tow JEEP LIBERTY 2002 KJ / 1.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 109 of 1803

(24) Rotate dial indicator out of the way on pilot

stud.

(25) Remove differential case and dummy bearings

from the housing.

(26) Install new side bearing cones and cups on

differential case.

(27) Install spreader W-129-B and some compo-

nents of Adapter Set 6987 on differential housing and

spread axle opening enough to receive differential

case.

(28) Place side bearing shims into the housing

against the axle tubes.

(29) Install differential case in the housing.

(30) Rotate the differential case several times to

seat the side bearings.

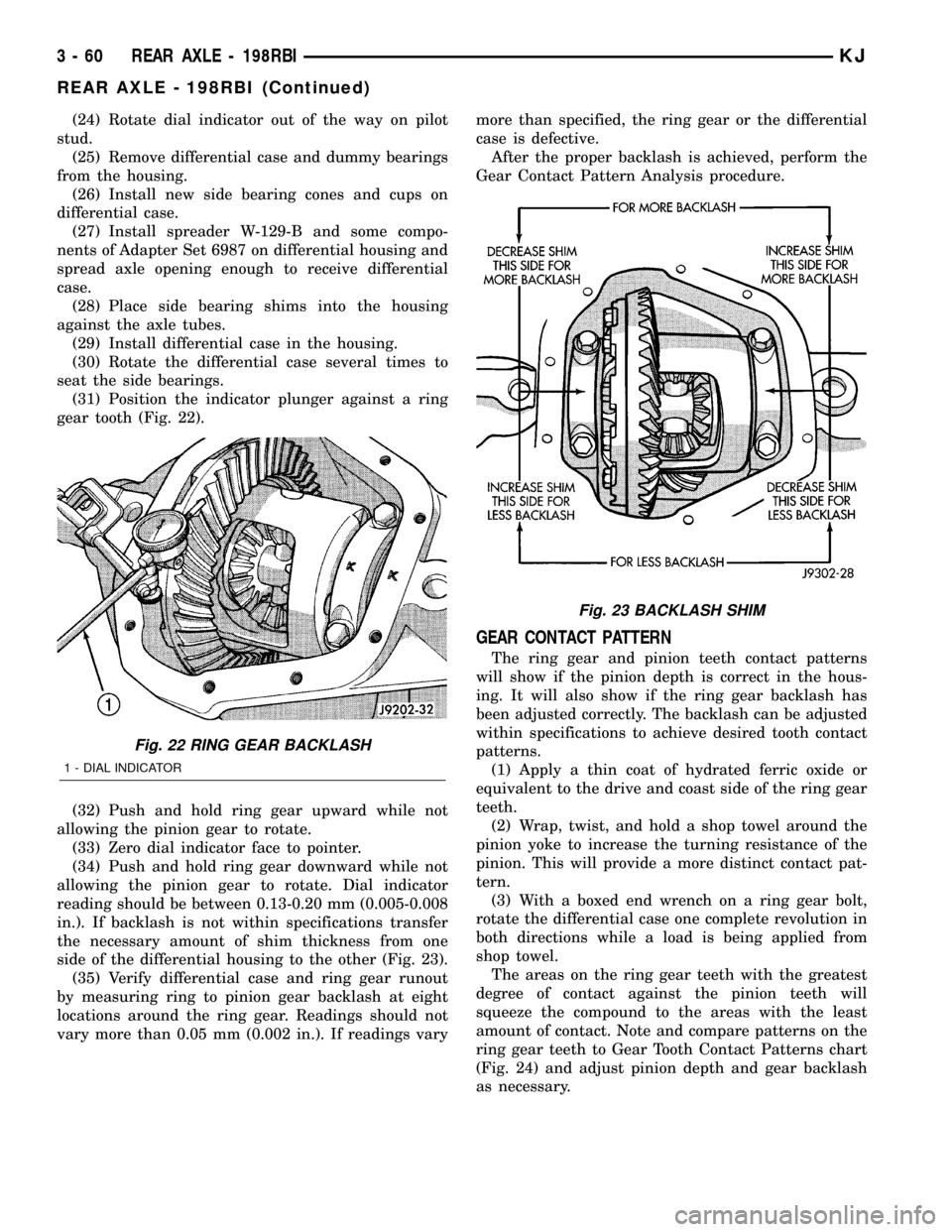

(31) Position the indicator plunger against a ring

gear tooth (Fig. 22).

(32) Push and hold ring gear upward while not

allowing the pinion gear to rotate.

(33) Zero dial indicator face to pointer.

(34) Push and hold ring gear downward while not

allowing the pinion gear to rotate. Dial indicator

reading should be between 0.13-0.20 mm (0.005-0.008

in.). If backlash is not within specifications transfer

the necessary amount of shim thickness from one

side of the differential housing to the other (Fig. 23).

(35) Verify differential case and ring gear runout

by measuring ring to pinion gear backlash at eight

locations around the ring gear. Readings should not

vary more than 0.05 mm (0.002 in.). If readings varymore than specified, the ring gear or the differential

case is defective.

After the proper backlash is achieved, perform the

Gear Contact Pattern Analysis procedure.

GEAR CONTACT PATTERN

The ring gear and pinion teeth contact patterns

will show if the pinion depth is correct in the hous-

ing. It will also show if the ring gear backlash has

been adjusted correctly. The backlash can be adjusted

within specifications to achieve desired tooth contact

patterns.

(1) Apply a thin coat of hydrated ferric oxide or

equivalent to the drive and coast side of the ring gear

teeth.

(2) Wrap, twist, and hold a shop towel around the

pinion yoke to increase the turning resistance of the

pinion. This will provide a more distinct contact pat-

tern.

(3) With a boxed end wrench on a ring gear bolt,

rotate the differential case one complete revolution in

both directions while a load is being applied from

shop towel.

The areas on the ring gear teeth with the greatest

degree of contact against the pinion teeth will

squeeze the compound to the areas with the least

amount of contact. Note and compare patterns on the

ring gear teeth to Gear Tooth Contact Patterns chart

(Fig. 24) and adjust pinion depth and gear backlash

as necessary.

Fig. 22 RING GEAR BACKLASH

1 - DIAL INDICATOR

Fig. 23 BACKLASH SHIM

3 - 60 REAR AXLE - 198RBIKJ

REAR AXLE - 198RBI (Continued)

Page 144 of 1803

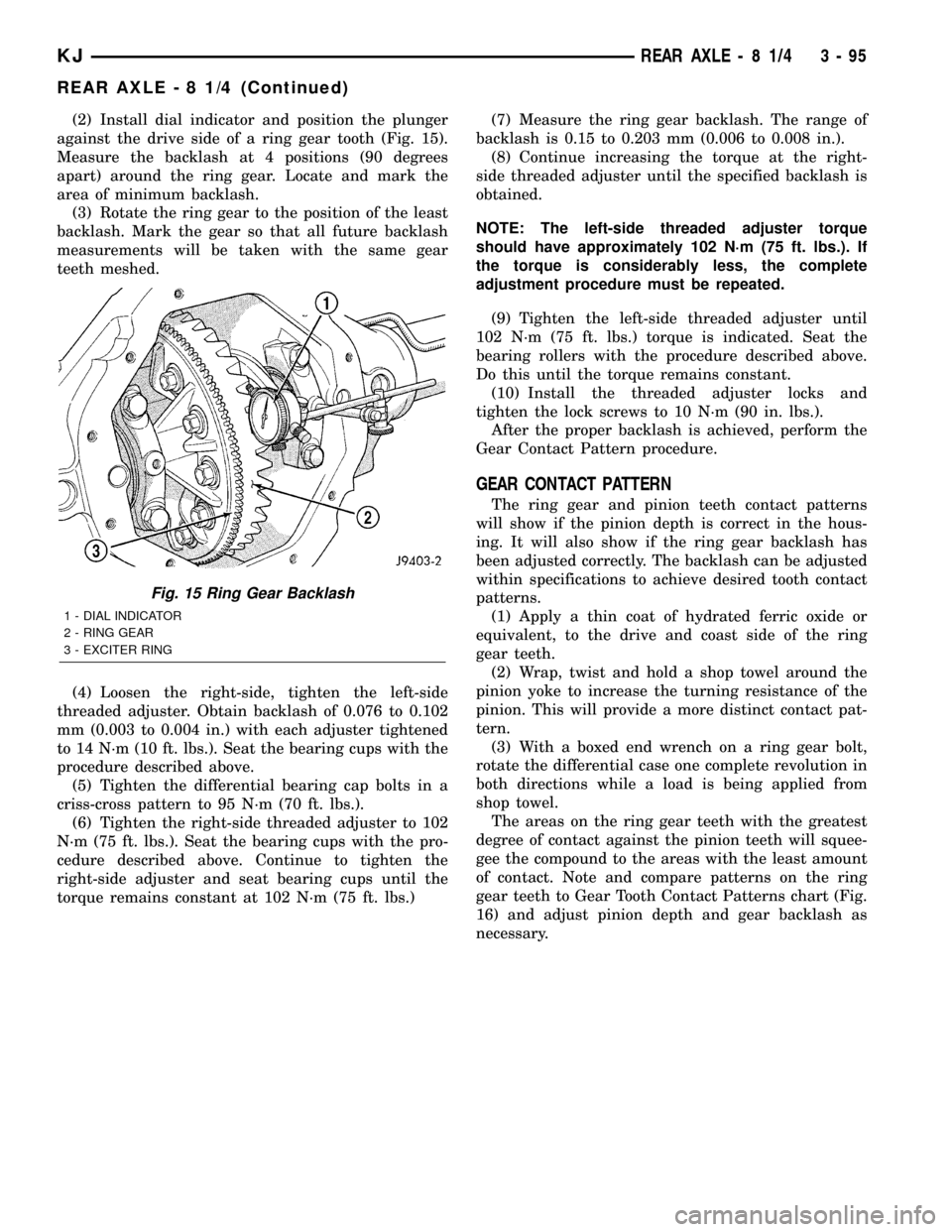

(2) Install dial indicator and position the plunger

against the drive side of a ring gear tooth (Fig. 15).

Measure the backlash at 4 positions (90 degrees

apart) around the ring gear. Locate and mark the

area of minimum backlash.

(3) Rotate the ring gear to the position of the least

backlash. Mark the gear so that all future backlash

measurements will be taken with the same gear

teeth meshed.

(4) Loosen the right-side, tighten the left-side

threaded adjuster. Obtain backlash of 0.076 to 0.102

mm (0.003 to 0.004 in.) with each adjuster tightened

to 14 N´m (10 ft. lbs.). Seat the bearing cups with the

procedure described above.

(5) Tighten the differential bearing cap bolts in a

criss-cross pattern to 95 N´m (70 ft. lbs.).

(6) Tighten the right-side threaded adjuster to 102

N´m (75 ft. lbs.). Seat the bearing cups with the pro-

cedure described above. Continue to tighten the

right-side adjuster and seat bearing cups until the

torque remains constant at 102 N´m (75 ft. lbs.)(7) Measure the ring gear backlash. The range of

backlash is 0.15 to 0.203 mm (0.006 to 0.008 in.).

(8) Continue increasing the torque at the right-

side threaded adjuster until the specified backlash is

obtained.

NOTE: The left-side threaded adjuster torque

should have approximately 102 N´m (75 ft. lbs.). If

the torque is considerably less, the complete

adjustment procedure must be repeated.

(9) Tighten the left-side threaded adjuster until

102 N´m (75 ft. lbs.) torque is indicated. Seat the

bearing rollers with the procedure described above.

Do this until the torque remains constant.

(10) Install the threaded adjuster locks and

tighten the lock screws to 10 N´m (90 in. lbs.).

After the proper backlash is achieved, perform the

Gear Contact Pattern procedure.

GEAR CONTACT PATTERN

The ring gear and pinion teeth contact patterns

will show if the pinion depth is correct in the hous-

ing. It will also show if the ring gear backlash has

been adjusted correctly. The backlash can be adjusted

within specifications to achieve desired tooth contact

patterns.

(1) Apply a thin coat of hydrated ferric oxide or

equivalent, to the drive and coast side of the ring

gear teeth.

(2) Wrap, twist and hold a shop towel around the

pinion yoke to increase the turning resistance of the

pinion. This will provide a more distinct contact pat-

tern.

(3) With a boxed end wrench on a ring gear bolt,

rotate the differential case one complete revolution in

both directions while a load is being applied from

shop towel.

The areas on the ring gear teeth with the greatest

degree of contact against the pinion teeth will squee-

gee the compound to the areas with the least amount

of contact. Note and compare patterns on the ring

gear teeth to Gear Tooth Contact Patterns chart (Fig.

16) and adjust pinion depth and gear backlash as

necessary.

Fig. 15 Ring Gear Backlash

1 - DIAL INDICATOR

2 - RING GEAR

3 - EXCITER RING

KJREAR AXLE - 8 1/4 3 - 95

REAR AXLE - 8 1/4 (Continued)

Page 178 of 1803

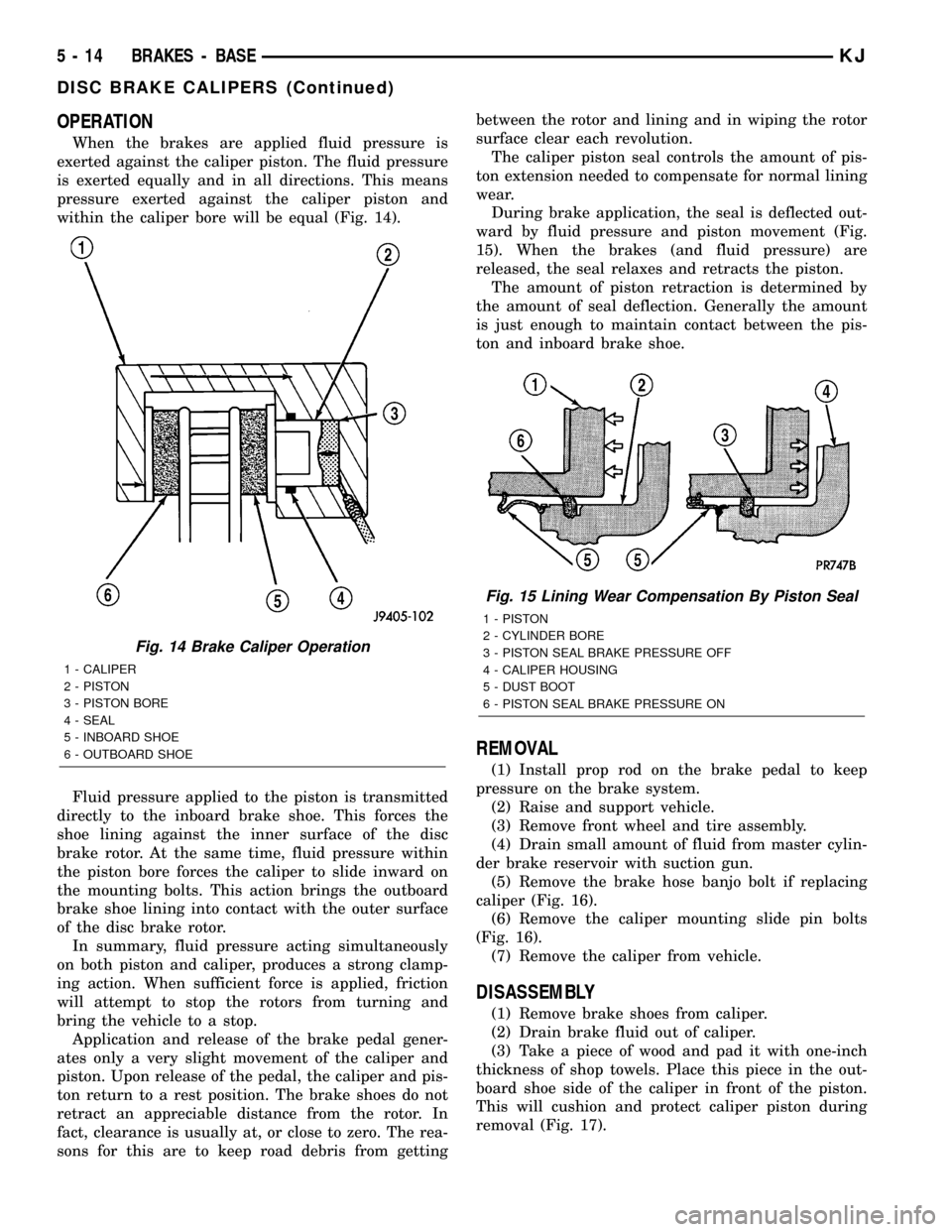

OPERATION

When the brakes are applied fluid pressure is

exerted against the caliper piston. The fluid pressure

is exerted equally and in all directions. This means

pressure exerted against the caliper piston and

within the caliper bore will be equal (Fig. 14).

Fluid pressure applied to the piston is transmitted

directly to the inboard brake shoe. This forces the

shoe lining against the inner surface of the disc

brake rotor. At the same time, fluid pressure within

the piston bore forces the caliper to slide inward on

the mounting bolts. This action brings the outboard

brake shoe lining into contact with the outer surface

of the disc brake rotor.

In summary, fluid pressure acting simultaneously

on both piston and caliper, produces a strong clamp-

ing action. When sufficient force is applied, friction

will attempt to stop the rotors from turning and

bring the vehicle to a stop.

Application and release of the brake pedal gener-

ates only a very slight movement of the caliper and

piston. Upon release of the pedal, the caliper and pis-

ton return to a rest position. The brake shoes do not

retract an appreciable distance from the rotor. In

fact, clearance is usually at, or close to zero. The rea-

sons for this are to keep road debris from gettingbetween the rotor and lining and in wiping the rotor

surface clear each revolution.

The caliper piston seal controls the amount of pis-

ton extension needed to compensate for normal lining

wear.

During brake application, the seal is deflected out-

ward by fluid pressure and piston movement (Fig.

15). When the brakes (and fluid pressure) are

released, the seal relaxes and retracts the piston.

The amount of piston retraction is determined by

the amount of seal deflection. Generally the amount

is just enough to maintain contact between the pis-

ton and inboard brake shoe.

REMOVAL

(1) Install prop rod on the brake pedal to keep

pressure on the brake system.

(2) Raise and support vehicle.

(3) Remove front wheel and tire assembly.

(4) Drain small amount of fluid from master cylin-

der brake reservoir with suction gun.

(5) Remove the brake hose banjo bolt if replacing

caliper (Fig. 16).

(6) Remove the caliper mounting slide pin bolts

(Fig. 16).

(7) Remove the caliper from vehicle.

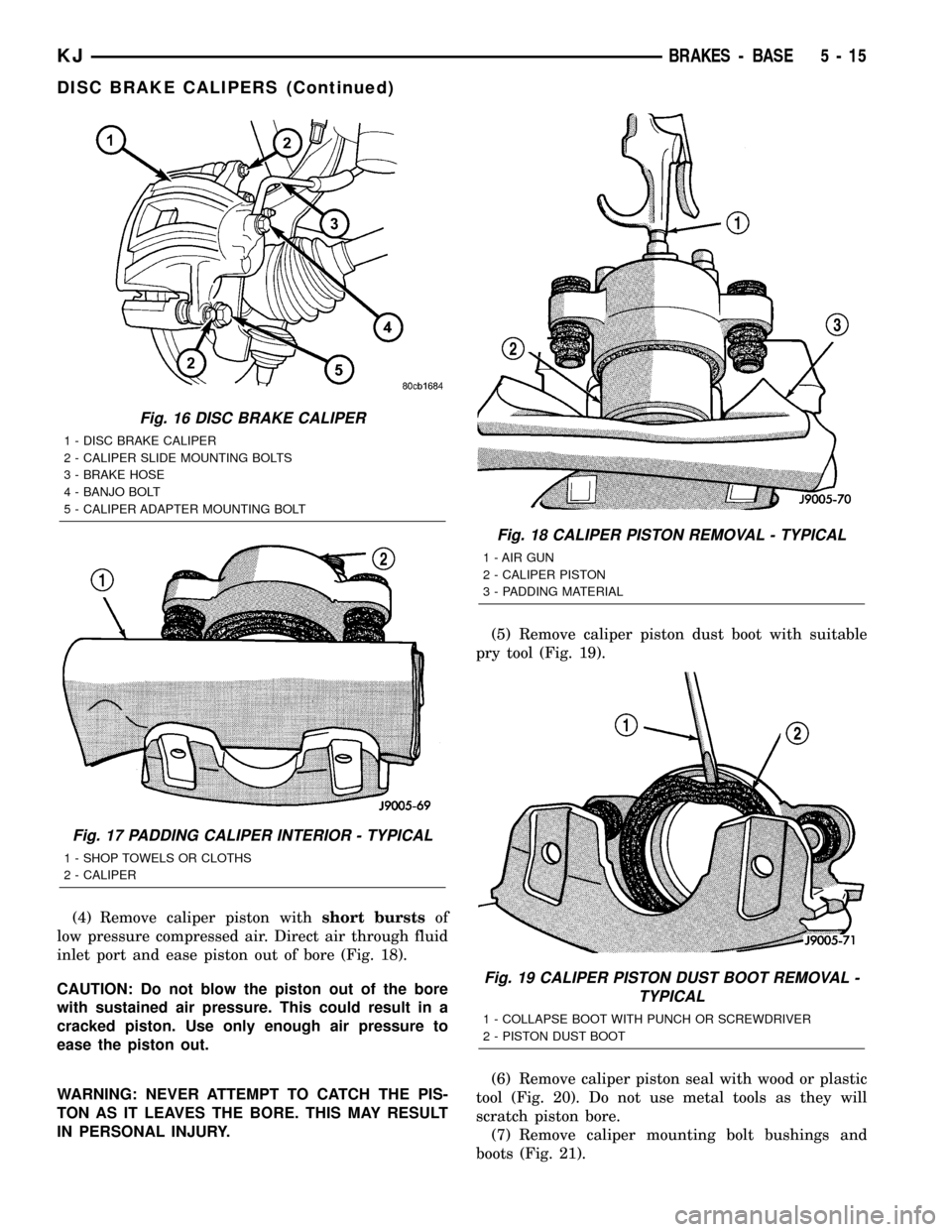

DISASSEMBLY

(1) Remove brake shoes from caliper.

(2) Drain brake fluid out of caliper.

(3) Take a piece of wood and pad it with one-inch

thickness of shop towels. Place this piece in the out-

board shoe side of the caliper in front of the piston.

This will cushion and protect caliper piston during

removal (Fig. 17).

Fig. 14 Brake Caliper Operation

1 - CALIPER

2 - PISTON

3 - PISTON BORE

4 - SEAL

5 - INBOARD SHOE

6 - OUTBOARD SHOE

Fig. 15 Lining Wear Compensation By Piston Seal

1 - PISTON

2 - CYLINDER BORE

3 - PISTON SEAL BRAKE PRESSURE OFF

4 - CALIPER HOUSING

5 - DUST BOOT

6 - PISTON SEAL BRAKE PRESSURE ON

5 - 14 BRAKES - BASEKJ

DISC BRAKE CALIPERS (Continued)

Page 179 of 1803

(4) Remove caliper piston withshort burstsof

low pressure compressed air. Direct air through fluid

inlet port and ease piston out of bore (Fig. 18).

CAUTION: Do not blow the piston out of the bore

with sustained air pressure. This could result in a

cracked piston. Use only enough air pressure to

ease the piston out.

WARNING: NEVER ATTEMPT TO CATCH THE PIS-

TON AS IT LEAVES THE BORE. THIS MAY RESULT

IN PERSONAL INJURY.(5) Remove caliper piston dust boot with suitable

pry tool (Fig. 19).

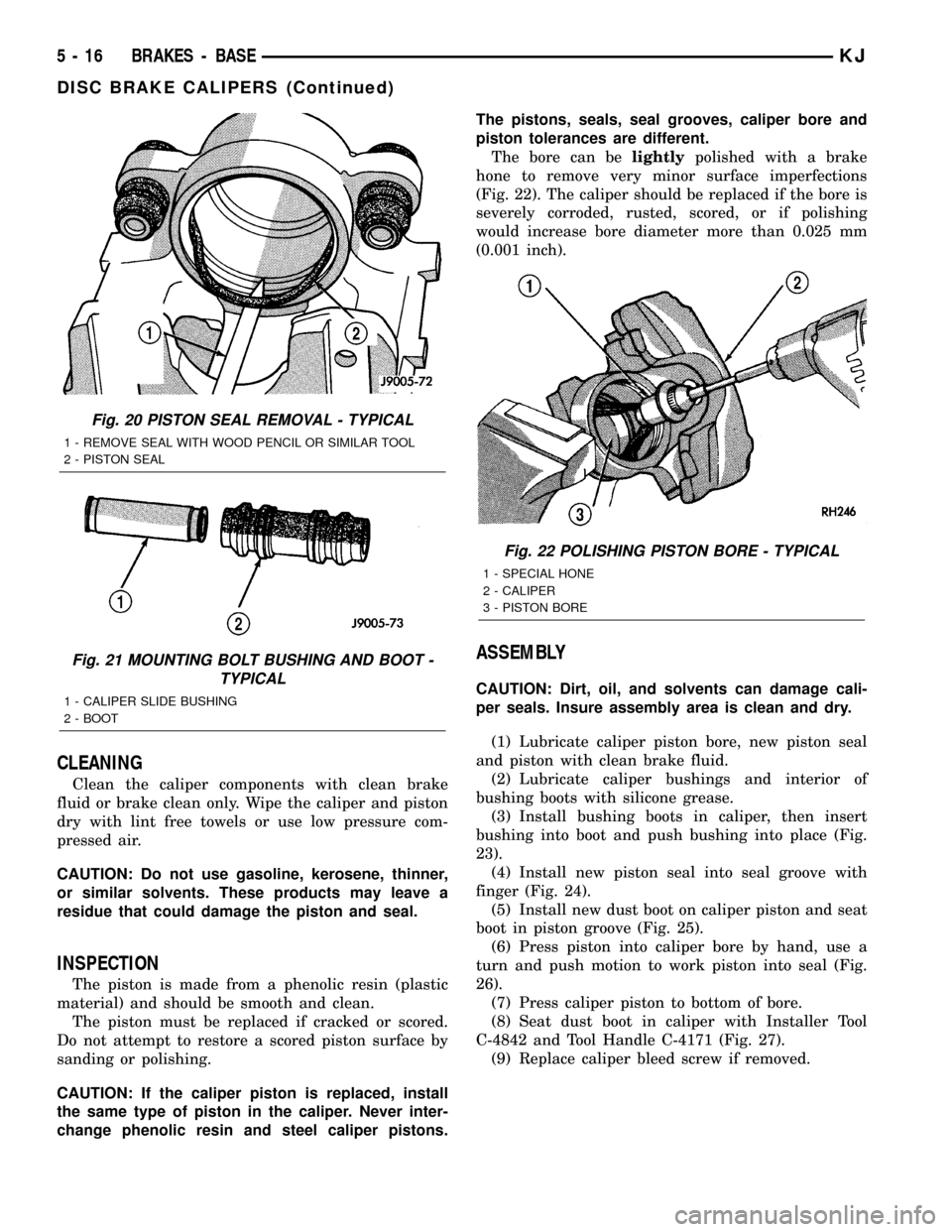

(6) Remove caliper piston seal with wood or plastic

tool (Fig. 20). Do not use metal tools as they will

scratch piston bore.

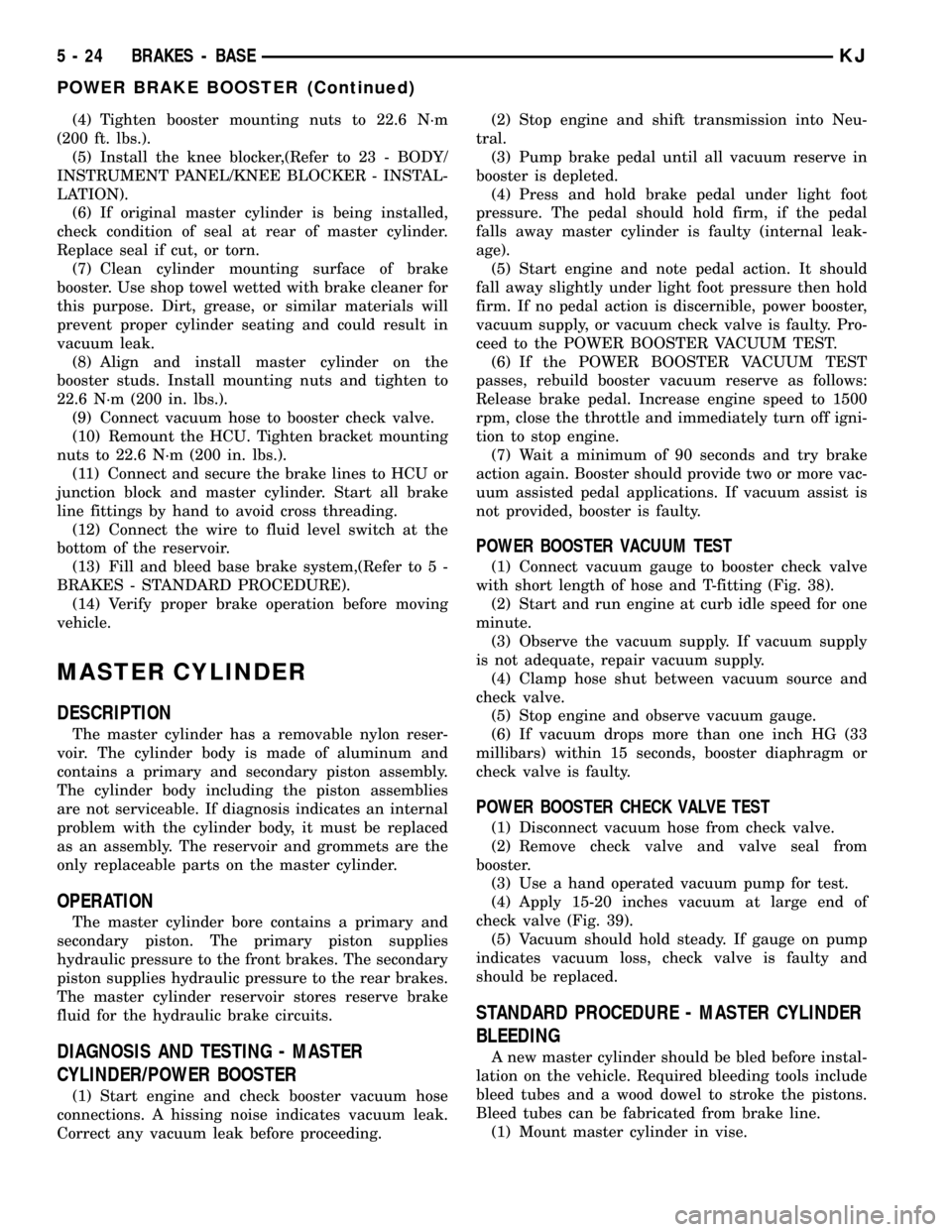

(7) Remove caliper mounting bolt bushings and

boots (Fig. 21).

Fig. 16 DISC BRAKE CALIPER

1 - DISC BRAKE CALIPER

2 - CALIPER SLIDE MOUNTING BOLTS

3 - BRAKE HOSE

4 - BANJO BOLT

5 - CALIPER ADAPTER MOUNTING BOLT

Fig. 17 PADDING CALIPER INTERIOR - TYPICAL

1 - SHOP TOWELS OR CLOTHS

2 - CALIPER

Fig. 18 CALIPER PISTON REMOVAL - TYPICAL

1 - AIR GUN

2 - CALIPER PISTON

3 - PADDING MATERIAL

Fig. 19 CALIPER PISTON DUST BOOT REMOVAL -

TYPICAL

1 - COLLAPSE BOOT WITH PUNCH OR SCREWDRIVER

2 - PISTON DUST BOOT

KJBRAKES - BASE 5 - 15

DISC BRAKE CALIPERS (Continued)

Page 180 of 1803

CLEANING

Clean the caliper components with clean brake

fluid or brake clean only. Wipe the caliper and piston

dry with lint free towels or use low pressure com-

pressed air.

CAUTION: Do not use gasoline, kerosene, thinner,

or similar solvents. These products may leave a

residue that could damage the piston and seal.

INSPECTION

The piston is made from a phenolic resin (plastic

material) and should be smooth and clean.

The piston must be replaced if cracked or scored.

Do not attempt to restore a scored piston surface by

sanding or polishing.

CAUTION: If the caliper piston is replaced, install

the same type of piston in the caliper. Never inter-

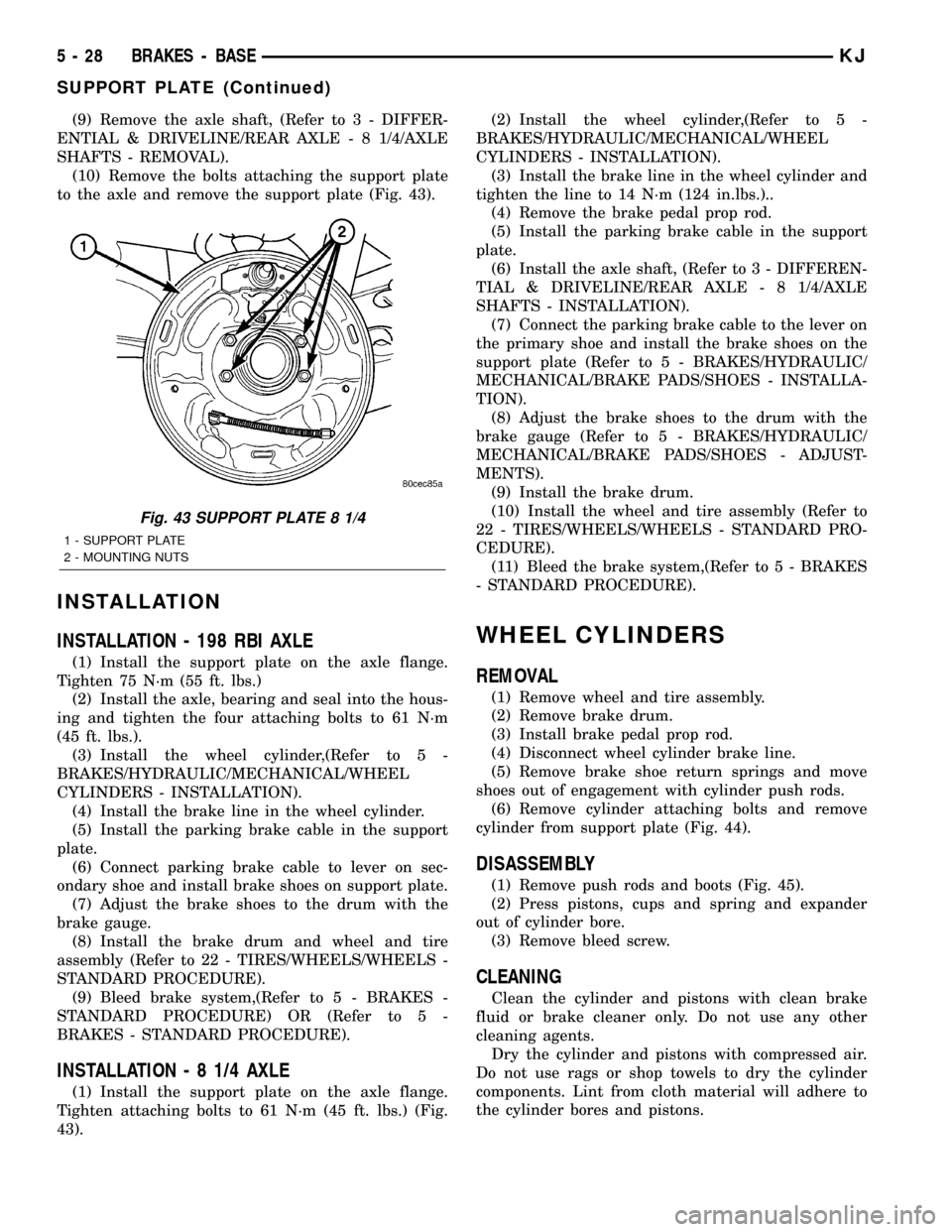

change phenolic resin and steel caliper pistons.The pistons, seals, seal grooves, caliper bore and

piston tolerances are different.

The bore can belightlypolished with a brake

hone to remove very minor surface imperfections

(Fig. 22). The caliper should be replaced if the bore is

severely corroded, rusted, scored, or if polishing

would increase bore diameter more than 0.025 mm

(0.001 inch).

ASSEMBLY

CAUTION: Dirt, oil, and solvents can damage cali-

per seals. Insure assembly area is clean and dry.

(1) Lubricate caliper piston bore, new piston seal

and piston with clean brake fluid.

(2) Lubricate caliper bushings and interior of

bushing boots with silicone grease.

(3) Install bushing boots in caliper, then insert

bushing into boot and push bushing into place (Fig.

23).

(4) Install new piston seal into seal groove with

finger (Fig. 24).

(5) Install new dust boot on caliper piston and seat

boot in piston groove (Fig. 25).

(6) Press piston into caliper bore by hand, use a

turn and push motion to work piston into seal (Fig.

26).

(7) Press caliper piston to bottom of bore.

(8) Seat dust boot in caliper with Installer Tool

C-4842 and Tool Handle C-4171 (Fig. 27).

(9) Replace caliper bleed screw if removed.

Fig. 20 PISTON SEAL REMOVAL - TYPICAL

1 - REMOVE SEAL WITH WOOD PENCIL OR SIMILAR TOOL

2 - PISTON SEAL

Fig. 21 MOUNTING BOLT BUSHING AND BOOT -

TYPICAL

1 - CALIPER SLIDE BUSHING

2 - BOOT

Fig. 22 POLISHING PISTON BORE - TYPICAL

1 - SPECIAL HONE

2 - CALIPER

3 - PISTON BORE

5 - 16 BRAKES - BASEKJ

DISC BRAKE CALIPERS (Continued)

Page 188 of 1803

(4) Tighten booster mounting nuts to 22.6 N´m

(200 ft. lbs.).

(5) Install the knee blocker,(Refer to 23 - BODY/

INSTRUMENT PANEL/KNEE BLOCKER - INSTAL-

LATION).

(6) If original master cylinder is being installed,

check condition of seal at rear of master cylinder.

Replace seal if cut, or torn.

(7) Clean cylinder mounting surface of brake

booster. Use shop towel wetted with brake cleaner for

this purpose. Dirt, grease, or similar materials will

prevent proper cylinder seating and could result in

vacuum leak.

(8) Align and install master cylinder on the

booster studs. Install mounting nuts and tighten to

22.6 N´m (200 in. lbs.).

(9) Connect vacuum hose to booster check valve.

(10) Remount the HCU. Tighten bracket mounting

nuts to 22.6 N´m (200 in. lbs.).

(11) Connect and secure the brake lines to HCU or

junction block and master cylinder. Start all brake

line fittings by hand to avoid cross threading.

(12) Connect the wire to fluid level switch at the

bottom of the reservoir.

(13) Fill and bleed base brake system,(Refer to 5 -

BRAKES - STANDARD PROCEDURE).

(14) Verify proper brake operation before moving

vehicle.

MASTER CYLINDER

DESCRIPTION

The master cylinder has a removable nylon reser-

voir. The cylinder body is made of aluminum and

contains a primary and secondary piston assembly.

The cylinder body including the piston assemblies

are not serviceable. If diagnosis indicates an internal

problem with the cylinder body, it must be replaced

as an assembly. The reservoir and grommets are the

only replaceable parts on the master cylinder.

OPERATION

The master cylinder bore contains a primary and

secondary piston. The primary piston supplies

hydraulic pressure to the front brakes. The secondary

piston supplies hydraulic pressure to the rear brakes.

The master cylinder reservoir stores reserve brake

fluid for the hydraulic brake circuits.

DIAGNOSIS AND TESTING - MASTER

CYLINDER/POWER BOOSTER

(1) Start engine and check booster vacuum hose

connections. A hissing noise indicates vacuum leak.

Correct any vacuum leak before proceeding.(2) Stop engine and shift transmission into Neu-

tral.

(3) Pump brake pedal until all vacuum reserve in

booster is depleted.

(4) Press and hold brake pedal under light foot

pressure. The pedal should hold firm, if the pedal

falls away master cylinder is faulty (internal leak-

age).

(5) Start engine and note pedal action. It should

fall away slightly under light foot pressure then hold

firm. If no pedal action is discernible, power booster,

vacuum supply, or vacuum check valve is faulty. Pro-

ceed to the POWER BOOSTER VACUUM TEST.

(6) If the POWER BOOSTER VACUUM TEST

passes, rebuild booster vacuum reserve as follows:

Release brake pedal. Increase engine speed to 1500

rpm, close the throttle and immediately turn off igni-

tion to stop engine.

(7) Wait a minimum of 90 seconds and try brake

action again. Booster should provide two or more vac-

uum assisted pedal applications. If vacuum assist is

not provided, booster is faulty.

POWER BOOSTER VACUUM TEST

(1) Connect vacuum gauge to booster check valve

with short length of hose and T-fitting (Fig. 38).

(2) Start and run engine at curb idle speed for one

minute.

(3) Observe the vacuum supply. If vacuum supply

is not adequate, repair vacuum supply.

(4) Clamp hose shut between vacuum source and

check valve.

(5) Stop engine and observe vacuum gauge.

(6) If vacuum drops more than one inch HG (33

millibars) within 15 seconds, booster diaphragm or

check valve is faulty.

POWER BOOSTER CHECK VALVE TEST

(1) Disconnect vacuum hose from check valve.

(2) Remove check valve and valve seal from

booster.

(3) Use a hand operated vacuum pump for test.

(4) Apply 15-20 inches vacuum at large end of

check valve (Fig. 39).

(5) Vacuum should hold steady. If gauge on pump

indicates vacuum loss, check valve is faulty and

should be replaced.

STANDARD PROCEDURE - MASTER CYLINDER

BLEEDING

A new master cylinder should be bled before instal-

lation on the vehicle. Required bleeding tools include

bleed tubes and a wood dowel to stroke the pistons.

Bleed tubes can be fabricated from brake line.

(1) Mount master cylinder in vise.

5 - 24 BRAKES - BASEKJ

POWER BRAKE BOOSTER (Continued)

Page 192 of 1803

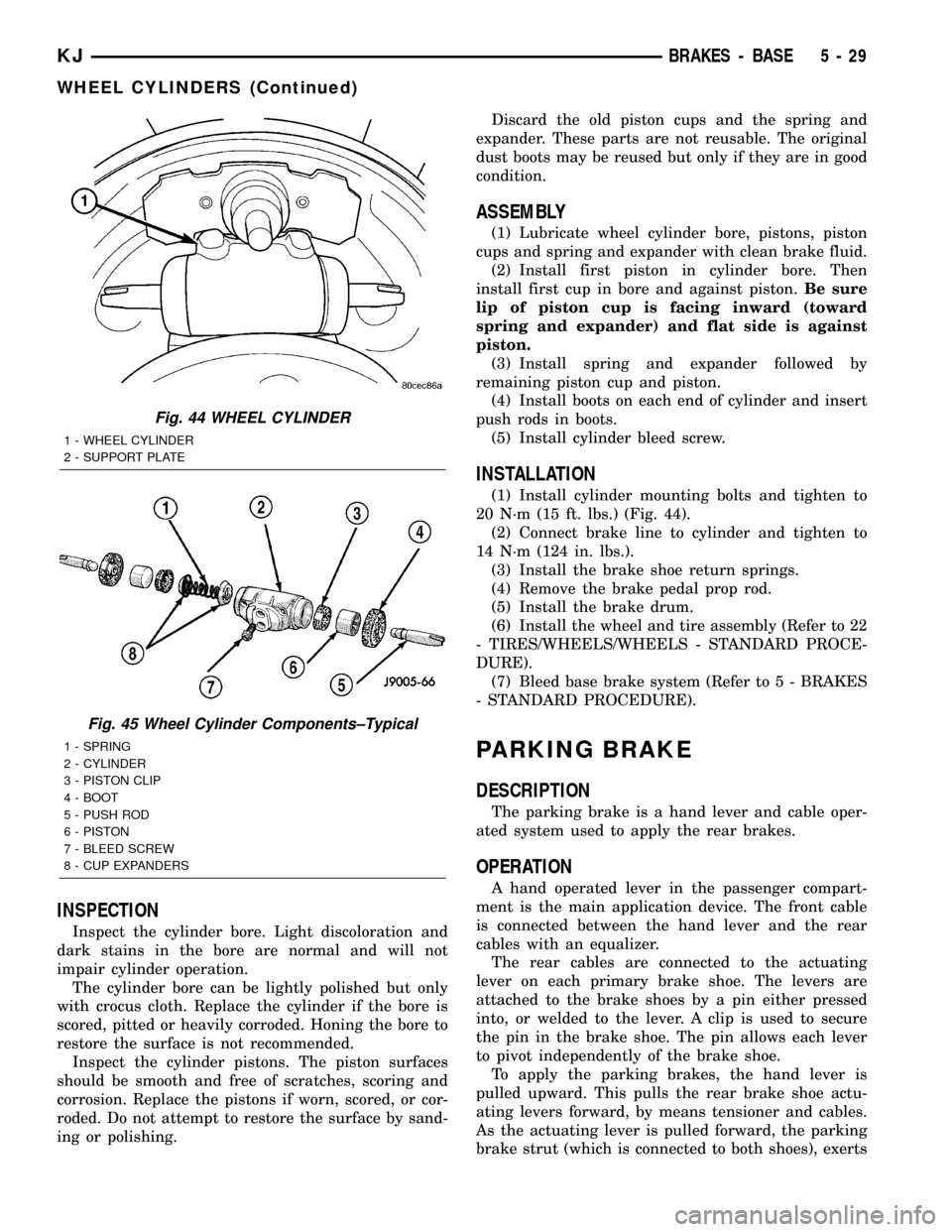

(9) Remove the axle shaft, (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/REAR AXLE - 8 1/4/AXLE

SHAFTS - REMOVAL).

(10) Remove the bolts attaching the support plate

to the axle and remove the support plate (Fig. 43).

INSTALLATION

INSTALLATION - 198 RBI AXLE

(1) Install the support plate on the axle flange.

Tighten 75 N´m (55 ft. lbs.)

(2) Install the axle, bearing and seal into the hous-

ing and tighten the four attaching bolts to 61 N´m

(45 ft. lbs.).

(3) Install the wheel cylinder,(Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/WHEEL

CYLINDERS - INSTALLATION).

(4) Install the brake line in the wheel cylinder.

(5) Install the parking brake cable in the support

plate.

(6) Connect parking brake cable to lever on sec-

ondary shoe and install brake shoes on support plate.

(7) Adjust the brake shoes to the drum with the

brake gauge.

(8) Install the brake drum and wheel and tire

assembly (Refer to 22 - TIRES/WHEELS/WHEELS -

STANDARD PROCEDURE).

(9) Bleed brake system,(Refer to 5 - BRAKES -

STANDARD PROCEDURE) OR (Refer to 5 -

BRAKES - STANDARD PROCEDURE).

INSTALLATION - 8 1/4 AXLE

(1) Install the support plate on the axle flange.

Tighten attaching bolts to 61 N´m (45 ft. lbs.) (Fig.

43).(2) Install the wheel cylinder,(Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/WHEEL

CYLINDERS - INSTALLATION).

(3) Install the brake line in the wheel cylinder and

tighten the line to 14 N´m (124 in.lbs.)..

(4) Remove the brake pedal prop rod.

(5) Install the parking brake cable in the support

plate.

(6) Install the axle shaft, (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/REAR AXLE - 8 1/4/AXLE

SHAFTS - INSTALLATION).

(7) Connect the parking brake cable to the lever on

the primary shoe and install the brake shoes on the

support plate (Refer to 5 - BRAKES/HYDRAULIC/

MECHANICAL/BRAKE PADS/SHOES - INSTALLA-

TION).

(8) Adjust the brake shoes to the drum with the

brake gauge (Refer to 5 - BRAKES/HYDRAULIC/

MECHANICAL/BRAKE PADS/SHOES - ADJUST-

MENTS).

(9) Install the brake drum.

(10) Install the wheel and tire assembly (Refer to

22 - TIRES/WHEELS/WHEELS - STANDARD PRO-

CEDURE).

(11) Bleed the brake system,(Refer to 5 - BRAKES

- STANDARD PROCEDURE).

WHEEL CYLINDERS

REMOVAL

(1) Remove wheel and tire assembly.

(2) Remove brake drum.

(3) Install brake pedal prop rod.

(4) Disconnect wheel cylinder brake line.

(5) Remove brake shoe return springs and move

shoes out of engagement with cylinder push rods.

(6) Remove cylinder attaching bolts and remove

cylinder from support plate (Fig. 44).

DISASSEMBLY

(1) Remove push rods and boots (Fig. 45).

(2) Press pistons, cups and spring and expander

out of cylinder bore.

(3) Remove bleed screw.

CLEANING

Clean the cylinder and pistons with clean brake

fluid or brake cleaner only. Do not use any other

cleaning agents.

Dry the cylinder and pistons with compressed air.

Do not use rags or shop towels to dry the cylinder

components. Lint from cloth material will adhere to

the cylinder bores and pistons.

Fig. 43 SUPPORT PLATE 8 1/4

1 - SUPPORT PLATE

2 - MOUNTING NUTS

5 - 28 BRAKES - BASEKJ

SUPPORT PLATE (Continued)

Page 193 of 1803

INSPECTION

Inspect the cylinder bore. Light discoloration and

dark stains in the bore are normal and will not

impair cylinder operation.

The cylinder bore can be lightly polished but only

with crocus cloth. Replace the cylinder if the bore is

scored, pitted or heavily corroded. Honing the bore to

restore the surface is not recommended.

Inspect the cylinder pistons. The piston surfaces

should be smooth and free of scratches, scoring and

corrosion. Replace the pistons if worn, scored, or cor-

roded. Do not attempt to restore the surface by sand-

ing or polishing.Discard the old piston cups and the spring and

expander. These parts are not reusable. The original

dust boots may be reused but only if they are in good

condition.

ASSEMBLY

(1) Lubricate wheel cylinder bore, pistons, piston

cups and spring and expander with clean brake fluid.

(2) Install first piston in cylinder bore. Then

install first cup in bore and against piston.Be sure

lip of piston cup is facing inward (toward

spring and expander) and flat side is against

piston.

(3) Install spring and expander followed by

remaining piston cup and piston.

(4) Install boots on each end of cylinder and insert

push rods in boots.

(5) Install cylinder bleed screw.

INSTALLATION

(1) Install cylinder mounting bolts and tighten to

20 N´m (15 ft. lbs.) (Fig. 44).

(2) Connect brake line to cylinder and tighten to

14 N´m (124 in. lbs.).

(3) Install the brake shoe return springs.

(4) Remove the brake pedal prop rod.

(5) Install the brake drum.

(6) Install the wheel and tire assembly (Refer to 22

- TIRES/WHEELS/WHEELS - STANDARD PROCE-

DURE).

(7) Bleed base brake system (Refer to 5 - BRAKES

- STANDARD PROCEDURE).

PARKING BRAKE

DESCRIPTION

The parking brake is a hand lever and cable oper-

ated system used to apply the rear brakes.

OPERATION

A hand operated lever in the passenger compart-

ment is the main application device. The front cable

is connected between the hand lever and the rear

cables with an equalizer.

The rear cables are connected to the actuating

lever on each primary brake shoe. The levers are

attached to the brake shoes by a pin either pressed

into, or welded to the lever. A clip is used to secure

the pin in the brake shoe. The pin allows each lever

to pivot independently of the brake shoe.

To apply the parking brakes, the hand lever is

pulled upward. This pulls the rear brake shoe actu-

ating levers forward, by means tensioner and cables.

As the actuating lever is pulled forward, the parking

brake strut (which is connected to both shoes), exerts

Fig. 44 WHEEL CYLINDER

1 - WHEEL CYLINDER

2 - SUPPORT PLATE

Fig. 45 Wheel Cylinder Components±Typical

1 - SPRING

2 - CYLINDER

3 - PISTON CLIP

4 - BOOT

5 - PUSH ROD

6 - PISTON

7 - BLEED SCREW

8 - CUP EXPANDERS

KJBRAKES - BASE 5 - 29

WHEEL CYLINDERS (Continued)

Page 201 of 1803

BRAKES

TABLE OF CONTENTS

page page

POWER BRAKE BOOSTER

REMOVAL - RHD........................1INSTALLATION - RHD.....................1

POWER BRAKE BOOSTER

REMOVAL - RHD

(1) Remove the air box (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER ELEMENT -

REMOVAL).

(2) Relocate the cruise control servo to gain access

to the booster for removal.

(3) Remove the brake lines from the master cylin-

der.

(4) Remove the master cylinder (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/MASTER

CYLINDER - REMOVAL).

(5) Disconnect vacuum hose from booster check

valve.

(6) Remove knee blocker under the steering colum-

n,(Refer to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(7) Remove the brake light switch.(Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL)

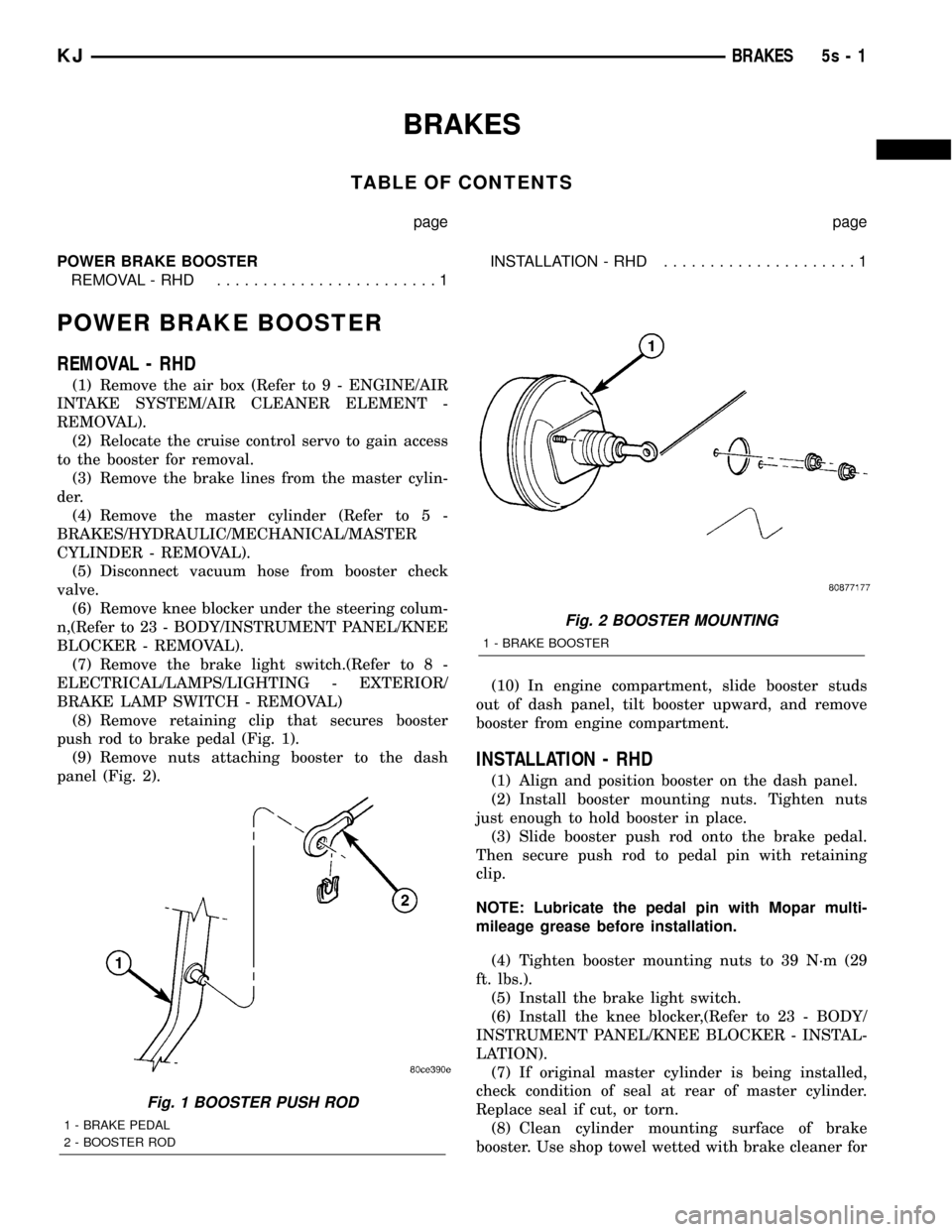

(8) Remove retaining clip that secures booster

push rod to brake pedal (Fig. 1).

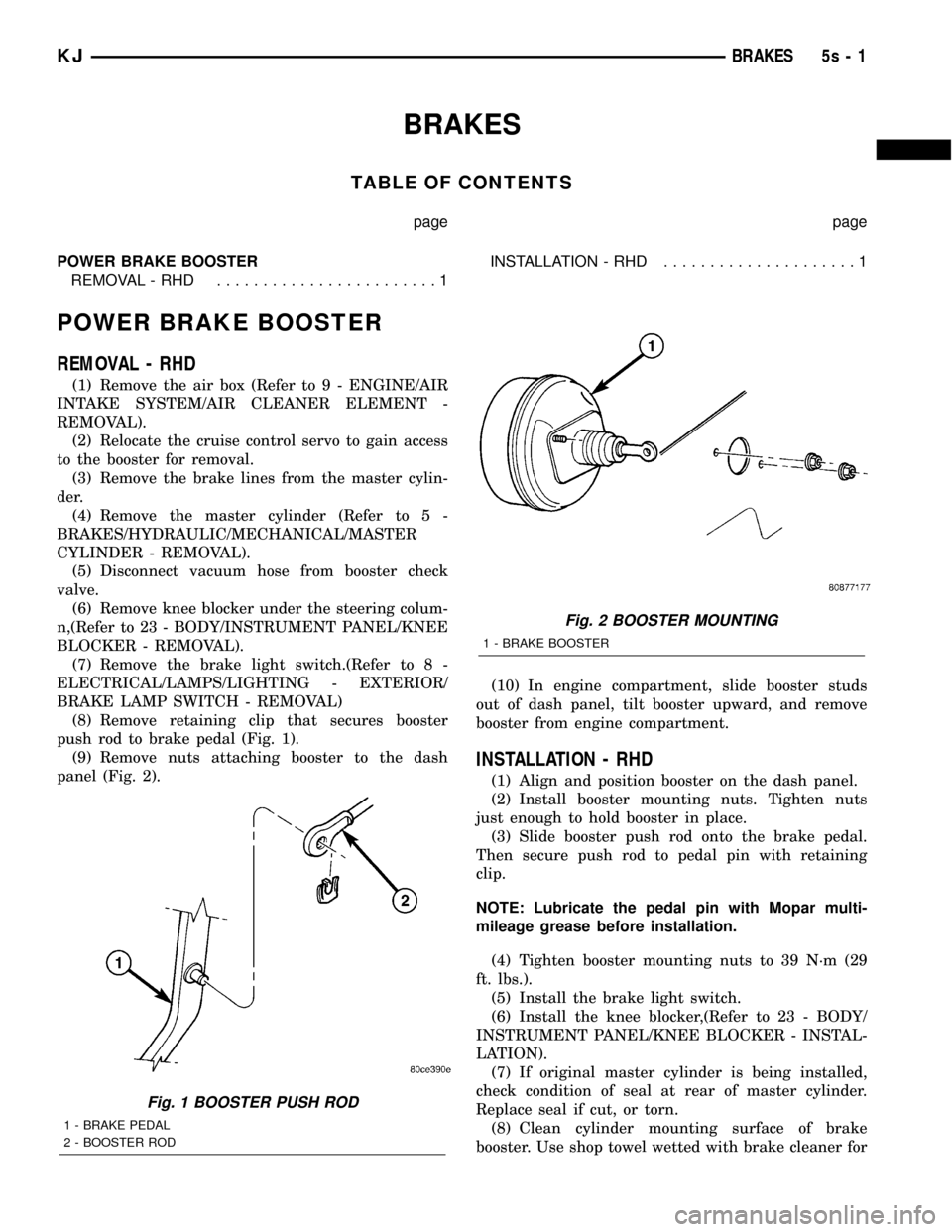

(9) Remove nuts attaching booster to the dash

panel (Fig. 2).(10) In engine compartment, slide booster studs

out of dash panel, tilt booster upward, and remove

booster from engine compartment.

INSTALLATION - RHD

(1) Align and position booster on the dash panel.

(2) Install booster mounting nuts. Tighten nuts

just enough to hold booster in place.

(3) Slide booster push rod onto the brake pedal.

Then secure push rod to pedal pin with retaining

clip.

NOTE: Lubricate the pedal pin with Mopar multi-

mileage grease before installation.

(4) Tighten booster mounting nuts to 39 N´m (29

ft. lbs.).

(5) Install the brake light switch.

(6) Install the knee blocker,(Refer to 23 - BODY/

INSTRUMENT PANEL/KNEE BLOCKER - INSTAL-

LATION).

(7) If original master cylinder is being installed,

check condition of seal at rear of master cylinder.

Replace seal if cut, or torn.

(8) Clean cylinder mounting surface of brake

booster. Use shop towel wetted with brake cleaner for

Fig. 1 BOOSTER PUSH ROD

1 - BRAKE PEDAL

2 - BOOSTER ROD

Fig. 2 BOOSTER MOUNTING

1 - BRAKE BOOSTER

KJBRAKES 5s - 1

Page 203 of 1803

BRAKES

TABLE OF CONTENTS

page page

POWER BRAKE BOOSTER

REMOVAL - RHD........................1INSTALLATION - RHD.....................1

POWER BRAKE BOOSTER

REMOVAL - RHD

(1) Remove the air box (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER ELEMENT -

REMOVAL).

(2) Relocate the cruise control servo to gain access

to the booster for removal.

(3) Remove the brake lines from the master cylin-

der.

(4) Remove the master cylinder (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/MASTER

CYLINDER - REMOVAL).

(5) Disconnect vacuum hose from booster check

valve.

(6) Remove knee blocker under the steering colum-

n,(Refer to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(7) Remove the brake light switch.(Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

BRAKE LAMP SWITCH - REMOVAL)

(8) Remove retaining clip that secures booster

push rod to brake pedal (Fig. 1).

(9) Remove nuts attaching booster to the dash

panel (Fig. 2).(10) In engine compartment, slide booster studs

out of dash panel, tilt booster upward, and remove

booster from engine compartment.

INSTALLATION - RHD

(1) Align and position booster on the dash panel.

(2) Install booster mounting nuts. Tighten nuts

just enough to hold booster in place.

(3) Slide booster push rod onto the brake pedal.

Then secure push rod to pedal pin with retaining

clip.

NOTE: Lubricate the pedal pin with Mopar multi-

mileage grease before installation.

(4) Tighten booster mounting nuts to 39 N´m (29

ft. lbs.).

(5) Install the brake light switch.

(6) Install the knee blocker,(Refer to 23 - BODY/

INSTRUMENT PANEL/KNEE BLOCKER - INSTAL-

LATION).

(7) If original master cylinder is being installed,

check condition of seal at rear of master cylinder.

Replace seal if cut, or torn.

(8) Clean cylinder mounting surface of brake

booster. Use shop towel wetted with brake cleaner for

Fig. 1 BOOSTER PUSH ROD

1 - BRAKE PEDAL

2 - BOOSTER ROD

Fig. 2 BOOSTER MOUNTING

1 - BRAKE BOOSTER

KJBRAKES 5s - 1