stop start JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 685 of 1803

ergize the combination flasher, the horn relay (except

vehicles with the Rest-Of-World or ROW premium

version of the VTA), and the security indicator. In

addition, in vehicles built for certain markets where

the ROW premium version of the VTA is required,

the BCM also exchanges electronic messages with

the Intrusion Transceiver Module (ITM) over the Pro-

grammable Communications Interface (PCI) data bus

network to provide the features found in this version

of the VTA.

The hard wired circuits and components of the

VTA may be diagnosed and tested using conventional

diagnostic tools and procedures. However, conven-

tional diagnostic methods may not prove conclusive

in the diagnosis of the Body Control Module (BCM),

the ElectroMechanical Instrument Cluster (EMIC),

the Intrusion Transceiver Module (ITM), or the Pro-

grammable Communications Interface (PCI) data bus

network. The most reliable, efficient, and accurate

means to diagnose the BCM, the EMIC, the ITM,

and the PCI data bus network inputs and outputs

related to the VTA requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation. Following are paragraphs that briefly

describe the operation of each of the VTA features.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the VTA.

²ENABLING- The BCM must have the VTA

function electronically enabled in order for the VTA

to perform as designed. The logic in the BCM keeps

its VTA function dormant until it is enabled using a

DRBIIItscan tool. The VTA function of the BCM is

enabled on vehicles equipped with the VTA option at

the factory, but a service replacement BCM must be

VTA-enabled by the dealer using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

²PRE-ARMING- The VTA has a pre-arming

sequence. Pre-arming occurs when a door, the tail-

gate, or the flip-up glass is open when the vehicle is

locked using a power lock switch, or when the ªLockº

button on the Remote Keyless Entry (RKE) transmit-

ter is depressed. The power lock switch will not ini-

tiate the pre-arming sequence if the key is in the

ignition switch. When the VTA is pre-armed, the

arming sequence is delayed until all of the doors, the

tailgate, and the flip-up glass are closed.

²ARMING- Passive arming of the VTA occurs

when the vehicle is exited with the key removed from

the ignition switch and the doors are locked while

they are open using the power lock switch (see Pre-

Arming). Active arming of the VTA occurs when the

ªLockº button on the Remote Keyless Entry (RKE)

transmitter is depressed to lock the vehicle after all

of the doors, the tailgate, and the flip-up glass are

closed. The VTA will not arm if the doors are lockedusing the key in a lock cylinder or using a mechani-

cal lock button. Once the VTA begins the passive or

active arming sequence, the security indicator in the

instrument cluster will flash rapidly for about six-

teen seconds. This indicates that the VTA arming

sequence is in progress. If the ignition switch is

turned to the On position, if a door is unlocked with

the power lock switch or the RKE transmitter, or if

the tailgate is unlocked by any means during the six-

teen second arming sequence, the security indicator

will stop flashing and the VTA arming sequence will

abort. On vehicles equipped with the hood ajar

switch, the VTA arming sequence will occur regard-

less of whether the hood is open or closed, but the

underhood area will not be protected unless the hood

is closed when the VTA arming sequence begins.

Also, if the status of the hood ajar switch changes

from open (hood closed) to closed (hood open) during

the sixteen second arming sequence, the security

indicator will stop flashing and the VTA arming

sequence will abort. Once the sixteen second arming

sequence is successfully completed, the security indi-

cator will flash at a slower rate, indicating that the

VTA is armed.

²DISARMING- For vehicles built for the North

American market, disarming of the VTA occurs when

the vehicle is unlocked using the key to unlock a door

or the tailgate. Disarming of the VTA for any market

also occurs when the vehicle is unlocked by depress-

ing the ªUnlockº button of the Remote Keyless Entry

(RKE) transmitter, or by turning the ignition switch

to the On position using a valid Sentry Key Immobi-

lizer System (SKIS) key. Once the alarm has been

activated, any of these disarming methods will also

deactivate the alarm.

²POWER-UP MODE- When the armed VTA

senses that the battery has been disconnected and

reconnected, it enters its power-up mode. In the pow-

er-up mode the alarm system returns to the mode

that was last selected prior to the battery failure or

disconnect. If the VTA was armed prior to the battery

disconnect or failure, the technician or vehicle opera-

tor will have to actively or passively disarm the sys-

tem after the battery is reconnected. The power-up

mode will also apply if the battery goes dead while

the system is armed, and battery jump-starting is

then attempted. The VTA will remain armed until

the technician or vehicle operator has actively or pas-

sively disarmed the system. If the VTA is in the dis-

armed mode prior to a battery disconnect or failure,

it will remain disarmed after the battery is recon-

nected or replaced, or if jump-starting is attempted.

²ALARM- The VTA alarm output varies by the

version of the VTA with which the vehicle is

equipped. In all cases, the alarm provides both visual

and audible outputs; however, the time intervals of

8Q - 4 VEHICLE THEFT SECURITYKJ

VEHICLE THEFT SECURITY (Continued)

Page 690 of 1803

SECURED ACCESS METHOD

The Secured Access method applies to all vehicles.

This method requires the use of a DRBIIItscan tool.

This method will also require that you have access to

the unique four-digit PIN code that was assigned to

the original SKIM. The PIN codemustbe used to

enter the Secured Access Mode in the SKIM. This

PIN number may be obtained from the vehicle owner,

from the original vehicle invoice, or from the

DaimlerChrysler Customer Center. Refer to the

appropriate diagnostic information for the proper

Secured Access method programming procedures.

CUSTOMER LEARN METHOD

The Customer Learn feature is only available on

domestic vehicles, or those vehicles which have a

U.S. country code designator. This programming

method also requires access to at least two valid Sen-

try Keys. If two valid Sentry Keys are not available,

or if the vehicle does not have a U.S. country code

designator, the Secured Access Methodmustbe used

to program new or additional valid keys to the SKIM.

The Customer Learn programming method proce-

dures are as follows:

(1) Obtain the blank Sentry Key(s) that are to be

programmed as valid keys for the vehicle. Cut the

blank key(s) to match the ignition switch lock cylin-

der mechanical key codes.

(2) Insert one of the two valid Sentry Keys into the

ignition switch and turn the ignition switch to the

On position.

(3) After the ignition switch has been in the On

position for longer than three seconds, but no more

than fifteen seconds, cycle the ignition switch back to

the Off position. Replace the first valid Sentry Key in

the ignition switch lock cylinder with the second

valid Sentry Key and turn the ignition switch back to

the On position. The second valid Sentry Key must

be inserted in the lock cylinder within fifteen seconds

of removing the first valid key.

(4) About ten seconds after the completion of Step

3, the SKIS indicator in the instrument cluster will

start to flash and a single audible chime tone will

sound to indicate that the system has entered the

Customer Learn programming mode.

(5) Within sixty seconds of entering the Customer

Learn programming mode, turn the ignition switch to

the Off position, replace the valid Sentry Key with a

blank Sentry Key transponder, and turn the ignition

switch back to the On position.

(6)

About ten seconds after the completion of Step 5,

a single audible chime tone will sound and the SKIS

indicator will stop flashing, stay on solid for three sec-

onds, then turn off to indicate that the blank Sentry

Key has been successfully programmed. The SKIS will

immediately exit the Customer Learn programmingmode and the vehicle may now be started using the

newly programmed valid Sentry Key.

Each of these steps must be repeated and com-

pleted in their entirety for each additional Sentry

Key that is to be programmed. If the above steps are

not completed in the given sequence, or within the

allotted time, the SKIS will exit the Customer Learn

programming mode and the programming will be

unsuccessful. The SKIS will also automatically exit

the Customer Learn programming mode if it sees a

non-blank Sentry Key transponder when it should

see a blank, if it has already programmed eight (8)

valid Sentry Keys, or if the ignition switch is turned

to the Off position for more than about fifty seconds.

NOTE: If an attempt is made to start the vehicle

while in the Customer Learn mode (SKIS indicator

flashing), the SKIS will respond as though the vehi-

cle were being started with an invalid key. In other

words, the engine will stall after about two seconds

of operation. No faults will be set.

NOTE: Once a Sentry Key has been programmed as

a valid key to a vehicle, it cannot be programmed

as a valid key for use on any other vehicle.

DOOR CYLINDER LOCK

SWITCH

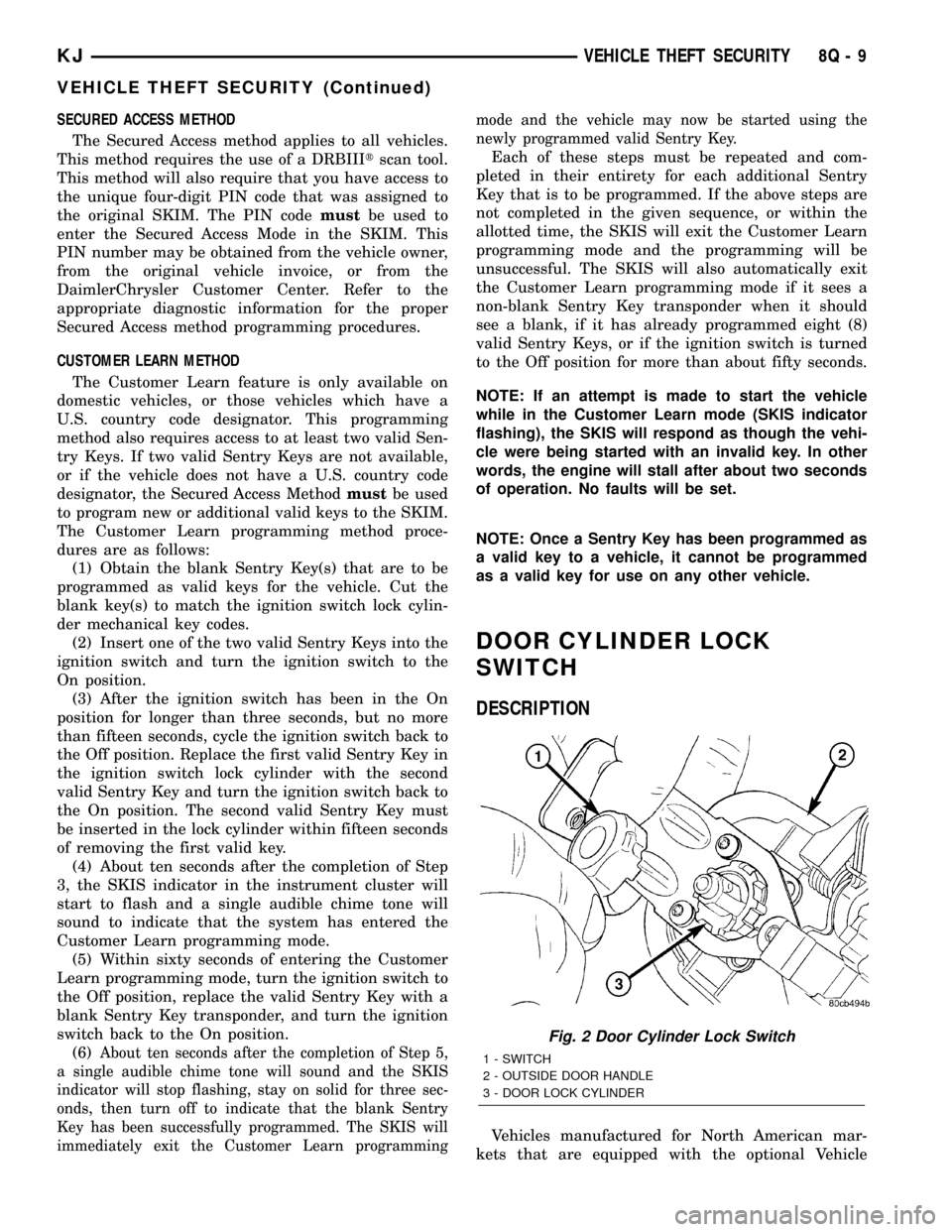

DESCRIPTION

Vehicles manufactured for North American mar-

kets that are equipped with the optional Vehicle

Fig. 2 Door Cylinder Lock Switch

1 - SWITCH

2 - OUTSIDE DOOR HANDLE

3 - DOOR LOCK CYLINDER

KJVEHICLE THEFT SECURITY 8Q - 9

VEHICLE THEFT SECURITY (Continued)

Page 763 of 1803

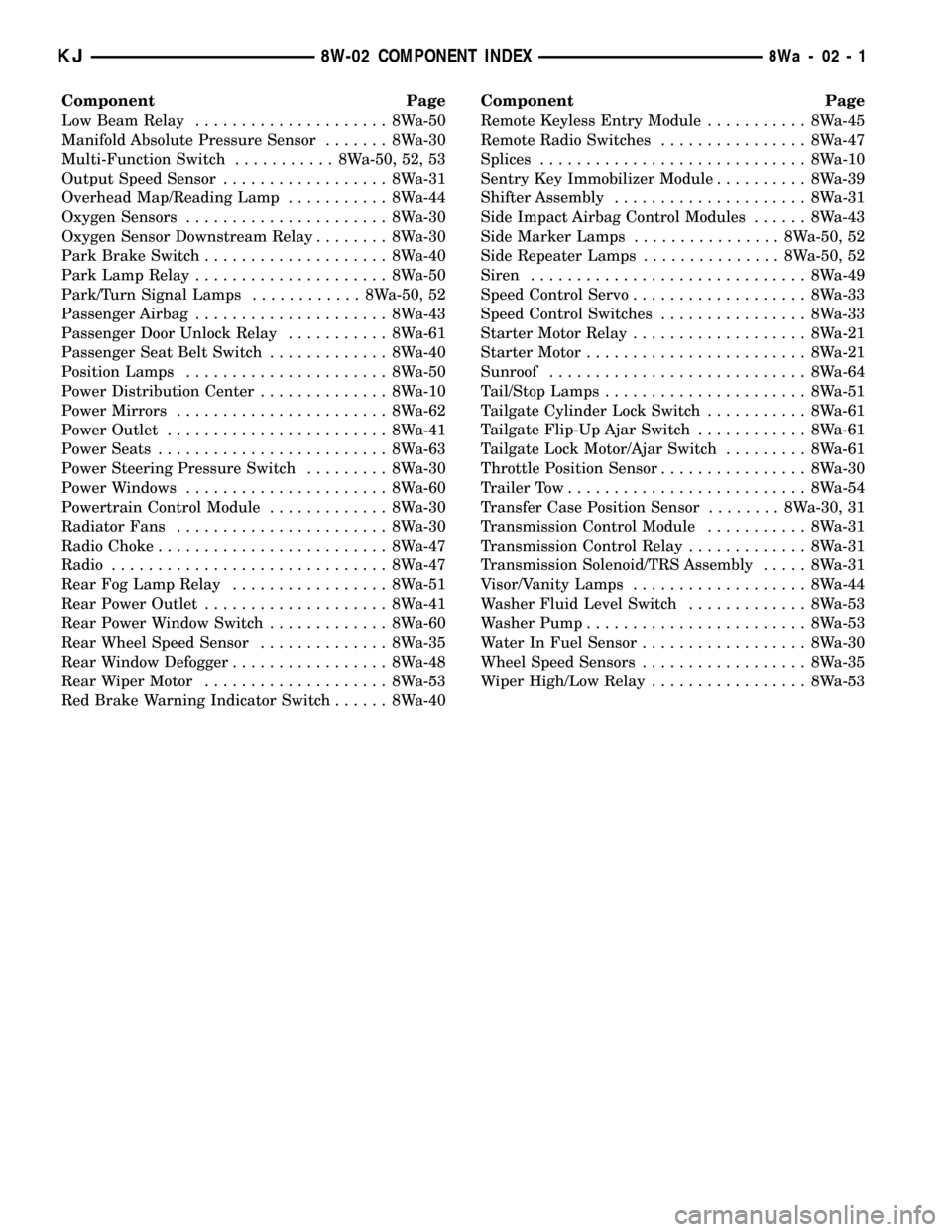

Component Page

Low Beam Relay..................... 8Wa-50

Manifold Absolute Pressure Sensor....... 8Wa-30

Multi-Function Switch........... 8Wa-50, 52, 53

Output Speed Sensor.................. 8Wa-31

Overhead Map/Reading Lamp........... 8Wa-44

Oxygen Sensors...................... 8Wa-30

Oxygen Sensor Downstream Relay........ 8Wa-30

Park Brake Switch.................... 8Wa-40

Park Lamp Relay..................... 8Wa-50

Park/Turn Signal Lamps............ 8Wa-50, 52

Passenger Airbag..................... 8Wa-43

Passenger Door Unlock Relay........... 8Wa-61

Passenger Seat Belt Switch............. 8Wa-40

Position Lamps...................... 8Wa-50

Power Distribution Center.............. 8Wa-10

Power Mirrors....................... 8Wa-62

Power Outlet........................ 8Wa-41

Power Seats......................... 8Wa-63

Power Steering Pressure Switch......... 8Wa-30

Power Windows...................... 8Wa-60

Powertrain Control Module............. 8Wa-30

Radiator Fans....................... 8Wa-30

Radio Choke......................... 8Wa-47

Radio.............................. 8Wa-47

Rear Fog Lamp Relay................. 8Wa-51

Rear Power Outlet.................... 8Wa-41

Rear Power Window Switch............. 8Wa-60

Rear Wheel Speed Sensor.............. 8Wa-35

Rear Window Defogger................. 8Wa-48

Rear Wiper Motor.................... 8Wa-53

Red Brake Warning Indicator Switch...... 8Wa-40Component Page

Remote Keyless Entry Module........... 8Wa-45

Remote Radio Switches................ 8Wa-47

Splices............................. 8Wa-10

Sentry Key Immobilizer Module.......... 8Wa-39

Shifter Assembly..................... 8Wa-31

Side Impact Airbag Control Modules...... 8Wa-43

Side Marker Lamps................ 8Wa-50, 52

Side Repeater Lamps............... 8Wa-50, 52

Siren.............................. 8Wa-49

Speed Control Servo................... 8Wa-33

Speed Control Switches................ 8Wa-33

Starter Motor Relay................... 8Wa-21

Starter Motor........................ 8Wa-21

Sunroof............................ 8Wa-64

Tail/Stop Lamps...................... 8Wa-51

Tailgate Cylinder Lock Switch........... 8Wa-61

Tailgate Flip-Up Ajar Switch............ 8Wa-61

Tailgate Lock Motor/Ajar Switch......... 8Wa-61

Throttle Position Sensor................ 8Wa-30

Trailer Tow.......................... 8Wa-54

Transfer Case Position Sensor........ 8Wa-30, 31

Transmission Control Module........... 8Wa-31

Transmission Control Relay............. 8Wa-31

Transmission Solenoid/TRS Assembly..... 8Wa-31

Visor/Vanity Lamps................... 8Wa-44

Washer Fluid Level Switch............. 8Wa-53

Washer Pump........................ 8Wa-53

Water In Fuel Sensor.................. 8Wa-30

Wheel Speed Sensors.................. 8Wa-35

Wiper High/Low Relay................. 8Wa-53

KJ8W-02 COMPONENT INDEX8Wa-02-1

Page 830 of 1803

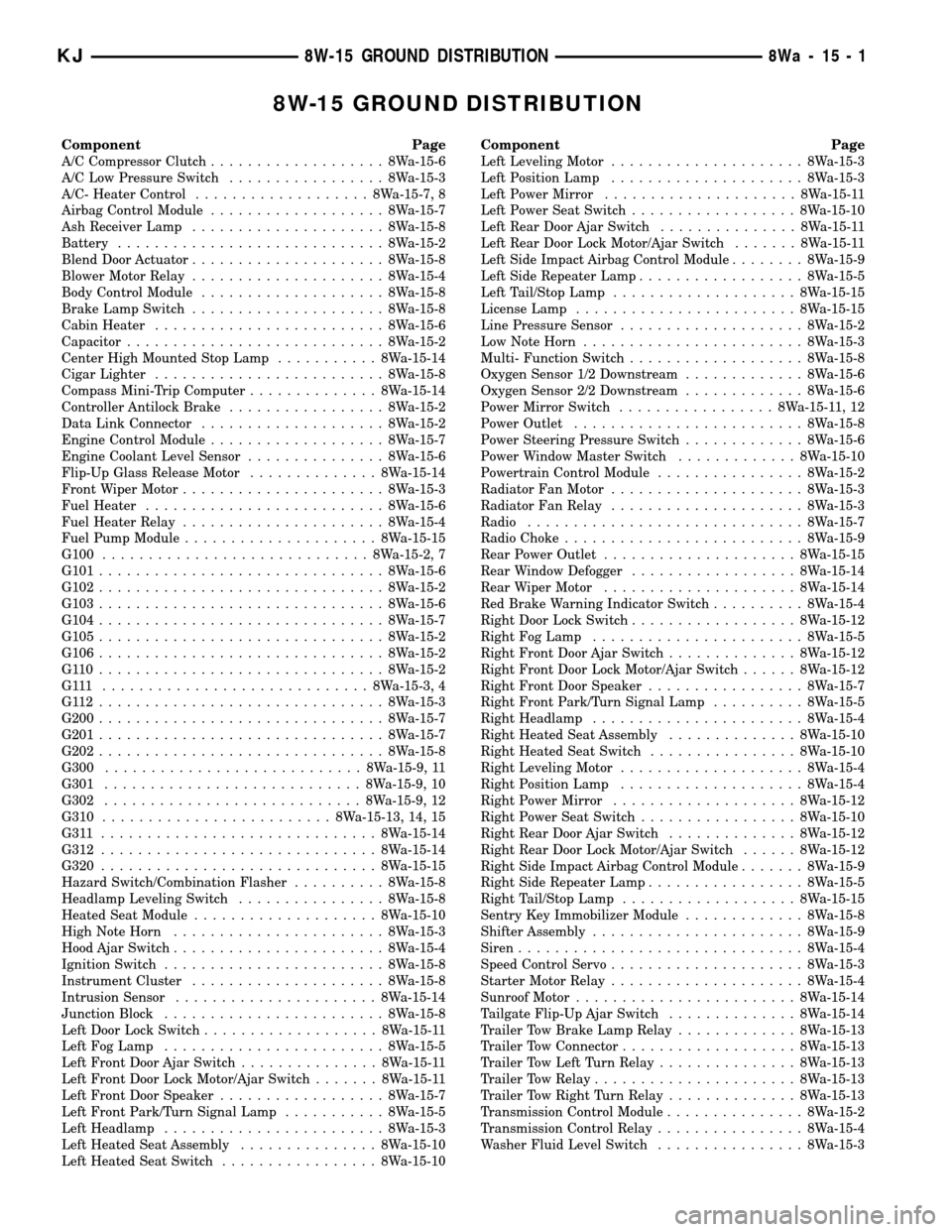

8W-15 GROUND DISTRIBUTION

Component Page

A/C Compressor Clutch...................8Wa-15-6

A/C Low Pressure Switch.................8Wa-15-3

A/C- Heater Control...................8Wa-15-7, 8

Airbag Control Module...................8Wa-15-7

Ash Receiver Lamp.....................8Wa-15-8

Battery.............................8Wa-15-2

Blend Door Actuator.....................8Wa-15-8

Blower Motor Relay.....................8Wa-15-4

Body Control Module....................8Wa-15-8

Brake Lamp Switch.....................8Wa-15-8

Cabin Heater.........................8Wa-15-6

Capacitor............................8Wa-15-2

Center High Mounted Stop Lamp...........8Wa-15-14

Cigar Lighter.........................8Wa-15-8

Compass Mini-Trip Computer..............8Wa-15-14

Controller Antilock Brake.................8Wa-15-2

Data Link Connector....................8Wa-15-2

Engine Control Module...................8Wa-15-7

Engine Coolant Level Sensor...............8Wa-15-6

Flip-Up Glass Release Motor..............8Wa-15-14

Front Wiper Motor......................8Wa-15-3

Fuel Heater..........................8Wa-15-6

Fuel Heater Relay......................8Wa-15-4

Fuel Pump Module.....................8Wa-15-15

G100.............................8Wa-15-2, 7

G101...............................8Wa-15-6

G102...............................8Wa-15-2

G103...............................8Wa-15-6

G104...............................8Wa-15-7

G105...............................8Wa-15-2

G106...............................8Wa-15-2

G110...............................8Wa-15-2

G111 .............................8Wa-15-3, 4

G112...............................8Wa-15-3

G200...............................8Wa-15-7

G201...............................8Wa-15-7

G202...............................8Wa-15-8

G300............................8Wa-15-9, 11

G301............................8Wa-15-9, 10

G302............................8Wa-15-9, 12

G310.........................8Wa-15-13, 14, 15

G311 ..............................8Wa-15-14

G312..............................8Wa-15-14

G320..............................8Wa-15-15

Hazard Switch/Combination Flasher..........8Wa-15-8

Headlamp Leveling Switch................8Wa-15-8

Heated Seat Module....................8Wa-15-10

High Note Horn.......................8Wa-15-3

Hood Ajar Switch.......................8Wa-15-4

Ignition Switch........................8Wa-15-8

Instrument Cluster.....................8Wa-15-8

Intrusion Sensor......................8Wa-15-14

Junction Block........................8Wa-15-8

Left Door Lock Switch...................8Wa-15-11

Left Fog Lamp........................8Wa-15-5

Left Front Door Ajar Switch...............8Wa-15-11

Left Front Door Lock Motor/Ajar Switch.......8Wa-15-11

Left Front Door Speaker..................8Wa-15-7

Left Front Park/Turn Signal Lamp...........8Wa-15-5

Left Headlamp........................8Wa-15-3

Left Heated Seat Assembly...............8Wa-15-10

Left Heated Seat Switch.................8Wa-15-10Component Page

Left Leveling Motor.....................8Wa-15-3

Left Position Lamp.....................8Wa-15-3

Left Power Mirror.....................8Wa-15-11

Left Power Seat Switch..................8Wa-15-10

Left Rear Door Ajar Switch...............8Wa-15-11

Left Rear Door Lock Motor/Ajar Switch.......8Wa-15-11

Left Side Impact Airbag Control Module........8Wa-15-9

Left Side Repeater Lamp..................8Wa-15-5

Left Tail/Stop Lamp....................8Wa-15-15

License Lamp........................8Wa-15-15

Line Pressure Sensor....................8Wa-15-2

Low Note Horn........................8Wa-15-3

Multi- Function Switch...................8Wa-15-8

Oxygen Sensor 1/2 Downstream.............8Wa-15-6

Oxygen Sensor 2/2 Downstream.............8Wa-15-6

Power Mirror Switch.................8Wa-15-11, 12

Power Outlet.........................8Wa-15-8

Power Steering Pressure Switch.............8Wa-15-6

Power Window Master Switch.............8Wa-15-10

Powertrain Control Module................8Wa-15-2

Radiator Fan Motor.....................8Wa-15-3

Radiator Fan Relay.....................8Wa-15-3

Radio..............................8Wa-15-7

Radio Choke..........................8Wa-15-9

Rear Power Outlet.....................8Wa-15-15

Rear Window Defogger..................8Wa-15-14

Rear Wiper Motor.....................8Wa-15-14

Red Brake Warning Indicator Switch..........8Wa-15-4

Right Door Lock Switch..................8Wa-15-12

Right Fog Lamp.......................8Wa-15-5

Right Front Door Ajar Switch..............8Wa-15-12

Right Front Door Lock Motor/Ajar Switch......8Wa-15-12

Right Front Door Speaker.................8Wa-15-7

Right Front Park/Turn Signal Lamp..........8Wa-15-5

Right Headlamp.......................8Wa-15-4

Right Heated Seat Assembly..............8Wa-15-10

Right Heated Seat Switch................8Wa-15-10

Right Leveling Motor....................8Wa-15-4

Right Position Lamp....................8Wa-15-4

Right Power Mirror....................8Wa-15-12

Right Power Seat Switch.................8Wa-15-10

Right Rear Door Ajar Switch..............8Wa-15-12

Right Rear Door Lock Motor/Ajar Switch......8Wa-15-12

Right Side Impact Airbag Control Module.......8Wa-15-9

Right Side Repeater Lamp.................8Wa-15-5

Right Tail/Stop Lamp...................8Wa-15-15

Sentry Key Immobilizer Module.............8Wa-15-8

Shifter Assembly.......................8Wa-15-9

Siren...............................8Wa-15-4

Speed Control Servo.....................8Wa-15-3

Starter Motor Relay.....................8Wa-15-4

Sunroof Motor........................8Wa-15-14

Tailgate Flip-Up Ajar Switch..............8Wa-15-14

Trailer Tow Brake Lamp Relay.............8Wa-15-13

Trailer Tow Connector...................8Wa-15-13

Trailer Tow Left Turn Relay...............8Wa-15-13

Trailer Tow Relay......................8Wa-15-13

Trailer Tow Right Turn Relay..............8Wa-15-13

Transmission Control Module...............8Wa-15-2

Transmission Control Relay................8Wa-15-4

Washer Fluid Level Switch................8Wa-15-3

KJ8W-15 GROUND DISTRIBUTION8Wa-15-1

Page 898 of 1803

8W-31 TRANSMISSION CONTROL SYSTEM

Component Page

A/C Compressor Clutch Relay.......... 8Wa-31-3

Auto Shut Down Relay............... 8Wa-31-3

Back-Up Lamp Switch............... 8Wa-31-4

Brake Lamp Switch................. 8Wa-31-5

Crankshaft Position Sensor............ 8Wa-31-6

Data Link Connector................. 8Wa-31-6

Diagnostic Junction Port.............. 8Wa-31-3

Engine Control Module............... 8Wa-31-6

Fuel Pump Relay................... 8Wa-31-3

Fuse 5............................ 8Wa-31-2

Fuse 15........................... 8Wa-31-3

Fuse 28........................... 8Wa-31-3

Fuse 38........................... 8Wa-31-5

Fuse 39........................... 8Wa-31-4

G102........................... 8Wa-31-7, 9

G111 ............................. 8Wa-31-2

G301............................. 8Wa-31-5

Input Speed Sensor.................. 8Wa-31-9Component Page

Instrument Cluster.................. 8Wa-31-5

Junction Block.................. 8Wa-31-3, 4, 5

Left Tail/Stop Lamp................. 8Wa-31-4

Line Pressure Sensor................ 8Wa-31-9

Output Speed Sensor................ 8Wa-31-9

Power Distribution Center.......... 8Wa-31-2, 3

Powertrain Control Module........ 8Wa-31-3, 5, 6

Right Tail/Stop Lamp................ 8Wa-31-4

Shifter Assembly.................... 8Wa-31-5

Starter Motor Relay................. 8Wa-31-8

Throttle Position Sensor.............. 8Wa-31-5

Trailer Tow Connector................ 8Wa-31-4

Transfer Case Position Sensor.......... 8Wa-31-5

Transmission Control Module . . 8Wa-31-2, 3, 5, 6, 7,

8, 9

Transmission Control Relay....... 8Wa-31-2, 7, 8

Transmission Solenoid/Trs Assembly . . 8Wa-31-2, 4,

7, 8, 9

KJ8W-31 TRANSMISSION CONTROL SYSTEM8Wa-31-1

Page 1148 of 1803

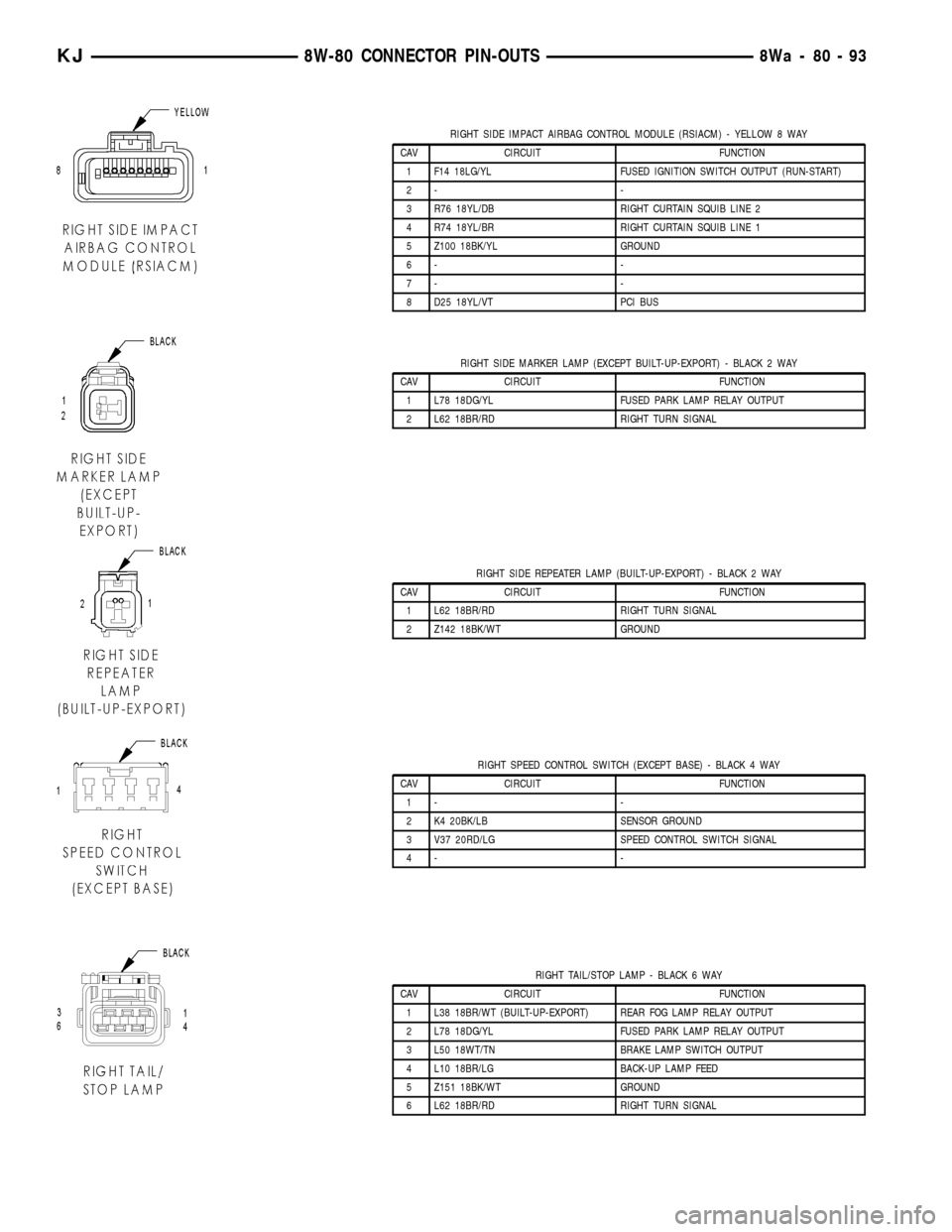

RIGHT SIDE IMPACT AIRBAG CONTROL MODULE (RSIACM) - YELLOW 8 WAY

CAV CIRCUIT FUNCTION

1 F14 18LG/YL FUSED IGNITION SWITCH OUTPUT (RUN-START)

2- -

3 R76 18YL/DB RIGHT CURTAIN SQUIB LINE 2

4 R74 18YL/BR RIGHT CURTAIN SQUIB LINE 1

5 Z100 18BK/YL GROUND

6- -

7- -

8 D25 18YL/VT PCI BUS

RIGHT SIDE MARKER LAMP (EXCEPT BUILT-UP-EXPORT) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 L78 18DG/YL FUSED PARK LAMP RELAY OUTPUT

2 L62 18BR/RD RIGHT TURN SIGNAL

RIGHT SIDE REPEATER LAMP (BUILT-UP-EXPORT) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 L62 18BR/RD RIGHT TURN SIGNAL

2 Z142 18BK/WT GROUND

RIGHT SPEED CONTROL SWITCH (EXCEPT BASE) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1- -

2 K4 20BK/LB SENSOR GROUND

3 V37 20RD/LG SPEED CONTROL SWITCH SIGNAL

4- -

RIGHT TAIL/STOP LAMP - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 L38 18BR/WT (BUILT-UP-EXPORT) REAR FOG LAMP RELAY OUTPUT

2 L78 18DG/YL FUSED PARK LAMP RELAY OUTPUT

3 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

4 L10 18BR/LG BACK-UP LAMP FEED

5 Z151 18BK/WT GROUND

6 L62 18BR/RD RIGHT TURN SIGNAL

KJ8W-80 CONNECTOR PIN-OUTS8Wa-80-93

Page 1275 of 1803

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat inspection.If the oil leak source is not pos-

itively identified at this time, proceed with the air

leak detection test method.

Air Leak Detection Test Method

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(5) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, camshaft bore

cup plugs oil galley pipe plugs, oil filter runoff, and

main bearing cap to cylinder block mating sur-

faces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE

(1) Remove oil pressure sending unit (Fig. 70)and

install gauge assembly C-3292.

(2) Run engine until thermostat opens.

(3) Oil Pressure:

²Curb IdleÐ25 Kpa (4 psi) minimum

²3000 rpmÐ170 - 550 KPa (25 - 80 psi)

(4) If oil pressure is 0 at idle, shut off engine.

Check for a clogged oil pick-up screen or a pressure

relief valve stuck open.

9 - 60 ENGINE - 3.7LKJ

LUBRICATION (Continued)

Page 1277 of 1803

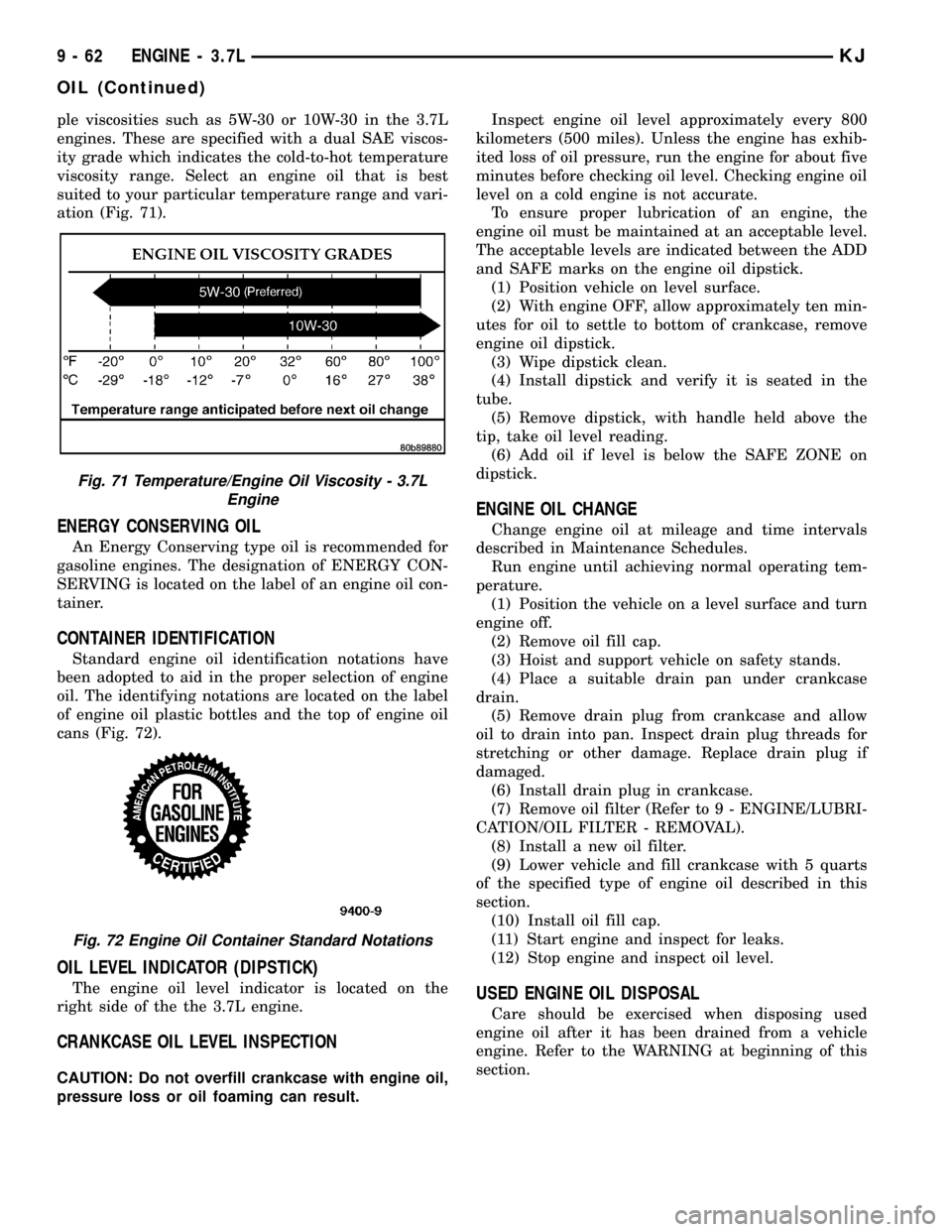

ple viscosities such as 5W-30 or 10W-30 in the 3.7L

engines. These are specified with a dual SAE viscos-

ity grade which indicates the cold-to-hot temperature

viscosity range. Select an engine oil that is best

suited to your particular temperature range and vari-

ation (Fig. 71).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 72).

OIL LEVEL INDICATOR (DIPSTICK)

The engine oil level indicator is located on the

right side of the the 3.7L engine.

CRANKCASE OIL LEVEL INSPECTION

CAUTION: Do not overfill crankcase with engine oil,

pressure loss or oil foaming can result.Inspect engine oil level approximately every 800

kilometers (500 miles). Unless the engine has exhib-

ited loss of oil pressure, run the engine for about five

minutes before checking oil level. Checking engine oil

level on a cold engine is not accurate.

To ensure proper lubrication of an engine, the

engine oil must be maintained at an acceptable level.

The acceptable levels are indicated between the ADD

and SAFE marks on the engine oil dipstick.

(1) Position vehicle on level surface.

(2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil if level is below the SAFE ZONE on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in Maintenance Schedules.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Remove oil fill cap.

(3) Hoist and support vehicle on safety stands.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug if

damaged.

(6) Install drain plug in crankcase.

(7) Remove oil filter (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL).

(8) Install a new oil filter.

(9) Lower vehicle and fill crankcase with 5 quarts

of the specified type of engine oil described in this

section.

(10) Install oil fill cap.

(11) Start engine and inspect for leaks.

(12) Stop engine and inspect oil level.

USED ENGINE OIL DISPOSAL

Care should be exercised when disposing used

engine oil after it has been drained from a vehicle

engine. Refer to the WARNING at beginning of this

section.

Fig. 71 Temperature/Engine Oil Viscosity - 3.7L

Engine

Fig. 72 Engine Oil Container Standard Notations

9 - 62 ENGINE - 3.7LKJ

OIL (Continued)

Page 1301 of 1803

(7) Crank engine until maximum pressure is

reached on gage. Record this pressure as #1 cylinder

pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair as necessary.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24 km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

²Disconnect the fresh air hose (make-up air) at

the cylinder head cover and plug or cap the nipple on

the cover.

²Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve nipple on the

cover.

²Attach an air hose with pressure gauge and reg-

ulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.²Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provides the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

²If the leakage occurs at the crankshaft rear oil

seal area, refer to the section, Inspection for Rear

Seal Area Leak.

(6) If no leaks are detected, turn off the air supply.

Remove the air hose, all plugs, and caps. Install the

PCV valve and fresh air hose (make-up air). Proceed

to next step.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

NOTE: If oil leakage is observed at the dipstick tube

to block location; remove the tube, clean and reseal

using MoparTStud & Bearing Mount (press fit tube

applications only), and for O-ring style tubes,

remove tube and replace the O-ring seal.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

9s - 4 ENGINEKJ

ENGINE - 2.4L (Continued)

Page 1344 of 1803

(6) Install oil pressure switch and connector. (Refer

to 9 - ENGINE/LUBRICATION/OIL PRESSURE

SENSOR/SWITCH - INSTALLATION)

OIL

STANDARD PROCEDURE

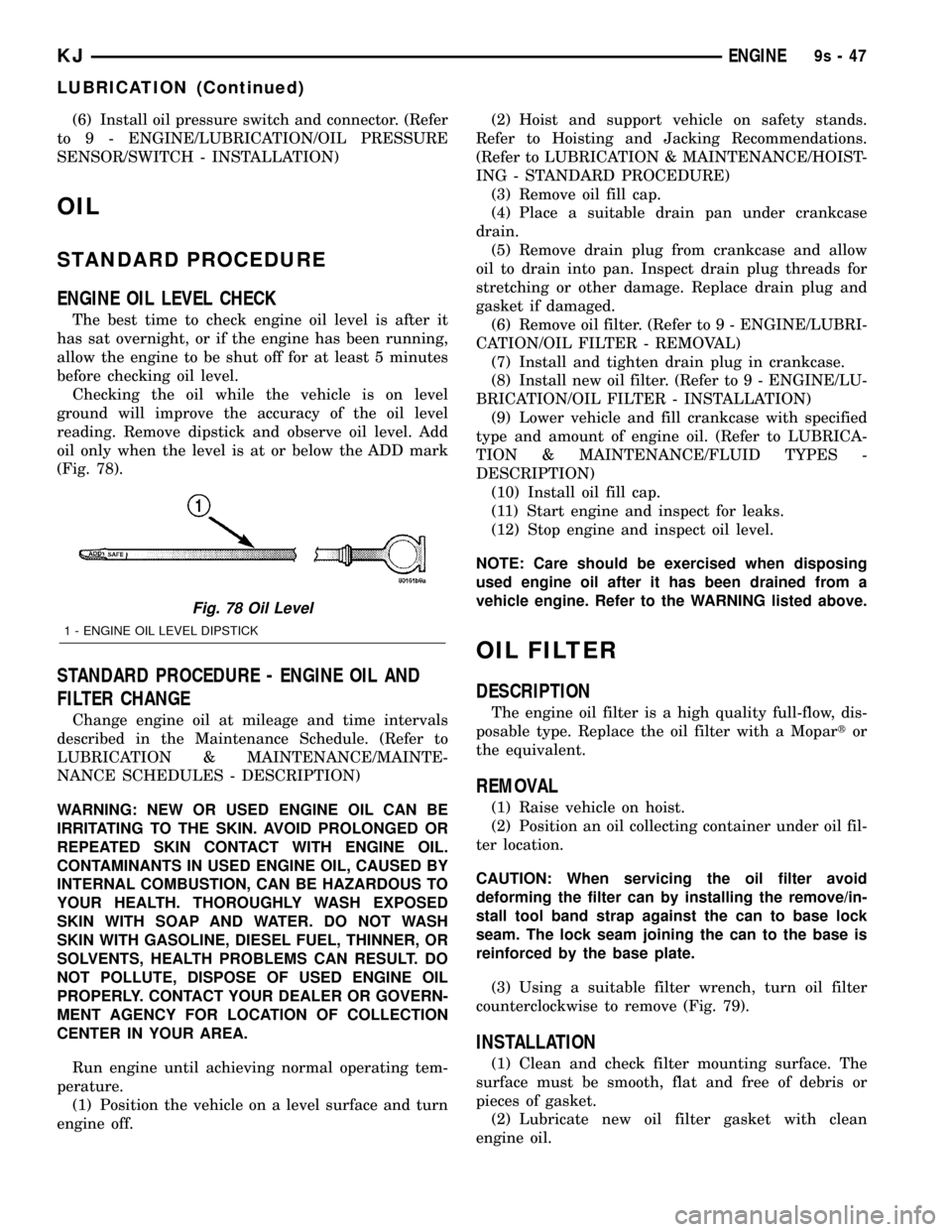

ENGINE OIL LEVEL CHECK

The best time to check engine oil level is after it

has sat overnight, or if the engine has been running,

allow the engine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading. Remove dipstick and observe oil level. Add

oil only when the level is at or below the ADD mark

(Fig. 78).

STANDARD PROCEDURE - ENGINE OIL AND

FILTER CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. (Refer to

LUBRICATION & MAINTENANCE/MAINTE-

NANCE SCHEDULES - DESCRIPTION)

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.(2) Hoist and support vehicle on safety stands.

Refer to Hoisting and Jacking Recommendations.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE)

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Remove oil filter. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL)

(7) Install and tighten drain plug in crankcase.

(8) Install new oil filter. (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION)

(9) Lower vehicle and fill crankcase with specified

type and amount of engine oil. (Refer to LUBRICA-

TION & MAINTENANCE/FLUID TYPES -

DESCRIPTION)

(10) Install oil fill cap.

(11) Start engine and inspect for leaks.

(12) Stop engine and inspect oil level.

NOTE: Care should be exercised when disposing

used engine oil after it has been drained from a

vehicle engine. Refer to the WARNING listed above.

OIL FILTER

DESCRIPTION

The engine oil filter is a high quality full-flow, dis-

posable type. Replace the oil filter with a Mopartor

the equivalent.

REMOVAL

(1) Raise vehicle on hoist.

(2) Position an oil collecting container under oil fil-

ter location.

CAUTION: When servicing the oil filter avoid

deforming the filter can by installing the remove/in-

stall tool band strap against the can to base lock

seam. The lock seam joining the can to the base is

reinforced by the base plate.

(3) Using a suitable filter wrench, turn oil filter

counterclockwise to remove (Fig. 79).

INSTALLATION

(1) Clean and check filter mounting surface. The

surface must be smooth, flat and free of debris or

pieces of gasket.

(2) Lubricate new oil filter gasket with clean

engine oil.

Fig. 78 Oil Level

1 - ENGINE OIL LEVEL DIPSTICK

KJENGINE9s-47

LUBRICATION (Continued)