Ignition coil JEEP LIBERTY 2002 KJ / 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 503 of 1803

Relays conforming to the ISO specifications have

common physical dimensions, current capacities, ter-

minal patterns, and terminal functions. The relay is

contained within a small, rectangular, molded plastic

housing and is connected to all of the required inputs

and outputs by five integral male spade-type termi-

nals that extend from the bottom of the relay base.

The trailer tow relays cannot be adjusted or

repaired and, if faulty or damaged, the inoperative

relay must be replaced.

OPERATION

The trailer tow relays are electromechanical

switches. The relays each use an input from the cir-

cuit that they isolate from the trailer wiring to con-

trol a high current output to the trailer. The movable

common feed contact point is held against the fixed

normally closed contact point by spring pressure.

When the relay coil is energized, an electromagnetic

field is produced by the coil windings. This electro-

magnetic field draws the movable relay contact point

away from the fixed normally closed contact point,

and holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The terminals of each trailer tow relay are con-

nected to the vehicle electrical system through a con-nector bank in the rear lighting wire harness above

the right rear wheelhouse. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds. The trailer tow relays can be diagnosed

using conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - TRAILER TOW

RELAY

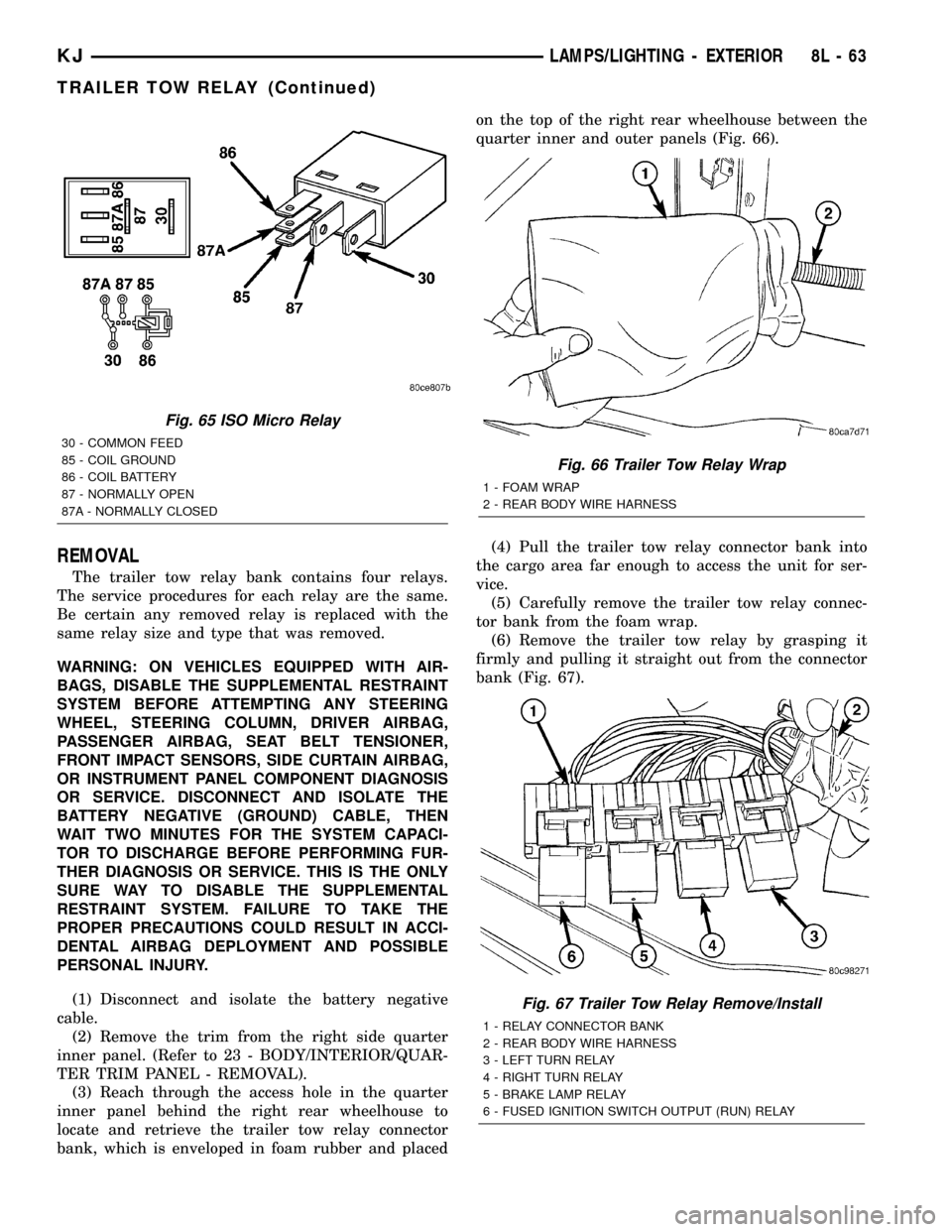

The trailer tow relays (Fig. 65) are located in a

connector bank above the right rear wheelhouse.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Remove the trailer tow relay from the connec-

tor bank. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/TRAILER TOW RELAY -

REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, test the input and output circuits of

the relay. Refer to the appropriate wiring informa-

tion.

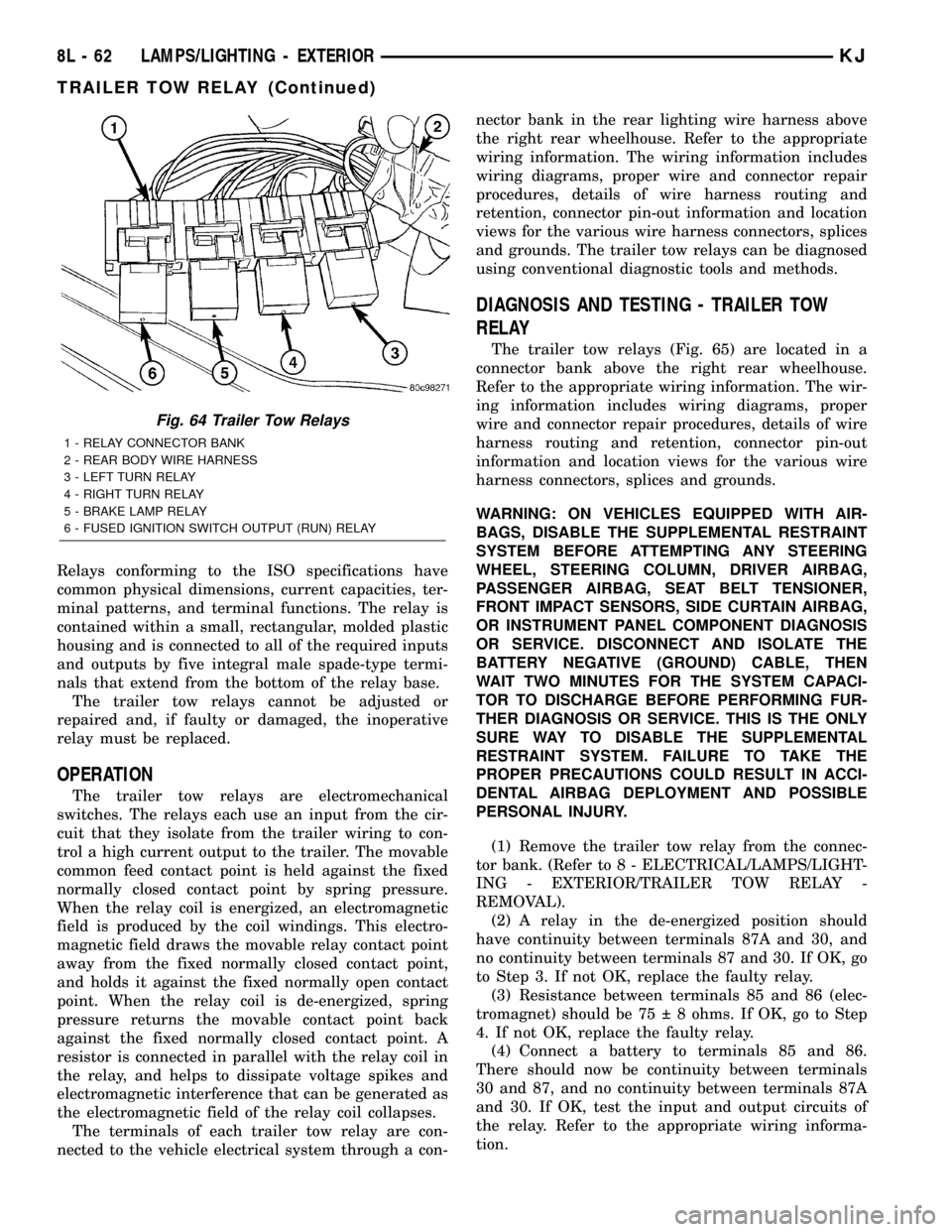

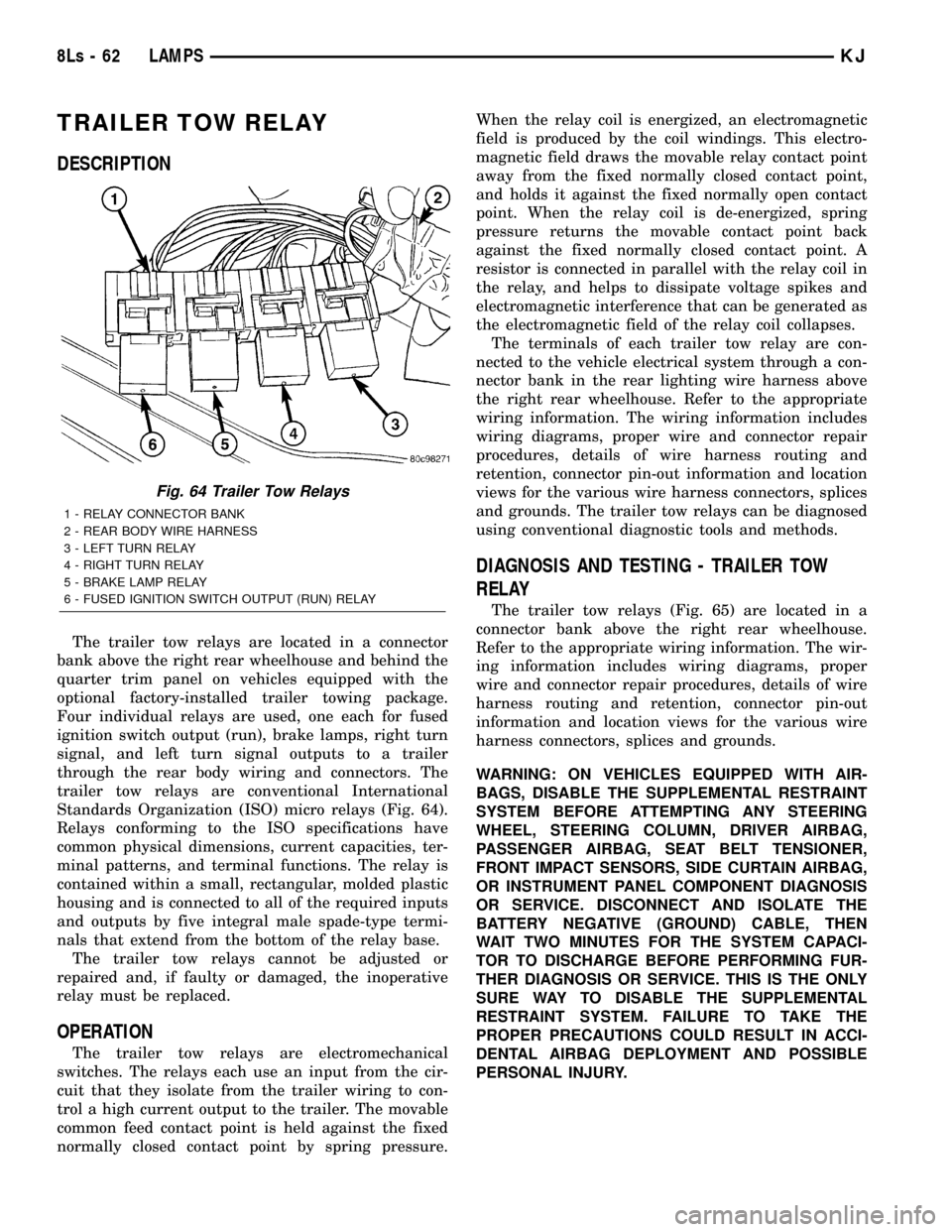

Fig. 64 Trailer Tow Relays

1 - RELAY CONNECTOR BANK

2 - REAR BODY WIRE HARNESS

3 - LEFT TURN RELAY

4 - RIGHT TURN RELAY

5 - BRAKE LAMP RELAY

6 - FUSED IGNITION SWITCH OUTPUT (RUN) RELAY

8L - 62 LAMPS/LIGHTING - EXTERIORKJ

TRAILER TOW RELAY (Continued)

Page 504 of 1803

REMOVAL

The trailer tow relay bank contains four relays.

The service procedures for each relay are the same.

Be certain any removed relay is replaced with the

same relay size and type that was removed.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim from the right side quarter

inner panel. (Refer to 23 - BODY/INTERIOR/QUAR-

TER TRIM PANEL - REMOVAL).

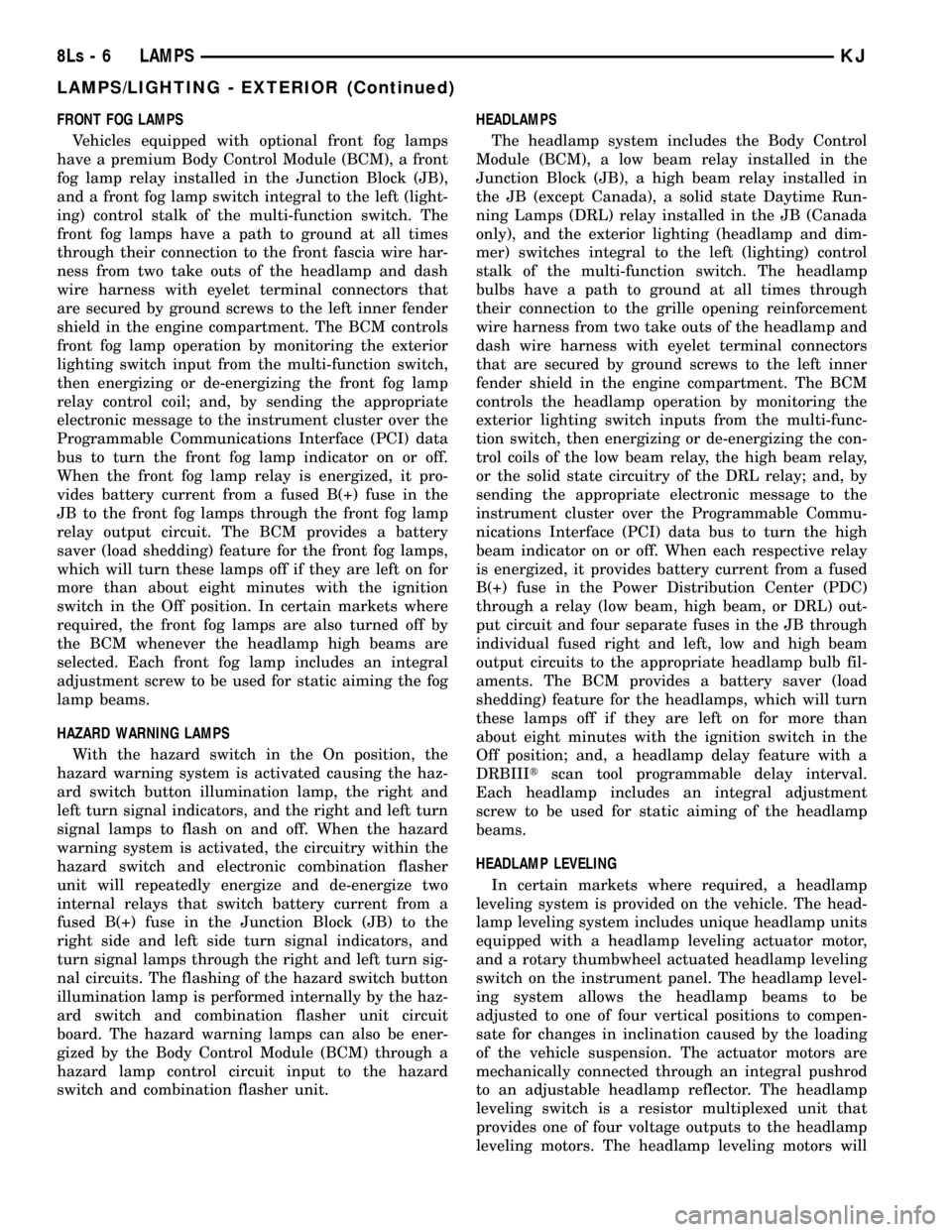

(3) Reach through the access hole in the quarter

inner panel behind the right rear wheelhouse to

locate and retrieve the trailer tow relay connector

bank, which is enveloped in foam rubber and placedon the top of the right rear wheelhouse between the

quarter inner and outer panels (Fig. 66).

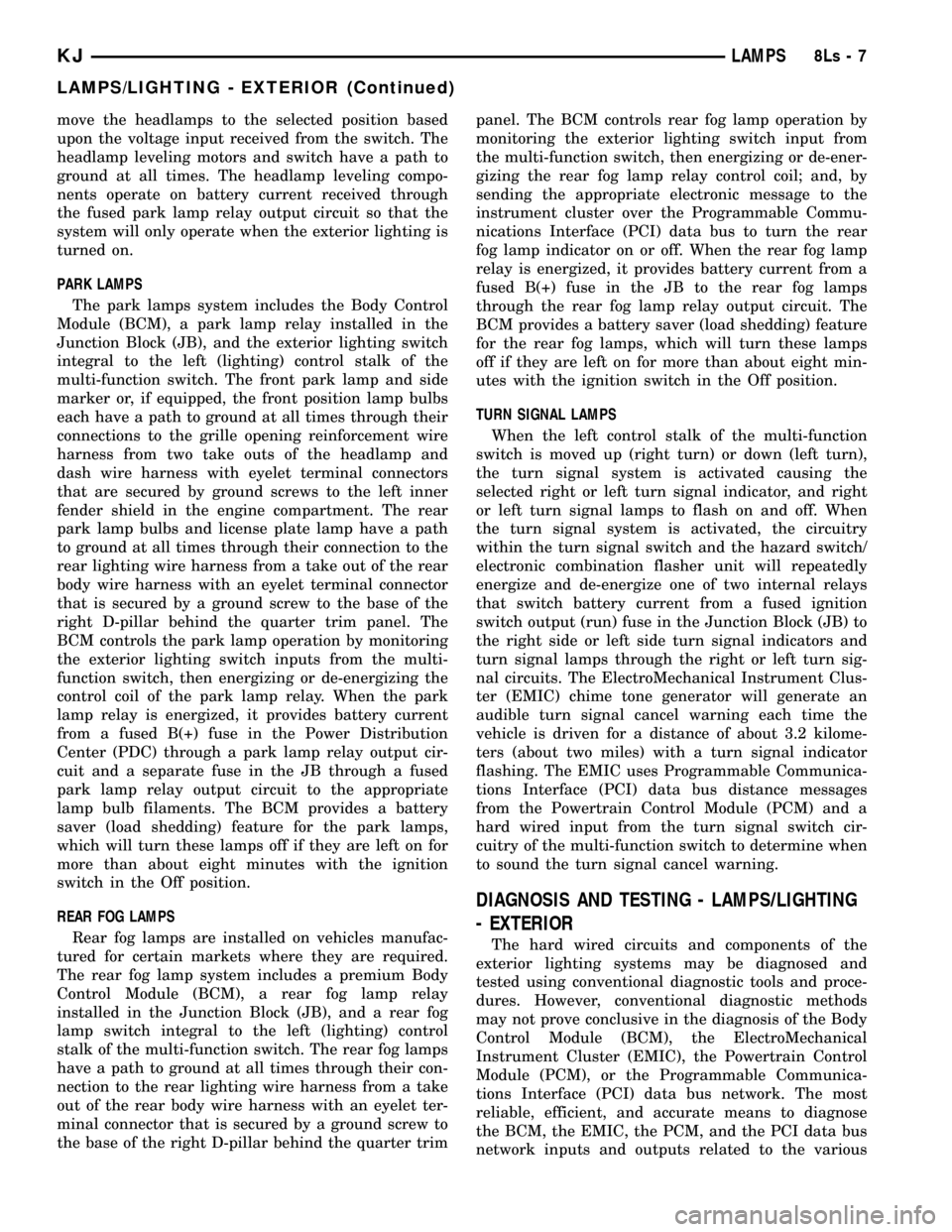

(4) Pull the trailer tow relay connector bank into

the cargo area far enough to access the unit for ser-

vice.

(5) Carefully remove the trailer tow relay connec-

tor bank from the foam wrap.

(6) Remove the trailer tow relay by grasping it

firmly and pulling it straight out from the connector

bank (Fig. 67).

Fig. 65 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

Fig. 66 Trailer Tow Relay Wrap

1 - FOAM WRAP

2 - REAR BODY WIRE HARNESS

Fig. 67 Trailer Tow Relay Remove/Install

1 - RELAY CONNECTOR BANK

2 - REAR BODY WIRE HARNESS

3 - LEFT TURN RELAY

4 - RIGHT TURN RELAY

5 - BRAKE LAMP RELAY

6 - FUSED IGNITION SWITCH OUTPUT (RUN) RELAY

KJLAMPS/LIGHTING - EXTERIOR 8L - 63

TRAILER TOW RELAY (Continued)

Page 531 of 1803

FRONT FOG LAMPS

Vehicles equipped with optional front fog lamps

have a premium Body Control Module (BCM), a front

fog lamp relay installed in the Junction Block (JB),

and a front fog lamp switch integral to the left (light-

ing) control stalk of the multi-function switch. The

front fog lamps have a path to ground at all times

through their connection to the front fascia wire har-

ness from two take outs of the headlamp and dash

wire harness with eyelet terminal connectors that

are secured by ground screws to the left inner fender

shield in the engine compartment. The BCM controls

front fog lamp operation by monitoring the exterior

lighting switch input from the multi-function switch,

then energizing or de-energizing the front fog lamp

relay control coil; and, by sending the appropriate

electronic message to the instrument cluster over the

Programmable Communications Interface (PCI) data

bus to turn the front fog lamp indicator on or off.

When the front fog lamp relay is energized, it pro-

vides battery current from a fused B(+) fuse in the

JB to the front fog lamps through the front fog lamp

relay output circuit. The BCM provides a battery

saver (load shedding) feature for the front fog lamps,

which will turn these lamps off if they are left on for

more than about eight minutes with the ignition

switch in the Off position. In certain markets where

required, the front fog lamps are also turned off by

the BCM whenever the headlamp high beams are

selected. Each front fog lamp includes an integral

adjustment screw to be used for static aiming the fog

lamp beams.

HAZARD WARNING LAMPS

With the hazard switch in the On position, the

hazard warning system is activated causing the haz-

ard switch button illumination lamp, the right and

left turn signal indicators, and the right and left turn

signal lamps to flash on and off. When the hazard

warning system is activated, the circuitry within the

hazard switch and electronic combination flasher

unit will repeatedly energize and de-energize two

internal relays that switch battery current from a

fused B(+) fuse in the Junction Block (JB) to the

right side and left side turn signal indicators, and

turn signal lamps through the right and left turn sig-

nal circuits. The flashing of the hazard switch button

illumination lamp is performed internally by the haz-

ard switch and combination flasher unit circuit

board. The hazard warning lamps can also be ener-

gized by the Body Control Module (BCM) through a

hazard lamp control circuit input to the hazard

switch and combination flasher unit.HEADLAMPS

The headlamp system includes the Body Control

Module (BCM), a low beam relay installed in the

Junction Block (JB), a high beam relay installed in

the JB (except Canada), a solid state Daytime Run-

ning Lamps (DRL) relay installed in the JB (Canada

only), and the exterior lighting (headlamp and dim-

mer) switches integral to the left (lighting) control

stalk of the multi-function switch. The headlamp

bulbs have a path to ground at all times through

their connection to the grille opening reinforcement

wire harness from two take outs of the headlamp and

dash wire harness with eyelet terminal connectors

that are secured by ground screws to the left inner

fender shield in the engine compartment. The BCM

controls the headlamp operation by monitoring the

exterior lighting switch inputs from the multi-func-

tion switch, then energizing or de-energizing the con-

trol coils of the low beam relay, the high beam relay,

or the solid state circuitry of the DRL relay; and, by

sending the appropriate electronic message to the

instrument cluster over the Programmable Commu-

nications Interface (PCI) data bus to turn the high

beam indicator on or off. When each respective relay

is energized, it provides battery current from a fused

B(+) fuse in the Power Distribution Center (PDC)

through a relay (low beam, high beam, or DRL) out-

put circuit and four separate fuses in the JB through

individual fused right and left, low and high beam

output circuits to the appropriate headlamp bulb fil-

aments. The BCM provides a battery saver (load

shedding) feature for the headlamps, which will turn

these lamps off if they are left on for more than

about eight minutes with the ignition switch in the

Off position; and, a headlamp delay feature with a

DRBIIItscan tool programmable delay interval.

Each headlamp includes an integral adjustment

screw to be used for static aiming of the headlamp

beams.

HEADLAMP LEVELING

In certain markets where required, a headlamp

leveling system is provided on the vehicle. The head-

lamp leveling system includes unique headlamp units

equipped with a headlamp leveling actuator motor,

and a rotary thumbwheel actuated headlamp leveling

switch on the instrument panel. The headlamp level-

ing system allows the headlamp beams to be

adjusted to one of four vertical positions to compen-

sate for changes in inclination caused by the loading

of the vehicle suspension. The actuator motors are

mechanically connected through an integral pushrod

to an adjustable headlamp reflector. The headlamp

leveling switch is a resistor multiplexed unit that

provides one of four voltage outputs to the headlamp

leveling motors. The headlamp leveling motors will

8Ls - 6 LAMPSKJ

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 532 of 1803

move the headlamps to the selected position based

upon the voltage input received from the switch. The

headlamp leveling motors and switch have a path to

ground at all times. The headlamp leveling compo-

nents operate on battery current received through

the fused park lamp relay output circuit so that the

system will only operate when the exterior lighting is

turned on.

PARK LAMPS

The park lamps system includes the Body Control

Module (BCM), a park lamp relay installed in the

Junction Block (JB), and the exterior lighting switch

integral to the left (lighting) control stalk of the

multi-function switch. The front park lamp and side

marker or, if equipped, the front position lamp bulbs

each have a path to ground at all times through their

connections to the grille opening reinforcement wire

harness from two take outs of the headlamp and

dash wire harness with eyelet terminal connectors

that are secured by ground screws to the left inner

fender shield in the engine compartment. The rear

park lamp bulbs and license plate lamp have a path

to ground at all times through their connection to the

rear lighting wire harness from a take out of the rear

body wire harness with an eyelet terminal connector

that is secured by a ground screw to the base of the

right D-pillar behind the quarter trim panel. The

BCM controls the park lamp operation by monitoring

the exterior lighting switch inputs from the multi-

function switch, then energizing or de-energizing the

control coil of the park lamp relay. When the park

lamp relay is energized, it provides battery current

from a fused B(+) fuse in the Power Distribution

Center (PDC) through a park lamp relay output cir-

cuit and a separate fuse in the JB through a fused

park lamp relay output circuit to the appropriate

lamp bulb filaments. The BCM provides a battery

saver (load shedding) feature for the park lamps,

which will turn these lamps off if they are left on for

more than about eight minutes with the ignition

switch in the Off position.

REAR FOG LAMPS

Rear fog lamps are installed on vehicles manufac-

tured for certain markets where they are required.

The rear fog lamp system includes a premium Body

Control Module (BCM), a rear fog lamp relay

installed in the Junction Block (JB), and a rear fog

lamp switch integral to the left (lighting) control

stalk of the multi-function switch. The rear fog lamps

have a path to ground at all times through their con-

nection to the rear lighting wire harness from a take

out of the rear body wire harness with an eyelet ter-

minal connector that is secured by a ground screw to

the base of the right D-pillar behind the quarter trimpanel. The BCM controls rear fog lamp operation by

monitoring the exterior lighting switch input from

the multi-function switch, then energizing or de-ener-

gizing the rear fog lamp relay control coil; and, by

sending the appropriate electronic message to the

instrument cluster over the Programmable Commu-

nications Interface (PCI) data bus to turn the rear

fog lamp indicator on or off. When the rear fog lamp

relay is energized, it provides battery current from a

fused B(+) fuse in the JB to the rear fog lamps

through the rear fog lamp relay output circuit. The

BCM provides a battery saver (load shedding) feature

for the rear fog lamps, which will turn these lamps

off if they are left on for more than about eight min-

utes with the ignition switch in the Off position.

TURN SIGNAL LAMPS

When the left control stalk of the multi-function

switch is moved up (right turn) or down (left turn),

the turn signal system is activated causing the

selected right or left turn signal indicator, and right

or left turn signal lamps to flash on and off. When

the turn signal system is activated, the circuitry

within the turn signal switch and the hazard switch/

electronic combination flasher unit will repeatedly

energize and de-energize one of two internal relays

that switch battery current from a fused ignition

switch output (run) fuse in the Junction Block (JB) to

the right side or left side turn signal indicators and

turn signal lamps through the right or left turn sig-

nal circuits. The ElectroMechanical Instrument Clus-

ter (EMIC) chime tone generator will generate an

audible turn signal cancel warning each time the

vehicle is driven for a distance of about 3.2 kilome-

ters (about two miles) with a turn signal indicator

flashing. The EMIC uses Programmable Communica-

tions Interface (PCI) data bus distance messages

from the Powertrain Control Module (PCM) and a

hard wired input from the turn signal switch cir-

cuitry of the multi-function switch to determine when

to sound the turn signal cancel warning.

DIAGNOSIS AND TESTING - LAMPS/LIGHTING

- EXTERIOR

The hard wired circuits and components of the

exterior lighting systems may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the Body

Control Module (BCM), the ElectroMechanical

Instrument Cluster (EMIC), the Powertrain Control

Module (PCM), or the Programmable Communica-

tions Interface (PCI) data bus network. The most

reliable, efficient, and accurate means to diagnose

the BCM, the EMIC, the PCM, and the PCI data bus

network inputs and outputs related to the various

KJLAMPS8Ls-7

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 587 of 1803

TRAILER TOW RELAY

DESCRIPTION

The trailer tow relays are located in a connector

bank above the right rear wheelhouse and behind the

quarter trim panel on vehicles equipped with the

optional factory-installed trailer towing package.

Four individual relays are used, one each for fused

ignition switch output (run), brake lamps, right turn

signal, and left turn signal outputs to a trailer

through the rear body wiring and connectors. The

trailer tow relays are conventional International

Standards Organization (ISO) micro relays (Fig. 64).

Relays conforming to the ISO specifications have

common physical dimensions, current capacities, ter-

minal patterns, and terminal functions. The relay is

contained within a small, rectangular, molded plastic

housing and is connected to all of the required inputs

and outputs by five integral male spade-type termi-

nals that extend from the bottom of the relay base.

The trailer tow relays cannot be adjusted or

repaired and, if faulty or damaged, the inoperative

relay must be replaced.

OPERATION

The trailer tow relays are electromechanical

switches. The relays each use an input from the cir-

cuit that they isolate from the trailer wiring to con-

trol a high current output to the trailer. The movable

common feed contact point is held against the fixed

normally closed contact point by spring pressure.When the relay coil is energized, an electromagnetic

field is produced by the coil windings. This electro-

magnetic field draws the movable relay contact point

away from the fixed normally closed contact point,

and holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The terminals of each trailer tow relay are con-

nected to the vehicle electrical system through a con-

nector bank in the rear lighting wire harness above

the right rear wheelhouse. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds. The trailer tow relays can be diagnosed

using conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - TRAILER TOW

RELAY

The trailer tow relays (Fig. 65) are located in a

connector bank above the right rear wheelhouse.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

Fig. 64 Trailer Tow Relays

1 - RELAY CONNECTOR BANK

2 - REAR BODY WIRE HARNESS

3 - LEFT TURN RELAY

4 - RIGHT TURN RELAY

5 - BRAKE LAMP RELAY

6 - FUSED IGNITION SWITCH OUTPUT (RUN) RELAY

8Ls - 62 LAMPSKJ

Page 724 of 1803

of the washer pump/motor unit is connected to the

front nipple.

(10) Engage the ªWº clip that secures the front

bumper fascia to the front bumper support. This clip

is located behind the bumper support and below the

right front lamp unit.

(11) Reinstall the splash shield into the right front

fender wheel house. (Refer to 23 - BODY/EXTERIOR/

WHEELHOUSE SPLASH SHIELD - INSTALLA-

TION).

(12) Lower the vehicle.

(13) Install and tighten the screw that secures the

washer reservoir filler neck support to upper radiator

crossmember (Fig. 23). Tighten the screw to 7 N´m

(65 in. lbs.).

(14) Reinstall the air cleaner housing onto the top

of the right front fender wheel house. (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

ELEMENT - INSTALLATION).

(15) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(16) Reconnect the battery negative cable.

WIPER HIGH/LOW RELAY

DESCRIPTION

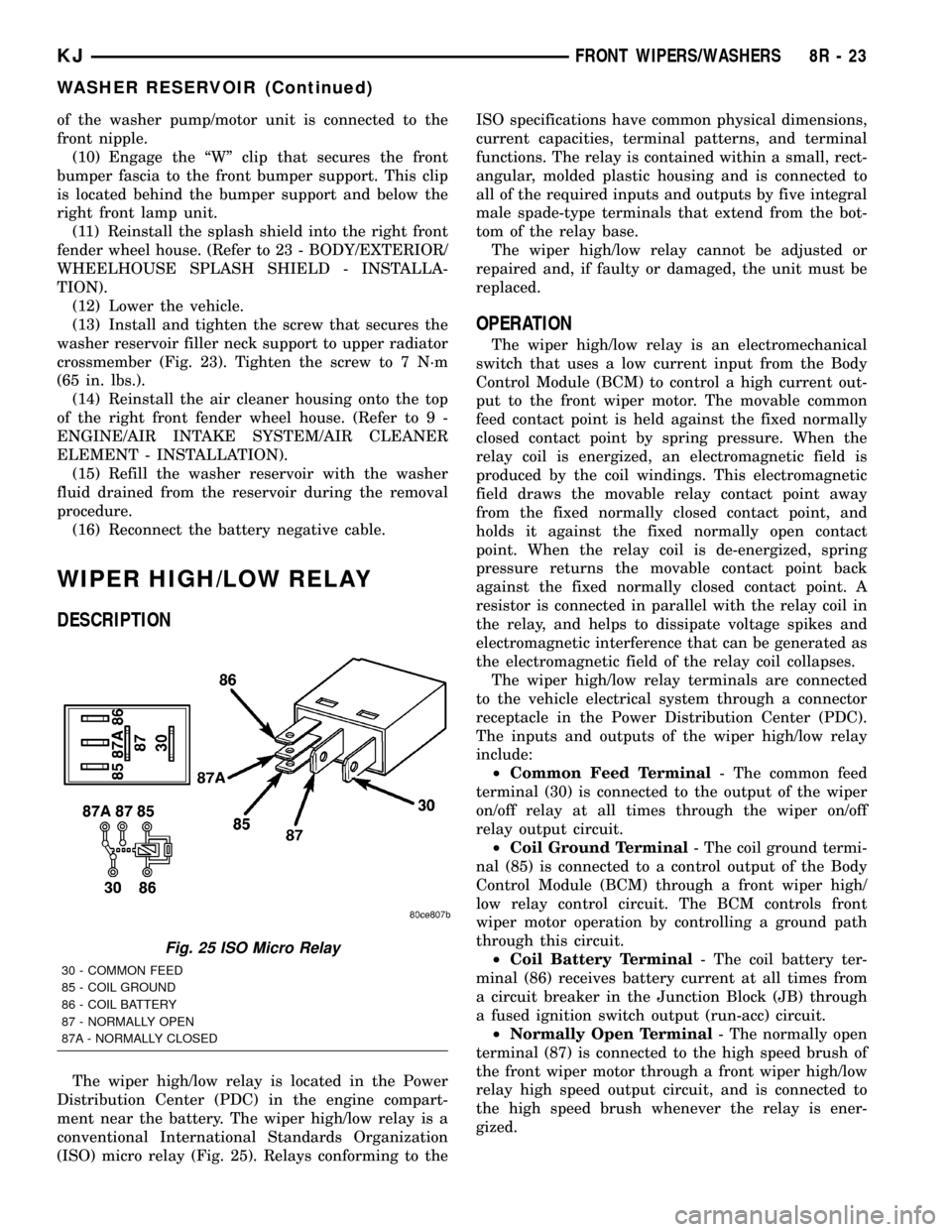

The wiper high/low relay is located in the Power

Distribution Center (PDC) in the engine compart-

ment near the battery. The wiper high/low relay is a

conventional International Standards Organization

(ISO) micro relay (Fig. 25). Relays conforming to theISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions. The relay is contained within a small, rect-

angular, molded plastic housing and is connected to

all of the required inputs and outputs by five integral

male spade-type terminals that extend from the bot-

tom of the relay base.

The wiper high/low relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The wiper high/low relay is an electromechanical

switch that uses a low current input from the Body

Control Module (BCM) to control a high current out-

put to the front wiper motor. The movable common

feed contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The wiper high/low relay terminals are connected

to the vehicle electrical system through a connector

receptacle in the Power Distribution Center (PDC).

The inputs and outputs of the wiper high/low relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the output of the wiper

on/off relay at all times through the wiper on/off

relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Body

Control Module (BCM) through a front wiper high/

low relay control circuit. The BCM controls front

wiper motor operation by controlling a ground path

through this circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a circuit breaker in the Junction Block (JB) through

a fused ignition switch output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) is connected to the high speed brush of

the front wiper motor through a front wiper high/low

relay high speed output circuit, and is connected to

the high speed brush whenever the relay is ener-

gized.

Fig. 25 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJFRONT WIPERS/WASHERS 8R - 23

WASHER RESERVOIR (Continued)

Page 726 of 1803

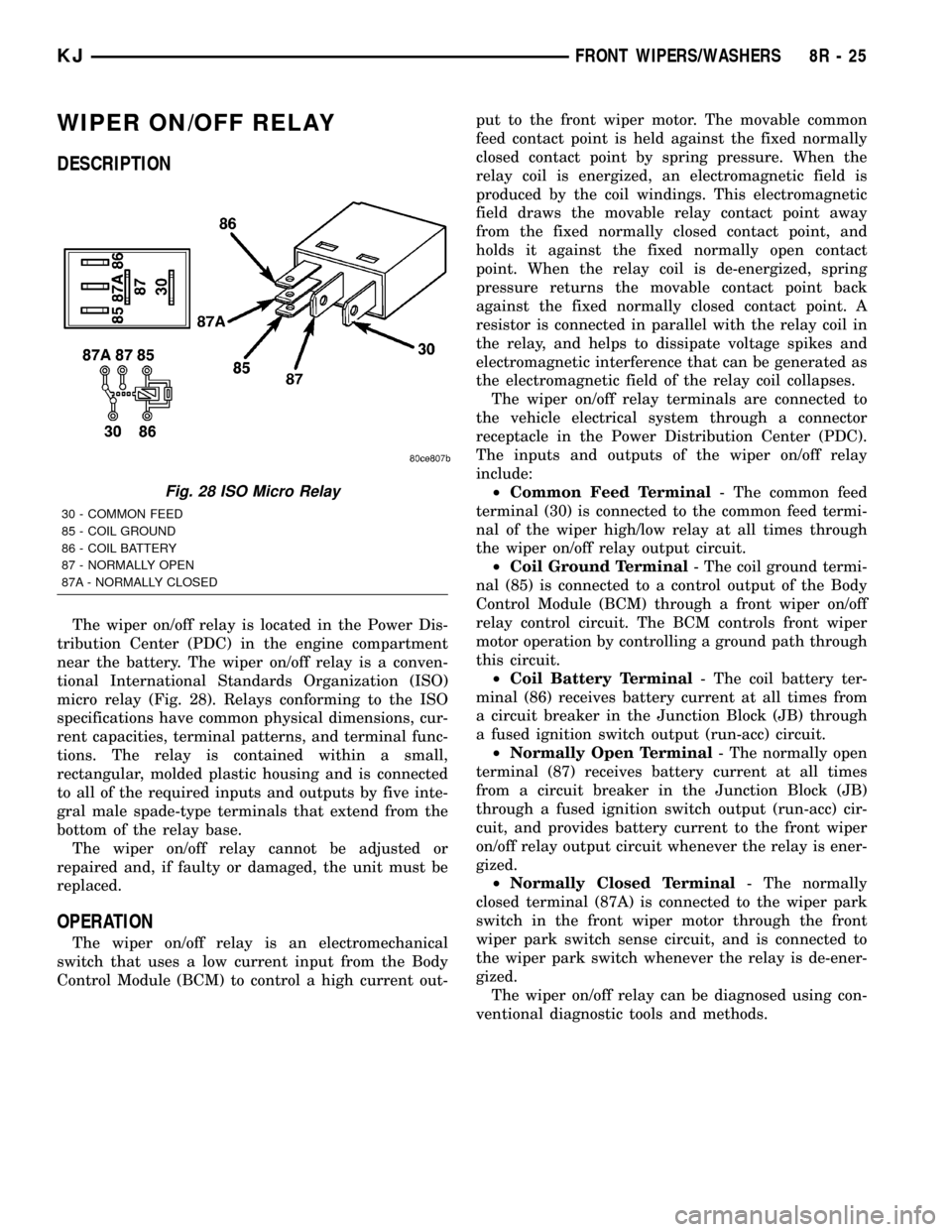

WIPER ON/OFF RELAY

DESCRIPTION

The wiper on/off relay is located in the Power Dis-

tribution Center (PDC) in the engine compartment

near the battery. The wiper on/off relay is a conven-

tional International Standards Organization (ISO)

micro relay (Fig. 28). Relays conforming to the ISO

specifications have common physical dimensions, cur-

rent capacities, terminal patterns, and terminal func-

tions. The relay is contained within a small,

rectangular, molded plastic housing and is connected

to all of the required inputs and outputs by five inte-

gral male spade-type terminals that extend from the

bottom of the relay base.

The wiper on/off relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The wiper on/off relay is an electromechanical

switch that uses a low current input from the Body

Control Module (BCM) to control a high current out-put to the front wiper motor. The movable common

feed contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The wiper on/off relay terminals are connected to

the vehicle electrical system through a connector

receptacle in the Power Distribution Center (PDC).

The inputs and outputs of the wiper on/off relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the common feed termi-

nal of the wiper high/low relay at all times through

the wiper on/off relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Body

Control Module (BCM) through a front wiper on/off

relay control circuit. The BCM controls front wiper

motor operation by controlling a ground path through

this circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a circuit breaker in the Junction Block (JB) through

a fused ignition switch output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) receives battery current at all times

from a circuit breaker in the Junction Block (JB)

through a fused ignition switch output (run-acc) cir-

cuit, and provides battery current to the front wiper

on/off relay output circuit whenever the relay is ener-

gized.

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to the wiper park

switch in the front wiper motor through the front

wiper park switch sense circuit, and is connected to

the wiper park switch whenever the relay is de-ener-

gized.

The wiper on/off relay can be diagnosed using con-

ventional diagnostic tools and methods.

Fig. 28 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJFRONT WIPERS/WASHERS 8R - 25

Page 762 of 1803

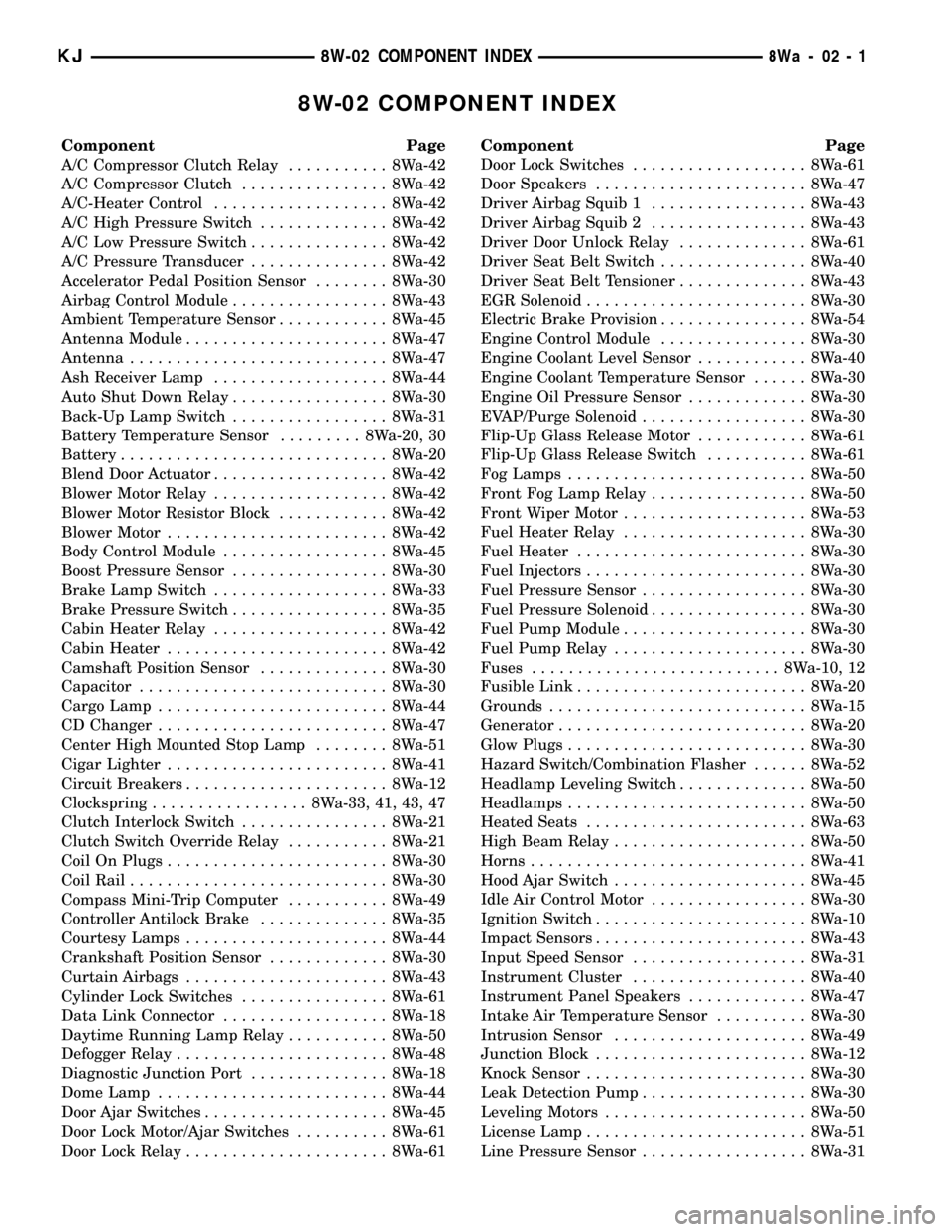

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch Relay........... 8Wa-42

A/C Compressor Clutch................ 8Wa-42

A/C-Heater Control................... 8Wa-42

A/C High Pressure Switch.............. 8Wa-42

A/C Low Pressure Switch............... 8Wa-42

A/C Pressure Transducer............... 8Wa-42

Accelerator Pedal Position Sensor........ 8Wa-30

Airbag Control Module................. 8Wa-43

Ambient Temperature Sensor............ 8Wa-45

Antenna Module...................... 8Wa-47

Antenna............................ 8Wa-47

Ash Receiver Lamp................... 8Wa-44

Auto Shut Down Relay................. 8Wa-30

Back-Up Lamp Switch................. 8Wa-31

Battery Temperature Sensor......... 8Wa-20, 30

Battery............................. 8Wa-20

Blend Door Actuator................... 8Wa-42

Blower Motor Relay................... 8Wa-42

Blower Motor Resistor Block............ 8Wa-42

Blower Motor........................ 8Wa-42

Body Control Module.................. 8Wa-45

Boost Pressure Sensor................. 8Wa-30

Brake Lamp Switch................... 8Wa-33

Brake Pressure Switch................. 8Wa-35

Cabin Heater Relay................... 8Wa-42

Cabin Heater........................ 8Wa-42

Camshaft Position Sensor.............. 8Wa-30

Capacitor........................... 8Wa-30

Cargo Lamp......................... 8Wa-44

CD Changer......................... 8Wa-47

Center High Mounted Stop Lamp........ 8Wa-51

Cigar Lighter........................ 8Wa-41

Circuit Breakers...................... 8Wa-12

Clockspring................. 8Wa-33, 41, 43, 47

Clutch Interlock Switch................ 8Wa-21

Clutch Switch Override Relay........... 8Wa-21

Coil On Plugs........................ 8Wa-30

Coil Rail............................ 8Wa-30

Compass Mini-Trip Computer........... 8Wa-49

Controller Antilock Brake.............. 8Wa-35

Courtesy Lamps...................... 8Wa-44

Crankshaft Position Sensor............. 8Wa-30

Curtain Airbags...................... 8Wa-43

Cylinder Lock Switches................ 8Wa-61

Data Link Connector.................. 8Wa-18

Daytime Running Lamp Relay........... 8Wa-50

Defogger Relay....................... 8Wa-48

Diagnostic Junction Port............... 8Wa-18

Dome Lamp......................... 8Wa-44

Door Ajar Switches.................... 8Wa-45

Door Lock Motor/Ajar Switches.......... 8Wa-61

Door Lock Relay...................... 8Wa-61Component Page

Door Lock Switches................... 8Wa-61

Door Speakers....................... 8Wa-47

Driver Airbag Squib 1................. 8Wa-43

Driver Airbag Squib 2................. 8Wa-43

Driver Door Unlock Relay.............. 8Wa-61

Driver Seat Belt Switch................ 8Wa-40

Driver Seat Belt Tensioner.............. 8Wa-43

EGR Solenoid........................ 8Wa-30

Electric Brake Provision................ 8Wa-54

Engine Control Module................ 8Wa-30

Engine Coolant Level Sensor............ 8Wa-40

Engine Coolant Temperature Sensor...... 8Wa-30

Engine Oil Pressure Sensor............. 8Wa-30

EVAP/Purge Solenoid.................. 8Wa-30

Flip-Up Glass Release Motor............ 8Wa-61

Flip-Up Glass Release Switch........... 8Wa-61

Fog Lamps.......................... 8Wa-50

Front Fog Lamp Relay................. 8Wa-50

Front Wiper Motor.................... 8Wa-53

Fuel Heater Relay.................... 8Wa-30

Fuel Heater......................... 8Wa-30

Fuel Injectors........................ 8Wa-30

Fuel Pressure Sensor.................. 8Wa-30

Fuel Pressure Solenoid................. 8Wa-30

Fuel Pump Module.................... 8Wa-30

Fuel Pump Relay..................... 8Wa-30

Fuses........................... 8Wa-10, 12

Fusible Link......................... 8Wa-20

Grounds............................ 8Wa-15

Generator........................... 8Wa-20

Glow Plugs.......................... 8Wa-30

Hazard Switch/Combination Flasher...... 8Wa-52

Headlamp Leveling Switch.............. 8Wa-50

Headlamps.......................... 8Wa-50

Heated Seats........................ 8Wa-63

High Beam Relay..................... 8Wa-50

Horns.............................. 8Wa-41

Hood Ajar Switch..................... 8Wa-45

Idle Air Control Motor................. 8Wa-30

Ignition Switch....................... 8Wa-10

Impact Sensors....................... 8Wa-43

Input Speed Sensor................... 8Wa-31

Instrument Cluster................... 8Wa-40

Instrument Panel Speakers............. 8Wa-47

Intake Air Temperature Sensor.......... 8Wa-30

Intrusion Sensor..................... 8Wa-49

Junction Block....................... 8Wa-12

Knock Sensor........................ 8Wa-30

Leak Detection Pump.................. 8Wa-30

Leveling Motors...................... 8Wa-50

License Lamp........................ 8Wa-51

Line Pressure Sensor.................. 8Wa-31

KJ8W-02 COMPONENT INDEX8Wa-02-1

Page 764 of 1803

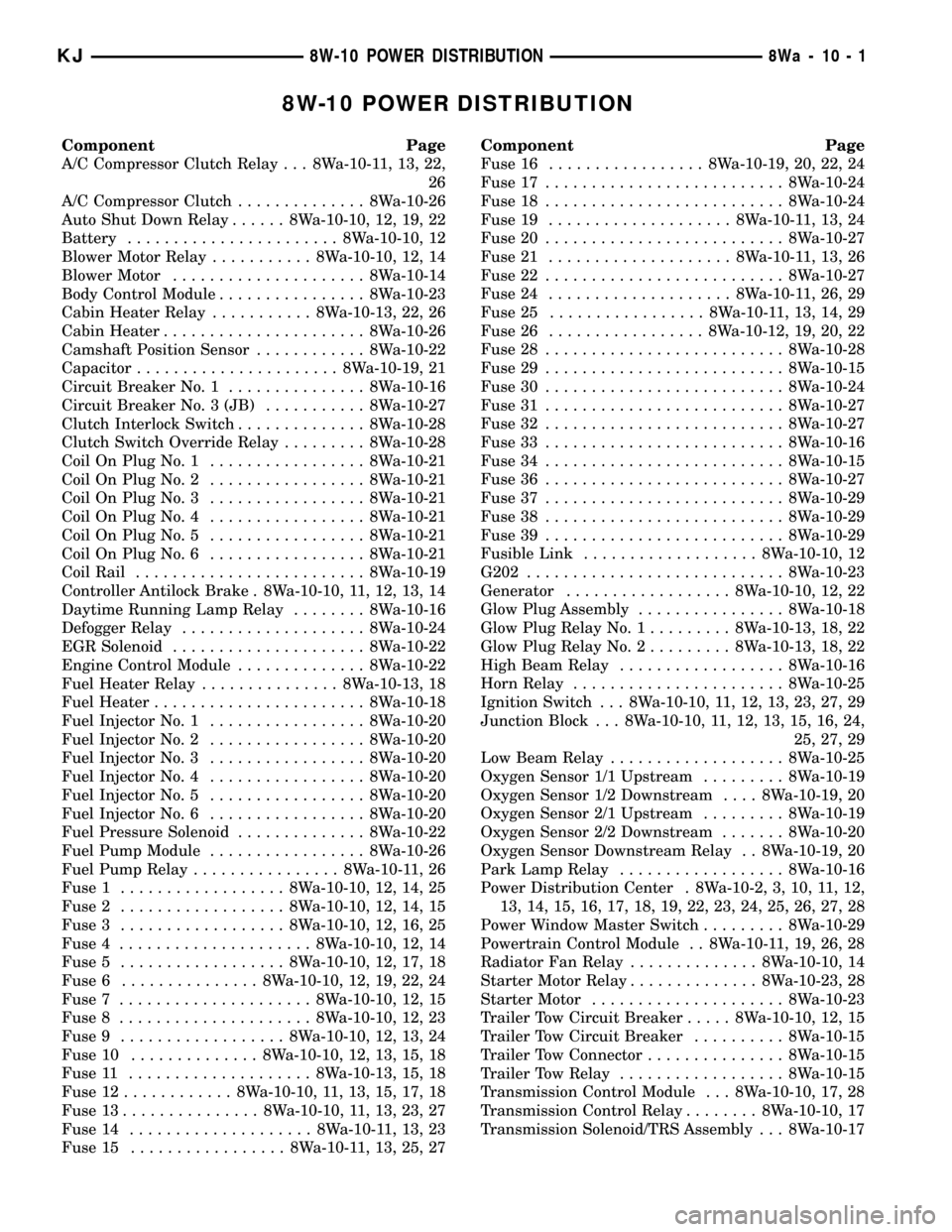

8W-10 POWER DISTRIBUTION

Component Page

A/C Compressor Clutch Relay . . . 8Wa-10-11, 13, 22,

26

A/C Compressor Clutch.............. 8Wa-10-26

Auto Shut Down Relay...... 8Wa-10-10, 12, 19, 22

Battery....................... 8Wa-10-10, 12

Blower Motor Relay........... 8Wa-10-10, 12, 14

Blower Motor..................... 8Wa-10-14

Body Control Module................ 8Wa-10-23

Cabin Heater Relay........... 8Wa-10-13, 22, 26

Cabin Heater...................... 8Wa-10-26

Camshaft Position Sensor............ 8Wa-10-22

Capacitor...................... 8Wa-10-19, 21

Circuit Breaker No. 1............... 8Wa-10-16

Circuit Breaker No. 3 (JB)........... 8Wa-10-27

Clutch Interlock Switch.............. 8Wa-10-28

Clutch Switch Override Relay......... 8Wa-10-28

Coil On Plug No. 1................. 8Wa-10-21

Coil On Plug No. 2................. 8Wa-10-21

Coil On Plug No. 3................. 8Wa-10-21

Coil On Plug No. 4................. 8Wa-10-21

Coil On Plug No. 5................. 8Wa-10-21

Coil On Plug No. 6................. 8Wa-10-21

Coil Rail......................... 8Wa-10-19

Controller Antilock Brake . 8Wa-10-10, 11, 12, 13, 14

Daytime Running Lamp Relay........ 8Wa-10-16

Defogger Relay.................... 8Wa-10-24

EGR Solenoid..................... 8Wa-10-22

Engine Control Module.............. 8Wa-10-22

Fuel Heater Relay............... 8Wa-10-13, 18

Fuel Heater....................... 8Wa-10-18

Fuel Injector No. 1................. 8Wa-10-20

Fuel Injector No. 2................. 8Wa-10-20

Fuel Injector No. 3................. 8Wa-10-20

Fuel Injector No. 4................. 8Wa-10-20

Fuel Injector No. 5................. 8Wa-10-20

Fuel Injector No. 6................. 8Wa-10-20

Fuel Pressure Solenoid.............. 8Wa-10-22

Fuel Pump Module................. 8Wa-10-26

Fuel Pump Relay................ 8Wa-10-11, 26

Fuse 1.................. 8Wa-10-10, 12, 14, 25

Fuse 2.................. 8Wa-10-10, 12, 14, 15

Fuse 3.................. 8Wa-10-10, 12, 16, 25

Fuse 4..................... 8Wa-10-10, 12, 14

Fuse 5.................. 8Wa-10-10, 12, 17, 18

Fuse 6............... 8Wa-10-10, 12, 19, 22, 24

Fuse 7..................... 8Wa-10-10, 12, 15

Fuse 8..................... 8Wa-10-10, 12, 23

Fuse 9.................. 8Wa-10-10, 12, 13, 24

Fuse 10.............. 8Wa-10-10, 12, 13, 15, 18

Fuse 11.................... 8Wa-10-13, 15, 18

Fuse 12............ 8Wa-10-10, 11, 13, 15, 17, 18

Fuse 13............... 8Wa-10-10, 11, 13, 23, 27

Fuse 14.................... 8Wa-10-11, 13, 23

Fuse 15................. 8Wa-10-11, 13, 25, 27Component Page

Fuse 16................. 8Wa-10-19, 20, 22, 24

Fuse 17.......................... 8Wa-10-24

Fuse 18.......................... 8Wa-10-24

Fuse 19.................... 8Wa-10-11, 13, 24

Fuse 20.......................... 8Wa-10-27

Fuse 21.................... 8Wa-10-11, 13, 26

Fuse 22.......................... 8Wa-10-27

Fuse 24.................... 8Wa-10-11, 26, 29

Fuse 25................. 8Wa-10-11, 13, 14, 29

Fuse 26................. 8Wa-10-12, 19, 20, 22

Fuse 28.......................... 8Wa-10-28

Fuse 29.......................... 8Wa-10-15

Fuse 30.......................... 8Wa-10-24

Fuse 31.......................... 8Wa-10-27

Fuse 32.......................... 8Wa-10-27

Fuse 33.......................... 8Wa-10-16

Fuse 34.......................... 8Wa-10-15

Fuse 36.......................... 8Wa-10-27

Fuse 37.......................... 8Wa-10-29

Fuse 38.......................... 8Wa-10-29

Fuse 39.......................... 8Wa-10-29

Fusible Link................... 8Wa-10-10, 12

G202............................ 8Wa-10-23

Generator.................. 8Wa-10-10, 12, 22

Glow Plug Assembly................ 8Wa-10-18

Glow Plug Relay No. 1......... 8Wa-10-13, 18, 22

Glow Plug Relay No. 2......... 8Wa-10-13, 18, 22

High Beam Relay.................. 8Wa-10-16

Horn Relay....................... 8Wa-10-25

Ignition Switch . . . 8Wa-10-10, 11, 12, 13, 23, 27, 29

Junction Block . . . 8Wa-10-10, 11, 12, 13, 15, 16, 24,

25, 27, 29

Low Beam Relay................... 8Wa-10-25

Oxygen Sensor 1/1 Upstream......... 8Wa-10-19

Oxygen Sensor 1/2 Downstream.... 8Wa-10-19, 20

Oxygen Sensor 2/1 Upstream......... 8Wa-10-19

Oxygen Sensor 2/2 Downstream....... 8Wa-10-20

Oxygen Sensor Downstream Relay . . 8Wa-10-19, 20

Park Lamp Relay.................. 8Wa-10-16

Power Distribution Center . 8Wa-10-2, 3, 10, 11, 12,

13, 14, 15, 16, 17, 18, 19, 22, 23, 24, 25, 26, 27, 28

Power Window Master Switch......... 8Wa-10-29

Powertrain Control Module . . 8Wa-10-11, 19, 26, 28

Radiator Fan Relay.............. 8Wa-10-10, 14

Starter Motor Relay.............. 8Wa-10-23, 28

Starter Motor..................... 8Wa-10-23

Trailer Tow Circuit Breaker..... 8Wa-10-10, 12, 15

Trailer Tow Circuit Breaker.......... 8Wa-10-15

Trailer Tow Connector............... 8Wa-10-15

Trailer Tow Relay.................. 8Wa-10-15

Transmission Control Module . . . 8Wa-10-10, 17, 28

Transmission Control Relay........ 8Wa-10-10, 17

Transmission Solenoid/TRS Assembly . . . 8Wa-10-17

KJ8W-10 POWER DISTRIBUTION8Wa-10-1

Page 862 of 1803

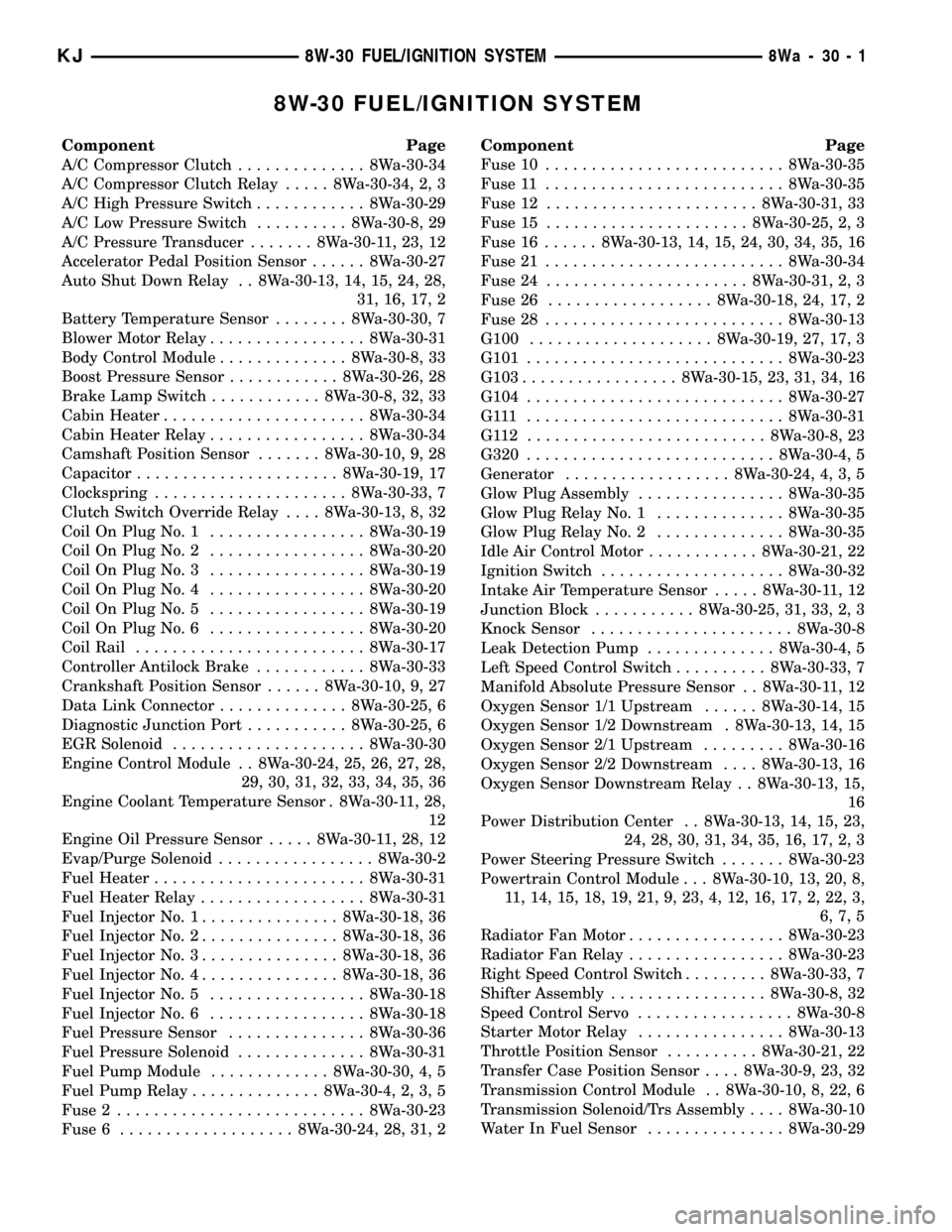

8W-30 FUEL/IGNITION SYSTEM

Component Page

A/C Compressor Clutch.............. 8Wa-30-34

A/C Compressor Clutch Relay..... 8Wa-30-34, 2, 3

A/C High Pressure Switch............ 8Wa-30-29

A/C Low Pressure Switch.......... 8Wa-30-8, 29

A/C Pressure Transducer....... 8Wa-30-11, 23, 12

Accelerator Pedal Position Sensor...... 8Wa-30-27

Auto Shut Down Relay . . 8Wa-30-13, 14, 15, 24, 28,

31, 16, 17, 2

Battery Temperature Sensor........ 8Wa-30-30, 7

Blower Motor Relay................. 8Wa-30-31

Body Control Module.............. 8Wa-30-8, 33

Boost Pressure Sensor............ 8Wa-30-26, 28

Brake Lamp Switch............ 8Wa-30-8, 32, 33

Cabin Heater...................... 8Wa-30-34

Cabin Heater Relay................. 8Wa-30-34

Camshaft Position Sensor....... 8Wa-30-10, 9, 28

Capacitor...................... 8Wa-30-19, 17

Clockspring..................... 8Wa-30-33, 7

Clutch Switch Override Relay.... 8Wa-30-13, 8, 32

Coil On Plug No. 1................. 8Wa-30-19

Coil On Plug No. 2................. 8Wa-30-20

Coil On Plug No. 3................. 8Wa-30-19

Coil On Plug No. 4................. 8Wa-30-20

Coil On Plug No. 5................. 8Wa-30-19

Coil On Plug No. 6................. 8Wa-30-20

Coil Rail......................... 8Wa-30-17

Controller Antilock Brake............ 8Wa-30-33

Crankshaft Position Sensor...... 8Wa-30-10, 9, 27

Data Link Connector.............. 8Wa-30-25, 6

Diagnostic Junction Port........... 8Wa-30-25, 6

EGR Solenoid..................... 8Wa-30-30

Engine Control Module . . 8Wa-30-24, 25, 26, 27, 28,

29, 30, 31, 32, 33, 34, 35, 36

Engine Coolant Temperature Sensor . 8Wa-30-11, 28,

12

Engine Oil Pressure Sensor..... 8Wa-30-11, 28, 12

Evap/Purge Solenoid................. 8Wa-30-2

Fuel Heater....................... 8Wa-30-31

Fuel Heater Relay.................. 8Wa-30-31

Fuel Injector No. 1............... 8Wa-30-18, 36

Fuel Injector No. 2............... 8Wa-30-18, 36

Fuel Injector No. 3............... 8Wa-30-18, 36

Fuel Injector No. 4............... 8Wa-30-18, 36

Fuel Injector No. 5................. 8Wa-30-18

Fuel Injector No. 6................. 8Wa-30-18

Fuel Pressure Sensor............... 8Wa-30-36

Fuel Pressure Solenoid.............. 8Wa-30-31

Fuel Pump Module............. 8Wa-30-30, 4, 5

Fuel Pump Relay.............. 8Wa-30-4, 2, 3, 5

Fuse 2........................... 8Wa-30-23

Fuse 6................... 8Wa-30-24, 28, 31, 2Component Page

Fuse 10.......................... 8Wa-30-35

Fuse 11.......................... 8Wa-30-35

Fuse 12....................... 8Wa-30-31, 33

Fuse 15...................... 8Wa-30-25, 2, 3

Fuse 16...... 8Wa-30-13, 14, 15, 24, 30, 34, 35, 16

Fuse 21.......................... 8Wa-30-34

Fuse 24...................... 8Wa-30-31, 2, 3

Fuse 26.................. 8Wa-30-18, 24, 17, 2

Fuse 28.......................... 8Wa-30-13

G100.................... 8Wa-30-19, 27, 17, 3

G101............................ 8Wa-30-23

G103................. 8Wa-30-15, 23, 31, 34, 16

G104............................ 8Wa-30-27

G111 ............................ 8Wa-30-31

G112 .......................... 8Wa-30-8, 23

G320........................... 8Wa-30-4, 5

Generator.................. 8Wa-30-24, 4, 3, 5

Glow Plug Assembly................ 8Wa-30-35

Glow Plug Relay No. 1.............. 8Wa-30-35

Glow Plug Relay No. 2.............. 8Wa-30-35

Idle Air Control Motor............ 8Wa-30-21, 22

Ignition Switch.................... 8Wa-30-32

Intake Air Temperature Sensor..... 8Wa-30-11, 12

Junction Block........... 8Wa-30-25, 31, 33, 2, 3

Knock Sensor...................... 8Wa-30-8

Leak Detection Pump.............. 8Wa-30-4, 5

Left Speed Control Switch.......... 8Wa-30-33, 7

Manifold Absolute Pressure Sensor . . 8Wa-30-11, 12

Oxygen Sensor 1/1 Upstream...... 8Wa-30-14, 15

Oxygen Sensor 1/2 Downstream . 8Wa-30-13, 14, 15

Oxygen Sensor 2/1 Upstream......... 8Wa-30-16

Oxygen Sensor 2/2 Downstream.... 8Wa-30-13, 16

Oxygen Sensor Downstream Relay . . 8Wa-30-13, 15,

16

Power Distribution Center . . 8Wa-30-13, 14, 15, 23,

24, 28, 30, 31, 34, 35, 16, 17, 2, 3

Power Steering Pressure Switch....... 8Wa-30-23

Powertrain Control Module . . . 8Wa-30-10, 13, 20, 8,

11, 14, 15, 18, 19, 21, 9, 23, 4, 12, 16, 17, 2, 22, 3,

6, 7, 5

Radiator Fan Motor................. 8Wa-30-23

Radiator Fan Relay................. 8Wa-30-23

Right Speed Control Switch......... 8Wa-30-33, 7

Shifter Assembly................. 8Wa-30-8, 32

Speed Control Servo................. 8Wa-30-8

Starter Motor Relay................ 8Wa-30-13

Throttle Position Sensor.......... 8Wa-30-21, 22

Transfer Case Position Sensor.... 8Wa-30-9, 23, 32

Transmission Control Module . . 8Wa-30-10, 8, 22, 6

Transmission Solenoid/Trs Assembly.... 8Wa-30-10

Water In Fuel Sensor............... 8Wa-30-29

KJ8W-30 FUEL/IGNITION SYSTEM8Wa-30-1