high beam JEEP LIBERTY 2002 KJ / 1.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 551 of 1803

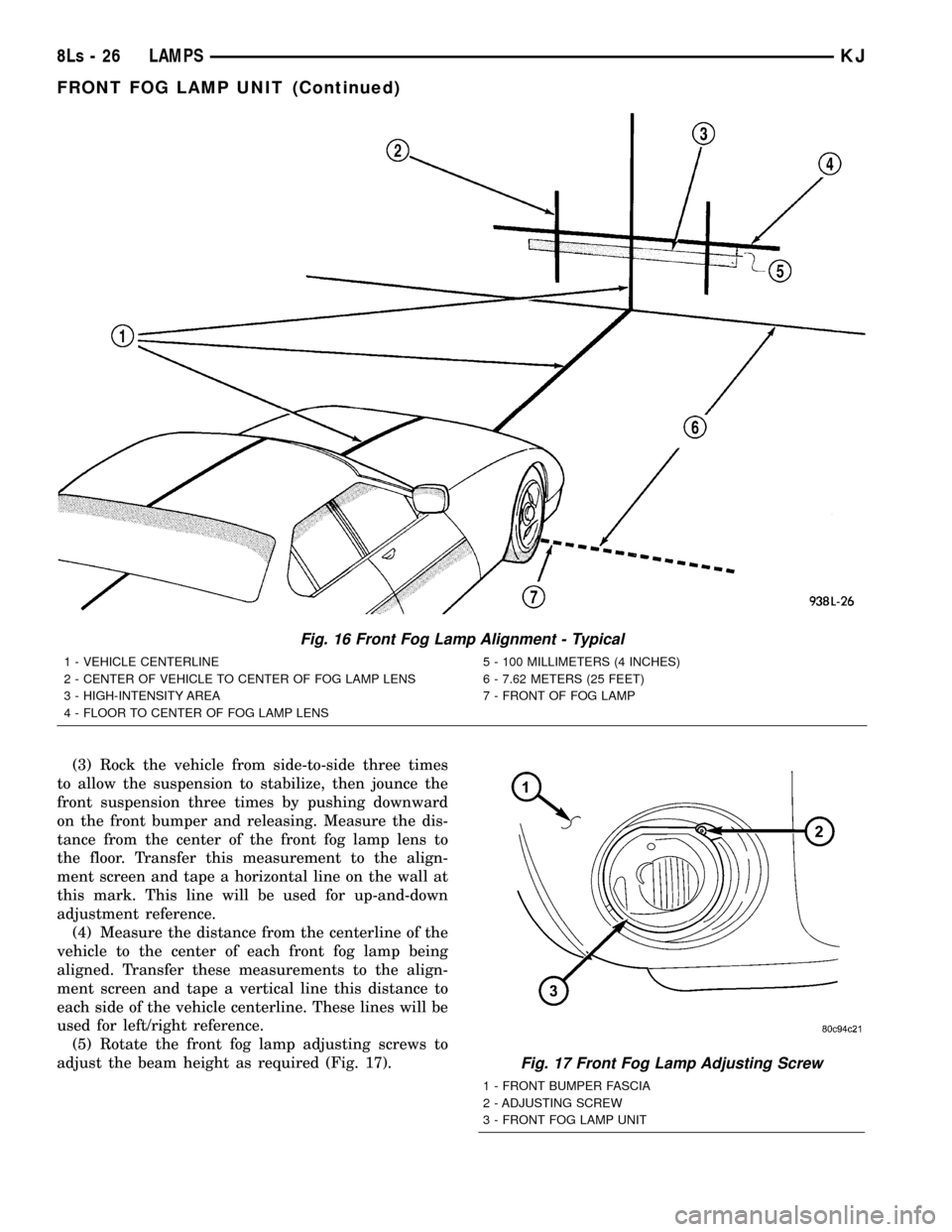

(3) Rock the vehicle from side-to-side three times

to allow the suspension to stabilize, then jounce the

front suspension three times by pushing downward

on the front bumper and releasing. Measure the dis-

tance from the center of the front fog lamp lens to

the floor. Transfer this measurement to the align-

ment screen and tape a horizontal line on the wall at

this mark. This line will be used for up-and-down

adjustment reference.

(4) Measure the distance from the centerline of the

vehicle to the center of each front fog lamp being

aligned. Transfer these measurements to the align-

ment screen and tape a vertical line this distance to

each side of the vehicle centerline. These lines will be

used for left/right reference.

(5) Rotate the front fog lamp adjusting screws to

adjust the beam height as required (Fig. 17).

Fig. 16 Front Fog Lamp Alignment - Typical

1 - VEHICLE CENTERLINE

2 - CENTER OF VEHICLE TO CENTER OF FOG LAMP LENS

3 - HIGH-INTENSITY AREA

4 - FLOOR TO CENTER OF FOG LAMP LENS5 - 100 MILLIMETERS (4 INCHES)

6 - 7.62 METERS (25 FEET)

7 - FRONT OF FOG LAMP

Fig. 17 Front Fog Lamp Adjusting Screw

1 - FRONT BUMPER FASCIA

2 - ADJUSTING SCREW

3 - FRONT FOG LAMP UNIT

8Ls - 26 LAMPSKJ

FRONT FOG LAMP UNIT (Continued)

Page 558 of 1803

(5) Position the outer circumference of the boot

seal over the flange on the back of the headlamp unit

housing and pull it downward until the seal is fully

engaged over the flange.

(6) Reinstall the headlamp unit onto the grille

opening reinforcement. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - EXTERIOR/HEADLAMP UNIT

- INSTALLATION).

(7) Reconnect the battery negative cable.

(8) Confirm proper headlamp unit alignment.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/HEADLAMP UNIT - ADJUSTMENTS).

HEADLAMP HIGH BEAM

RELAY

DESCRIPTION

The headlamp high beam relay is located in the

Junction Block (JB) on the driver side outboard end

of the instrument panel in the passenger compart-

ment of the vehicle. The headlamp high beam relay

is omitted from vehicles manufactured for sale in

Canada, which have a Daytime Running Lamp (DRL)

solid state relay installed in the JB that also per-

forms the function of the headlamp high beam relay.

The headlamp high beam relay is a conventional

International Standards Organization (ISO) micro

relay (Fig. 28). Relays conforming to the ISO specifi-

cations have common physical dimensions, current

capacities, terminal patterns, and terminal functions.

The relay is contained within a small, rectangular,molded plastic housing and is connected to all of the

required inputs and outputs by five integral male

spade-type terminals that extend from the bottom of

the relay base.

The headlamp high beam relay cannot be adjusted

or repaired and, if faulty or damaged, the unit must

be replaced.

OPERATION

The headlamp high beam relay is an electrome-

chanical switch that uses a low current input from

the Body Control Module (BCM) to control a high

current output to the headlamp high beam filaments.

The movable common feed contact point is held

against the fixed normally closed contact point by

spring pressure. When the relay coil is energized, an

electromagnetic field is produced by the coil wind-

ings. This electromagnetic field draws the movable

relay contact point away from the fixed normally

closed contact point, and holds it against the fixed

normally open contact point. When the relay coil is

de-energized, spring pressure returns the movable

contact point back against the fixed normally closed

contact point. A resistor is connected in parallel with

the relay coil in the relay, and helps to dissipate volt-

age spikes and electromagnetic interference that can

be generated as the electromagnetic field of the relay

coil collapses.

The headlamp high beam relay terminals are con-

nected to the vehicle electrical system through a con-

nector receptacle in the Junction Block (JB). The

inputs and outputs of the headlamp high beam relay

include:

²Common Feed Terminal- The common feed

terminal (30) receives battery current at all times

from a fuse in the Power Distribution Center (PDC)

through a fused B(+) circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Body

Control Module (BCM) through a head lamp relay

control circuit. The BCM controls head lamp opera-

tion by controlling a ground path through this circuit

²Coil Battery Terminal- The coil battery ter-

minal (86) is connected to a control output of the

Body Control Module (BCM) and to the momentary

optical horn (flash-to-pass) output of the multi-func-

tion switch through a high beam relay control circuit.

The BCM and/or the multi-function switch controls

headlamp high beam operation by controlling a

ground path through this circuit.

²Normally Open Terminal- The normally open

terminal (87) is connected to the headlamp high

beam filaments through the high beam relay output

circuit and provides battery current to the headlamp

high beams whenever the relay is energized.

Fig. 28 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJLAMPS8Ls-33

HEADLAMP BULB (Continued)

Page 559 of 1803

²Normally Closed Terminal- The normally

closed terminal (87A) is not connected in this appli-

cation.

The headlamp high beam relay can be diagnosed

using conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - HEADLAMP HIGH

BEAM RELAY

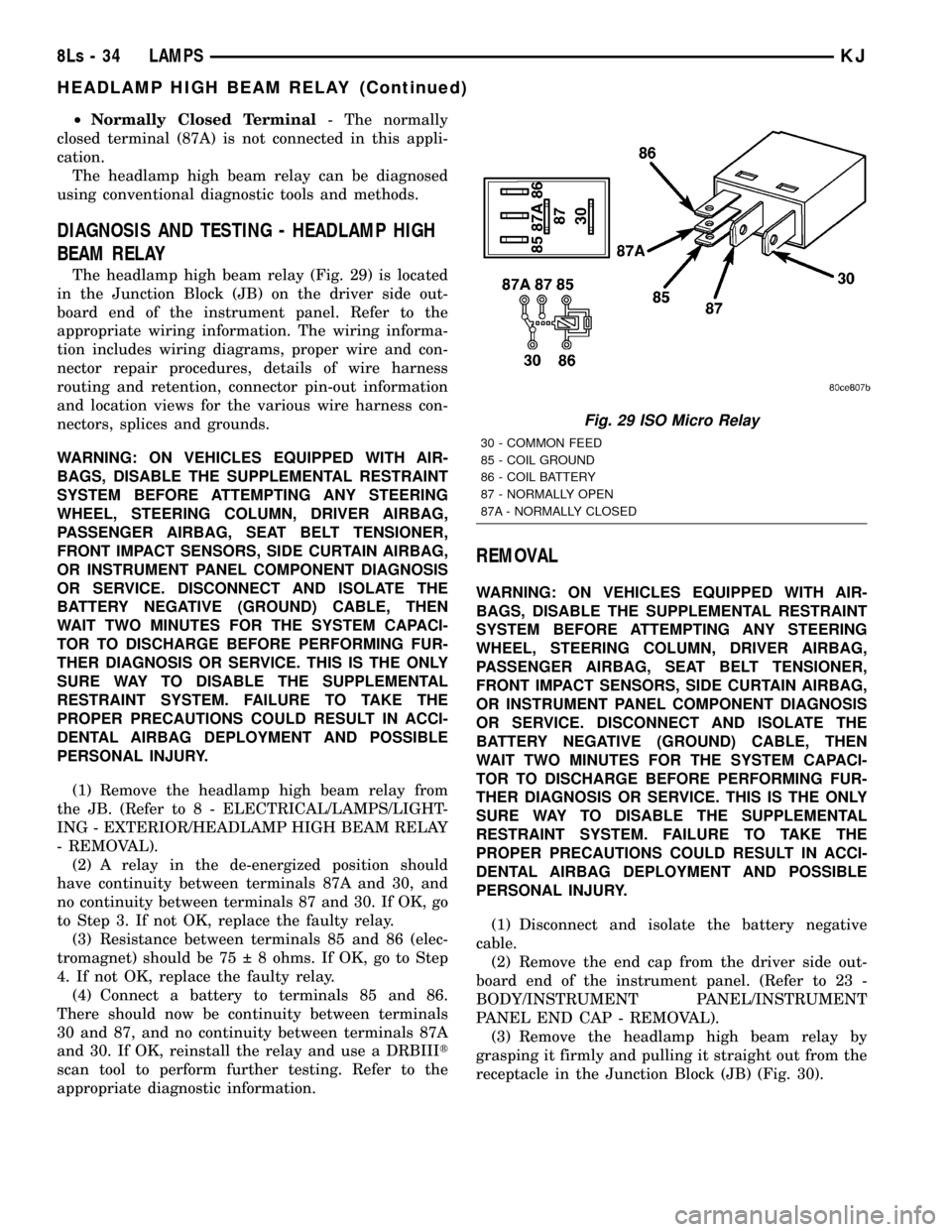

The headlamp high beam relay (Fig. 29) is located

in the Junction Block (JB) on the driver side out-

board end of the instrument panel. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Remove the headlamp high beam relay from

the JB. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/HEADLAMP HIGH BEAM RELAY

- REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the end cap from the driver side out-

board end of the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL END CAP - REMOVAL).

(3) Remove the headlamp high beam relay by

grasping it firmly and pulling it straight out from the

receptacle in the Junction Block (JB) (Fig. 30).

Fig. 29 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

8Ls - 34 LAMPSKJ

HEADLAMP HIGH BEAM RELAY (Continued)

Page 560 of 1803

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the headlamp high beam relay to the

proper receptacle in the Junction Block (JB) (Fig. 30).

(2) Align the headlamp high beam relay terminals

with the terminal cavities in the JB receptacle.

(3) Push firmly and evenly on the top of the head-

lamp high beam relay until the terminals are fully

seated in the terminal cavities in the JB receptacle.

(4) Reinstall the end cap onto the driver side out-

board end of the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL END CAP - INSTALLATION).

(5) Reconnect the battery negative cable.

HEADLAMP LEVELING MOTOR

DESCRIPTION

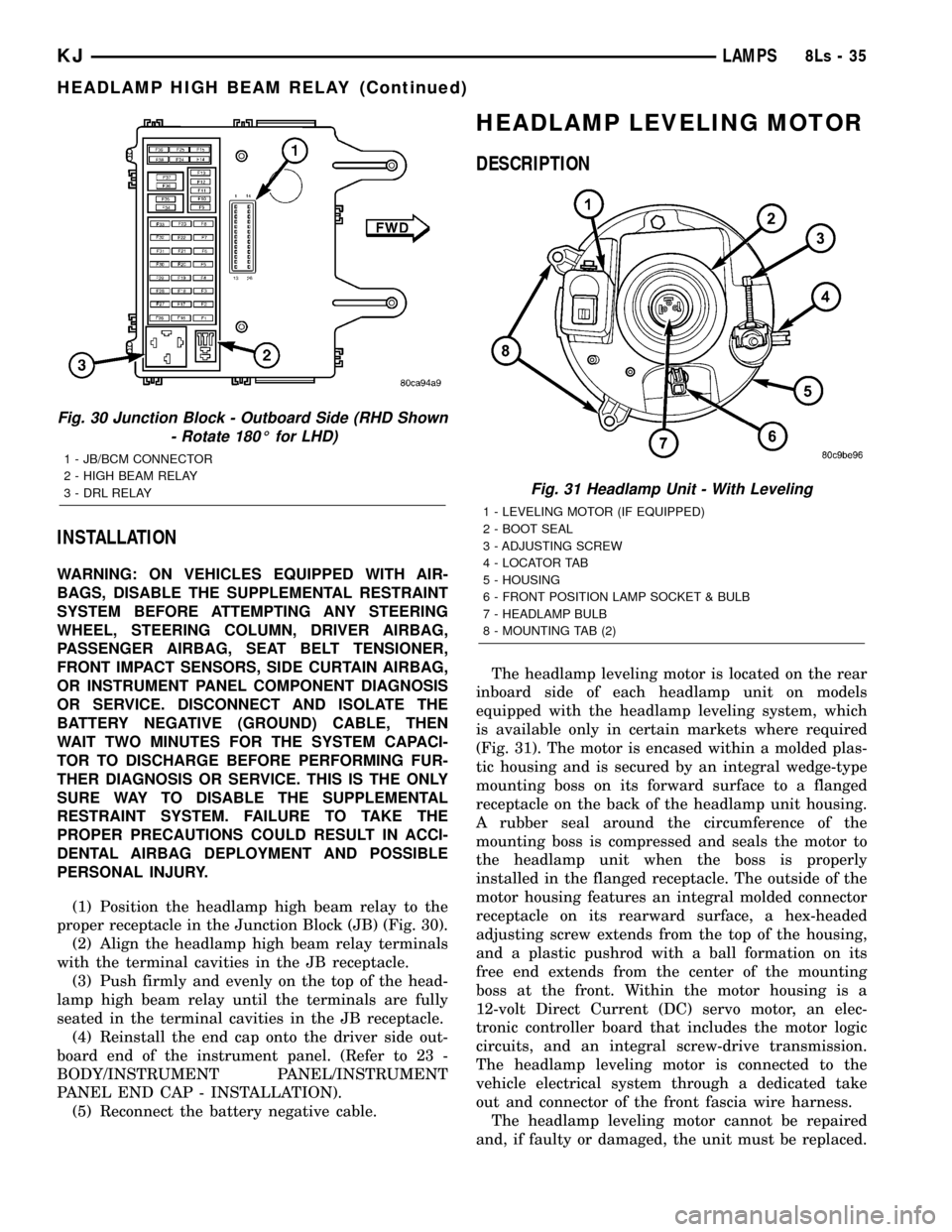

The headlamp leveling motor is located on the rear

inboard side of each headlamp unit on models

equipped with the headlamp leveling system, which

is available only in certain markets where required

(Fig. 31). The motor is encased within a molded plas-

tic housing and is secured by an integral wedge-type

mounting boss on its forward surface to a flanged

receptacle on the back of the headlamp unit housing.

A rubber seal around the circumference of the

mounting boss is compressed and seals the motor to

the headlamp unit when the boss is properly

installed in the flanged receptacle. The outside of the

motor housing features an integral molded connector

receptacle on its rearward surface, a hex-headed

adjusting screw extends from the top of the housing,

and a plastic pushrod with a ball formation on its

free end extends from the center of the mounting

boss at the front. Within the motor housing is a

12-volt Direct Current (DC) servo motor, an elec-

tronic controller board that includes the motor logic

circuits, and an integral screw-drive transmission.

The headlamp leveling motor is connected to the

vehicle electrical system through a dedicated take

out and connector of the front fascia wire harness.

The headlamp leveling motor cannot be repaired

and, if faulty or damaged, the unit must be replaced.

Fig. 30 Junction Block - Outboard Side (RHD Shown

- Rotate 180É for LHD)

1 - JB/BCM CONNECTOR

2 - HIGH BEAM RELAY

3 - DRL RELAY

Fig. 31 Headlamp Unit - With Leveling

1 - LEVELING MOTOR (IF EQUIPPED)

2 - BOOT SEAL

3 - ADJUSTING SCREW

4 - LOCATOR TAB

5 - HOUSING

6 - FRONT POSITION LAMP SOCKET & BULB

7 - HEADLAMP BULB

8 - MOUNTING TAB (2)

KJLAMPS8Ls-35

HEADLAMP HIGH BEAM RELAY (Continued)

Page 562 of 1803

the center of the headlamp reflector and thoroughly

clean any fingerprints from the reflector.

(6) Push the mounting flange of the headlamp lev-

eling motor into the mounting hole on the back of

headlamp unit housing unit the motor is firmly

seated (Fig. 32).

(7) Rotate the headlamp leveling motor on the

back of the headlamp unit housing clockwise about

30 degrees.

(8) Reinstall the headlamp bulb into the headlamp

unit housing. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/HEADLAMP BULB -

INSTALLATION).

(9) Reconnect the battery negative cable.

HEADLAMP LEVELING

SWITCH

DESCRIPTION

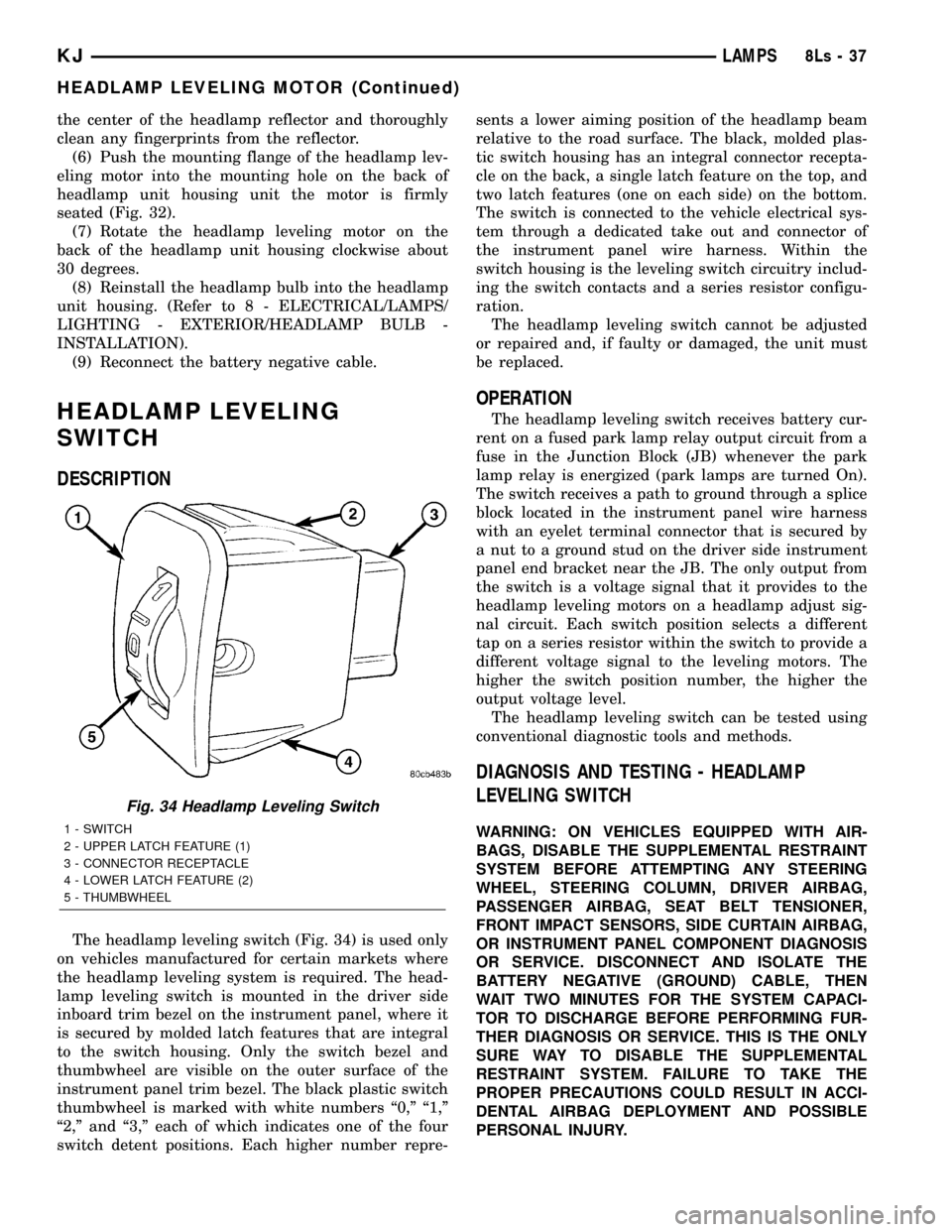

The headlamp leveling switch (Fig. 34) is used only

on vehicles manufactured for certain markets where

the headlamp leveling system is required. The head-

lamp leveling switch is mounted in the driver side

inboard trim bezel on the instrument panel, where it

is secured by molded latch features that are integral

to the switch housing. Only the switch bezel and

thumbwheel are visible on the outer surface of the

instrument panel trim bezel. The black plastic switch

thumbwheel is marked with white numbers ª0,º ª1,º

ª2,º and ª3,º each of which indicates one of the four

switch detent positions. Each higher number repre-sents a lower aiming position of the headlamp beam

relative to the road surface. The black, molded plas-

tic switch housing has an integral connector recepta-

cle on the back, a single latch feature on the top, and

two latch features (one on each side) on the bottom.

The switch is connected to the vehicle electrical sys-

tem through a dedicated take out and connector of

the instrument panel wire harness. Within the

switch housing is the leveling switch circuitry includ-

ing the switch contacts and a series resistor configu-

ration.

The headlamp leveling switch cannot be adjusted

or repaired and, if faulty or damaged, the unit must

be replaced.

OPERATION

The headlamp leveling switch receives battery cur-

rent on a fused park lamp relay output circuit from a

fuse in the Junction Block (JB) whenever the park

lamp relay is energized (park lamps are turned On).

The switch receives a path to ground through a splice

block located in the instrument panel wire harness

with an eyelet terminal connector that is secured by

a nut to a ground stud on the driver side instrument

panel end bracket near the JB. The only output from

the switch is a voltage signal that it provides to the

headlamp leveling motors on a headlamp adjust sig-

nal circuit. Each switch position selects a different

tap on a series resistor within the switch to provide a

different voltage signal to the leveling motors. The

higher the switch position number, the higher the

output voltage level.

The headlamp leveling switch can be tested using

conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - HEADLAMP

LEVELING SWITCH

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

Fig. 34 Headlamp Leveling Switch

1 - SWITCH

2 - UPPER LATCH FEATURE (1)

3 - CONNECTOR RECEPTACLE

4 - LOWER LATCH FEATURE (2)

5 - THUMBWHEEL

KJLAMPS8Ls-37

HEADLAMP LEVELING MOTOR (Continued)

Page 564 of 1803

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) From the face of the driver side inboard bezel,

align the headlamp leveling switch housing to the

mounting hole in the bezel (Fig. 36).

(2) Push the headlamp leveling switch into the

mounting hole until it is fully seated and the upper

latch and two lower latch features on the switch

housing are engaged on the back of the bezel.

(3) Position the switch and bezel unit to the

instrument panel.

(4) Reconnect the instrument panel wire harness

connector for the headlamp leveling switch to the

switch connector receptacle.

(5) Reinstall the driver side inboard bezel onto the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/INSTRUMENT PANEL DRIVER

SIDE BEZEL - INSTALLATION).

(6) Reconnect the battery negative cable.

HEADLAMP LOW BEAM RELAY

DESCRIPTION

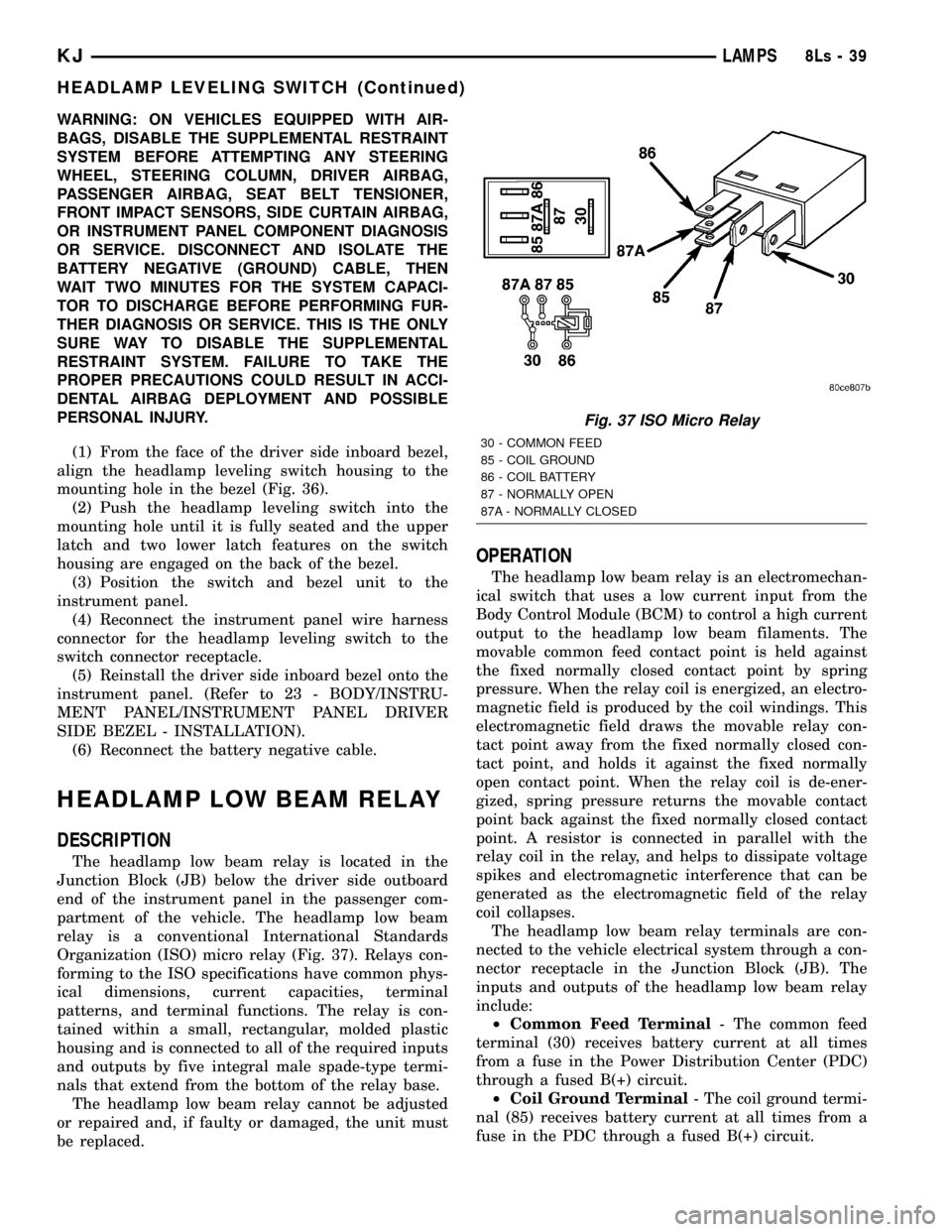

The headlamp low beam relay is located in the

Junction Block (JB) below the driver side outboard

end of the instrument panel in the passenger com-

partment of the vehicle. The headlamp low beam

relay is a conventional International Standards

Organization (ISO) micro relay (Fig. 37). Relays con-

forming to the ISO specifications have common phys-

ical dimensions, current capacities, terminal

patterns, and terminal functions. The relay is con-

tained within a small, rectangular, molded plastic

housing and is connected to all of the required inputs

and outputs by five integral male spade-type termi-

nals that extend from the bottom of the relay base.

The headlamp low beam relay cannot be adjusted

or repaired and, if faulty or damaged, the unit must

be replaced.

OPERATION

The headlamp low beam relay is an electromechan-

ical switch that uses a low current input from the

Body Control Module (BCM) to control a high current

output to the headlamp low beam filaments. The

movable common feed contact point is held against

the fixed normally closed contact point by spring

pressure. When the relay coil is energized, an electro-

magnetic field is produced by the coil windings. This

electromagnetic field draws the movable relay con-

tact point away from the fixed normally closed con-

tact point, and holds it against the fixed normally

open contact point. When the relay coil is de-ener-

gized, spring pressure returns the movable contact

point back against the fixed normally closed contact

point. A resistor is connected in parallel with the

relay coil in the relay, and helps to dissipate voltage

spikes and electromagnetic interference that can be

generated as the electromagnetic field of the relay

coil collapses.

The headlamp low beam relay terminals are con-

nected to the vehicle electrical system through a con-

nector receptacle in the Junction Block (JB). The

inputs and outputs of the headlamp low beam relay

include:

²Common Feed Terminal- The common feed

terminal (30) receives battery current at all times

from a fuse in the Power Distribution Center (PDC)

through a fused B(+) circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) receives battery current at all times from a

fuse in the PDC through a fused B(+) circuit.

Fig. 37 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

KJLAMPS8Ls-39

HEADLAMP LEVELING SWITCH (Continued)

Page 567 of 1803

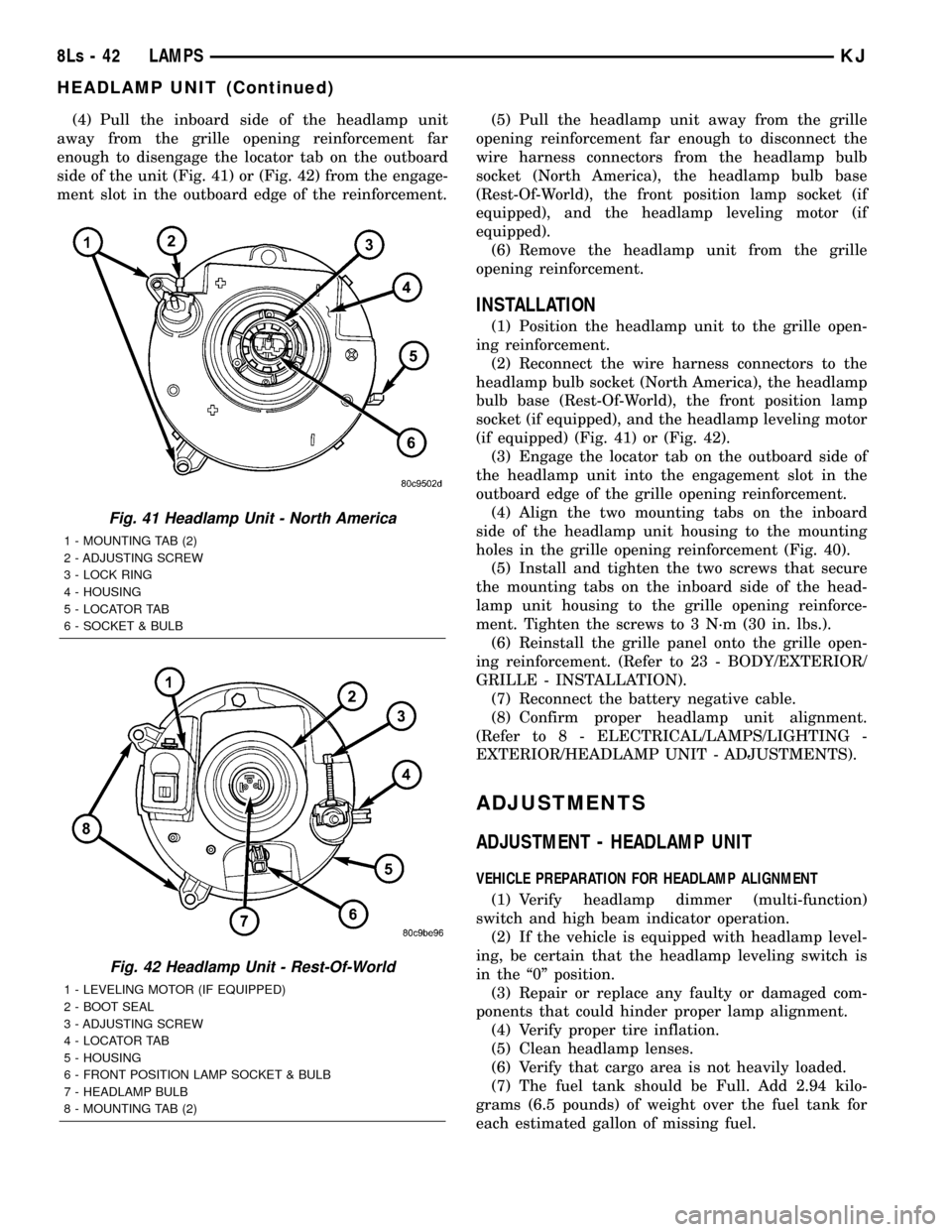

(4) Pull the inboard side of the headlamp unit

away from the grille opening reinforcement far

enough to disengage the locator tab on the outboard

side of the unit (Fig. 41) or (Fig. 42) from the engage-

ment slot in the outboard edge of the reinforcement.(5) Pull the headlamp unit away from the grille

opening reinforcement far enough to disconnect the

wire harness connectors from the headlamp bulb

socket (North America), the headlamp bulb base

(Rest-Of-World), the front position lamp socket (if

equipped), and the headlamp leveling motor (if

equipped).

(6) Remove the headlamp unit from the grille

opening reinforcement.

INSTALLATION

(1) Position the headlamp unit to the grille open-

ing reinforcement.

(2) Reconnect the wire harness connectors to the

headlamp bulb socket (North America), the headlamp

bulb base (Rest-Of-World), the front position lamp

socket (if equipped), and the headlamp leveling motor

(if equipped) (Fig. 41) or (Fig. 42).

(3) Engage the locator tab on the outboard side of

the headlamp unit into the engagement slot in the

outboard edge of the grille opening reinforcement.

(4) Align the two mounting tabs on the inboard

side of the headlamp unit housing to the mounting

holes in the grille opening reinforcement (Fig. 40).

(5) Install and tighten the two screws that secure

the mounting tabs on the inboard side of the head-

lamp unit housing to the grille opening reinforce-

ment. Tighten the screws to 3 N´m (30 in. lbs.).

(6) Reinstall the grille panel onto the grille open-

ing reinforcement. (Refer to 23 - BODY/EXTERIOR/

GRILLE - INSTALLATION).

(7) Reconnect the battery negative cable.

(8) Confirm proper headlamp unit alignment.

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

EXTERIOR/HEADLAMP UNIT - ADJUSTMENTS).

ADJUSTMENTS

ADJUSTMENT - HEADLAMP UNIT

VEHICLE PREPARATION FOR HEADLAMP ALIGNMENT

(1) Verify headlamp dimmer (multi-function)

switch and high beam indicator operation.

(2) If the vehicle is equipped with headlamp level-

ing, be certain that the headlamp leveling switch is

in the ª0º position.

(3) Repair or replace any faulty or damaged com-

ponents that could hinder proper lamp alignment.

(4) Verify proper tire inflation.

(5) Clean headlamp lenses.

(6) Verify that cargo area is not heavily loaded.

(7) The fuel tank should be Full. Add 2.94 kilo-

grams (6.5 pounds) of weight over the fuel tank for

each estimated gallon of missing fuel.

Fig. 41 Headlamp Unit - North America

1 - MOUNTING TAB (2)

2 - ADJUSTING SCREW

3 - LOCK RING

4 - HOUSING

5 - LOCATOR TAB

6 - SOCKET & BULB

Fig. 42 Headlamp Unit - Rest-Of-World

1 - LEVELING MOTOR (IF EQUIPPED)

2 - BOOT SEAL

3 - ADJUSTING SCREW

4 - LOCATOR TAB

5 - HOUSING

6 - FRONT POSITION LAMP SOCKET & BULB

7 - HEADLAMP BULB

8 - MOUNTING TAB (2)

8Ls - 42 LAMPSKJ

HEADLAMP UNIT (Continued)

Page 568 of 1803

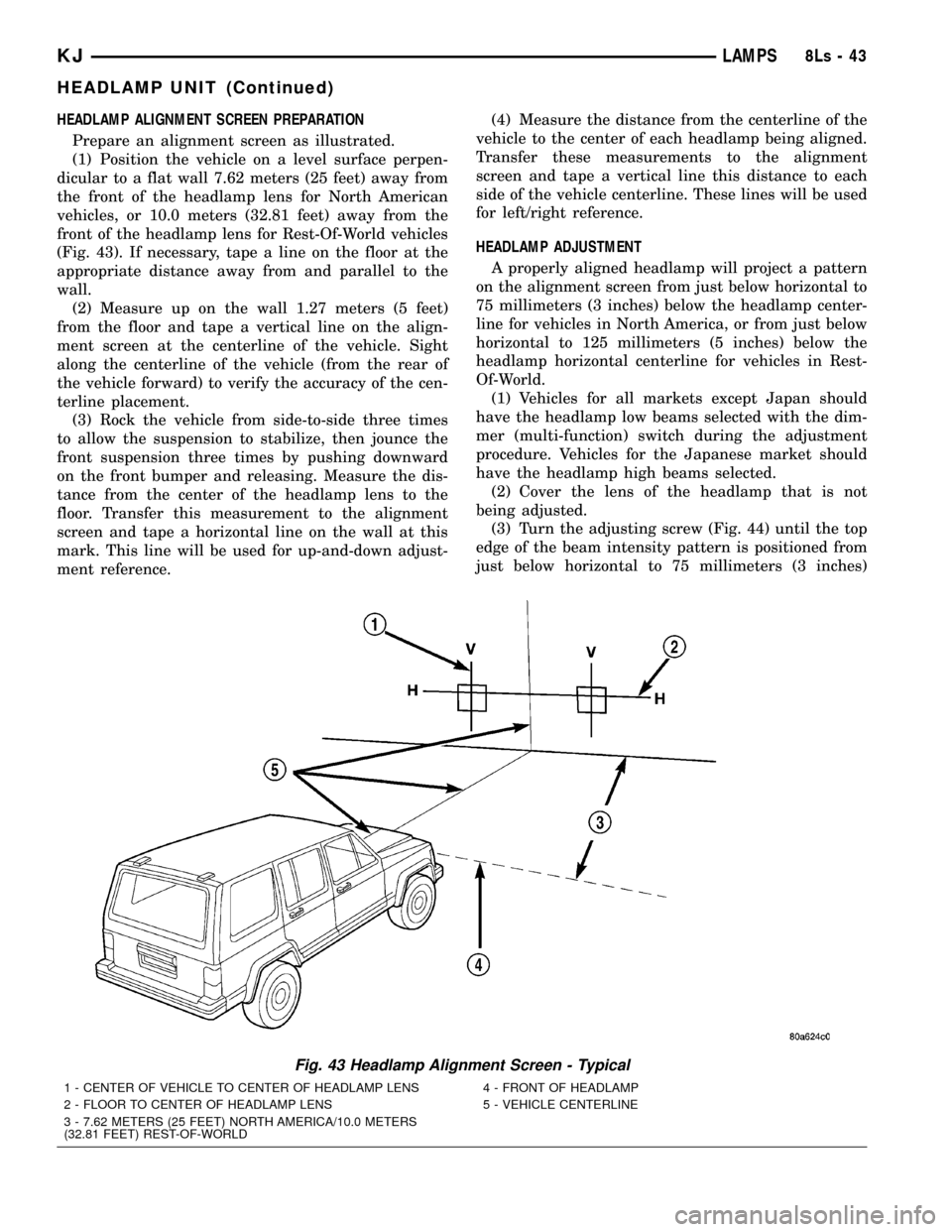

HEADLAMP ALIGNMENT SCREEN PREPARATION

Prepare an alignment screen as illustrated.

(1) Position the vehicle on a level surface perpen-

dicular to a flat wall 7.62 meters (25 feet) away from

the front of the headlamp lens for North American

vehicles, or 10.0 meters (32.81 feet) away from the

front of the headlamp lens for Rest-Of-World vehicles

(Fig. 43). If necessary, tape a line on the floor at the

appropriate distance away from and parallel to the

wall.

(2) Measure up on the wall 1.27 meters (5 feet)

from the floor and tape a vertical line on the align-

ment screen at the centerline of the vehicle. Sight

along the centerline of the vehicle (from the rear of

the vehicle forward) to verify the accuracy of the cen-

terline placement.

(3) Rock the vehicle from side-to-side three times

to allow the suspension to stabilize, then jounce the

front suspension three times by pushing downward

on the front bumper and releasing. Measure the dis-

tance from the center of the headlamp lens to the

floor. Transfer this measurement to the alignment

screen and tape a horizontal line on the wall at this

mark. This line will be used for up-and-down adjust-

ment reference.(4) Measure the distance from the centerline of the

vehicle to the center of each headlamp being aligned.

Transfer these measurements to the alignment

screen and tape a vertical line this distance to each

side of the vehicle centerline. These lines will be used

for left/right reference.

HEADLAMP ADJUSTMENT

A properly aligned headlamp will project a pattern

on the alignment screen from just below horizontal to

75 millimeters (3 inches) below the headlamp center-

line for vehicles in North America, or from just below

horizontal to 125 millimeters (5 inches) below the

headlamp horizontal centerline for vehicles in Rest-

Of-World.

(1) Vehicles for all markets except Japan should

have the headlamp low beams selected with the dim-

mer (multi-function) switch during the adjustment

procedure. Vehicles for the Japanese market should

have the headlamp high beams selected.

(2) Cover the lens of the headlamp that is not

being adjusted.

(3) Turn the adjusting screw (Fig. 44) until the top

edge of the beam intensity pattern is positioned from

just below horizontal to 75 millimeters (3 inches)

Fig. 43 Headlamp Alignment Screen - Typical

1 - CENTER OF VEHICLE TO CENTER OF HEADLAMP LENS

2 - FLOOR TO CENTER OF HEADLAMP LENS

3 - 7.62 METERS (25 FEET) NORTH AMERICA/10.0 METERS

(32.81 FEET) REST-OF-WORLD4 - FRONT OF HEADLAMP

5 - VEHICLE CENTERLINE

KJLAMPS8Ls-43

HEADLAMP UNIT (Continued)

Page 572 of 1803

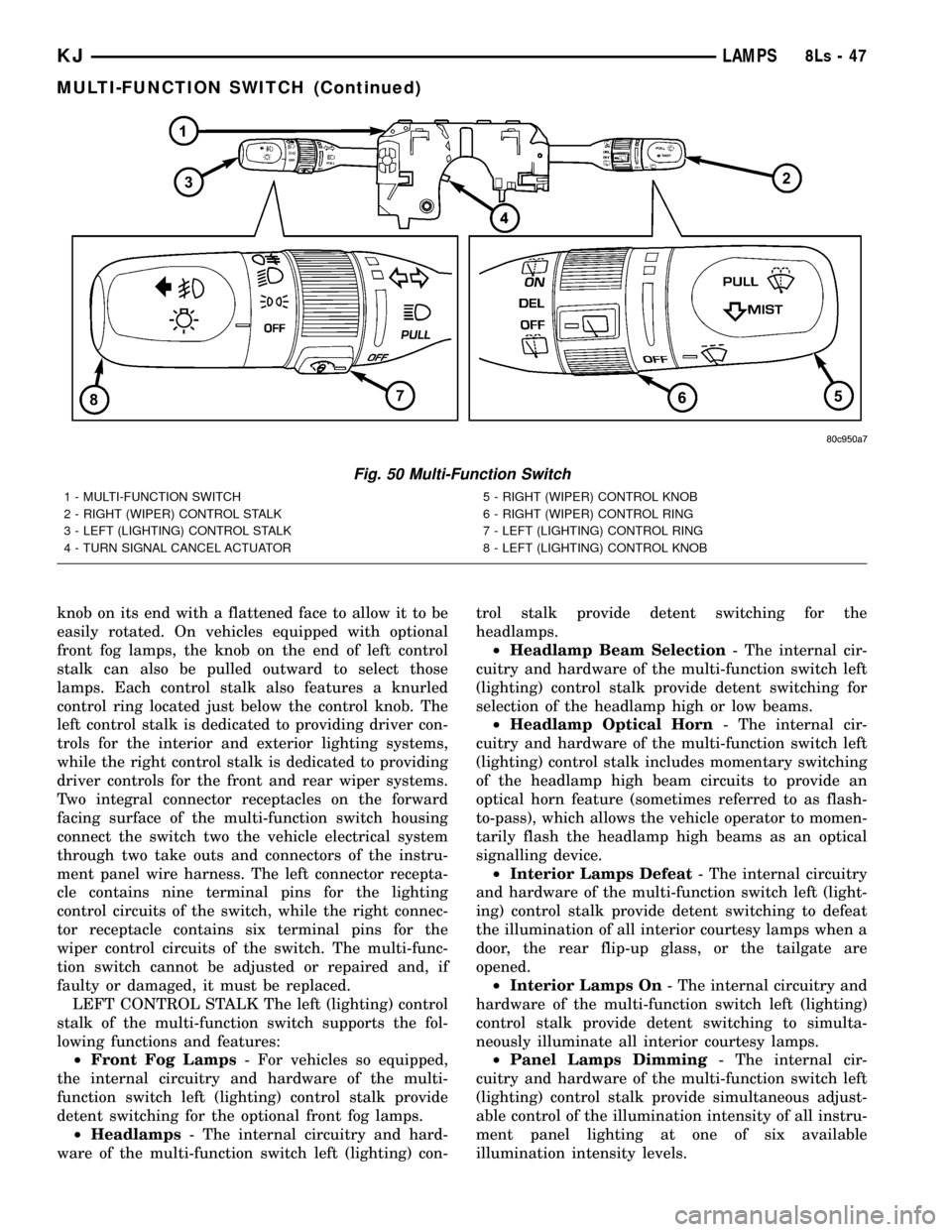

knob on its end with a flattened face to allow it to be

easily rotated. On vehicles equipped with optional

front fog lamps, the knob on the end of left control

stalk can also be pulled outward to select those

lamps. Each control stalk also features a knurled

control ring located just below the control knob. The

left control stalk is dedicated to providing driver con-

trols for the interior and exterior lighting systems,

while the right control stalk is dedicated to providing

driver controls for the front and rear wiper systems.

Two integral connector receptacles on the forward

facing surface of the multi-function switch housing

connect the switch two the vehicle electrical system

through two take outs and connectors of the instru-

ment panel wire harness. The left connector recepta-

cle contains nine terminal pins for the lighting

control circuits of the switch, while the right connec-

tor receptacle contains six terminal pins for the

wiper control circuits of the switch. The multi-func-

tion switch cannot be adjusted or repaired and, if

faulty or damaged, it must be replaced.

LEFT CONTROL STALK The left (lighting) control

stalk of the multi-function switch supports the fol-

lowing functions and features:

²Front Fog Lamps- For vehicles so equipped,

the internal circuitry and hardware of the multi-

function switch left (lighting) control stalk provide

detent switching for the optional front fog lamps.

²Headlamps- The internal circuitry and hard-

ware of the multi-function switch left (lighting) con-trol stalk provide detent switching for the

headlamps.

²Headlamp Beam Selection- The internal cir-

cuitry and hardware of the multi-function switch left

(lighting) control stalk provide detent switching for

selection of the headlamp high or low beams.

²Headlamp Optical Horn- The internal cir-

cuitry and hardware of the multi-function switch left

(lighting) control stalk includes momentary switching

of the headlamp high beam circuits to provide an

optical horn feature (sometimes referred to as flash-

to-pass), which allows the vehicle operator to momen-

tarily flash the headlamp high beams as an optical

signalling device.

²Interior Lamps Defeat- The internal circuitry

and hardware of the multi-function switch left (light-

ing) control stalk provide detent switching to defeat

the illumination of all interior courtesy lamps when a

door, the rear flip-up glass, or the tailgate are

opened.

²Interior Lamps On- The internal circuitry and

hardware of the multi-function switch left (lighting)

control stalk provide detent switching to simulta-

neously illuminate all interior courtesy lamps.

²Panel Lamps Dimming- The internal cir-

cuitry and hardware of the multi-function switch left

(lighting) control stalk provide simultaneous adjust-

able control of the illumination intensity of all instru-

ment panel lighting at one of six available

illumination intensity levels.

Fig. 50 Multi-Function Switch

1 - MULTI-FUNCTION SWITCH

2 - RIGHT (WIPER) CONTROL STALK

3 - LEFT (LIGHTING) CONTROL STALK

4 - TURN SIGNAL CANCEL ACTUATOR5 - RIGHT (WIPER) CONTROL KNOB

6 - RIGHT (WIPER) CONTROL RING

7 - LEFT (LIGHTING) CONTROL RING

8 - LEFT (LIGHTING) CONTROL KNOB

KJLAMPS8Ls-47

MULTI-FUNCTION SWITCH (Continued)

Page 573 of 1803

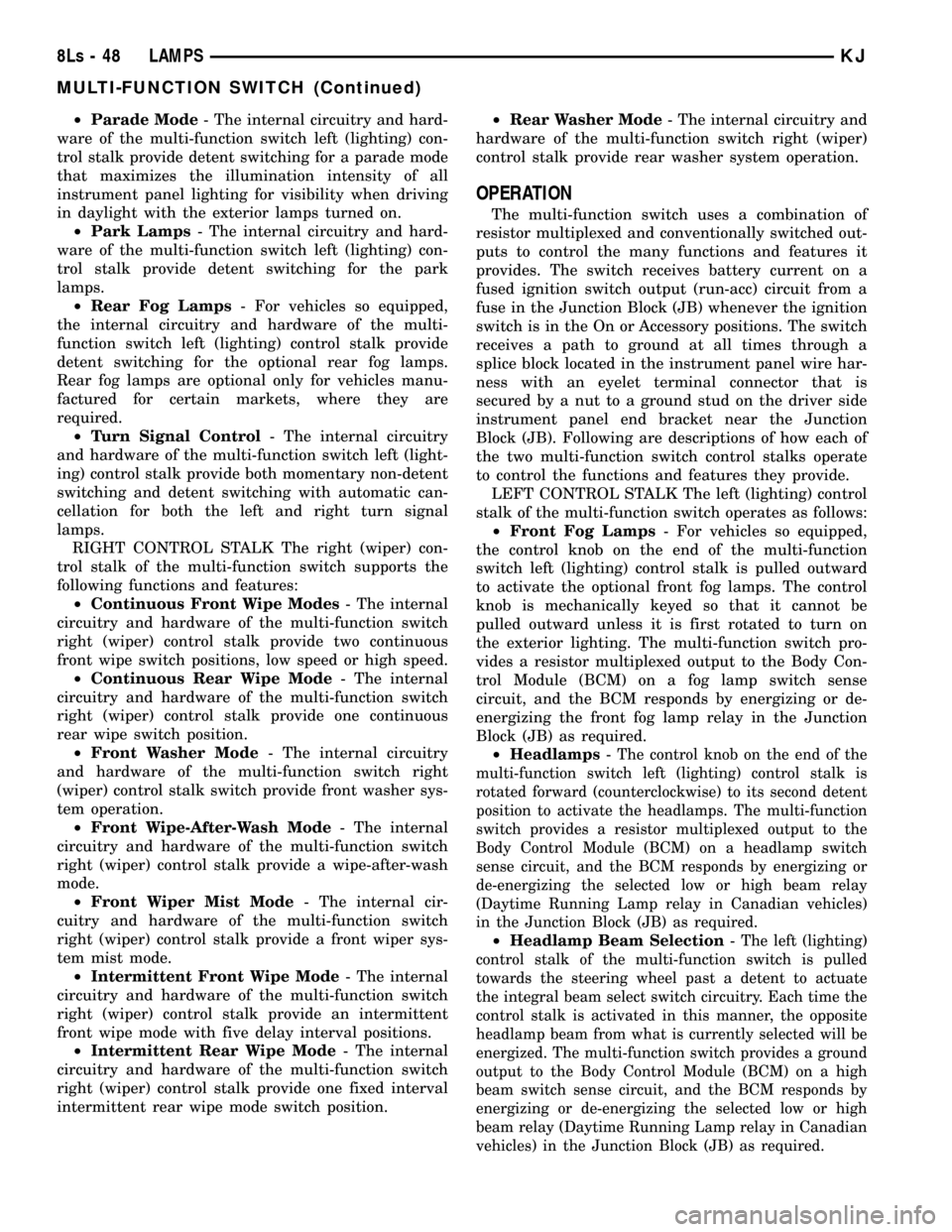

²Parade Mode- The internal circuitry and hard-

ware of the multi-function switch left (lighting) con-

trol stalk provide detent switching for a parade mode

that maximizes the illumination intensity of all

instrument panel lighting for visibility when driving

in daylight with the exterior lamps turned on.

²Park Lamps- The internal circuitry and hard-

ware of the multi-function switch left (lighting) con-

trol stalk provide detent switching for the park

lamps.

²Rear Fog Lamps- For vehicles so equipped,

the internal circuitry and hardware of the multi-

function switch left (lighting) control stalk provide

detent switching for the optional rear fog lamps.

Rear fog lamps are optional only for vehicles manu-

factured for certain markets, where they are

required.

²Turn Signal Control- The internal circuitry

and hardware of the multi-function switch left (light-

ing) control stalk provide both momentary non-detent

switching and detent switching with automatic can-

cellation for both the left and right turn signal

lamps.

RIGHT CONTROL STALK The right (wiper) con-

trol stalk of the multi-function switch supports the

following functions and features:

²Continuous Front Wipe Modes- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide two continuous

front wipe switch positions, low speed or high speed.

²Continuous Rear Wipe Mode- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide one continuous

rear wipe switch position.

²Front Washer Mode- The internal circuitry

and hardware of the multi-function switch right

(wiper) control stalk switch provide front washer sys-

tem operation.

²Front Wipe-After-Wash Mode- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide a wipe-after-wash

mode.

²Front Wiper Mist Mode- The internal cir-

cuitry and hardware of the multi-function switch

right (wiper) control stalk provide a front wiper sys-

tem mist mode.

²Intermittent Front Wipe Mode- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide an intermittent

front wipe mode with five delay interval positions.

²Intermittent Rear Wipe Mode- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide one fixed interval

intermittent rear wipe mode switch position.²Rear Washer Mode- The internal circuitry and

hardware of the multi-function switch right (wiper)

control stalk provide rear washer system operation.

OPERATION

The multi-function switch uses a combination of

resistor multiplexed and conventionally switched out-

puts to control the many functions and features it

provides. The switch receives battery current on a

fused ignition switch output (run-acc) circuit from a

fuse in the Junction Block (JB) whenever the ignition

switch is in the On or Accessory positions. The switch

receives a path to ground at all times through a

splice block located in the instrument panel wire har-

ness with an eyelet terminal connector that is

secured by a nut to a ground stud on the driver side

instrument panel end bracket near the Junction

Block (JB). Following are descriptions of how each of

the two multi-function switch control stalks operate

to control the functions and features they provide.

LEFT CONTROL STALK The left (lighting) control

stalk of the multi-function switch operates as follows:

²Front Fog Lamps- For vehicles so equipped,

the control knob on the end of the multi-function

switch left (lighting) control stalk is pulled outward

to activate the optional front fog lamps. The control

knob is mechanically keyed so that it cannot be

pulled outward unless it is first rotated to turn on

the exterior lighting. The multi-function switch pro-

vides a resistor multiplexed output to the Body Con-

trol Module (BCM) on a fog lamp switch sense

circuit, and the BCM responds by energizing or de-

energizing the front fog lamp relay in the Junction

Block (JB) as required.

²Headlamps-

The control knob on the end of the

multi-function switch left (lighting) control stalk is

rotated forward (counterclockwise) to its second detent

position to activate the headlamps. The multi-function

switch provides a resistor multiplexed output to the

Body Control Module (BCM) on a headlamp switch

sense circuit, and the BCM responds by energizing or

de-energizing the selected low or high beam relay

(Daytime Running Lamp relay in Canadian vehicles)

in the Junction Block (JB) as required.

²Headlamp Beam Selection-The left (lighting)

control stalk of the multi-function switch is pulled

towards the steering wheel past a detent to actuate

the integral beam select switch circuitry. Each time the

control stalk is activated in this manner, the opposite

headlamp beam from what is currently selected will be

energized. The multi-function switch provides a ground

output to the Body Control Module (BCM) on a high

beam switch sense circuit, and the BCM responds by

energizing or de-energizing the selected low or high

beam relay (Daytime Running Lamp relay in Canadian

vehicles) in the Junction Block (JB) as required.

8Ls - 48 LAMPSKJ

MULTI-FUNCTION SWITCH (Continued)