fuse diagram JEEP LIBERTY 2002 KJ / 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 509 of 1803

path to the switches using another internal driver

through the courtesy lamp load shed circuit. The

BCM provides a battery saver (load shedding) feature

for all courtesy lamps, which will automatically turn

these lamps off if they are left on for more than

about eight minutes with the ignition switch in the

Off position.

PANEL LAMPS DIMMER CIRCUIT The panel

lamps dimmer circuit includes the ElectroMechanical

Instrument Cluster (EMIC), heater-air conditioner

control, hazard switch and, depending upon the

selected vehicle options, ash receiver, and automatic

transmission range indicator illumination lamps. All

lamps in the panel lamps dimmer circuit are pro-

vided a path to ground at all times through a hard

wired ground circuit. These lamps illuminate based

upon inputs to the Body Control Module (BCM) from

the exterior lighting control knob and the interior

lighting control ring on the left (lighting) control

stalk of the multi-function switch. The control knob

on the left control stalk of the multi-function switch

selects the exterior lights, while the control ring

selects the panel lamps intensity (dimming) level.

When the exterior lighting is turned On, the BCM

energizes the park lamp relay and provides an elec-

tronic dimming level message to the ElectroMechani-

cal Instrument Cluster (EMIC), the radio, and the

Compass Mini-Trip Computer (CMTC) over the Pro-

grammable Communications Interface (PCI) data

bus. The energized park lamp relay provides a hard

wired battery current signal input to the EMIC on

the park lamp relay output circuit. The EMIC

responds to these inputs by supplying a 12-volt Pulse

Width Modulated (PWM) output to all of the incan-

descent lamps in the panel lamps dimmer circuit

over the fused panel lamps dimmer switch signal cir-

cuit. This shared PWM output synchronizes the

selected illumination intensity level of all of the

incandescent lamps in the panel lamps dimmer cir-

cuit.

The EMIC and the radio each use the electronic

dimming level message from the BCM to control and

synchronize the illumination intensity of their own

Vacuum Fluorescent Display (VFD), while the CMTC

uses the dimming level message to control the illumi-

nation intensity of both its VFD and its incandescent

lighting. In addition, when the control ring on the

left (lighting) control stalk of the multi-function

switch is moved to the Parade Mode detent position,

all of the VFDs are illuminated at their full intensity

levels for increased visibility when the vehicle is

driven during daylight hours with the exterior lights

turned On.DIAGNOSIS AND TESTING - LAMPS/LIGHTING

- INTERIOR

The hard wired circuits and components of the

interior lighting system may be diagnosed and tested

using conventional diagnostic tools and procedures.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the Body Control

Module (BCM), the ElectroMechanical Instrument

Cluster (EMIC), or the Programmable Communica-

tions Interface (PCI) data bus network. The most

reliable, efficient, and accurate means to diagnose

the BCM, the EMIC, and the PCI data bus network

inputs and outputs related to the various interior

lighting systems requires the use of a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

When diagnosing the interior lighting circuits,

remember that high generator output can burn out

bulbs rapidly and repeatedly; and, that dim or flick-

ering bulbs can be caused by low generator output or

poor battery condition. If one of these symptoms is a

problem on the vehicle being diagnosed, be certain to

diagnose and repair the battery and charging system

as required. Also keep in mind that a good ground is

necessary for proper lighting operation. If a lighting

problem is being diagnosed that involves multiple

symptoms, systems, or components the problem can

often be traced to a loose, corroded, or open ground.

For complete circuit diagrams, refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

8L - 68 LAMPS/LIGHTING - INTERIORKJ

LAMPS/LIGHTING - INTERIOR (Continued)

Page 533 of 1803

exterior lighting systems requires the use of a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information.

When diagnosing the exterior lighting circuits,

remember that high generator output can burn out

bulbs rapidly and repeatedly; and, that dim or flick-

ering bulbs can be caused by low generator output or

poor battery condition. If one of these symptoms is a

problem on the vehicle being diagnosed, be certain to

diagnose and repair the battery and charging system

as required. Also keep in mind that a good ground is

necessary for proper lighting operation. If a lighting

problem is being diagnosed that involves multiple

symptoms, systems, or components the problem can

often be traced to a loose, corroded, or open ground.

For complete circuit diagrams, refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information andlocation views for the various wire harness connec-

tors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

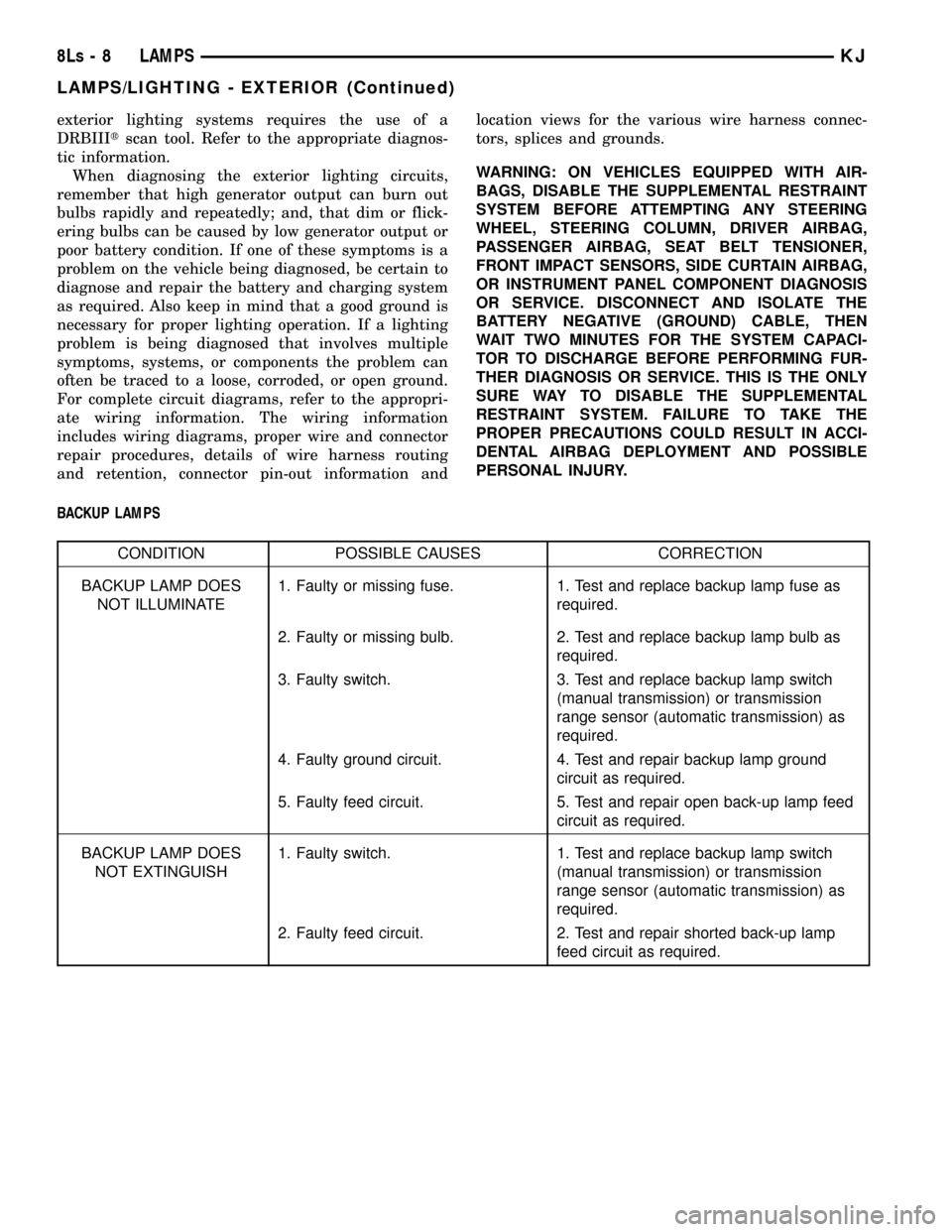

BACKUP LAMPS

CONDITION POSSIBLE CAUSES CORRECTION

BACKUP LAMP DOES

NOT ILLUMINATE1. Faulty or missing fuse. 1. Test and replace backup lamp fuse as

required.

2. Faulty or missing bulb. 2. Test and replace backup lamp bulb as

required.

3. Faulty switch. 3. Test and replace backup lamp switch

(manual transmission) or transmission

range sensor (automatic transmission) as

required.

4. Faulty ground circuit. 4. Test and repair backup lamp ground

circuit as required.

5. Faulty feed circuit. 5. Test and repair open back-up lamp feed

circuit as required.

BACKUP LAMP DOES

NOT EXTINGUISH1. Faulty switch. 1. Test and replace backup lamp switch

(manual transmission) or transmission

range sensor (automatic transmission) as

required.

2. Faulty feed circuit. 2. Test and repair shorted back-up lamp

feed circuit as required.

8Ls - 8 LAMPSKJ

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 548 of 1803

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The front fog lamp relay terminals are connected

to the vehicle electrical system through a connector

receptacle in the Junction Block (JB). The inputs and

outputs of the front fog lamp relay include:

²Common Feed Terminal- The common feed

terminal (30) receives battery current at all times

from a fuse in the JB through a fused B(+) circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the pre-

mium Body Control Module (BCM) through a front

fog lamp relay control circuit. The BCM controls

front fog lamp operation by controlling a ground path

through this circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a fuse in the JB through a fused B(+) circuit.

²Normally Open Terminal- The normally open

terminal (87) is connected to the front fog lamps

through a front fog lamp relay output circuit and

provides battery current to the front fog lamps when-

ever the relay is energized.

²Normally Closed Terminal- The normally

closed terminal (87A) is not connected in this appli-

cation.

The front fog lamp relay can be diagnosed using

conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - FRONT FOG LAMP

RELAY

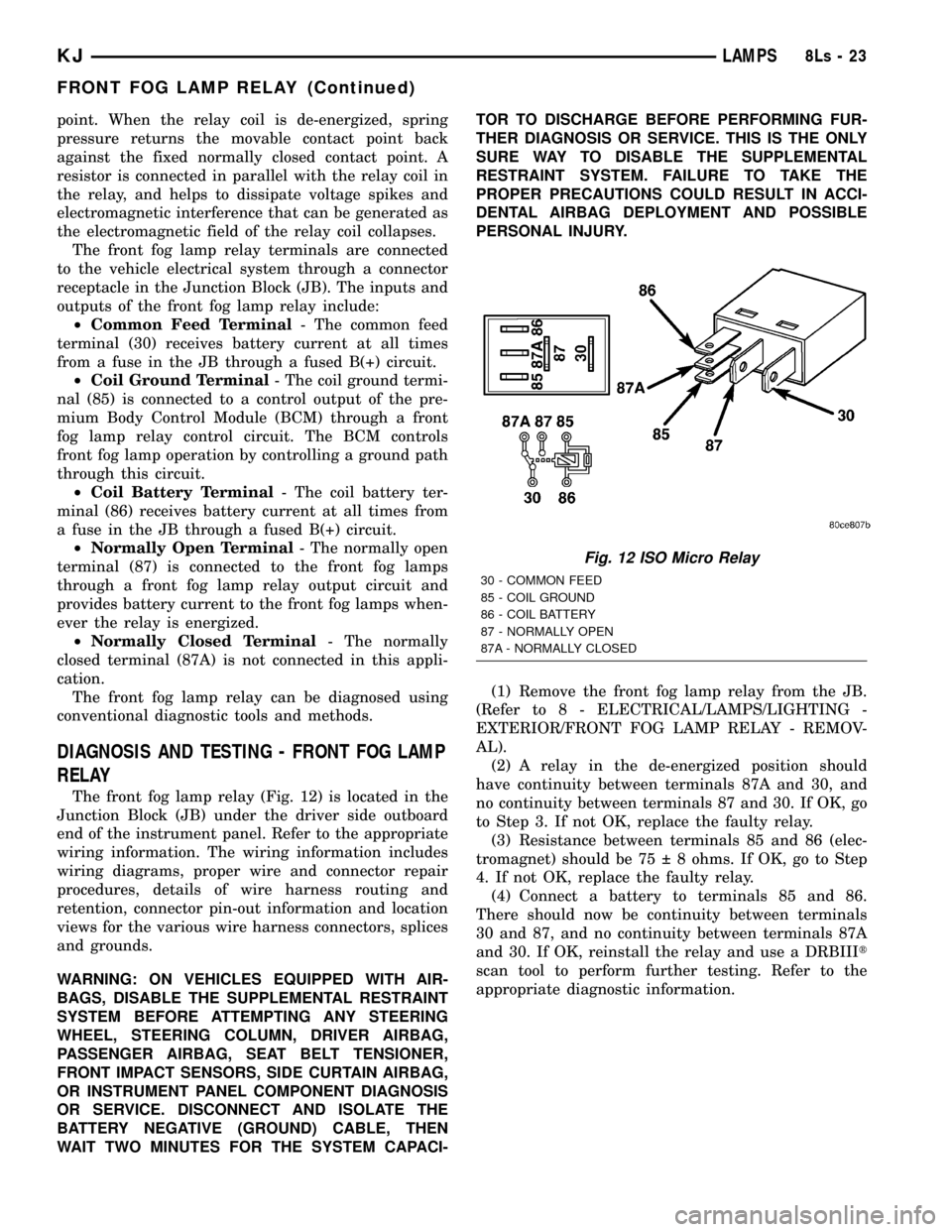

The front fog lamp relay (Fig. 12) is located in the

Junction Block (JB) under the driver side outboard

end of the instrument panel. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Remove the front fog lamp relay from the JB.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/FRONT FOG LAMP RELAY - REMOV-

AL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

Fig. 12 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJLAMPS8Ls-23

FRONT FOG LAMP RELAY (Continued)

Page 582 of 1803

OPERATION

The rear fog lamp relay is an electromechanical

switch that uses a low current input from the Body

Control Module (BCM) to control a high current out-

put to the rear fog lamps. The movable common feed

contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The rear fog lamp relay terminals are connected to

the vehicle electrical system through a connector

receptacle in the Junction Block (JB). The inputs and

outputs of the rear fog lamp relay include:

²Common Feed Terminal- The common feed

terminal (30) receives battery current at all times

from a fuse in the JB through a fused B(+) circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the pre-

mium Body Control Module (BCM) through a rear

fog lamp relay control circuit. The BCM controls rear

fog lamp operation by controlling a ground path

through this circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a fuse in the JB through a fused B(+) circuit.

²Normally Open Terminal- The normally open

terminal (87) is connected to the rear fog lamps

through a rear fog lamp relay output circuit and pro-

vides battery current to the rear fog lamps whenever

the relay is energized.

²Normally Closed Terminal- The normally

closed terminal (87A) is not connected in this appli-

cation.

The rear fog lamp relay can be diagnosed using

conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - REAR FOG LAMP

RELAY

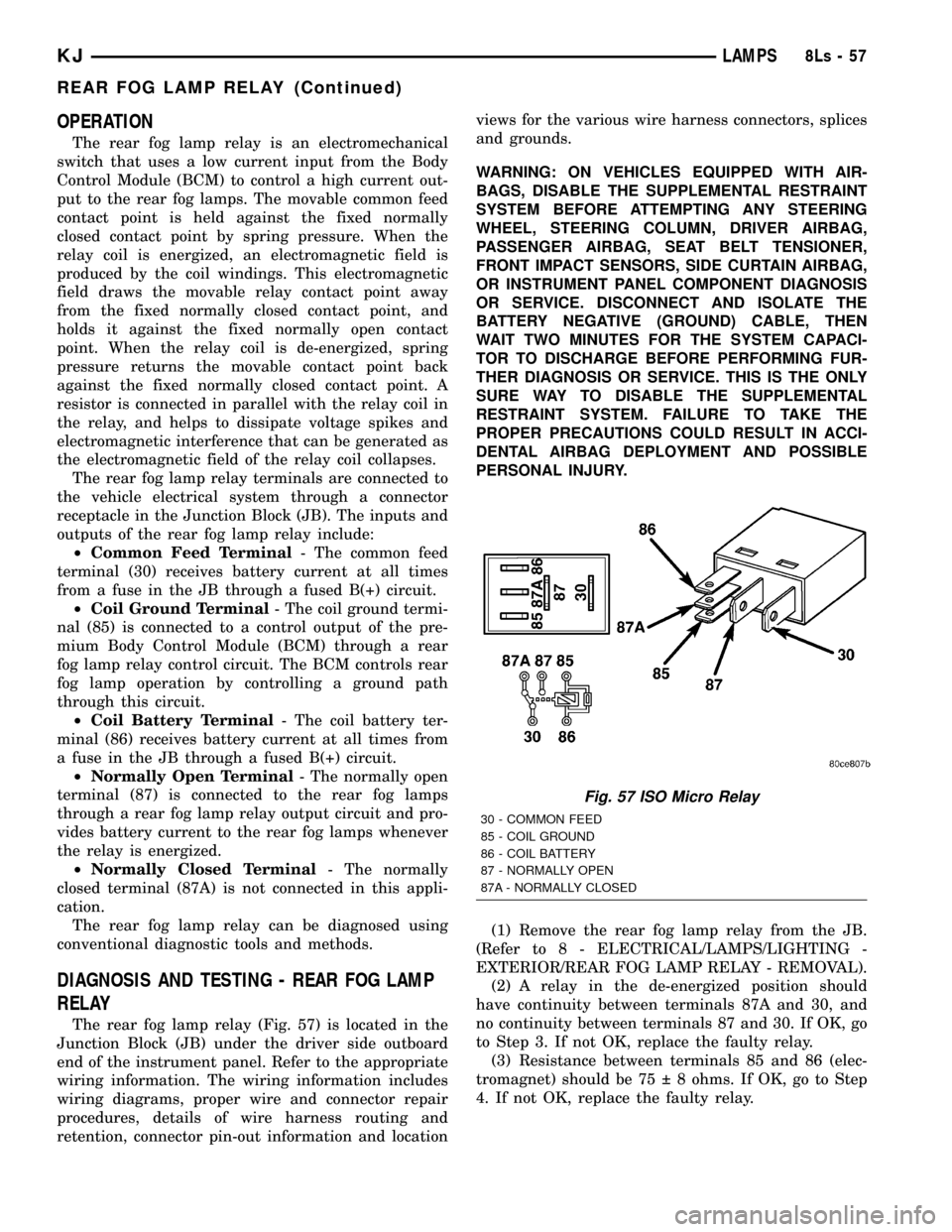

The rear fog lamp relay (Fig. 57) is located in the

Junction Block (JB) under the driver side outboard

end of the instrument panel. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and locationviews for the various wire harness connectors, splices

and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Remove the rear fog lamp relay from the JB.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/REAR FOG LAMP RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

Fig. 57 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJLAMPS8Ls-57

REAR FOG LAMP RELAY (Continued)

Page 587 of 1803

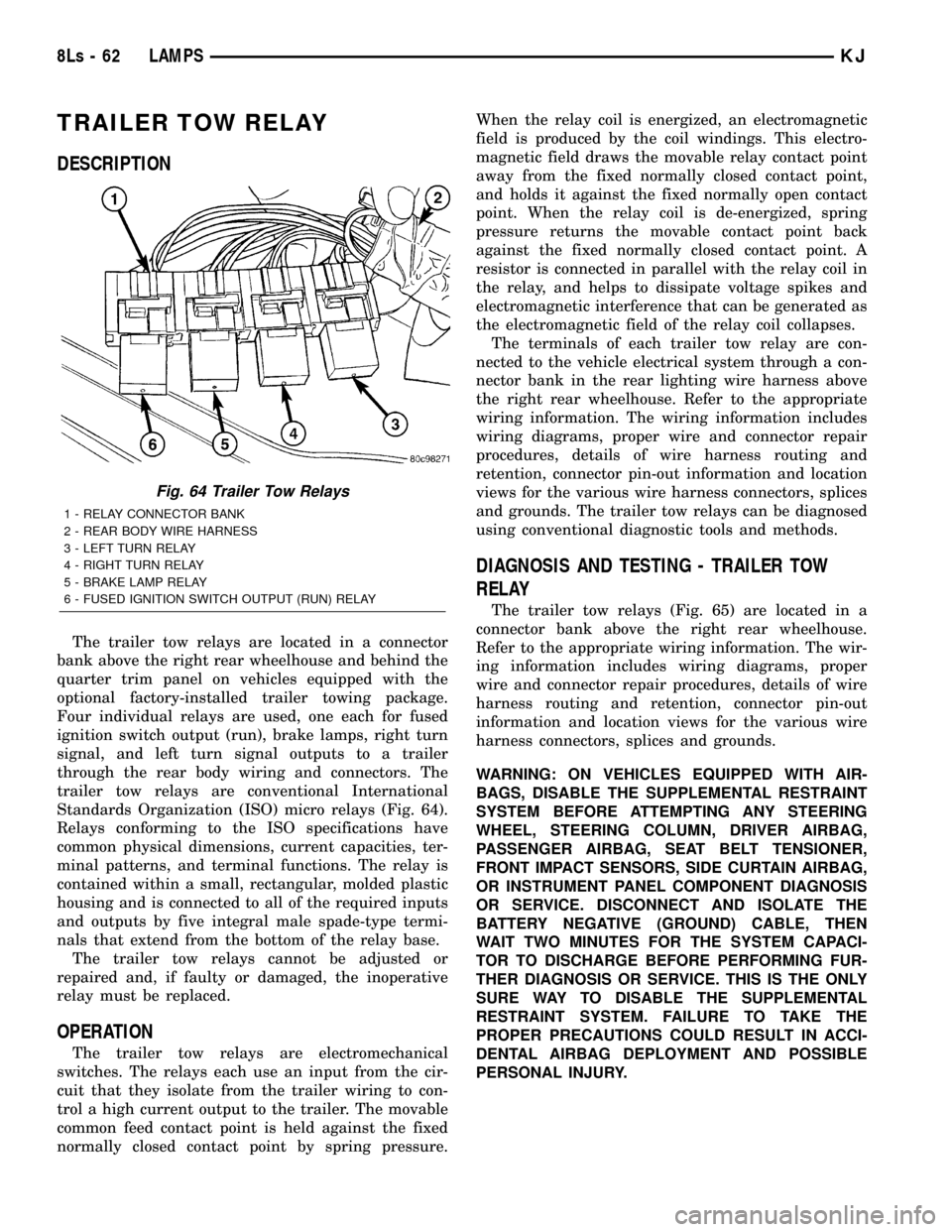

TRAILER TOW RELAY

DESCRIPTION

The trailer tow relays are located in a connector

bank above the right rear wheelhouse and behind the

quarter trim panel on vehicles equipped with the

optional factory-installed trailer towing package.

Four individual relays are used, one each for fused

ignition switch output (run), brake lamps, right turn

signal, and left turn signal outputs to a trailer

through the rear body wiring and connectors. The

trailer tow relays are conventional International

Standards Organization (ISO) micro relays (Fig. 64).

Relays conforming to the ISO specifications have

common physical dimensions, current capacities, ter-

minal patterns, and terminal functions. The relay is

contained within a small, rectangular, molded plastic

housing and is connected to all of the required inputs

and outputs by five integral male spade-type termi-

nals that extend from the bottom of the relay base.

The trailer tow relays cannot be adjusted or

repaired and, if faulty or damaged, the inoperative

relay must be replaced.

OPERATION

The trailer tow relays are electromechanical

switches. The relays each use an input from the cir-

cuit that they isolate from the trailer wiring to con-

trol a high current output to the trailer. The movable

common feed contact point is held against the fixed

normally closed contact point by spring pressure.When the relay coil is energized, an electromagnetic

field is produced by the coil windings. This electro-

magnetic field draws the movable relay contact point

away from the fixed normally closed contact point,

and holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The terminals of each trailer tow relay are con-

nected to the vehicle electrical system through a con-

nector bank in the rear lighting wire harness above

the right rear wheelhouse. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds. The trailer tow relays can be diagnosed

using conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - TRAILER TOW

RELAY

The trailer tow relays (Fig. 65) are located in a

connector bank above the right rear wheelhouse.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

Fig. 64 Trailer Tow Relays

1 - RELAY CONNECTOR BANK

2 - REAR BODY WIRE HARNESS

3 - LEFT TURN RELAY

4 - RIGHT TURN RELAY

5 - BRAKE LAMP RELAY

6 - FUSED IGNITION SWITCH OUTPUT (RUN) RELAY

8Ls - 62 LAMPSKJ

Page 589 of 1803

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

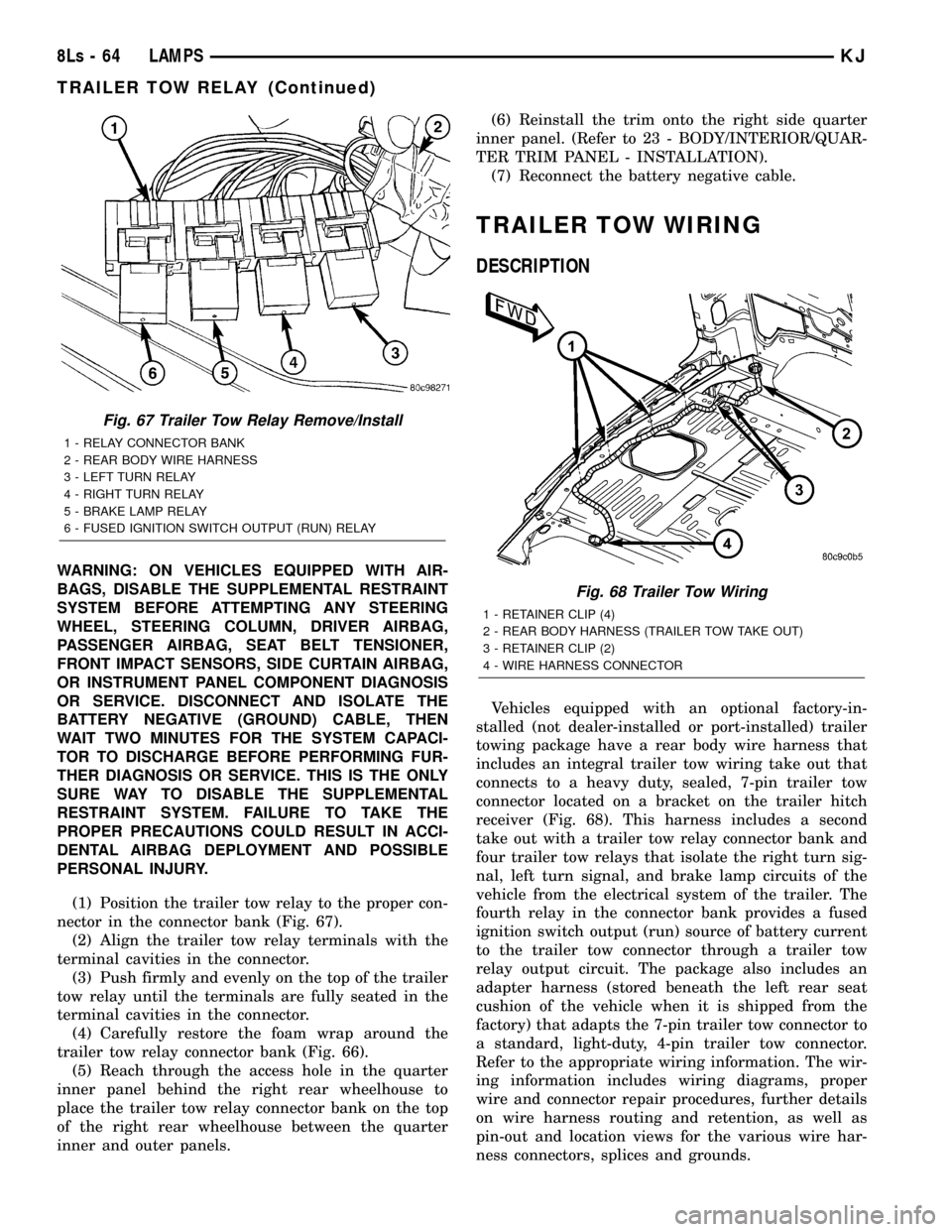

(1) Position the trailer tow relay to the proper con-

nector in the connector bank (Fig. 67).

(2) Align the trailer tow relay terminals with the

terminal cavities in the connector.

(3) Push firmly and evenly on the top of the trailer

tow relay until the terminals are fully seated in the

terminal cavities in the connector.

(4) Carefully restore the foam wrap around the

trailer tow relay connector bank (Fig. 66).

(5) Reach through the access hole in the quarter

inner panel behind the right rear wheelhouse to

place the trailer tow relay connector bank on the top

of the right rear wheelhouse between the quarter

inner and outer panels.(6) Reinstall the trim onto the right side quarter

inner panel. (Refer to 23 - BODY/INTERIOR/QUAR-

TER TRIM PANEL - INSTALLATION).

(7) Reconnect the battery negative cable.

TRAILER TOW WIRING

DESCRIPTION

Vehicles equipped with an optional factory-in-

stalled (not dealer-installed or port-installed) trailer

towing package have a rear body wire harness that

includes an integral trailer tow wiring take out that

connects to a heavy duty, sealed, 7-pin trailer tow

connector located on a bracket on the trailer hitch

receiver (Fig. 68). This harness includes a second

take out with a trailer tow relay connector bank and

four trailer tow relays that isolate the right turn sig-

nal, left turn signal, and brake lamp circuits of the

vehicle from the electrical system of the trailer. The

fourth relay in the connector bank provides a fused

ignition switch output (run) source of battery current

to the trailer tow connector through a trailer tow

relay output circuit. The package also includes an

adapter harness (stored beneath the left rear seat

cushion of the vehicle when it is shipped from the

factory) that adapts the 7-pin trailer tow connector to

a standard, light-duty, 4-pin trailer tow connector.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

Fig. 67 Trailer Tow Relay Remove/Install

1 - RELAY CONNECTOR BANK

2 - REAR BODY WIRE HARNESS

3 - LEFT TURN RELAY

4 - RIGHT TURN RELAY

5 - BRAKE LAMP RELAY

6 - FUSED IGNITION SWITCH OUTPUT (RUN) RELAY

Fig. 68 Trailer Tow Wiring

1 - RETAINER CLIP (4)

2 - REAR BODY HARNESS (TRAILER TOW TAKE OUT)

3 - RETAINER CLIP (2)

4 - WIRE HARNESS CONNECTOR

8Ls - 64 LAMPSKJ

TRAILER TOW RELAY (Continued)

Page 607 of 1803

proper Diagnostic Procedures manual. The

DRBIIItscan tool can provide confirmation

that the PCI data bus is functional, that all of

the electronic modules are sending and receiv-

ing the proper messages on the PCI data bus,

and that the power lock motors are being sent

the proper hard wired outputs by the relays for

them to perform their power lock system func-

tions.

Following are tests that will help to diagnose the

hard wired components and circuits of the power lock

system. However, these tests may not prove conclu-

sive in the diagnosis of this system. In order to

obtain conclusive testing of the power lock system,

the Programmable Communications Interface (PCI)

data bus network and all of the electronic modules

that provide inputs to, or receive outputs from the

power lock system components must be checked.

The Body Control Module (BCM) will set Diagnos-

tic Trouble Codes (DTC) for the power lock system.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

PRELIMINARY DIAGNOSIS

As a preliminary diagnosis for the power lock sys-

tem, note the system operation while you actuate

both the Lock and Unlock functions with the power

lock switches and with the Remote Keyless Entry

(RKE) transmitter. Then, proceed as follows:

²If the entire power lock system fails to function

with either the power lock switches or the RKE

transmitter, check the fused B(+) fuse in the junction

Block (JB).

²If the power lock system functions with both

power lock switches, but not with the RKE transmit-

ter, proceed to diagnosis of the Remote Keyless Entry

(RKE) system. (Refer to 8 - ELECTRICAL/POWER

LOCKS/KEYLESS ENTRY TRANSMITTER - DIAG-

NOSIS AND TESTING) or (Refer to 8 - ELECTRI-

CAL/POWER LOCKS/REMOTE KEYLESS ENTRY

MODULE - DIAGNOSIS AND TESTING).

²If the power lock system functions with the RKE

transmitter, but not with one or both power lock

switches, proceed to diagnosis of the door lock

switches. (Refer to 8 - ELECTRICAL/POWER

LOCKS/POWER LOCK SWITCH - DIAGNOSIS AND

TESTING).

²If the driver side power lock switch operates

only the driver side front door power lock motor, but

all other power lock motors operate with the passen-

ger side power lock switch or the RKE transmitter,

use a DRBIIItscan tool and the appropriate diagnos-tic information to diagnose the Programmable Com-

munications Interface (PCI) data bus.

²If only one power lock motor fails to operate

with both power lock switches and the RKE trans-

mitter, proceed to diagnosis of the power lock motor.

(Refer to 8 - ELECTRICAL/POWER LOCKS/POWER

LOCK MOTOR - DIAGNOSIS AND TESTING).

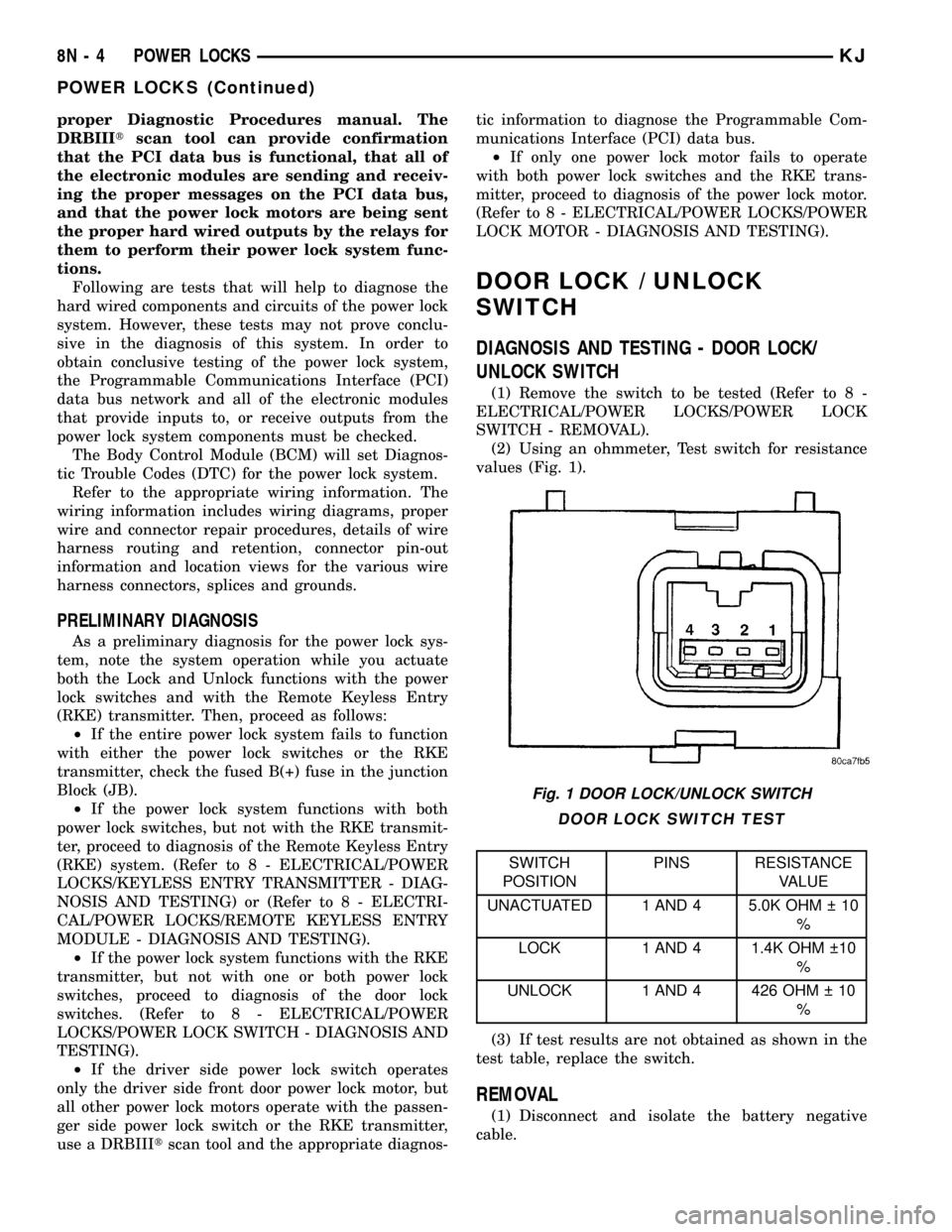

DOOR LOCK / UNLOCK

SWITCH

DIAGNOSIS AND TESTING - DOOR LOCK/

UNLOCK SWITCH

(1) Remove the switch to be tested (Refer to 8 -

ELECTRICAL/POWER LOCKS/POWER LOCK

SWITCH - REMOVAL).

(2) Using an ohmmeter, Test switch for resistance

values (Fig. 1).

DOOR LOCK SWITCH TEST

SWITCH

POSITIONPINS RESISTANCE

VALUE

UNACTUATED 1 AND 4 5.0K OHM 10

%

LOCK 1 AND 4 1.4K OHM 10

%

UNLOCK 1 AND 4 426 OHM 10

%

(3) If test results are not obtained as shown in the

test table, replace the switch.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

Fig. 1 DOOR LOCK/UNLOCK SWITCH

8N - 4 POWER LOCKSKJ

POWER LOCKS (Continued)

Page 614 of 1803

POWER MIRRORS

TABLE OF CONTENTS

page page

POWER MIRRORS

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING - POWER

MIRRORS...........................11

POWER MIRROR SWITCH

DIAGNOSIS AND TESTING - POWER MIRROR

SWITCH............................12REMOVAL.............................13

INSTALLATION.........................13

SIDEVIEW MIRROR

REMOVAL.............................13

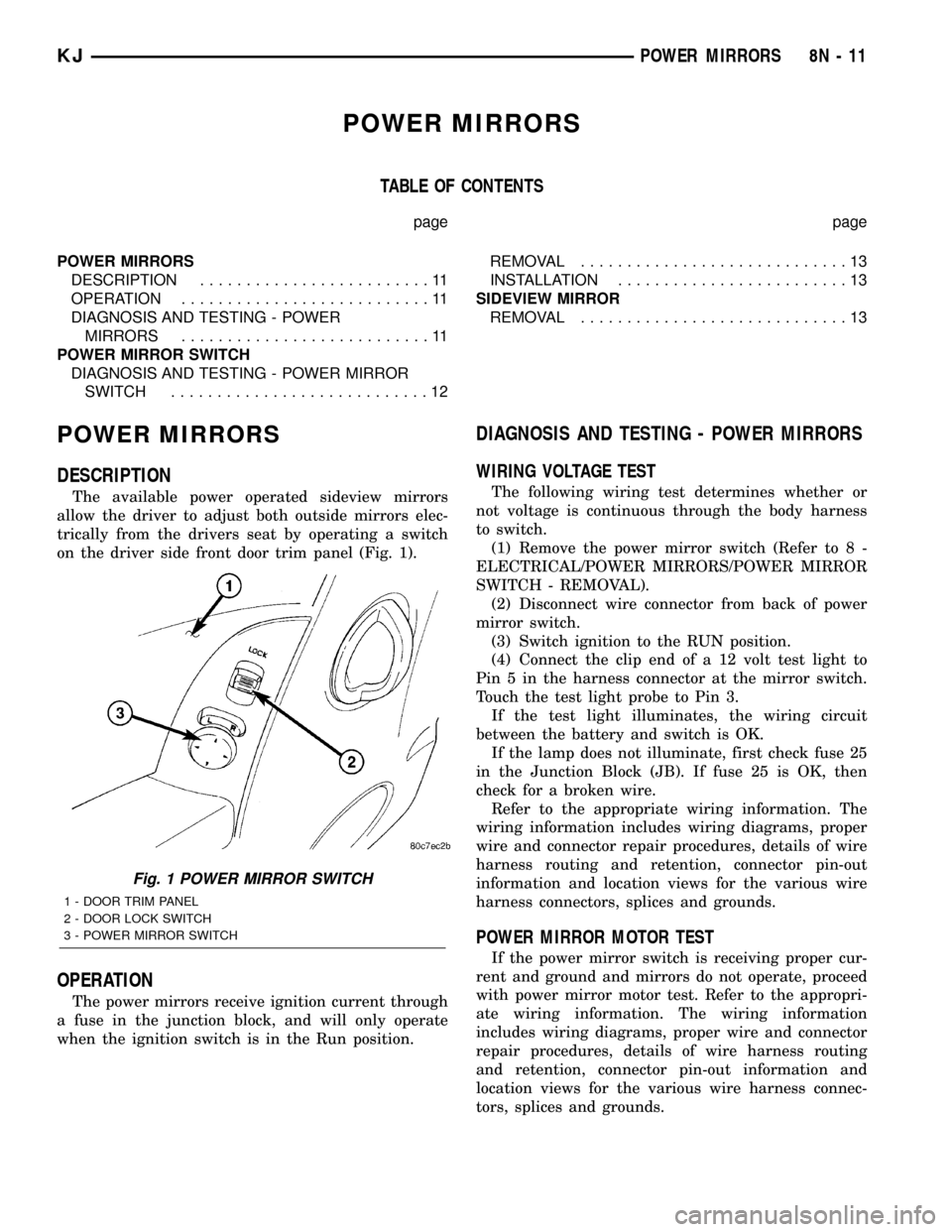

POWER MIRRORS

DESCRIPTION

The available power operated sideview mirrors

allow the driver to adjust both outside mirrors elec-

trically from the drivers seat by operating a switch

on the driver side front door trim panel (Fig. 1).

OPERATION

The power mirrors receive ignition current through

a fuse in the junction block, and will only operate

when the ignition switch is in the Run position.

DIAGNOSIS AND TESTING - POWER MIRRORS

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to switch.

(1) Remove the power mirror switch (Refer to 8 -

ELECTRICAL/POWER MIRRORS/POWER MIRROR

SWITCH - REMOVAL).

(2) Disconnect wire connector from back of power

mirror switch.

(3) Switch ignition to the RUN position.

(4) Connect the clip end of a 12 volt test light to

Pin 5 in the harness connector at the mirror switch.

Touch the test light probe to Pin 3.

If the test light illuminates, the wiring circuit

between the battery and switch is OK.

If the lamp does not illuminate, first check fuse 25

in the Junction Block (JB). If fuse 25 is OK, then

check for a broken wire.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

POWER MIRROR MOTOR TEST

If the power mirror switch is receiving proper cur-

rent and ground and mirrors do not operate, proceed

with power mirror motor test. Refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

Fig. 1 POWER MIRROR SWITCH

1 - DOOR TRIM PANEL

2 - DOOR LOCK SWITCH

3 - POWER MIRROR SWITCH

KJPOWER MIRRORS 8N - 11

Page 618 of 1803

OPERATION

The power seat system receives battery current

through a fuse in the Power Distribution Center

(PDC) and a circuit breaker in the Junction Block,

regardless of the ignition switch position.

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the appropri-

ate power seat track adjuster motor. The selected

adjuster motor operates to move the seat track

through its drive unit in the selected direction until

the switch is released, or until the travel limit of the

seat track is reached. When the switch is moved in

the opposite direction, the battery feed and ground

path to the motor are reversed through the switch

contacts. This causes the adjuster motor to run in the

opposite direction.

Refer to the owner's manual in the vehicle glove

box for more information on the features, use and

operation of the power seat system.

DIAGNOSIS AND TESTING - POWER SEATS

Before any testing of the power seat system is

attempted, the battery should be fully-charged and

all wire harness connections and pins cleaned and

tightened to ensure proper continuity and grounds.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and joint connector location views for the var-

ious wire harness connectors, splices and grounds.

(1) If all power seats are inoperative, check the

automatic resetting circuit breaker in the Junction

Block. (Refer to 8 - ELECTRICAL/POWER DISTRI-

BUTION/CIRCUIT BREAKER - DIAGNOSIS AND

TESTING).

(2) With the dome lamp on, apply the power seat

switch in the direction of the failure.

(3) If the dome lamp dims, the seat or the power

seat track may be jammed. Check under and behind

the seat for binding or obstructions.

(4) If the dome lamp does not dim, proceed with

testing of the individual power seat system compo-

nents and circuits.

SEAT TRACK

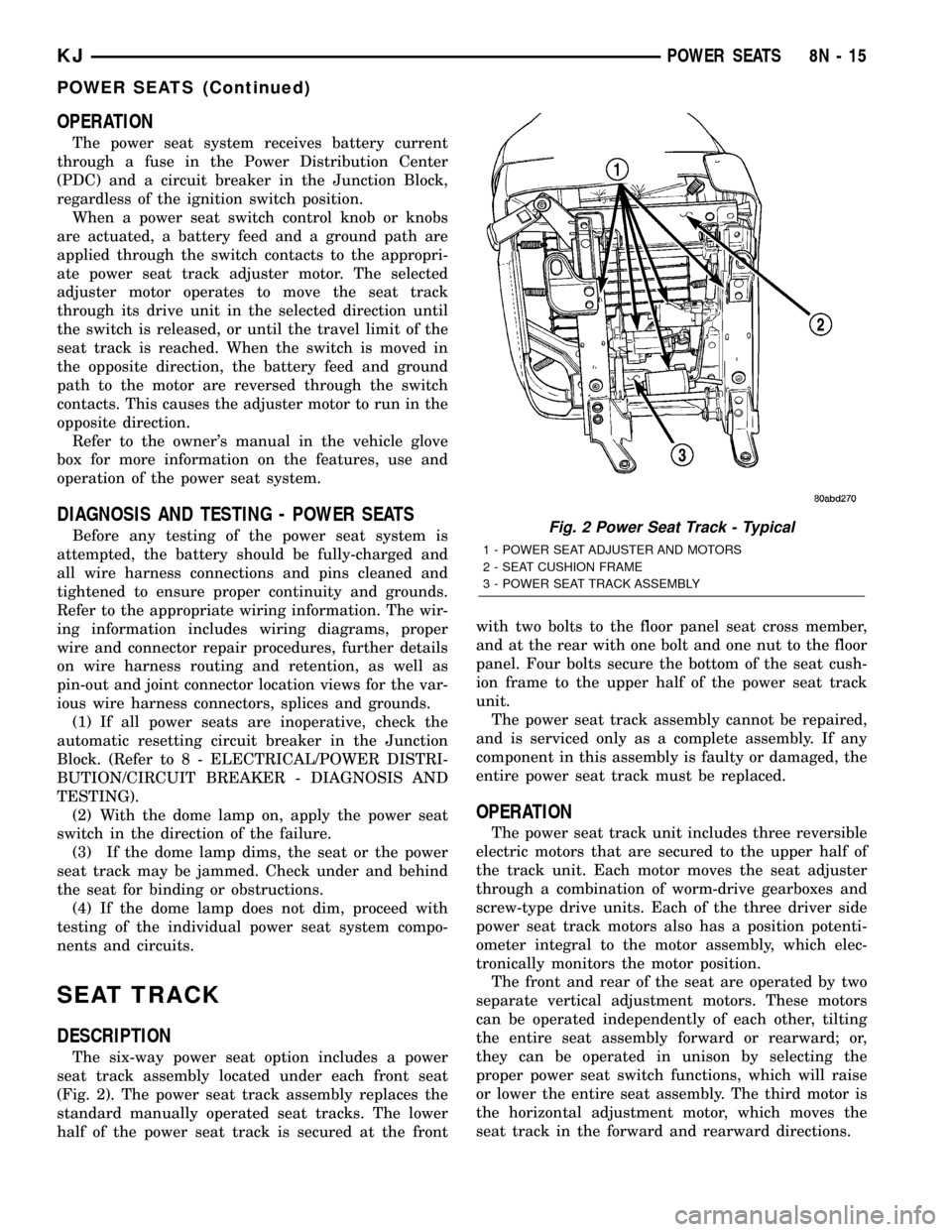

DESCRIPTION

The six-way power seat option includes a power

seat track assembly located under each front seat

(Fig. 2). The power seat track assembly replaces the

standard manually operated seat tracks. The lower

half of the power seat track is secured at the frontwith two bolts to the floor panel seat cross member,

and at the rear with one bolt and one nut to the floor

panel. Four bolts secure the bottom of the seat cush-

ion frame to the upper half of the power seat track

unit.

The power seat track assembly cannot be repaired,

and is serviced only as a complete assembly. If any

component in this assembly is faulty or damaged, the

entire power seat track must be replaced.

OPERATION

The power seat track unit includes three reversible

electric motors that are secured to the upper half of

the track unit. Each motor moves the seat adjuster

through a combination of worm-drive gearboxes and

screw-type drive units. Each of the three driver side

power seat track motors also has a position potenti-

ometer integral to the motor assembly, which elec-

tronically monitors the motor position.

The front and rear of the seat are operated by two

separate vertical adjustment motors. These motors

can be operated independently of each other, tilting

the entire seat assembly forward or rearward; or,

they can be operated in unison by selecting the

proper power seat switch functions, which will raise

or lower the entire seat assembly. The third motor is

the horizontal adjustment motor, which moves the

seat track in the forward and rearward directions.

Fig. 2 Power Seat Track - Typical

1 - POWER SEAT ADJUSTER AND MOTORS

2 - SEAT CUSHION FRAME

3 - POWER SEAT TRACK ASSEMBLY

KJPOWER SEATS 8N - 15

POWER SEATS (Continued)

Page 624 of 1803

POWER WINDOWS

TABLE OF CONTENTS

page page

POWER WINDOWS

DESCRIPTION.........................21

OPERATION...........................21

DIAGNOSIS AND TESTING - POWER

WINDOWS...........................21

WINDOW MOTOR

REMOVAL.............................22WINDOW SWITCH

DIAGNOSIS AND TESTING - WINDOW

SWITCH............................22

REMOVAL.............................23

INSTALLATION.........................23

POWER WINDOWS

DESCRIPTION

The power window system allows each of the door

windows to be raised and lowered electrically by

actuating a switch on the center console. A master

switch on the front of the center console allows the

driver to raise or lower each of the passenger door

windows and to lock out the individual switches on

the rear of the center console from operation. The

power window system receives battery feed through

fuse 13 in the Power Distribution Center (PDC), only

when the ignition switch is in the RUN or ACCES-

SORY position.

OPERATION

WINDOW SWITCH

The power window switches control the battery

and ground feeds to the power window motors. Both

of the rear door power window switches receive their

battery and ground feeds through the circuitry of the

front window switch. When the power window lock-

out switch is in the Lock position, the battery feed

for the rear door window switches is interrupted.

WINDOW MOTOR

Front door window lift motors use permanent type

magnets. The B+ and ground applied at the motor

terminal pins will cause the motor to rotate in one

direction. Reversing current through the motor ter-

minals will cause the motor to rotate in the opposite

direction.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - POWER

WINDOWS

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to the front switch.

(1) Remove the power window switch and bezel

(Refer to 8 - ELECTRICAL/POWER WINDOWS/

POWER WINDOW SWITCH - REMOVAL).

(2) Disconnect wire connector from back of power

window switch.

(3) Switch ignition to the ON position.

(4) Connect the clip end of a 12 volt test light to

Pin 14 of the window switch harness connector.

Touch the test light probe to Pin 10.

²If the test light illuminates, the wiring circuit

between the battery and switch is OK.

²If the lamp does not illuminate, first check fuse

13 in the Power Distribution Center (PDC). If fuse 13

is OK, then check for a broken wire.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

POWER WINDOW MOTOR TEST

If the power window motor is receiving proper cur-

rent and ground and does not operate, proceed with

motor test. Refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

details of wire harness routing and retention, connec-

tor pin-out information and location views for the

various wire harness connectors, splices and grounds.

(1) Remove front door trim panel as necessary to

gain access to power window motor wire connector

KJPOWER WINDOWS 8N - 21