

8P - 2 SPEED CONTROLKJ

SPEED CONTROL (Continued)

Page 1435 of 1803

COLUMN

TABLE OF CONTENTS

page page

COLUMN

DESCRIPTION..........................5

OPERATION - SERVICE PRECAUTIONS......5

REMOVAL.............................5

INSTALLATION..........................7

SPECIFICATIONS

TORQUE CHART......................8

SPECIAL TOOLS

STEERING COLUMN....................8

IGNITION SWITCH

DESCRIPTION..........................8

DIAGNOSIS AND TESTING - IGNITION

SWITCH.............................8

REMOVAL

IGNITION SWITCH REMOVAL.............9INSTALLATION

IGNITION SWITCH INSTALLATION.........9

KEY-IN IGNITION SWITCH

DESCRIPTION.........................10

DIAGNOSIS AND TESTING - KEY-IN IGNITION

SWITCH............................10

LOCK CYLINDER

REMOVAL.............................10

INSTALLATION.........................11

INTERMEDIATE SHAFT

REMOVAL.............................11

INSTALLATION.........................11

STEERING WHEEL

REMOVAL.............................12

INSTALLATION.........................12

COLUMN

DESCRIPTION

The standard non-tilt and tilt steering column has

been designed to be serviced as an assembly. The col-

umn is connected to the steering gear with a one

piece shaft. The upper half has a support bearing

mounted to a bracket. The bracket mounts to the

frame rail with two nuts. The shaft is serviceable.

The key cylinder, switches, clock spring, trim shrouds

and steering wheel are serviced separately.

OPERATION - SERVICE PRECAUTIONS

Safety goggles should be worn at all times when

working on steering columns.

To service the steering wheel, switches or airbag,

refer to Electrical - Restraints and follow all WARN-

INGS and CAUTIONS.

WARNING: THE AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIRBAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. THEN WAIT TWOMINUTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE. FAILURE TO DO SO COULD RESULT IN

ACCIDENTAL DEPLOYMENT OF THE AIRBAG AND

POSSIBLE PERSONAL INJURY. THE FASTENERS,

SCREWS, AND BOLTS, ORIGINALLY USED FOR

THE AIRBAG COMPONENTS, HAVE SPECIAL COAT-

INGS AND ARE SPECIFICALLY DESIGNED FOR THE

AIRBAG SYSTEM. THEY MUST NEVER BE

REPLACED WITH ANY SUBSTITUTES. ANYTIME A

NEW FASTENER IS NEEDED, REPLACE WITH THE

CORRECT FASTENERS PROVIDED IN THE SERVICE

PACKAGE OR FASTENERS LISTED IN THE PARTS

BOOKS.REMOVAL

(1) Position front wheelsstraight ahead.

(2) Remove and isolate the negative ground cable

from the battery.

(3) Remove the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - REMOVAL).

NOTE: If equipped with cruise control, disconnect

clock spring harness from the cruise switch har-

ness on the steering wheel.

KJCOLUMN 19 - 5

Page 1437 of 1803

INSTALLATION

(1) Align and install column into the steering cou-

pler.(2) Install column harness and connect harness to

switches.

(3) Reroute the shifter interlock cable through the

tie straps.

(4) Install the column onto the mounting studs.

(5) Install the two mounting nuts and the two

mounting bolts all finger tight.

CAUTION: Lower nuts must be installed and tight-

ened first then the upper nuts in order to prevent

damage to the capsules.

(6) Tighten the lower mounting nuts to 17 N´m

(150 in. lbs.).

(7) Tighten the upper mounting nuts to 17 N´m

(150 in. lbs.).

(8) Install the steering column coupler bolt and

tighten to 49 N´m (36 ft. lbs.).

(9) Reconnect the shifter interlock cable.

(10) Center the clock spring (if necessary) and

install it on the column, (Refer to 8 - ELECTRICAL/

RESTRAINTS/CLOCKSPRING - INSTALLATION).

(11) Snap together the column shrouds and install

the mounting screws.

(12) Install the knee blocker and the knee blocker

cover, (Refer to 23 - BODY/INSTRUMENT PANEL/

KNEE BLOCKER - INSTALLATION).

(13)

NOTE: Do not reuse the old steering wheel bolt (a

new bolt must be used)

NOTE: Be certain that the steering wheel mounting

bolt is tightened to the proper torque specification

to ensure proper clockspring operation.Install the

steering wheel and tighten bolt to 54 N´m (40 ft.

lbs.) (Refer to 19 - STEERING/COLUMN/STEERING

WHEEL - INSTALLATION).

NOTE: If equipped with cruise control, connect

clock spring harness to cruise switch harness on

the steering wheel.

(14) Install the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(15) Install the negative battery terminal.

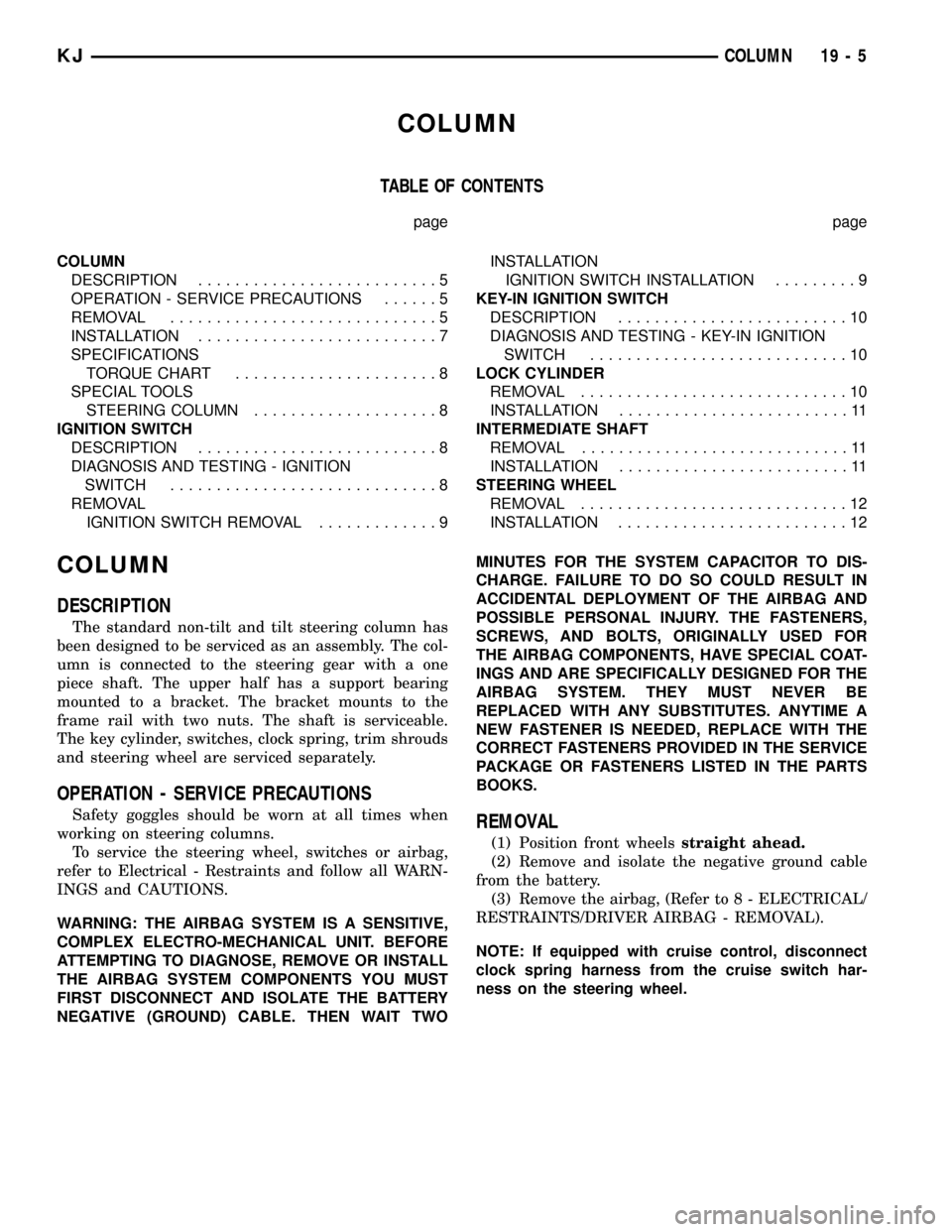

Fig. 5 WIRING HARNESS COLUMN

1 - Column Wiring Harness

2 - Multi-function Switch

3 - Ignition Switch

4 - Steering Column

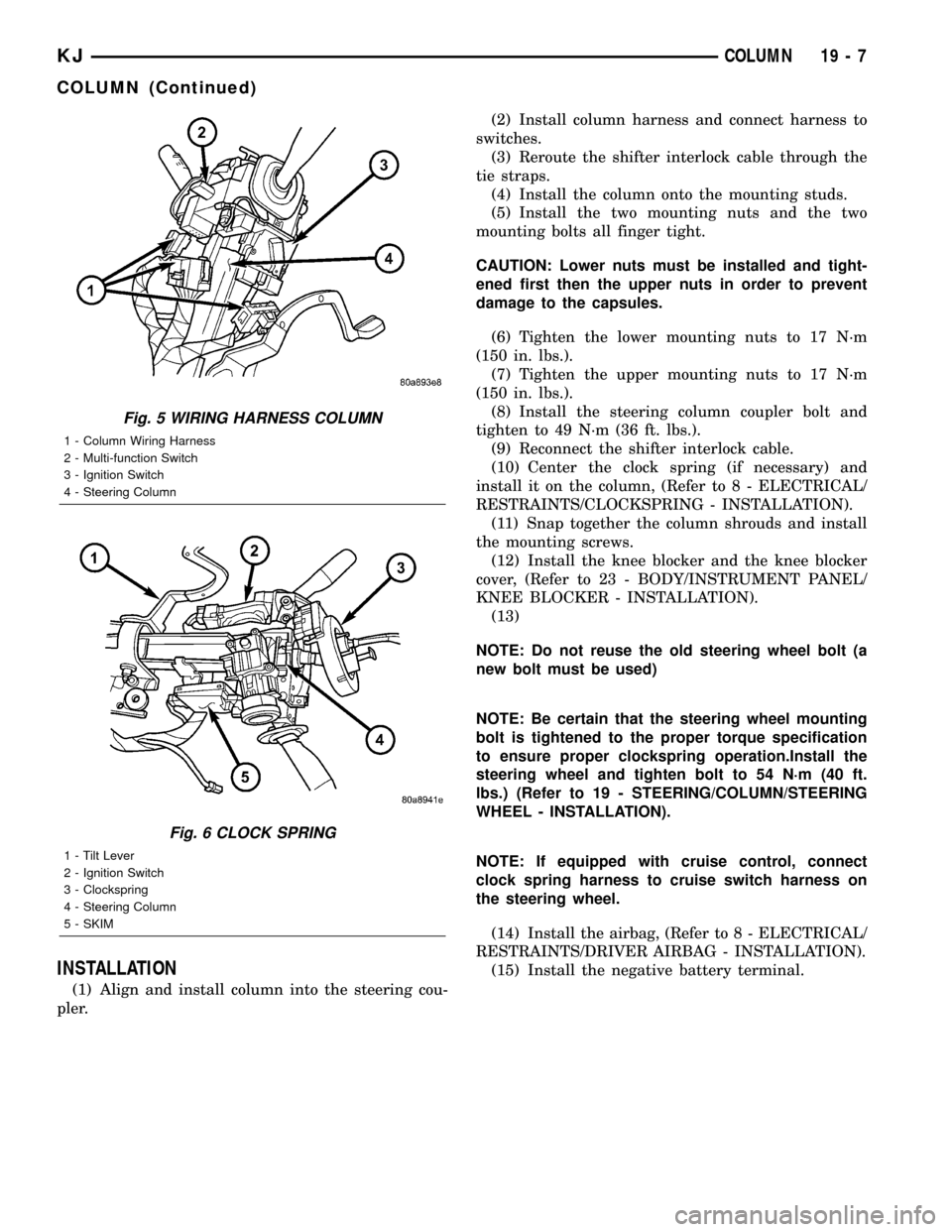

Fig. 6 CLOCK SPRING

1 - Tilt Lever

2 - Ignition Switch

3 - Clockspring

4 - Steering Column

5 - SKIM

KJCOLUMN 19 - 7

COLUMN (Continued)