Speed sensor JEEP LIBERTY 2002 KJ / 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 303 of 1803

²Fog Lamp Control- The premium BCM pro-

vides fog lamp control for front fog lamps (optional),

and rear fog lamps (in required markets only).

²Front Wiper System Status- The BCM moni-

tors the status of the front wiper motor park switch.

²Fuel Economy and Distance to Empty Cal-

culations- The BCM calculates and transmits the

fuel economy and Distance To Empty (DTE) data.

²Headlamp Time Delay- The BCM provides a

headlamp time delay feature with the ignition switch

in the Off position.

²Heated Rear Glass Control- The BCM pro-

vides control and timer functions for the heated rear

glass feature and transmits the system status.

²Ignition On/Off Timer- The BCM monitors

and transmits the elapsed ignition On timer data

and monitors the ignition Off time.

²Ignition Switch Position Status- The BCM

monitors and transmits the status of the ignition

switch.

²Instrument Panel Dimming- The BCM mon-

itors and transmits the selected illumination inten-

sity level of the panel lamps dimmer switch.

²Interior Lamp Load Shedding- The BCM

provides a battery saver feature which will automat-

ically turn off all interior lamps that remain on after

a timed interval.

²Interior Lighting Control- The BCM moni-

tors inputs from the interior lighting switch, the door

ajar switches, the flip-up glass ajar switch, the tail-

gate ajar switch, the cargo lamp switch, the reading

lamp switches, and the Remote Keyless Entry (RKE)

module to provide courtesy lamp control. This

includes support for timed illuminated entry with

theater-style fade-to-off and courtesy illumination

defeat features.

²Intermittent Wipe and Front Wiper System

Control- The BCM monitors inputs from the front

wiper and washer switch and the front wiper motor

park switch to provide front wiper system control

through the wiper on/off and high/low relays. This

includes support for adjustable intermittent wipe,

mist wipe (also known as pulse wipe), and wipe-after-

wash features.

²Key-In-Ignition Switch Status- The BCM

monitors and transmits the status of the key-in-igni-

tion switch.

²Panic Mode- The BCM provides support for

the Remote Keyless Entry (RKE) system panic mode

feature.

²Parade Mode- The BCM provides a parade

mode (also known as funeral mode) that allows the

interior Vacuum Fluorescent Displays (VFD) to be

illuminated at full intensity while driving in daylight

with the exterior lamps On.²Power Locks- The BCM monitors inputs from

the power lock switches and the Remote Keyless

Entry (RKE) module (optional) to provide control of

the power lock motors through outputs to the lock,

unlock, and driver unlock (RKE only) relays. This

includes support for rolling door locks (also known as

automatic door locks) and a door lock inhibit mode.

²Programmable Features- The BCM provides

support for several standard and optional program-

mable features, including: rolling door locks, head-

lamp time delay interval, Remote Keyless Entry

(RKE) driver-door-only or unlock-all-doors, RKE opti-

cal chirp, and RKE audible chirp.

²Remote Keyless Entry- The premium BCM

provides the optional Remote Keyless Entry (RKE)

system features, including support for the RKE Lock,

Unlock (with optional driver-door-only unlock, and

unlock-all-doors), rear flip-up glass control, Panic,

audible chirp, optical chirp, and illuminated entry

modes, as well as the ability to be programmed to

recognize up to four RKE transmitters.

²Rolling Door Locks- The BCM provides sup-

port for the power lock system rolling door locks fea-

ture (also known as automatic door locks).

²Tailgate and Flip-Up Glass Ajar Status- The

BCM monitors and transmits the status of the tail-

gate and rear flip-up glass ajar switches.

²Remote Radio Switch Interface- The pre-

mium BCM monitors and transmits the status of the

optional remote radio switches.

²Self-Diagnostics- The BCM provides support

for diagnostics through communication with the

DRBIIItscan tool over the PCI data bus network.

Each analog and digital input can be verified, and

each output can be actuated through the use of this

diagnostic protocol. The BCM also stores Diagnostic

Trouble Codes (DTCs) to assist in troubleshooting

this unit.

²Vacuum Fluorescent Display Synchroniza-

tion- The BCM transmits panel lamp intensity data

which allows modules with Vacuum Fluorescent Dis-

plays (VFD) to coordinate their illumination inten-

sity.

²Vehicle Speed System- The BCM monitors a

vehicle speed input from the vehicle speed sensor

(without Antilock Brake System [ABS]) or from the

Controller Antilock Brake (CAB)(with ABS), calcu-

lates the vehicle speed based upon a programmed

axle ratio/tire size (electronic pinion factor), and

transmits the vehicle speed information to the Pow-

ertrain Control Module (PCM) on a hard wired out-

put circuit.

²Vehicle Theft Security System- The pre-

mium BCM monitors inputs from the door cylinder

lock switches, the tailgate cylinder lock switch, the

door ajar switches, the tailgate ajar switch, the

8E - 4 ELECTRONIC CONTROL MODULESKJ

BODY CONTROL MODULE (Continued)

Page 305 of 1803

²RKE antenna (two circuits) - premium with

RKE only

²Tailgate ajar switch sense

²Tailgate cylinder lock switch sense

²Vehicle speed sensor

Refer to the appropriate wiring information for

additional details.

HARD WIRED OUTPUTS The hard wired outputs

of the BCM include the following:

²Courtesy lamp driver

²Courtesy lamp load shed

²Door lock relay control

²Driver door unlock relay control - premium

with RKE only

²Flip-up glass release motor driver

²Front fog lamp relay control - premium

with front fog lamps only

²Front wiper high/low relay control

²Front wiper on/off relay control

²Hazard lamp control

²High beam relay control

²Horn relay control - premium with RKE

only

²Instrument cluster wake up signal

²Low beam relay control

²Park lamp relay control

²Passenger door unlock relay control

²Rear fog lamp relay control - premium with

rear fog lamps in markets where required only

²Rear window defogger relay control

²RKE supply - premium with RKE only

²Tailgate lock driver

²Tailgate unlock driver

²Vehicle speed output

²Vehicle speed sensor supply

²VTSS indicator driver - premium with

VTSS only

Refer to the appropriate wiring information for

additional details.

GROUNDS The BCM receives ground through five

separate circuits, and also supplies a ground path to

several switches through the following hard wired

circuits:

²Ambient temperature sensor return

²Door lock switch ground

²Headlamp switch return

²Radio control mux return

²RKE ground - premium with RKE only

²Tailgate switch ground

Refer to the appropriate wiring information for

additional details.

COMMUNICATION Not including the two RKE

antenna circuits (RKE antenna + and ±), which

merely pass through the premium BCM from the

RKE module to the external RKE antenna in theinstrument panel wire harness, the BCM has the fol-

lowing communication circuits:

²PCI bus

²RKE program serial data - premium with

RKE only

²RKE transmit serial data - premium with

RKE only

Refer to the appropriate wiring information for

additional details.

MESSAGING The BCM uses the following mes-

sages received from other electronic modules over the

PCI data bus:

²Battery Temperature (PCM)

²Compass Mini-Trip Computer Button Sta-

tus (CMTC) - premium only

²Coolant Temperature (PCM)

²Distance Pulses (PCM)

²Engine Speed (PCM)

²Fuel Tank Level (PCM)

²Fuel Used (PCM)

²Intrusion Transceiver Module Commands

(ITM) - premium in markets where required

only

²Manifold Absolute Pressure (PCM)

²OK to Lock - Rolling Locks (PCM)

²SKIS Status (SKIM)

²Vehicle Identification Number (PCM)

²Vehicle Speed (PCM)

The BCM provides the following messages to other

electronic modules over the PCI data bus:

²A/C Select Switch Status (PCM)

²Country Code (EMIC, PCM, CMTC)

²Distance to Empty (CMTC) - premium only

²Door Ajar Status (EMIC)

²Exterior Lighting Status (EMIC)

²Flip-up Glass Ajar Status (EMIC)

²Fuel Economy (Average and Instantaneous)

(CMTC) - premium only

²Hood Ajar Status (ITM) - premium in mar-

kets where required only

²Ignition On Timer (CMTC) - premium only

²Intrusion Transceiver Module Commands

(ITM) - premium in markets where required

only

²Key-In Ignition Switch Status (EMIC)

²Outside Temperature (CMTC) - premium

only

²Panel Lamp Intensity (CMTC, Radio)

²Tailgate Ajar Status (EMIC)

²Radio Mode (Radio) - premium only

²Radio Preset Scan (Radio) - premium only

²Radio Seek Down (Radio) - premium only

²Radio Seek Up (Radio) - premium only

²Radio Volume Down (Radio) - premium

only

²Radio Volume Up (Radio) - premium only

8E - 6 ELECTRONIC CONTROL MODULESKJ

BODY CONTROL MODULE (Continued)

Page 307 of 1803

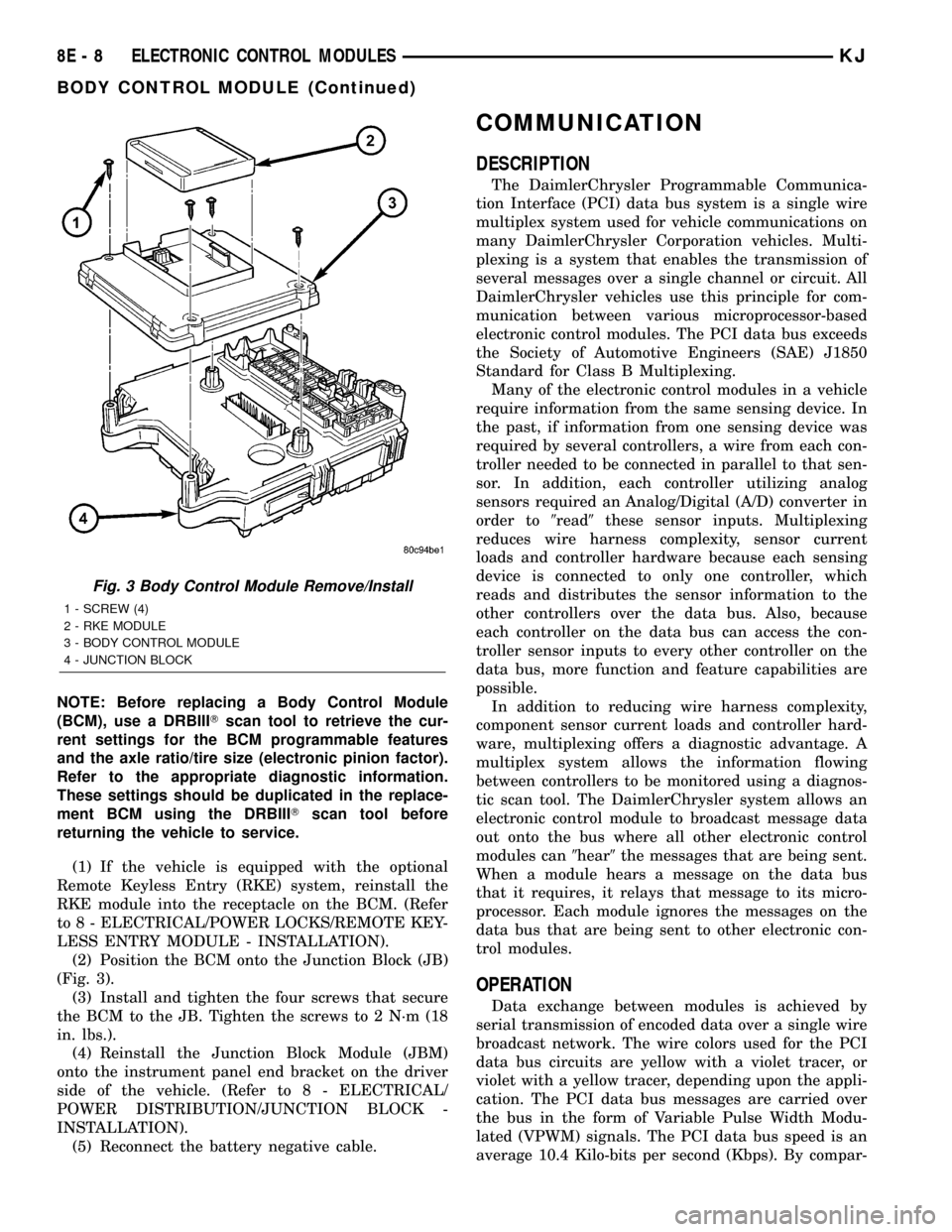

NOTE: Before replacing a Body Control Module

(BCM), use a DRBIIITscan tool to retrieve the cur-

rent settings for the BCM programmable features

and the axle ratio/tire size (electronic pinion factor).

Refer to the appropriate diagnostic information.

These settings should be duplicated in the replace-

ment BCM using the DRBIIITscan tool before

returning the vehicle to service.

(1) If the vehicle is equipped with the optional

Remote Keyless Entry (RKE) system, reinstall the

RKE module into the receptacle on the BCM. (Refer

to 8 - ELECTRICAL/POWER LOCKS/REMOTE KEY-

LESS ENTRY MODULE - INSTALLATION).

(2) Position the BCM onto the Junction Block (JB)

(Fig. 3).

(3) Install and tighten the four screws that secure

the BCM to the JB. Tighten the screws to 2 N´m (18

in. lbs.).

(4) Reinstall the Junction Block Module (JBM)

onto the instrument panel end bracket on the driver

side of the vehicle. (Refer to 8 - ELECTRICAL/

POWER DISTRIBUTION/JUNCTION BLOCK -

INSTALLATION).

(5) Reconnect the battery negative cable.

COMMUNICATION

DESCRIPTION

The DaimlerChrysler Programmable Communica-

tion Interface (PCI) data bus system is a single wire

multiplex system used for vehicle communications on

many DaimlerChrysler Corporation vehicles. Multi-

plexing is a system that enables the transmission of

several messages over a single channel or circuit. All

DaimlerChrysler vehicles use this principle for com-

munication between various microprocessor-based

electronic control modules. The PCI data bus exceeds

the Society of Automotive Engineers (SAE) J1850

Standard for Class B Multiplexing.

Many of the electronic control modules in a vehicle

require information from the same sensing device. In

the past, if information from one sensing device was

required by several controllers, a wire from each con-

troller needed to be connected in parallel to that sen-

sor. In addition, each controller utilizing analog

sensors required an Analog/Digital (A/D) converter in

order to9read9these sensor inputs. Multiplexing

reduces wire harness complexity, sensor current

loads and controller hardware because each sensing

device is connected to only one controller, which

reads and distributes the sensor information to the

other controllers over the data bus. Also, because

each controller on the data bus can access the con-

troller sensor inputs to every other controller on the

data bus, more function and feature capabilities are

possible.

In addition to reducing wire harness complexity,

component sensor current loads and controller hard-

ware, multiplexing offers a diagnostic advantage. A

multiplex system allows the information flowing

between controllers to be monitored using a diagnos-

tic scan tool. The DaimlerChrysler system allows an

electronic control module to broadcast message data

out onto the bus where all other electronic control

modules can9hear9the messages that are being sent.

When a module hears a message on the data bus

that it requires, it relays that message to its micro-

processor. Each module ignores the messages on the

data bus that are being sent to other electronic con-

trol modules.

OPERATION

Data exchange between modules is achieved by

serial transmission of encoded data over a single wire

broadcast network. The wire colors used for the PCI

data bus circuits are yellow with a violet tracer, or

violet with a yellow tracer, depending upon the appli-

cation. The PCI data bus messages are carried over

the bus in the form of Variable Pulse Width Modu-

lated (VPWM) signals. The PCI data bus speed is an

average 10.4 Kilo-bits per second (Kbps). By compar-

Fig. 3 Body Control Module Remove/Install

1 - SCREW (4)

2 - RKE MODULE

3 - BODY CONTROL MODULE

4 - JUNCTION BLOCK

8E - 8 ELECTRONIC CONTROL MODULESKJ

BODY CONTROL MODULE (Continued)

Page 311 of 1803

²The fuel pump is energized through the fuel

pump relay by the PCM. The fuel pump will operate

for approximately three seconds unless the engine is

operating or the starter motor is engaged.

²The O2S sensor heater element is energized via

the ASD or O2S heater relay. The O2S sensor input

is not used by the PCM to calibrate air-fuel ratio dur-

ing this mode of operation.

ENGINE START-UP MODE

This is an Open Loop mode. The following actions

occur when the starter motor is engaged.

The PCM receives inputs from:

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

The PCM monitors the crankshaft position sensor.

If the PCM does not receive a crankshaft position

sensor signal within 3 seconds of cranking the

engine, it will shut down the fuel injection system.

The fuel pump is activated by the PCM through

the fuel pump relay.

Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.

The PCM determines the proper ignition timing

according to input received from the crankshaft posi-

tion sensor.

ENGINE WARM-UP MODE

This is an Open Loop mode. During engine warm-

up, the PCM receives inputs from:

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

Based on these inputs the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off.²The PCM adjusts engine idle speed through the

idle air control (IAC) motor and adjusts ignition tim-

ing.

²The PCM operates the A/C compressor clutch

through the A/C compressor clutch relay. This is done

if A/C has been selected by the vehicle operator and

specified pressures are met at the high and low±pres-

sure A/C switches. Refer to Heating and Air Condi-

tioning for additional information.

²When engine has reached operating tempera-

ture, the PCM will begin monitoring O2S sensor

input. The system will then leave the warm-up mode

and go into closed loop operation.

IDLE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At idle speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Battery voltage

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen sensors

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

injection sequence and injector pulse width by turn-

ing the ground circuit to each individual injector on

and off.

²The PCM monitors the O2S sensor input and

adjusts air-fuel ratio by varying injector pulse width.

It also adjusts engine idle speed through the idle air

control (IAC) motor.

²The PCM adjusts ignition timing by increasing

and decreasing spark advance.

²The PCM operates the A/C compressor clutch

through the A/C compressor clutch relay. This is done

if A/C has been selected by the vehicle operator and

specified pressures are met at the high and low±pres-

sure A/C switches. Refer to Heating and Air Condi-

tioning for additional information.

CRUISE MODE

When the engine is at operating temperature, this

is a Closed Loop mode. At cruising speed, the PCM

receives inputs from:

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

8E - 12 ELECTRONIC CONTROL MODULESKJ

POWERTRAIN CONTROL MODULE (Continued)

Page 312 of 1803

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Oxygen (O2S) sensors

Based on these inputs, the following occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then adjust

the injector pulse width by turning the ground circuit

to each individual injector on and off.

²The PCM monitors the O2S sensor input and

adjusts air-fuel ratio. It also adjusts engine idle

speed through the idle air control (IAC) motor.

²The PCM adjusts ignition timing by turning the

ground path to the coil(s) on and off.

²The PCM operates the A/C compressor clutch

through the clutch relay. This happens if A/C has

been selected by the vehicle operator and requested

by the A/C thermostat.

ACCELERATION MODE

This is an Open Loop mode. The PCM recognizes

an abrupt increase in throttle position or MAP pres-

sure as a demand for increased engine output and

vehicle acceleration. The PCM increases injector

pulse width in response to increased throttle opening.

DECELERATION MODE

When the engine is at operating temperature, this

is an Open Loop mode. During hard deceleration, the

PCM receives the following inputs.

²Air conditioning select signal (if equipped)

²Air conditioning request signal (if equipped)

²Battery voltage

²Engine coolant temperature sensor

²Crankshaft position sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

²Park/neutral switch (gear indicator signalÐauto.

trans. only)

²Vehicle speed

If the vehicle is under hard deceleration with the

proper rpm and closed throttle conditions, the PCM

will ignore the oxygen sensor input signal. The PCM

will enter a fuel cut-off strategy in which it will not

supply a ground to the injectors. If a hard decelera-

tion does not exist, the PCM will determine the

proper injector pulse width and continue injection.Based on the above inputs, the PCM will adjust

engine idle speed through the idle air control (IAC)

motor.

The PCM adjusts ignition timing by turning the

ground path to the coil on and off.

WIDE OPEN THROTTLE MODE

This is an Open Loop mode. During wide open

throttle operation, the PCM receives the following

inputs.

²Battery voltage

²Crankshaft position sensor

²Engine coolant temperature sensor

²Intake manifold air temperature sensor

²Manifold absolute pressure (MAP) sensor

²Throttle position sensor (TPS)

²Camshaft position sensor signal

During wide open throttle conditions, the following

occurs:

²Voltage is applied to the fuel injectors with the

ASD relay via the PCM. The PCM will then control

the injection sequence and injector pulse width by

turning the ground circuit to each individual injector

on and off. The PCM ignores the oxygen sensor input

signal and provides a predetermined amount of addi-

tional fuel. This is done by adjusting injector pulse

width.

²The PCM adjusts ignition timing by turning the

ground path to the coil(s) on and off.

IGNITION SWITCH OFF MODE

When ignition switch is turned to OFF position,

the PCM stops operating the injectors, ignition coil,

ASD relay and fuel pump relay.

DESCRIPTION - 5 VOLT SUPPLIES

Two different Powertrain Control Module (PCM)

five volt supply circuits are used; primary and sec-

ondary.

DESCRIPTION - IGNITION CIRCUIT SENSE

This circuit ties the ignition switch to the Power-

train Control Module (PCM).

DESCRIPTION - POWER GROUNDS

The Powertrain Control Module (PCM) has 2 main

grounds. Both of these grounds are referred to as

power grounds. All of the high-current, noisy, electri-

cal devices are connected to these grounds as well as

all of the sensor returns. The sensor return comes

into the sensor return circuit, passes through noise

suppression, and is then connected to the power

ground.

The power ground is used to control ground cir-

cuits for the following PCM loads:

²Generator field winding

KJELECTRONIC CONTROL MODULES 8E - 13

POWERTRAIN CONTROL MODULE (Continued)

Page 313 of 1803

²Fuel injectors

²Ignition coil(s)

²Certain relays/solenoids

²Certain sensors

DESCRIPTION - SENSOR RETURN

The Sensor Return circuits are internal to the Pow-

ertrain Control Module (PCM).

Sensor Return provides a low±noise ground refer-

ence for all engine control system sensors. Refer to

Power Grounds for more information.

OPERATION

OPERATION - PCM

The PCM operates the fuel system. The PCM is a

pre-programmed, triple microprocessor digital com-

puter. It regulates ignition timing, air-fuel ratio,

emission control devices, charging system, certain

transmission features, speed control, air conditioning

compressor clutch engagement and idle speed. The

PCM can adapt its programming to meet changing

operating conditions.

The PCM receives input signals from various

switches and sensors. Based on these inputs, the

PCM regulates various engine and vehicle operations

through different system components. These compo-

nents are referred to as Powertrain Control Module

(PCM) Outputs. The sensors and switches that pro-

vide inputs to the PCM are considered Powertrain

Control Module (PCM) Inputs.

The PCM adjusts ignition timing based upon

inputs it receives from sensors that react to: engine

rpm, manifold absolute pressure, engine coolant tem-

perature, throttle position, transmission gear selec-

tion (automatic transmission), vehicle speed, power

steering pump pressure, and the brake switch.

The PCM adjusts idle speed based on inputs it

receives from sensors that react to: throttle position,

vehicle speed, transmission gear selection, engine

coolant temperature and from inputs it receives from

the air conditioning clutch switch and brake switch.

Based on inputs that it receives, the PCM adjusts

ignition coil dwell. The PCM also adjusts the gener-

ator charge rate through control of the generator

field and provides speed control operation.

NOTE: PCM Inputs:

²A/C request (if equipped with factory A/C)

²A/C select (if equipped with factory A/C)

²A/C pressure transducer

²Auto shutdown (ASD) sense

²Battery temperature

²Battery voltage

²Brake switch²J1850 bus (+) circuits

²J1850 bus (-) circuits

²Camshaft position sensor signal

²Crankshaft position sensor

²Data link connection for DRB scan tool

²Engine coolant temperature sensor

²Fuel level (through J1850 circuitry)

²Generator (battery voltage) output

²Ignition circuit sense (ignition switch in on/off/

crank/run position)

²Intake manifold air temperature sensor

²Knock sensors (2 on 3.7L engine)

²Leak detection pump (switch) sense (if equipped)

²Manifold absolute pressure (MAP) sensor

²Oil pressure

²Oxygen sensors

²Park/neutral switch (auto. trans. only)

²Power ground

²Power steering pressure switch

²Sensor return

²Signal ground

²Speed control multiplexed single wire input

²Throttle position sensor

²Transfer case switch (4WD range position)

²Vehicle speed sensor

NOTE: PCM Outputs:

²A/C clutch relay

²Auto shutdown (ASD) relay

²J1850 bus (+/-) circuits for: speedometer, voltme-

ter, fuel gauge, oil pressure gauge/lamp, engine temp.

gauge and speed control warn. lamp

²Clutch pedal position switch override relay

²Data link connection for DRB scan tool

²EGR valve control solenoid (if equipped)

²EVAP canister purge solenoid

²Five volt sensor supply (primary)

²Five volt sensor supply (secondary)

²Fuel injectors

²Fuel pump relay

²Generator field driver (-)

²Generator field driver (+)

²Idle air control (IAC) motor

²Ignition coil(s)

²Leak detection pump (if equipped)

²Malfunction indicator lamp (Check engine lamp).

Driven through J1850 circuits.

²Oxygen sensor heater relays

²Oxygen sensors (pulse width modulated)

²Radiator cooling fan relay (pulse width modu-

lated)

²Speed control vacuum solenoid

²Speed control vent solenoid

²Tachometer (if equipped). Driven through J1850

circuits.

8E - 14 ELECTRONIC CONTROL MODULESKJ

POWERTRAIN CONTROL MODULE (Continued)

Page 314 of 1803

²Transmission convertor clutch circuit. Driven

through J1850 circuits.

OPERATION - 5 VOLT SUPPLIES

Primary 5±volt supply:

²supplies the required 5 volt power source to the

Crankshaft Position (CKP) sensor.

²supplies the required 5 volt power source to the

Camshaft Position (CMP) sensor.

²supplies a reference voltage for the Manifold

Absolute Pressure (MAP) sensor.

²supplies a reference voltage for the Throttle

Position Sensor (TPS) sensor.

Secondary 5±volt supply:

²supplies the required 5 volt power source to the

oil pressure sensor.

²supplies the required 5 volt power source for the

Vehicle Speed Sensor (VSS) (if equipped).

²supplies the 5 volt power source to the transmis-

sion pressure sensor (certain automatic transmis-

sions).

OPERATION - IGNITION CIRCUIT SENSE

The ignition circuit sense input tells the PCM the

ignition switch has energized the ignition circuit.

Battery voltage is also supplied to the PCM

through the ignition switch when the ignition is in

the RUN or START position. This is referred to as

the9ignition sense9circuit and is used to9wake up9

the PCM. Voltage on the ignition input can be as low

as 6 volts and the PCM will still function. Voltage is

supplied to this circuit to power the PCM's 8-volt reg-

ulator and to allow the PCM to perform fuel, ignition

and emissions control functions.

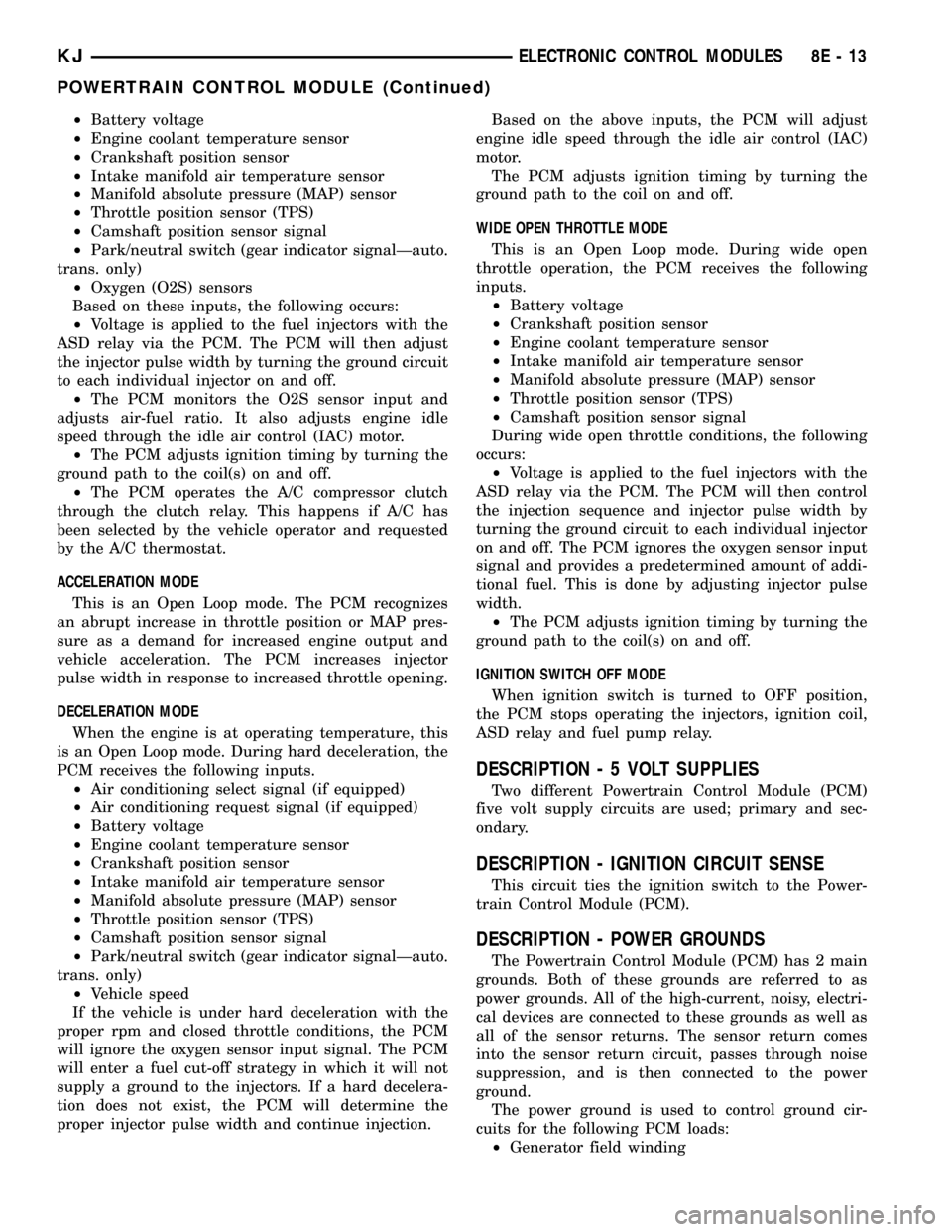

REMOVAL

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW POWERTRAIN CONTROL MODULE

(PCM) WITH THE VEHICLES ORIGINAL IDEN-

TIFICATION NUMBER (VIN) AND THE VEHI-

CLES ORIGINAL MILEAGE. IF THIS STEP IS

NOT DONE, A DIAGNOSTIC TROUBLE CODE

(DTC) MAY BE SET.

The PCM is located in the engine compartment

near the battery (Fig. 9).

To avoid possible voltage spike damage to the

PCM, ignition key must be off, and negative battery

cable must be disconnected before unplugging PCM

connectors.

(1) Disconnect negative battery cable at battery.

(2) Remove cover over electrical connectors. Cover

snaps onto PCM.

(3) Carefully unplug the three 32±way connectors

from PCM.

(4) Remove three PCM mounting bolts and remove

PCM from vehicle.

INSTALLATION

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW POWERTRAIN CONTROL MODULE

(PCM) WITH THE VEHICLES ORIGINAL IDEN-

TIFICATION NUMBER (VIN) AND THE VEHI-

CLES ORIGINAL MILEAGE. IF THIS STEP IS

NOT DONE, A DIAGNOSTIC TROUBLE CODE

(DTC) MAY BE SET.

(1) Install PCM and 3 mounting bolts to vehicle.

(2) Tighten bolts. Refer to torque specifications.

(3) Check pin connectors in the PCM and the three

32±way connectors for corrosion or damage. Also, the

pin heights in connectors should all be same. Repair

as necessary before installing connectors.

(4) Install three 32±way connectors.

(5) Install cover over electrical connectors. Cover

snaps onto PCM.

(6) Install battery cable.

(7) Use the DRB scan tool to reprogram new PCM

with vehicles original Identification Number (VIN)

and original vehicle mileage.

SENTRY KEY IMMOBILIZER

MODULE

DESCRIPTION

The Sentry Key Immobilizer Module (SKIM) is the

primary component of the Sentry Key Immobilizer

System (SKIS) (Fig. 10). The SKIM is located on the

right side of the steering column, below the ignition

Fig. 9 PCM REMOVE/INSTALL

1 - PCM

2 - MOUNTING BOLTS (3)

3 - 32-WAY CONNECTORS

KJELECTRONIC CONTROL MODULES 8E - 15

POWERTRAIN CONTROL MODULE (Continued)

Page 317 of 1803

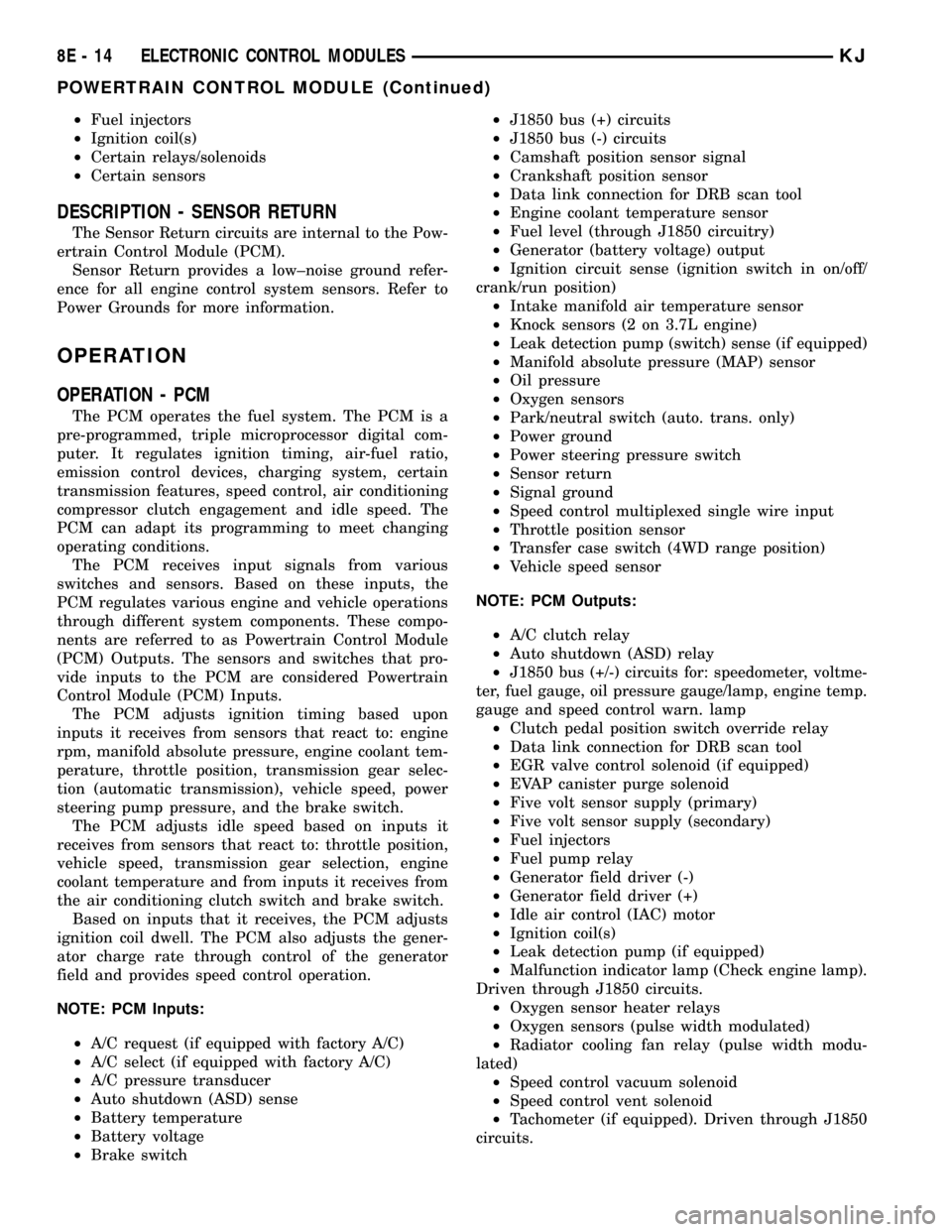

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the Sentry Key Immobilizer Module

(SKIM) to the right side of the steering column (Fig.

11). Lift the multi-function switch upward off of the

upper steering column housing far enough to insert

the SKIM antenna ring formation between the igni-

tion key release button and the multi-function switch

housing.

(2) Slide the SKIM antenna ring around the igni-

tion switch lock cylinder housing, then rotate the

SKIM and its mounting bracket upwards and toward

the steering column.

(3) Align the SKIM mounting bracket clip forma-

tion with the right lower flange of the steering col-

umn jacket and, using hand pressure, push upward

firmly and evenly on the connector end of the SKIM

mounting bracket to engage this clip with the steer-

ing column jacket.

(4) Reconnect the instrument panel wire harness

connector for the SKIM to the module connector

receptacle.

(5) Position both the upper and lower shrouds onto

the steering column.

(6) Align the snap features on the lower shroud

with the receptacles on the upper shroud and apply

hand pressure to snap them together.

(7) From below the steering column, install and

tighten the two screws that secure the lower shroud

to the upper shroud. Tighten the screws to 2 N´m (18

in. lbs.).

(8) If the vehicle is equipped with the optional tilt

steering column, move the tilt steering column to the

fully raised position and secure it in place by moving

the tilt release lever back to the locked (up) position.

(9) Reconnect the battery negative cable.NOTE: If the SKIM has been replaced with a new

unit, the Sentry Key Immobilizer System (SKIS)

MUST be initialized before the vehicle can be oper-

ated. (Refer to 8 - ELECTRICAL/VEHICLE THEFT

SECURITY - STANDARD PROCEDURE - SKIS INI-

TIALIZATION).

TRANSMISSION CONTROL

MODULE

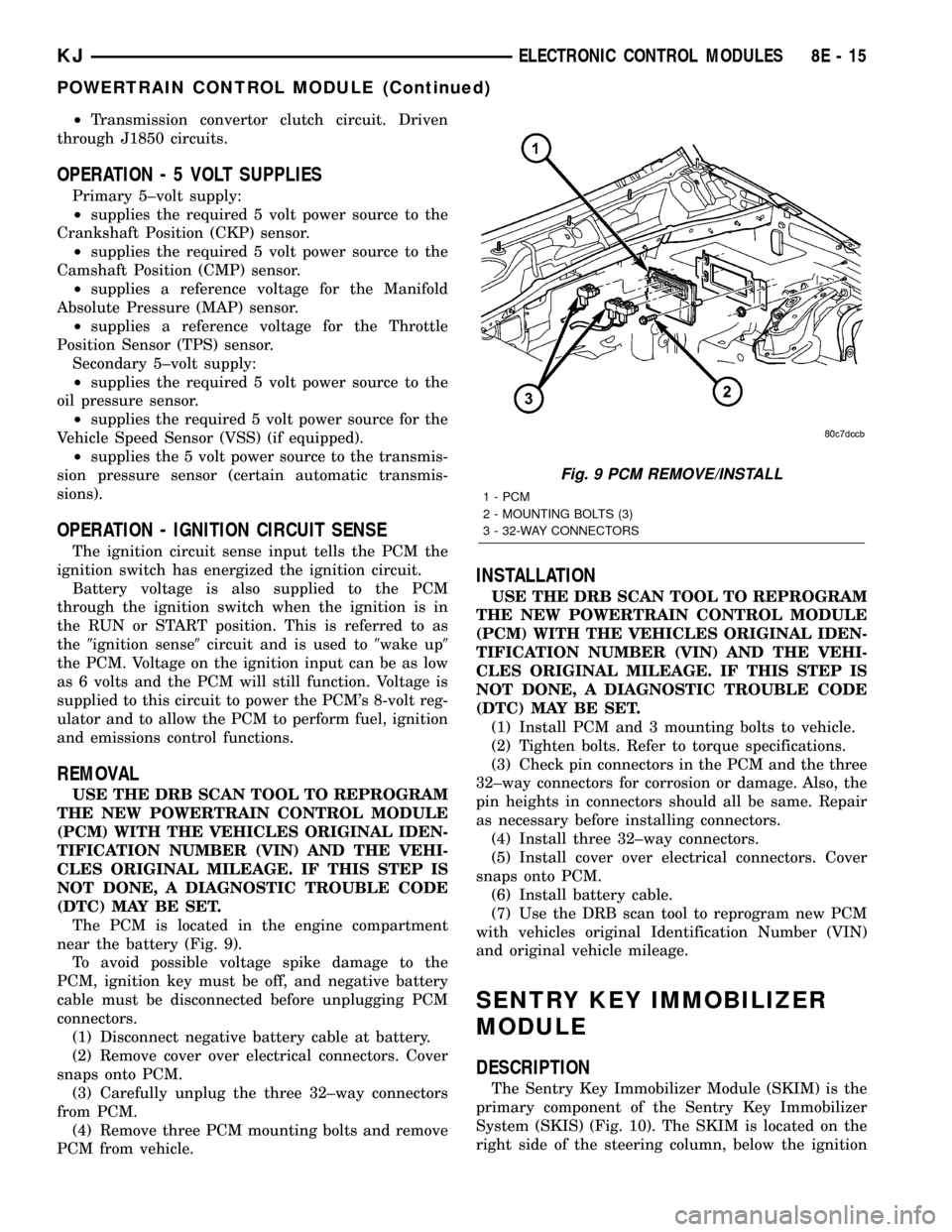

DESCRIPTION

The Transmission Control Module (TCM) is located

in the engine compartment on the right (passenger)

side and is mounted to the inner fender (Fig. 12).

OPERATION

The Transmission Control Module (TCM) is the

controlling unit for all electronic operations of the

transmission. The TCM receives information regard-

ing vehicle operation from both direct and indirect

inputs, and selects the operational mode of the trans-

mission. Direct inputs are hardwired to, and used

specifically by the TCM. Indirect inputs originate

from other components/modules, and are shared with

the TCM via the vehicle communication bus.

Some examples ofdirect inputsto the TCM are:

²Battery (B+) voltage

²Ignition ªONº voltage

²Transmission Control Relay (Switched B+)

²Throttle Position Sensor

²Crankshaft Position Sensor

²Transmission Range Sensor

²Pressure Switches

²Transmission Temperature Sensor

²Input Shaft Speed Sensor

Fig. 12 Transmission Control Module Location

1 - Transmission Control Module

8E - 18 ELECTRONIC CONTROL MODULESKJ

SENTRY KEY IMMOBILIZER MODULE (Continued)

Page 318 of 1803

²Output Shaft Speed Sensor

²Line Pressure Sensor

Some examples ofindirect inputsto the TCM are:

²Engine/Body Identification

²Manifold Pressure

²Target Idle

²Torque Reduction Confirmation

²Engine Coolant Temperature

²Ambient/Battery Temperature

²DRBtScan Tool Communication

Based on the information received from these var-

ious inputs, the TCM determines the appropriate

shift schedule and shift points, depending on the

present operating conditions and driver demand.

This is possible through the control of various direct

and indirect outputs.

Some examples of TCMdirect outputsare:

²Transmission Control Relay

²Solenoids

²Torque Reduction Request

Some examples of TCMindirect outputsare:

²Transmission Temperature (to PCM)

²PRNDL Position (to BCM)

In addition to monitoring inputs and controlling

outputs, the TCM has other important responsibili-

ties and functions:

²Storing and maintaining Clutch Volume Indexes

(CVI)

²Storing and selecting appropriate Shift Sched-

ules

²System self-diagnostics

²Diagnostic capabilities (with DRBtscan tool)

NOTE: If the TCM has been replaced, the ªQuick

Learn Procedureº must be performed. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MODULES/

TRANSMISSION CONTROL MODULE - STANDARD

PROCEDURE)

BATTERY FEED

A fused, direct battery feed to the TCM is used for

continuous power. This battery voltage is necessary

to retain adaptive learn values in the TCM's RAM

(Random Access Memory). When the battery (B+) is

disconnected, this memory is lost. When the battery

(B+) is restored, this memory loss is detected by the

TCM and a Diagnostic Trouble Code (DTC) is set.

CLUTCH VOLUME INDEXES (CVI)

An important function of the TCM is to monitor

Clutch Volume Indexes (CVI). CVIs represent the vol-

ume of fluid needed to compress a clutch pack.

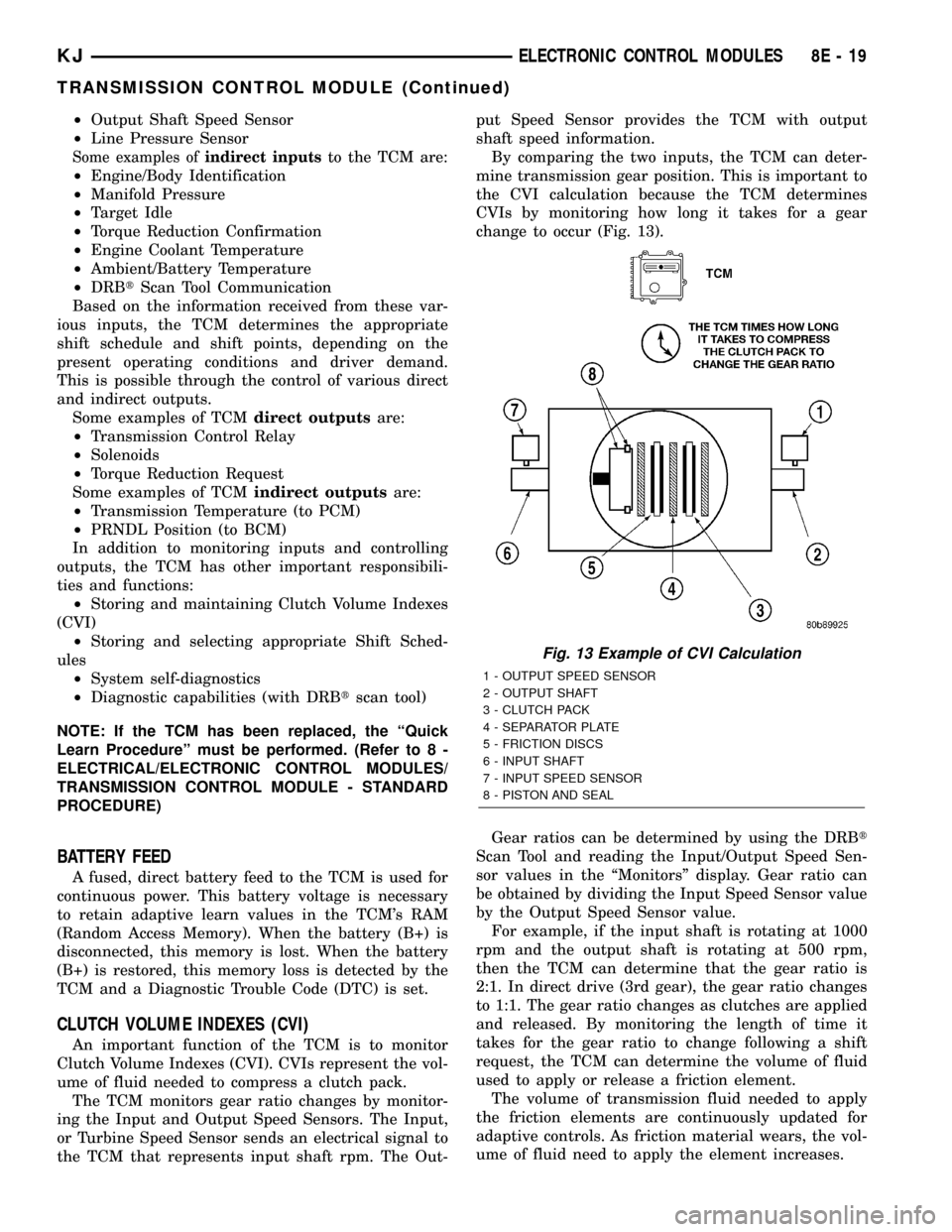

The TCM monitors gear ratio changes by monitor-

ing the Input and Output Speed Sensors. The Input,

or Turbine Speed Sensor sends an electrical signal to

the TCM that represents input shaft rpm. The Out-put Speed Sensor provides the TCM with output

shaft speed information.

By comparing the two inputs, the TCM can deter-

mine transmission gear position. This is important to

the CVI calculation because the TCM determines

CVIs by monitoring how long it takes for a gear

change to occur (Fig. 13).

Gear ratios can be determined by using the DRBt

Scan Tool and reading the Input/Output Speed Sen-

sor values in the ªMonitorsº display. Gear ratio can

be obtained by dividing the Input Speed Sensor value

by the Output Speed Sensor value.

For example, if the input shaft is rotating at 1000

rpm and the output shaft is rotating at 500 rpm,

then the TCM can determine that the gear ratio is

2:1. In direct drive (3rd gear), the gear ratio changes

to 1:1. The gear ratio changes as clutches are applied

and released. By monitoring the length of time it

takes for the gear ratio to change following a shift

request, the TCM can determine the volume of fluid

used to apply or release a friction element.

The volume of transmission fluid needed to apply

the friction elements are continuously updated for

adaptive controls. As friction material wears, the vol-

ume of fluid need to apply the element increases.

Fig. 13 Example of CVI Calculation

1 - OUTPUT SPEED SENSOR

2 - OUTPUT SHAFT

3 - CLUTCH PACK

4 - SEPARATOR PLATE

5 - FRICTION DISCS

6 - INPUT SHAFT

7 - INPUT SPEED SENSOR

8 - PISTON AND SEAL

KJELECTRONIC CONTROL MODULES 8E - 19

TRANSMISSION CONTROL MODULE (Continued)

Page 319 of 1803

Certain mechanical problems within the input

clutch assembly (broken return springs, out of posi-

tion snap rings, excessive clutch pack clearance,

improper assembly, etc.) can cause inadequate or out-

of-range element volumes. Also, defective Input/Out-

put Speed Sensors and wiring can cause these

conditions. The following chart identifies the appro-

priate clutch volumes and when they are monitored/

updated:

CLUTCH VOLUMES

Clutch When UpdatedProper Clutch

Volume

L/R2-1 or 3-1

downshift45 to 134

2C3-2 kickdown

shift25 to 85

OD 2-3 upshift 30 to 100

CLUTCH VOLUMES

4C 3-4 upshift 30 to 85

UD4-3 kickdown

shift30 to 100

SHIFT SCHEDULES

As mentioned earlier, the TCM has programming

that allows it to select a variety of shift schedules.

Shift schedule selection is dependent on the follow-

ing:

²Shift lever position

²Throttle position

²Engine load

²Fluid temperature

²Software level

As driving conditions change, the TCM appropri-

ately adjusts the shift schedule. Refer to the follow-

ing chart to determine the appropriate operation

expected, depending on driving conditions.

Schedule Condition Expected Operation

Extreme ColdOil temperature below -16É F -Park, Reverse, Neutral and 1st and

3rd gear only in D position, 2nd

gear only in Manual 2 or L

-No EMCC

Super ColdOil temperature between -12É F and

10É F- Delayed 2-3 upshift

- Delayed 3-4 upshift

- Early 4-3 coastdown shift

- High speed 4-2, 3-2, 2-1 kickdown

shifts are prevented

-Shifts at high throttle openings willl

be early.

- No EMCC

ColdOil temperature between 10É F and

36É F-Shift schedule is the same as

Super Cold except that the 2-3

upshifts are not delayed.

WarmOil temperature between 40É F and

80É F- Normal operation (upshift,

kickdowns, and coastdowns)

- No EMCC

HotOil temperature between 80É F and

240É F- Normal operation (upshift,

kickdowns, and coastdowns)

- Normal EMCC operation

8E - 20 ELECTRONIC CONTROL MODULESKJ

TRANSMISSION CONTROL MODULE (Continued)