removal JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 723 of 1803

(6) Raise and support the vehicle.

(7) Remove the splash shield from the right front

fender wheel house. (Refer to 23 - BODY/EXTERIOR/

WHEELHOUSE SPLASH SHIELD - REMOVAL).

(8) Release the ªWº clip that secures the front

bumper fascia to the front bumper support. This clip

is located behind the bumper support and below the

right front lamp unit.

(9) Place a clean container on the floor beneath the

washer pump/motor location to catch any washer

fluid that is spilled during the following procedure.

(10) Disconnect the front and rear washer hoses

from the washer pump/motor unit outlet nipples and

allow the washer fluid to drain into the container for

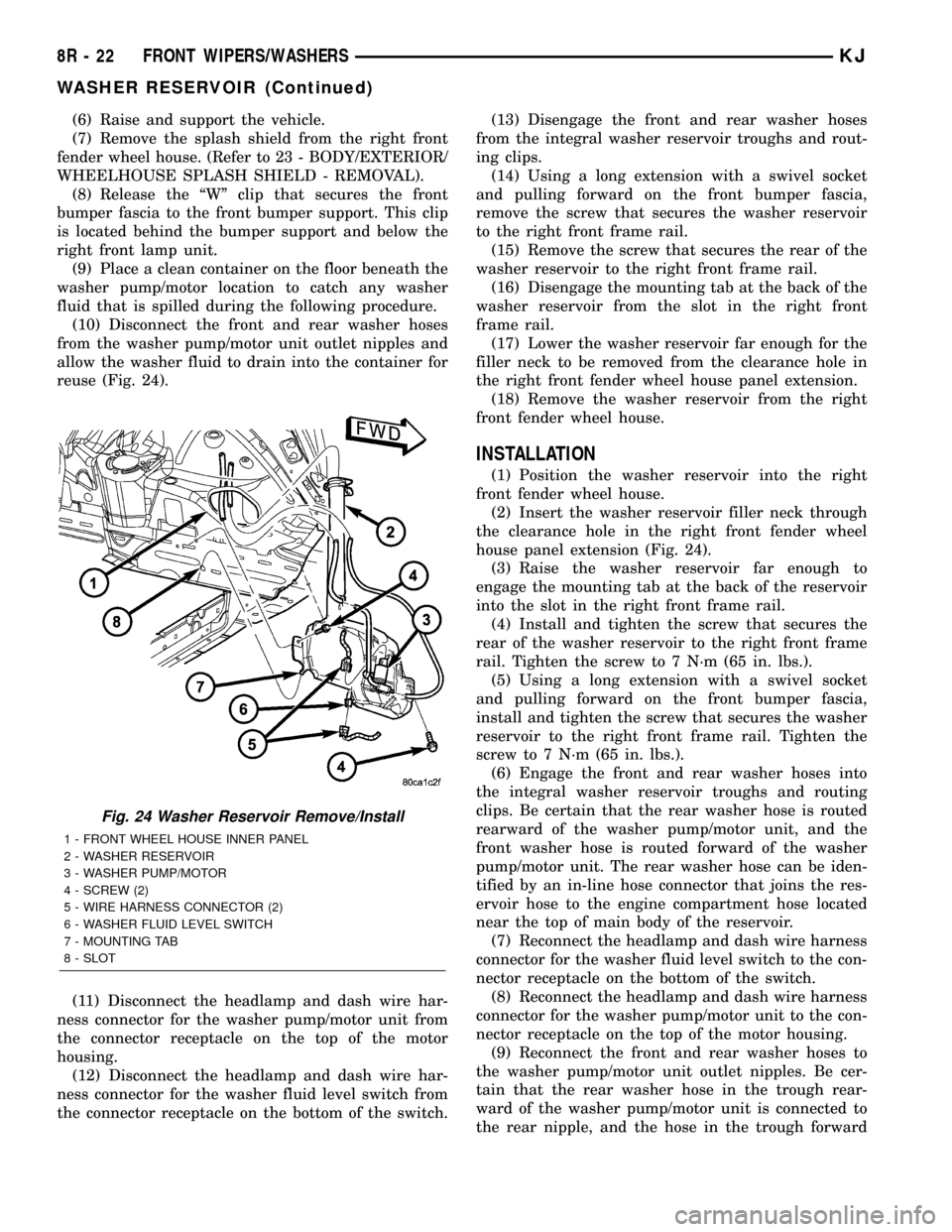

reuse (Fig. 24).

(11) Disconnect the headlamp and dash wire har-

ness connector for the washer pump/motor unit from

the connector receptacle on the top of the motor

housing.

(12) Disconnect the headlamp and dash wire har-

ness connector for the washer fluid level switch from

the connector receptacle on the bottom of the switch.(13) Disengage the front and rear washer hoses

from the integral washer reservoir troughs and rout-

ing clips.

(14) Using a long extension with a swivel socket

and pulling forward on the front bumper fascia,

remove the screw that secures the washer reservoir

to the right front frame rail.

(15) Remove the screw that secures the rear of the

washer reservoir to the right front frame rail.

(16) Disengage the mounting tab at the back of the

washer reservoir from the slot in the right front

frame rail.

(17) Lower the washer reservoir far enough for the

filler neck to be removed from the clearance hole in

the right front fender wheel house panel extension.

(18) Remove the washer reservoir from the right

front fender wheel house.

INSTALLATION

(1) Position the washer reservoir into the right

front fender wheel house.

(2) Insert the washer reservoir filler neck through

the clearance hole in the right front fender wheel

house panel extension (Fig. 24).

(3) Raise the washer reservoir far enough to

engage the mounting tab at the back of the reservoir

into the slot in the right front frame rail.

(4) Install and tighten the screw that secures the

rear of the washer reservoir to the right front frame

rail. Tighten the screw to 7 N´m (65 in. lbs.).

(5) Using a long extension with a swivel socket

and pulling forward on the front bumper fascia,

install and tighten the screw that secures the washer

reservoir to the right front frame rail. Tighten the

screw to 7 N´m (65 in. lbs.).

(6) Engage the front and rear washer hoses into

the integral washer reservoir troughs and routing

clips. Be certain that the rear washer hose is routed

rearward of the washer pump/motor unit, and the

front washer hose is routed forward of the washer

pump/motor unit. The rear washer hose can be iden-

tified by an in-line hose connector that joins the res-

ervoir hose to the engine compartment hose located

near the top of main body of the reservoir.

(7) Reconnect the headlamp and dash wire harness

connector for the washer fluid level switch to the con-

nector receptacle on the bottom of the switch.

(8) Reconnect the headlamp and dash wire harness

connector for the washer pump/motor unit to the con-

nector receptacle on the top of the motor housing.

(9) Reconnect the front and rear washer hoses to

the washer pump/motor unit outlet nipples. Be cer-

tain that the rear washer hose in the trough rear-

ward of the washer pump/motor unit is connected to

the rear nipple, and the hose in the trough forward

Fig. 24 Washer Reservoir Remove/Install

1 - FRONT WHEEL HOUSE INNER PANEL

2 - WASHER RESERVOIR

3 - WASHER PUMP/MOTOR

4 - SCREW (2)

5 - WIRE HARNESS CONNECTOR (2)

6 - WASHER FLUID LEVEL SWITCH

7 - MOUNTING TAB

8 - SLOT

8R - 22 FRONT WIPERS/WASHERSKJ

WASHER RESERVOIR (Continued)

Page 724 of 1803

of the washer pump/motor unit is connected to the

front nipple.

(10) Engage the ªWº clip that secures the front

bumper fascia to the front bumper support. This clip

is located behind the bumper support and below the

right front lamp unit.

(11) Reinstall the splash shield into the right front

fender wheel house. (Refer to 23 - BODY/EXTERIOR/

WHEELHOUSE SPLASH SHIELD - INSTALLA-

TION).

(12) Lower the vehicle.

(13) Install and tighten the screw that secures the

washer reservoir filler neck support to upper radiator

crossmember (Fig. 23). Tighten the screw to 7 N´m

(65 in. lbs.).

(14) Reinstall the air cleaner housing onto the top

of the right front fender wheel house. (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

ELEMENT - INSTALLATION).

(15) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(16) Reconnect the battery negative cable.

WIPER HIGH/LOW RELAY

DESCRIPTION

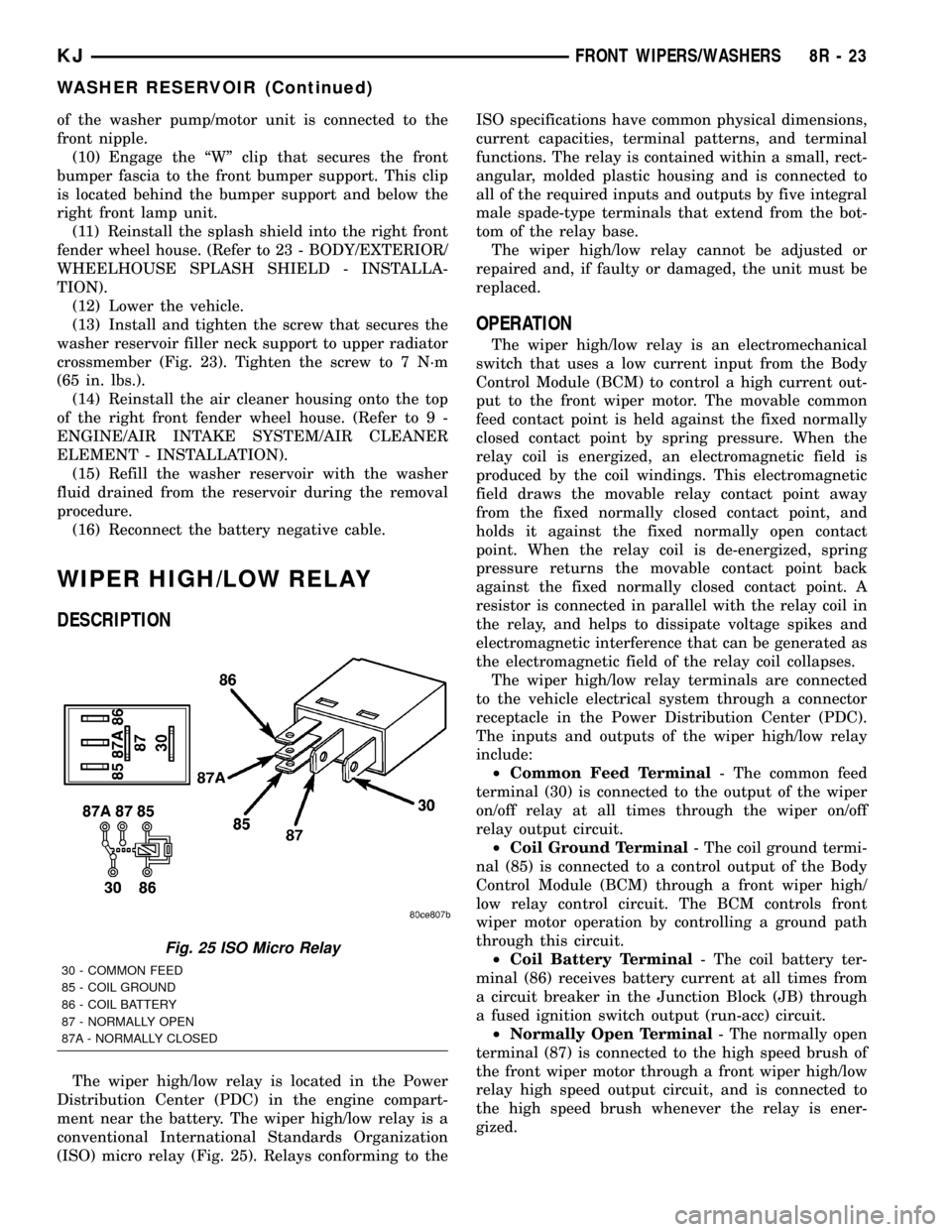

The wiper high/low relay is located in the Power

Distribution Center (PDC) in the engine compart-

ment near the battery. The wiper high/low relay is a

conventional International Standards Organization

(ISO) micro relay (Fig. 25). Relays conforming to theISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions. The relay is contained within a small, rect-

angular, molded plastic housing and is connected to

all of the required inputs and outputs by five integral

male spade-type terminals that extend from the bot-

tom of the relay base.

The wiper high/low relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The wiper high/low relay is an electromechanical

switch that uses a low current input from the Body

Control Module (BCM) to control a high current out-

put to the front wiper motor. The movable common

feed contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The wiper high/low relay terminals are connected

to the vehicle electrical system through a connector

receptacle in the Power Distribution Center (PDC).

The inputs and outputs of the wiper high/low relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the output of the wiper

on/off relay at all times through the wiper on/off

relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Body

Control Module (BCM) through a front wiper high/

low relay control circuit. The BCM controls front

wiper motor operation by controlling a ground path

through this circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a circuit breaker in the Junction Block (JB) through

a fused ignition switch output (run-acc) circuit.

²Normally Open Terminal- The normally open

terminal (87) is connected to the high speed brush of

the front wiper motor through a front wiper high/low

relay high speed output circuit, and is connected to

the high speed brush whenever the relay is ener-

gized.

Fig. 25 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJFRONT WIPERS/WASHERS 8R - 23

WASHER RESERVOIR (Continued)

Page 725 of 1803

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to the low speed

brush of the front wiper motor through a front wiper

high/low relay low speed output circuit, and is con-

nected to the low speed brush whenever the relay is

de-energized.

The wiper high/low relay can be diagnosed using

conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - WIPER HIGH/LOW

RELAY

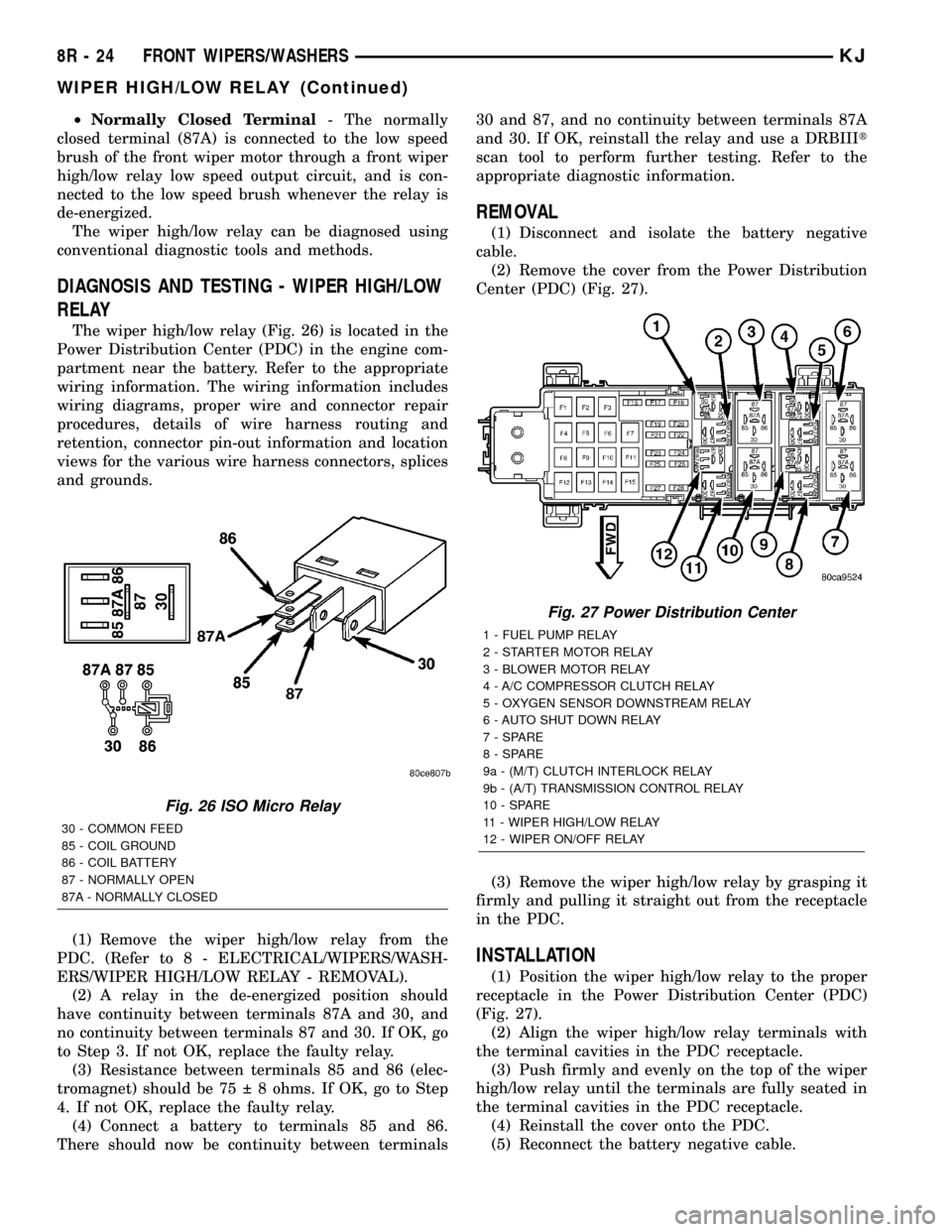

The wiper high/low relay (Fig. 26) is located in the

Power Distribution Center (PDC) in the engine com-

partment near the battery. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

(1) Remove the wiper high/low relay from the

PDC. (Refer to 8 - ELECTRICAL/WIPERS/WASH-

ERS/WIPER HIGH/LOW RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 27).

(3) Remove the wiper high/low relay by grasping it

firmly and pulling it straight out from the receptacle

in the PDC.

INSTALLATION

(1) Position the wiper high/low relay to the proper

receptacle in the Power Distribution Center (PDC)

(Fig. 27).

(2) Align the wiper high/low relay terminals with

the terminal cavities in the PDC receptacle.

(3) Push firmly and evenly on the top of the wiper

high/low relay until the terminals are fully seated in

the terminal cavities in the PDC receptacle.

(4) Reinstall the cover onto the PDC.

(5) Reconnect the battery negative cable.

Fig. 26 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

Fig. 27 Power Distribution Center

1 - FUEL PUMP RELAY

2 - STARTER MOTOR RELAY

3 - BLOWER MOTOR RELAY

4 - A/C COMPRESSOR CLUTCH RELAY

5 - OXYGEN SENSOR DOWNSTREAM RELAY

6 - AUTO SHUT DOWN RELAY

7-SPARE

8-SPARE

9a - (M/T) CLUTCH INTERLOCK RELAY

9b - (A/T) TRANSMISSION CONTROL RELAY

10 - SPARE

11 - WIPER HIGH/LOW RELAY

12 - WIPER ON/OFF RELAY

8R - 24 FRONT WIPERS/WASHERSKJ

WIPER HIGH/LOW RELAY (Continued)

Page 727 of 1803

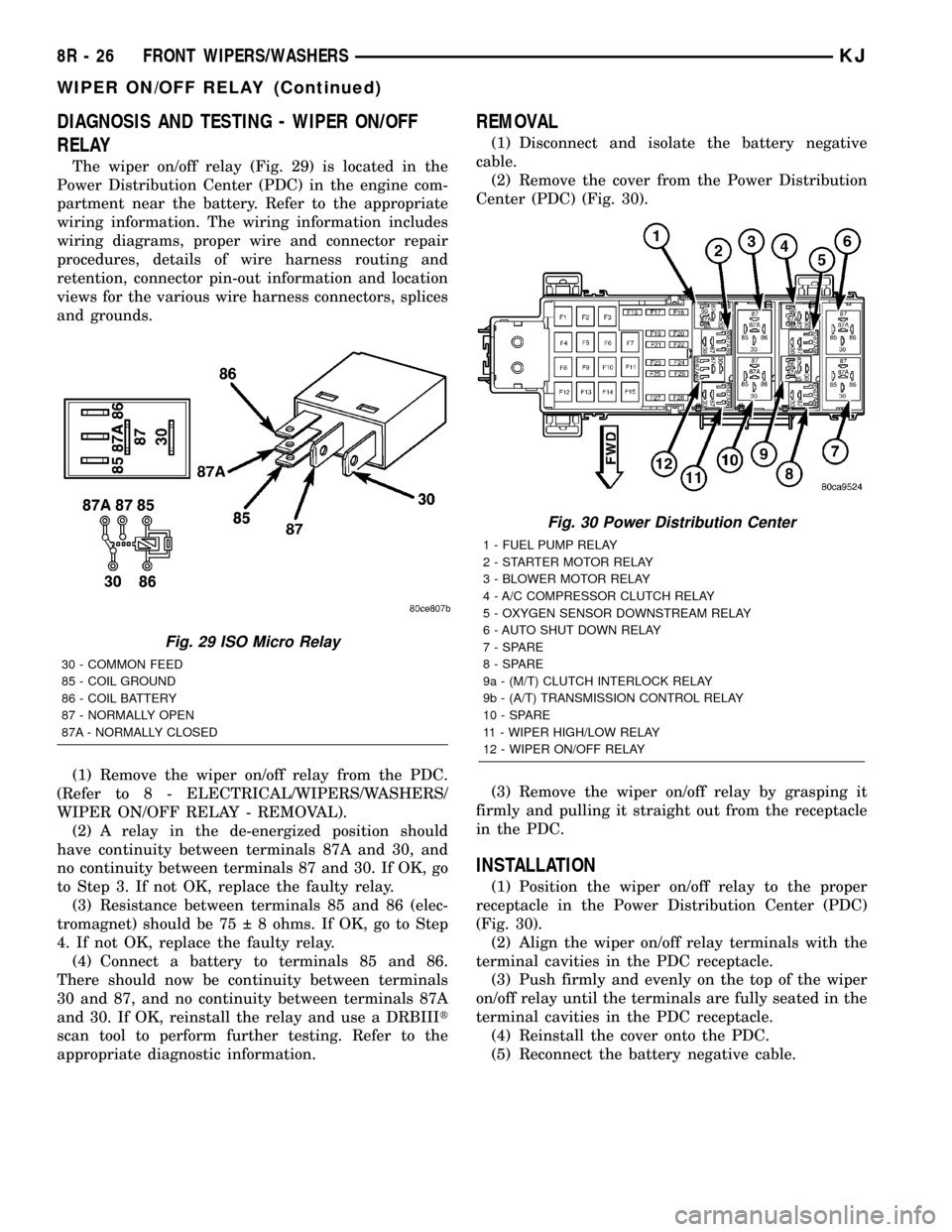

DIAGNOSIS AND TESTING - WIPER ON/OFF

RELAY

The wiper on/off relay (Fig. 29) is located in the

Power Distribution Center (PDC) in the engine com-

partment near the battery. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

(1) Remove the wiper on/off relay from the PDC.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER ON/OFF RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 30).

(3) Remove the wiper on/off relay by grasping it

firmly and pulling it straight out from the receptacle

in the PDC.

INSTALLATION

(1) Position the wiper on/off relay to the proper

receptacle in the Power Distribution Center (PDC)

(Fig. 30).

(2) Align the wiper on/off relay terminals with the

terminal cavities in the PDC receptacle.

(3) Push firmly and evenly on the top of the wiper

on/off relay until the terminals are fully seated in the

terminal cavities in the PDC receptacle.

(4) Reinstall the cover onto the PDC.

(5) Reconnect the battery negative cable.

Fig. 29 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

Fig. 30 Power Distribution Center

1 - FUEL PUMP RELAY

2 - STARTER MOTOR RELAY

3 - BLOWER MOTOR RELAY

4 - A/C COMPRESSOR CLUTCH RELAY

5 - OXYGEN SENSOR DOWNSTREAM RELAY

6 - AUTO SHUT DOWN RELAY

7-SPARE

8-SPARE

9a - (M/T) CLUTCH INTERLOCK RELAY

9b - (A/T) TRANSMISSION CONTROL RELAY

10 - SPARE

11 - WIPER HIGH/LOW RELAY

12 - WIPER ON/OFF RELAY

8R - 26 FRONT WIPERS/WASHERSKJ

WIPER ON/OFF RELAY (Continued)

Page 728 of 1803

REAR WIPERS/WASHERS

TABLE OF CONTENTS

page page

REAR WIPERS/WASHERS

DESCRIPTION.........................27

OPERATION...........................29

DIAGNOSIS AND TESTING - REAR WIPER &

WASHER SYSTEM....................30

CLEANING - REAR WIPER & WASHER

SYSTEM............................32

INSPECTION - REAR WIPER & WASHER

SYSTEM............................33

REAR CHECK VALVE

DESCRIPTION.........................34

OPERATION...........................34

REMOVAL.............................34

INSTALLATION.........................35

REAR WASHER HOSES/TUBES

DESCRIPTION.........................35

OPERATION...........................36

REAR WASHER NOZZLE

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................36

INSTALLATION.........................37REAR WIPER ARM

DESCRIPTION.........................37

OPERATION...........................38

REMOVAL.............................38

INSTALLATION.........................38

REAR WIPER BLADE

DESCRIPTION.........................39

OPERATION...........................39

REMOVAL.............................40

INSTALLATION.........................40

REAR WIPER MOTOR

DESCRIPTION.........................41

OPERATION...........................41

REMOVAL.............................42

INSTALLATION.........................42

REAR WIPER/WASHER SWITCH

DESCRIPTION.........................43

OPERATION...........................43

WIPER ARM PARK RAMP

REMOVAL.............................43

INSTALLATION.........................43

REAR WIPERS/WASHERS

DESCRIPTION

An electrically operated fixed interval intermittent

rear wiper and washer system is standard factory-in-

stalled equipment on this model (Fig. 1). The rear

wiper and washer system includes the following

major components, which are described in further

detail elsewhere in this service information:

²Multi-Function Switch- The multi-function

switch is located on the top of the steering column,

just below the steering wheel. The multi-function

switch includes a left (lighting) control stalk and a

right (wiper) control stalk. The right control stalk is

dedicated to providing all of the driver controls for

both the front and rear wiper systems. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

MULTI-FUNCTION SWITCH - DESCRIPTION).

²Rear Check Valve- The rear washer system

check valve is located in the washer plumbing

between the rear roof header and the roof outer

panel near the rear washer nozzle.

²Rear Washer Nozzle- The rear washer nozzle

is secured by a snap fit into a mounting hole in the

roof outer panel above the rear flip-up glass opening.²Rear Washer Plumbing- The plumbing for

the rear washer system consists of rubber hoses and

molded plastic fittings. The plumbing is routed along

the right side of the engine compartment from the

washer reservoir, through the dash into the passen-

ger compartment, up the right cowl side and A-pillar

to the headliner, and above the headliner to the rear

washer nozzle fitting within the rear roof header.

²Rear Wiper Arm- The single rear wiper arm is

secured by a nut directly to the rear wiper motor out-

put shaft, which extends through the center of the

tailgate outer panel near the base of the rear flip-up

glass.

²Rear Wiper Arm Park Ramp- The molded

rubber rear wiper arm park ramp is secured with a

screw to the tailgate outer panel to the right of the

rear wiper motor output shaft bezel. When the rear

wiper system is not in operation, the rear wiper arm

is parked off of the rear flip-up glass on this ramp so

that it will not interfere with or be damaged by the

flip-up glass operation.

²Rear Wiper Blade- The single rear wiper

blade is secured to the rear wiper arm with an inte-

gral latch, and is parked off of the rear flip-up glass

when the rear wiper system is not in operation.

KJREAR WIPERS/WASHERS 8R - 27

Page 735 of 1803

REAR WASHER SYSTEM

The washer system components should be

inspected periodically, not just when washer perfor-

mance problems are experienced. This inspection

should include the following points:

(1) Check for ice or other foreign material in the

washer reservoir. If contaminated, clean and flush

the washer system. (Refer to 8 - ELECTRICAL/

REAR WIPERS/WASHERS - CLEANING).

(2) Inspect the washer plumbing for pinched, leak-

ing, deteriorated, or incorrectly routed hoses and

damaged or disconnected hose fittings. Replace dam-

aged or deteriorated hoses and hose fittings. Leaking

washer hoses can sometimes be repaired by cutting

the hose at the leak and splicing it back together

using an in-line connector fitting. Similarly, sections

of deteriorated hose can be cut out and replaced by

splicing in new sections of hose using in-line connec-

tor fittings. Whenever routing a washer hose or a

wire harness containing a washer hose, it must be

routed away from hot, sharp, or moving parts. Also,

sharp bends that might pinch the washer hose must

be avoided.

REAR CHECK VALVE

DESCRIPTION

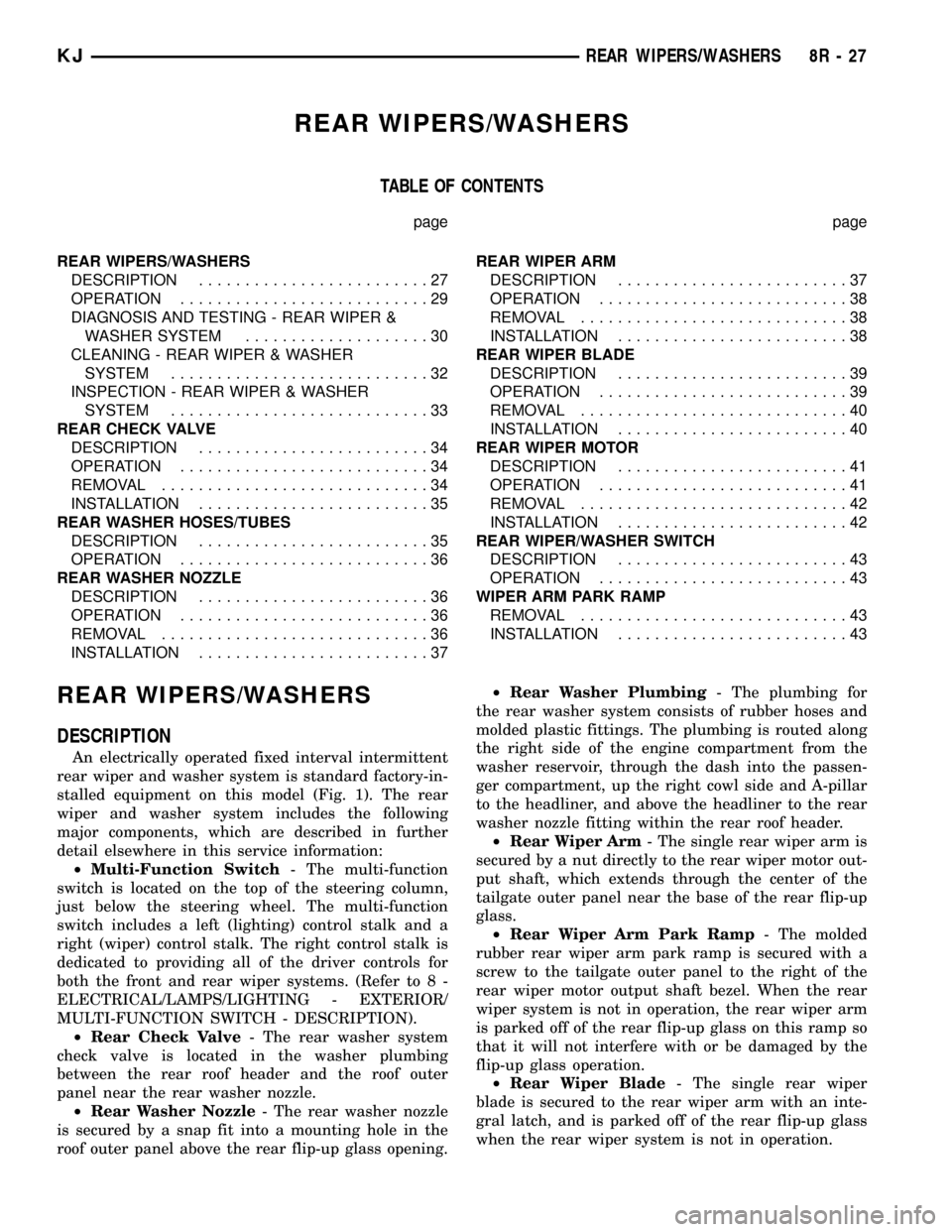

A rear washer system check valve is standard

equipment on this model (Fig. 3). The rear check

valve is located in the washer plumbing between the

rear roof header and the roof outer panel near the

rear washer nozzle. The rear check valve consists of

a molded plastic body with a round center sectionand barbed hose nipples at each end. An arrow for-

mation molded into the center section of the valve

body indicates the direction of flow through the

valve. The rear check valve cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

OPERATION

The rear check valve prevents washer fluid from

draining out of the rear washer supply hoses back to

the washer reservoir. This drain-back would result in

a lengthy delay from when the rear washer switch is

actuated until washer fluid was dispensed through

the rear washer nozzle, because the washer pump

would have to refill the rear washer plumbing from

the reservoir to the nozzle. The check valve also pre-

vents washer fluid from siphoning through the rear

washer nozzle after the rear washer system is turned

Off.

Within the check valve body, a small check valve is

held in place against a seat by a small coiled spring

to restrict flow through the unit until the valve is

unseated by a predetermined inlet fluid pressure.

When the washer pump pressurizes and pumps

washer fluid from the reservoir through the rear

washer plumbing, the fluid pressure overrides the

spring pressure applied to the check ball within the

valve and unseats the valve, allowing washer fluid to

flow toward the rear washer nozzle. When the

washer pump stops operating, spring pressure seats

the check valve and fluid flow in either direction

within the rear washer plumbing is prevented.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the Center High Mounted Stop Lamp

(CHMSL) unit from the rear of the roof panel. (Refer

to 8 - ELECTRICAL/LAMPS/LIGHTING - EXTERI-

OR/CENTER HIGH MOUNTED STOP LAMP UNIT

- REMOVAL).

WARNING: THE EDGES OF THE SHEET METAL

AROUND THE CENTER HIGH MOUNTED STOP

LAMP MOUNTING HOLE IN THE ROOF PANEL.

TAKE THE PROPER PRECAUTIONS TO AVOID PER-

SONAL INJURY.

(3) Reach through the CHMSL unit mounting hole

in the rear of the roof panel to access and disconnect

the rear washer hose at the barbed nipple of the rear

washer nozzle (Fig. 4).

(4) Pull the rear washer hose through the CHMSL

unit mounting hole far enough to access and discon-

nect the headliner washer hose from the barbed nip-

ple of the rear check valve.

Fig. 3 Rear Check Valve

1 - INLET NIPPLE

2 - REAR CHECK VALVE

3 - OUTLET NIPPLE

4 - FLOW DIRECTION ARROW

8R - 34 REAR WIPERS/WASHERSKJ

REAR WIPERS/WASHERS (Continued)

Page 737 of 1803

headliner hose is glued to top of the headliner and

routed along the right roof side rail to the rear of the

vehicle. At the rear of the vehicle, the headliner hose

passes through a hole at the rear portion of the roof

rear inner header panel and is connected to the rear

check valve. From the rear check valve, there is a

short section of hose that connects the rear check

valve to the rear washer nozzle.

Washer hose is available for service only as roll

stock, which must then be cut to length. The head-

liner washer hose is integral to the headliner unit

and, if faulty or damaged, the headliner unit must be

replaced. However, the headliner hose is marked

with a white cut line on the A-pillar where the hose

should be cut and spliced with a plastic in-line con-

nector fitting to facilitate headliner removal without

the need to remove the instrument panel. (Refer to

23 - BODY/INTERIOR/HEADLINER - REMOVAL

AND INSTALLATION). The molded plastic washer

hose fittings cannot be repaired. If these fittings are

faulty or damaged, they must be replaced.

OPERATION

Washer fluid in the washer reservoir is pressurized

and fed by the washer pump/motor through the rear

washer system plumbing and fittings to the rear

washer nozzle located on the roof panel above the

rear flip-up glass opening. Whenever routing the

washer hose or a wire harness containing a washer

hose, it must be routed away from hot, sharp, or

moving parts; and, sharp bends that might pinch the

hose must be avoided.

REAR WASHER NOZZLE

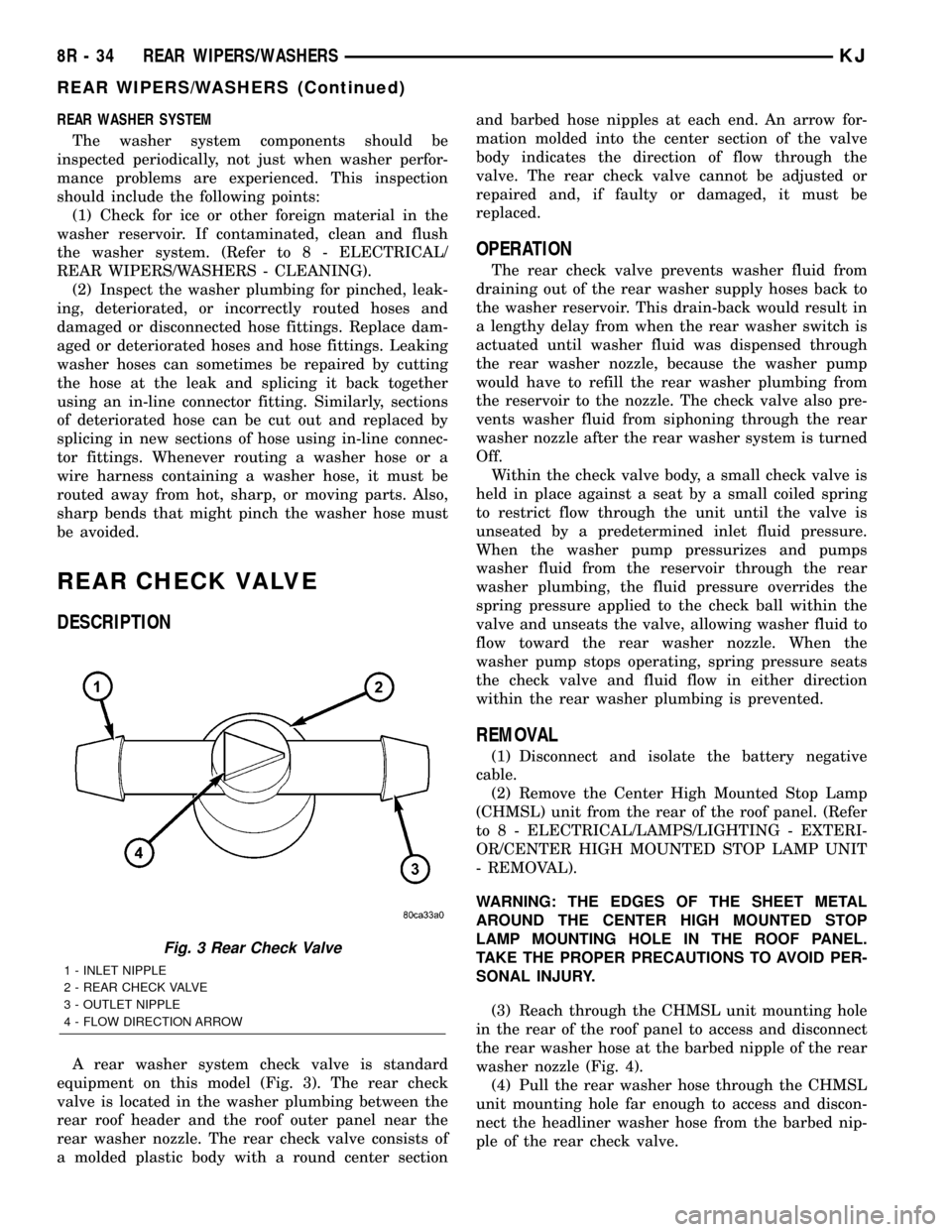

DESCRIPTION

The rear washer nozzle is a fluidic-type unit con-

structed of molded plastic (Fig. 6). The nozzle is

secured by a snap fit in a dedicated mounting hole

located in the rear edge of the roof panel above the

rear flip-up glass opening and to the right of the

Center High Mounted Stop Lamp (CHMSL) unit. A

rubber gasket on the back of the nozzle seals the noz-

zle to the roof panel opening. The back of the nozzle

includes an integral alignment feature on the left

side, an integral engagement tab on the top, an inte-

gral latch feature on the bottom, and the washer

plumbing nipple which are all concealed between the

outer roof panel and the rear roof inner header. The

rear washer nozzle latch feature is a one time com-

ponent, and will be damaged if the nozzle is removed

from its mounting hole for service. The rear washer

nozzle cannot be adjusted or repaired. If faulty or

damaged, the entire nozzle unit must be replaced.

OPERATION

The rear washer nozzle is designed to dispense

washer fluid into the wiper pattern area on the out-

side of the rear flip-up glass. Pressurized washer

fluid is fed to the nozzle from the washer reservoir by

the washer pump/motor through a single hose, which

is attached to a barbed nipple on the back of the rear

washer nozzle. The rear washer nozzle incorporates a

fluidic design, which causes the nozzle to emit the

pressurized washer fluid as an oscillating stream to

more effectively cover a larger area of the glass area

to be cleaned.

REMOVAL

NOTE: The rear washer nozzle latch feature is a one

time component, and will be damaged if the nozzle is

removed from its mounting hole for service. If

removed from its mounting hole for any reason, the

rear washer nozzle must be replaced with a new unit.

(1) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the bottom of the rear

washer nozzle away from the roof panel until the

latch feature at the bottom of the nozzle that secures

it in the mounting hole of the roof panel snaps.

(2) Pull the rear washer nozzle out from the roof

panel far enough to access the washer hose (Fig. 7).

(3) Disconnect the washer hose from the barbed

nipple on the back of the rear washer nozzle.

(4) Discard the rear washer nozzle.

Fig. 6 Rear Washer Nozzle

1 - ENGAGEMENT TAB (TOP)

2 - GASKET

3 - REAR WASHER NOZZLE

4 - ALIGNMENT FEATURE

5 - ORIFICE

6 - LATCH FEATURE (BOTTOM)

7 - NIPPLE

8R - 36 REAR WIPERS/WASHERSKJ

REAR WASHER HOSES/TUBES (Continued)

Page 739 of 1803

A wiper arm cannot be adjusted or repaired. If

damaged or faulty, the entire wiper arm unit must be

replaced.

OPERATION

The rear wiper arm is designed to mechanically

transmit the motion from the rear wiper motor out-

put shaft to the rear wiper blade. The wiper arm

must be properly indexed to the motor output shaft

in order to maintain the proper wiper blade travel on

the glass. The wiper arm support is designed to lift

and support the rear wiper arm and blade off of the

glass when the rear wiper blade is parked. This sup-

port and the park ramp on the tailgate outer panel

below the glass also provide an alignment reference

to ensure accurate rear wiper arm and blade instal-

lation. The tapered hole in the wiper arm pivot end

is interlocks with the serrations on the outer circum-

ference of the tapered motor output shaft, allowing

positive engagement and finite adjustment of this

connection. A hex nut secures the wiper arm pivot

end to the threads on the rear wiper motor output

shaft and the pivot cover hinges and snaps over this

connection for a neat appearance. The spring-loaded

wiper arm hinge controls the down-force applied

through the tip of the wiper arm to the wiper blade

on the glass. The hook formation on the tip of the

wiper arm provides a cradle for securing and latching

the wiper blade pivot block to the wiper arm.

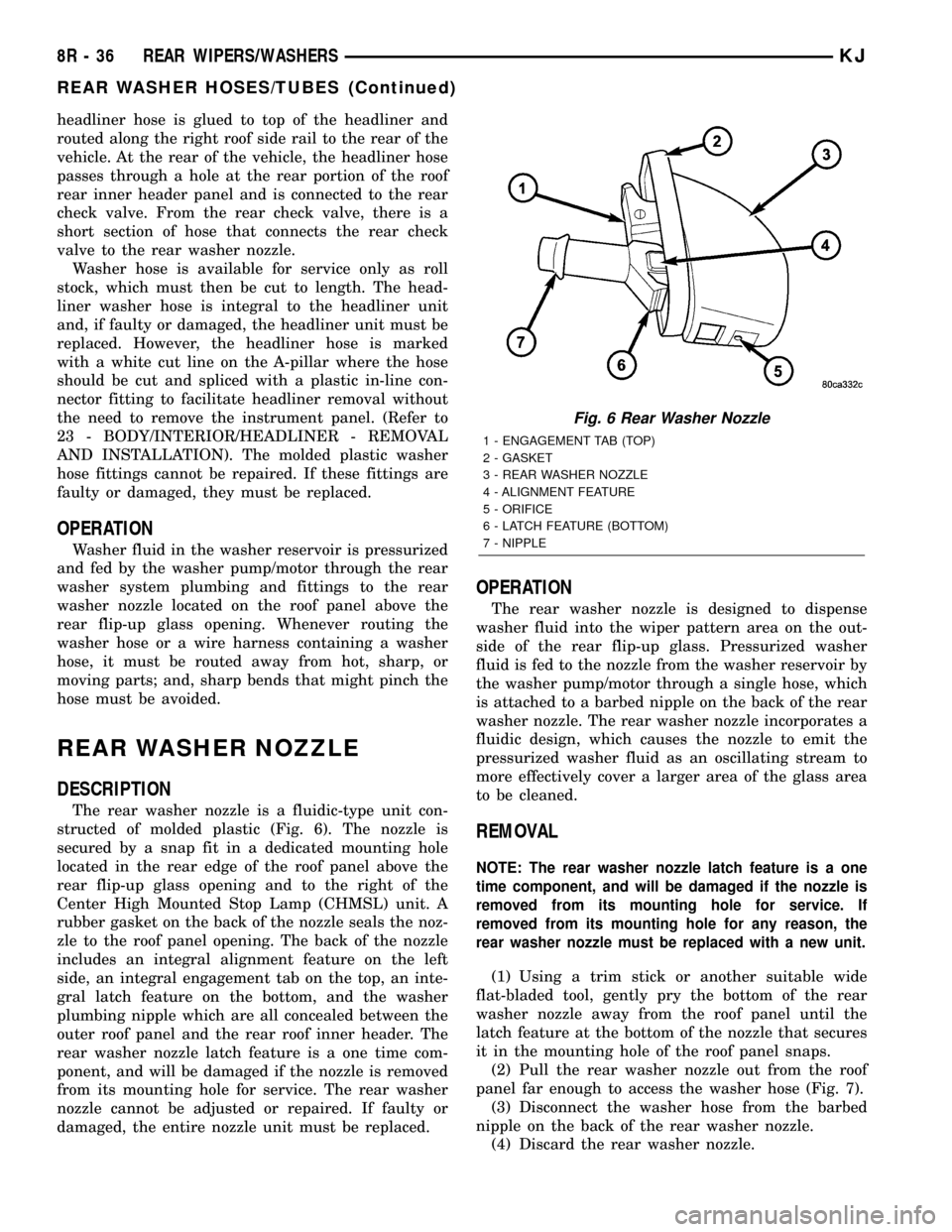

REMOVAL

(1) Lift the rear wiper arm pivot cover by lifting it

at the rear wiper motor output shaft end of the arm

(Fig. 9).

(2) Remove the nut that secures the rear wiper

arm to the rear wiper motor output shaft.

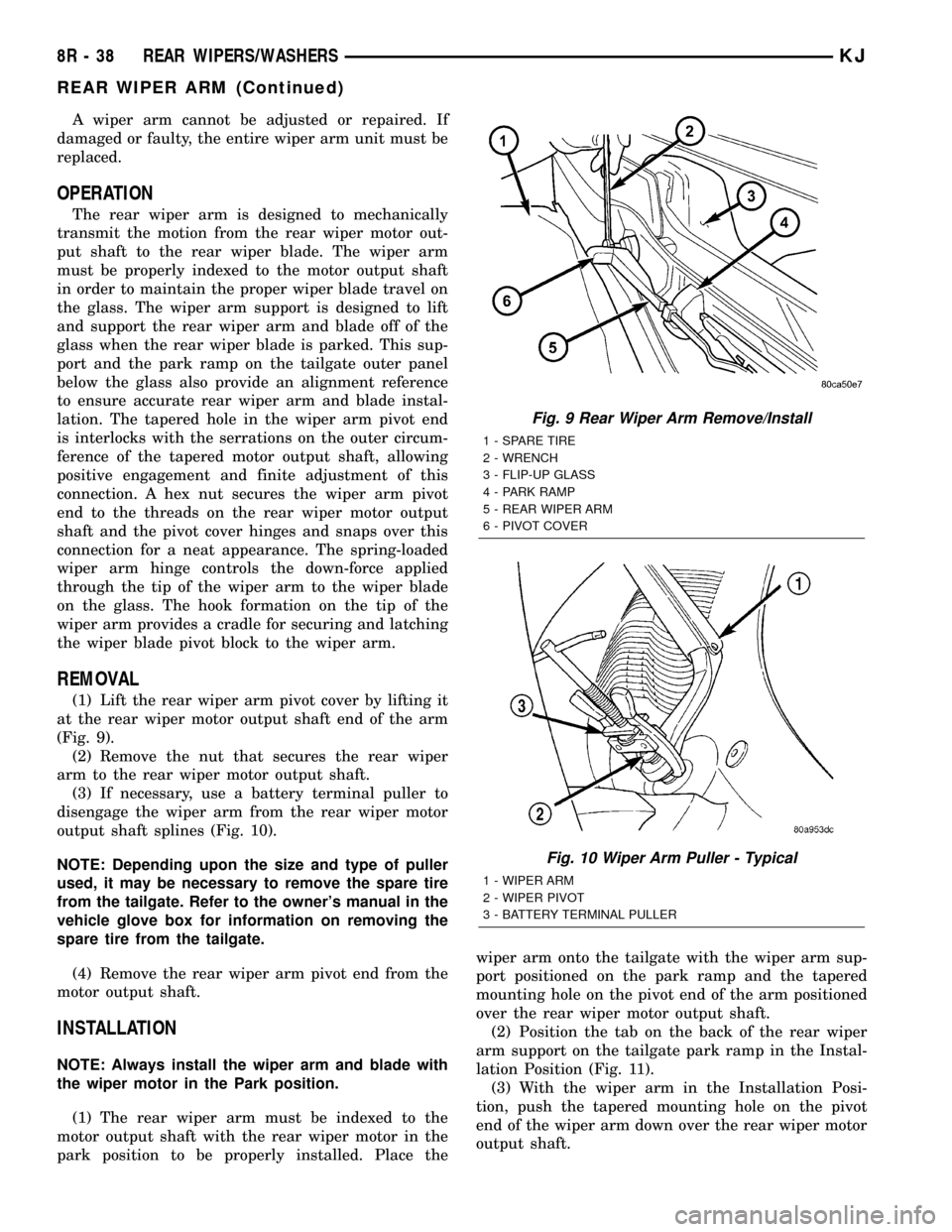

(3) If necessary, use a battery terminal puller to

disengage the wiper arm from the rear wiper motor

output shaft splines (Fig. 10).

NOTE: Depending upon the size and type of puller

used, it may be necessary to remove the spare tire

from the tailgate. Refer to the owner's manual in the

vehicle glove box for information on removing the

spare tire from the tailgate.

(4) Remove the rear wiper arm pivot end from the

motor output shaft.

INSTALLATION

NOTE: Always install the wiper arm and blade with

the wiper motor in the Park position.

(1) The rear wiper arm must be indexed to the

motor output shaft with the rear wiper motor in the

park position to be properly installed. Place thewiper arm onto the tailgate with the wiper arm sup-

port positioned on the park ramp and the tapered

mounting hole on the pivot end of the arm positioned

over the rear wiper motor output shaft.

(2) Position the tab on the back of the rear wiper

arm support on the tailgate park ramp in the Instal-

lation Position (Fig. 11).

(3) With the wiper arm in the Installation Posi-

tion, push the tapered mounting hole on the pivot

end of the wiper arm down over the rear wiper motor

output shaft.

Fig. 9 Rear Wiper Arm Remove/Install

1 - SPARE TIRE

2 - WRENCH

3 - FLIP-UP GLASS

4 - PARK RAMP

5 - REAR WIPER ARM

6 - PIVOT COVER

Fig. 10 Wiper Arm Puller - Typical

1 - WIPER ARM

2 - WIPER PIVOT

3 - BATTERY TERMINAL PULLER

8R - 38 REAR WIPERS/WASHERSKJ

REAR WIPER ARM (Continued)

Page 741 of 1803

and maintain proper contact with the glass, even as

the blade is moved over the varied curvature found

across the glass surface. The wiper element flexor

provides the claws of the blade superstructure with a

rigid, yet flexible component on the element which

can be gripped. The rubber element is designed to be

stiff enough to maintain an even cleaning edge as it

is drawn across the glass, but resilient enough to

conform to the glass surface and flip from one clean-

ing edge to the other each time the wiper blade

changes directions.

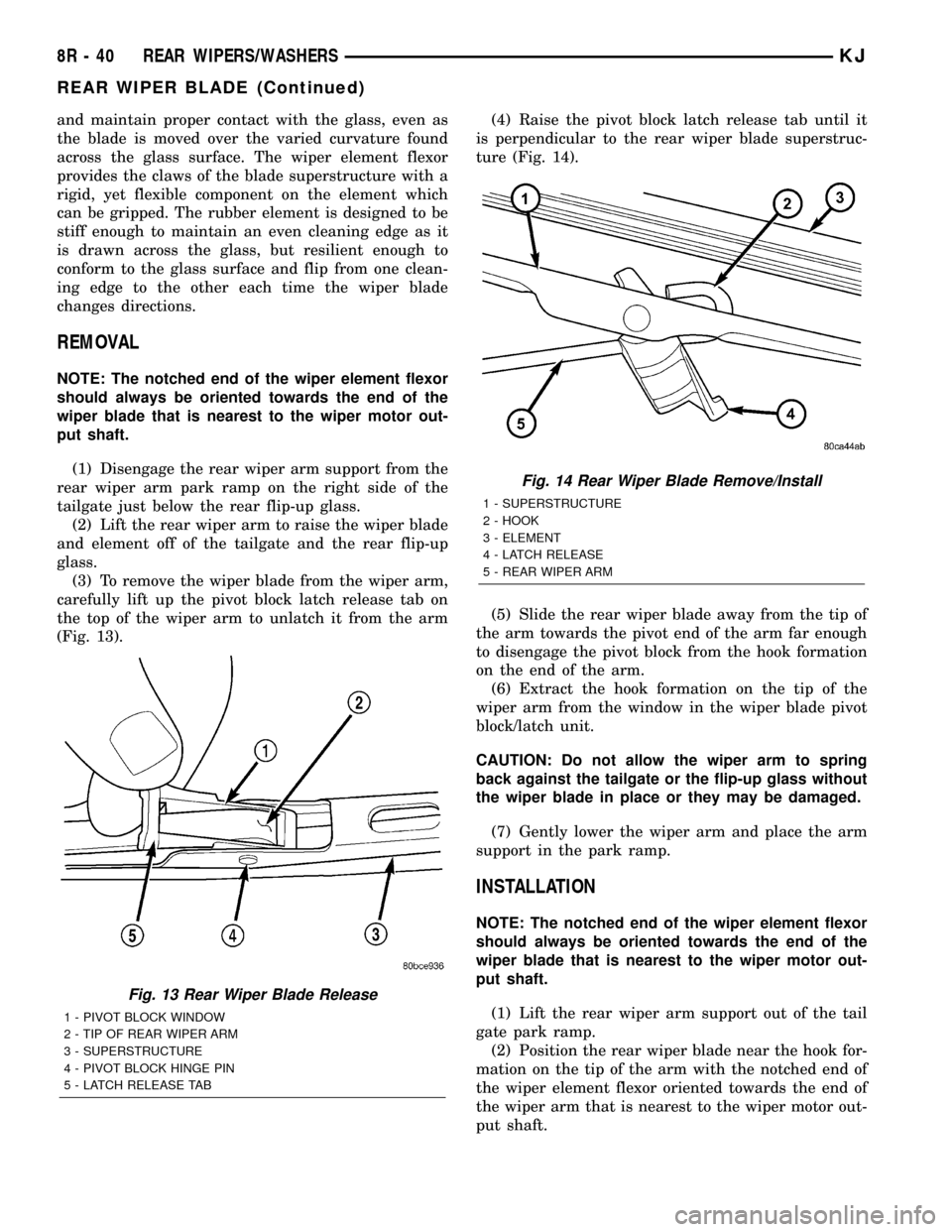

REMOVAL

NOTE: The notched end of the wiper element flexor

should always be oriented towards the end of the

wiper blade that is nearest to the wiper motor out-

put shaft.

(1) Disengage the rear wiper arm support from the

rear wiper arm park ramp on the right side of the

tailgate just below the rear flip-up glass.

(2) Lift the rear wiper arm to raise the wiper blade

and element off of the tailgate and the rear flip-up

glass.

(3) To remove the wiper blade from the wiper arm,

carefully lift up the pivot block latch release tab on

the top of the wiper arm to unlatch it from the arm

(Fig. 13).(4) Raise the pivot block latch release tab until it

is perpendicular to the rear wiper blade superstruc-

ture (Fig. 14).

(5) Slide the rear wiper blade away from the tip of

the arm towards the pivot end of the arm far enough

to disengage the pivot block from the hook formation

on the end of the arm.

(6) Extract the hook formation on the tip of the

wiper arm from the window in the wiper blade pivot

block/latch unit.

CAUTION: Do not allow the wiper arm to spring

back against the tailgate or the flip-up glass without

the wiper blade in place or they may be damaged.

(7) Gently lower the wiper arm and place the arm

support in the park ramp.

INSTALLATION

NOTE: The notched end of the wiper element flexor

should always be oriented towards the end of the

wiper blade that is nearest to the wiper motor out-

put shaft.

(1) Lift the rear wiper arm support out of the tail

gate park ramp.

(2) Position the rear wiper blade near the hook for-

mation on the tip of the arm with the notched end of

the wiper element flexor oriented towards the end of

the wiper arm that is nearest to the wiper motor out-

put shaft.

Fig. 13 Rear Wiper Blade Release

1 - PIVOT BLOCK WINDOW

2 - TIP OF REAR WIPER ARM

3 - SUPERSTRUCTURE

4 - PIVOT BLOCK HINGE PIN

5 - LATCH RELEASE TAB

Fig. 14 Rear Wiper Blade Remove/Install

1 - SUPERSTRUCTURE

2 - HOOK

3 - ELEMENT

4 - LATCH RELEASE

5 - REAR WIPER ARM

8R - 40 REAR WIPERS/WASHERSKJ

REAR WIPER BLADE (Continued)

Page 743 of 1803

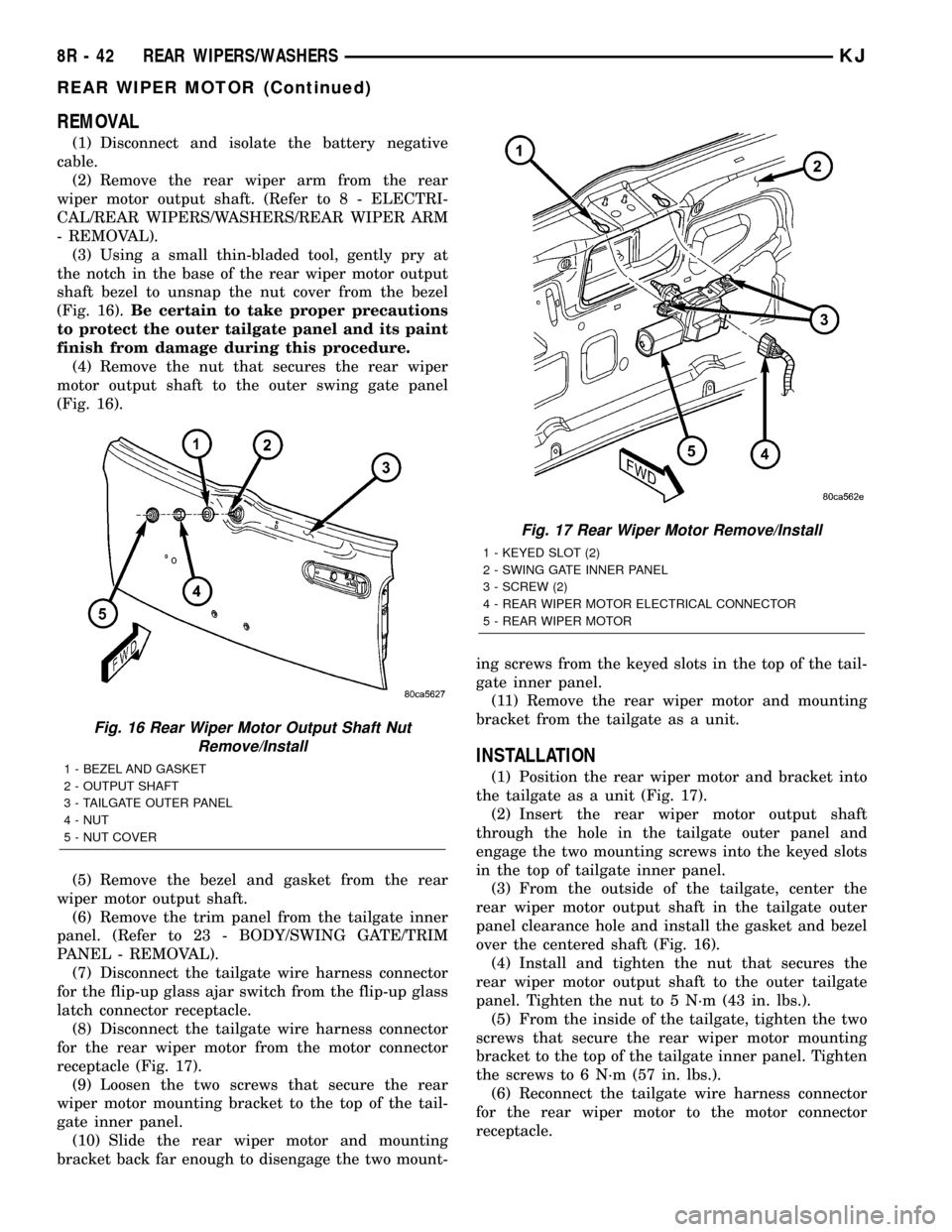

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the rear wiper arm from the rear

wiper motor output shaft. (Refer to 8 - ELECTRI-

CAL/REAR WIPERS/WASHERS/REAR WIPER ARM

- REMOVAL).

(3) Using a small thin-bladed tool, gently pry at

the notch in the base of the rear wiper motor output

shaft bezel to unsnap the nut cover from the bezel

(Fig. 16).Be certain to take proper precautions

to protect the outer tailgate panel and its paint

finish from damage during this procedure.

(4) Remove the nut that secures the rear wiper

motor output shaft to the outer swing gate panel

(Fig. 16).

(5) Remove the bezel and gasket from the rear

wiper motor output shaft.

(6) Remove the trim panel from the tailgate inner

panel. (Refer to 23 - BODY/SWING GATE/TRIM

PANEL - REMOVAL).

(7) Disconnect the tailgate wire harness connector

for the flip-up glass ajar switch from the flip-up glass

latch connector receptacle.

(8) Disconnect the tailgate wire harness connector

for the rear wiper motor from the motor connector

receptacle (Fig. 17).

(9) Loosen the two screws that secure the rear

wiper motor mounting bracket to the top of the tail-

gate inner panel.

(10) Slide the rear wiper motor and mounting

bracket back far enough to disengage the two mount-ing screws from the keyed slots in the top of the tail-

gate inner panel.

(11) Remove the rear wiper motor and mounting

bracket from the tailgate as a unit.

INSTALLATION

(1) Position the rear wiper motor and bracket into

the tailgate as a unit (Fig. 17).

(2) Insert the rear wiper motor output shaft

through the hole in the tailgate outer panel and

engage the two mounting screws into the keyed slots

in the top of tailgate inner panel.

(3) From the outside of the tailgate, center the

rear wiper motor output shaft in the tailgate outer

panel clearance hole and install the gasket and bezel

over the centered shaft (Fig. 16).

(4) Install and tighten the nut that secures the

rear wiper motor output shaft to the outer tailgate

panel. Tighten the nut to 5 N´m (43 in. lbs.).

(5) From the inside of the tailgate, tighten the two

screws that secure the rear wiper motor mounting

bracket to the top of the tailgate inner panel. Tighten

the screws to 6 N´m (57 in. lbs.).

(6) Reconnect the tailgate wire harness connector

for the rear wiper motor to the motor connector

receptacle.

Fig. 16 Rear Wiper Motor Output Shaft Nut

Remove/Install

1 - BEZEL AND GASKET

2 - OUTPUT SHAFT

3 - TAILGATE OUTER PANEL

4 - NUT

5 - NUT COVER

Fig. 17 Rear Wiper Motor Remove/Install

1 - KEYED SLOT (2)

2 - SWING GATE INNER PANEL

3 - SCREW (2)

4 - REAR WIPER MOTOR ELECTRICAL CONNECTOR

5 - REAR WIPER MOTOR

8R - 42 REAR WIPERS/WASHERSKJ

REAR WIPER MOTOR (Continued)