tow JEEP LIBERTY 2002 KJ / 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 210 of 1803

CLUTCH DISC

REMOVAL

(1) Remove transmission.

(2) Mark position of pressure plate on flywheel

with paint or a scriber for assembly reference, if

clutch is not being replaced.

(3) Loosen pressure plate bolts evenly and in rota-

tion to relieve spring tension and avoid warping the

plate.

(4) Remove pressure plate bolts and pressure plate

and disc.

INSTALLATION

(1) Lightly scuff sand flywheel face with 180 grit

emery cloth, then clean with a wax and grease

remover.

(2) Lubricate pilot bearing with Mopar high tem-

perature bearing grease or equivalent.

(3) Check runout and operation ofnewclutch disc.

NOTE: Disc must slide freely on transmission input

shaft splines.

(4) With the disc on the input shaft, check face

runout with dial indicator. Check runout at disc hub

6 mm (1/4 in.) from outer edge of facing. Obtain

another clutch disc if runout exceed 0.5 mm (0.020

in.).

(5) Position clutch disc on flywheel with side

marked flywheel against the flywheel.

NOTE: If not marked, the flat side of disc hub goes

towards the flywheel on the 3.7L engine and

towards the transmission on 2.4L engine.

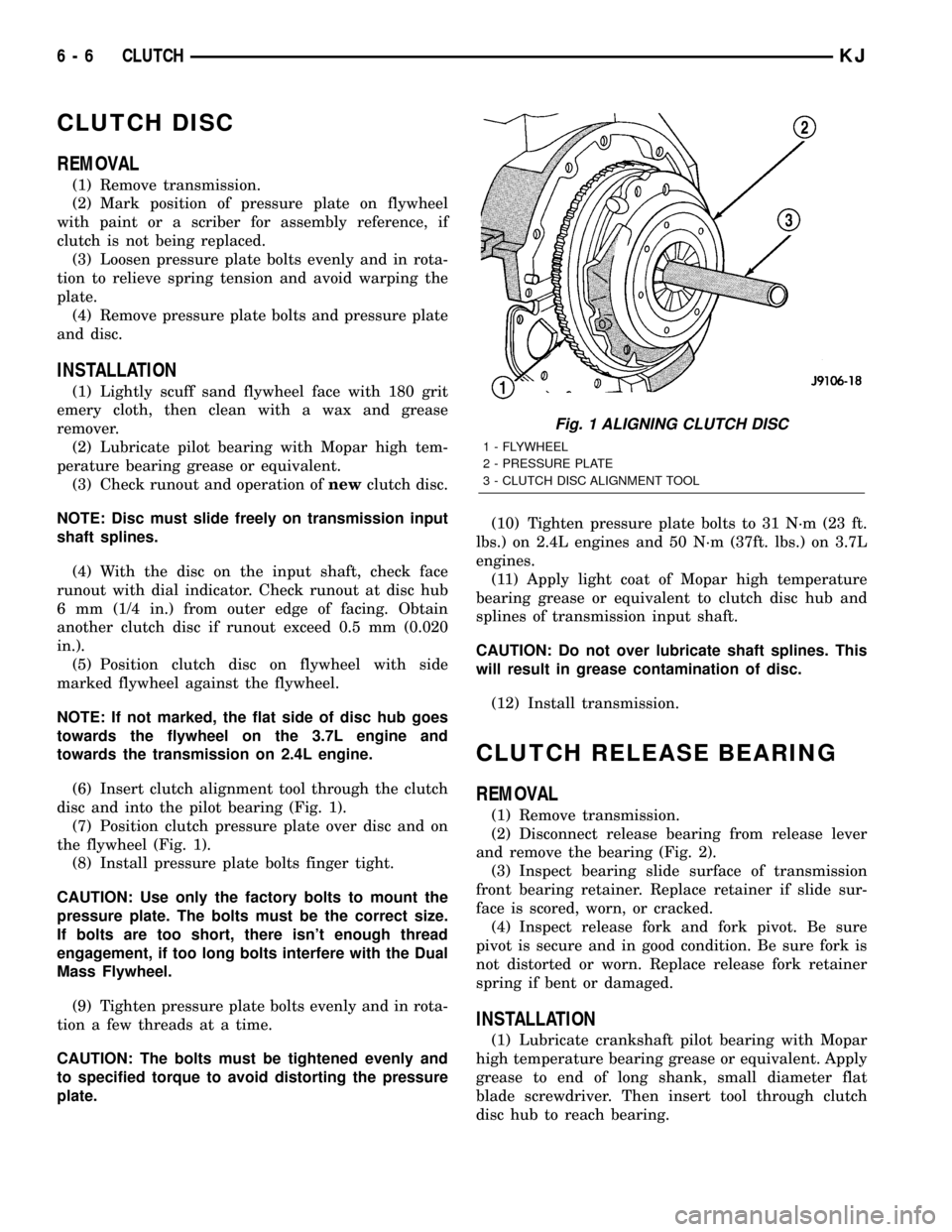

(6) Insert clutch alignment tool through the clutch

disc and into the pilot bearing (Fig. 1).

(7) Position clutch pressure plate over disc and on

the flywheel (Fig. 1).

(8) Install pressure plate bolts finger tight.

CAUTION: Use only the factory bolts to mount the

pressure plate. The bolts must be the correct size.

If bolts are too short, there isn't enough thread

engagement, if too long bolts interfere with the Dual

Mass Flywheel.

(9) Tighten pressure plate bolts evenly and in rota-

tion a few threads at a time.

CAUTION: The bolts must be tightened evenly and

to specified torque to avoid distorting the pressure

plate.(10) Tighten pressure plate bolts to 31 N´m (23 ft.

lbs.) on 2.4L engines and 50 N´m (37ft. lbs.) on 3.7L

engines.

(11) Apply light coat of Mopar high temperature

bearing grease or equivalent to clutch disc hub and

splines of transmission input shaft.

CAUTION: Do not over lubricate shaft splines. This

will result in grease contamination of disc.

(12) Install transmission.

CLUTCH RELEASE BEARING

REMOVAL

(1) Remove transmission.

(2) Disconnect release bearing from release lever

and remove the bearing (Fig. 2).

(3) Inspect bearing slide surface of transmission

front bearing retainer. Replace retainer if slide sur-

face is scored, worn, or cracked.

(4) Inspect release fork and fork pivot. Be sure

pivot is secure and in good condition. Be sure fork is

not distorted or worn. Replace release fork retainer

spring if bent or damaged.

INSTALLATION

(1) Lubricate crankshaft pilot bearing with Mopar

high temperature bearing grease or equivalent. Apply

grease to end of long shank, small diameter flat

blade screwdriver. Then insert tool through clutch

disc hub to reach bearing.

Fig. 1 ALIGNING CLUTCH DISC

1 - FLYWHEEL

2 - PRESSURE PLATE

3 - CLUTCH DISC ALIGNMENT TOOL

6 - 6 CLUTCHKJ

Page 218 of 1803

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

OPERATION - HOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The powertrain control module (PCM) has been

programmed to monitor certain cooling system com-

ponents:

²If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) can be set.

²If an open or shorted condition has developed in

the relay circuit controlling the electric radiator fan,

a Diagnostic Trouble Code (DTC) can be set.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the PCM mem-

ory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC's and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ERASING TROUBLE CODES

After the problem has been repaired, use the DRB

scan tool to erase a DTC. Refer to the appropriate

Powertrain Diagnostic Procedures service informa-

tion for operation of the DRB scan tool.

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

²PROLONGED IDLE

²VERY HIGH AMBIENT TEMPERATURE

²SLIGHT TAIL WIND AT IDLE

²SLOW TRAFFIC

²TRAFFIC JAMS

²HIGH SPEED

²STEEP GRADES

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.

(1) TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

(2) RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been per-

formed on vehicle that may effect cooling system.

This may be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt(s)

²Brakes (possibly dragging)

²Changed parts. Incorrect water pump, or pump

rotating in wrong direction due to belt not correctly

routed

²Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, refer to following Cooling System Diagnosis

charts.

These charts are to be used as a quick-reference

only. Refer to the group text for information.

Fig. 2 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

KJCOOLING 7 - 3

COOLING (Continued)

Page 221 of 1803

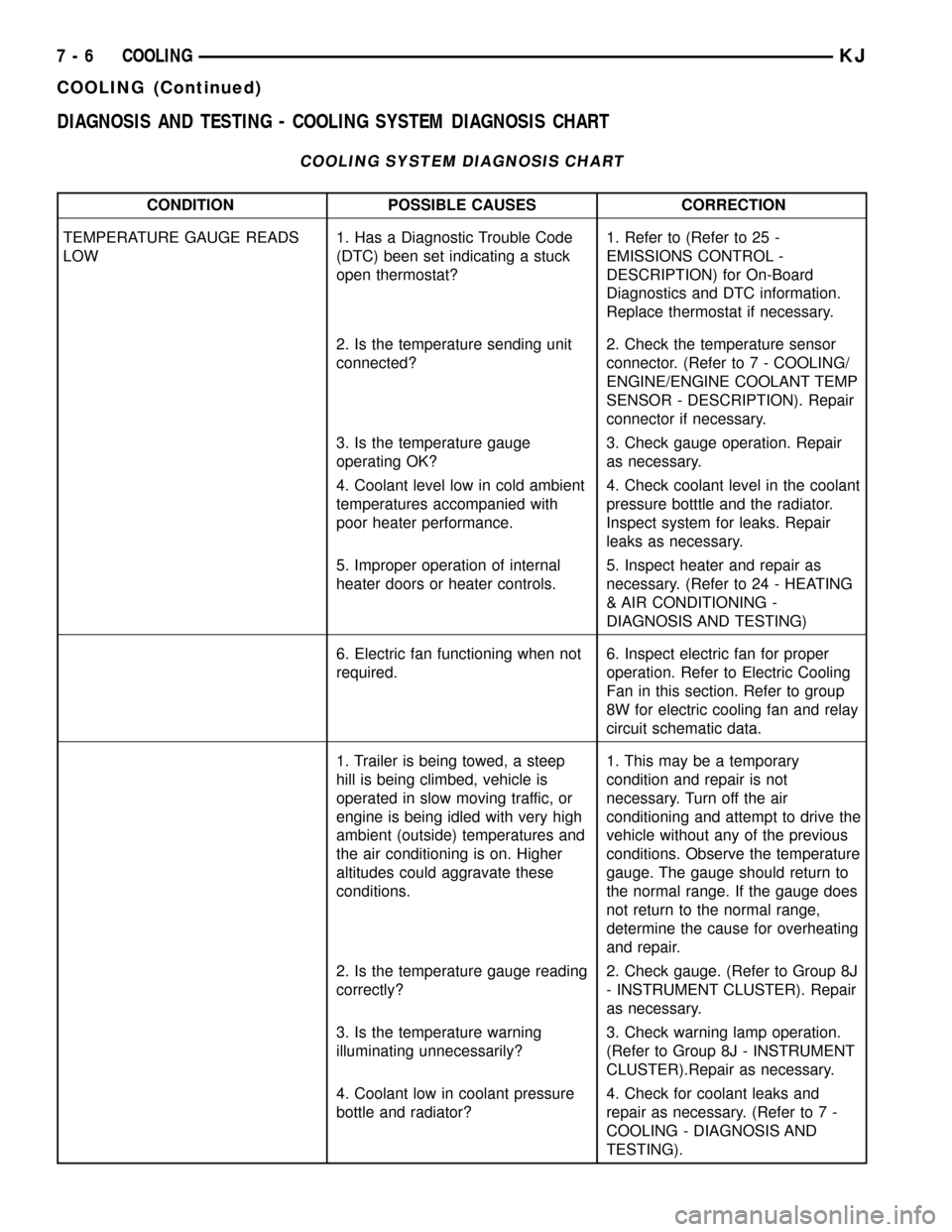

DIAGNOSIS AND TESTING - COOLING SYSTEM DIAGNOSIS CHART

COOLING SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READS

LOW1. Has a Diagnostic Trouble Code

(DTC) been set indicating a stuck

open thermostat?1. Refer to (Refer to 25 -

EMISSIONS CONTROL -

DESCRIPTION) for On-Board

Diagnostics and DTC information.

Replace thermostat if necessary.

2. Is the temperature sending unit

connected?2. Check the temperature sensor

connector. (Refer to 7 - COOLING/

ENGINE/ENGINE COOLANT TEMP

SENSOR - DESCRIPTION). Repair

connector if necessary.

3. Is the temperature gauge

operating OK?3. Check gauge operation. Repair

as necessary.

4. Coolant level low in cold ambient

temperatures accompanied with

poor heater performance.4. Check coolant level in the coolant

pressure botttle and the radiator.

Inspect system for leaks. Repair

leaks as necessary.

5. Improper operation of internal

heater doors or heater controls.5. Inspect heater and repair as

necessary. (Refer to 24 - HEATING

& AIR CONDITIONING -

DIAGNOSIS AND TESTING)

6. Electric fan functioning when not

required.6. Inspect electric fan for proper

operation. Refer to Electric Cooling

Fan in this section. Refer to group

8W for electric cooling fan and relay

circuit schematic data.

1. Trailer is being towed, a steep

hill is being climbed, vehicle is

operated in slow moving traffic, or

engine is being idled with very high

ambient (outside) temperatures and

the air conditioning is on. Higher

altitudes could aggravate these

conditions.1. This may be a temporary

condition and repair is not

necessary. Turn off the air

conditioning and attempt to drive the

vehicle without any of the previous

conditions. Observe the temperature

gauge. The gauge should return to

the normal range. If the gauge does

not return to the normal range,

determine the cause for overheating

and repair.

2. Is the temperature gauge reading

correctly?2. Check gauge. (Refer to Group 8J

- INSTRUMENT CLUSTER). Repair

as necessary.

3. Is the temperature warning

illuminating unnecessarily?3. Check warning lamp operation.

(Refer to Group 8J - INSTRUMENT

CLUSTER).Repair as necessary.

4. Coolant low in coolant pressure

bottle and radiator?4. Check for coolant leaks and

repair as necessary. (Refer to 7 -

COOLING - DIAGNOSIS AND

TESTING).

7 - 6 COOLINGKJ

COOLING (Continued)

Page 241 of 1803

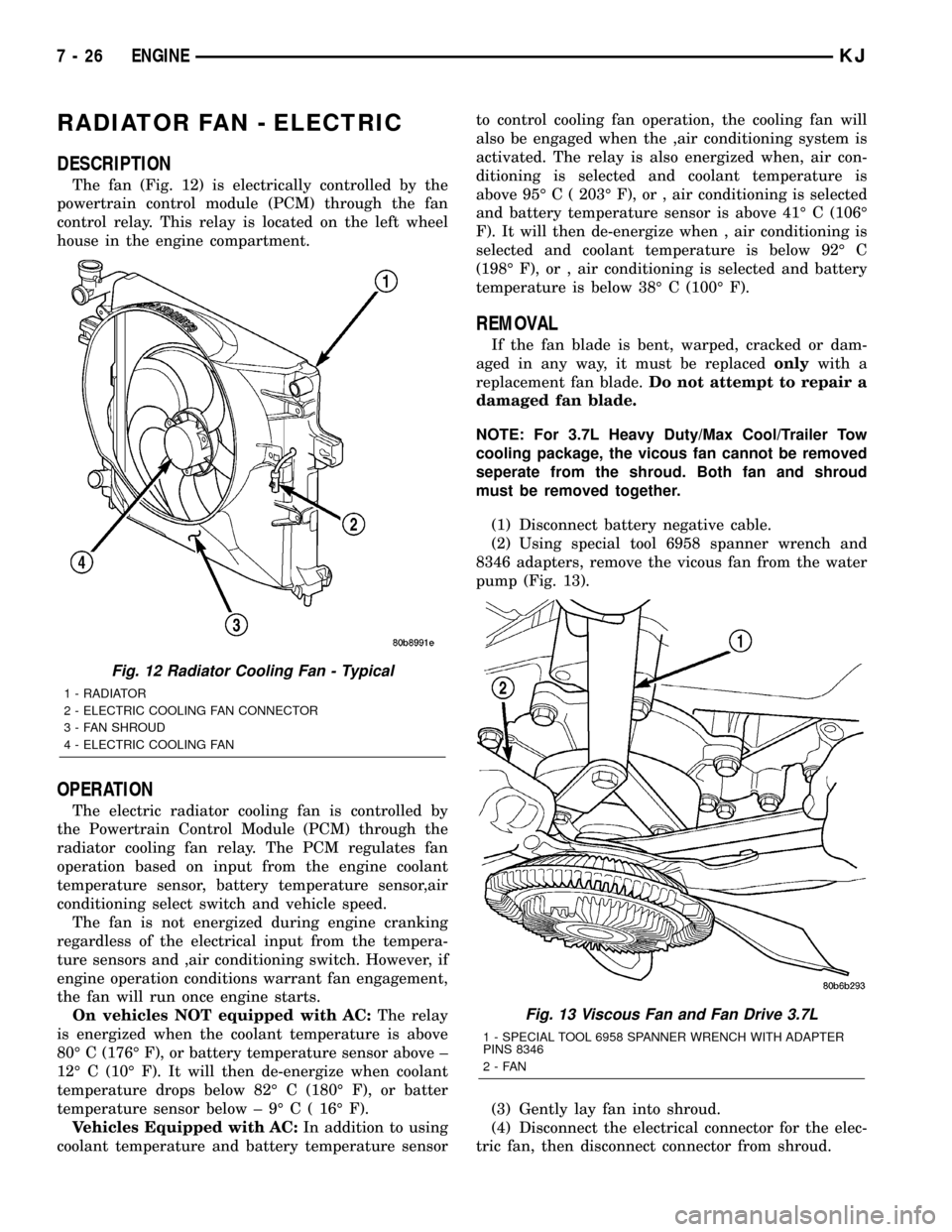

RADIATOR FAN - ELECTRIC

DESCRIPTION

The fan (Fig. 12) is electrically controlled by the

powertrain control module (PCM) through the fan

control relay. This relay is located on the left wheel

house in the engine compartment.

OPERATION

The electric radiator cooling fan is controlled by

the Powertrain Control Module (PCM) through the

radiator cooling fan relay. The PCM regulates fan

operation based on input from the engine coolant

temperature sensor, battery temperature sensor,air

conditioning select switch and vehicle speed.

The fan is not energized during engine cranking

regardless of the electrical input from the tempera-

ture sensors and ,air conditioning switch. However, if

engine operation conditions warrant fan engagement,

the fan will run once engine starts.

On vehicles NOT equipped with AC:The relay

is energized when the coolant temperature is above

80É C (176É F), or battery temperature sensor above ±

12É C (10É F). It will then de-energize when coolant

temperature drops below 82É C (180É F), or batter

temperature sensor below ± 9É C ( 16É F).

Vehicles Equipped with AC:In addition to using

coolant temperature and battery temperature sensorto control cooling fan operation, the cooling fan will

also be engaged when the ,air conditioning system is

activated. The relay is also energized when, air con-

ditioning is selected and coolant temperature is

above 95É C ( 203É F), or , air conditioning is selected

and battery temperature sensor is above 41É C (106É

F). It will then de-energize when , air conditioning is

selected and coolant temperature is below 92É C

(198É F), or , air conditioning is selected and battery

temperature is below 38É C (100É F).

REMOVAL

If the fan blade is bent, warped, cracked or dam-

aged in any way, it must be replacedonlywith a

replacement fan blade.Do not attempt to repair a

damaged fan blade.

NOTE: For 3.7L Heavy Duty/Max Cool/Trailer Tow

cooling package, the vicous fan cannot be removed

seperate from the shroud. Both fan and shroud

must be removed together.

(1) Disconnect battery negative cable.

(2) Using special tool 6958 spanner wrench and

8346 adapters, remove the vicous fan from the water

pump (Fig. 13).

(3) Gently lay fan into shroud.

(4) Disconnect the electrical connector for the elec-

tric fan, then disconnect connector from shroud.

Fig. 12 Radiator Cooling Fan - Typical

1 - RADIATOR

2 - ELECTRIC COOLING FAN CONNECTOR

3 - FAN SHROUD

4 - ELECTRIC COOLING FAN

Fig. 13 Viscous Fan and Fan Drive 3.7L

1 - SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2-FAN

7 - 26 ENGINEKJ

Page 242 of 1803

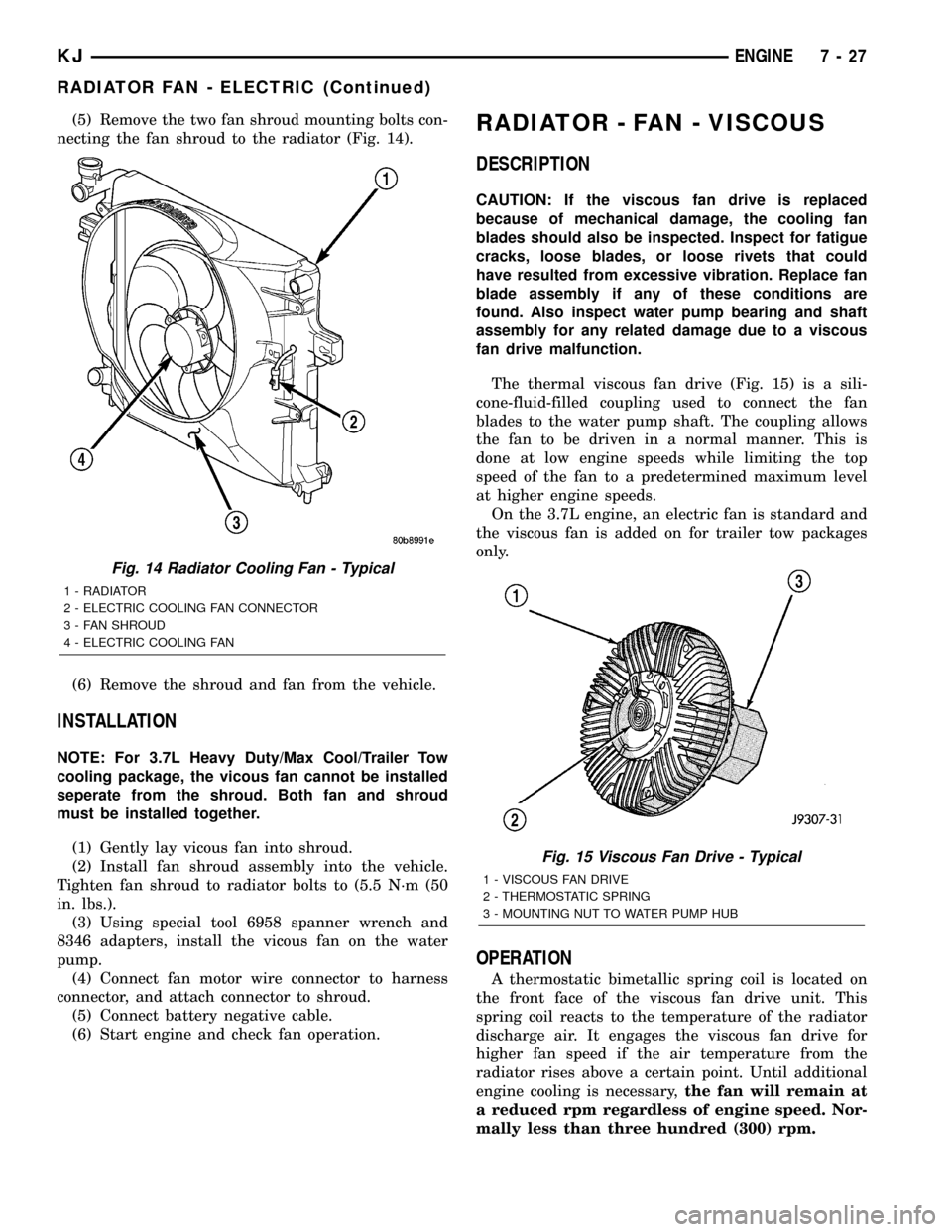

(5) Remove the two fan shroud mounting bolts con-

necting the fan shroud to the radiator (Fig. 14).

(6) Remove the shroud and fan from the vehicle.

INSTALLATION

NOTE: For 3.7L Heavy Duty/Max Cool/Trailer Tow

cooling package, the vicous fan cannot be installed

seperate from the shroud. Both fan and shroud

must be installed together.

(1) Gently lay vicous fan into shroud.

(2) Install fan shroud assembly into the vehicle.

Tighten fan shroud to radiator bolts to (5.5 N´m (50

in. lbs.).

(3) Using special tool 6958 spanner wrench and

8346 adapters, install the vicous fan on the water

pump.

(4) Connect fan motor wire connector to harness

connector, and attach connector to shroud.

(5) Connect battery negative cable.

(6) Start engine and check fan operation.

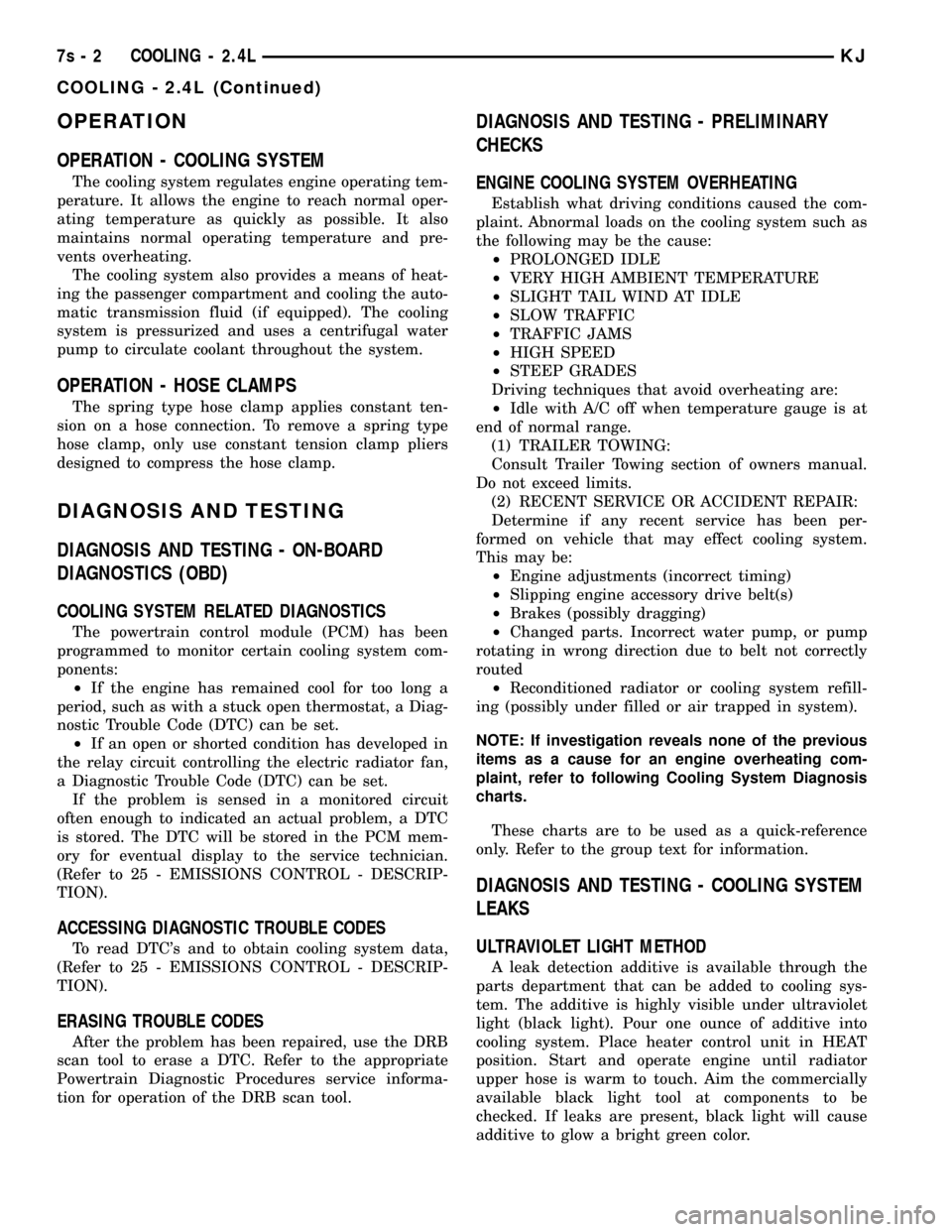

RADIATOR - FAN - VISCOUS

DESCRIPTION

CAUTION: If the viscous fan drive is replaced

because of mechanical damage, the cooling fan

blades should also be inspected. Inspect for fatigue

cracks, loose blades, or loose rivets that could

have resulted from excessive vibration. Replace fan

blade assembly if any of these conditions are

found. Also inspect water pump bearing and shaft

assembly for any related damage due to a viscous

fan drive malfunction.

The thermal viscous fan drive (Fig. 15) is a sili-

cone-fluid-filled coupling used to connect the fan

blades to the water pump shaft. The coupling allows

the fan to be driven in a normal manner. This is

done at low engine speeds while limiting the top

speed of the fan to a predetermined maximum level

at higher engine speeds.

On the 3.7L engine, an electric fan is standard and

the viscous fan is added on for trailer tow packages

only.

OPERATION

A thermostatic bimetallic spring coil is located on

the front face of the viscous fan drive unit. This

spring coil reacts to the temperature of the radiator

discharge air. It engages the viscous fan drive for

higher fan speed if the air temperature from the

radiator rises above a certain point. Until additional

engine cooling is necessary,the fan will remain at

a reduced rpm regardless of engine speed. Nor-

mally less than three hundred (300) rpm.

Fig. 14 Radiator Cooling Fan - Typical

1 - RADIATOR

2 - ELECTRIC COOLING FAN CONNECTOR

3 - FAN SHROUD

4 - ELECTRIC COOLING FAN

Fig. 15 Viscous Fan Drive - Typical

1 - VISCOUS FAN DRIVE

2 - THERMOSTATIC SPRING

3 - MOUNTING NUT TO WATER PUMP HUB

KJENGINE 7 - 27

RADIATOR FAN - ELECTRIC (Continued)

Page 249 of 1803

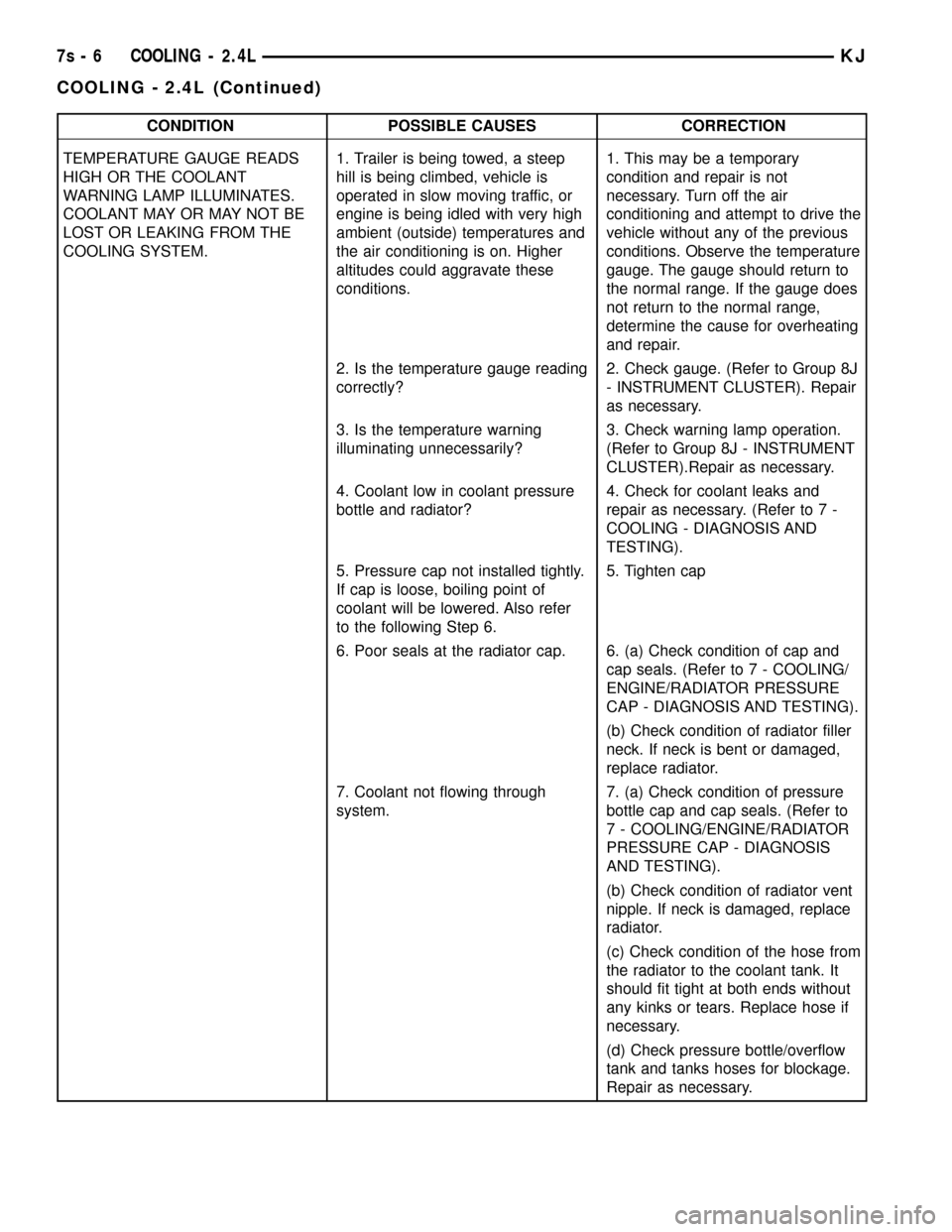

OPERATION

OPERATION - COOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It also

maintains normal operating temperature and pre-

vents overheating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

OPERATION - HOSE CLAMPS

The spring type hose clamp applies constant ten-

sion on a hose connection. To remove a spring type

hose clamp, only use constant tension clamp pliers

designed to compress the hose clamp.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTICS (OBD)

COOLING SYSTEM RELATED DIAGNOSTICS

The powertrain control module (PCM) has been

programmed to monitor certain cooling system com-

ponents:

²If the engine has remained cool for too long a

period, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) can be set.

²If an open or shorted condition has developed in

the relay circuit controlling the electric radiator fan,

a Diagnostic Trouble Code (DTC) can be set.

If the problem is sensed in a monitored circuit

often enough to indicated an actual problem, a DTC

is stored. The DTC will be stored in the PCM mem-

ory for eventual display to the service technician.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ACCESSING DIAGNOSTIC TROUBLE CODES

To read DTC's and to obtain cooling system data,

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

ERASING TROUBLE CODES

After the problem has been repaired, use the DRB

scan tool to erase a DTC. Refer to the appropriate

Powertrain Diagnostic Procedures service informa-

tion for operation of the DRB scan tool.

DIAGNOSIS AND TESTING - PRELIMINARY

CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause:

²PROLONGED IDLE

²VERY HIGH AMBIENT TEMPERATURE

²SLIGHT TAIL WIND AT IDLE

²SLOW TRAFFIC

²TRAFFIC JAMS

²HIGH SPEED

²STEEP GRADES

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.

(1) TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

(2) RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been per-

formed on vehicle that may effect cooling system.

This may be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt(s)

²Brakes (possibly dragging)

²Changed parts. Incorrect water pump, or pump

rotating in wrong direction due to belt not correctly

routed

²Reconditioned radiator or cooling system refill-

ing (possibly under filled or air trapped in system).

NOTE: If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, refer to following Cooling System Diagnosis

charts.

These charts are to be used as a quick-reference

only. Refer to the group text for information.

DIAGNOSIS AND TESTING - COOLING SYSTEM

LEAKS

ULTRAVIOLET LIGHT METHOD

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate engine until radiator

upper hose is warm to touch. Aim the commercially

available black light tool at components to be

checked. If leaks are present, black light will cause

additive to glow a bright green color.

7s - 2 COOLING - 2.4LKJ

COOLING - 2.4L (Continued)

Page 253 of 1803

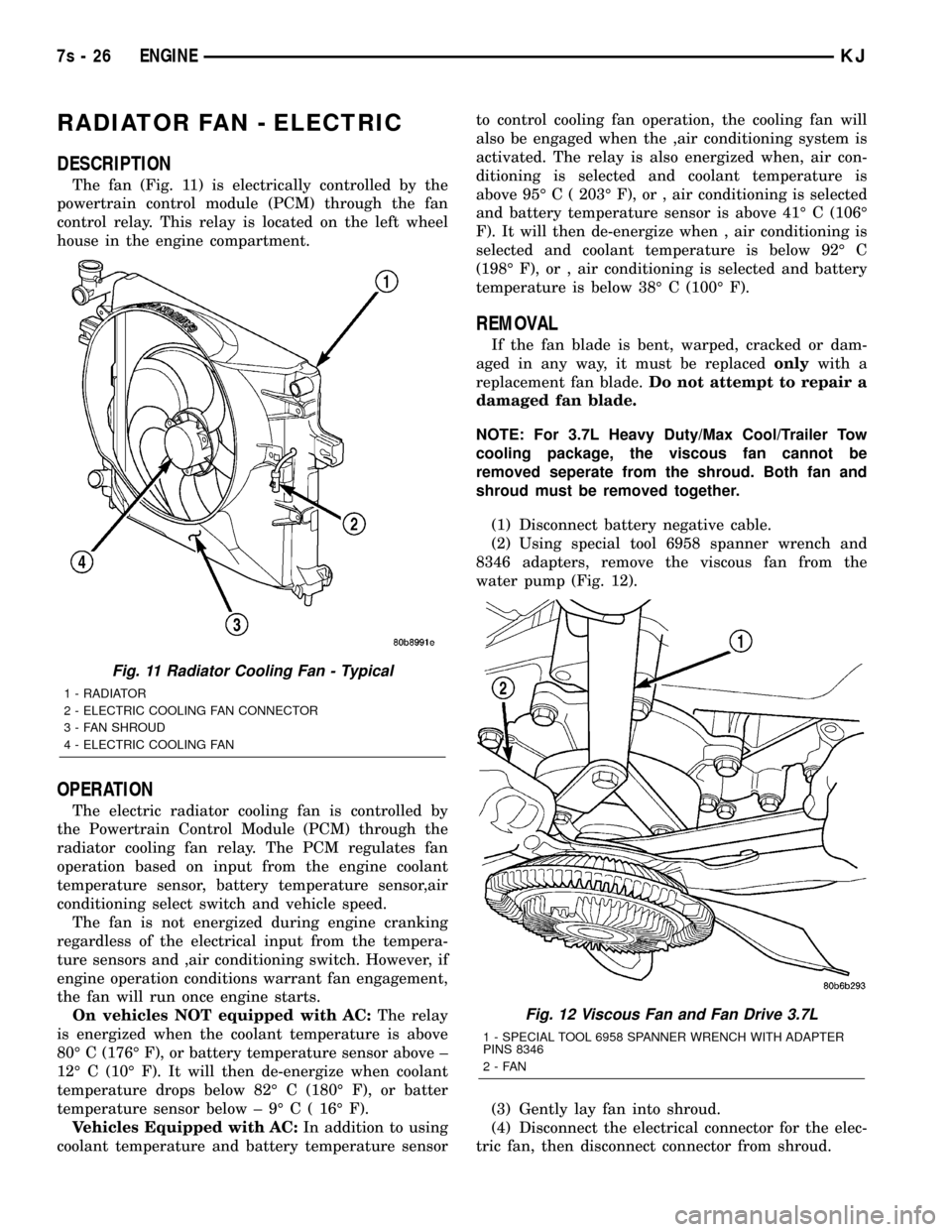

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE READS

HIGH OR THE COOLANT

WARNING LAMP ILLUMINATES.

COOLANT MAY OR MAY NOT BE

LOST OR LEAKING FROM THE

COOLING SYSTEM.1. Trailer is being towed, a steep

hill is being climbed, vehicle is

operated in slow moving traffic, or

engine is being idled with very high

ambient (outside) temperatures and

the air conditioning is on. Higher

altitudes could aggravate these

conditions.1. This may be a temporary

condition and repair is not

necessary. Turn off the air

conditioning and attempt to drive the

vehicle without any of the previous

conditions. Observe the temperature

gauge. The gauge should return to

the normal range. If the gauge does

not return to the normal range,

determine the cause for overheating

and repair.

2. Is the temperature gauge reading

correctly?2. Check gauge. (Refer to Group 8J

- INSTRUMENT CLUSTER). Repair

as necessary.

3. Is the temperature warning

illuminating unnecessarily?3. Check warning lamp operation.

(Refer to Group 8J - INSTRUMENT

CLUSTER).Repair as necessary.

4. Coolant low in coolant pressure

bottle and radiator?4. Check for coolant leaks and

repair as necessary. (Refer to 7 -

COOLING - DIAGNOSIS AND

TESTING).

5. Pressure cap not installed tightly.

If cap is loose, boiling point of

coolant will be lowered. Also refer

to the following Step 6.5. Tighten cap

6. Poor seals at the radiator cap. 6. (a) Check condition of cap and

cap seals. (Refer to 7 - COOLING/

ENGINE/RADIATOR PRESSURE

CAP - DIAGNOSIS AND TESTING).

(b) Check condition of radiator filler

neck. If neck is bent or damaged,

replace radiator.

7. Coolant not flowing through

system.7. (a) Check condition of pressure

bottle cap and cap seals. (Refer to

7 - COOLING/ENGINE/RADIATOR

PRESSURE CAP - DIAGNOSIS

AND TESTING).

(b) Check condition of radiator vent

nipple. If neck is damaged, replace

radiator.

(c) Check condition of the hose from

the radiator to the coolant tank. It

should fit tight at both ends without

any kinks or tears. Replace hose if

necessary.

(d) Check pressure bottle/overflow

tank and tanks hoses for blockage.

Repair as necessary.

7s - 6 COOLING - 2.4LKJ

COOLING - 2.4L (Continued)

Page 273 of 1803

RADIATOR FAN - ELECTRIC

DESCRIPTION

The fan (Fig. 11) is electrically controlled by the

powertrain control module (PCM) through the fan

control relay. This relay is located on the left wheel

house in the engine compartment.

OPERATION

The electric radiator cooling fan is controlled by

the Powertrain Control Module (PCM) through the

radiator cooling fan relay. The PCM regulates fan

operation based on input from the engine coolant

temperature sensor, battery temperature sensor,air

conditioning select switch and vehicle speed.

The fan is not energized during engine cranking

regardless of the electrical input from the tempera-

ture sensors and ,air conditioning switch. However, if

engine operation conditions warrant fan engagement,

the fan will run once engine starts.

On vehicles NOT equipped with AC:The relay

is energized when the coolant temperature is above

80É C (176É F), or battery temperature sensor above ±

12É C (10É F). It will then de-energize when coolant

temperature drops below 82É C (180É F), or batter

temperature sensor below ± 9É C ( 16É F).

Vehicles Equipped with AC:In addition to using

coolant temperature and battery temperature sensorto control cooling fan operation, the cooling fan will

also be engaged when the ,air conditioning system is

activated. The relay is also energized when, air con-

ditioning is selected and coolant temperature is

above 95É C ( 203É F), or , air conditioning is selected

and battery temperature sensor is above 41É C (106É

F). It will then de-energize when , air conditioning is

selected and coolant temperature is below 92É C

(198É F), or , air conditioning is selected and battery

temperature is below 38É C (100É F).

REMOVAL

If the fan blade is bent, warped, cracked or dam-

aged in any way, it must be replacedonlywith a

replacement fan blade.Do not attempt to repair a

damaged fan blade.

NOTE: For 3.7L Heavy Duty/Max Cool/Trailer Tow

cooling package, the viscous fan cannot be

removed seperate from the shroud. Both fan and

shroud must be removed together.

(1) Disconnect battery negative cable.

(2) Using special tool 6958 spanner wrench and

8346 adapters, remove the viscous fan from the

water pump (Fig. 12).

(3) Gently lay fan into shroud.

(4) Disconnect the electrical connector for the elec-

tric fan, then disconnect connector from shroud.

Fig. 11 Radiator Cooling Fan - Typical

1 - RADIATOR

2 - ELECTRIC COOLING FAN CONNECTOR

3 - FAN SHROUD

4 - ELECTRIC COOLING FAN

Fig. 12 Viscous Fan and Fan Drive 3.7L

1 - SPECIAL TOOL 6958 SPANNER WRENCH WITH ADAPTER

PINS 8346

2-FAN

7s - 26 ENGINEKJ

Page 274 of 1803

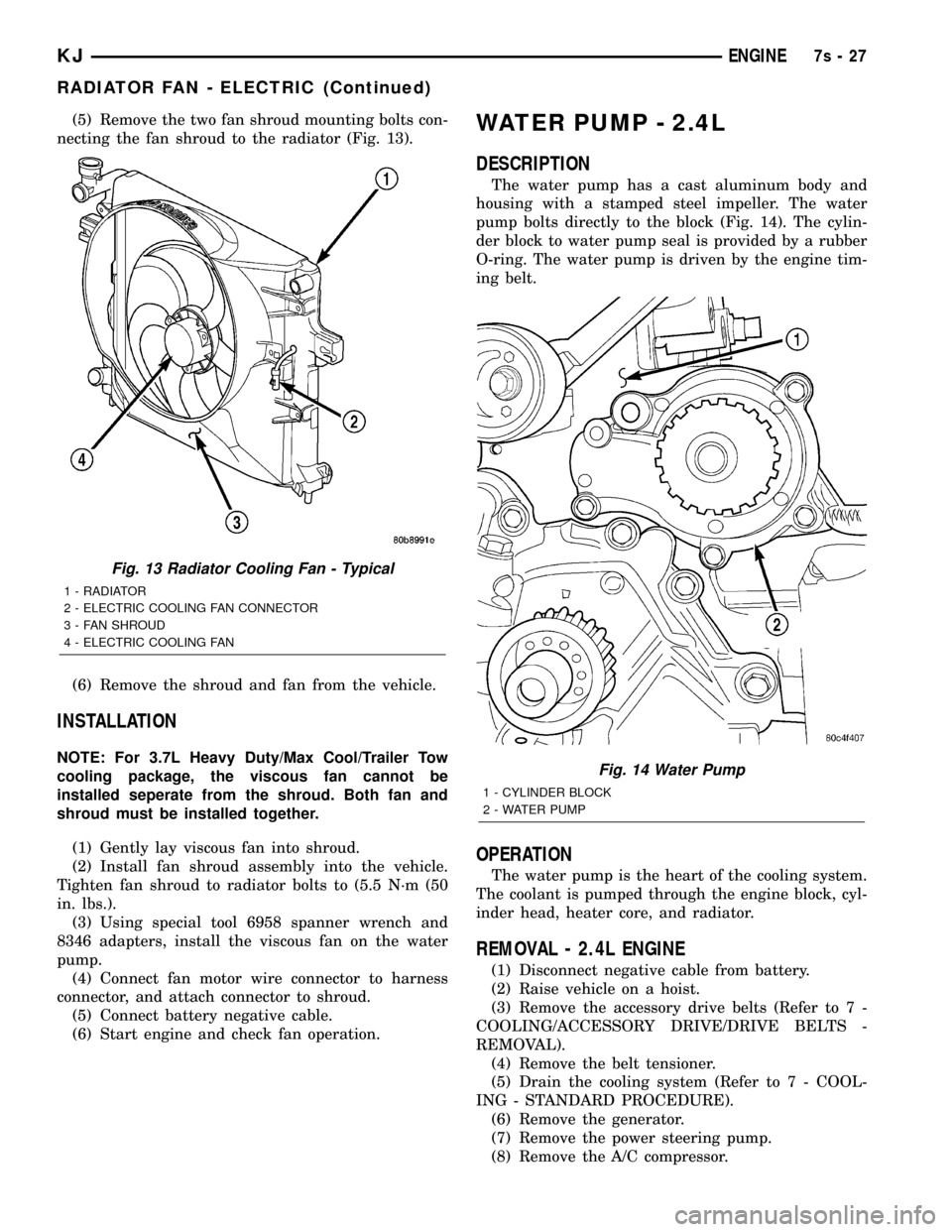

(5) Remove the two fan shroud mounting bolts con-

necting the fan shroud to the radiator (Fig. 13).

(6) Remove the shroud and fan from the vehicle.

INSTALLATION

NOTE: For 3.7L Heavy Duty/Max Cool/Trailer Tow

cooling package, the viscous fan cannot be

installed seperate from the shroud. Both fan and

shroud must be installed together.

(1) Gently lay viscous fan into shroud.

(2) Install fan shroud assembly into the vehicle.

Tighten fan shroud to radiator bolts to (5.5 N´m (50

in. lbs.).

(3) Using special tool 6958 spanner wrench and

8346 adapters, install the viscous fan on the water

pump.

(4) Connect fan motor wire connector to harness

connector, and attach connector to shroud.

(5) Connect battery negative cable.

(6) Start engine and check fan operation.

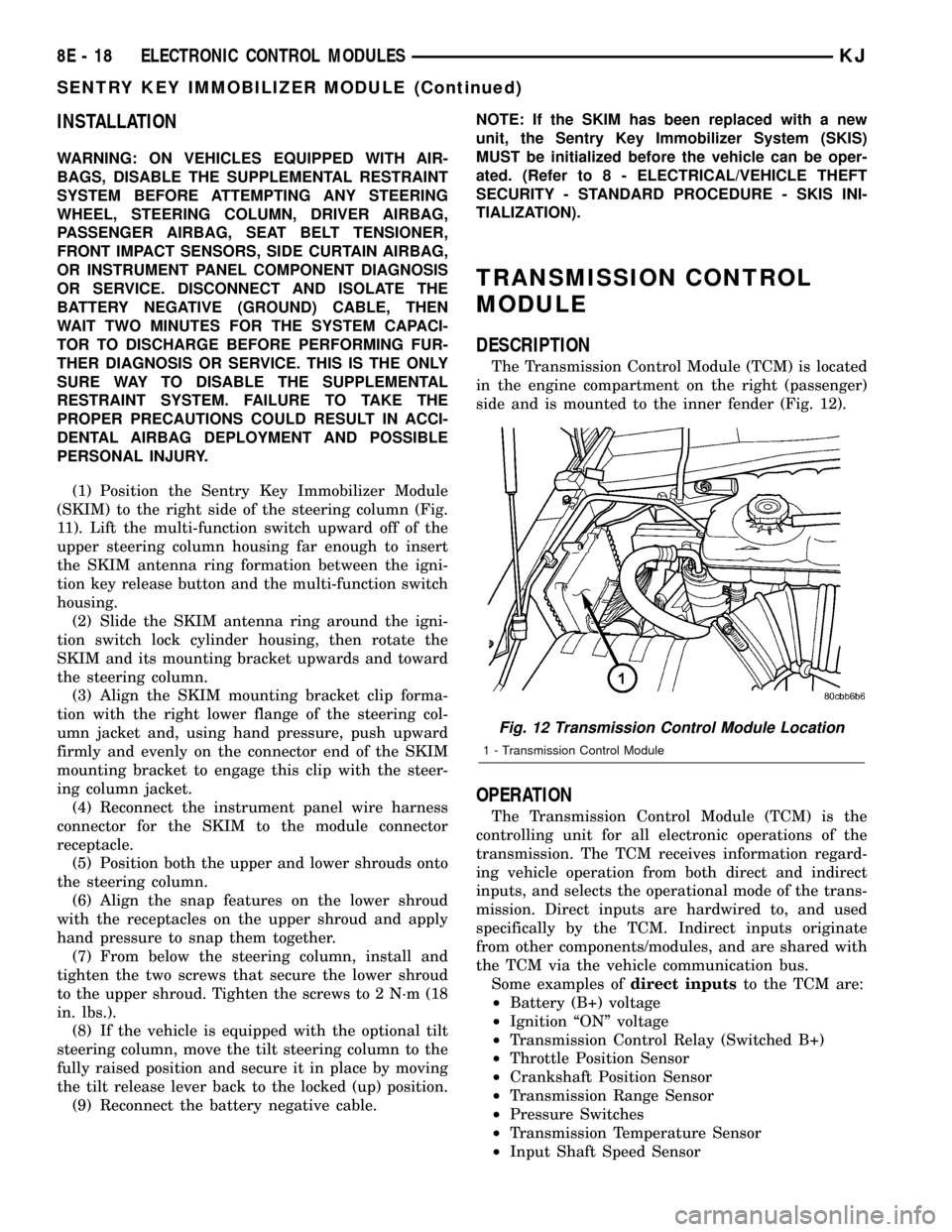

WATER PUMP - 2.4L

DESCRIPTION

The water pump has a cast aluminum body and

housing with a stamped steel impeller. The water

pump bolts directly to the block (Fig. 14). The cylin-

der block to water pump seal is provided by a rubber

O-ring. The water pump is driven by the engine tim-

ing belt.

OPERATION

The water pump is the heart of the cooling system.

The coolant is pumped through the engine block, cyl-

inder head, heater core, and radiator.

REMOVAL - 2.4L ENGINE

(1) Disconnect negative cable from battery.

(2) Raise vehicle on a hoist.

(3) Remove the accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove the belt tensioner.

(5) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(6) Remove the generator.

(7) Remove the power steering pump.

(8) Remove the A/C compressor.

Fig. 13 Radiator Cooling Fan - Typical

1 - RADIATOR

2 - ELECTRIC COOLING FAN CONNECTOR

3 - FAN SHROUD

4 - ELECTRIC COOLING FAN

Fig. 14 Water Pump

1 - CYLINDER BLOCK

2 - WATER PUMP

KJENGINE7s-27

RADIATOR FAN - ELECTRIC (Continued)

Page 317 of 1803

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the Sentry Key Immobilizer Module

(SKIM) to the right side of the steering column (Fig.

11). Lift the multi-function switch upward off of the

upper steering column housing far enough to insert

the SKIM antenna ring formation between the igni-

tion key release button and the multi-function switch

housing.

(2) Slide the SKIM antenna ring around the igni-

tion switch lock cylinder housing, then rotate the

SKIM and its mounting bracket upwards and toward

the steering column.

(3) Align the SKIM mounting bracket clip forma-

tion with the right lower flange of the steering col-

umn jacket and, using hand pressure, push upward

firmly and evenly on the connector end of the SKIM

mounting bracket to engage this clip with the steer-

ing column jacket.

(4) Reconnect the instrument panel wire harness

connector for the SKIM to the module connector

receptacle.

(5) Position both the upper and lower shrouds onto

the steering column.

(6) Align the snap features on the lower shroud

with the receptacles on the upper shroud and apply

hand pressure to snap them together.

(7) From below the steering column, install and

tighten the two screws that secure the lower shroud

to the upper shroud. Tighten the screws to 2 N´m (18

in. lbs.).

(8) If the vehicle is equipped with the optional tilt

steering column, move the tilt steering column to the

fully raised position and secure it in place by moving

the tilt release lever back to the locked (up) position.

(9) Reconnect the battery negative cable.NOTE: If the SKIM has been replaced with a new

unit, the Sentry Key Immobilizer System (SKIS)

MUST be initialized before the vehicle can be oper-

ated. (Refer to 8 - ELECTRICAL/VEHICLE THEFT

SECURITY - STANDARD PROCEDURE - SKIS INI-

TIALIZATION).

TRANSMISSION CONTROL

MODULE

DESCRIPTION

The Transmission Control Module (TCM) is located

in the engine compartment on the right (passenger)

side and is mounted to the inner fender (Fig. 12).

OPERATION

The Transmission Control Module (TCM) is the

controlling unit for all electronic operations of the

transmission. The TCM receives information regard-

ing vehicle operation from both direct and indirect

inputs, and selects the operational mode of the trans-

mission. Direct inputs are hardwired to, and used

specifically by the TCM. Indirect inputs originate

from other components/modules, and are shared with

the TCM via the vehicle communication bus.

Some examples ofdirect inputsto the TCM are:

²Battery (B+) voltage

²Ignition ªONº voltage

²Transmission Control Relay (Switched B+)

²Throttle Position Sensor

²Crankshaft Position Sensor

²Transmission Range Sensor

²Pressure Switches

²Transmission Temperature Sensor

²Input Shaft Speed Sensor

Fig. 12 Transmission Control Module Location

1 - Transmission Control Module

8E - 18 ELECTRONIC CONTROL MODULESKJ

SENTRY KEY IMMOBILIZER MODULE (Continued)