Front oil seal JEEP LIBERTY 2002 KJ / 1.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1692 of 1803

CAUTION - REFRIGERANT HOSES/LINES/

TUBES PRECAUTIONS

Kinks or sharp bends in the refrigerant plumbing will

reduce the capacity of the entire system. High pressures

are produced in the system when it is operating.

Extreme care must be exercised to make sure that all

refrigerant system connections are pressure tight.

A good rule for the flexible hose refrigerant lines is

to keep the radius of all bends at least ten times the

diameter of the hose. Sharp bends will reduce the

flow of refrigerant. The flexible hose lines should be

routed so they are at least 80 millimeters (3 inches)

from the exhaust manifold. It is a good practice to

inspect all flexible refrigerant system hose lines at

least once a year to make sure they are in good con-

dition and properly routed.

There are two types of refrigerant fittings:

²

All fittings with O-rings need to be coated with

refrigerant oil before installation. Use only O-rings that

are the correct size and approved for use with R-134a

refrigerant. Failure to do so may result in a leak.

²Unified plumbing connections with gaskets can-

not be serviced with O-rings. The gaskets are not

reusable and new gaskets do not require lubrication

before installing.

Using the proper tools when making a refrigerant

plumbing connection is very important. Improper

tools or improper use of the tools can damage the

refrigerant fittings. Always use two wrenches when

loosening or tightening tube fittings. Use one wrench

to hold one side of the connection stationary, while

loosening or tightening the other side of the connec-

tion with a second wrench.

The refrigerant must be recovered completely from

the system before opening any fitting or connection.

Open the fittings with caution, even after the refrig-

erant has been recovered. If any pressure is noticed

as a fitting is loosened, tighten the fitting and

recover the refrigerant from the system again.

Do not discharge refrigerant into the atmosphere.

Use an R-134a refrigerant recovery/recycling device

that meets SAE Standard J2210.

The refrigerant system will remain chemically sta-

ble as long as pure, moisture-free R-134a refrigerant

and refrigerant oil is used. Dirt, moisture, or air can

upset this chemical stability. Operational troubles or

serious damage can occur if foreign material is

present in the refrigerant system.

When it is necessary to open the refrigerant sys-

tem, have everything needed to service the system

ready. The refrigerant system should not be left open

to the atmosphere any longer than necessary. Cap or

plug all lines and fittings as soon as they are opened

to prevent the entrance of dirt and moisture. All lines

and components in parts stock should be capped or

sealed until they are to be installed.All tools, including the refrigerant recycling equip-

ment, the manifold gauge set, and test hoses should

be kept clean and dry. All tools and equipment must

be designed for R-134a refrigerant.

STANDARD PROCEDURE

STANDARD PROCEDURE - REFRIGERANT

SYSTEM SERVICE EQUIPMENT

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

When servicing the air conditioning system, a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 must be used.

Contact an automotive service equipment supplier for

refrigerant recovery/recycling/charging equipment.

Refer to the operating instructions supplied by the

equipment manufacturer for proper care and use of

this equipment.

A manifold gauge set may be needed with some

recovery/recycling/charging equipment (Fig. 1). The

service hoses on the gauge set being used should

have manual (turn wheel), or automatic back-flow

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere.

MANIFOLD GAUGE SET CONNECTIONS

CAUTION: Do not use an R-12 manifold gauge set

on an R-134a system. The refrigerants are not com-

patible and system damage will result.

LOW PRESSURE GAUGE HOSE The low pressure

hose (Blue with Black stripe) attaches to the suction

service port. This port is located on the suction line

between the accumulator outlet and the compressor.

HIGH PRESSURE GAUGE HOSE The high pres-

sure hose (Red with Black stripe) attaches to the dis-

charge service port. This port is located on the

discharge line between the compressor and the con-

denser inlet.

RECOVERY/RECYCLING/EVACUATION/CHARG-

ING HOSE The center manifold hose (Yellow, or

White, with Black stripe) is used to recover, evacu-

ate, and charge the refrigerant system. When the low

or high pressure valves on the manifold gauge set

are opened, the refrigerant in the system will escape

through this hose.

24 - 40 PLUMBINGKJ

PLUMBING (Continued)

Page 1697 of 1803

(5) Plug in the compressor clutch coil wire harness

connector.

(6) Connect the battery negative cable.

(7) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM EVACUATE)

(8) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - REFRIGERANT SYS-

TEM CHARGE)

A/C CONDENSER

DESCRIPTION

The condenser is located in the air flow in front of

the engine cooling radiator. The condenser is a heat

exchanger that allows the high-pressure refrigerant

gas being discharged by the compressor to give up its

heat to the air passing over the condenser fins.

OPERATION

When the refrigerant gas gives up its heat, it con-

denses. When the refrigerant leaves the condenser, it

has become a high-pressure liquid refrigerant. Thevolume of air flowing over the condenser fins is crit-

ical to the proper cooling performance of the air con-

ditioning system. Therefore, it is important that

there are no objects placed in front of the radiator

grille openings in the front of the vehicle or foreign

material on the condenser fins that might obstruct

proper air flow. Also, any factory-installed air seals or

shrouds must be properly reinstalled following radia-

tor or condenser service.

The condenser cannot be repaired and, if faulty or

damaged, it must be replaced.

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Disconnect the discharge line refrigerant line

fitting at the condenser inlet. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE - A/C LINE COUPLERS)

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

(4) Disconnect the liquid line (Left-Hand Drive) or

liquid line jumper (Right-Hand Drive) refrigerant

line fitting at the condenser outlet. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

(5) Remove the radiator and the condenser from

the vehicle as a unit. Refer to Cooling for the proce-

dures.

(6) Remove the two nuts that secure the condenser

studs to the upper brackets of the radiator (Fig. 6).

(7) Slide the condenser down from the radiator far

enough for the condenser studs to clear the upper

radiator bracket holes, and for the lower condenser

bracket holes to clear the dowel pins on the bottom of

the radiator.

(8) Remove the condenser from the radiator.

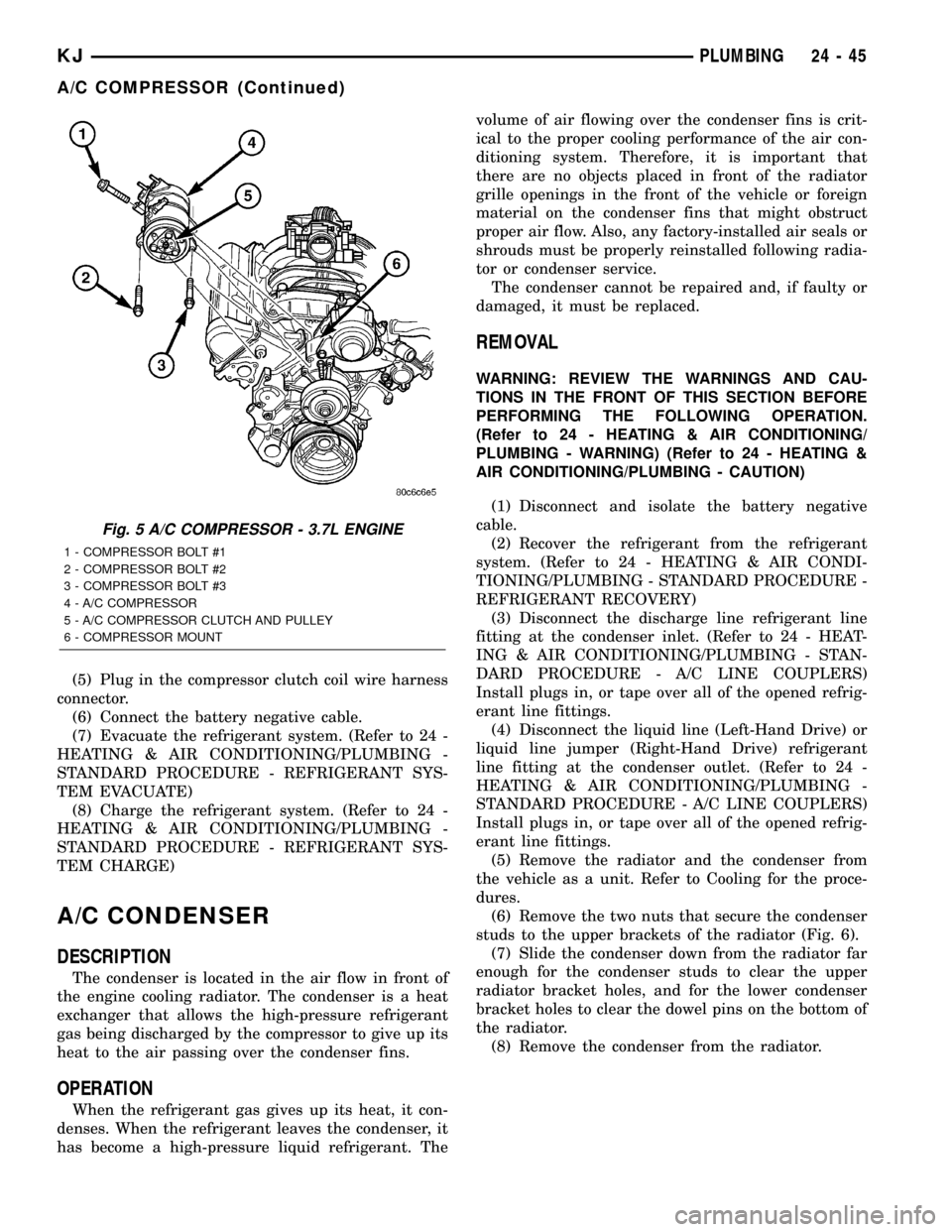

Fig. 5 A/C COMPRESSOR - 3.7L ENGINE

1 - COMPRESSOR BOLT #1

2 - COMPRESSOR BOLT #2

3 - COMPRESSOR BOLT #3

4 - A/C COMPRESSOR

5 - A/C COMPRESSOR CLUTCH AND PULLEY

6 - COMPRESSOR MOUNT

KJPLUMBING 24 - 45

A/C COMPRESSOR (Continued)

Page 1703 of 1803

replaced. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/LIQUID LINE - REMOVAL)

ACCUMULATOR

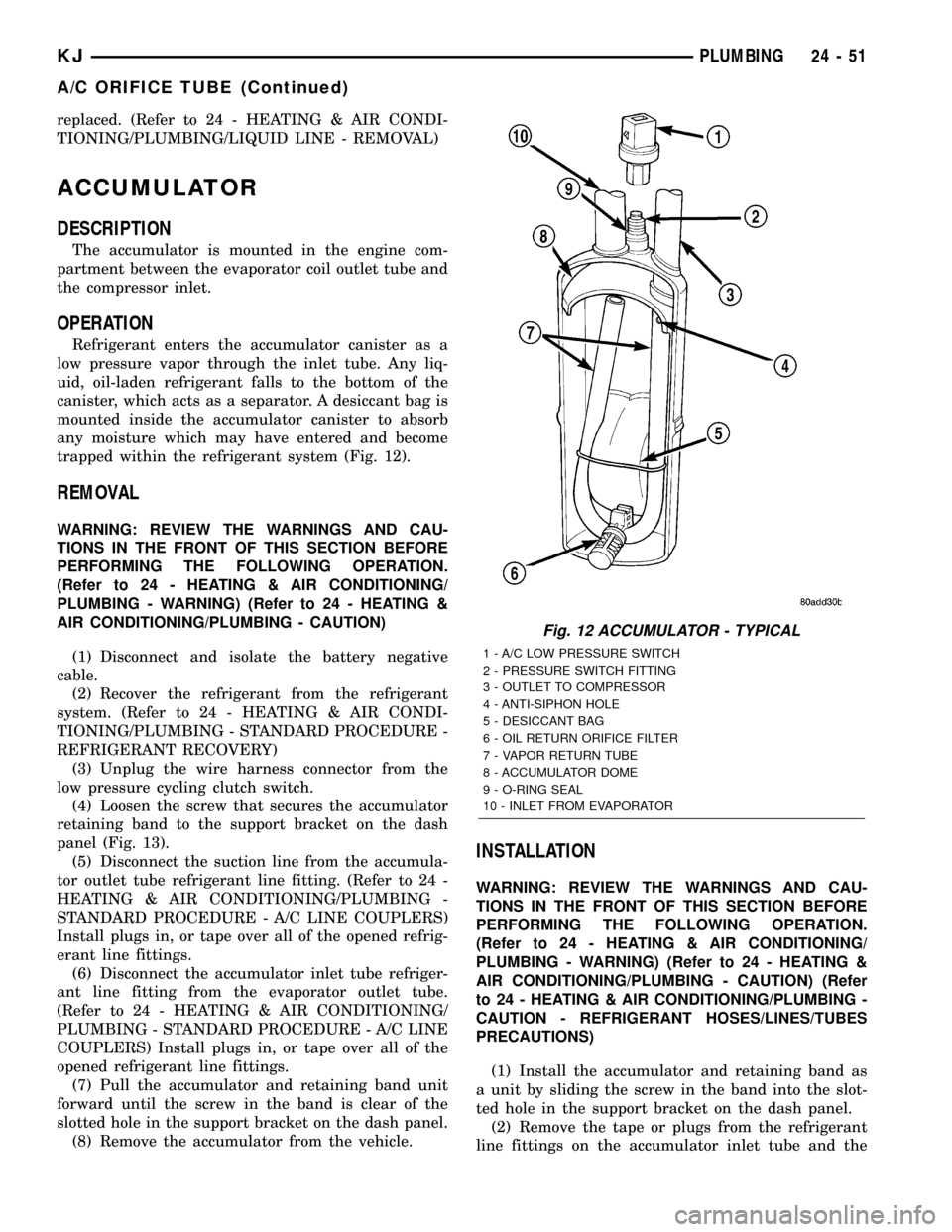

DESCRIPTION

The accumulator is mounted in the engine com-

partment between the evaporator coil outlet tube and

the compressor inlet.

OPERATION

Refrigerant enters the accumulator canister as a

low pressure vapor through the inlet tube. Any liq-

uid, oil-laden refrigerant falls to the bottom of the

canister, which acts as a separator. A desiccant bag is

mounted inside the accumulator canister to absorb

any moisture which may have entered and become

trapped within the refrigerant system (Fig. 12).

REMOVAL

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(3) Unplug the wire harness connector from the

low pressure cycling clutch switch.

(4) Loosen the screw that secures the accumulator

retaining band to the support bracket on the dash

panel (Fig. 13).

(5) Disconnect the suction line from the accumula-

tor outlet tube refrigerant line fitting. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE - A/C LINE COUPLERS)

Install plugs in, or tape over all of the opened refrig-

erant line fittings.

(6) Disconnect the accumulator inlet tube refriger-

ant line fitting from the evaporator outlet tube.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - STANDARD PROCEDURE - A/C LINE

COUPLERS) Install plugs in, or tape over all of the

opened refrigerant line fittings.

(7) Pull the accumulator and retaining band unit

forward until the screw in the band is clear of the

slotted hole in the support bracket on the dash panel.

(8) Remove the accumulator from the vehicle.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN THE FRONT OF THIS SECTION BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - WARNING) (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - CAUTION) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION - REFRIGERANT HOSES/LINES/TUBES

PRECAUTIONS)

(1) Install the accumulator and retaining band as

a unit by sliding the screw in the band into the slot-

ted hole in the support bracket on the dash panel.

(2) Remove the tape or plugs from the refrigerant

line fittings on the accumulator inlet tube and the

Fig. 12 ACCUMULATOR - TYPICAL

1 - A/C LOW PRESSURE SWITCH

2 - PRESSURE SWITCH FITTING

3 - OUTLET TO COMPRESSOR

4 - ANTI-SIPHON HOLE

5 - DESICCANT BAG

6 - OIL RETURN ORIFICE FILTER

7 - VAPOR RETURN TUBE

8 - ACCUMULATOR DOME

9 - O-RING SEAL

10 - INLET FROM EVAPORATOR

KJPLUMBING 24 - 51

A/C ORIFICE TUBE (Continued)

Page 1735 of 1803

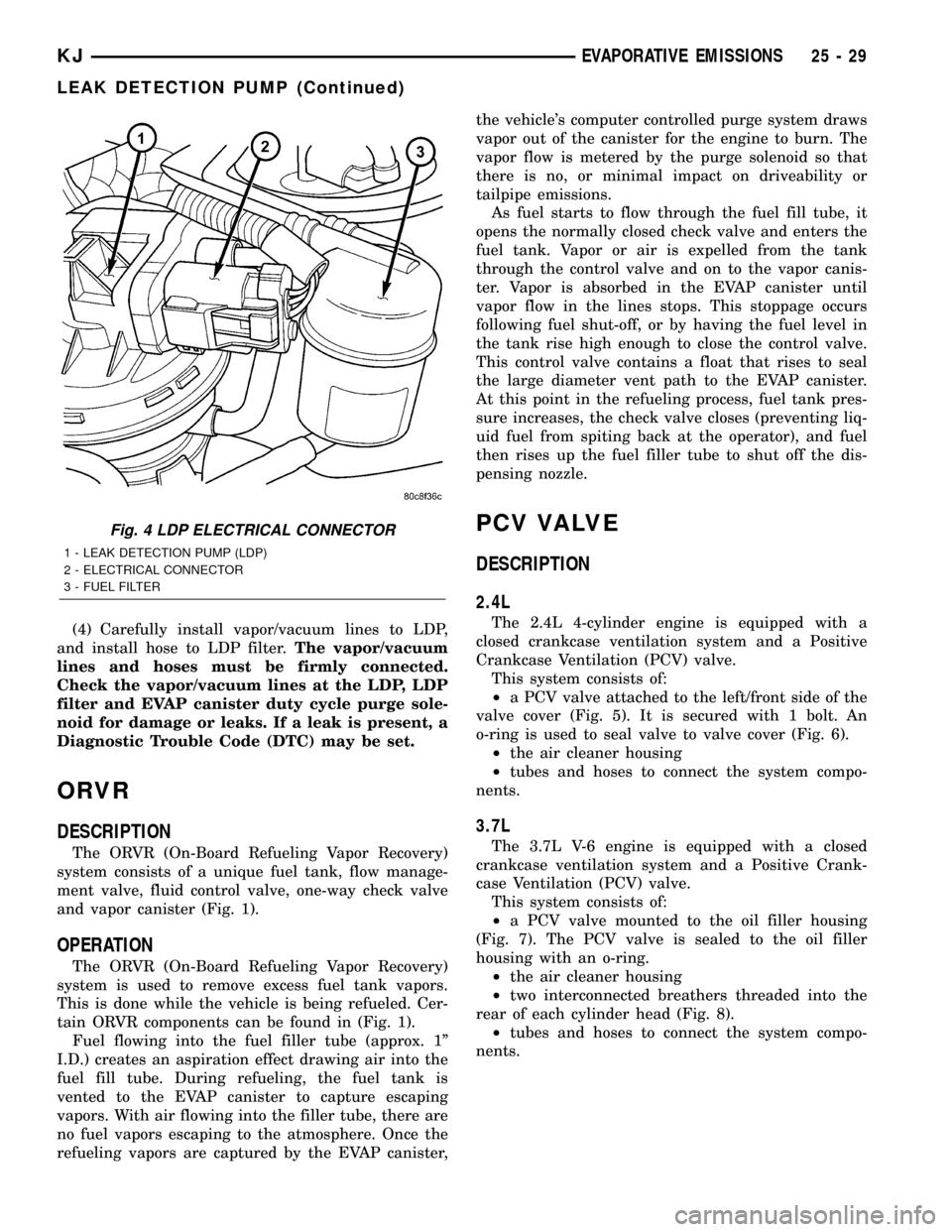

(4) Carefully install vapor/vacuum lines to LDP,

and install hose to LDP filter.The vapor/vacuum

lines and hoses must be firmly connected.

Check the vapor/vacuum lines at the LDP, LDP

filter and EVAP canister duty cycle purge sole-

noid for damage or leaks. If a leak is present, a

Diagnostic Trouble Code (DTC) may be set.

ORVR

DESCRIPTION

The ORVR (On-Board Refueling Vapor Recovery)

system consists of a unique fuel tank, flow manage-

ment valve, fluid control valve, one-way check valve

and vapor canister (Fig. 1).

OPERATION

The ORVR (On-Board Refueling Vapor Recovery)

system is used to remove excess fuel tank vapors.

This is done while the vehicle is being refueled. Cer-

tain ORVR components can be found in (Fig. 1).

Fuel flowing into the fuel filler tube (approx. 1º

I.D.) creates an aspiration effect drawing air into the

fuel fill tube. During refueling, the fuel tank is

vented to the EVAP canister to capture escaping

vapors. With air flowing into the filler tube, there are

no fuel vapors escaping to the atmosphere. Once the

refueling vapors are captured by the EVAP canister,the vehicle's computer controlled purge system draws

vapor out of the canister for the engine to burn. The

vapor flow is metered by the purge solenoid so that

there is no, or minimal impact on driveability or

tailpipe emissions.

As fuel starts to flow through the fuel fill tube, it

opens the normally closed check valve and enters the

fuel tank. Vapor or air is expelled from the tank

through the control valve and on to the vapor canis-

ter. Vapor is absorbed in the EVAP canister until

vapor flow in the lines stops. This stoppage occurs

following fuel shut-off, or by having the fuel level in

the tank rise high enough to close the control valve.

This control valve contains a float that rises to seal

the large diameter vent path to the EVAP canister.

At this point in the refueling process, fuel tank pres-

sure increases, the check valve closes (preventing liq-

uid fuel from spiting back at the operator), and fuel

then rises up the fuel filler tube to shut off the dis-

pensing nozzle.

PCV VALVE

DESCRIPTION

2.4L

The 2.4L 4-cylinder engine is equipped with a

closed crankcase ventilation system and a Positive

Crankcase Ventilation (PCV) valve.

This system consists of:

²a PCV valve attached to the left/front side of the

valve cover (Fig. 5). It is secured with 1 bolt. An

o-ring is used to seal valve to valve cover (Fig. 6).

²the air cleaner housing

²tubes and hoses to connect the system compo-

nents.

3.7L

The 3.7L V-6 engine is equipped with a closed

crankcase ventilation system and a Positive Crank-

case Ventilation (PCV) valve.

This system consists of:

²a PCV valve mounted to the oil filler housing

(Fig. 7). The PCV valve is sealed to the oil filler

housing with an o-ring.

²the air cleaner housing

²two interconnected breathers threaded into the

rear of each cylinder head (Fig. 8).

²tubes and hoses to connect the system compo-

nents.

Fig. 4 LDP ELECTRICAL CONNECTOR

1 - LEAK DETECTION PUMP (LDP)

2 - ELECTRICAL CONNECTOR

3 - FUEL FILTER

KJEVAPORATIVE EMISSIONS 25 - 29

LEAK DETECTION PUMP (Continued)

Page 1738 of 1803

(13) If vacuum is not present, disconnect each PCV

system hose at top of each crankcase breather (Fig.

8). Check for obstructions or restrictions.

(14) If vacuum is still not present, remove each

PCV system crankcase breather (Fig. 8) from each

cylinder head. Check for obstructions or restrictions.

If plugged, replace breather. Tighten breather to 12

N´m (106 in. lbs.) torque. Do not attempt to clean

breather

(15) If vacuum is still not present, disconnect each

PCV system hose at each fitting and check for

obstructions or restrictions.

REMOVAL

2.4L

The PCV valve is attached to the left/front side of

the valve cover (Fig. 5). It is secured with 1 bolt. An

o-ring is used to seal valve to valve cover (Fig. 6).

(1) Remove hose from valve (Fig. 5). Check condi-

tion of hose.

(2) Remove 1 bolt.

(3) Remove PCV valve from valve cover.

(4) Check condition of valve o-ring.

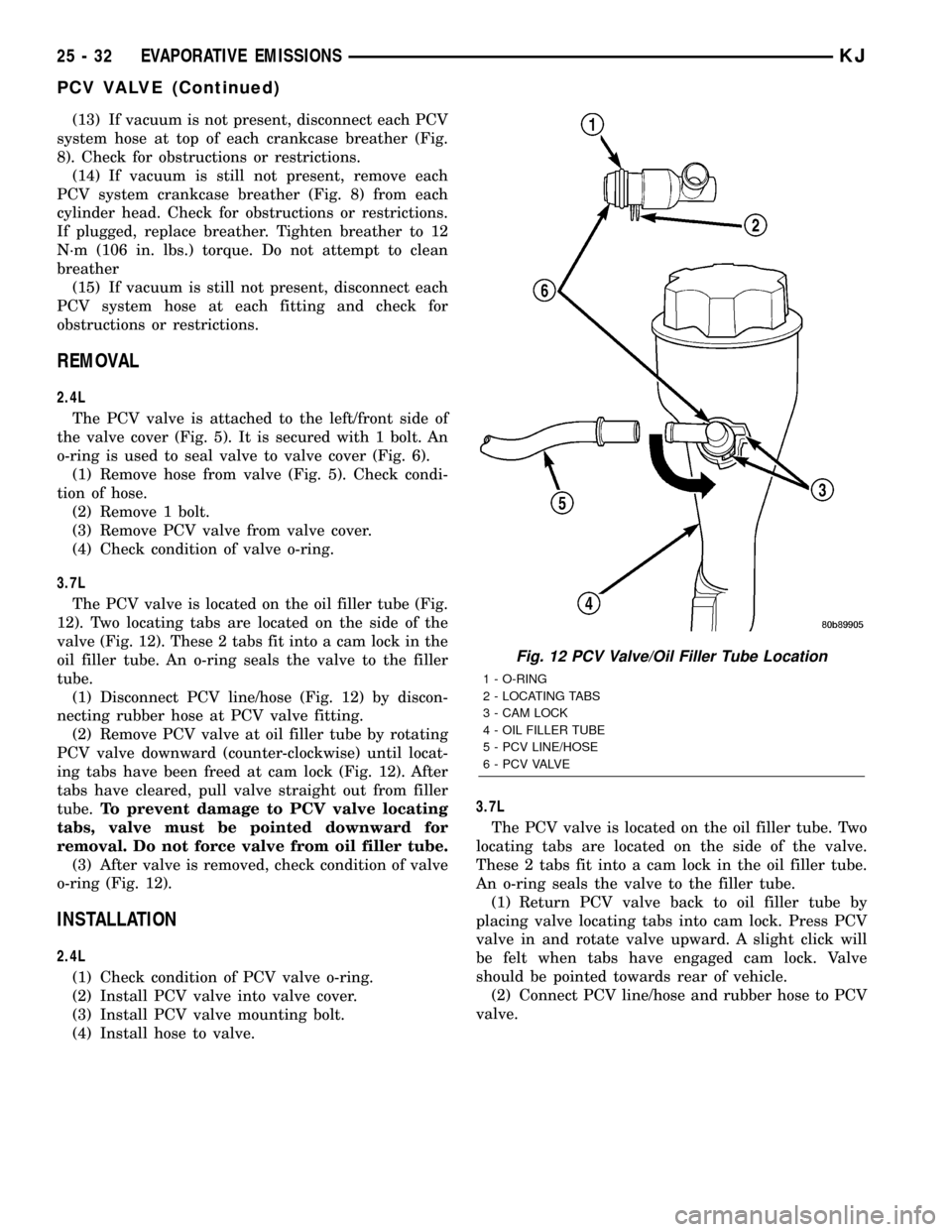

3.7L

The PCV valve is located on the oil filler tube (Fig.

12). Two locating tabs are located on the side of the

valve (Fig. 12). These 2 tabs fit into a cam lock in the

oil filler tube. An o-ring seals the valve to the filler

tube.

(1) Disconnect PCV line/hose (Fig. 12) by discon-

necting rubber hose at PCV valve fitting.

(2) Remove PCV valve at oil filler tube by rotating

PCV valve downward (counter-clockwise) until locat-

ing tabs have been freed at cam lock (Fig. 12). After

tabs have cleared, pull valve straight out from filler

tube.To prevent damage to PCV valve locating

tabs, valve must be pointed downward for

removal. Do not force valve from oil filler tube.

(3) After valve is removed, check condition of valve

o-ring (Fig. 12).

INSTALLATION

2.4L

(1) Check condition of PCV valve o-ring.

(2) Install PCV valve into valve cover.

(3) Install PCV valve mounting bolt.

(4) Install hose to valve.3.7L

The PCV valve is located on the oil filler tube. Two

locating tabs are located on the side of the valve.

These 2 tabs fit into a cam lock in the oil filler tube.

An o-ring seals the valve to the filler tube.

(1) Return PCV valve back to oil filler tube by

placing valve locating tabs into cam lock. Press PCV

valve in and rotate valve upward. A slight click will

be felt when tabs have engaged cam lock. Valve

should be pointed towards rear of vehicle.

(2) Connect PCV line/hose and rubber hose to PCV

valve.

Fig. 12 PCV Valve/Oil Filler Tube Location

1 - O-RING

2 - LOCATING TABS

3 - CAM LOCK

4 - OIL FILLER TUBE

5 - PCV LINE/HOSE

6 - P C V VA LV E

25 - 32 EVAPORATIVE EMISSIONSKJ

PCV VALVE (Continued)

Page 1740 of 1803

ABS - DESCRIPTION, BRAKES...........5-32

ABS - OPERATION, BRAKES.............5-32

ABS - SPECIFICATIONS, BRAKES.........5-33

ABS BRAKE BLEEDING - STANDARD

PROCEDURE.........................5-33

ABS INDICATOR - DESCRIPTION.........8J-11

ABS INDICATOR - OPERATION..........8J-11

A/C APPLICATION TABLE,

SPECIFICATIONS......................24-9

A/C COMPRESSOR CLUTCH -

INSPECTION........................24-14

A/C COMPRESSOR CLUTCH -

INSTALLATION.......................24-14

A/C COMPRESSOR CLUTCH - REMOVAL . . 24-13

A/C COMPRESSOR CLUTCH BREAK-IN -

STANDARD PROCEDURE...............24-12

A/C COMPRESSOR CLUTCH COIL -

DIAGNOSIS AND TESTING.............24-12

A/C COMPRESSOR CLUTCH RELAY -

DESCRIPTION.......................24-15

A/C COMPRESSOR CLUTCH RELAY -

INSTALLATION.......................24-16

A/C COMPRESSOR CLUTCH RELAY -

OPERATION.........................24-15

A/C COMPRESSOR CLUTCH RELAY -

REMOVAL..........................24-16

A/C COMPRESSOR NOISE - DIAGNOSIS

AND TESTING.......................24-42

A/C CONDENSER - DESCRIPTION........24-45

A/C CONDENSER - INSTALLATION.......24-46

A/C CONDENSER - OPERATION...........24-45

A/C CONDENSER - REMOVAL...........24-45

A/C DISCHARGE LINE - INSTALLATION . . . 24-47

A/C DISCHARGE LINE - REMOVAL.......24-46

A/C EVAPORATOR - DESCRIPTION.......24-49

A/C EVAPORATOR - INSTALLATION......24-49

A/C EVAPORATOR - OPERATION.........24-49

A/C EVAPORATOR - REMOVAL..........24-49

A/C HEATER CONTROL - DESCRIPTION . . . 24-16

A/C HEATER CONTROL - INSTALLATION . . . 24-17

A/C HEATER CONTROL - REMOVAL......24-17

A/C HIGH PRESSURE SWITCH -

DESCRIPTION.......................24-17

A/C HIGH PRESSURE SWITCH -

DIAGNOSIS AND TESTING.............24-18

A/C HIGH PRESSURE SWITCH -

INSTALLATION.......................24-18

A/C HIGH PRESSURE SWITCH -

OPERATION.........................24-18

A/C HIGH PRESSURE SWITCH -

REMOVAL..........................24-18

A/C LIQUID LINE - INSTALLATION.......24-47

A/C LIQUID LINE - REMOVAL...........24-47

A/C LOW PRESSURE SWITCH -

DESCRIPTION.......................24-18

A/C LOW PRESSURE SWITCH -

DIAGNOSIS AND TESTING.............24-19

A/C LOW PRESSURE SWITCH -

INSTALLATION.......................24-19

A/C LOW PRESSURE SWITCH -

OPERATION.........................24-18

A/C LOW PRESSURE SWITCH -

REMOVAL..........................24-19

A/C ORIFICE TUBE - DESCRIPTION.......24-50

A/C ORIFICE TUBE - INSTALLATION......24-50

A/C ORIFICE TUBE - OPERATION........24-50

A/C ORIFICE TUBE - REMOVAL..........24-50

A/C PERFORMANCE - DIAGNOSIS AND

TESTING............................24-2

A/C SUCTION LINE - INSTALLATION......24-49

A/C SUCTION LINE - REMOVAL.........24-48

ACCELERATOR PEDAL - INSTALLATION . . . 14-30

ACCELERATOR PEDAL - REMOVAL.......14-29

ACCESS PANEL - DESCRIPTION, LATCH . . 23-139

ACCESS PANEL - INSTALLATION, LATCH . 23-139

ACCESS PANEL - REMOVAL, LATCH.....23-139

ACCUMULATOR - DESCRIPTION.........24-51

ACCUMULATOR - INSTALLATION........24-51

ACCUMULATOR - OPERATION..........24-51

ACCUMULATOR - REMOVAL

............24-51

ACTUATION TEST MODE - DESCRIPTION,

CIRCUIT

.............................25-2

ACTUATOR - INSTALLATION, BLEND

DOOR

.............................24-20

ACTUATOR - INSTALLATION, FLOOR -

DEFROST DOOR

.....................24-25

ACTUATOR - INSTALLATION, PANEL

DOOR

.............................24-25ACTUATOR - INSTALLATION,

RECIRCULATION DOOR................24-26

ACTUATOR - REMOVAL, BLEND DOOR....24-20

ACTUATOR - REMOVAL, FLOOR -

DEFROST DOOR.....................24-24

ACTUATOR - REMOVAL, PANEL DOOR....24-24

ACTUATOR - REMOVAL, RECIRCULATION

DOOR.............................24-26

ADAPTER - INSTALLATION, DISC BRAKE

CALIPER............................5-18

ADAPTER - REMOVAL, DISC BRAKE

CALIPER............................5-18

ADAPTER HOUSING SEAL -

INSTALLATION......................21-124

ADAPTER HOUSING SEAL - REMOVAL . . . 21-124

ADAPTOR - REMOVAL, DEFROST

DUCT/DEMISTER.....................24-32

ADHESIVE LOCATIONS -

SPECIFICATIONS, WELD AND

STRUCTURAL........................23-9

ADJUSTER - DIAGNOSIS AND TESTING,

HYDRAULIC LASH.................9-19,9-30

ADJUSTER - INSTALLATION, SEAT BELT

TURNING LOOP.....................8O-38

ADJUSTER - REMOVAL, SEAT BELT

TURNING LOOP.....................8O-37

ADJUSTMENT - STANDARD

PROCEDURE, CAMBER AND CASTER.......2-5

ADJUSTMENT - STANDARD

PROCEDURE, CAMBER, CASTER AND

TOE .................................2-5

ADJUSTMENT - STANDARD

PROCEDURE, COMPASS VARIATION......8M-3

ADJUSTMENT - STANDARD

PROCEDURE, TOE......................2-5

ADJUSTMENT, ADJUSTMENTS . . . 23-119,23-124,

23-131

ADJUSTMENT, ADJUSTMENTS...........3-55

ADJUSTMENT, ADJUSTMENTS -

SUNROOF GLASS PANEL.............23-178

ADJUSTMENT, FRONT FOG LAMP UNIT . . . 8L-25

ADJUSTMENT, HEADLAMP UNIT.........8L-42

ADJUSTMENT, LOCK OUT...............5-30

ADJUSTMENT, REAR DRUM BRAKE.......5-12

ADJUSTMENTS - ADJUSTMENT . . 23-119,23-124,

23-131

ADJUSTMENTS - ADJUSTMENT..........3-55

ADJUSTMENTS - SUNROOF GLASS

PANEL ADJUSTMENT................23-178

ADJUSTMENTS, FRONT AXLE - 186FIA....3-25

ADJUSTMENTS, GEARSHIFT CABLE.....21-130

ADJUSTMENTS, PARK-INTERLOCK

CABLE............................21-154

ADJUSTMENTS, REAR AXLE - 8 1/4 .......3-92

AFTER A SUPPLEMENTAL RESTRAINT

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE.................8O-6

AIR CHECKING TRANSMISSION CLUTCH

OPERATION - DIAGNOSIS AND

TESTING...........................21-80

AIR CONDITIONER - DESCRIPTION,

HEATER .............................24-1

AIR CONDITIONER - OPERATION,

HEATER .............................24-2

AIR CONTROL MOTOR - DESCRIPTION,

IDLE...............................14-35

AIR CONTROL MOTOR - INSTALLATION,

IDLE...............................14-36

AIR CONTROL MOTOR - OPERATION,

IDLE...............................14-35

AIR CONTROL MOTOR - REMOVAL, IDLE . . 14-36

AIR TEMPERATURE SENSOR -

DESCRIPTION, INTAKE................14-36

AIR TEMPERATURE SENSOR -

INSTALLATION, INTAKE................14-38

AIR TEMPERATURE SENSOR -

OPERATION, INTAKE..................14-36

AIR TEMPERATURE SENSOR -

REMOVAL, INTAKE...................14-37

AIRBAG - DESCRIPTION, DRIVER........8O-17

AIRBAG - DESCRIPTION, PASSENGER....8O-27

AIRBAG - DESCRIPTION, SIDE CURTAIN . . 8O-38

AIRBAG - INSTALLATION, DRIVER.......8O-20

AIRBAG - INSTALLATION, PASSENGER

. . . 8O-29

AIRBAG - INSTALLATION, SIDE CURTAIN

. . 8O-41

AIRBAG - OPERATION, DRIVER

.........8O-18

AIRBAG - OPERATION, PASSENGER

......8O-27

AIRBAG - OPERATION, SIDE CURTAIN

....8O-39AIRBAG - REMOVAL, DRIVER...........8O-19

AIRBAG - REMOVAL, PASSENGER.......8O-28

AIRBAG - REMOVAL, SIDE CURTAIN.....8O-40

AIRBAG CONTROL MODULE -

DESCRIPTION........................8O-9

AIRBAG CONTROL MODULE -

DESCRIPTION, SIDE IMPACT...........8O-43

AIRBAG CONTROL MODULE -

INSTALLATION......................8O-12

AIRBAG CONTROL MODULE -

INSTALLATION, SIDE IMPACT...........8O-45

AIRBAG CONTROL MODULE -

OPERATION.........................8O-10

AIRBAG CONTROL MODULE -

OPERATION, SIDE IMPACT.............8O-43

AIRBAG CONTROL MODULE - REMOVAL . . 8O-11

AIRBAG CONTROL MODULE - REMOVAL,

SIDE IMPACT.......................8O-44

AIRBAG DOOR - INSTALLATION,

PASSENGER........................8O-30

AIRBAG DOOR - REMOVAL, PASSENGER . . 8O-29

AIRBAG INDICATOR - DESCRIPTION......8J-12

AIRBAG INDICATOR - OPERATION.......8J-12

AIRBAG MOUNTING BRACKET -

INSTALLATION, PASSENGER...........8O-31

AIRBAG MOUNTING BRACKET -

REMOVAL, PASSENGER...............8O-31

AJAR INDICATOR - DESCRIPTION, DOOR . . 8J-17

AJAR INDICATOR - DESCRIPTION, GATE . . 8J-20

AJAR INDICATOR - DESCRIPTION,

GLASS..............................8J-21

AJAR INDICATOR - OPERATION, DOOR . . . 8J-17

AJAR INDICATOR - OPERATION, GATE....8J-20

AJAR INDICATOR - OPERATION, GLASS . . . 8J-21

AJAR SWITCH - DESCRIPTION, DOOR....8L-77

AJAR SWITCH - DESCRIPTION, FLIP-UP

GLASS.............................8L-77

AJAR SWITCH - DESCRIPTION, HOOD....8Q-11

AJAR SWITCH - DESCRIPTION,

TAILGATE...........................8L-82

AJAR SWITCH - DIAGNOSIS AND

TESTING, HOOD.....................8Q-12

AJAR SWITCH - INSTALLATION, HOOD . . . 8Q-12

AJAR SWITCH - OPERATION, DOOR......8L-77

AJAR SWITCH - OPERATION, FLIP-UP

GLASS.............................8L-77

AJAR SWITCH - OPERATION, HOOD.....8Q-12

AJAR SWITCH - OPERATION, TAILGATE . . . 8L-82

AJAR SWITCH - REMOVAL, HOOD.......8Q-12

AJAR SWITCH BRACKET -

INSTALLATION, HOOD.................8Q-13

AJAR SWITCH BRACKET - REMOVAL,

HOOD.............................8Q-13

AJAR SWITCH STRIKER -

INSTALLATION, HOOD.................8Q-14

AJAR SWITCH STRIKER - REMOVAL,

HOOD.............................8Q-13

ALIGNMENT - DESCRIPTION, WHEEL.......2-3

ALIGNMENT - OPERATION, WHEEL........2-3

ALIGNMENT, SPECIFICATIONS............2-6

ALUMINUM THREAD REPAIR -

STANDARD PROCEDURE...............21-81

AMBIENT TEMP SENSOR - DESCRIPTION . . 8M-9

AMBIENT TEMP SENSOR - OPERATION . . . 8M-9

AMBIENT TEMPERATURE SENSOR -

DIAGNOSIS AND TESTING..............8M-9

AMBIENT TEMPERATURE SENSOR

CIRCUIT - DIAGNOSIS AND TESTING.....8M-9

AMPERAGE TEST - DIAGNOSIS AND

TESTING, FUEL PUMP.................14-16

AMPLIFIER CHOKE AND RELAY -

DESCRIPTION........................8A-3

AMPLIFIER CHOKE AND RELAY -

DIAGNOSIS AND TESTING..............8A-4

AMPLIFIER CHOKE AND RELAY -

INSTALLATION.......................8A-4

AMPLIFIER CHOKE AND RELAY -

OPERATION..........................8A-3

AMPLIFIER CHOKE AND RELAY -

REMOVAL...........................8A-4

ANCHOR - DESCRIPTION, CHILD TETHER

. 8O-13

ANCHOR - OPERATION, CHILD TETHER

. . . 8O-13

ANGLE - STANDARD PROCEDURES,

PROPELLER SHAFT

.....................3-3

ANTENNA BODY & CABLE -

DESCRIPTION

........................8A-4

ANTENNA BODY & CABLE -

INSTALLATION

.......................8A-6

KJINDEX 1

Description Group-Page Description Group-Page Description Group-Page

Page 1741 of 1803

ANTENNA BODY & CABLE - OPERATION . . . 8A-5

ANTENNA BODY & CABLE - REMOVAL.....8A-6

ANTENNA BODY AND CABLE -

DIAGNOSIS AND TESTING..............8A-5

ANTENNA CABLE - INSTALLATION,

INSTRUMENT PANEL..................8A-8

ANTENNA CABLE - REMOVAL,

INSTRUMENT PANEL..................8A-7

ANTILOCK BRAKE - INSTALLATION,

CONTROLLER.......................8E-10

ANTILOCK BRAKE - REMOVAL,

CONTROLLER.......................8E-10

ANTILOCK BRAKING SYSTEM -

DIAGNOSIS AND TESTING..............5-33

A-PILLAR SEAL - INSTALLATION.......23-185

A-PILLAR SEAL - REMOVAL...........23-185

A-PILLAR TRIM AND GRAB HANDLE -

INSTALLATION......................23-156

A-PILLAR TRIM AND GRAB HANDLE -

REMOVAL.........................23-156

A-PILLAR WEATHERSTRIP/RETAINER -

INSTALLATION, WINDSHIELD..........23-187

A-PILLAR WEATHERSTRIP/RETAINER -

REMOVAL, WINDSHIELD..............23-186

APPLICATION TABLE, SPECIFICATIONS -

A/C ................................24-9

AREA LEAKS - DIAGNOSIS AND

TESTING, REAR SEAL..................9-61

ARM - DESCRIPTION, FRONT WIPER.....8R-12

ARM - DESCRIPTION, LOWER CONTROL . . . 2-21

ARM - DESCRIPTION, REAR WIPER......8R-37

ARM - DESCRIPTION, ROCKER......9-29,9-37

ARM - INSTALLATION, FRONT WIPER....8R-13

ARM - INSTALLATION, LOWER CONTROL . . 2-10,

2-21

ARM - INSTALLATION, REAR WIPER.....8R-38

ARM - INSTALLATION, ROCKER..........9-37

ARM - INSTALLATION, UPPER CONTROL . . . 2-21

ARM - OPERATION, FRONT WIPER......8R-12

ARM - OPERATION, LOWER CONTROL.....2-21

ARM - OPERATION, REAR WIPER.......8R-38

ARM - REMOVAL, FRONT WIPER........8R-12

ARM - REMOVAL, LOWER CONTROL . . 2-10,2-21

ARM - REMOVAL, REAR WIPER.........8R-38

ARM - REMOVAL, ROCKER..............9-37

ARM - REMOVAL, UPPER CONTROL......2-20

ARM, BUSHINGS, AND BALL JOINT -

DESCRIPTION, UPPER SUSPENSION......2-20

ARM, BUSHINGS, AND BALL JOINT -

OPERATION, UPPER SUSPENSION........2-20

ARM PARK RAMP - INSTALLATION,

WIPER.............................8R-43

ARM PARK RAMP - REMOVAL, WIPER . . . 8R-43

ASD AND FUEL PUMP RELAYS -

DIAGNOSIS AND TESTING...............8I-4

ASD SENSE - PCM INPUT - OPERATION....8I-4

ASH RECEIVER LAMP BULB -

INSTALLATION.......................8L-71

ASH RECEIVER LAMP BULB - REMOVAL . . 8L-71

ASH RECEIVER LAMP UNIT -

INSTALLATION.......................8L-72

ASH RECEIVER LAMP UNIT - REMOVAL . . 8L-72

ASSEMBLY - ASSEMBLY, INPUT CLUTCH . 21-138

ASSEMBLY - DESCRIPTION, INPUT

CLUTCH...........................21-133

ASSEMBLY - DESCRIPTION,

TRANSMISSION SOLENOID/TRS........21-169

ASSEMBLY - DISASSEMBLY, INPUT

CLUTCH...........................21-135

ASSEMBLY - INSTALLATION.........8W-97-11

ASSEMBLY - INSTALLATION, GUIDE.....23-179

ASSEMBLY - INSTALLATION,

INSTRUMENT PANEL.................23-151

ASSEMBLY - INSTALLATION, MODULE . . . 23-181

ASSEMBLY - INSTALLATION,

TRANSMISSION SOLENOID/TRS........21-170

ASSEMBLY - OPERATION, INPUT

CLUTCH...........................21-135

ASSEMBLY - OPERATION,

TRANSMISSION SOLENOID/TRS........21-169

ASSEMBLY - POWER DISTRIBUTION

CENTER ASSEMBLY

...............8W-97-10

ASSEMBLY - REMOVAL, GUIDE

........23-179

ASSEMBLY - REMOVAL, INSTRUMENT

PANEL

............................23-149

ASSEMBLY - REMOVAL, MODULE

......23-181

ASSEMBLY - REMOVAL, TRANSMISSION

SOLENOID/TRS

.....................21-170ASSEMBLY, 4C RETAINER/BULKHEAD....21-123

ASSEMBLY, ASSEMBLY - POWER

DISTRIBUTION CENTER............8W-97-10

ASSEMBLY, DIAGNOSIS AND TESTING....21-90

ASSEMBLY, DIFFERENTIAL.........3-105,3-41

ASSEMBLY, DIFFERENTIAL - TRAC-LOK . . . 3-109,

3-77

ASSEMBLY, DISC BRAKE CALIPERS.......5-16

ASSEMBLY, HVAC HOUSING............24-34

ASSEMBLY, INPUT CLUTCH ASSEMBLY . . 21-138

ASSEMBLY, INSTRUMENT CLUSTER......8J-10

ASSEMBLY, LOW/REVERSE CLUTCH.....21-146

ASSEMBLY, MANUAL - NV1500.........21-13

ASSEMBLY, MANUAL - NV3550.........21-48

ASSEMBLY, OIL PUMP.................9-67

ASSEMBLY, OIL PUMP...............21-151

ASSEMBLY, PLANETARY GEARTRAIN....21-160

ASSEMBLY, SINGLE CARDAN

UNIVERSAL JOINTS....................3-9

ASSEMBLY, TRANSFER CASE - NV231 . . . 21-194

ASSEMBLY, TRANSFER CASE - NV242 . . . 21-230

ASSEMBLY, VALVE BODY.............21-176

ASSEMBLY, WHEEL CYLINDERS..........5-29

ASSEMBLY WINDOW DEFOGGER

FUNCTION - DIAGNOSIS AND TESTING,

REAR HVAC CONTROL.................8G-9

ASSIST HANDLE - INSTALLATION.......23-157

ASSIST HANDLE - REMOVAL............23-157

AUDIO - DESCRIPTION.................8A-1

AUDIO - DIAGNOSIS AND TESTING.......8A-2

AUDIO - OPERATION...................8A-1

AUTOMATIC TRANSMISSION - 45RFE -

DESCRIPTION.......................21-76

AUTOMATIC TRANSMISSION - 45RFE -

OPERATION.........................21-77

AUTOMATIC TRANSMISSION -

DIAGNOSIS AND TESTING.............21-77

AUTOMATIC TRANSMISSION FLUID -

DESCRIPTION.........................0-2

AUTOMATIC TRANSMISSION FLUID -

OPERATION...........................0-4

AXLE - 186FIA - ADJUSTMENTS, FRONT . . . 3-25

AXLE - 186FIA - DESCRIPTION, FRONT....3-19

AXLE - 186FIA - INSTALLATION, FRONT....3-24

AXLE - 186FIA - OPERATION, FRONT......3-19

AXLE - 186FIA - REMOVAL, FRONT.......3-24

AXLE - 198RBI - DESCRIPTION, REAR.....3-49

AXLE - 198RBI - INSTALLATION, REAR....3-54

AXLE - 198RBI - OPERATION, REAR.......3-49

AXLE - 198RBI - REMOVAL, REAR........3-54

AXLE - 8 1/4 - ADJUSTMENTS, REAR.....3-92

AXLE - 8 1/4 - DESCRIPTION, REAR......3-86

AXLE - 8 1/4 - INSTALLATION, REAR......3-91

AXLE - 8 1/4 - OPERATION, REAR........3-86

AXLE - 8 1/4 - REMOVAL, REAR..........3-91

AXLE - DESCRIPTION...................0-2

AXLE - DIAGNOSIS AND TESTING....3-20,3-51,

3-88

AXLE - INSTALLATION, 198 RBI..........5-28

AXLE - INSTALLATION, 8 1/4............5-28

AXLE - REMOVAL, 198 RBI..............5-27

AXLE - REMOVAL, 8 1/4................5-27

AXLE - SPECIFICATIONS, FRONT.........3-33

AXLE - SPECIFICATIONS, REAR..........3-62

AXLE BEARINGS - INSTALLATION....3-102,3-38

AXLE BEARINGS - REMOVAL.......3-102,3-38

AXLE BEARING/SEAL - INSTALLATION.....3-67

AXLE BEARING/SEAL - REMOVAL.........3-66

AXLE SHAFT SEALS - INSTALLATION . 3-102,3-38

AXLE SHAFT SEALS - REMOVAL....3-101,3-37

AXLE SHAFTS - INSTALLATION . . 3-101,3-37,3-65

AXLE SHAFTS - REMOVAL.....3-101,3-37,3-65

AXLE, SPECIAL TOOLS - 8 1/4 ...........3-98

AXLE, SPECIAL TOOLS - FRONT..........3-34

AXLE, SPECIAL TOOLS - REAR...........3-63

AXLE, SPECIFICATIONS - REAR..........3-98

BACK - FRONT - INSTALLATION, SEAT . . . 23-166

BACK - FRONT - REMOVAL, SEAT.......23-166

BACK - REAR - INSTALLATION, SEAT....23-168

BACK - REAR - REMOVAL, SEAT.......23-168

BACK COVER - FRONT - INSTALLATION,

SEAT

.............................23-167

BACK COVER - FRONT - REMOVAL, SEAT

. 23-166

BACK COVER - REAR - INSTALLATION,

SEAT

.............................23-169

BACK COVER - REAR - REMOVAL, SEAT

. 23-169

BACK CUSHION - FRONT -

INSTALLATION, SEAT

.................23-167BACK CUSHION - FRONT - REMOVAL,

SEAT .............................23-167

BACK CUSHION - REAR - INSTALLATION,

SEAT .............................23-170

BACK CUSHION - REAR - REMOVAL,

SEAT .............................23-170

BACK FRAME - REAR - INSTALLATION,

SEAT .............................23-171

BACK FRAME - REAR - REMOVAL, SEAT . 23-171

BACK LATCH / LOCK - INSTALLATION,

FOLDING REAR SEAT................23-170

BACK LATCH / LOCK - REMOVAL,

FOLDING REAR SEAT................23-170

BACK LATCH STRIKER - INSTALLATION,

REAR SEAT........................23-171

BACK LATCH STRIKER - REMOVAL,

REAR SEAT........................23-170

BACK RECLINER - FRONT -

INSTALLATION, SEAT.................23-166

BACK RECLINER - FRONT - REMOVAL,

SEAT .............................23-166

BACKUP LAMP SWITCH - DESCRIPTION . . 8L-15

BACKUP LAMP SWITCH - DIAGNOSIS

AND TESTING.......................8L-15

BACKUP LAMP SWITCH - OPERATION....8L-15

BAFFLE SEAL - INSTALLATION,

COWL/PLENUM WINDOW.............23-187

BAFFLE SEAL - REMOVAL, COWL/

PLENUM WINDOW..................23-187

BALANCE SHAFT - INSTALLATION........9-74

BALANCE SHAFT - REMOVAL............9-74

BALANCING - STANDARD PROCEDURE,

WHEEL.............................22-4

BALL JOINT - DESCRIPTION, UPPER

SUSPENSION ARM, BUSHINGS..........2-20

BALL JOINT - DIAGNOSIS AND TESTING,

LOWER.............................2-10

BALL JOINT - INSTALLATION, UPPER.....2-20

BALL JOINT - OPERATION, UPPER

SUSPENSION ARM, BUSHINGS..........2-20

BALL JOINT - REMOVAL, UPPER.........2-20

BAR - INSTALLATION, STABILIZER....2-14,2-19

BAR - REMOVAL, STABILIZER.......2-14,2-19

BAR BUSHINGS - INSTALLATION,

STABILIZER...........................2-9

BAR BUSHINGS - REMOVAL, STABILIZER . . . 2-9

BARRELS - INSTALLATION, PANEL

OUTLET............................24-29

BARRELS - REMOVAL, PANEL OUTLET . . . 24-29

BASE - DESCRIPTION, BRAKES...........5-2

BASE - WARNING, BRAKES..............5-2

BASE BRAKE SYSTEM - DIAGNOSIS AND

TESTING.............................5-3

BASE BRAKES, SPECIAL TOOLS...........5-7

BASE COAT/CLEAR COAT FINISH -

DESCRIPTION......................23-162

BATTERIES - STANDARD PROCEDURE,

RKE TRANSMITTER...................8N-8

BATTERY - DESCRIPTION...............8F-7

BATTERY - DIAGNOSIS AND TESTING.....8F-8

BATTERY CABLES - DESCRIPTION.......8F-18

BATTERY CABLES - DIAGNOSIS AND

TESTING...........................8F-19

BATTERY CABLES - OPERATION.........8F-18

BATTERY CHARGING - STANDARD

PROCEDURE.........................8F-8

BATTERY HOLDDOWN - DESCRIPTION....8F-17

BATTERY HOLDDOWN - INSTALLATION . . . 8F-17

BATTERY HOLDDOWN - OPERATION.....8F-17

BATTERY HOLDDOWN - REMOVAL.......8F-17

BATTERY SYSTEM - CLEANING...........8F-5

BATTERY SYSTEM - DESCRIPTION........8F-1

BATTERY SYSTEM - DIAGNOSIS AND

TESTING............................8F-2

BATTERY SYSTEM - INSPECTION.........8F-6

BATTERY SYSTEM - OPERATION.........8F-2

BATTERY SYSTEM - SPECIAL TOOLS......8F-7

BATTERY SYSTEM - SPECIFICATIONS......8F-6

BATTERY TEMPERATURE SENSOR -

DESCRIPTION.......................8F-24

BATTERY TEMPERATURE SENSOR -

INSTALLATION

.......................8F-24

BATTERY TEMPERATURE SENSOR -

OPERATION

.........................8F-24

BATTERY TEMPERATURE SENSOR -

REMOVAL

..........................8F-24

BATTERY TRAY - DESCRIPTION

.........8F-21

BATTERY TRAY - INSTALLATION

.........8F-21

2 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page

Page 1746 of 1803

COVER - REMOVAL, COWL TRIM.......23-157

COVER - REMOVAL, INSTRUMENT

PANEL TOP........................23-152

COVER - REMOVAL, STRUCTURAL........9-55

COVER(S) - DESCRIPTION, CYLINDER

HEAD...............................9-25

COVER(S) - INSTALLATION, CYLINDER

HEAD...........................9-26,9-34

COVER(S) - INSTALLATION, TIMING

BELT / CHAIN........................9-76

COVER(S) - REMOVAL, CYLINDER HEAD . . 9-25,

9-34

COVER(S) - REMOVAL, TIMING BELT /

CHAIN..............................9-74

COWL GRILLE - INSTALLATION........23-140

COWL GRILLE - REMOVAL............23-140

COWL TRIM COVER - INSTALLATION....23-157

COWL TRIM COVER - REMOVAL.......23-157

COWL WEATHERSTRIP - INSTALLATION . 23-185

COWL WEATHERSTRIP - REMOVAL.....23-185

COWL/PLENUM SEAL - INSTALLATION . . . 23-187

COWL/PLENUM SEAL - REMOVAL......23-187

COWL/PLENUM WINDOW BAFFLE SEAL -

INSTALLATION......................23-187

COWL/PLENUM WINDOW BAFFLE SEAL -

REMOVAL.........................23-187

CRADLE CROSSMEMBER -

INSTALLATION, ENGINE................13-6

CRADLE CROSSMEMBER - REMOVAL,

ENGINE.............................13-6

CRANKSHAFT - DESCRIPTION...........9-42

CRANKSHAFT - INSPECTION.............9-43

CRANKSHAFT - INSTALLATION...........9-43

CRANKSHAFT - REMOVAL..............9-43

CRANKSHAFT OIL SEAL - FRONT -

INSTALLATION........................9-47

CRANKSHAFT OIL SEAL - FRONT -

REMOVAL...........................9-46

CRANKSHAFT OIL SEAL - REAR -

INSTALLATION........................9-48

CRANKSHAFT OIL SEAL - REAR -

REMOVAL...........................9-48

CRANKSHAFT POSITION SENSOR -

DESCRIPTION.......................14-30

CRANKSHAFT POSITION SENSOR -

INSTALLATION.......................14-32

CRANKSHAFT POSITION SENSOR -

OPERATION.........................14-31

CRANKSHAFT POSITION SENSOR -

REMOVAL..........................14-31

CROSSMEMBER - INSTALLATION,

ENGINE CRADLE......................13-6

CROSSMEMBER - INSTALLATION,

RADIATOR.........................23-146

CROSSMEMBER - INSTALLATION, REAR . . . 13-7

CROSSMEMBER - REMOVAL, ENGINE

CRADLE.............................13-6

CROSSMEMBER - REMOVAL, RADIATOR . 23-146

CROSSMEMBER - REMOVAL, REAR.......13-7

CROSS-OVER PIPE - INSTALLATION.......11-3

CROSS-OVER PIPE - REMOVAL..........11-3

CRUISE INDICATOR - DESCRIPTION......8J-16

CRUISE INDICATOR - OPERATION.......8J-17

CURTAIN AIRBAG - DESCRIPTION, SIDE . . 8O-38

CURTAIN AIRBAG - INSTALLATION, SIDE . . 8O-41

CURTAIN AIRBAG - OPERATION, SIDE....8O-39

CURTAIN AIRBAG - REMOVAL, SIDE.....8O-40

CUSHION - FRONT - INSTALLATION,

SEAT .............................23-167

CUSHION - FRONT - INSTALLATION,

SEAT BACK........................23-167

CUSHION - FRONT - REMOVAL, SEAT . . . 23-167

CUSHION - FRONT - REMOVAL, SEAT

BACK.............................23-167

CUSHION - REAR - INSTALLATION, SEAT . 23-171

CUSHION - REAR - INSTALLATION, SEAT

BACK.............................23-170

CUSHION - REAR - REMOVAL, SEAT....23-171

CUSHION - REAR - REMOVAL, SEAT

BACK

.............................23-170

CUSHION COVER - FRONT -

INSTALLATION, SEAT

.................23-167

CUSHION COVER - FRONT - REMOVAL,

SEAT

.............................23-167

CUSHION SIDE SHIELDS -

INSTALLATION, SEAT

.................23-167

CUSHION SIDE SHIELDS - REMOVAL,

SEAT

.............................23-167CUSTOMER PREFERENCES - STANDARD

PROCEDURE, RKE TRANSMITTER........8N-8

CV JOINT/BOOT-INNER - INSTALLATION . . . 3-17

CV JOINT/BOOT-INNER - REMOVAL.......3-15

CV JOINT/BOOT-OUTER - INSTALLATION . . . 3-13

CV JOINT/BOOT-OUTER - REMOVAL.......3-12

CYLINDER - DESCRIPTION, MASTER......5-24

CYLINDER - INSPECTION, MASTER........6-9

CYLINDER - INSTALLATION, FLIP-UP

GLASS SUPPORT...................23-139

CYLINDER - INSTALLATION, LOCK......23-125,

23-138

CYLINDER - INSTALLATION, LOCK.......19-11

CYLINDER - INSTALLATION, MASTER.....5-25

CYLINDER - INSTALLATION, SUPPORT . . . 23-120

CYLINDER - OPERATION, MASTER........5-24

CYLINDER - REMOVAL, FLIP-UP GLASS

SUPPORT.........................23-139

CYLINDER - REMOVAL, LOCK....23-125,23-137

CYLINDER - REMOVAL, LOCK...........19-10

CYLINDER - REMOVAL, MASTER.........5-25

CYLINDER - REMOVAL, SUPPORT......23-120

CYLINDER BLEEDING - STANDARD

PROCEDURE, MASTER.................5-24

CYLINDER BORE HONING - STANDARD

PROCEDURE.........................9-39

CYLINDER COMBUSTION PRESSURE

LEAKAGE - DIAGNOSIS AND TESTING......9-8

CYLINDER COMPRESSION PRESSURE -

DIAGNOSIS AND TESTING...............9-8

CYLINDER FLUID LEVEL - STANDARD

PROCEDURES, MASTER................5-26

CYLINDER HEAD - DESCRIPTION.........9-30

CYLINDER HEAD COVER(S) -

DESCRIPTION........................9-25

CYLINDER HEAD COVER(S) -

INSTALLATION....................9-26,9-34

CYLINDER HEAD COVER(S) - REMOVAL . . . 9-25,

9-34

CYLINDER HEAD GASKET - DIAGNOSIS

AND TESTING....................9-19,9-30

CYLINDER LOCK SWITCH -

DESCRIPTION, DOOR..................8Q-9

CYLINDER LOCK SWITCH -

DESCRIPTION, TAILGATE...............8N-9

CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, DOOR.................8Q-10

CYLINDER LOCK SWITCH - DIAGNOSIS

AND TESTING, TAILGATE...............8N-9

CYLINDER LOCK SWITCH -

INSTALLATION, DOOR.................8Q-10

CYLINDER LOCK SWITCH -

INSTALLATION, TAILGATE..............8N-10

CYLINDER LOCK SWITCH - OPERATION,

DOOR.............................8Q-10

CYLINDER LOCK SWITCH - OPERATION,

TAILGATE...........................8N-9

CYLINDER LOCK SWITCH - REMOVAL,

DOOR.............................8Q-10

CYLINDER LOCK SWITCH - REMOVAL,

TAILGATE..........................8N-10

CYLINDER/POWER BOOSTER -

DIAGNOSIS AND TESTING, MASTER . . 5-21,5-24

CYLINDERS - ASSEMBLY, WHEEL.........5-29

CYLINDERS - CLEANING, WHEEL.........5-28

CYLINDERS - DISASSEMBLY, WHEEL......5-28

CYLINDERS - INSPECTION, WHEEL.......5-29

CYLINDERS - INSTALLATION, WHEEL

.....5-29

CYLINDERS - REMOVAL, WHEEL

.........5-28

DAMAGED OR WORN THREADS -

STANDARD PROCEDURE, REPAIR

.........9-9

DAMPER - INSTALLATION, VIBRATION

.....9-55

DAMPER - REMOVAL, VIBRATION

........9-54

DATA LINK CONNECTOR - DESCRIPTION

. . 8E-10

DATA LINK CONNECTOR - OPERATION

....8E-10

DAYTIME RUNNING LAMP RELAY -

DESCRIPTION

.......................8L-20

DAYTIME RUNNING LAMP RELAY -

INSTALLATION

.......................8L-21

DAYTIME RUNNING LAMP RELAY -

OPERATION

.........................8L-20

DAYTIME RUNNING LAMP RELAY -

REMOVAL

..........................8L-21

DECOUPLER - DIAGNOSIS AND

TESTING, GENERATOR

................8F-27

DECOUPLER PULLEY - DESCRIPTION,

GENERATOR

........................8F-26DECOUPLER PULLEY - INSTALLATION,

GENERATOR........................8F-30

DECOUPLER PULLEY - OPERATION,

GENERATOR........................8F-27

DECOUPLER PULLEY - REMOVAL,

GENERATOR........................8F-27

DEFINITION - DESCRIPTION, TRIP.......25-19

DEFLECTOR - INSTALLATION, WIND.....23-180

DEFLECTOR - REMOVAL, WIND........23-180

DEFOGGER - DESCRIPTION, REAR

WINDOW............................8G-3

DEFOGGER - OPERATION, REAR

WINDOW............................8G-3

DEFOGGER FUNCTION - DIAGNOSIS AND

TESTING, REAR HVAC CONTROL

ASSEMBLY WINDOW..................8G-9

DEFOGGER GRID - DESCRIPTION, REAR

WINDOW............................8G-5

DEFOGGER GRID - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-5

DEFOGGER GRID - OPERATION, REAR

WINDOW............................8G-5

DEFOGGER RELAY - DESCRIPTION,

REAR WINDOW.......................8G-6

DEFOGGER RELAY - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-6

DEFOGGER RELAY - INSTALLATION,

REAR WINDOW.......................8G-7

DEFOGGER RELAY - OPERATION, REAR

WINDOW............................8G-6

DEFOGGER RELAY - REMOVAL, REAR

WINDOW............................8G-7

DEFOGGER SWITCH - DESCRIPTION,

REAR WINDOW.......................8G-8

DEFOGGER SWITCH - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-8

DEFOGGER SWITCH - OPERATION, REAR

WINDOW............................8G-8

DEFOGGER SYSTEM - DIAGNOSIS AND

TESTING, REAR WINDOW..............8G-4

DEFROST DOO - INSTALLATION, FLOOR . . 24-37

DEFROST DOOR - REMOVAL...........24-35

DEFROST DOOR - REMOVAL, FLOOR.....24-36

DEFROST DOOR ACTUATOR -

INSTALLATION, FLOOR................24-25

DEFROST DOOR ACTUATOR - REMOVAL,

FLOOR.............................24-24

DEFROST DUCT/DEMISTER ADAPTOR -

REMOVAL..........................24-32

DEFROST/DEMISTER DUCT -

INSTALLATION.......................24-32

DELIVERY - DESCRIPTION, FUEL.........14-2

DELIVERY - OPERATION, FUEL...........14-3

DEMAGNETIZING - STANDARD

PROCEDURE, COMPASS...............8M-2

DEMISTER OUTLETS - DESCRIPTION.....24-29

DEPLOYMENT - STANDARD

PROCEDURE, SERVICE AFTER A

SUPPLEMENTAL RESTRAINT............8O-6

DETECTION PUMP - DESCRIPTION, LEAK . 25-27

DETECTION PUMP - INSTALLATION,

LEAK..............................25-28

DETECTION PUMP - OPERATION, LEAK . . . 25-28

DETECTION PUMP - REMOVAL, LEAK....25-28

DEVICES - STANDARD PROCEDURE,

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE........................8W-01-8

DIAGNOSIS CHART - DIAGNOSIS AND

TESTING, COOLING SYSTEM.............7-6

DIAGNOSIS, DIAGNOSIS AND TESTING -

WATER DRAINAGE AND WIND NOISE . . . 23-176

DIAGNOSTIC PROCEDURES, DIAGNOSIS

AND TESTING......................23-176

DIAGNOSTIC TROUBLE CODES -

DESCRIPTION........................25-2

DIAGNOSTICS (OBD) - DIAGNOSIS AND

TESTING, ON-BOARD...................7-3

DIAGRAMS - DESCRIPTION, HOW TO

USE WIRING......................8W-01-1

DIAGRAMS - HYDRAULIC SCHEMATICS,

SCHEMATICS.......................21-100

DIESEL - TORQUE, EXCEPT.............8F-23

DIFFERENTIAL - ASSEMBLY

........3-105,3-41

DIFFERENTIAL - DISASSEMBLY

.....3-105,3-41

DIFFERENTIAL - INSTALLATION

. 3-105,3-42,3-73

DIFFERENTIAL - REMOVAL

.....3-104,3-40,3-71

DIFFERENTIAL - TRAC-LOK - ASSEMBLY

. . 3-109,

3-77

KJINDEX 7

Description Group-Page Description Group-Page Description Group-Page

Page 1748 of 1803

ENGINE - DESCRIPTION, COOLING

SYSTEM 3.7L.........................7-1

ENGINE - DESCRIPTION, COOLING

SYSTEM ROUTING 3.7L.................7-2

ENGINE - INSTALLATION, 3.7L . . . 7-17,7-18,7-22

ENGINE - REMOVAL, 3.7L...........7-17,7-21

ENGINE - STANDARD PROCEDURE,

DRAINING COOLING SYSTEM 3.7L........7-12

ENGINE - STANDARD PROCEDURE,

REFILLING COOLING SYSTEM 3.7L.......7-12

ENGINE BLOCK - CLEANING.............9-39

ENGINE BLOCK - DESCRIPTION..........9-39

ENGINE BLOCK - INSPECTION...........9-40

ENGINE COOLANT - DESCRIPTION.........0-3

ENGINE COOLANT TEMPERATURE

SENSOR - DESCRIPTION...............7-19

ENGINE COOLANT TEMPERATURE

SENSOR - INSTALLATION...............7-21

ENGINE COOLANT TEMPERATURE

SENSOR - OPERATION.................7-20

ENGINE COOLANT TEMPERATURE

SENSOR - REMOVAL...................7-20

ENGINE COOLANT THERMOSTAT -

OPERATION..........................7-21

ENGINE CORE AND OIL GALLERY PLUGS

- STANDARD PROCEDURE..............9-10

ENGINE CRADLE CROSSMEMBER -

INSTALLATION........................13-6

ENGINE CRADLE CROSSMEMBER -

REMOVAL...........................13-6

ENGINE DIAGNOSIS - INTRODUCTION -

DIAGNOSIS AND TESTING.................9-4

ENGINE DIAGNOSIS - LUBRICATION -

DIAGNOSIS AND TESTING...............9-7

ENGINE DIAGNOSIS - MECHANICAL -

DIAGNOSIS AND TESTING...............9-6

ENGINE DIAGNOSIS - PERFORMANCE -

DIAGNOSIS AND TESTING...............9-4

ENGINE FIRING ORDER, 2.4L 4-

CYLINDER...........................8I-2

ENGINE FIRING ORDER, 3.7L V-6.........8I-2

ENGINE GASKET SURFACE

PREPARATION - STANDARD

PROCEDURE..........................9-9

ENGINE OIL - STANDARD PROCEDURE....9-61

ENGINE OIL LEAK - DIAGNOSIS AND

TESTING............................9-60

ENGINE OIL PRESSURE - DIAGNOSIS

AND TESTING........................9-60

ENGINE, SPECIAL TOOLS - 3.7L..........9-15

ENGINE, SPECIFICATIONS - 3.7L.........9-12

ENGINE TEMPERATURE GAUGE -

DESCRIPTION.......................8J-18

ENGINE TEMPERATURE GAUGE -

OPERATION.........................8J-18

ENGINES - GENERATOR RATINGS, GAS . . . 8F-23

ENTRY MODULE - DESCRIPTION,

REMOTE KEYLESS....................8N-7

ENTRY MODULE - DIAGNOSIS AND

TESTING, REMOTE KEYLESS............8N-7

ENTRY MODULE - INSTALLATION,

REMOTE KEYLESS....................8N-7

ENTRY MODULE - OPERATION, REMOTE

KEYLESS............................8N-7

ENTRY MODULE - REMOVAL, REMOTE

KEYLESS............................8N-7

ENTRY TRANSMITTER - DIAGNOSIS AND

TESTING, REMOTE KEYLESS............8N-8

ENTRY TRANSMITTER -

SPECIFICATIONS, REMOTE KEYLESS......8N-9

EQUIPMENT - STANDARD PROCEDURE,

REFRIGERANT SYSTEM SERVICE........24-40

ERASING TRANSMITTER CODES -

STANDARD PROCEDURE...............8M-8

EVACUATE - STANDARD PROCEDURE,

REFRIGERANT SYSTEM...............24-41

EVAPORATION CONTROL SYSTEM -

DESCRIPTION.......................25-24

EVAPORATOR - DESCRIPTION, A/C.......24-49

EVAPORATOR - INSTALLATION, A/C......24-49

EVAPORATOR - OPERATION, A/C........24-49

EVAPORATOR - REMOVAL, A/C..........24-49

EVAP/PURGE SOLENOID - DESCRIPTION . . 25-27

EVAP/PURGE SOLENOID - INSTALLATION

. 25-27

EVAP/PURGE SOLENOID - OPERATION

....25-27

EVAP/PURGE SOLENOID - REMOVAL

.....25-27

EXCEPT DIESEL - TORQUE

.............8F-23

EXHAUST MANIFOLD - DESCRIPTION

.....9-69EXHAUST MANIFOLD - INSTALLATION.....9-70

EXHAUST MANIFOLD - REMOVAL.........9-69

EXHAUST SYSTEM - DESCRIPTION.......11-1

EXHAUST SYSTEM - DIAGNOSIS AND

TESTING............................11-2

EXTENSION HOUSING BUSHING -

NV3550 - INSTALLATION...............21-74

EXTENSION HOUSING BUSHING -

NV3550 - REMOVAL..................21-73

EXTENSION HOUSING SEAL - NV1500 -

INSTALLATION.......................21-32

EXTENSION HOUSING SEAL - NV1500 -

REMOVAL..........................21-32

EXTENSION HOUSING SEAL - NV3550 -

INSTALLATION.......................21-74

EXTENSION HOUSING SEAL - NV3550 -

REMOVAL..........................21-74

EXTERIOR - DESCRIPTION, LAMPS/

LIGHTING...........................8L-2

EXTERIOR - DIAGNOSIS AND TESTING,

LAMPS/LIGHTING.....................8L-7

EXTERIOR - OPERATION, LAMPS/

LIGHTING...........................8L-5

EXTERIOR - SPECIFICATIONS,

LAMPS/LIGHTING....................8L-15

EXTERIOR HANDLE - INSTALLATION....23-123,

23-130,23-136

EXTERIOR HANDLE - REMOVAL . 23-123,23-130,

23-136

EXTERIOR NAME PLATES -

INSTALLATION......................23-141

EXTERIOR NAME PLATES - REMOVAL . . . 23-140

FAN - ELECTRIC - DESCRIPTION,

RADIATOR...........................7-26

FAN - ELECTRIC - INSTALLATION,

RADIATOR...........................7-27

FAN - ELECTRIC - OPERATION,

RADIATOR...........................7-26

FAN - ELECTRIC - REMOVAL, RADIATOR . . . 7-26

FAN - VISCOUS - CLEANING, RADIATOR . . . 7-29

FAN - VISCOUS - DESCRIPTION,

RADIATOR...........................7-27

FAN - VISCOUS - INSPECTION,

RADIATOR...........................7-29

FAN - VISCOUS - INSTALLATION,

RADIATOR...........................7-29

FAN - VISCOUS - OPERATION,

RADIATOR...........................7-27

FAN - VISCOUS - REMOVAL, RADIATOR....7-28

FAN DRIVE - DIAGNOSIS AND TESTING,

VISCOUS............................7-28

FASCIA - INSTALLATION, FRONT.........13-2

FASCIA - INSTALLATION, REAR..........13-2

FASCIA - REMOVAL, FRONT.............13-1

FASCIA - REMOVAL, REAR..............13-2

FASCIA SUPPORT - INSTALLATION,

REAR...............................13-3

FASCIA SUPPORT - REMOVAL, REAR......13-3

FASTENER IDENTIFICATION -

DESCRIPTION......................Intro.-1

FENDER - INSTALLATION, FRONT.......23-141

FENDER - REMOVAL, FRONT..........23-141

FILL - STANDARD PROCEDURE, FLUID

DRAIN......................21-208,21-246

FILL - STANDARD PROCEDURE,

TRANSMISSION.....................21-128

FILL DOOR/HOUSING - INSTALLATION,

FUEL.............................23-141

FILL DOOR/HOUSING - REMOVAL, FUEL . 23-141

FILL/CHECK LOCATIONS - DESCRIPTION,

FLUID...............................0-4

FILLER CAP - DESCRIPTION, FUEL.......25-27

FILLER CAP - OPERATION, FUEL........25-27

FILTER - DESCRIPTION, FUEL............14-7

FILTER - INSTALLATION, FUEL...........14-8

FILTER - INSTALLATION, INLET..........14-28

FILTER - INSTALLATION, OIL............9-63

FILTER - REMOVAL, FUEL...............14-7

FILTER - REMOVAL, INLET.............14-28

FILTER - REMOVAL, OIL

................9-63

FILTER REPLACEMENT - STANDARD

PROCEDURE, FLUID

.................21-126

FINESSE SANDING/BUFFING &

POLISHING - DESCRIPTION

...........23-163

FINISH - DESCRIPTION, BASE

COAT/CLEAR COAT

..................23-162

FIRING ORDER, 2.4L 4-CYLINDER -

ENGINE

..............................8I-2FIRING ORDER, 3.7L V-6 - ENGINE........8I-2

FITTING - CONNECTING ROD BEARING....9-49

FITTING - DESCRIPTION, QUICK

CONNECT...........................14-10

FITTING - MAIN BEARING...............9-45

FITTING - STANDARD PROCEDURE,

CONNECTING ROD BEARING............9-40

FITTING - STANDARD PROCEDURE,

PISTON.............................9-50

FITTING - STANDARD PROCEDURE,

PISTON RING........................9-52

FITTINGS - STANDARD PROCEDURE,

QUICK-CONNECT.....................14-10

FLARE MOLDINGS - INSTALLATION,

FRONT WHEEL OPENING.............23-145

FLARE MOLDINGS - INSTALLATION,

REAR WHEEL OPENING..............23-145

FLARE MOLDINGS - REMOVAL, FRONT

WHEEL OPENING...................23-145

FLARE MOLDINGS - REMOVAL, REAR

WHEEL OPENING...................23-145

FLARING - STANDARD PROCEDURE,

DOUBLE INVERTED.....................5-8

FLARING - STANDARD PROCEDURE, ISO....5-8

FLASHER - DESCRIPTION, COMBINATION . 8L-19

FLASHER - OPERATION, COMBINATION . . . 8L-19

FLEX PLATE - INSTALLATION............9-49

FLEX PLATE - REMOVAL................9-49

FLIP-UP GLASS - INSTALLATION.......23-136

FLIP-UP GLASS - REMOVAL...........23-136

FLIP-UP GLASS AJAR SWITCH -

DESCRIPTION.......................8L-77

FLIP-UP GLASS AJAR SWITCH -

OPERATION.........................8L-77

FLIP-UP GLASS LATCH - INSTALLATION . 23-136

FLIP-UP GLASS LATCH - REMOVAL.....23-136

FLIP-UP GLASS RELEASE SWITCH -

DIAGNOSIS AND TESTING..............8N-5

FLIP-UP GLASS SUPPORT CYLINDER -

INSTALLATION......................23-139

FLIP-UP GLASS SUPPORT CYLINDER -

REMOVAL.........................23-139

FLOOR - DEFROST DOO - INSTALLATION . . 24-37

FLOOR - DEFROST DOOR - REMOVAL....24-36

FLOOR - DEFROST DOOR ACTUATOR -

INSTALLATION.......................24-25

FLOOR - DEFROST DOOR ACTUATOR -

REMOVAL..........................24-24

FLOOR CONSOLE - INSTALLATION......23-158

FLOOR CONSOLE - REMOVAL..........23-158

FLOOR CONSOLE DUCT - INSTALLATION . . 24-31

FLOOR CONSOLE DUCT - REMOVAL.....24-31

FLOOR CONSOLE LID LATCH -

INSTALLATION......................23-158

FLOOR CONSOLE LID LATCH - REMOVAL . 23-158

FLOOR DUCT - INSTALLATION..........24-32

FLOOR DUCT - REMOVAL..............24-32

FLOOR MATS - INSTALLATION, CARPETS . 23-158

FLOOR MATS - REMOVAL, CARPETS....23-158

FLOOR SHIFT BOOT - INSTALLATION,

4WD .............................23-156

FLOOR SHIFT BOOT - REMOVAL, 4WD . . . 23-156

FLOW AND PRESSURE - DIAGNOSIS

AND TESTING, POWER STEERING........19-3

FLOW MANAGEMENT VALVE -

DESCRIPTION........................14-6

FLOW MANAGEMENT VALVE -

INSTALLATION........................14-7

FLOW MANAGEMENT VALVE -

OPERATION..........................14-6

FLOW MANAGEMENT VALVE - REMOVAL . . . 14-6

FLUID - DESCRIPTION, AUTOMATIC

TRANSMISSION.......................0-2

FLUID - DIAGNOSIS AND TESTING,

CAUSES OF BURNT..................21-125

FLUID - OPERATION, AUTOMATIC

TRANSMISSION.......................0-4

FLUID AND FILTER REPLACEMENT -

STANDARD PROCEDURE..............21-126

FLUID CAPACITIES - SPECIFICATIONS......0-4

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING......................21-125

FLUID CONTAMINATION - DIAGNOSIS

AND TESTING, BRAKE

..................5-26

FLUID COOLER - DESCRIPTION

.........19-20

FLUID COOLER - INSTALLATION

.........19-20

FLUID COOLER - OPERATION

...........19-20

FLUID COOLER - REMOVAL

............19-20

KJINDEX 9

Description Group-Page Description Group-Page Description Group-Page

Page 1749 of 1803

FLUID DRAIN AND FILL - STANDARD

PROCEDURE.................21-208,21-246

FLUID FILL/CHECK LOCATIONS -

DESCRIPTION.........................0-4

FLUID INDICATOR - DESCRIPTION,

WASHER...........................8J-35

FLUID INDICATOR - DIAGNOSIS AND

TESTING, WASHER...................8J-36

FLUID INDICATOR - OPERATION,

WASHER...........................8J-36

FLUID LEAK - DIAGNOSIS AND TESTING,

CONVERTER HOUSING................21-80

FLUID LEVEL - DIAGNOSIS AND

TESTING, EFFECTS OF INCORRECT......21-125

FLUID LEVEL - STANDARD

PROCEDURES, MASTER CYLINDER.......5-26

FLUID LEVEL CHECK - STANDARD

PROCEDURE.......................21-126

FLUID LEVEL SWITCH - DESCRIPTION,

WASHER...........................8R-17

FLUID LEVEL SWITCH - INSTALLATION,

WASHER...........................8R-18

FLUID LEVEL SWITCH - OPERATION,

WASHER...........................8R-17

FLUID LEVEL SWITCH - REMOVAL,

WASHER...........................8R-17

FLUID RESERVOIR - INSTALLATION.......5-26

FLUID RESERVOIR - REMOVAL..........5-26

FLUID, SPECIFICATIONS - BRAKE.........5-27

FLUID TYPES - DESCRIPTION.............0-1

FLUSH - SPECIFICATIONS, GAP........23-116

FLUSHING - STANDARD PROCEDURE,

COOLING SYSTEM - REVERSE...........7-12

FLYWHEEL - DESCRIPTION...............6-7

FLYWHEEL - DIAGNOSIS AND TESTING.....6-8

FLYWHEEL - OPERATION................6-7

FOG LAMP BULB - INSTALLATION,

FRONT.............................8L-22

FOG LAMP BULB - REMOVAL, FRONT....8L-21

FOG LAMP INDICATOR - DESCRIPTION,

FRONT.............................8J-19

FOG LAMP INDICATOR - DESCRIPTION,

REAR..............................8J-27

FOG LAMP INDICATOR - OPERATION,

FRONT.............................8J-19

FOG LAMP INDICATOR - OPERATION,

REAR..............................8J-27

FOG LAMP RELAY - DESCRIPTION,

FRONT.............................8L-22

FOG LAMP RELAY - DESCRIPTION, REAR . 8L-56

FOG LAMP RELAY - DIAGNOSIS AND

TESTING, FRONT.....................8L-23

FOG LAMP RELAY - DIAGNOSIS AND

TESTING, REAR......................8L-57

FOG LAMP RELAY - INSTALLATION,

FRONT.............................8L-24

FOG LAMP RELAY - INSTALLATION,

REAR..............................8L-58

FOG LAMP RELAY - OPERATION, FRONT . . 8L-22

FOG LAMP RELAY - OPERATION, REAR . . . 8L-57

FOG LAMP RELAY - REMOVAL, FRONT . . . 8L-24

FOG LAMP RELAY - REMOVAL, REAR....8L-58

FOG LAMP UNIT - ADJUSTMENT, FRONT . . 8L-25

FOG LAMP UNIT - INSTALLATION,

FRONT.............................8L-25

FOG LAMP UNIT - REMOVAL, FRONT.....8L-25

FOLDING REAR SEAT BACK LATCH /

LOCK - INSTALLATION

...............23-170

FOLDING REAR SEAT BACK LATCH /

LOCK - REMOVAL

...................23-170

FOUR LOW MODE INDICATOR -

DESCRIPTION

.......................8J-29

FOUR LOW MODE INDICATOR -

OPERATION

.........................8J-30

FRAME - REAR - INSTALLATION, SEAT

BACK

.............................23-171

FRAME - REAR - REMOVAL, SEAT BACK

. 23-171

FRAME DIMENSIONS - SPECIFICATIONS

. . . 13-3

FRONT - DESCRIPTION

..................2-7

FRONT - INSTALLATION, CRANKSHAFT

OIL SEAL

............................9-47

FRONT - INSTALLATION, PROPELLER

SHAFT

...............................3-6

FRONT - INSTALLATION, SEAT

.........23-165

FRONT - INSTALLATION, SEAT BACK

....23-166

FRONT - INSTALLATION, SEAT BACK

COVER

............................23-167FRONT - INSTALLATION, SEAT BACK

CUSHION..........................23-167

FRONT - INSTALLATION, SEAT BACK

RECLINER.........................23-166

FRONT - INSTALLATION, SEAT CUSHION . 23-167

FRONT - INSTALLATION, SEAT CUSHION

COVER............................23-167

FRONT - REMOVAL, CRANKSHAFT OIL

SEAL...............................9-46

FRONT - REMOVAL, PROPELLER SHAFT....3-6

FRONT - REMOVAL, SEAT.............23-165

FRONT - REMOVAL, SEAT BACK........23-166

FRONT - REMOVAL, SEAT BACK COVER . . 23-166

FRONT - REMOVAL, SEAT BACK

CUSHION..........................23-167

FRONT - REMOVAL, SEAT BACK

RECLINER.........................23-166

FRONT - REMOVAL, SEAT CUSHION.....23-167

FRONT - REMOVAL, SEAT CUSHION

COVER............................23-167

FRONT - WARNING.....................2-7

FRONT AXLE - 186FIA - ADJUSTMENTS....3-25

FRONT AXLE - 186FIA - DESCRIPTION.....3-19

FRONT AXLE - 186FIA - INSTALLATION....3-24

FRONT AXLE - 186FIA - OPERATION......3-19

FRONT AXLE - 186FIA - REMOVAL........3-24

FRONT AXLE - SPECIFICATIONS..........3-33

FRONT AXLE, SPECIAL TOOLS...........3-34

FRONT BRAKE HOSE - INSTALLATION.......5-10

FRONT BRAKE PADS - INSTALLATION.....5-11

FRONT BRAKE PADS - REMOVAL.........5-11

FRONT CHECK VALVE - DESCRIPTION.....8R-8

FRONT CHECK VALVE - INSTALLATION....8R-9

FRONT CHECK VALVE - OPERATION.......8R-9

FRONT CHECK VALVE - REMOVAL........8R-9

FRONT DOOR OUTER BELT MOLDING -

INSTALLATION......................23-186

FRONT DOOR OUTER BELT MOLDING -

REMOVAL.........................23-186

FRONT FASCIA - INSTALLATION..........13-2

FRONT FASCIA - REMOVAL..............13-1

FRONT FENDER - INSTALLATION.......23-141

FRONT FENDER - REMOVAL...........23-141

FRONT FOG LAMP BULB -

INSTALLATION.......................8L-22

FRONT FOG LAMP BULB - REMOVAL.....8L-21

FRONT FOG LAMP INDICATOR -

DESCRIPTION.......................8J-19

FRONT FOG LAMP INDICATOR -

OPERATION.........................8J-19

FRONT FOG LAMP RELAY -

DESCRIPTION.......................8L-22

FRONT FOG LAMP RELAY - DIAGNOSIS

AND TESTING.......................8L-23

FRONT FOG LAMP RELAY -

INSTALLATION.......................8L-24

FRONT FOG LAMP RELAY - OPERATION . . 8L-22

FRONT FOG LAMP RELAY - REMOVAL....8L-24

FRONT FOG LAMP UNIT - ADJUSTMENT . . 8L-25

FRONT FOG LAMP UNIT - INSTALLATION . . 8L-25

FRONT FOG LAMP UNIT - REMOVAL.....8L-25

FRONT HOSE - REMOVAL................5-9

FRONT IMPACT SENSOR - DESCRIPTION . 8O-21

FRONT IMPACT SENSOR -

INSTALLATION......................8O-22

FRONT IMPACT SENSOR - OPERATION . . . 8O-21

FRONT IMPACT SENSOR - REMOVAL....8O-22

FRONT LAMP BULB - INSTALLATION.....8L-27

FRONT LAMP BULB - REMOVAL.........8L-26

FRONT LAMP UNIT - INSTALLATION.....8L-28

FRONT LAMP UNIT - REMOVAL.........8L-27

FRONT MOUNT - INSTALLATION..........9-57

FRONT MOUNT - REMOVAL.............9-56

FRONT OUTPUT SHAFT SEAL -

INSTALLATION................21-208,21-246

FRONT OUTPUT SHAFT SEAL -

REMOVAL...................21-208,21-246

FRONT POSITION LAMP BULB -

INSTALLATION.......................8L-28

FRONT POSITION LAMP BULB -

REMOVAL

..........................8L-28

FRONT SEAL - INSTALLATION, OIL

PUMP

............................21-152

FRONT SEAL - REMOVAL, OIL PUMP

....21-152

FRONT SEAT BELT & RETRACTOR -

INSTALLATION

......................8O-24

FRONT SEAT BELT & RETRACTOR -

REMOVAL

..........................8O-23FRONT SEAT BELT BUCKLE -

INSTALLATION......................8O-26

FRONT SEAT BELT BUCKLE - REMOVAL . . 8O-25

FRONT SKID PLATE - INSTALLATION......13-6

FRONT SKID PLATE - REMOVAL..........13-6

FRONT SUSPENSION, SPECIAL TOOLS.....2-8

FRONT TOW HOOK - INSTALLATION......13-8

FRONT TOW HOOK - REMOVAL..........13-8

FRONT WASHER HOSES/TUBES -

DESCRIPTION.......................8R-10

FRONT WASHER HOSES/TUBES -

OPERATION.........................8R-10

FRONT WASHER NOZZLE -

DESCRIPTION.......................8R-11

FRONT WASHER NOZZLE -

INSTALLATION......................8R-11

FRONT WASHER NOZZLE - OPERATION . . . 8R-11

FRONT WASHER NOZZLE - REMOVAL....8R-11

FRONT WHEEL OPENING FLARE

MOLDINGS - INSTALLATION...........23-145

FRONT WHEEL OPENING FLARE

MOLDINGS - REMOVAL..............23-145

FRONT WHEEL SPEED SENSOR -

INSTALLATION........................5-34

FRONT WHEEL SPEED SENSOR -

REMOVAL...........................5-34

FRONT WHEELHOUSE SPLASH SHIELD -

INSTALLATION......................23-143

FRONT WHEELHOUSE SPLASH SHIELD -

REMOVAL.........................23-143

FRONT WIPER & WASHER SYSTEM -

CLEANING...........................8R-7

FRONT WIPER & WASHER SYSTEM -

DIAGNOSIS AND TESTING..............8R-6

FRONT WIPER & WASHER SYSTEM -

INSPECTION.........................8R-7

FRONT WIPER ARM - DESCRIPTION.....8R-12

FRONT WIPER ARM - INSTALLATION.....8R-13

FRONT WIPER ARM - OPERATION.......8R-12

FRONT WIPER ARM - REMOVAL........8R-12

FRONT WIPER BLADE - DESCRIPTION....8R-13

FRONT WIPER BLADE - INSTALLATION . . . 8R-14

FRONT WIPER BLADE - OPERATION.....8R-14

FRONT WIPER BLADE - REMOVAL.......8R-14

FRONT WIPER MODULE - DESCRIPTION . . 8R-15

FRONT WIPER MODULE - INSTALLATION . 8R-16

FRONT WIPER MODULE - OPERATION....8R-15

FRONT WIPER MODULE - REMOVAL.....8R-16

FRONT WIPERS/WASHERS -

DESCRIPTION........................8R-2

FRONT WIPERS/WASHERS - OPERATION . . 8R-4

FRONT WIPER/WASHER SWITCH -

DESCRIPTION.......................8R-16

FRONT WIPER/WASHER SWITCH -

OPERATION.........................8R-16

FUEL DELIVERY - DESCRIPTION..........14-2

FUEL DELIVERY - OPERATION...........14-3

FUEL FILL DOOR/HOUSING -

INSTALLATION......................23-141

FUEL FILL DOOR/HOUSING - REMOVAL . . 23-141

FUEL FILLER CAP - DESCRIPTION.......25-27

FUEL FILLER CAP - OPERATION.........25-27

FUEL FILTER - DESCRIPTION............14-7

FUEL FILTER - INSTALLATION............14-8

FUEL FILTER - REMOVAL...............14-7

FUEL GAUGE - DESCRIPTION...........8J-19

FUEL GAUGE - OPERATION.............8J-20

FUEL INDICATOR - DESCRIPTION, LOW

. . . 8J-22

FUEL INDICATOR - OPERATION, LOW

.....8J-22

FUEL INJECTION - DESCRIPTION

........14-29

FUEL INJECTOR - DESCRIPTION

.........14-33

FUEL INJECTOR - DIAGNOSIS AND

TESTING

...........................14-33

FUEL INJECTOR - OPERATION

..........14-33

FUEL LEVEL SENDING UNIT -

DIAGNOSIS AND TESTING

..............14-9

FUEL LEVEL SENDING UNIT / SENSOR -

DESCRIPTION

........................14-9

FUEL LEVEL SENDING UNIT / SENSOR -

INSTALLATION

.......................14-10

FUEL LEVEL SENDING UNIT / SENSOR -

OPERATION

..........................14-9

FUEL LEVEL SENDING UNIT / SENSOR -

REMOVAL

...........................14-9

FUEL LINES - DESCRIPTION

............14-10

FUEL PRESSURE LEAK DOWN TEST -

DIAGNOSIS AND TESTING

..............14-3

10 INDEXKJ

Description Group-Page Description Group-Page Description Group-Page