ignition JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1438 of 1803

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Tilt Steering Column

Steering Wheel Bolt54 40 Ð

Tilt Steering Column

Mounting Bolts17 Ð 150

Tilt Steering Column

Coupler Bolt49 36 Ð

Non-Tilt Steering Column

Steering Wheel Bolt54 40 Ð

Non-Tilt Steering Column

Mounting Bolts17 Ð 150

Non-Tilt Steering Column

Coupler Bolt49 36 Ð

Ignition Switch Screws 2 Ð 17

SPECIAL TOOLS

STEERING COLUMN

IGNITION SWITCH

DESCRIPTION

The electrical ignition switch is located on the

steering column. It is used as the main on/off switch-

ing device for most electrical components. The

mechanical key lock cylinder is used to engage/disen-

gage the electrical ignition switch.

DIAGNOSIS AND TESTING - IGNITION SWITCH

ELECTRICAL DIAGNOSIS

For ignition switch electrical schematics, Refer to

the appropriate section for the component.

MECHANICAL DIAGNOSIS (KEY DIFFICULT TO

ROTATE)

Vehicles equipped with an automatic trans-

mission and a floor mounted shifter:a cable is

used to connect the interlock device in the steering

column assembly, to the transmission floor shift

lever. This interlock system is used to lock the trans-

mission shifter in the PARK position when the key

lock cylinder is rotated to the LOCKED or ACCES-

SORY position. If the ignition key is difficult to

rotate to or from the LOCK or ACCESSORY position,

it may not be the fault of the key cylinder or the

steering column components. The brake transmission

shift interlock cable may be out of adjustment. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 30RH/GEAR SHIFT CABLE - ADJUSTMENTS).

The interlock system within the steering column is

not serviceable. If repair is necessary, the steering

column assembly must be replaced. (Refer to 19 -

STEERING/COLUMN - REMOVAL).

Vehicles equipped with a manual transmis-

sion and a floor mounted shifter:on certain mod-

els, a button is located on the steering column behind

the ignition key lock cylinder. The button must be

manually depressed to allow rotation of the ignition

key lock cylinder to the LOCK or ACCESSORY posi-

tion. If it is difficult to rotate the key to the LOCK or

ACCESSORY position, the lever mechanism may be

defective. This mechanism is not serviceable. If

repair is necessary, the steering column assembly

must be replaced.(Refer to 19 - STEERING/COL-

UMN - REMOVAL).

Puller C-3894-A

19 - 8 COLUMNKJ

COLUMN (Continued)

Page 1439 of 1803

REMOVAL

IGNITION SWITCH REMOVAL

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before removing ignition switch.

(1) Remove lower steering column cover screws

and remove cover.

(2) Remove lock cylinder.(Refer to 19 - STEERING/

COLUMN/KEY/LOCK CYLINDER - REMOVAL).

(3) Remove the multi-function switch.

(4) Disconnect the electrical connector at the rear

of the ignition switch.

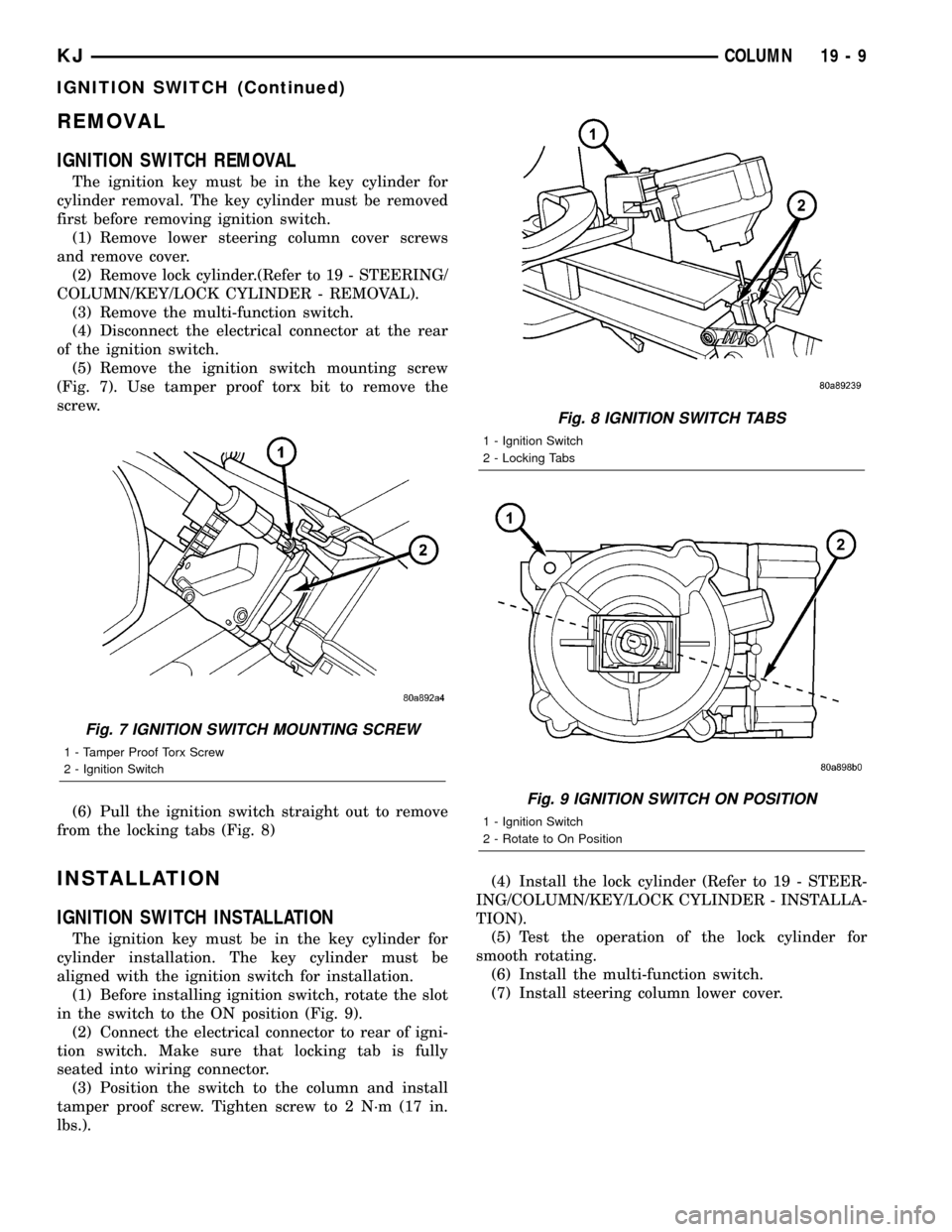

(5) Remove the ignition switch mounting screw

(Fig. 7). Use tamper proof torx bit to remove the

screw.

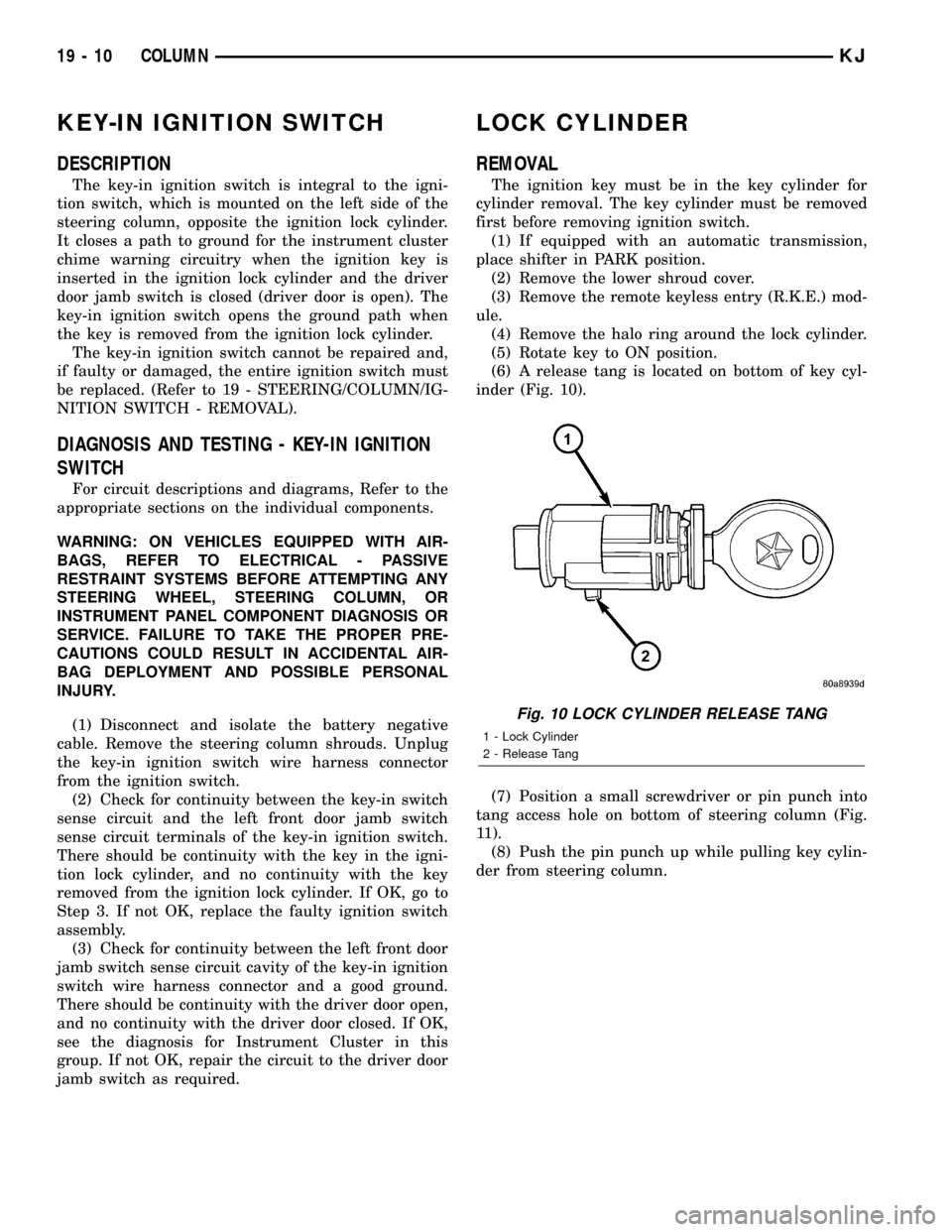

(6) Pull the ignition switch straight out to remove

from the locking tabs (Fig. 8)

INSTALLATION

IGNITION SWITCH INSTALLATION

The ignition key must be in the key cylinder for

cylinder installation. The key cylinder must be

aligned with the ignition switch for installation.

(1) Before installing ignition switch, rotate the slot

in the switch to the ON position (Fig. 9).

(2) Connect the electrical connector to rear of igni-

tion switch. Make sure that locking tab is fully

seated into wiring connector.

(3) Position the switch to the column and install

tamper proof screw. Tighten screw to 2 N´m (17 in.

lbs.).(4) Install the lock cylinder (Refer to 19 - STEER-

ING/COLUMN/KEY/LOCK CYLINDER - INSTALLA-

TION).

(5) Test the operation of the lock cylinder for

smooth rotating.

(6) Install the multi-function switch.

(7) Install steering column lower cover.

Fig. 7 IGNITION SWITCH MOUNTING SCREW

1 - Tamper Proof Torx Screw

2 - Ignition Switch

Fig. 8 IGNITION SWITCH TABS

1 - Ignition Switch

2 - Locking Tabs

Fig. 9 IGNITION SWITCH ON POSITION

1 - Ignition Switch

2 - Rotate to On Position

KJCOLUMN 19 - 9

IGNITION SWITCH (Continued)

Page 1440 of 1803

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is integral to the igni-

tion switch, which is mounted on the left side of the

steering column, opposite the ignition lock cylinder.

It closes a path to ground for the instrument cluster

chime warning circuitry when the ignition key is

inserted in the ignition lock cylinder and the driver

door jamb switch is closed (driver door is open). The

key-in ignition switch opens the ground path when

the key is removed from the ignition lock cylinder.

The key-in ignition switch cannot be repaired and,

if faulty or damaged, the entire ignition switch must

be replaced. (Refer to 19 - STEERING/COLUMN/IG-

NITION SWITCH - REMOVAL).

DIAGNOSIS AND TESTING - KEY-IN IGNITION

SWITCH

For circuit descriptions and diagrams, Refer to the

appropriate sections on the individual components.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Remove the steering column shrouds. Unplug

the key-in ignition switch wire harness connector

from the ignition switch.

(2) Check for continuity between the key-in switch

sense circuit and the left front door jamb switch

sense circuit terminals of the key-in ignition switch.

There should be continuity with the key in the igni-

tion lock cylinder, and no continuity with the key

removed from the ignition lock cylinder. If OK, go to

Step 3. If not OK, replace the faulty ignition switch

assembly.

(3) Check for continuity between the left front door

jamb switch sense circuit cavity of the key-in ignition

switch wire harness connector and a good ground.

There should be continuity with the driver door open,

and no continuity with the driver door closed. If OK,

see the diagnosis for Instrument Cluster in this

group. If not OK, repair the circuit to the driver door

jamb switch as required.

LOCK CYLINDER

REMOVAL

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before removing ignition switch.

(1) If equipped with an automatic transmission,

place shifter in PARK position.

(2) Remove the lower shroud cover.

(3) Remove the remote keyless entry (R.K.E.) mod-

ule.

(4) Remove the halo ring around the lock cylinder.

(5) Rotate key to ON position.

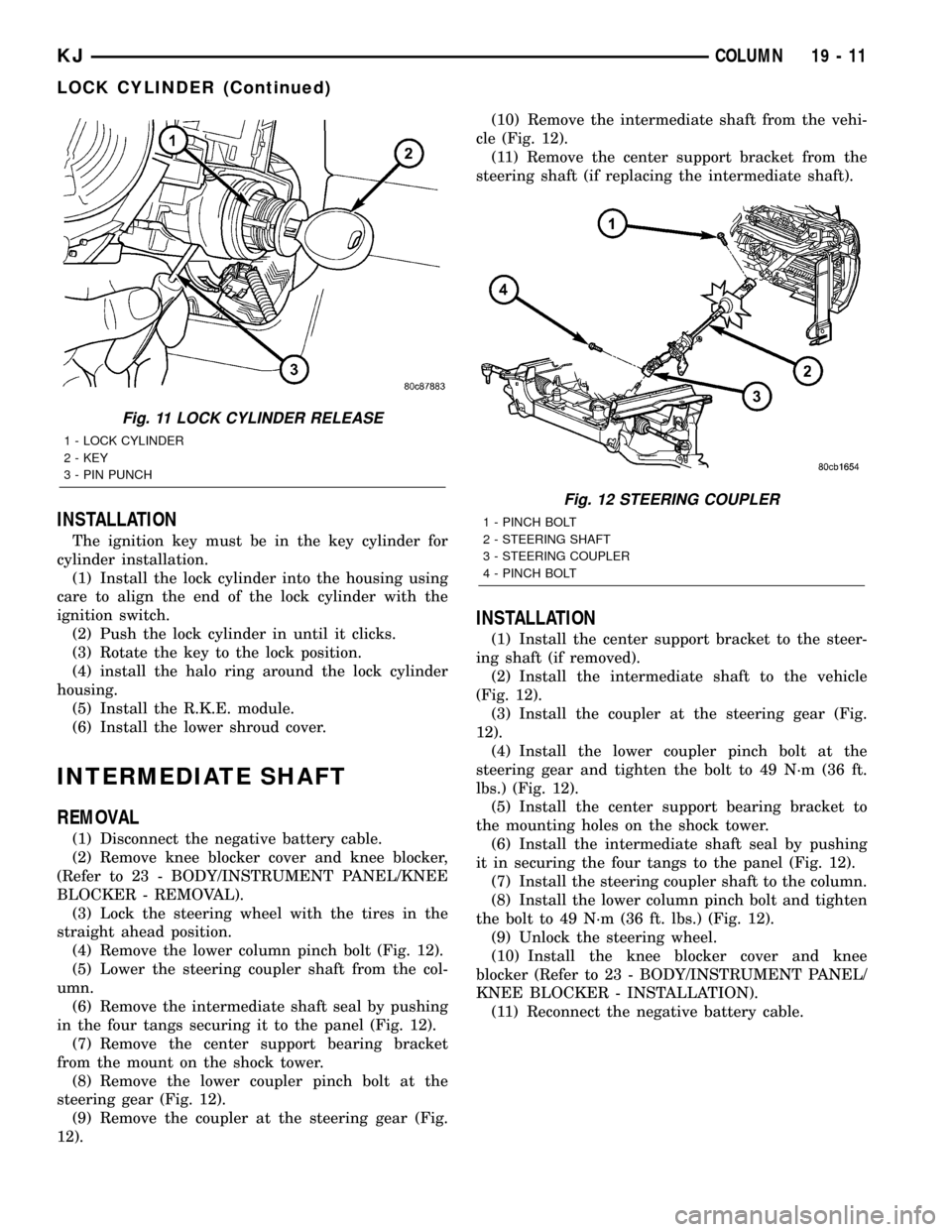

(6) A release tang is located on bottom of key cyl-

inder (Fig. 10).

(7) Position a small screwdriver or pin punch into

tang access hole on bottom of steering column (Fig.

11).

(8) Push the pin punch up while pulling key cylin-

der from steering column.

Fig. 10 LOCK CYLINDER RELEASE TANG

1 - Lock Cylinder

2 - Release Tang

19 - 10 COLUMNKJ

Page 1441 of 1803

INSTALLATION

The ignition key must be in the key cylinder for

cylinder installation.

(1) Install the lock cylinder into the housing using

care to align the end of the lock cylinder with the

ignition switch.

(2) Push the lock cylinder in until it clicks.

(3) Rotate the key to the lock position.

(4) install the halo ring around the lock cylinder

housing.

(5) Install the R.K.E. module.

(6) Install the lower shroud cover.

INTERMEDIATE SHAFT

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove knee blocker cover and knee blocker,

(Refer to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(3) Lock the steering wheel with the tires in the

straight ahead position.

(4) Remove the lower column pinch bolt (Fig. 12).

(5) Lower the steering coupler shaft from the col-

umn.

(6) Remove the intermediate shaft seal by pushing

in the four tangs securing it to the panel (Fig. 12).

(7) Remove the center support bearing bracket

from the mount on the shock tower.

(8) Remove the lower coupler pinch bolt at the

steering gear (Fig. 12).

(9) Remove the coupler at the steering gear (Fig.

12).(10) Remove the intermediate shaft from the vehi-

cle (Fig. 12).

(11) Remove the center support bracket from the

steering shaft (if replacing the intermediate shaft).

INSTALLATION

(1) Install the center support bracket to the steer-

ing shaft (if removed).

(2) Install the intermediate shaft to the vehicle

(Fig. 12).

(3) Install the coupler at the steering gear (Fig.

12).

(4) Install the lower coupler pinch bolt at the

steering gear and tighten the bolt to 49 N´m (36 ft.

lbs.) (Fig. 12).

(5) Install the center support bearing bracket to

the mounting holes on the shock tower.

(6) Install the intermediate shaft seal by pushing

it in securing the four tangs to the panel (Fig. 12).

(7) Install the steering coupler shaft to the column.

(8) Install the lower column pinch bolt and tighten

the bolt to 49 N´m (36 ft. lbs.) (Fig. 12).

(9) Unlock the steering wheel.

(10) Install the knee blocker cover and knee

blocker (Refer to 23 - BODY/INSTRUMENT PANEL/

KNEE BLOCKER - INSTALLATION).

(11) Reconnect the negative battery cable.

Fig. 11 LOCK CYLINDER RELEASE

1 - LOCK CYLINDER

2 - KEY

3 - PIN PUNCH

Fig. 12 STEERING COUPLER

1 - PINCH BOLT

2 - STEERING SHAFT

3 - STEERING COUPLER

4 - PINCH BOLT

KJCOLUMN 19 - 11

LOCK CYLINDER (Continued)

Page 1466 of 1803

BODY

TABLE OF CONTENTS

page page

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS . . . 1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS . 2

DIAGNOSIS AND TESTING - WIND NOISE . . . 3

STANDARD PROCEDURE

STANDARD PROCEDURE - BODY

LUBRICATION.........................3

STANDARD PROCEDURE - HEAT STAKING . . 3

SPECIFICATIONS........................4

SPECIAL TOOLS

BODY...............................5BODY STRUCTURE.......................6

HOOD................................119

DOOR - FRONT........................121

DOORS - REAR........................128

SWING GATE..........................135

EXTERIOR............................140

INSTRUMENT PANEL....................147

INTERIOR.............................156

PAINT................................162

SEATS...............................164

STATIONARY GLASS....................172

SUNROOF.............................175

WEATHERSTRIP/SEALS..................185

BODY

WARNING

SAFETY PRECAUTIONS AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

²USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

²AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL±BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

²DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

²Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

²Always have a fire extinguisher ready for use

when welding.

²Disconnect the negative (-) cable clamp from

the battery when servicing electrical components

that are live when the ignition is OFF. Damage to

electrical system can result.²Do not use abrasive chemicals or compounds

on painted surfaces. Damage to finish can result.

²Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

²Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

DaimlerChrysler Corporation uses many different

types of push-in fasteners to secure the interior and

exterior trim to the body. Most of these fasteners can

be reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

KJBODY 23 - 1

Page 1640 of 1803

SUNROOF

TABLE OF CONTENTS

page page

SUNROOF

DESCRIPTION........................175

DIAGNOSIS AND TESTING

WATER DRAINAGE AND WIND NOISE

DIAGNOSIS.........................176

DIAGNOSTIC PROCEDURES...........176

GLASS PANEL

REMOVAL............................178

INSTALLATION........................178

ADJUSTMENTS

SUNROOF GLASS PANEL ADJUSTMENT . . 178

GLASS PANEL SEAL

REMOVAL............................178

INSTALLATION........................178

SUNSHADE

REMOVAL............................179

INSTALLATION........................179

GUIDE ASSEMBLY

REMOVAL............................179

INSTALLATION........................179

WIND DEFLECTOR

REMOVAL............................180INSTALLATION........................180

OPENING TRIM LACE

REMOVAL............................180

INSTALLATION........................180

DRAIN TUBE

REMOVAL............................180

INSTALLATION........................181

MODULE ASSEMBLY

REMOVAL............................181

INSTALLATION........................181

DRIVE MOTOR

REMOVAL............................182

INSTALLATION........................182

CONTROL MODULE

REMOVAL............................183

INSTALLATION........................183

CONTROL SWITCH

DESCRIPTION........................184

OPERATION..........................184

DIAGNOSIS AND TESTING...............184

REMOVAL............................184

INSTALLATION........................184

SUNROOF

DESCRIPTION

WARNING: Keep fingers and other body parts out

of sunroof opening at all times.

The sunroof features a power sliding glass panel

and a sunshade which can be manually positioned

anywhere along its travel, rearward of glass panel

front edge.

The sunroof is electrically operated from two

switches located on the windshield header, rearwardof the map lamp. To operate the sunroof the ignition

switch must be in either the Accessory or On/Run

position. One switch (vent) is a push button type and

opens the sunroof to the vent position only. The other

switch (open/close) is a rocker type for opening and

closing the sunroof. Pressing and releasing the open

button once the sunroof will express open and the

wind deflector will raise. If the button is pressed a

second time the sunroof will stop in that position.

Pressing and holding the close button will close the

sunroof. If the close button is released the sunroof

will stop in that position.

KJSUNROOF 23 - 175

Page 1668 of 1803

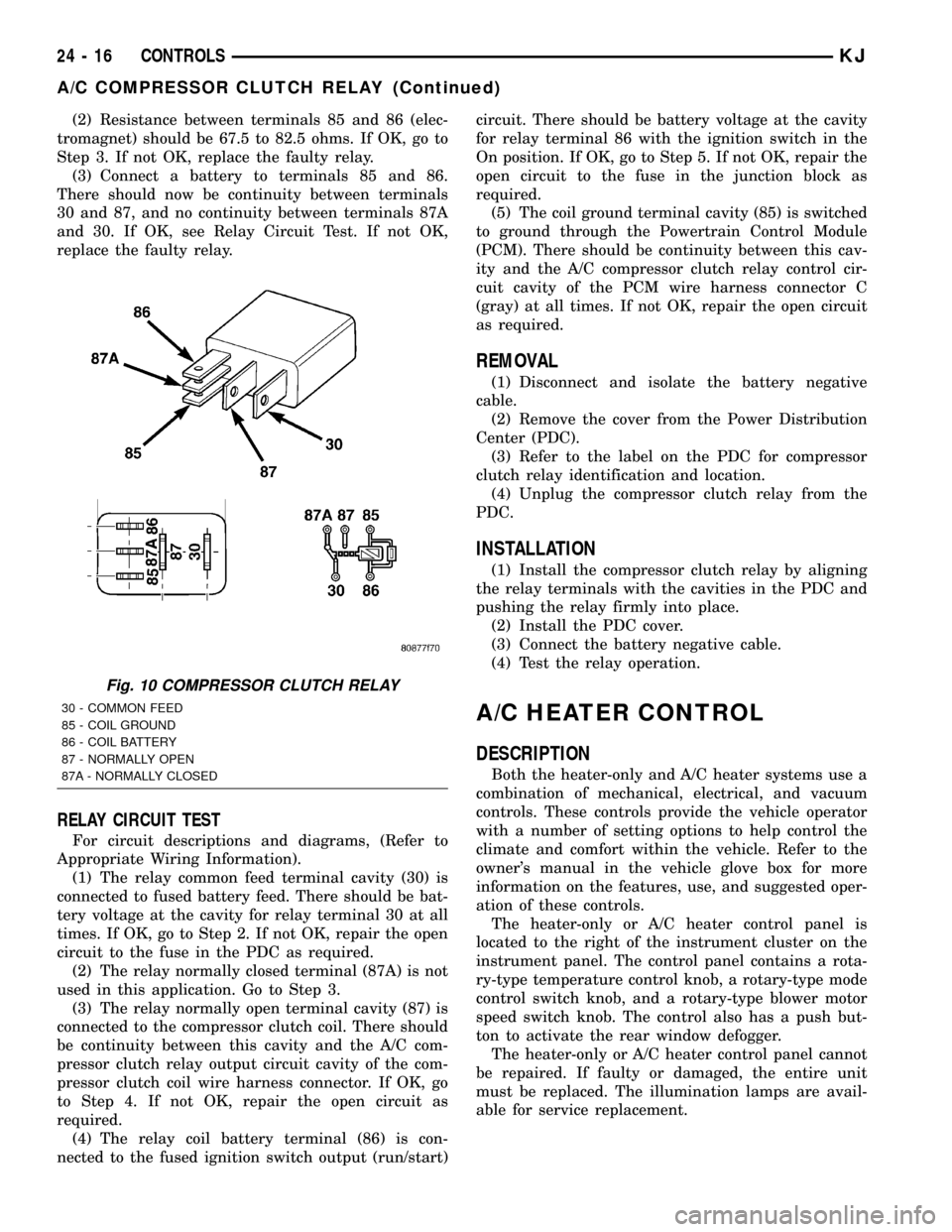

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 67.5 to 82.5 ohms. If OK, go to

Step 3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see Relay Circuit Test. If not OK,

replace the faulty relay.

RELAY CIRCUIT TEST

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed. There should be bat-

tery voltage at the cavity for relay terminal 30 at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is not

used in this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the compressor clutch coil. There should

be continuity between this cavity and the A/C com-

pressor clutch relay output circuit cavity of the com-

pressor clutch coil wire harness connector. If OK, go

to Step 4. If not OK, repair the open circuit as

required.

(4) The relay coil battery terminal (86) is con-

nected to the fused ignition switch output (run/start)circuit. There should be battery voltage at the cavity

for relay terminal 86 with the ignition switch in the

On position. If OK, go to Step 5. If not OK, repair the

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C HEATER CONTROL

DESCRIPTION

Both the heater-only and A/C heater systems use a

combination of mechanical, electrical, and vacuum

controls. These controls provide the vehicle operator

with a number of setting options to help control the

climate and comfort within the vehicle. Refer to the

owner's manual in the vehicle glove box for more

information on the features, use, and suggested oper-

ation of these controls.

The heater-only or A/C heater control panel is

located to the right of the instrument cluster on the

instrument panel. The control panel contains a rota-

ry-type temperature control knob, a rotary-type mode

control switch knob, and a rotary-type blower motor

speed switch knob. The control also has a push but-

ton to activate the rear window defogger.

The heater-only or A/C heater control panel cannot

be repaired. If faulty or damaged, the entire unit

must be replaced. The illumination lamps are avail-

able for service replacement.

Fig. 10 COMPRESSOR CLUTCH RELAY

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

24 - 16 CONTROLSKJ

A/C COMPRESSOR CLUTCH RELAY (Continued)

Page 1672 of 1803

(2) Install and tighten the a/c low pressure switch

on the accumulator fitting. The switch should be

hand-tightened onto the accumulator fitting.

(3) Plug the wire harness connector into the a/c

low pressure switch.

(4) Connect the battery negative cable.

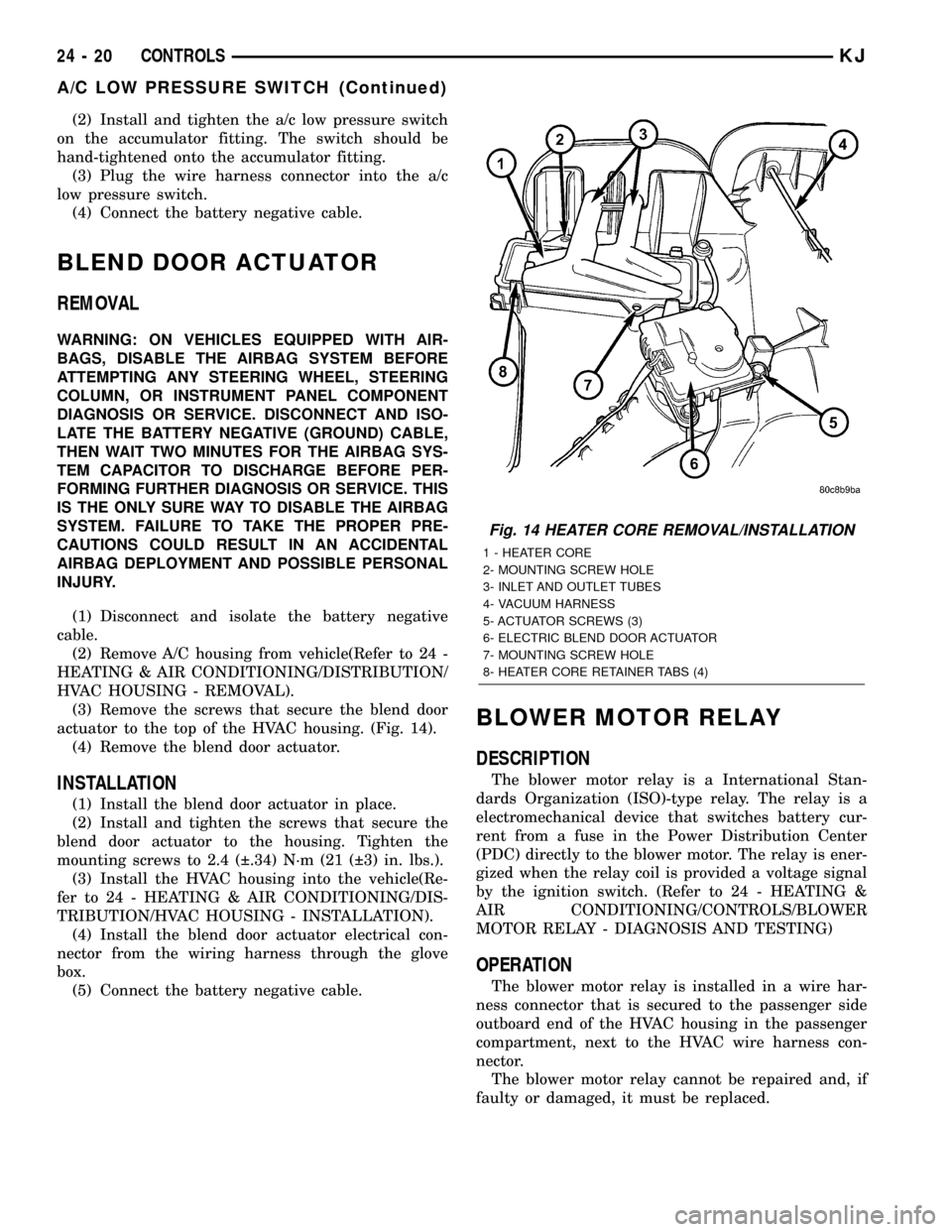

BLEND DOOR ACTUATOR

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove A/C housing from vehicle(Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL).

(3) Remove the screws that secure the blend door

actuator to the top of the HVAC housing. (Fig. 14).

(4) Remove the blend door actuator.

INSTALLATION

(1) Install the blend door actuator in place.

(2) Install and tighten the screws that secure the

blend door actuator to the housing. Tighten the

mounting screws to 2.4 ( .34) N´m (21 ( 3) in. lbs.).

(3) Install the HVAC housing into the vehicle(Re-

fer to 24 - HEATING & AIR CONDITIONING/DIS-

TRIBUTION/HVAC HOUSING - INSTALLATION).

(4) Install the blend door actuator electrical con-

nector from the wiring harness through the glove

box.

(5) Connect the battery negative cable.

BLOWER MOTOR RELAY

DESCRIPTION

The blower motor relay is a International Stan-

dards Organization (ISO)-type relay. The relay is a

electromechanical device that switches battery cur-

rent from a fuse in the Power Distribution Center

(PDC) directly to the blower motor. The relay is ener-

gized when the relay coil is provided a voltage signal

by the ignition switch. (Refer to 24 - HEATING &

AIR CONDITIONING/CONTROLS/BLOWER

MOTOR RELAY - DIAGNOSIS AND TESTING)

OPERATION

The blower motor relay is installed in a wire har-

ness connector that is secured to the passenger side

outboard end of the HVAC housing in the passenger

compartment, next to the HVAC wire harness con-

nector.

The blower motor relay cannot be repaired and, if

faulty or damaged, it must be replaced.

Fig. 14 HEATER CORE REMOVAL/INSTALLATION

1 - HEATER CORE

2- MOUNTING SCREW HOLE

3- INLET AND OUTLET TUBES

4- VACUUM HARNESS

5- ACTUATOR SCREWS (3)

6- ELECTRIC BLEND DOOR ACTUATOR

7- MOUNTING SCREW HOLE

8- HEATER CORE RETAINER TABS (4)

24 - 20 CONTROLSKJ

A/C LOW PRESSURE SWITCH (Continued)

Page 1673 of 1803

DIAGNOSIS AND TESTING - BLOWER MOTOR

RELAY

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

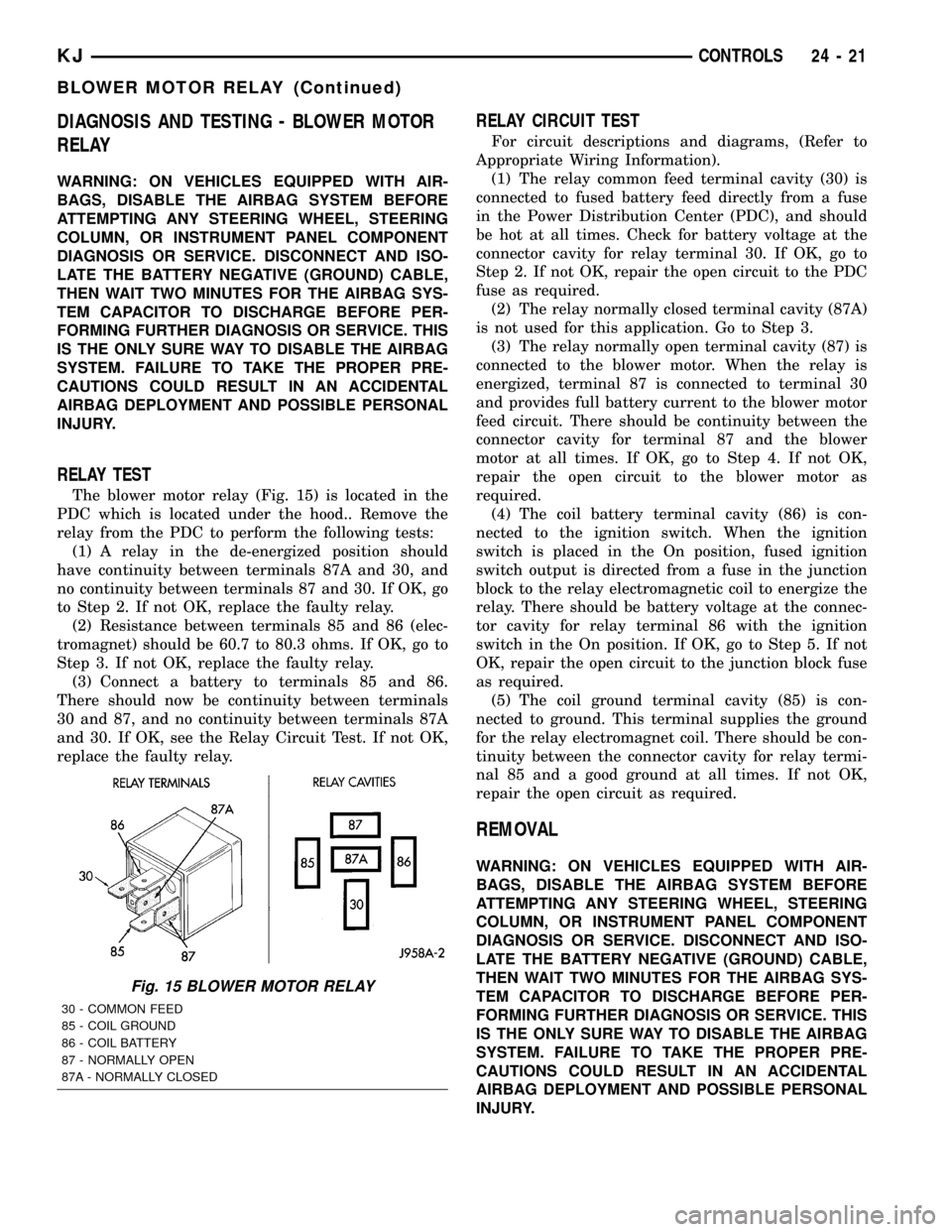

RELAY TEST

The blower motor relay (Fig. 15) is located in the

PDC which is located under the hood.. Remove the

relay from the PDC to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 60.7 to 80.3 ohms. If OK, go to

Step 3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, see the Relay Circuit Test. If not OK,

replace the faulty relay.

RELAY CIRCUIT TEST

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

(1) The relay common feed terminal cavity (30) is

connected to fused battery feed directly from a fuse

in the Power Distribution Center (PDC), and should

be hot at all times. Check for battery voltage at the

connector cavity for relay terminal 30. If OK, go to

Step 2. If not OK, repair the open circuit to the PDC

fuse as required.

(2) The relay normally closed terminal cavity (87A)

is not used for this application. Go to Step 3.

(3) The relay normally open terminal cavity (87) is

connected to the blower motor. When the relay is

energized, terminal 87 is connected to terminal 30

and provides full battery current to the blower motor

feed circuit. There should be continuity between the

connector cavity for terminal 87 and the blower

motor at all times. If OK, go to Step 4. If not OK,

repair the open circuit to the blower motor as

required.

(4) The coil battery terminal cavity (86) is con-

nected to the ignition switch. When the ignition

switch is placed in the On position, fused ignition

switch output is directed from a fuse in the junction

block to the relay electromagnetic coil to energize the

relay. There should be battery voltage at the connec-

tor cavity for relay terminal 86 with the ignition

switch in the On position. If OK, go to Step 5. If not

OK, repair the open circuit to the junction block fuse

as required.

(5) The coil ground terminal cavity (85) is con-

nected to ground. This terminal supplies the ground

for the relay electromagnet coil. There should be con-

tinuity between the connector cavity for relay termi-

nal 85 and a good ground at all times. If not OK,

repair the open circuit as required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Fig. 15 BLOWER MOTOR RELAY

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJCONTROLS 24 - 21

BLOWER MOTOR RELAY (Continued)

Page 1675 of 1803

BLOWER MOTOR SWITCH

DESCRIPTION

The heater-only or A/C Heater blower motor is con-

trolled by a four position rotary-type blower motor

switch, mounted in the A/C Heater control panel. The

switch allows the selection of one of four blower

motor speeds, but can only be turned off by selecting

the Off position with the heater-only or A/C Heater

mode control switch knob.

OPERATION

The blower motor switch directs the blower motor

ground path through the mode control switch to the

blower motor resistor, or directly to ground, as

required to achieve the selected blower motor speed.

The blower motor switch cannot be repaired and, if

faulty or damaged, the entire heater-only or A/C

Heater control unit must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

SWITCH

For circuit descriptions and diagrams, (Refer to

Appropriate Wiring Information).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check for battery voltage at the fuse in the

Power Distribution Center (PDC). If OK, go to Step

2. If not OK, repair the shorted circuit or component

as required and replace the faulty fuse.

(2) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the A/C Heater control from the instrument

panel. Check for continuity between the ground cir-

cuit cavity of the A/C Heater control wire harness

connector and a good ground. There should be conti-

nuity. If OK, go to Step 3. If not OK, repair the open

circuit to ground as required.

(3) With the A/C Heater control wire harness con-

nector unplugged, place the A/C Heater mode control

switch knob in any position except the Off position.

Check for continuity between the ground circuit ter-minal and each of the blower motor driver circuit ter-

minals of the A/C Heater control as you move the

blower motor switch knob to each of the four speed

positions. There should be continuity at each driver

circuit terminal in only one blower motor switch

speed position. If OK, test and repair the blower

driver circuits between the A/C Heater control con-

nector and the blower motor resistor as required. If

not OK, replace the faulty A/C Heater control unit.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The blower motor switch cannot be repaired and, if

faulty or damaged, the entire heater-only or A/C

Heater control unit must be replaced. (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS/A/C

HEATER CONTROL - REMOVAL)

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) The blower motor switch cannot be repaired

and, if faulty or damaged the entire heater-only or

A/C heater control unit must be replaced(Refer to 24

- HEATING & AIR CONDITIONING/CONTROLS/

A/C HEATER CONTROL - INSTALLATION).

KJCONTROLS 24 - 23