removal JEEP LIBERTY 2002 KJ / 1.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 115 of 1803

AXLE BEARING/SEAL

REMOVAL

(1) Remove axle shaft from vehicle.

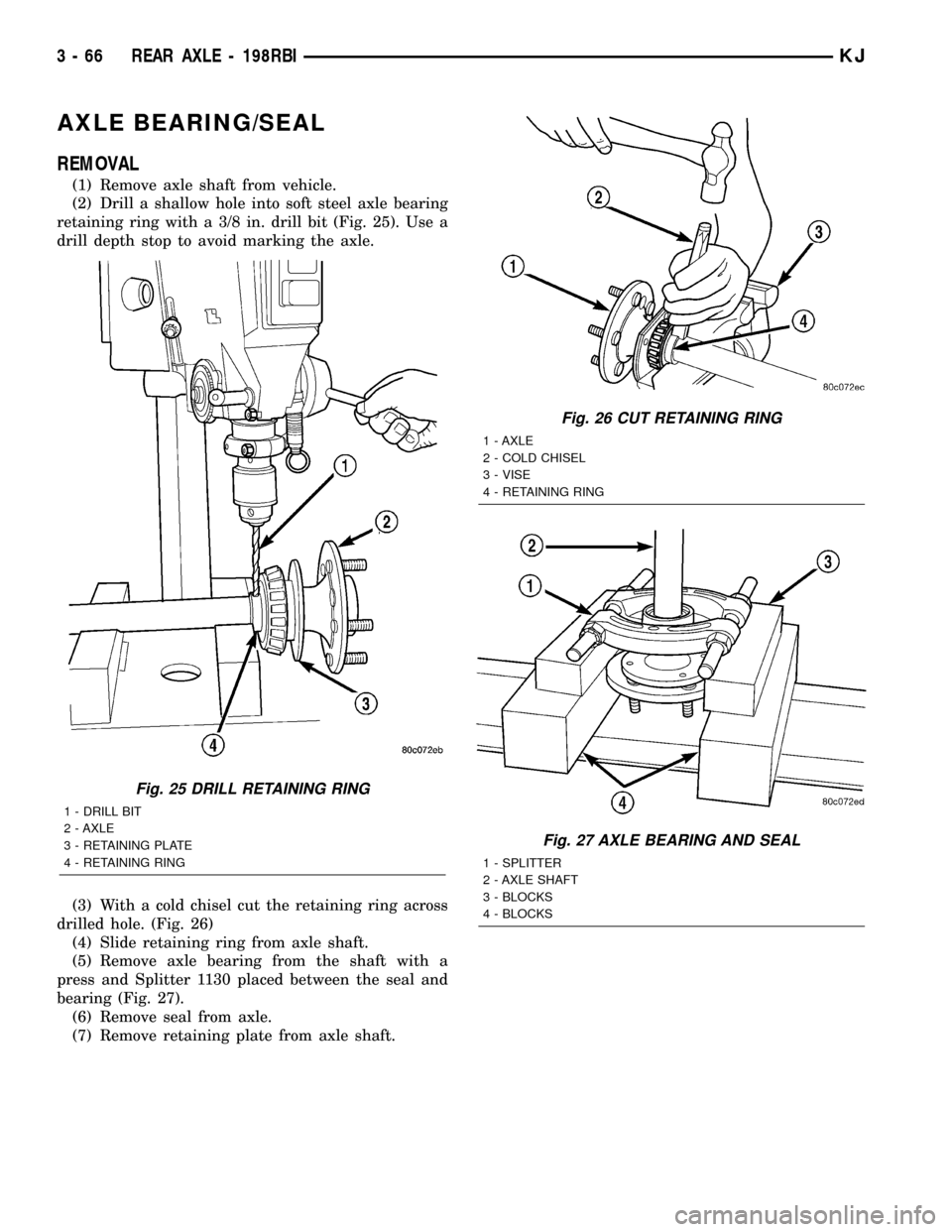

(2) Drill a shallow hole into soft steel axle bearing

retaining ring with a 3/8 in. drill bit (Fig. 25). Use a

drill depth stop to avoid marking the axle.

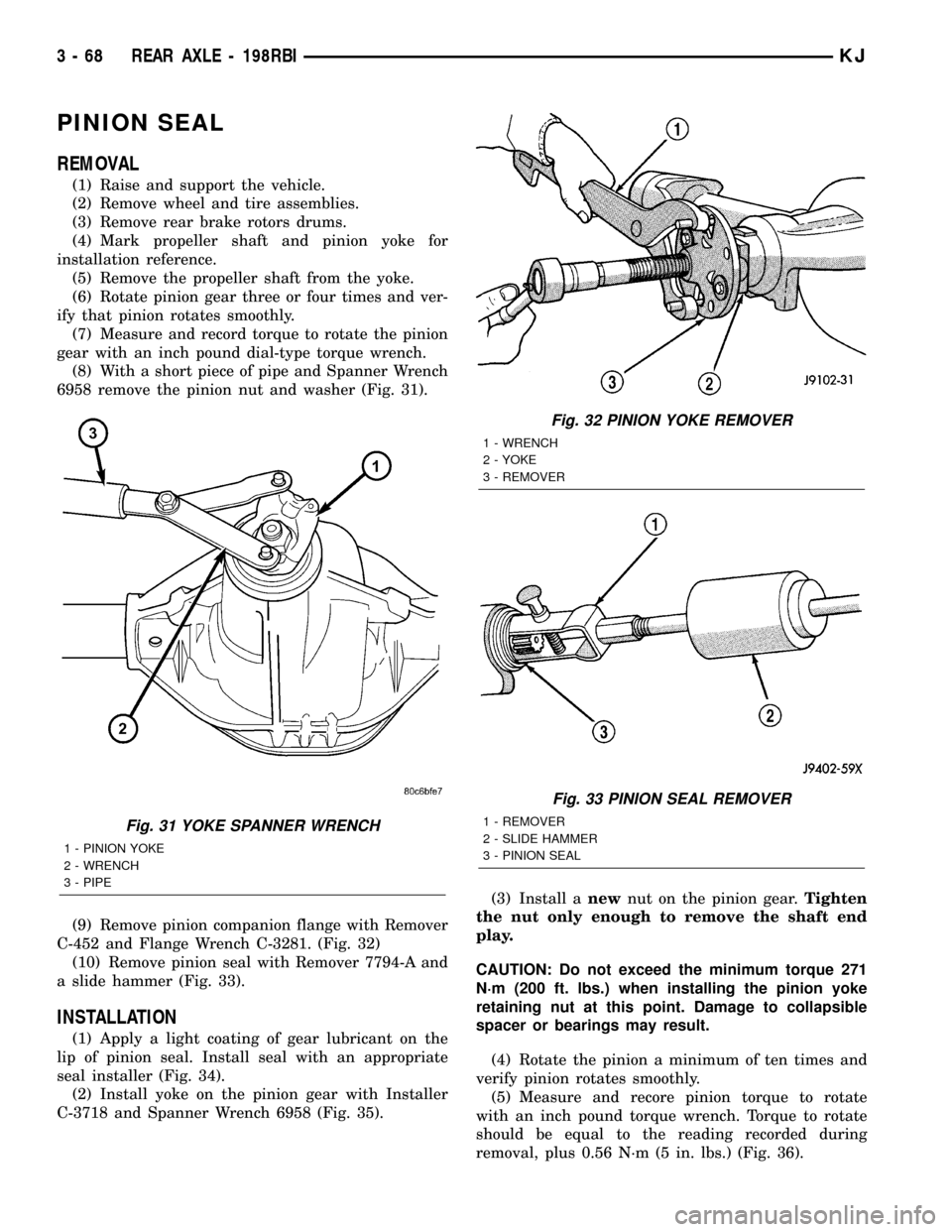

(3) With a cold chisel cut the retaining ring across

drilled hole. (Fig. 26)

(4) Slide retaining ring from axle shaft.

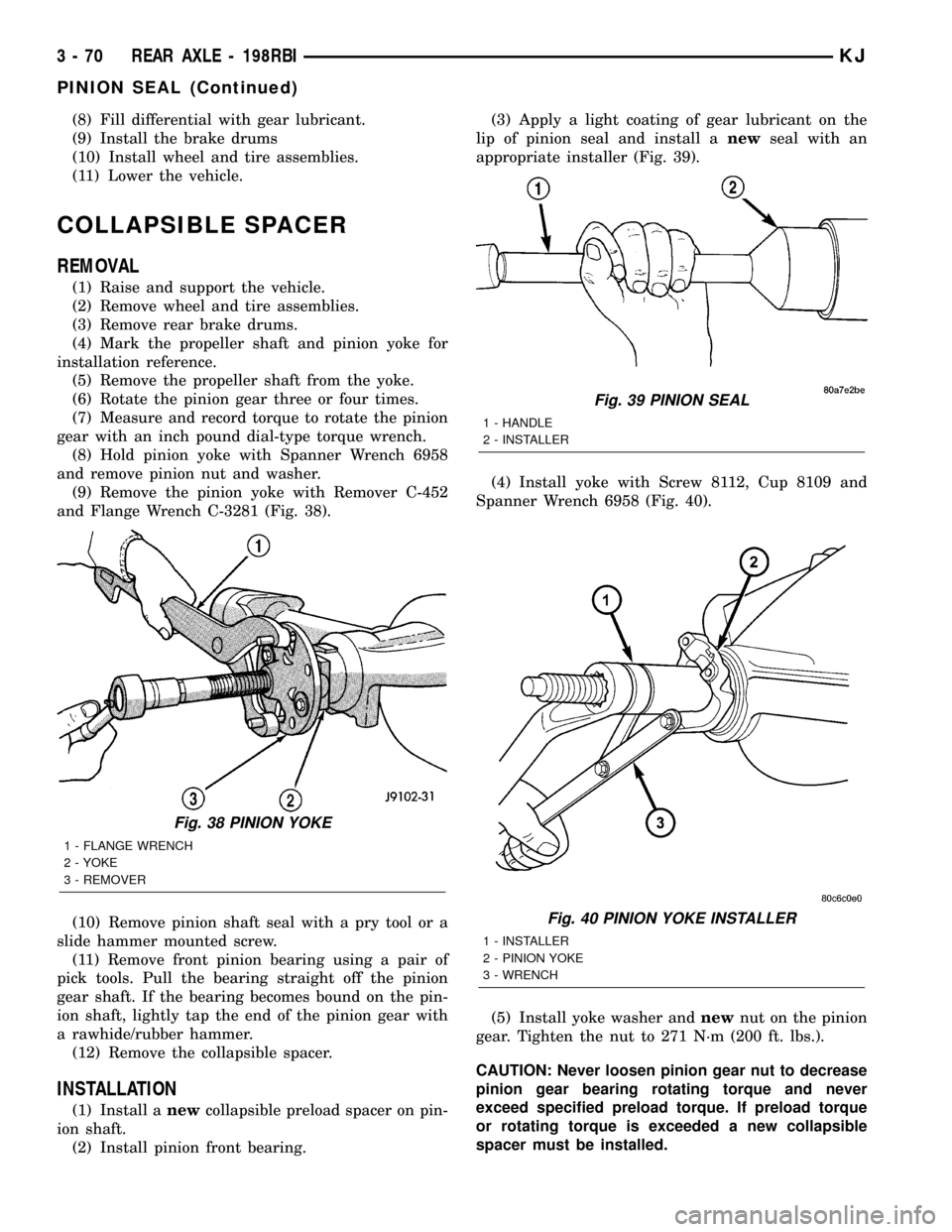

(5) Remove axle bearing from the shaft with a

press and Splitter 1130 placed between the seal and

bearing (Fig. 27).

(6) Remove seal from axle.

(7) Remove retaining plate from axle shaft.

Fig. 25 DRILL RETAINING RING

1 - DRILL BIT

2 - AXLE

3 - RETAINING PLATE

4 - RETAINING RING

Fig. 26 CUT RETAINING RING

1 - AXLE

2 - COLD CHISEL

3 - VISE

4 - RETAINING RING

Fig. 27 AXLE BEARING AND SEAL

1 - SPLITTER

2 - AXLE SHAFT

3 - BLOCKS

4 - BLOCKS

3 - 66 REAR AXLE - 198RBIKJ

Page 117 of 1803

PINION SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove rear brake rotors drums.

(4) Mark propeller shaft and pinion yoke for

installation reference.

(5) Remove the propeller shaft from the yoke.

(6) Rotate pinion gear three or four times and ver-

ify that pinion rotates smoothly.

(7) Measure and record torque to rotate the pinion

gear with an inch pound dial-type torque wrench.

(8) With a short piece of pipe and Spanner Wrench

6958 remove the pinion nut and washer (Fig. 31).

(9) Remove pinion companion flange with Remover

C-452 and Flange Wrench C-3281. (Fig. 32)

(10) Remove pinion seal with Remover 7794-A and

a slide hammer (Fig. 33).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with an appropriate

seal installer (Fig. 34).

(2) Install yoke on the pinion gear with Installer

C-3718 and Spanner Wrench 6958 (Fig. 35).(3) Install anewnut on the pinion gear.Tighten

the nut only enough to remove the shaft end

play.

CAUTION: Do not exceed the minimum torque 271

N´m (200 ft. lbs.) when installing the pinion yoke

retaining nut at this point. Damage to collapsible

spacer or bearings may result.

(4) Rotate the pinion a minimum of ten times and

verify pinion rotates smoothly.

(5) Measure and recore pinion torque to rotate

with an inch pound torque wrench. Torque to rotate

should be equal to the reading recorded during

removal, plus 0.56 N´m (5 in. lbs.) (Fig. 36).

Fig. 31 YOKE SPANNER WRENCH

1 - PINION YOKE

2 - WRENCH

3 - PIPE

Fig. 32 PINION YOKE REMOVER

1 - WRENCH

2 - YOKE

3 - REMOVER

Fig. 33 PINION SEAL REMOVER

1 - REMOVER

2 - SLIDE HAMMER

3 - PINION SEAL

3 - 68 REAR AXLE - 198RBIKJ

Page 119 of 1803

(8) Fill differential with gear lubricant.

(9) Install the brake drums

(10) Install wheel and tire assemblies.

(11) Lower the vehicle.

COLLAPSIBLE SPACER

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove rear brake drums.

(4) Mark the propeller shaft and pinion yoke for

installation reference.

(5) Remove the propeller shaft from the yoke.

(6) Rotate the pinion gear three or four times.

(7) Measure and record torque to rotate the pinion

gear with an inch pound dial-type torque wrench.

(8) Hold pinion yoke with Spanner Wrench 6958

and remove pinion nut and washer.

(9) Remove the pinion yoke with Remover C-452

and Flange Wrench C-3281 (Fig. 38).

(10) Remove pinion shaft seal with a pry tool or a

slide hammer mounted screw.

(11) Remove front pinion bearing using a pair of

pick tools. Pull the bearing straight off the pinion

gear shaft. If the bearing becomes bound on the pin-

ion shaft, lightly tap the end of the pinion gear with

a rawhide/rubber hammer.

(12) Remove the collapsible spacer.

INSTALLATION

(1) Install anewcollapsible preload spacer on pin-

ion shaft.

(2) Install pinion front bearing.(3) Apply a light coating of gear lubricant on the

lip of pinion seal and install anewseal with an

appropriate installer (Fig. 39).

(4) Install yoke with Screw 8112, Cup 8109 and

Spanner Wrench 6958 (Fig. 40).

(5) Install yoke washer andnewnut on the pinion

gear. Tighten the nut to 271 N´m (200 ft. lbs.).

CAUTION: Never loosen pinion gear nut to decrease

pinion gear bearing rotating torque and never

exceed specified preload torque. If preload torque

or rotating torque is exceeded a new collapsible

spacer must be installed.

Fig. 38 PINION YOKE

1 - FLANGE WRENCH

2 - YOKE

3 - REMOVER

Fig. 39 PINION SEAL

1 - HANDLE

2 - INSTALLER

Fig. 40 PINION YOKE INSTALLER

1 - INSTALLER

2 - PINION YOKE

3 - WRENCH

3 - 70 REAR AXLE - 198RBIKJ

PINION SEAL (Continued)

Page 120 of 1803

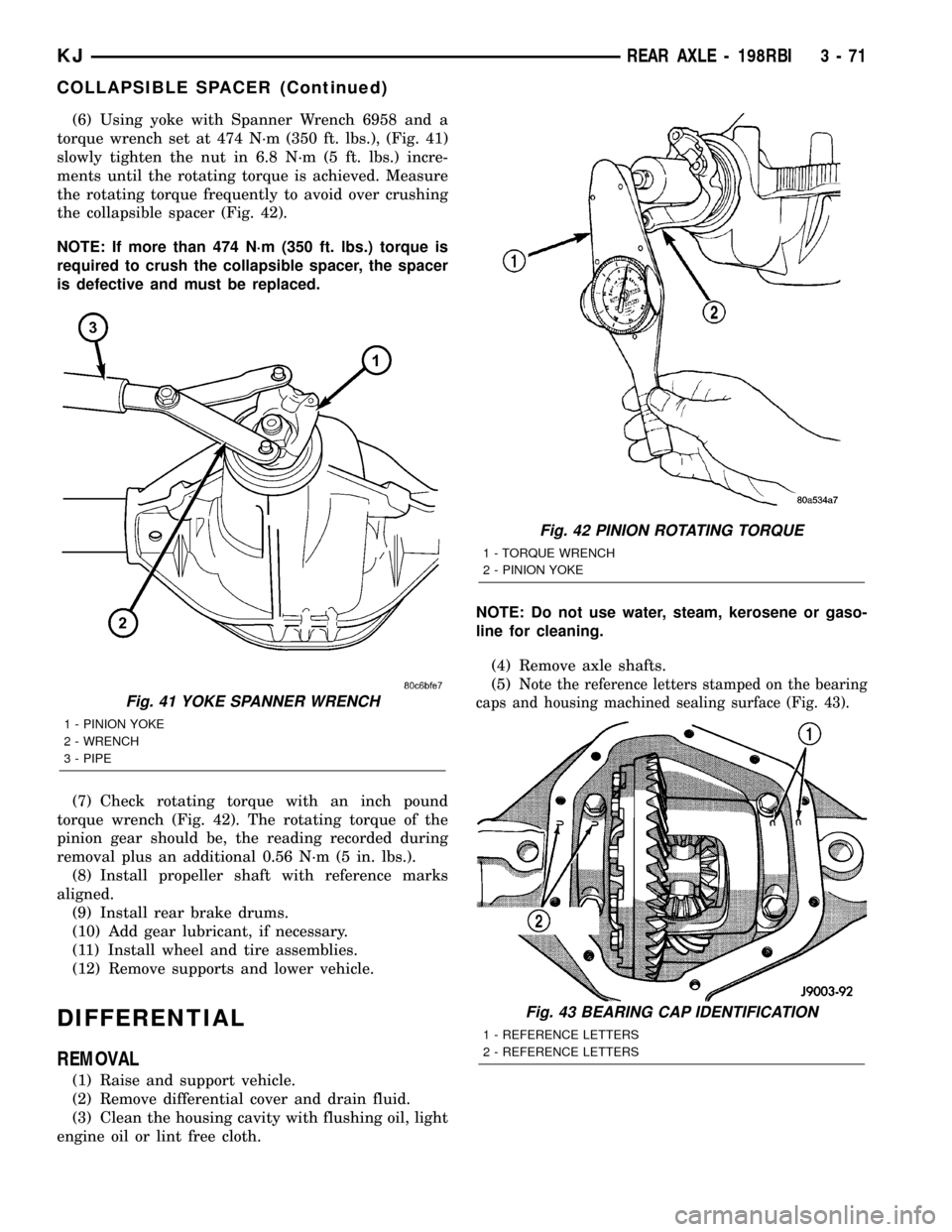

(6) Using yoke with Spanner Wrench 6958 and a

torque wrench set at 474 N´m (350 ft. lbs.), (Fig. 41)

slowly tighten the nut in 6.8 N´m (5 ft. lbs.) incre-

ments until the rotating torque is achieved. Measure

the rotating torque frequently to avoid over crushing

the collapsible spacer (Fig. 42).

NOTE: If more than 474 N´m (350 ft. lbs.) torque is

required to crush the collapsible spacer, the spacer

is defective and must be replaced.

(7) Check rotating torque with an inch pound

torque wrench (Fig. 42). The rotating torque of the

pinion gear should be, the reading recorded during

removal plus an additional 0.56 N´m (5 in. lbs.).

(8) Install propeller shaft with reference marks

aligned.

(9) Install rear brake drums.

(10) Add gear lubricant, if necessary.

(11) Install wheel and tire assemblies.

(12) Remove supports and lower vehicle.

DIFFERENTIAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove differential cover and drain fluid.

(3) Clean the housing cavity with flushing oil, light

engine oil or lint free cloth.NOTE: Do not use water, steam, kerosene or gaso-

line for cleaning.

(4) Remove axle shafts.

(5)

Note the reference letters stamped on the bearing

caps and housing machined sealing surface (Fig. 43).

Fig. 41 YOKE SPANNER WRENCH

1 - PINION YOKE

2 - WRENCH

3 - PIPE

Fig. 42 PINION ROTATING TORQUE

1 - TORQUE WRENCH

2 - PINION YOKE

Fig. 43 BEARING CAP IDENTIFICATION

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

KJREAR AXLE - 198RBI 3 - 71

COLLAPSIBLE SPACER (Continued)

Page 126 of 1803

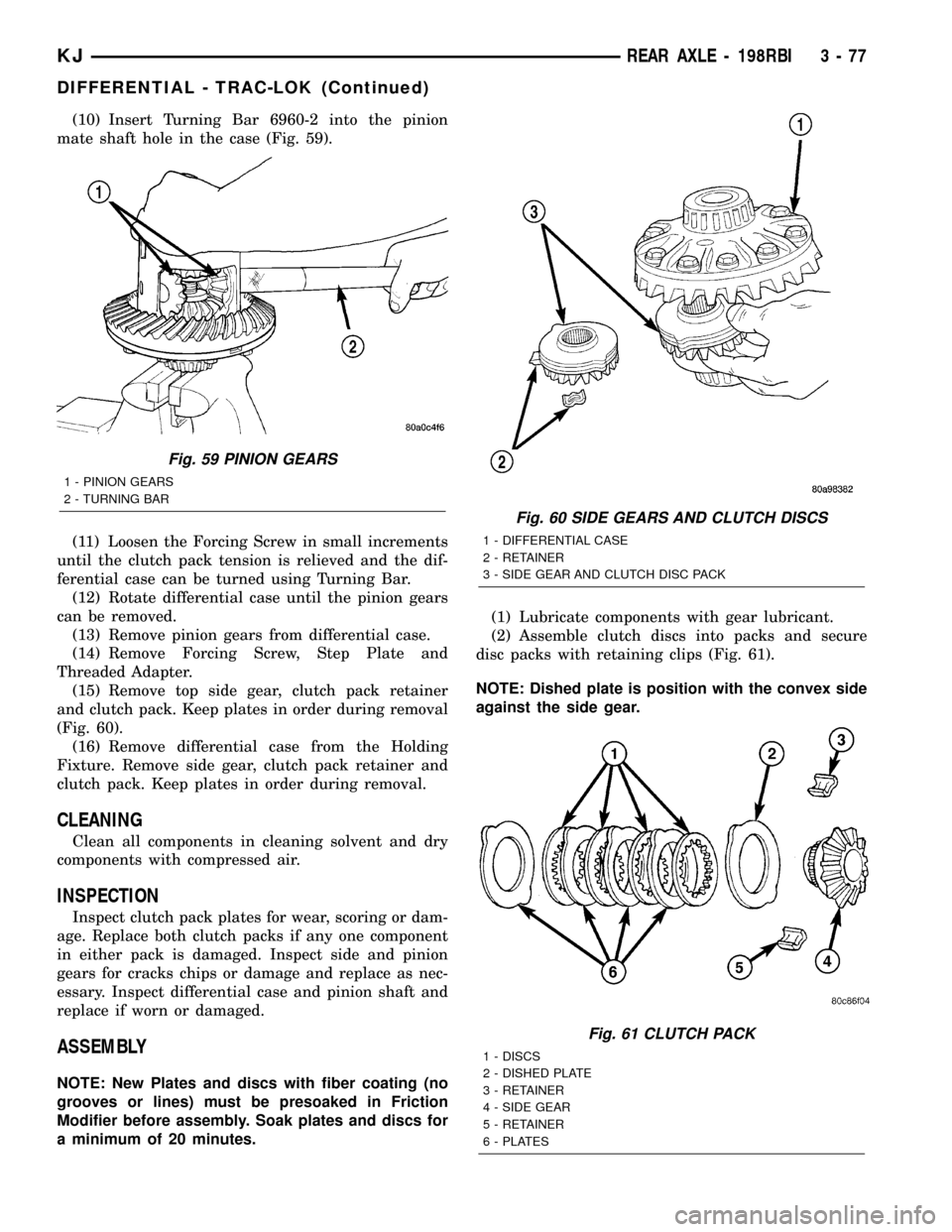

(10) Insert Turning Bar 6960-2 into the pinion

mate shaft hole in the case (Fig. 59).

(11) Loosen the Forcing Screw in small increments

until the clutch pack tension is relieved and the dif-

ferential case can be turned using Turning Bar.

(12) Rotate differential case until the pinion gears

can be removed.

(13) Remove pinion gears from differential case.

(14) Remove Forcing Screw, Step Plate and

Threaded Adapter.

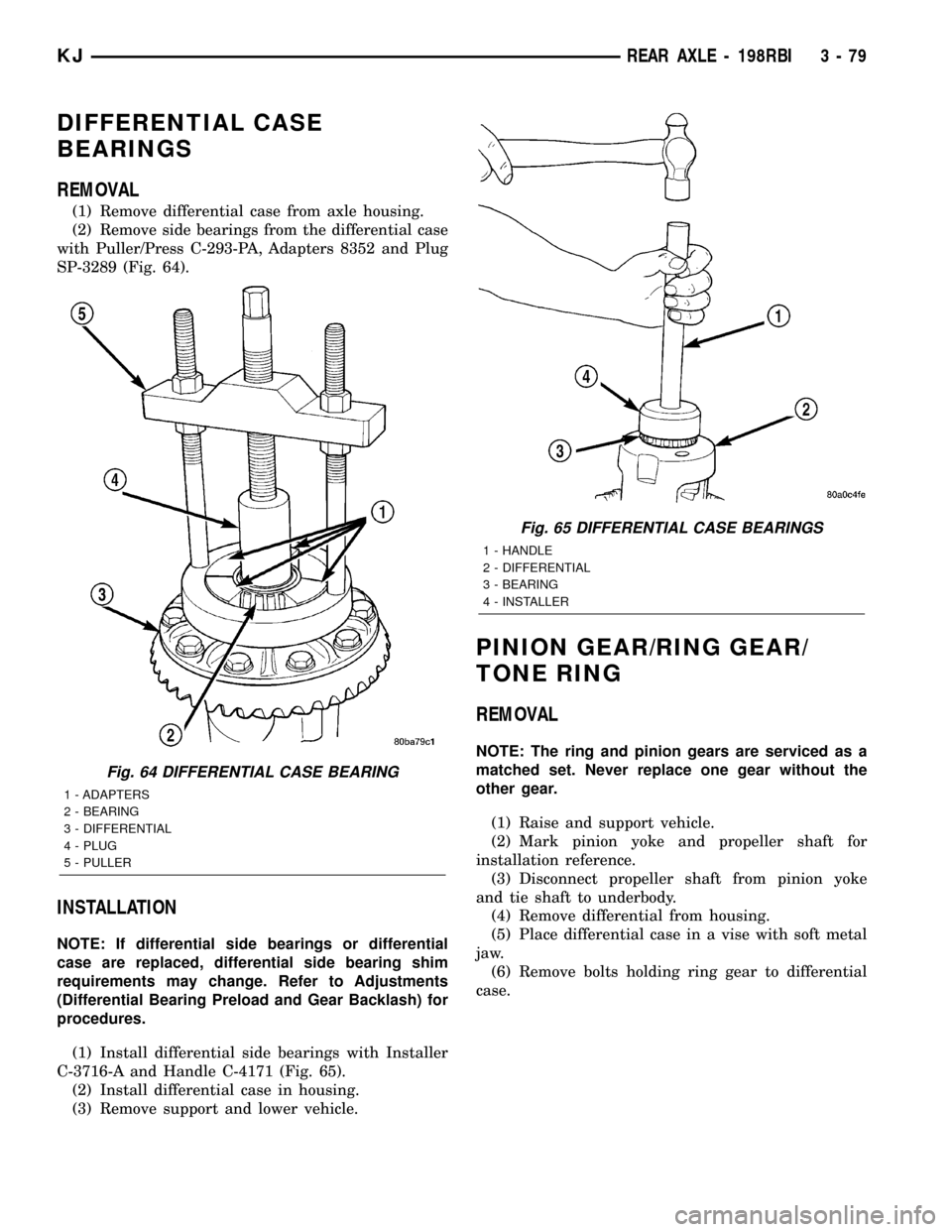

(15) Remove top side gear, clutch pack retainer

and clutch pack. Keep plates in order during removal

(Fig. 60).

(16) Remove differential case from the Holding

Fixture. Remove side gear, clutch pack retainer and

clutch pack. Keep plates in order during removal.

CLEANING

Clean all components in cleaning solvent and dry

components with compressed air.

INSPECTION

Inspect clutch pack plates for wear, scoring or dam-

age. Replace both clutch packs if any one component

in either pack is damaged. Inspect side and pinion

gears for cracks chips or damage and replace as nec-

essary. Inspect differential case and pinion shaft and

replace if worn or damaged.

ASSEMBLY

NOTE: New Plates and discs with fiber coating (no

grooves or lines) must be presoaked in Friction

Modifier before assembly. Soak plates and discs for

a minimum of 20 minutes.(1) Lubricate components with gear lubricant.

(2) Assemble clutch discs into packs and secure

disc packs with retaining clips (Fig. 61).

NOTE: Dished plate is position with the convex side

against the side gear.

Fig. 59 PINION GEARS

1 - PINION GEARS

2 - TURNING BAR

Fig. 60 SIDE GEARS AND CLUTCH DISCS

1 - DIFFERENTIAL CASE

2 - RETAINER

3 - SIDE GEAR AND CLUTCH DISC PACK

Fig. 61 CLUTCH PACK

1 - DISCS

2 - DISHED PLATE

3 - RETAINER

4 - SIDE GEAR

5 - RETAINER

6 - PLATES

KJREAR AXLE - 198RBI 3 - 77

DIFFERENTIAL - TRAC-LOK (Continued)

Page 128 of 1803

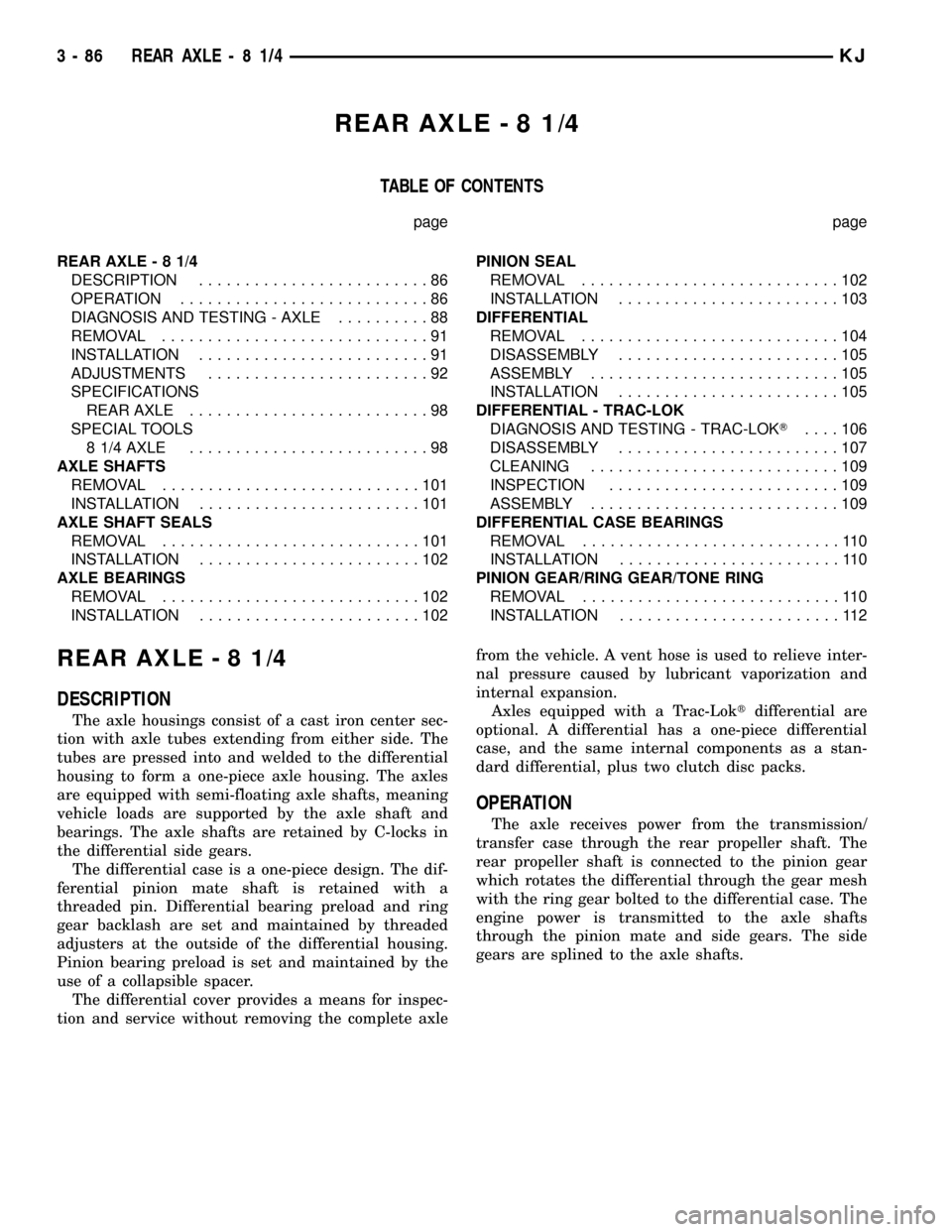

DIFFERENTIAL CASE

BEARINGS

REMOVAL

(1) Remove differential case from axle housing.

(2) Remove side bearings from the differential case

with Puller/Press C-293-PA, Adapters 8352 and Plug

SP-3289 (Fig. 64).

INSTALLATION

NOTE: If differential side bearings or differential

case are replaced, differential side bearing shim

requirements may change. Refer to Adjustments

(Differential Bearing Preload and Gear Backlash) for

procedures.

(1) Install differential side bearings with Installer

C-3716-A and Handle C-4171 (Fig. 65).

(2) Install differential case in housing.

(3) Remove support and lower vehicle.

PINION GEAR/RING GEAR/

TONE RING

REMOVAL

NOTE: The ring and pinion gears are serviced as a

matched set. Never replace one gear without the

other gear.

(1) Raise and support vehicle.

(2) Mark pinion yoke and propeller shaft for

installation reference.

(3) Disconnect propeller shaft from pinion yoke

and tie shaft to underbody.

(4) Remove differential from housing.

(5) Place differential case in a vise with soft metal

jaw.

(6) Remove bolts holding ring gear to differential

case.

Fig. 64 DIFFERENTIAL CASE BEARING

1 - ADAPTERS

2 - BEARING

3 - DIFFERENTIAL

4 - PLUG

5 - PULLER

Fig. 65 DIFFERENTIAL CASE BEARINGS

1 - HANDLE

2 - DIFFERENTIAL

3 - BEARING

4 - INSTALLER

KJREAR AXLE - 198RBI 3 - 79

Page 135 of 1803

REAR AXLE-81/4

TABLE OF CONTENTS

page page

REAR AXLE-81/4

DESCRIPTION.........................86

OPERATION...........................86

DIAGNOSIS AND TESTING - AXLE..........88

REMOVAL.............................91

INSTALLATION.........................91

ADJUSTMENTS........................92

SPECIFICATIONS

REAR AXLE..........................98

SPECIAL TOOLS

8 1/4 AXLE..........................98

AXLE SHAFTS

REMOVAL............................101

INSTALLATION........................101

AXLE SHAFT SEALS

REMOVAL............................101

INSTALLATION........................102

AXLE BEARINGS

REMOVAL............................102

INSTALLATION........................102PINION SEAL

REMOVAL............................102

INSTALLATION........................103

DIFFERENTIAL

REMOVAL............................104

DISASSEMBLY........................105

ASSEMBLY...........................105

INSTALLATION........................105

DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING - TRAC-LOKT....106

DISASSEMBLY........................107

CLEANING...........................109

INSPECTION.........................109

ASSEMBLY...........................109

DIFFERENTIAL CASE BEARINGS

REMOVAL............................110

INSTALLATION........................110

PINION GEAR/RING GEAR/TONE RING

REMOVAL............................110

INSTALLATION........................112

REAR AXLE-81/4

DESCRIPTION

The axle housings consist of a cast iron center sec-

tion with axle tubes extending from either side. The

tubes are pressed into and welded to the differential

housing to form a one-piece axle housing. The axles

are equipped with semi-floating axle shafts, meaning

vehicle loads are supported by the axle shaft and

bearings. The axle shafts are retained by C-locks in

the differential side gears.

The differential case is a one-piece design. The dif-

ferential pinion mate shaft is retained with a

threaded pin. Differential bearing preload and ring

gear backlash are set and maintained by threaded

adjusters at the outside of the differential housing.

Pinion bearing preload is set and maintained by the

use of a collapsible spacer.

The differential cover provides a means for inspec-

tion and service without removing the complete axlefrom the vehicle. A vent hose is used to relieve inter-

nal pressure caused by lubricant vaporization and

internal expansion.

Axles equipped with a Trac-Loktdifferential are

optional. A differential has a one-piece differential

case, and the same internal components as a stan-

dard differential, plus two clutch disc packs.

OPERATION

The axle receives power from the transmission/

transfer case through the rear propeller shaft. The

rear propeller shaft is connected to the pinion gear

which rotates the differential through the gear mesh

with the ring gear bolted to the differential case. The

engine power is transmitted to the axle shafts

through the pinion mate and side gears. The side

gears are splined to the axle shafts.

3 - 86 REAR AXLE-81/4KJ

Page 140 of 1803

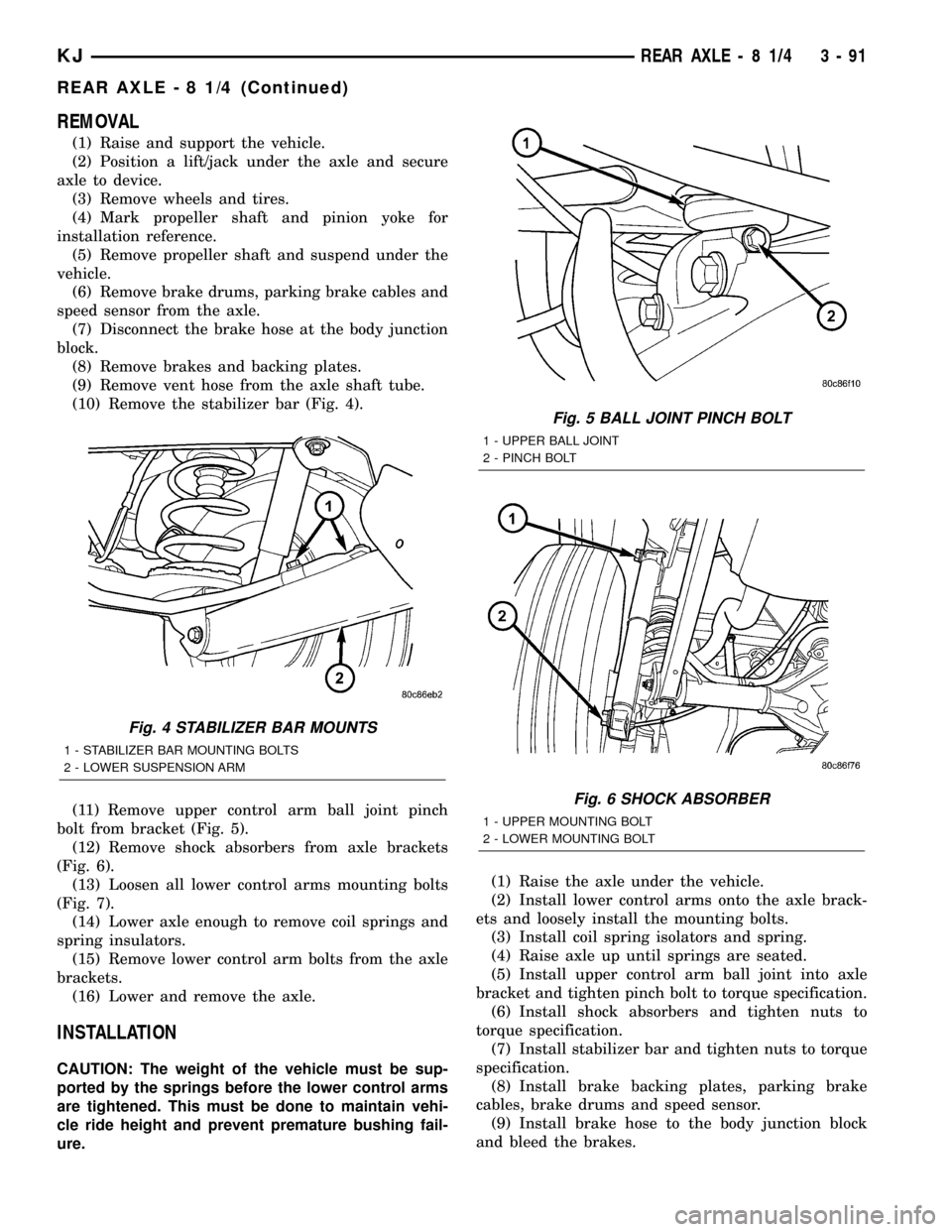

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lift/jack under the axle and secure

axle to device.

(3) Remove wheels and tires.

(4) Mark propeller shaft and pinion yoke for

installation reference.

(5) Remove propeller shaft and suspend under the

vehicle.

(6) Remove brake drums, parking brake cables and

speed sensor from the axle.

(7) Disconnect the brake hose at the body junction

block.

(8) Remove brakes and backing plates.

(9) Remove vent hose from the axle shaft tube.

(10) Remove the stabilizer bar (Fig. 4).

(11) Remove upper control arm ball joint pinch

bolt from bracket (Fig. 5).

(12) Remove shock absorbers from axle brackets

(Fig. 6).

(13) Loosen all lower control arms mounting bolts

(Fig. 7).

(14) Lower axle enough to remove coil springs and

spring insulators.

(15) Remove lower control arm bolts from the axle

brackets.

(16) Lower and remove the axle.

INSTALLATION

CAUTION: The weight of the vehicle must be sup-

ported by the springs before the lower control arms

are tightened. This must be done to maintain vehi-

cle ride height and prevent premature bushing fail-

ure.(1) Raise the axle under the vehicle.

(2) Install lower control arms onto the axle brack-

ets and loosely install the mounting bolts.

(3) Install coil spring isolators and spring.

(4) Raise axle up until springs are seated.

(5) Install upper control arm ball joint into axle

bracket and tighten pinch bolt to torque specification.

(6) Install shock absorbers and tighten nuts to

torque specification.

(7) Install stabilizer bar and tighten nuts to torque

specification.

(8) Install brake backing plates, parking brake

cables, brake drums and speed sensor.

(9) Install brake hose to the body junction block

and bleed the brakes.

Fig. 4 STABILIZER BAR MOUNTS

1 - STABILIZER BAR MOUNTING BOLTS

2 - LOWER SUSPENSION ARM

Fig. 5 BALL JOINT PINCH BOLT

1 - UPPER BALL JOINT

2 - PINCH BOLT

Fig. 6 SHOCK ABSORBER

1 - UPPER MOUNTING BOLT

2 - LOWER MOUNTING BOLT

KJREAR AXLE - 8 1/4 3 - 91

REAR AXLE - 8 1/4 (Continued)

Page 150 of 1803

AXLE SHAFTS

REMOVAL

(1) Place the transmission in NEUTRAL and raise

and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove brake drum.

(4) Remove the housing cover and drain lubricant.

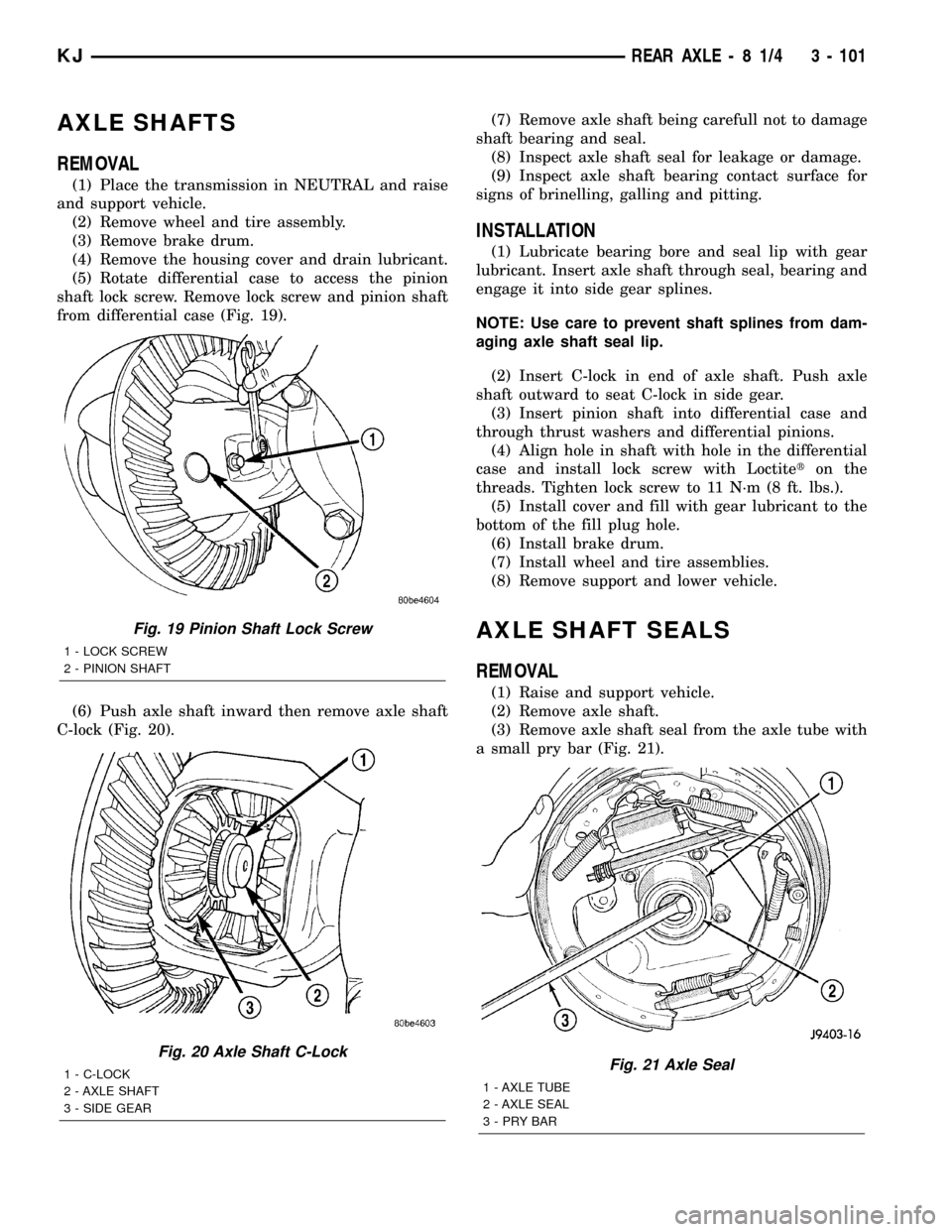

(5) Rotate differential case to access the pinion

shaft lock screw. Remove lock screw and pinion shaft

from differential case (Fig. 19).

(6) Push axle shaft inward then remove axle shaft

C-lock (Fig. 20).(7) Remove axle shaft being carefull not to damage

shaft bearing and seal.

(8) Inspect axle shaft seal for leakage or damage.

(9) Inspect axle shaft bearing contact surface for

signs of brinelling, galling and pitting.

INSTALLATION

(1) Lubricate bearing bore and seal lip with gear

lubricant. Insert axle shaft through seal, bearing and

engage it into side gear splines.

NOTE: Use care to prevent shaft splines from dam-

aging axle shaft seal lip.

(2) Insert C-lock in end of axle shaft. Push axle

shaft outward to seat C-lock in side gear.

(3) Insert pinion shaft into differential case and

through thrust washers and differential pinions.

(4) Align hole in shaft with hole in the differential

case and install lock screw with Loctiteton the

threads. Tighten lock screw to 11 N´m (8 ft. lbs.).

(5) Install cover and fill with gear lubricant to the

bottom of the fill plug hole.

(6) Install brake drum.

(7) Install wheel and tire assemblies.

(8) Remove support and lower vehicle.

AXLE SHAFT SEALS

REMOVAL

(1) Raise and support vehicle.

(2) Remove axle shaft.

(3) Remove axle shaft seal from the axle tube with

a small pry bar (Fig. 21).

Fig. 19 Pinion Shaft Lock Screw

1 - LOCK SCREW

2 - PINION SHAFT

Fig. 20 Axle Shaft C-Lock

1 - C-LOCK

2 - AXLE SHAFT

3 - SIDE GEARFig. 21 Axle Seal

1 - AXLE TUBE

2 - AXLE SEAL

3-PRYBAR

KJREAR AXLE - 8 1/4 3 - 101

Page 151 of 1803

INSTALLATION

(1) Wipe the axle tube bore clean. Remove any old

sealer or burrs from the tube.

(2) Install anewaxle seal with Installer C-4076-B

and Handle C-4735-1. When the tool contacts the

axle tube, the seal is installed to the correct depth.

(3) Coat the lip of the seal with axle lubricant for

protection prior to installing the axle shaft.

(4) Install the axle shaft.

(5) Check and fill gear lubricant.

(6) Install wheel and tire assembly.

(7) Remove support and lower vehicle.

AXLE BEARINGS

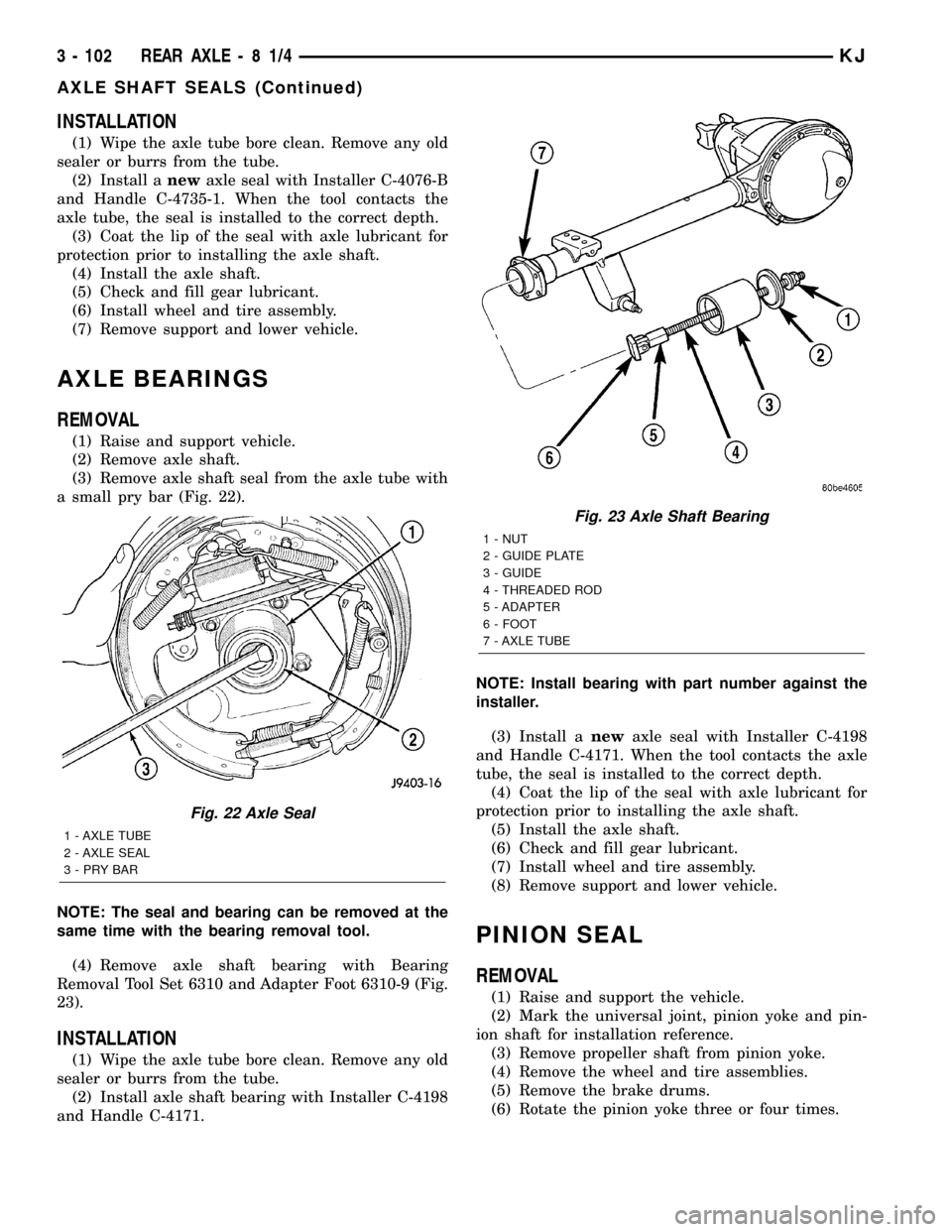

REMOVAL

(1) Raise and support vehicle.

(2) Remove axle shaft.

(3) Remove axle shaft seal from the axle tube with

a small pry bar (Fig. 22).

NOTE: The seal and bearing can be removed at the

same time with the bearing removal tool.

(4) Remove axle shaft bearing with Bearing

Removal Tool Set 6310 and Adapter Foot 6310-9 (Fig.

23).

INSTALLATION

(1) Wipe the axle tube bore clean. Remove any old

sealer or burrs from the tube.

(2) Install axle shaft bearing with Installer C-4198

and Handle C-4171.NOTE: Install bearing with part number against the

installer.

(3) Install anewaxle seal with Installer C-4198

and Handle C-4171. When the tool contacts the axle

tube, the seal is installed to the correct depth.

(4) Coat the lip of the seal with axle lubricant for

protection prior to installing the axle shaft.

(5) Install the axle shaft.

(6) Check and fill gear lubricant.

(7) Install wheel and tire assembly.

(8) Remove support and lower vehicle.

PINION SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Mark the universal joint, pinion yoke and pin-

ion shaft for installation reference.

(3) Remove propeller shaft from pinion yoke.

(4) Remove the wheel and tire assemblies.

(5) Remove the brake drums.

(6) Rotate the pinion yoke three or four times.

Fig. 22 Axle Seal

1 - AXLE TUBE

2 - AXLE SEAL

3-PRYBAR

Fig. 23 Axle Shaft Bearing

1 - NUT

2 - GUIDE PLATE

3 - GUIDE

4 - THREADED ROD

5 - ADAPTER

6 - FOOT

7 - AXLE TUBE

3 - 102 REAR AXLE-81/4KJ

AXLE SHAFT SEALS (Continued)