lock JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1353 of 1803

INSTALLATION

INSTALLATION - CRANKSHAFT SPROCKET

CAUTION: The crankshaft sprocket is set to a pre-

determined depth from the factory for correct tim-

ing belt tracking. If removed, use of Special Tool

6792 is required to set the sprocket to original

installation depth. An incorrectly installed sprocket

will result in timing belt and engine damage.

(1) Install crankshaft sprocket using Special Tool

6792 (Fig. 98).

(2) Install timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

INSTALLATION - TIMING BELT

CAUTION: The crankshaft sprocket is set to a pre-

determined depth from the factory for correct tim-

ing belt tracking. If removed, use of Special Tool

6792 is required to set the sprocket to original

installation depth. An incorrectly installed sprocket

will result in timing belt and engine damage.

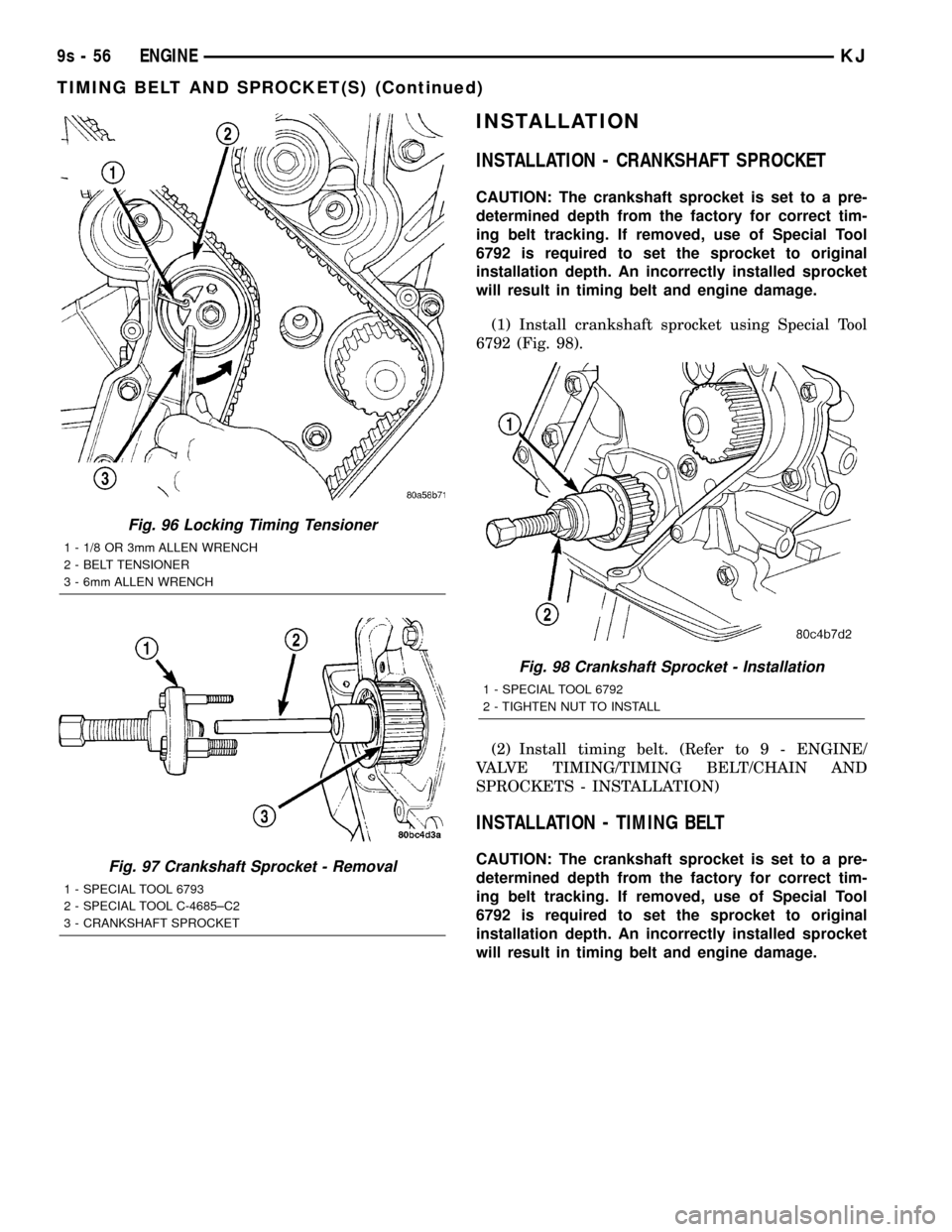

Fig. 96 Locking Timing Tensioner

1 - 1/8 OR 3mm ALLEN WRENCH

2 - BELT TENSIONER

3 - 6mm ALLEN WRENCH

Fig. 97 Crankshaft Sprocket - Removal

1 - SPECIAL TOOL 6793

2 - SPECIAL TOOL C-4685±C2

3 - CRANKSHAFT SPROCKET

Fig. 98 Crankshaft Sprocket - Installation

1 - SPECIAL TOOL 6792

2 - TIGHTEN NUT TO INSTALL

9s - 56 ENGINEKJ

TIMING BELT AND SPROCKET(S) (Continued)

Page 1354 of 1803

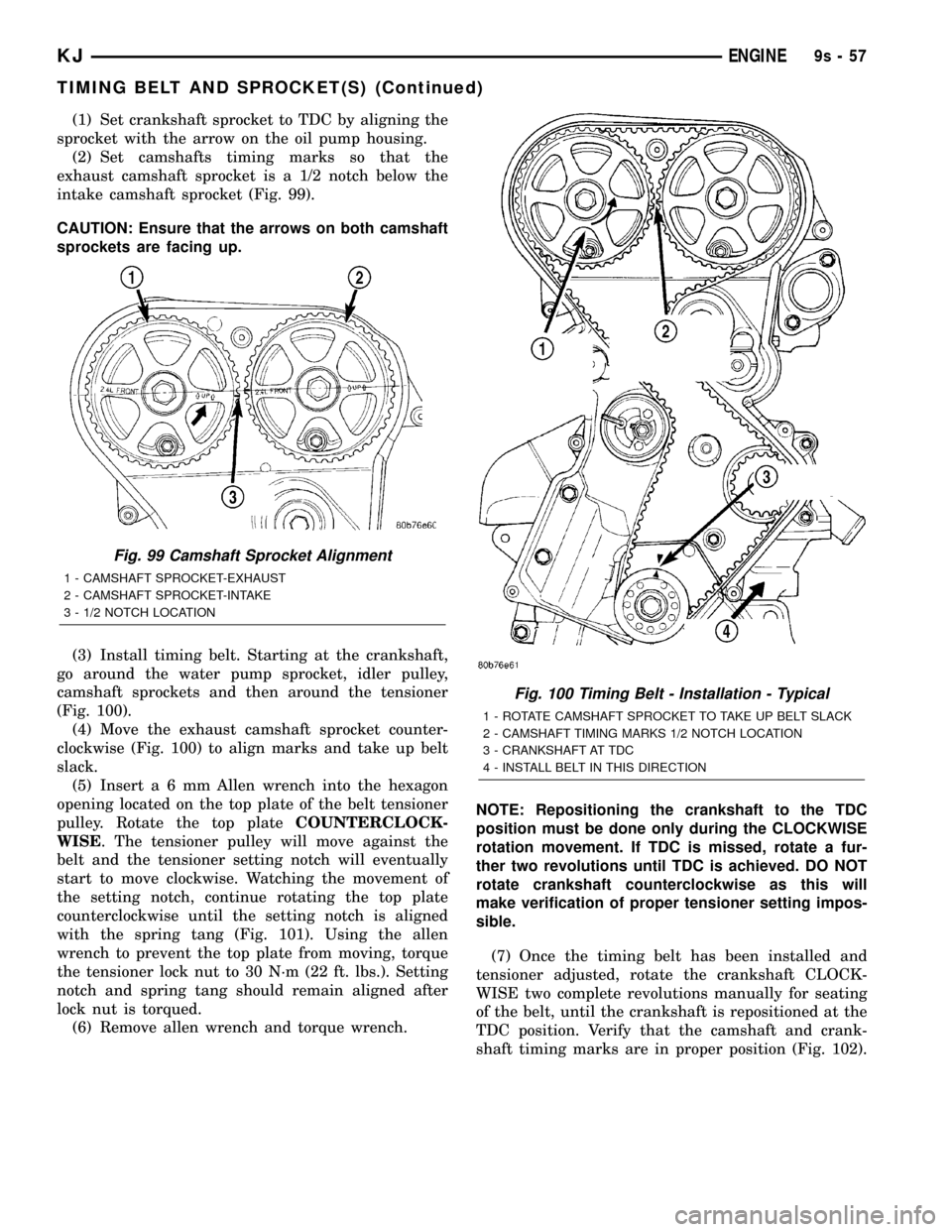

(1) Set crankshaft sprocket to TDC by aligning the

sprocket with the arrow on the oil pump housing.

(2) Set camshafts timing marks so that the

exhaust camshaft sprocket is a 1/2 notch below the

intake camshaft sprocket (Fig. 99).

CAUTION: Ensure that the arrows on both camshaft

sprockets are facing up.

(3) Install timing belt. Starting at the crankshaft,

go around the water pump sprocket, idler pulley,

camshaft sprockets and then around the tensioner

(Fig. 100).

(4) Move the exhaust camshaft sprocket counter-

clockwise (Fig. 100) to align marks and take up belt

slack.

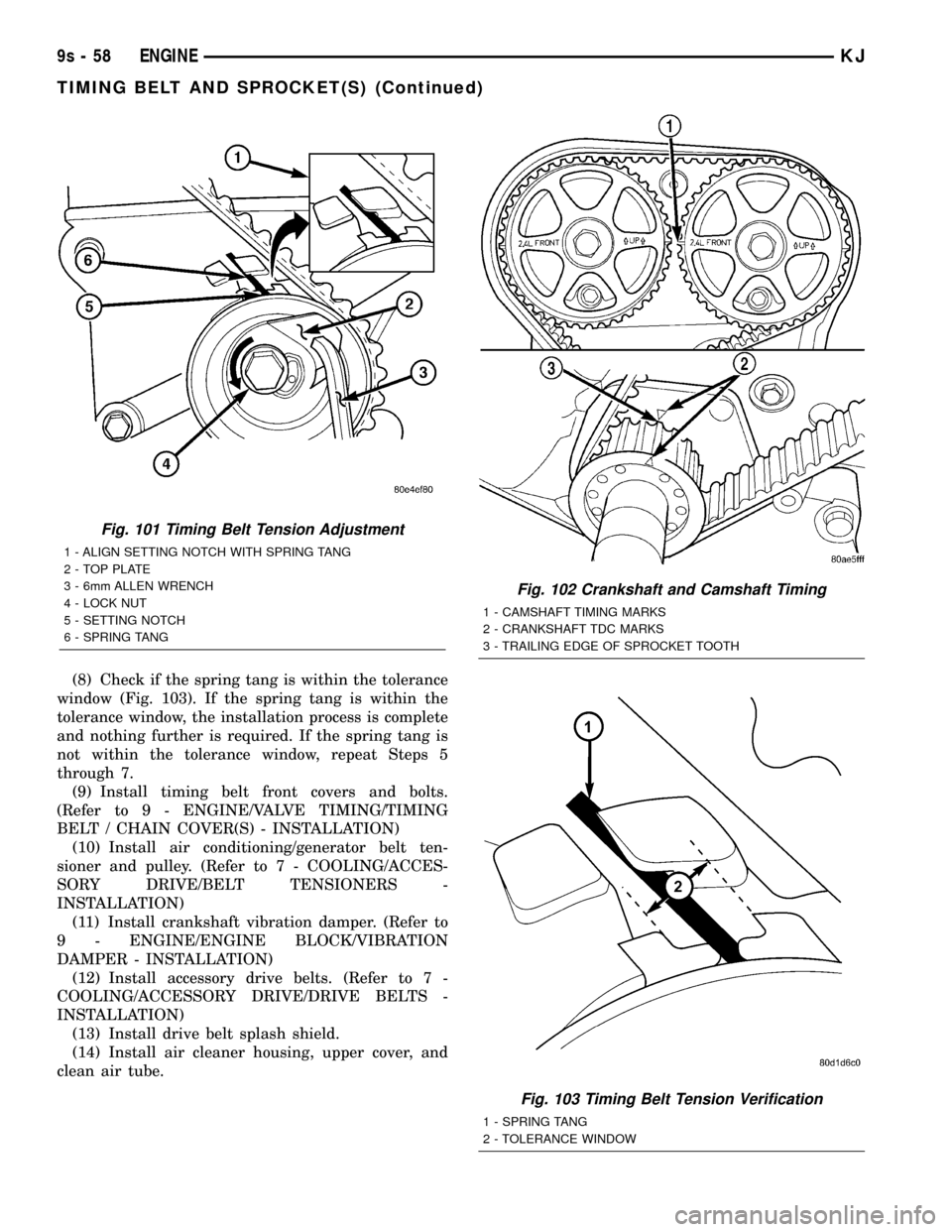

(5) Inserta6mmAllen wrench into the hexagon

opening located on the top plate of the belt tensioner

pulley. Rotate the top plateCOUNTERCLOCK-

WISE. The tensioner pulley will move against the

belt and the tensioner setting notch will eventually

start to move clockwise. Watching the movement of

the setting notch, continue rotating the top plate

counterclockwise until the setting notch is aligned

with the spring tang (Fig. 101). Using the allen

wrench to prevent the top plate from moving, torque

the tensioner lock nut to 30 N´m (22 ft. lbs.). Setting

notch and spring tang should remain aligned after

lock nut is torqued.

(6) Remove allen wrench and torque wrench.NOTE: Repositioning the crankshaft to the TDC

position must be done only during the CLOCKWISE

rotation movement. If TDC is missed, rotate a fur-

ther two revolutions until TDC is achieved. DO NOT

rotate crankshaft counterclockwise as this will

make verification of proper tensioner setting impos-

sible.

(7) Once the timing belt has been installed and

tensioner adjusted, rotate the crankshaft CLOCK-

WISE two complete revolutions manually for seating

of the belt, until the crankshaft is repositioned at the

TDC position. Verify that the camshaft and crank-

shaft timing marks are in proper position (Fig. 102).

Fig. 99 Camshaft Sprocket Alignment

1 - CAMSHAFT SPROCKET-EXHAUST

2 - CAMSHAFT SPROCKET-INTAKE

3 - 1/2 NOTCH LOCATION

Fig. 100 Timing Belt - Installation - Typical

1 - ROTATE CAMSHAFT SPROCKET TO TAKE UP BELT SLACK

2 - CAMSHAFT TIMING MARKS 1/2 NOTCH LOCATION

3 - CRANKSHAFT AT TDC

4 - INSTALL BELT IN THIS DIRECTION

KJENGINE9s-57

TIMING BELT AND SPROCKET(S) (Continued)

Page 1355 of 1803

(8) Check if the spring tang is within the tolerance

window (Fig. 103). If the spring tang is within the

tolerance window, the installation process is complete

and nothing further is required. If the spring tang is

not within the tolerance window, repeat Steps 5

through 7.

(9) Install timing belt front covers and bolts.

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT / CHAIN COVER(S) - INSTALLATION)

(10) Install air conditioning/generator belt ten-

sioner and pulley. (Refer to 7 - COOLING/ACCES-

SORY DRIVE/BELT TENSIONERS -

INSTALLATION)

(11) Install crankshaft vibration damper. (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION)

(12) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(13) Install drive belt splash shield.

(14) Install air cleaner housing, upper cover, and

clean air tube.

Fig. 101 Timing Belt Tension Adjustment

1 - ALIGN SETTING NOTCH WITH SPRING TANG

2 - TOP PLATE

3 - 6mm ALLEN WRENCH

4 - LOCK NUT

5 - SETTING NOTCH

6 - SPRING TANG

Fig. 102 Crankshaft and Camshaft Timing

1 - CAMSHAFT TIMING MARKS

2 - CRANKSHAFT TDC MARKS

3 - TRAILING EDGE OF SPROCKET TOOTH

Fig. 103 Timing Belt Tension Verification

1 - SPRING TANG

2 - TOLERANCE WINDOW

9s - 58 ENGINEKJ

TIMING BELT AND SPROCKET(S) (Continued)

Page 1356 of 1803

TIMING BELT TENSIONER &

PULLEY

REMOVAL

(1) Remove the timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

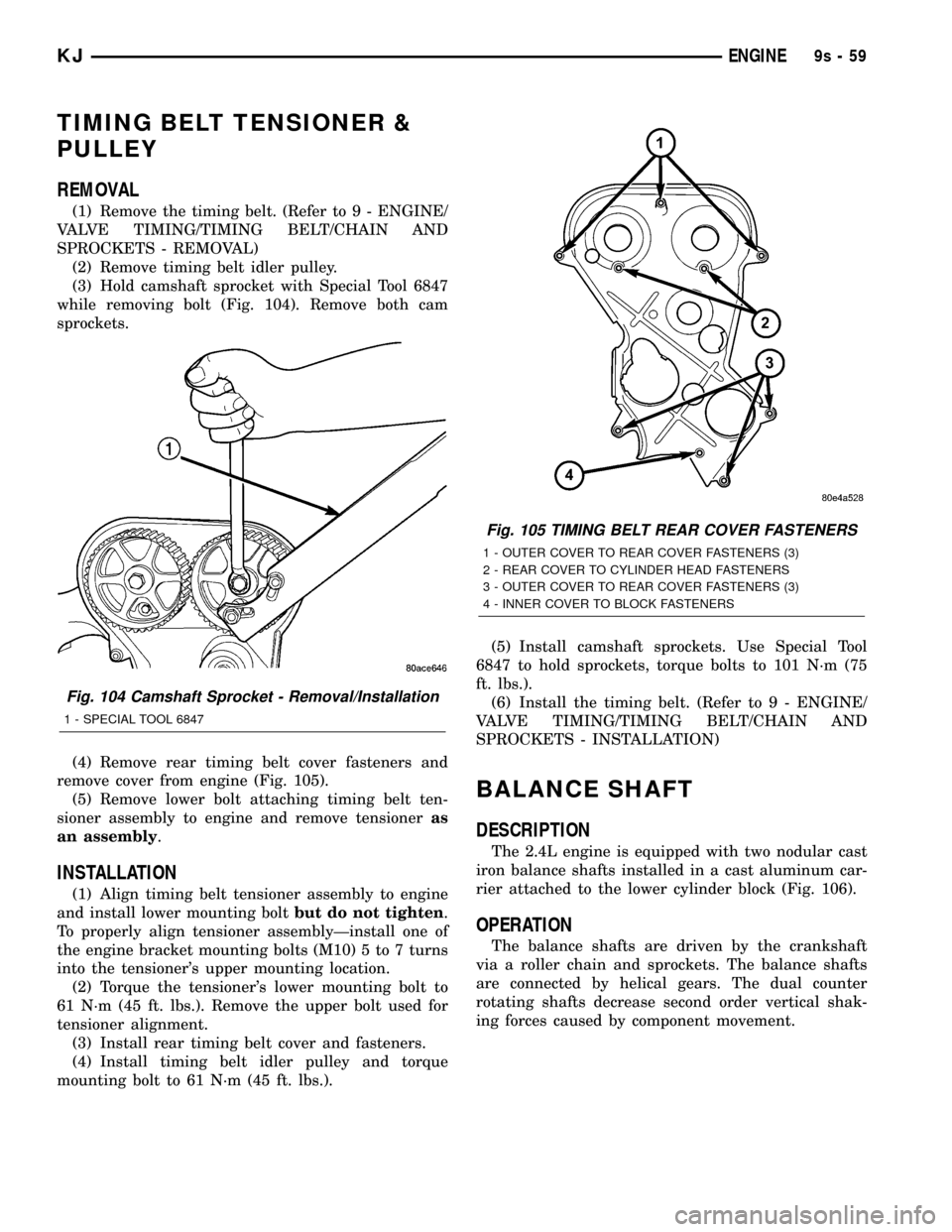

(2) Remove timing belt idler pulley.

(3) Hold camshaft sprocket with Special Tool 6847

while removing bolt (Fig. 104). Remove both cam

sprockets.

(4) Remove rear timing belt cover fasteners and

remove cover from engine (Fig. 105).

(5) Remove lower bolt attaching timing belt ten-

sioner assembly to engine and remove tensioneras

an assembly.

INSTALLATION

(1) Align timing belt tensioner assembly to engine

and install lower mounting boltbut do not tighten.

To properly align tensioner assemblyÐinstall one of

the engine bracket mounting bolts (M10) 5 to 7 turns

into the tensioner's upper mounting location.

(2) Torque the tensioner's lower mounting bolt to

61 N´m (45 ft. lbs.). Remove the upper bolt used for

tensioner alignment.

(3) Install rear timing belt cover and fasteners.

(4) Install timing belt idler pulley and torque

mounting bolt to 61 N´m (45 ft. lbs.).(5) Install camshaft sprockets. Use Special Tool

6847 to hold sprockets, torque bolts to 101 N´m (75

ft. lbs.).

(6) Install the timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

BALANCE SHAFT

DESCRIPTION

The 2.4L engine is equipped with two nodular cast

iron balance shafts installed in a cast aluminum car-

rier attached to the lower cylinder block (Fig. 106).

OPERATION

The balance shafts are driven by the crankshaft

via a roller chain and sprockets. The balance shafts

are connected by helical gears. The dual counter

rotating shafts decrease second order vertical shak-

ing forces caused by component movement.

Fig. 104 Camshaft Sprocket - Removal/Installation

1 - SPECIAL TOOL 6847

Fig. 105 TIMING BELT REAR COVER FASTENERS

1 - OUTER COVER TO REAR COVER FASTENERS (3)

2 - REAR COVER TO CYLINDER HEAD FASTENERS

3 - OUTER COVER TO REAR COVER FASTENERS (3)

4 - INNER COVER TO BLOCK FASTENERS

KJENGINE9s-59

Page 1360 of 1803

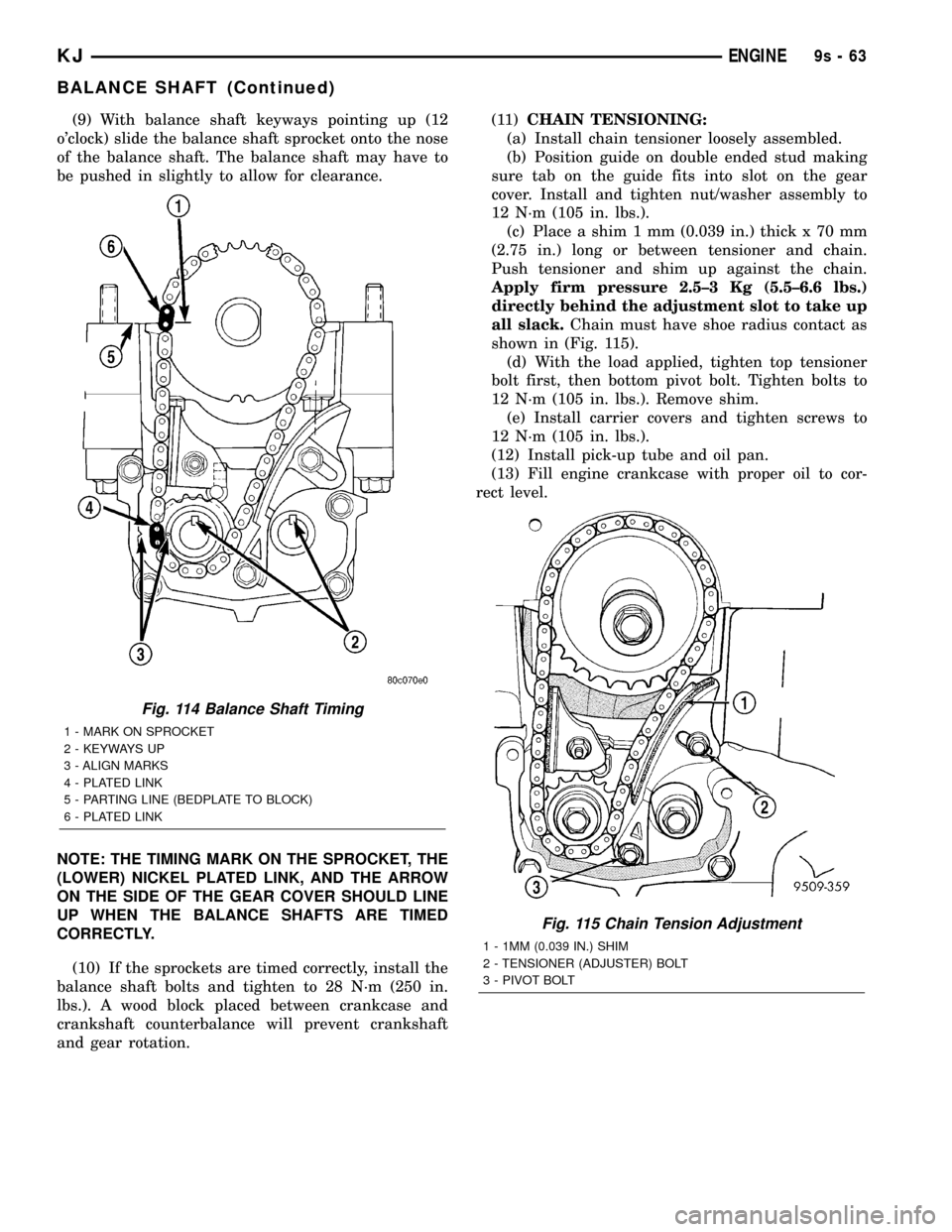

(9) With balance shaft keyways pointing up (12

o'clock) slide the balance shaft sprocket onto the nose

of the balance shaft. The balance shaft may have to

be pushed in slightly to allow for clearance.

NOTE: THE TIMING MARK ON THE SPROCKET, THE

(LOWER) NICKEL PLATED LINK, AND THE ARROW

ON THE SIDE OF THE GEAR COVER SHOULD LINE

UP WHEN THE BALANCE SHAFTS ARE TIMED

CORRECTLY.

(10) If the sprockets are timed correctly, install the

balance shaft bolts and tighten to 28 N´m (250 in.

lbs.). A wood block placed between crankcase and

crankshaft counterbalance will prevent crankshaft

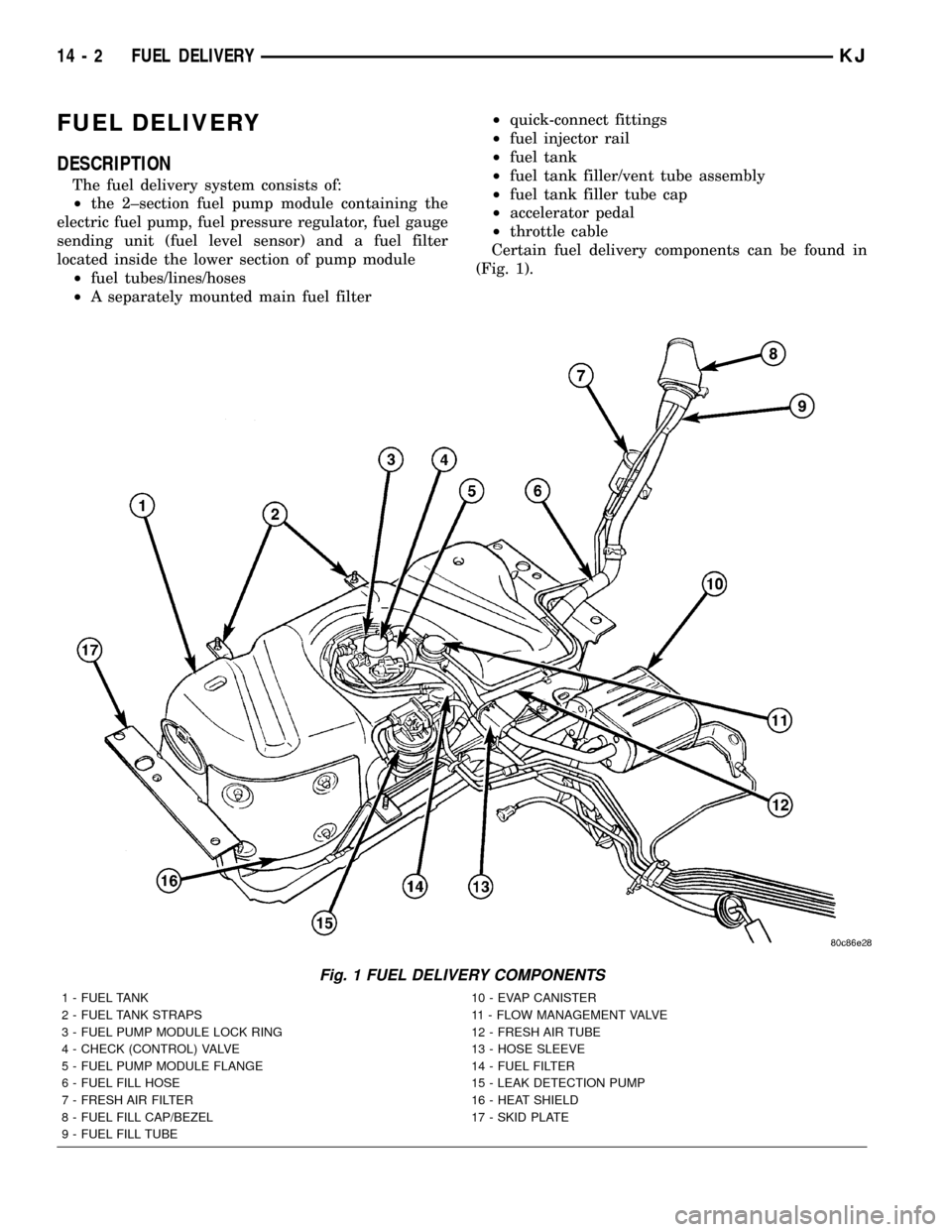

and gear rotation.(11)CHAIN TENSIONING:

(a) Install chain tensioner loosely assembled.

(b) Position guide on double ended stud making

sure tab on the guide fits into slot on the gear

cover. Install and tighten nut/washer assembly to

12 N´m (105 in. lbs.).

(c) Place a shim 1 mm (0.039 in.) thick x 70 mm

(2.75 in.) long or between tensioner and chain.

Push tensioner and shim up against the chain.

Apply firm pressure 2.5±3 Kg (5.5±6.6 lbs.)

directly behind the adjustment slot to take up

all slack.Chain must have shoe radius contact as

shown in (Fig. 115).

(d) With the load applied, tighten top tensioner

bolt first, then bottom pivot bolt. Tighten bolts to

12 N´m (105 in. lbs.). Remove shim.

(e) Install carrier covers and tighten screws to

12 N´m (105 in. lbs.).

(12) Install pick-up tube and oil pan.

(13) Fill engine crankcase with proper oil to cor-

rect level.

Fig. 114 Balance Shaft Timing

1 - MARK ON SPROCKET

2 - KEYWAYS UP

3 - ALIGN MARKS

4 - PLATED LINK

5 - PARTING LINE (BEDPLATE TO BLOCK)

6 - PLATED LINK

Fig. 115 Chain Tension Adjustment

1 - 1MM (0.039 IN.) SHIM

2 - TENSIONER (ADJUSTER) BOLT

3 - PIVOT BOLT

KJENGINE9s-63

BALANCE SHAFT (Continued)

Page 1384 of 1803

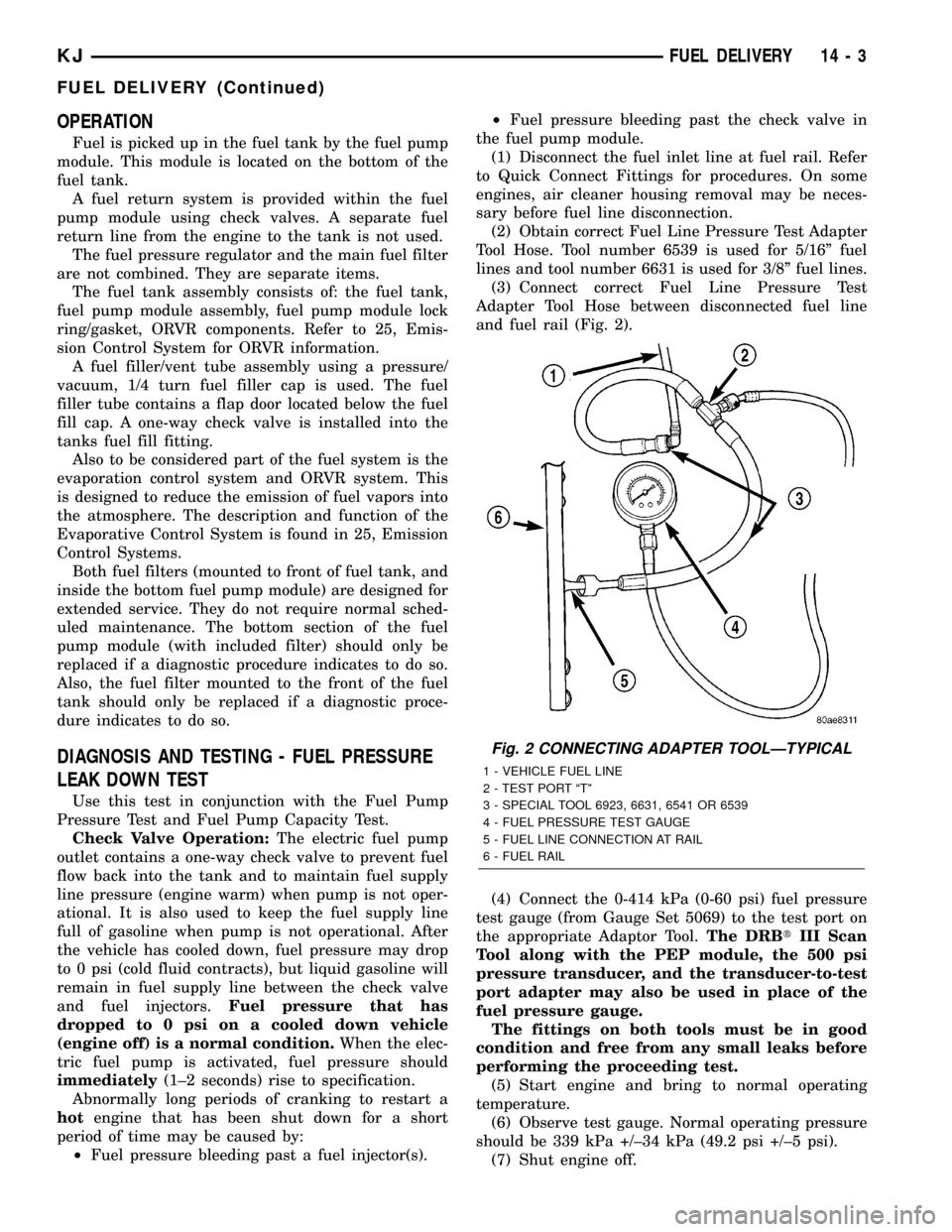

FUEL DELIVERY

DESCRIPTION

The fuel delivery system consists of:

²the 2±section fuel pump module containing the

electric fuel pump, fuel pressure regulator, fuel gauge

sending unit (fuel level sensor) and a fuel filter

located inside the lower section of pump module

²fuel tubes/lines/hoses

²A separately mounted main fuel filter²quick-connect fittings

²fuel injector rail

²fuel tank

²fuel tank filler/vent tube assembly

²fuel tank filler tube cap

²accelerator pedal

²throttle cable

Certain fuel delivery components can be found in

(Fig. 1).

Fig. 1 FUEL DELIVERY COMPONENTS

1 - FUEL TANK 10 - EVAP CANISTER

2 - FUEL TANK STRAPS 11 - FLOW MANAGEMENT VALVE

3 - FUEL PUMP MODULE LOCK RING 12 - FRESH AIR TUBE

4 - CHECK (CONTROL) VALVE 13 - HOSE SLEEVE

5 - FUEL PUMP MODULE FLANGE 14 - FUEL FILTER

6 - FUEL FILL HOSE 15 - LEAK DETECTION PUMP

7 - FRESH AIR FILTER 16 - HEAT SHIELD

8 - FUEL FILL CAP/BEZEL 17 - SKID PLATE

9 - FUEL FILL TUBE

14 - 2 FUEL DELIVERYKJ

Page 1385 of 1803

OPERATION

Fuel is picked up in the fuel tank by the fuel pump

module. This module is located on the bottom of the

fuel tank.

A fuel return system is provided within the fuel

pump module using check valves. A separate fuel

return line from the engine to the tank is not used.

The fuel pressure regulator and the main fuel filter

are not combined. They are separate items.

The fuel tank assembly consists of: the fuel tank,

fuel pump module assembly, fuel pump module lock

ring/gasket, ORVR components. Refer to 25, Emis-

sion Control System for ORVR information.

A fuel filler/vent tube assembly using a pressure/

vacuum, 1/4 turn fuel filler cap is used. The fuel

filler tube contains a flap door located below the fuel

fill cap. A one-way check valve is installed into the

tanks fuel fill fitting.

Also to be considered part of the fuel system is the

evaporation control system and ORVR system. This

is designed to reduce the emission of fuel vapors into

the atmosphere. The description and function of the

Evaporative Control System is found in 25, Emission

Control Systems.

Both fuel filters (mounted to front of fuel tank, and

inside the bottom fuel pump module) are designed for

extended service. They do not require normal sched-

uled maintenance. The bottom section of the fuel

pump module (with included filter) should only be

replaced if a diagnostic procedure indicates to do so.

Also, the fuel filter mounted to the front of the fuel

tank should only be replaced if a diagnostic proce-

dure indicates to do so.

DIAGNOSIS AND TESTING - FUEL PRESSURE

LEAK DOWN TEST

Use this test in conjunction with the Fuel Pump

Pressure Test and Fuel Pump Capacity Test.

Check Valve Operation:The electric fuel pump

outlet contains a one-way check valve to prevent fuel

flow back into the tank and to maintain fuel supply

line pressure (engine warm) when pump is not oper-

ational. It is also used to keep the fuel supply line

full of gasoline when pump is not operational. After

the vehicle has cooled down, fuel pressure may drop

to 0 psi (cold fluid contracts), but liquid gasoline will

remain in fuel supply line between the check valve

and fuel injectors.Fuel pressure that has

dropped to 0 psi on a cooled down vehicle

(engine off) is a normal condition.When the elec-

tric fuel pump is activated, fuel pressure should

immediately(1±2 seconds) rise to specification.

Abnormally long periods of cranking to restart a

hotengine that has been shut down for a short

period of time may be caused by:

²Fuel pressure bleeding past a fuel injector(s).²Fuel pressure bleeding past the check valve in

the fuel pump module.

(1) Disconnect the fuel inlet line at fuel rail. Refer

to Quick Connect Fittings for procedures. On some

engines, air cleaner housing removal may be neces-

sary before fuel line disconnection.

(2) Obtain correct Fuel Line Pressure Test Adapter

Tool Hose. Tool number 6539 is used for 5/16º fuel

lines and tool number 6631 is used for 3/8º fuel lines.

(3) Connect correct Fuel Line Pressure Test

Adapter Tool Hose between disconnected fuel line

and fuel rail (Fig. 2).

(4) Connect the 0-414 kPa (0-60 psi) fuel pressure

test gauge (from Gauge Set 5069) to the test port on

the appropriate Adaptor Tool.The DRBtIII Scan

Tool along with the PEP module, the 500 psi

pressure transducer, and the transducer-to-test

port adapter may also be used in place of the

fuel pressure gauge.

The fittings on both tools must be in good

condition and free from any small leaks before

performing the proceeding test.

(5) Start engine and bring to normal operating

temperature.

(6) Observe test gauge. Normal operating pressure

should be 339 kPa +/±34 kPa (49.2 psi +/±5 psi).

(7) Shut engine off.

Fig. 2 CONNECTING ADAPTER TOOLÐTYPICAL

1 - VEHICLE FUEL LINE

2 - TEST PORT ªTº

3 - SPECIAL TOOL 6923, 6631, 6541 OR 6539

4 - FUEL PRESSURE TEST GAUGE

5 - FUEL LINE CONNECTION AT RAIL

6 - FUEL RAIL

KJFUEL DELIVERY 14 - 3

FUEL DELIVERY (Continued)

Page 1389 of 1803

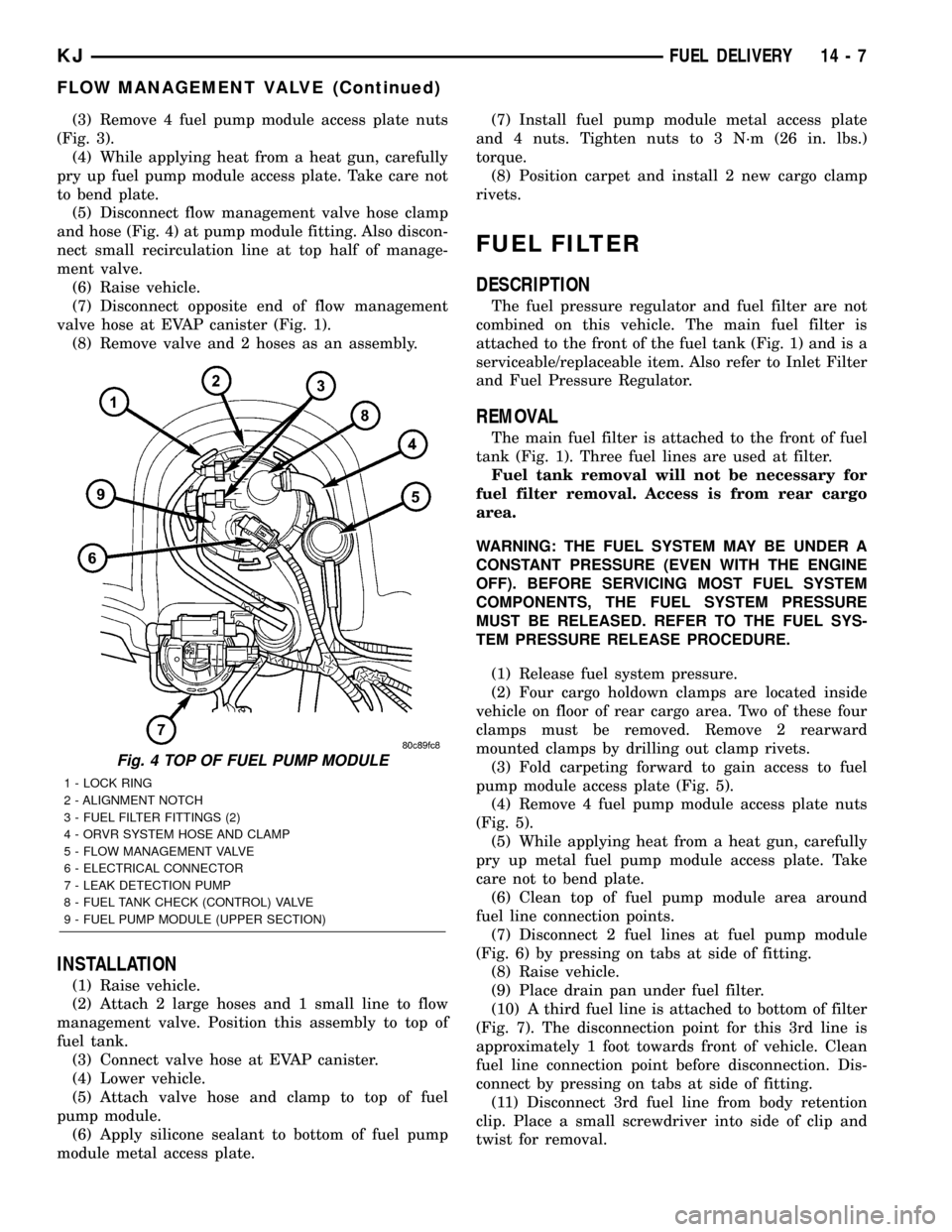

(3) Remove 4 fuel pump module access plate nuts

(Fig. 3).

(4) While applying heat from a heat gun, carefully

pry up fuel pump module access plate. Take care not

to bend plate.

(5) Disconnect flow management valve hose clamp

and hose (Fig. 4) at pump module fitting. Also discon-

nect small recirculation line at top half of manage-

ment valve.

(6) Raise vehicle.

(7) Disconnect opposite end of flow management

valve hose at EVAP canister (Fig. 1).

(8) Remove valve and 2 hoses as an assembly.

INSTALLATION

(1) Raise vehicle.

(2) Attach 2 large hoses and 1 small line to flow

management valve. Position this assembly to top of

fuel tank.

(3) Connect valve hose at EVAP canister.

(4) Lower vehicle.

(5) Attach valve hose and clamp to top of fuel

pump module.

(6) Apply silicone sealant to bottom of fuel pump

module metal access plate.(7) Install fuel pump module metal access plate

and 4 nuts. Tighten nuts to 3 N´m (26 in. lbs.)

torque.

(8) Position carpet and install 2 new cargo clamp

rivets.

FUEL FILTER

DESCRIPTION

The fuel pressure regulator and fuel filter are not

combined on this vehicle. The main fuel filter is

attached to the front of the fuel tank (Fig. 1) and is a

serviceable/replaceable item. Also refer to Inlet Filter

and Fuel Pressure Regulator.

REMOVAL

The main fuel filter is attached to the front of fuel

tank (Fig. 1). Three fuel lines are used at filter.

Fuel tank removal will not be necessary for

fuel filter removal. Access is from rear cargo

area.

WARNING: THE FUEL SYSTEM MAY BE UNDER A

CONSTANT PRESSURE (EVEN WITH THE ENGINE

OFF). BEFORE SERVICING MOST FUEL SYSTEM

COMPONENTS, THE FUEL SYSTEM PRESSURE

MUST BE RELEASED. REFER TO THE FUEL SYS-

TEM PRESSURE RELEASE PROCEDURE.

(1) Release fuel system pressure.

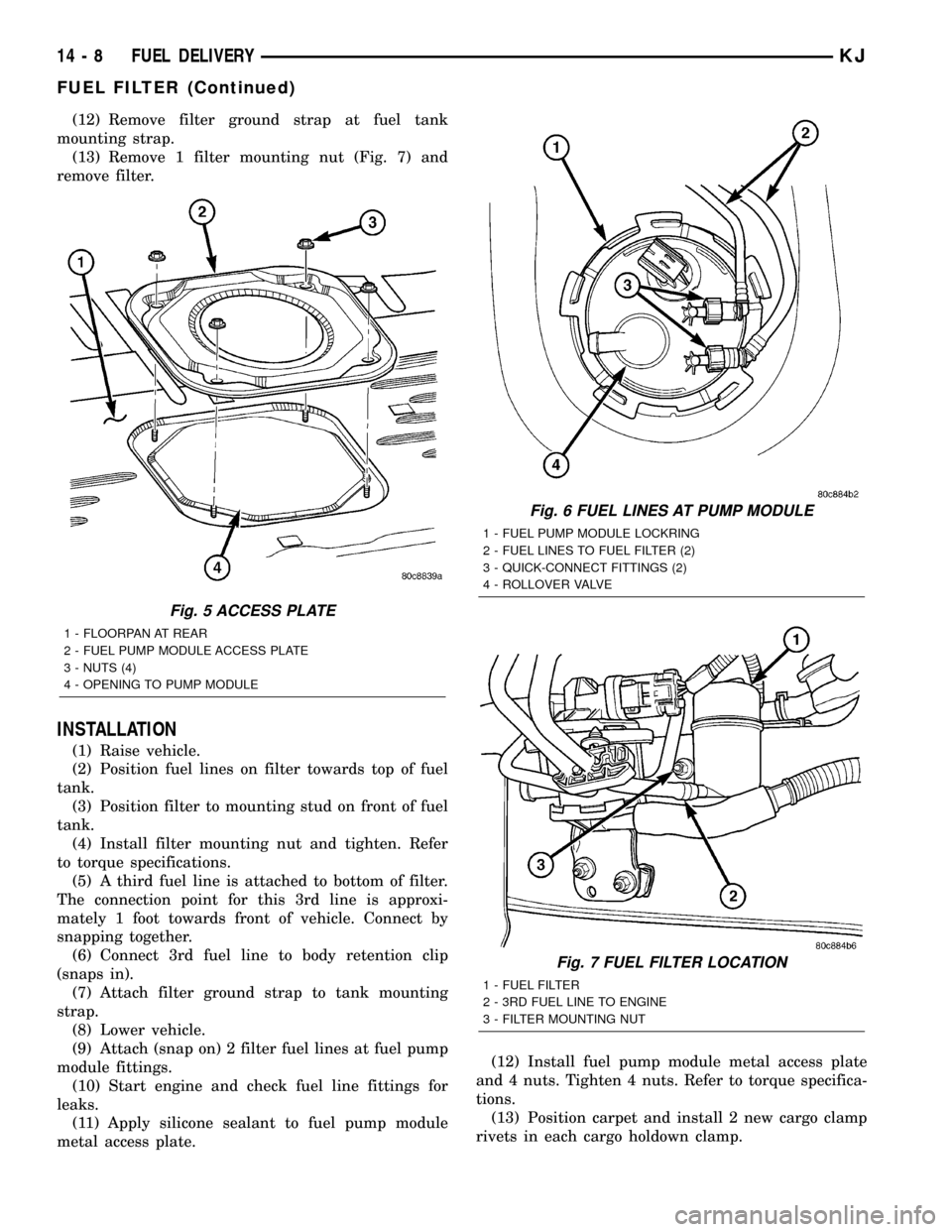

(2) Four cargo holdown clamps are located inside

vehicle on floor of rear cargo area. Two of these four

clamps must be removed. Remove 2 rearward

mounted clamps by drilling out clamp rivets.

(3) Fold carpeting forward to gain access to fuel

pump module access plate (Fig. 5).

(4) Remove 4 fuel pump module access plate nuts

(Fig. 5).

(5) While applying heat from a heat gun, carefully

pry up metal fuel pump module access plate. Take

care not to bend plate.

(6) Clean top of fuel pump module area around

fuel line connection points.

(7) Disconnect 2 fuel lines at fuel pump module

(Fig. 6) by pressing on tabs at side of fitting.

(8) Raise vehicle.

(9) Place drain pan under fuel filter.

(10) A third fuel line is attached to bottom of filter

(Fig. 7). The disconnection point for this 3rd line is

approximately 1 foot towards front of vehicle. Clean

fuel line connection point before disconnection. Dis-

connect by pressing on tabs at side of fitting.

(11) Disconnect 3rd fuel line from body retention

clip. Place a small screwdriver into side of clip and

twist for removal.

Fig. 4 TOP OF FUEL PUMP MODULE

1 - LOCK RING

2 - ALIGNMENT NOTCH

3 - FUEL FILTER FITTINGS (2)

4 - ORVR SYSTEM HOSE AND CLAMP

5 - FLOW MANAGEMENT VALVE

6 - ELECTRICAL CONNECTOR

7 - LEAK DETECTION PUMP

8 - FUEL TANK CHECK (CONTROL) VALVE

9 - FUEL PUMP MODULE (UPPER SECTION)

KJFUEL DELIVERY 14 - 7

FLOW MANAGEMENT VALVE (Continued)

Page 1390 of 1803

(12) Remove filter ground strap at fuel tank

mounting strap.

(13) Remove 1 filter mounting nut (Fig. 7) and

remove filter.

INSTALLATION

(1) Raise vehicle.

(2) Position fuel lines on filter towards top of fuel

tank.

(3) Position filter to mounting stud on front of fuel

tank.

(4) Install filter mounting nut and tighten. Refer

to torque specifications.

(5) A third fuel line is attached to bottom of filter.

The connection point for this 3rd line is approxi-

mately 1 foot towards front of vehicle. Connect by

snapping together.

(6) Connect 3rd fuel line to body retention clip

(snaps in).

(7) Attach filter ground strap to tank mounting

strap.

(8) Lower vehicle.

(9) Attach (snap on) 2 filter fuel lines at fuel pump

module fittings.

(10) Start engine and check fuel line fittings for

leaks.

(11) Apply silicone sealant to fuel pump module

metal access plate.(12) Install fuel pump module metal access plate

and 4 nuts. Tighten 4 nuts. Refer to torque specifica-

tions.

(13) Position carpet and install 2 new cargo clamp

rivets in each cargo holdown clamp.

Fig. 5 ACCESS PLATE

1 - FLOORPAN AT REAR

2 - FUEL PUMP MODULE ACCESS PLATE

3 - NUTS (4)

4 - OPENING TO PUMP MODULE

Fig. 6 FUEL LINES AT PUMP MODULE

1 - FUEL PUMP MODULE LOCKRING

2 - FUEL LINES TO FUEL FILTER (2)

3 - QUICK-CONNECT FITTINGS (2)

4 - ROLLOVER VALVE

Fig. 7 FUEL FILTER LOCATION

1 - FUEL FILTER

2 - 3RD FUEL LINE TO ENGINE

3 - FILTER MOUNTING NUT

14 - 8 FUEL DELIVERYKJ

FUEL FILTER (Continued)

Page 1391 of 1803

FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel pump module. The

sending unit consists of a float, an arm, and a vari-

able resistor track (card).

OPERATION

The fuel pump module has 4 different circuits

(wires). Two of these circuits are used for the fuel

gauge sending unit for fuel gauge operation, and for

certain OBD II emission requirements. The other 2

wires are used for electric fuel pump operation.

For Fuel Gauge Operation:A constant current

source of approximately 32 milliamps is supplied to

the resistor track on the fuel gauge sending unit.

This is fed directly from the Powertrain Control Mod-

ule (PCM).NOTE: For diagnostic purposes, this

12V power source can only be verified with the

circuit opened (fuel pump module electrical

connector unplugged). With the connectors

plugged, output voltages will vary from about

0.6 volts at FULL, to about 8.6 volts at EMPTY

(about 8.6 volts at EMPTY for Jeep models, and

about 7.0 volts at EMPTY for Dodge Truck mod-

els).The resistor track is used to vary the voltage

(resistance) depending on fuel tank float level. As

fuel level increases, the float and arm move up,

which decreases voltage. As fuel level decreases, the

float and arm move down, which increases voltage.

The varied voltage signal is returned back to the

PCM through the sensor return circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the PCM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the PCM, the PCM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

For OBD II Emission Monitor Requirements:

The PCM will monitor the voltage output sent from

the resistor track on the sending unit to indicate fuel

level. The purpose of this feature is to prevent the

OBD II system from recording/setting false misfire

and fuel system monitor diagnostic trouble codes.

The feature is activated if the fuel level in the tank

is less than approximately 15 percent of its rated

capacity. If equipped with a Leak Detection Pump

(EVAP system monitor), this feature will also be acti-

vated if the fuel level in the tank is more than

approximately 85 percent of its rated capacity.

DIAGNOSIS AND TESTING - FUEL LEVEL

SENDING UNIT

The fuel level sending unit contains a variable

resistor (track). As the float moves up or down, elec-

trical resistance will change. Refer to Instrument

Panel and Gauges for Fuel Gauge testing. To test the

gauge sending unit only, it must be removed from

vehicle. The unit is a separate part of the lower fuel

pump module section. Refer to Fuel Pump Module

Removal/Installation for procedures (remove only the

upper section of the fuel pump module). Measure the

resistance across the sending unit terminals. With

float in up position, resistance should be 20 ohms (+/-

5%). With float in down position, resistance should be

270 ohms (+/- 5%).

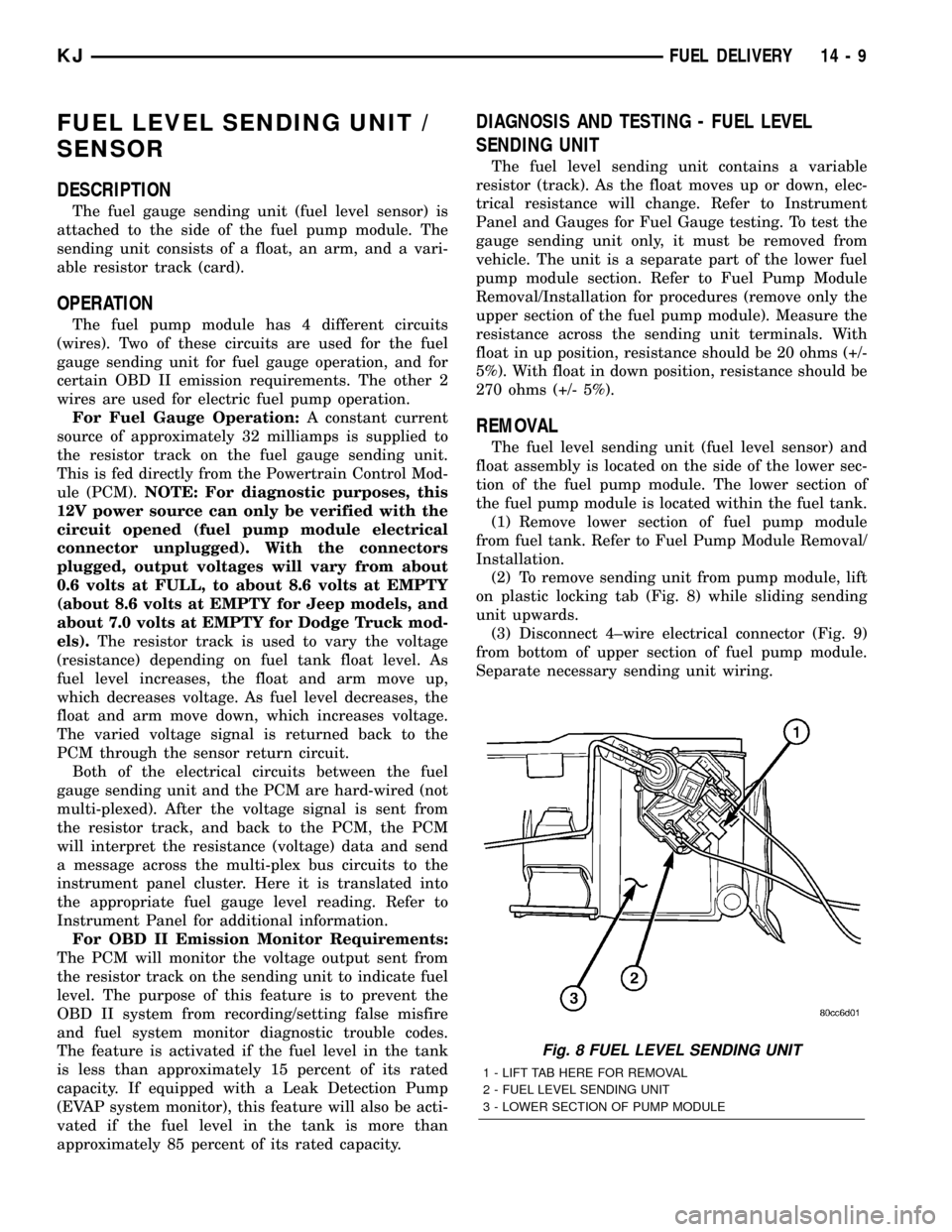

REMOVAL

The fuel level sending unit (fuel level sensor) and

float assembly is located on the side of the lower sec-

tion of the fuel pump module. The lower section of

the fuel pump module is located within the fuel tank.

(1) Remove lower section of fuel pump module

from fuel tank. Refer to Fuel Pump Module Removal/

Installation.

(2) To remove sending unit from pump module, lift

on plastic locking tab (Fig. 8) while sliding sending

unit upwards.

(3) Disconnect 4±wire electrical connector (Fig. 9)

from bottom of upper section of fuel pump module.

Separate necessary sending unit wiring.

Fig. 8 FUEL LEVEL SENDING UNIT

1 - LIFT TAB HERE FOR REMOVAL

2 - FUEL LEVEL SENDING UNIT

3 - LOWER SECTION OF PUMP MODULE

KJFUEL DELIVERY 14 - 9