oil JEEP LIBERTY 2002 KJ / 1.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 131 of 1803

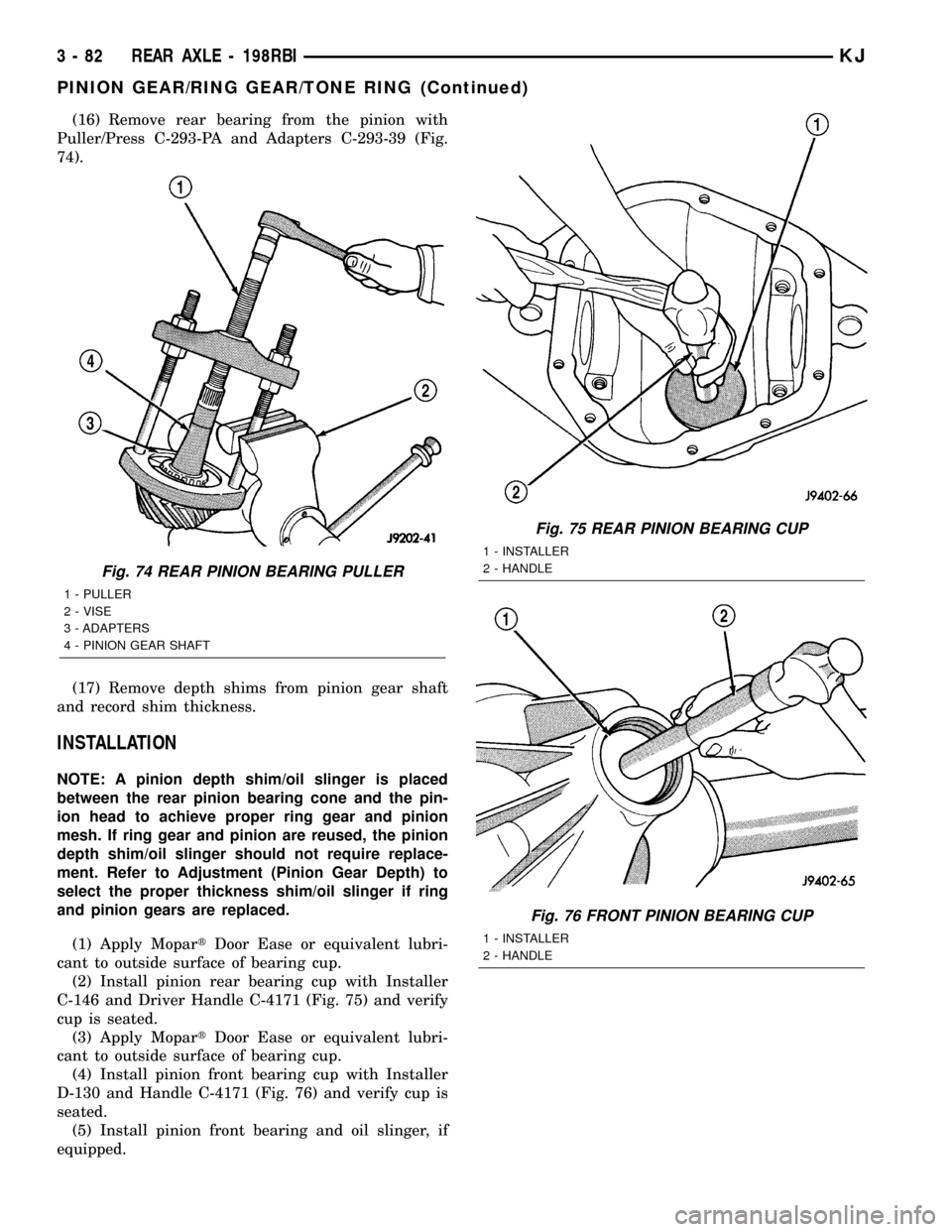

(16) Remove rear bearing from the pinion with

Puller/Press C-293-PA and Adapters C-293-39 (Fig.

74).

(17) Remove depth shims from pinion gear shaft

and record shim thickness.

INSTALLATION

NOTE: A pinion depth shim/oil slinger is placed

between the rear pinion bearing cone and the pin-

ion head to achieve proper ring gear and pinion

mesh. If ring gear and pinion are reused, the pinion

depth shim/oil slinger should not require replace-

ment. Refer to Adjustment (Pinion Gear Depth) to

select the proper thickness shim/oil slinger if ring

and pinion gears are replaced.

(1) Apply MopartDoor Ease or equivalent lubri-

cant to outside surface of bearing cup.

(2) Install pinion rear bearing cup with Installer

C-146 and Driver Handle C-4171 (Fig. 75) and verify

cup is seated.

(3) Apply MopartDoor Ease or equivalent lubri-

cant to outside surface of bearing cup.

(4) Install pinion front bearing cup with Installer

D-130 and Handle C-4171 (Fig. 76) and verify cup is

seated.

(5) Install pinion front bearing and oil slinger, if

equipped.

Fig. 74 REAR PINION BEARING PULLER

1 - PULLER

2 - VISE

3 - ADAPTERS

4 - PINION GEAR SHAFT

Fig. 75 REAR PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

Fig. 76 FRONT PINION BEARING CUP

1 - INSTALLER

2 - HANDLE

3 - 82 REAR AXLE - 198RBIKJ

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 140 of 1803

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lift/jack under the axle and secure

axle to device.

(3) Remove wheels and tires.

(4) Mark propeller shaft and pinion yoke for

installation reference.

(5) Remove propeller shaft and suspend under the

vehicle.

(6) Remove brake drums, parking brake cables and

speed sensor from the axle.

(7) Disconnect the brake hose at the body junction

block.

(8) Remove brakes and backing plates.

(9) Remove vent hose from the axle shaft tube.

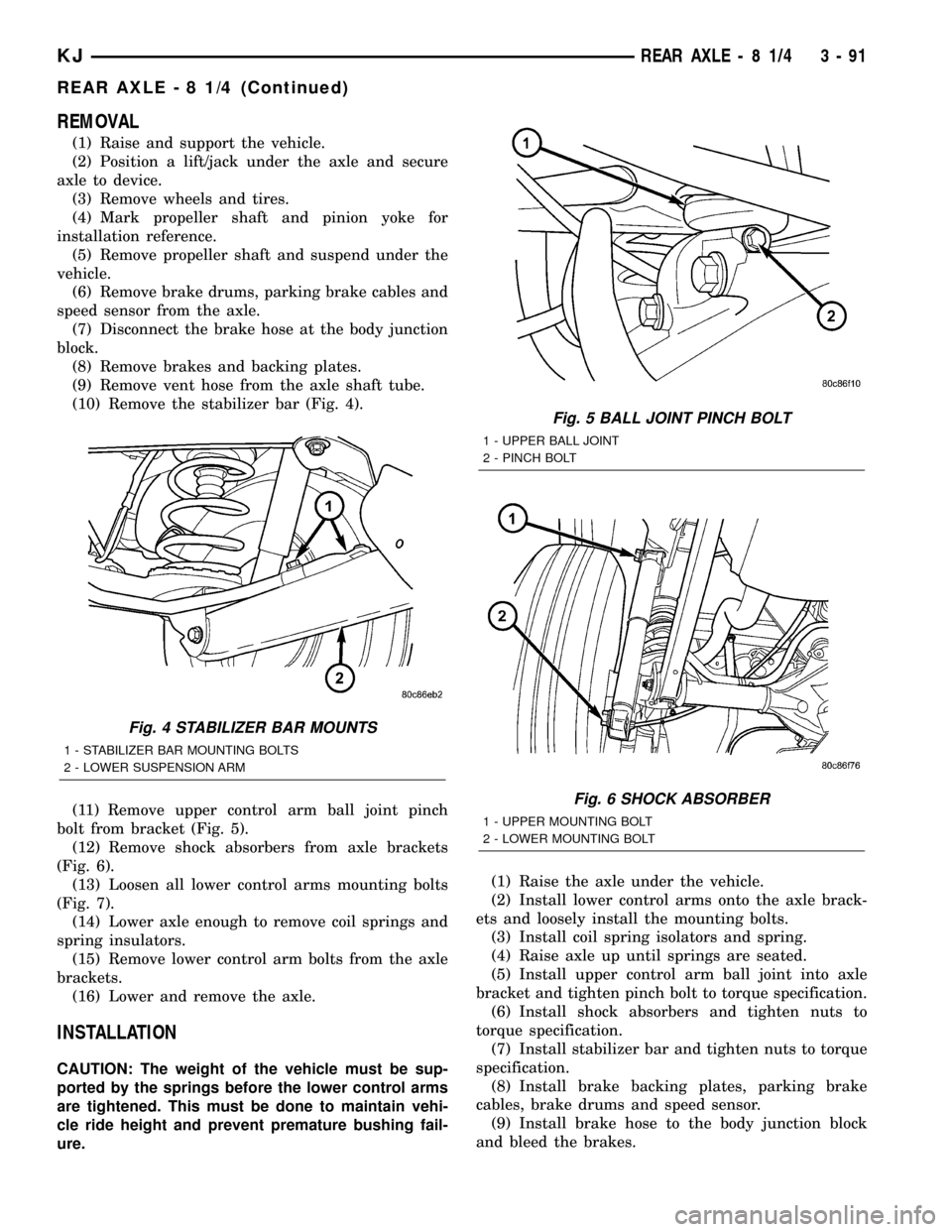

(10) Remove the stabilizer bar (Fig. 4).

(11) Remove upper control arm ball joint pinch

bolt from bracket (Fig. 5).

(12) Remove shock absorbers from axle brackets

(Fig. 6).

(13) Loosen all lower control arms mounting bolts

(Fig. 7).

(14) Lower axle enough to remove coil springs and

spring insulators.

(15) Remove lower control arm bolts from the axle

brackets.

(16) Lower and remove the axle.

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before the lower control arms

are tightened. This must be done to maintain vehi-

cle ride height and prevent premature bushing fail-

ure.(1) Raise the axle under the vehicle.

(2) Install lower control arms onto the axle brack-

ets and loosely install the mounting bolts.

(3) Install coil spring isolators and spring.

(4) Raise axle up until springs are seated.

(5) Install upper control arm ball joint into axle

bracket and tighten pinch bolt to torque specification.

(6) Install shock absorbers and tighten nuts to

torque specification.

(7) Install stabilizer bar and tighten nuts to torque

specification.

(8) Install brake backing plates, parking brake

cables, brake drums and speed sensor.

(9) Install brake hose to the body junction block

and bleed the brakes.

Fig. 4 STABILIZER BAR MOUNTS

1 - STABILIZER BAR MOUNTING BOLTS

2 - LOWER SUSPENSION ARM

Fig. 5 BALL JOINT PINCH BOLT

1 - UPPER BALL JOINT

2 - PINCH BOLT

Fig. 6 SHOCK ABSORBER

1 - UPPER MOUNTING BOLT

2 - LOWER MOUNTING BOLT

KJREAR AXLE - 8 1/4 3 - 91

REAR AXLE - 8 1/4 (Continued)

Page 153 of 1803

lbs.) increments until proper rotating torque is

achieved.

NOTE: The bearing rotating torque should be con-

stant during a complete revolution of the pinion. If

the rotating torque varies, it indicates a binding

condition.

(9) The seal replacement is unacceptable if the

final pinion nut torque is less than 285 N´m (210 ft.

lbs.).

(10) Install the propeller shaft with the installa-

tion reference marks aligned.

(11) Install the brake drums.

(12) Check the differential housing lubricant level.

(13) Install wheel and tire assemblies and lower

the vehicle.

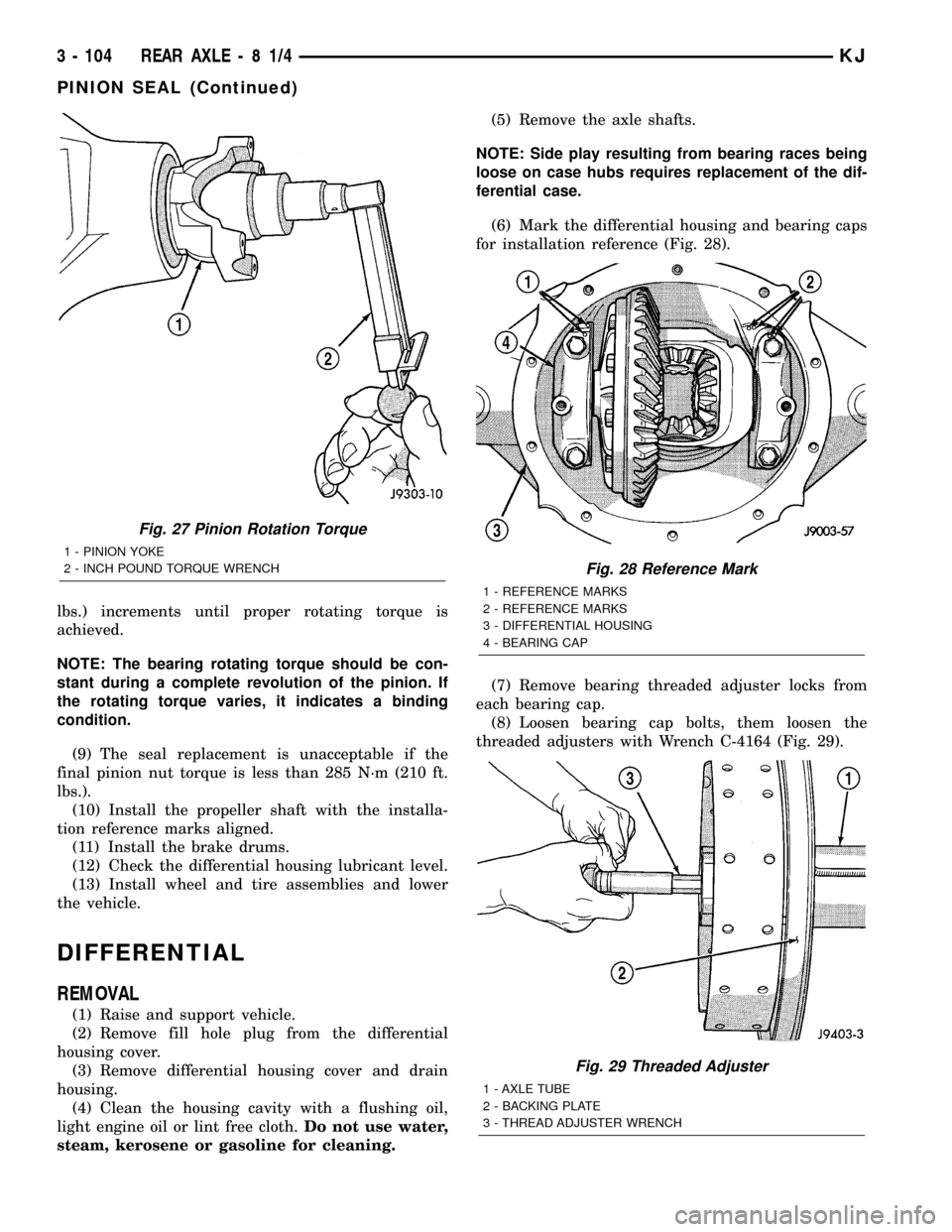

DIFFERENTIAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove fill hole plug from the differential

housing cover.

(3) Remove differential housing cover and drain

housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.(5) Remove the axle shafts.

NOTE: Side play resulting from bearing races being

loose on case hubs requires replacement of the dif-

ferential case.

(6) Mark the differential housing and bearing caps

for installation reference (Fig. 28).

(7) Remove bearing threaded adjuster locks from

each bearing cap.

(8) Loosen bearing cap bolts, them loosen the

threaded adjusters with Wrench C-4164 (Fig. 29).

Fig. 27 Pinion Rotation Torque

1 - PINION YOKE

2 - INCH POUND TORQUE WRENCH

Fig. 28 Reference Mark

1 - REFERENCE MARKS

2 - REFERENCE MARKS

3 - DIFFERENTIAL HOUSING

4 - BEARING CAP

Fig. 29 Threaded Adjuster

1 - AXLE TUBE

2 - BACKING PLATE

3 - THREAD ADJUSTER WRENCH

3 - 104 REAR AXLE-81/4KJ

PINION SEAL (Continued)

Page 161 of 1803

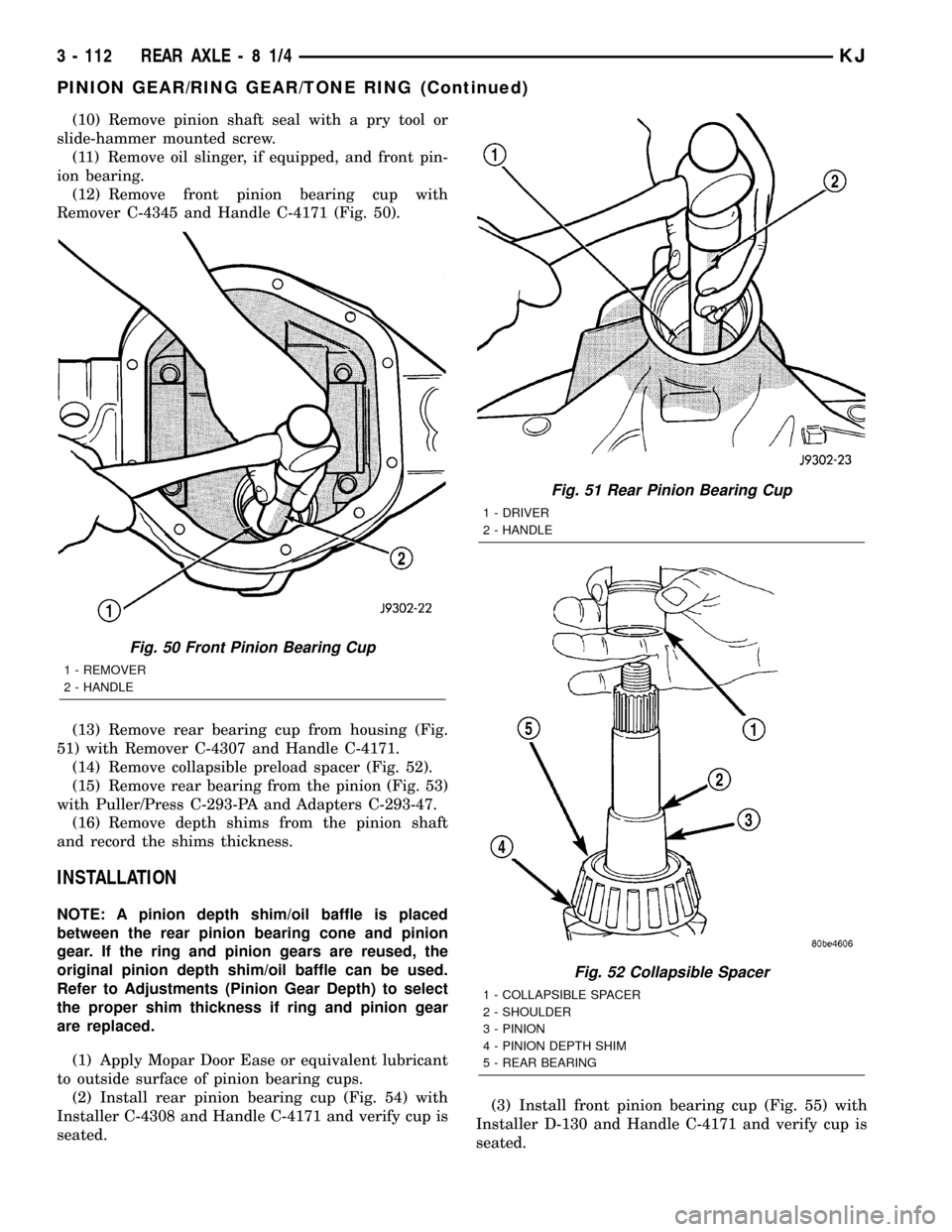

(10) Remove pinion shaft seal with a pry tool or

slide-hammer mounted screw.

(11) Remove oil slinger, if equipped, and front pin-

ion bearing.

(12) Remove front pinion bearing cup with

Remover C-4345 and Handle C-4171 (Fig. 50).

(13) Remove rear bearing cup from housing (Fig.

51) with Remover C-4307 and Handle C-4171.

(14) Remove collapsible preload spacer (Fig. 52).

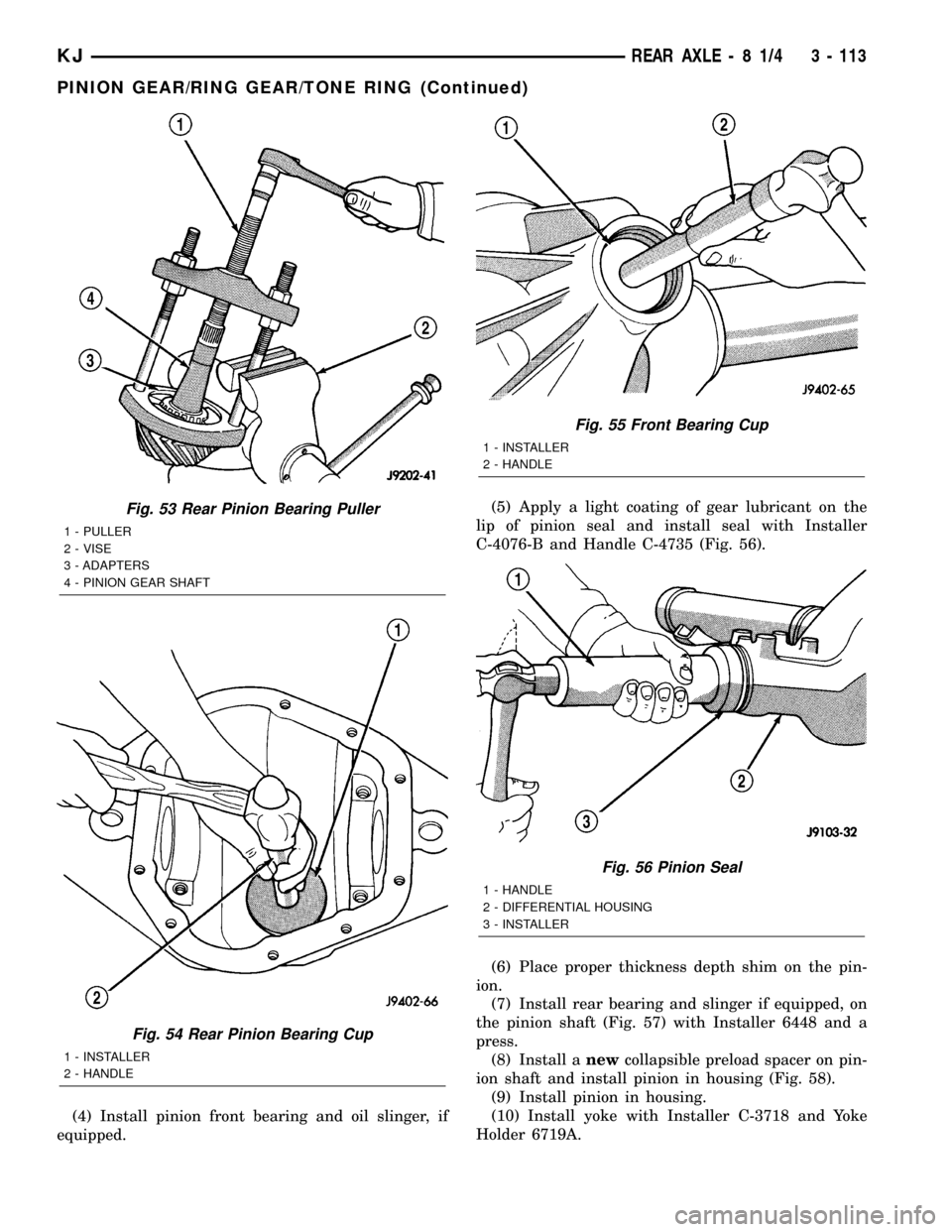

(15) Remove rear bearing from the pinion (Fig. 53)

with Puller/Press C-293-PA and Adapters C-293-47.

(16) Remove depth shims from the pinion shaft

and record the shims thickness.

INSTALLATION

NOTE: A pinion depth shim/oil baffle is placed

between the rear pinion bearing cone and pinion

gear. If the ring and pinion gears are reused, the

original pinion depth shim/oil baffle can be used.

Refer to Adjustments (Pinion Gear Depth) to select

the proper shim thickness if ring and pinion gear

are replaced.

(1) Apply Mopar Door Ease or equivalent lubricant

to outside surface of pinion bearing cups.

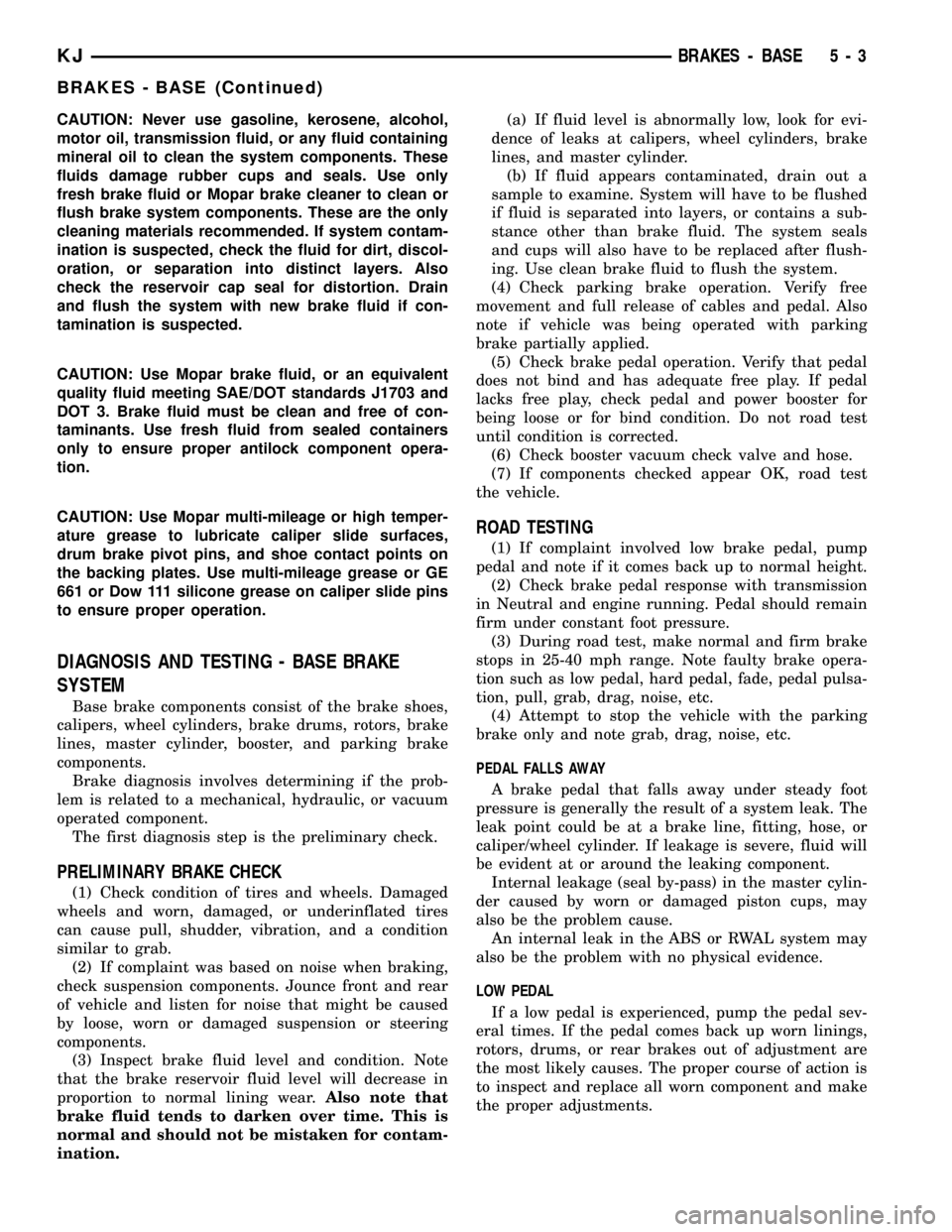

(2) Install rear pinion bearing cup (Fig. 54) with

Installer C-4308 and Handle C-4171 and verify cup is

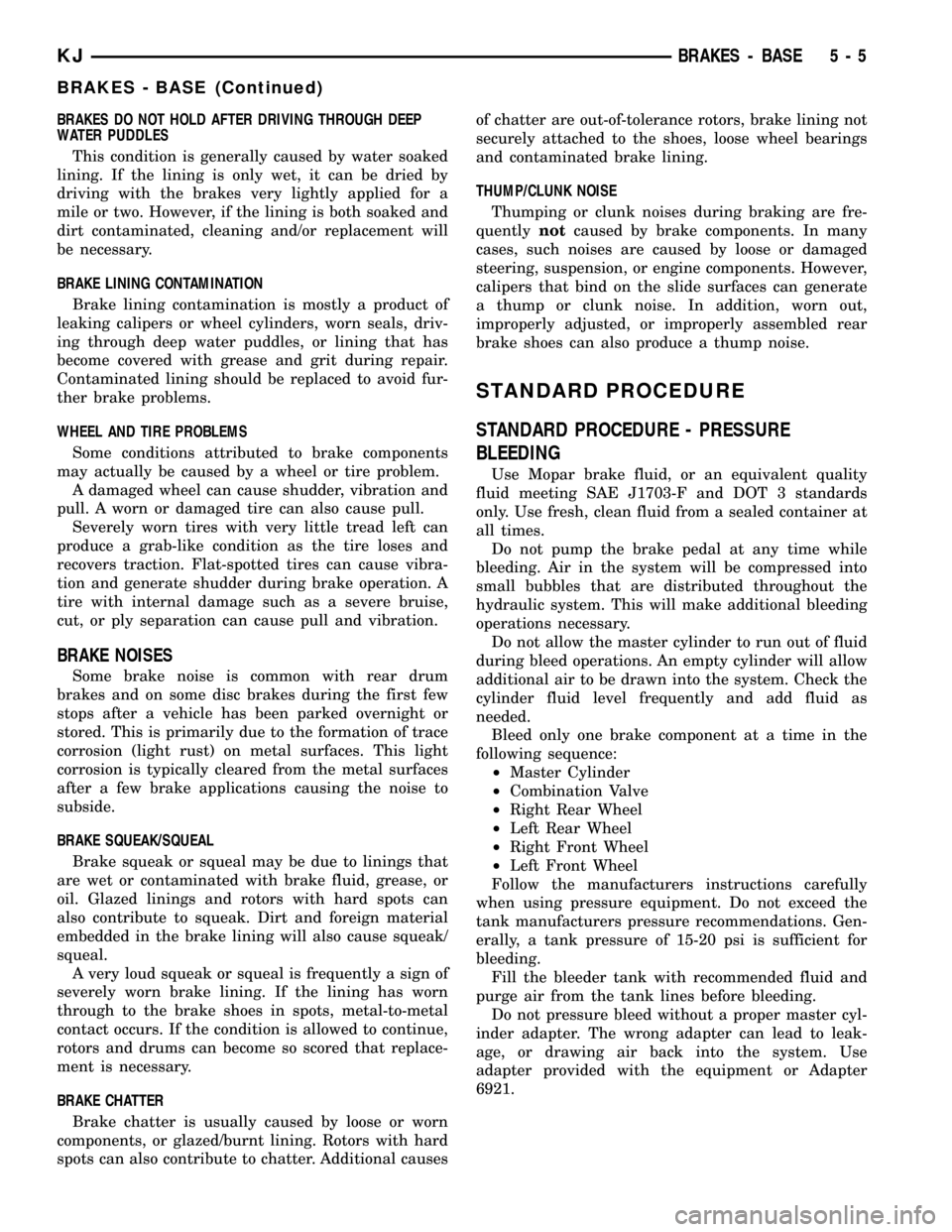

seated.(3) Install front pinion bearing cup (Fig. 55) with

Installer D-130 and Handle C-4171 and verify cup is

seated.

Fig. 50 Front Pinion Bearing Cup

1 - REMOVER

2 - HANDLE

Fig. 51 Rear Pinion Bearing Cup

1 - DRIVER

2 - HANDLE

Fig. 52 Collapsible Spacer

1 - COLLAPSIBLE SPACER

2 - SHOULDER

3 - PINION

4 - PINION DEPTH SHIM

5 - REAR BEARING

3 - 112 REAR AXLE-81/4KJ

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 162 of 1803

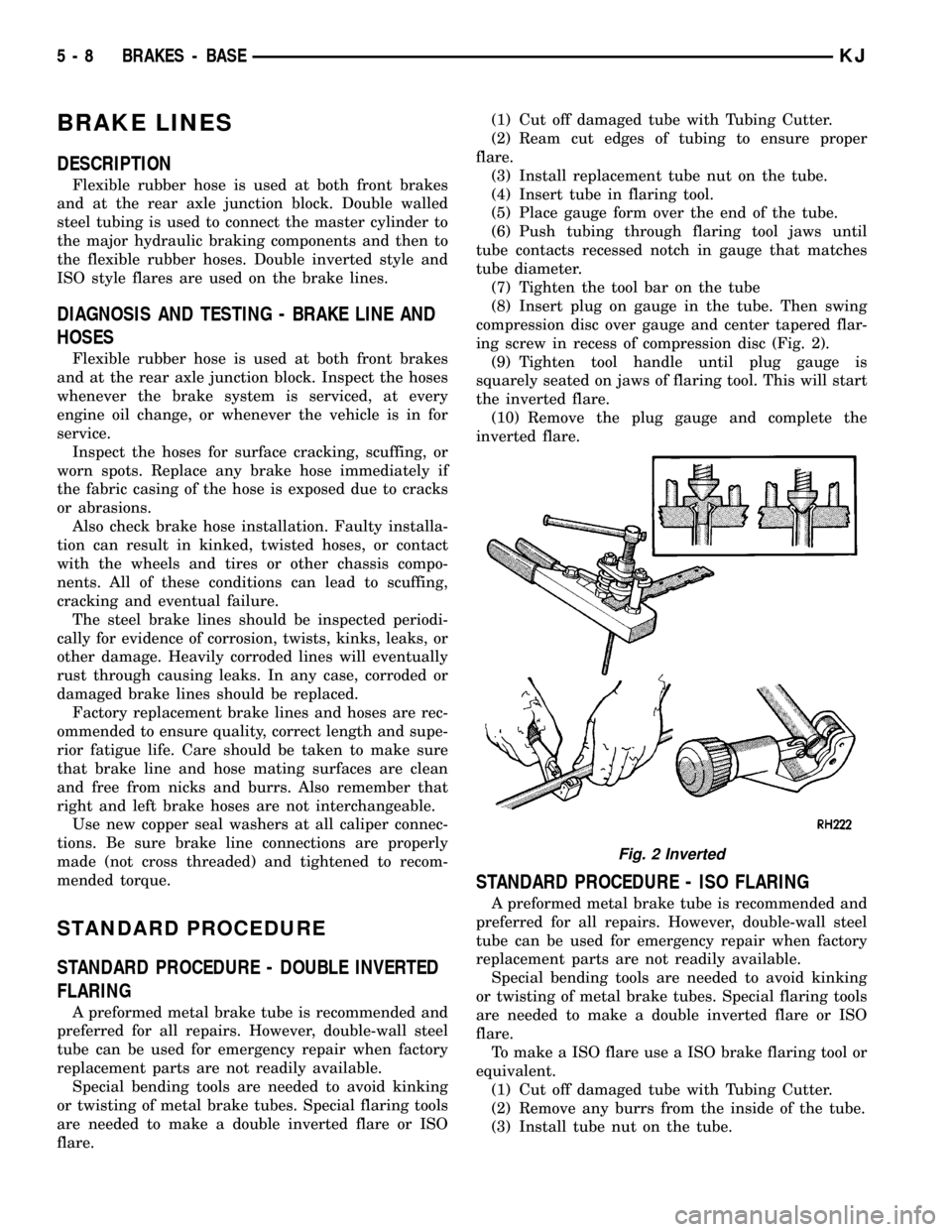

(4) Install pinion front bearing and oil slinger, if

equipped.(5) Apply a light coating of gear lubricant on the

lip of pinion seal and install seal with Installer

C-4076-B and Handle C-4735 (Fig. 56).

(6) Place proper thickness depth shim on the pin-

ion.

(7) Install rear bearing and slinger if equipped, on

the pinion shaft (Fig. 57) with Installer 6448 and a

press.

(8) Install anewcollapsible preload spacer on pin-

ion shaft and install pinion in housing (Fig. 58).

(9) Install pinion in housing.

(10) Install yoke with Installer C-3718 and Yoke

Holder 6719A.

Fig. 53 Rear Pinion Bearing Puller

1 - PULLER

2 - VISE

3 - ADAPTERS

4 - PINION GEAR SHAFT

Fig. 54 Rear Pinion Bearing Cup

1 - INSTALLER

2 - HANDLE

Fig. 55 Front Bearing Cup

1 - INSTALLER

2 - HANDLE

Fig. 56 Pinion Seal

1 - HANDLE

2 - DIFFERENTIAL HOUSING

3 - INSTALLER

KJREAR AXLE - 8 1/4 3 - 113

PINION GEAR/RING GEAR/TONE RING (Continued)

Page 167 of 1803

CAUTION: Never use gasoline, kerosene, alcohol,

motor oil, transmission fluid, or any fluid containing

mineral oil to clean the system components. These

fluids damage rubber cups and seals. Use only

fresh brake fluid or Mopar brake cleaner to clean or

flush brake system components. These are the only

cleaning materials recommended. If system contam-

ination is suspected, check the fluid for dirt, discol-

oration, or separation into distinct layers. Also

check the reservoir cap seal for distortion. Drain

and flush the system with new brake fluid if con-

tamination is suspected.

CAUTION: Use Mopar brake fluid, or an equivalent

quality fluid meeting SAE/DOT standards J1703 and

DOT 3. Brake fluid must be clean and free of con-

taminants. Use fresh fluid from sealed containers

only to ensure proper antilock component opera-

tion.

CAUTION: Use Mopar multi-mileage or high temper-

ature grease to lubricate caliper slide surfaces,

drum brake pivot pins, and shoe contact points on

the backing plates. Use multi-mileage grease or GE

661 or Dow 111 silicone grease on caliper slide pins

to ensure proper operation.

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

Base brake components consist of the brake shoes,

calipers, wheel cylinders, brake drums, rotors, brake

lines, master cylinder, booster, and parking brake

components.

Brake diagnosis involves determining if the prob-

lem is related to a mechanical, hydraulic, or vacuum

operated component.

The first diagnosis step is the preliminary check.

PRELIMINARY BRAKE CHECK

(1) Check condition of tires and wheels. Damaged

wheels and worn, damaged, or underinflated tires

can cause pull, shudder, vibration, and a condition

similar to grab.

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

normal and should not be mistaken for contam-

ination.(a) If fluid level is abnormally low, look for evi-

dence of leaks at calipers, wheel cylinders, brake

lines, and master cylinder.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a sub-

stance other than brake fluid. The system seals

and cups will also have to be replaced after flush-

ing. Use clean brake fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and pedal. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only and note grab, drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper/wheel cylinder. If leakage is severe, fluid will

be evident at or around the leaking component.

Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS or RWAL system may

also be the problem with no physical evidence.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up worn linings,

rotors, drums, or rear brakes out of adjustment are

the most likely causes. The proper course of action is

to inspect and replace all worn component and make

the proper adjustments.

KJBRAKES - BASE 5 - 3

BRAKES - BASE (Continued)

Page 169 of 1803

BRAKES DO NOT HOLD AFTER DRIVING THROUGH DEEP

WATER PUDDLES

This condition is generally caused by water soaked

lining. If the lining is only wet, it can be dried by

driving with the brakes very lightly applied for a

mile or two. However, if the lining is both soaked and

dirt contaminated, cleaning and/or replacement will

be necessary.

BRAKE LINING CONTAMINATION

Brake lining contamination is mostly a product of

leaking calipers or wheel cylinders, worn seals, driv-

ing through deep water puddles, or lining that has

become covered with grease and grit during repair.

Contaminated lining should be replaced to avoid fur-

ther brake problems.

WHEEL AND TIRE PROBLEMS

Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

Severely worn tires with very little tread left can

produce a grab-like condition as the tire loses and

recovers traction. Flat-spotted tires can cause vibra-

tion and generate shudder during brake operation. A

tire with internal damage such as a severe bruise,

cut, or ply separation can cause pull and vibration.

BRAKE NOISES

Some brake noise is common with rear drum

brakes and on some disc brakes during the first few

stops after a vehicle has been parked overnight or

stored. This is primarily due to the formation of trace

corrosion (light rust) on metal surfaces. This light

corrosion is typically cleared from the metal surfaces

after a few brake applications causing the noise to

subside.

BRAKE SQUEAK/SQUEAL

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or

oil. Glazed linings and rotors with hard spots can

also contribute to squeak. Dirt and foreign material

embedded in the brake lining will also cause squeak/

squeal.

A very loud squeak or squeal is frequently a sign of

severely worn brake lining. If the lining has worn

through to the brake shoes in spots, metal-to-metal

contact occurs. If the condition is allowed to continue,

rotors and drums can become so scored that replace-

ment is necessary.

BRAKE CHATTER

Brake chatter is usually caused by loose or worn

components, or glazed/burnt lining. Rotors with hard

spots can also contribute to chatter. Additional causesof chatter are out-of-tolerance rotors, brake lining not

securely attached to the shoes, loose wheel bearings

and contaminated brake lining.

THUMP/CLUNK NOISE

Thumping or clunk noises during braking are fre-

quentlynotcaused by brake components. In many

cases, such noises are caused by loose or damaged

steering, suspension, or engine components. However,

calipers that bind on the slide surfaces can generate

a thump or clunk noise. In addition, worn out,

improperly adjusted, or improperly assembled rear

brake shoes can also produce a thump noise.

STANDARD PROCEDURE

STANDARD PROCEDURE - PRESSURE

BLEEDING

Use Mopar brake fluid, or an equivalent quality

fluid meeting SAE J1703-F and DOT 3 standards

only. Use fresh, clean fluid from a sealed container at

all times.

Do not pump the brake pedal at any time while

bleeding. Air in the system will be compressed into

small bubbles that are distributed throughout the

hydraulic system. This will make additional bleeding

operations necessary.

Do not allow the master cylinder to run out of fluid

during bleed operations. An empty cylinder will allow

additional air to be drawn into the system. Check the

cylinder fluid level frequently and add fluid as

needed.

Bleed only one brake component at a time in the

following sequence:

²Master Cylinder

²Combination Valve

²Right Rear Wheel

²Left Rear Wheel

²Right Front Wheel

²Left Front Wheel

Follow the manufacturers instructions carefully

when using pressure equipment. Do not exceed the

tank manufacturers pressure recommendations. Gen-

erally, a tank pressure of 15-20 psi is sufficient for

bleeding.

Fill the bleeder tank with recommended fluid and

purge air from the tank lines before bleeding.

Do not pressure bleed without a proper master cyl-

inder adapter. The wrong adapter can lead to leak-

age, or drawing air back into the system. Use

adapter provided with the equipment or Adapter

6921.

KJBRAKES - BASE 5 - 5

BRAKES - BASE (Continued)

Page 172 of 1803

BRAKE LINES

DESCRIPTION

Flexible rubber hose is used at both front brakes

and at the rear axle junction block. Double walled

steel tubing is used to connect the master cylinder to

the major hydraulic braking components and then to

the flexible rubber hoses. Double inverted style and

ISO style flares are used on the brake lines.

DIAGNOSIS AND TESTING - BRAKE LINE AND

HOSES

Flexible rubber hose is used at both front brakes

and at the rear axle junction block. Inspect the hoses

whenever the brake system is serviced, at every

engine oil change, or whenever the vehicle is in for

service.

Inspect the hoses for surface cracking, scuffing, or

worn spots. Replace any brake hose immediately if

the fabric casing of the hose is exposed due to cracks

or abrasions.

Also check brake hose installation. Faulty installa-

tion can result in kinked, twisted hoses, or contact

with the wheels and tires or other chassis compo-

nents. All of these conditions can lead to scuffing,

cracking and eventual failure.

The steel brake lines should be inspected periodi-

cally for evidence of corrosion, twists, kinks, leaks, or

other damage. Heavily corroded lines will eventually

rust through causing leaks. In any case, corroded or

damaged brake lines should be replaced.

Factory replacement brake lines and hoses are rec-

ommended to ensure quality, correct length and supe-

rior fatigue life. Care should be taken to make sure

that brake line and hose mating surfaces are clean

and free from nicks and burrs. Also remember that

right and left brake hoses are not interchangeable.

Use new copper seal washers at all caliper connec-

tions. Be sure brake line connections are properly

made (not cross threaded) and tightened to recom-

mended torque.

STANDARD PROCEDURE

STANDARD PROCEDURE - DOUBLE INVERTED

FLARING

A preformed metal brake tube is recommended and

preferred for all repairs. However, double-wall steel

tube can be used for emergency repair when factory

replacement parts are not readily available.

Special bending tools are needed to avoid kinking

or twisting of metal brake tubes. Special flaring tools

are needed to make a double inverted flare or ISO

flare.(1) Cut off damaged tube with Tubing Cutter.

(2) Ream cut edges of tubing to ensure proper

flare.

(3) Install replacement tube nut on the tube.

(4) Insert tube in flaring tool.

(5) Place gauge form over the end of the tube.

(6) Push tubing through flaring tool jaws until

tube contacts recessed notch in gauge that matches

tube diameter.

(7) Tighten the tool bar on the tube

(8) Insert plug on gauge in the tube. Then swing

compression disc over gauge and center tapered flar-

ing screw in recess of compression disc (Fig. 2).

(9) Tighten tool handle until plug gauge is

squarely seated on jaws of flaring tool. This will start

the inverted flare.

(10) Remove the plug gauge and complete the

inverted flare.

STANDARD PROCEDURE - ISO FLARING

A preformed metal brake tube is recommended and

preferred for all repairs. However, double-wall steel

tube can be used for emergency repair when factory

replacement parts are not readily available.

Special bending tools are needed to avoid kinking

or twisting of metal brake tubes. Special flaring tools

are needed to make a double inverted flare or ISO

flare.

To make a ISO flare use a ISO brake flaring tool or

equivalent.

(1) Cut off damaged tube with Tubing Cutter.

(2) Remove any burrs from the inside of the tube.

(3) Install tube nut on the tube.

Fig. 2 Inverted

5 - 8 BRAKES - BASEKJ

Page 174 of 1803

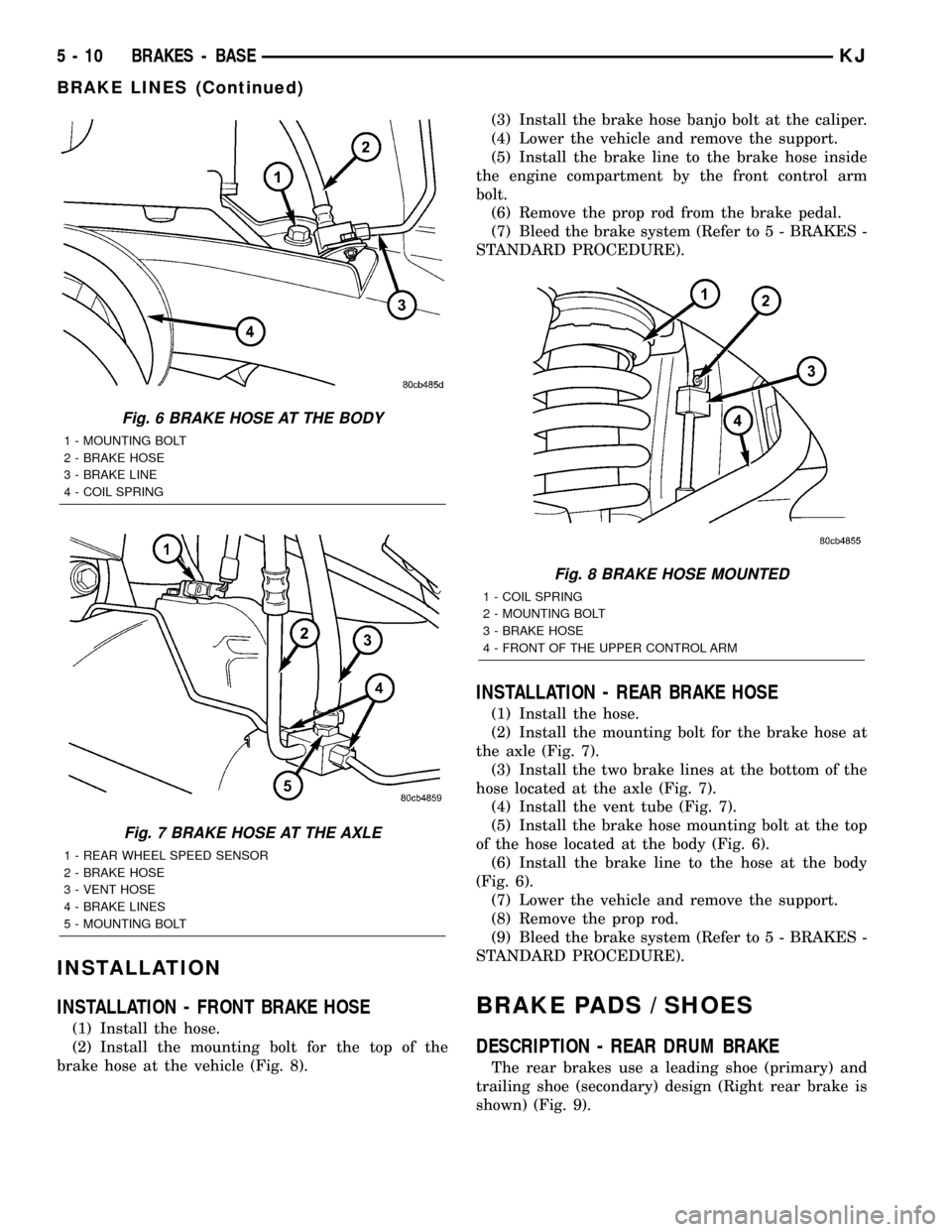

INSTALLATION

INSTALLATION - FRONT BRAKE HOSE

(1) Install the hose.

(2) Install the mounting bolt for the top of the

brake hose at the vehicle (Fig. 8).(3) Install the brake hose banjo bolt at the caliper.

(4) Lower the vehicle and remove the support.

(5) Install the brake line to the brake hose inside

the engine compartment by the front control arm

bolt.

(6) Remove the prop rod from the brake pedal.

(7) Bleed the brake system (Refer to 5 - BRAKES -

STANDARD PROCEDURE).

INSTALLATION - REAR BRAKE HOSE

(1) Install the hose.

(2) Install the mounting bolt for the brake hose at

the axle (Fig. 7).

(3) Install the two brake lines at the bottom of the

hose located at the axle (Fig. 7).

(4) Install the vent tube (Fig. 7).

(5) Install the brake hose mounting bolt at the top

of the hose located at the body (Fig. 6).

(6) Install the brake line to the hose at the body

(Fig. 6).

(7) Lower the vehicle and remove the support.

(8) Remove the prop rod.

(9) Bleed the brake system (Refer to 5 - BRAKES -

STANDARD PROCEDURE).

BRAKE PADS / SHOES

DESCRIPTION - REAR DRUM BRAKE

The rear brakes use a leading shoe (primary) and

trailing shoe (secondary) design (Right rear brake is

shown) (Fig. 9).

Fig. 6 BRAKE HOSE AT THE BODY

1 - MOUNTING BOLT

2 - BRAKE HOSE

3 - BRAKE LINE

4 - COIL SPRING

Fig. 7 BRAKE HOSE AT THE AXLE

1 - REAR WHEEL SPEED SENSOR

2 - BRAKE HOSE

3 - VENT HOSE

4 - BRAKE LINES

5 - MOUNTING BOLT

Fig. 8 BRAKE HOSE MOUNTED

1 - COIL SPRING

2 - MOUNTING BOLT

3 - BRAKE HOSE

4 - FRONT OF THE UPPER CONTROL ARM

5 - 10 BRAKES - BASEKJ

BRAKE LINES (Continued)

Page 180 of 1803

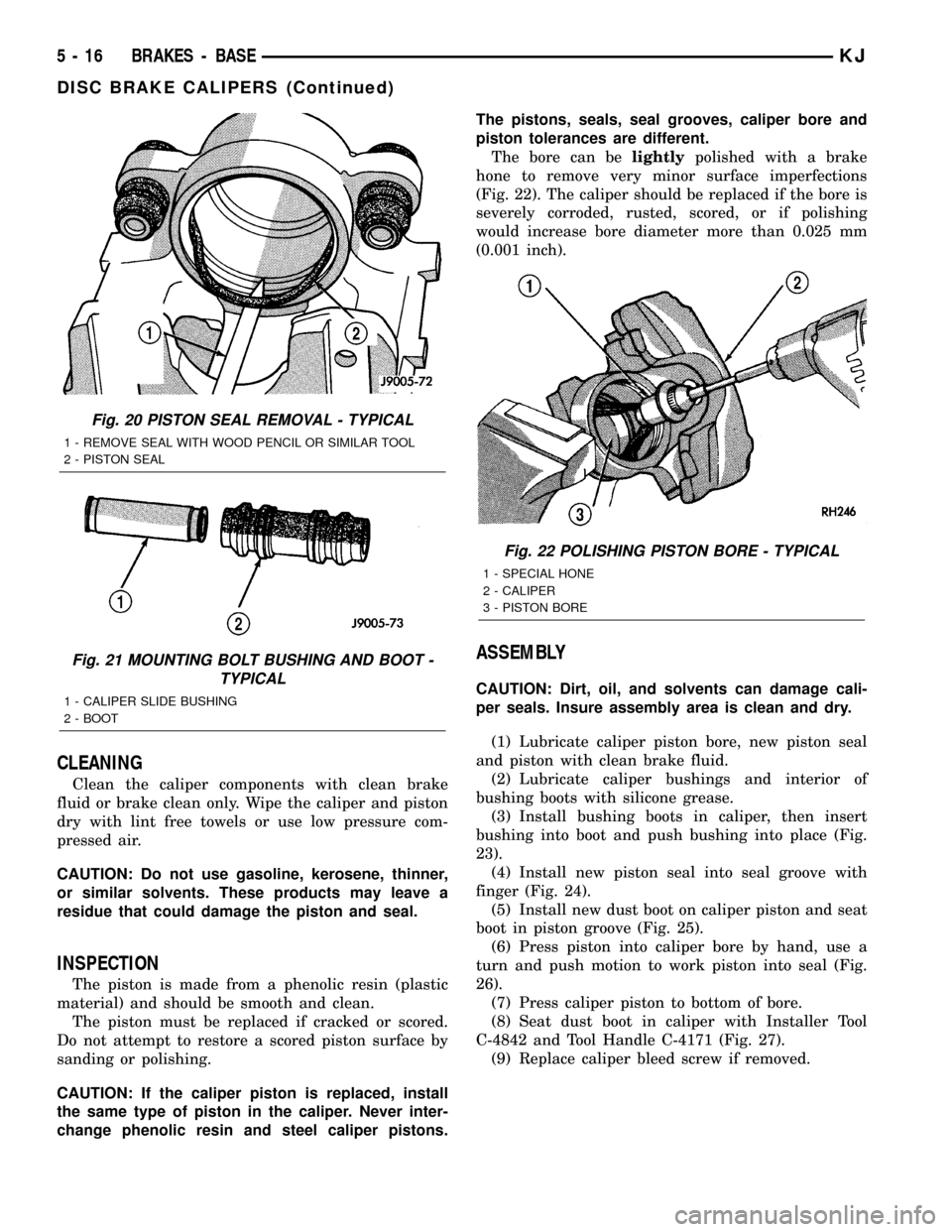

CLEANING

Clean the caliper components with clean brake

fluid or brake clean only. Wipe the caliper and piston

dry with lint free towels or use low pressure com-

pressed air.

CAUTION: Do not use gasoline, kerosene, thinner,

or similar solvents. These products may leave a

residue that could damage the piston and seal.

INSPECTION

The piston is made from a phenolic resin (plastic

material) and should be smooth and clean.

The piston must be replaced if cracked or scored.

Do not attempt to restore a scored piston surface by

sanding or polishing.

CAUTION: If the caliper piston is replaced, install

the same type of piston in the caliper. Never inter-

change phenolic resin and steel caliper pistons.The pistons, seals, seal grooves, caliper bore and

piston tolerances are different.

The bore can belightlypolished with a brake

hone to remove very minor surface imperfections

(Fig. 22). The caliper should be replaced if the bore is

severely corroded, rusted, scored, or if polishing

would increase bore diameter more than 0.025 mm

(0.001 inch).

ASSEMBLY

CAUTION: Dirt, oil, and solvents can damage cali-

per seals. Insure assembly area is clean and dry.

(1) Lubricate caliper piston bore, new piston seal

and piston with clean brake fluid.

(2) Lubricate caliper bushings and interior of

bushing boots with silicone grease.

(3) Install bushing boots in caliper, then insert

bushing into boot and push bushing into place (Fig.

23).

(4) Install new piston seal into seal groove with

finger (Fig. 24).

(5) Install new dust boot on caliper piston and seat

boot in piston groove (Fig. 25).

(6) Press piston into caliper bore by hand, use a

turn and push motion to work piston into seal (Fig.

26).

(7) Press caliper piston to bottom of bore.

(8) Seat dust boot in caliper with Installer Tool

C-4842 and Tool Handle C-4171 (Fig. 27).

(9) Replace caliper bleed screw if removed.

Fig. 20 PISTON SEAL REMOVAL - TYPICAL

1 - REMOVE SEAL WITH WOOD PENCIL OR SIMILAR TOOL

2 - PISTON SEAL

Fig. 21 MOUNTING BOLT BUSHING AND BOOT -

TYPICAL

1 - CALIPER SLIDE BUSHING

2 - BOOT

Fig. 22 POLISHING PISTON BORE - TYPICAL

1 - SPECIAL HONE

2 - CALIPER

3 - PISTON BORE

5 - 16 BRAKES - BASEKJ

DISC BRAKE CALIPERS (Continued)