Body JEEP LIBERTY 2002 KJ / 1.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1597 of 1803

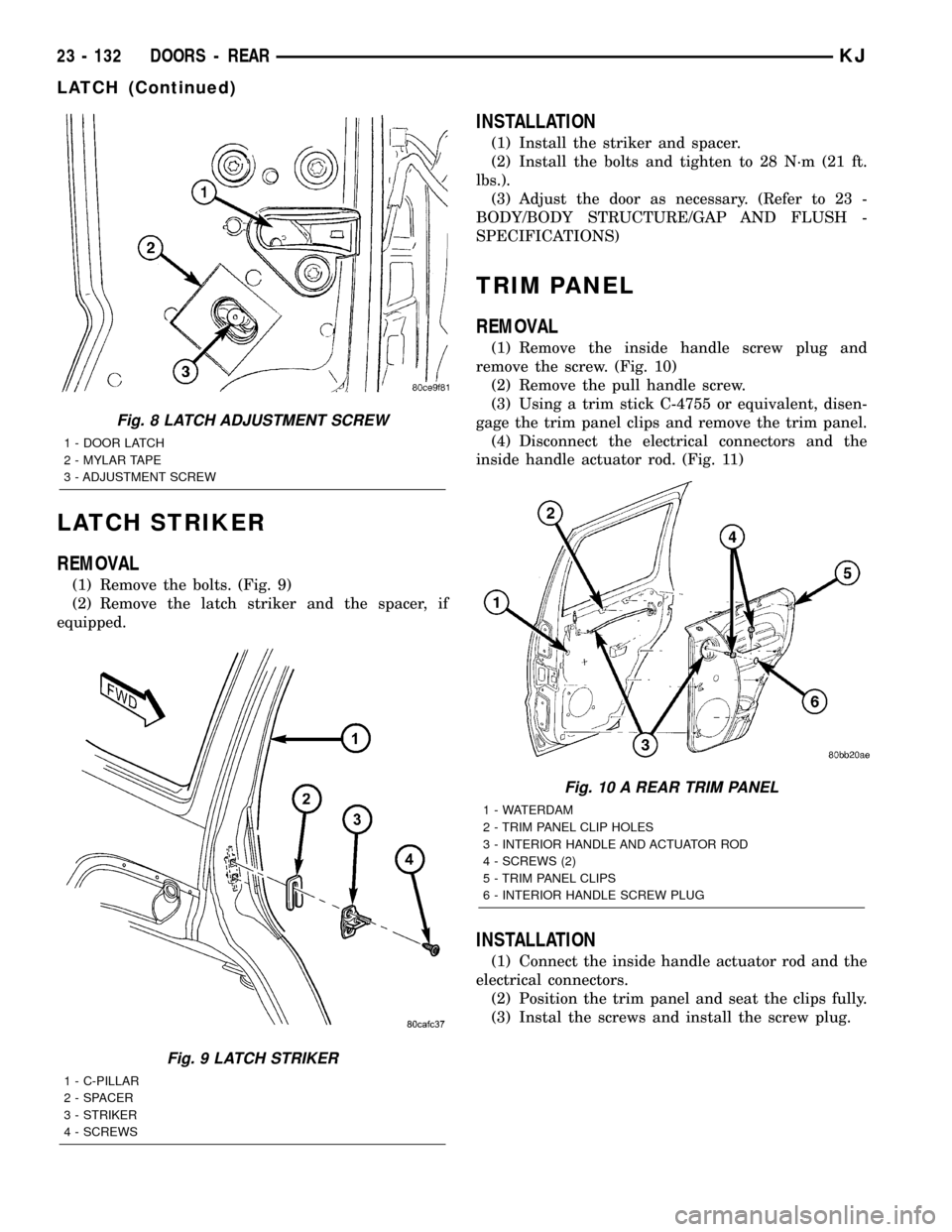

LATCH STRIKER

REMOVAL

(1) Remove the bolts. (Fig. 9)

(2) Remove the latch striker and the spacer, if

equipped.

INSTALLATION

(1) Install the striker and spacer.

(2) Install the bolts and tighten to 28 N´m (21 ft.

lbs.).

(3) Adjust the door as necessary. (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

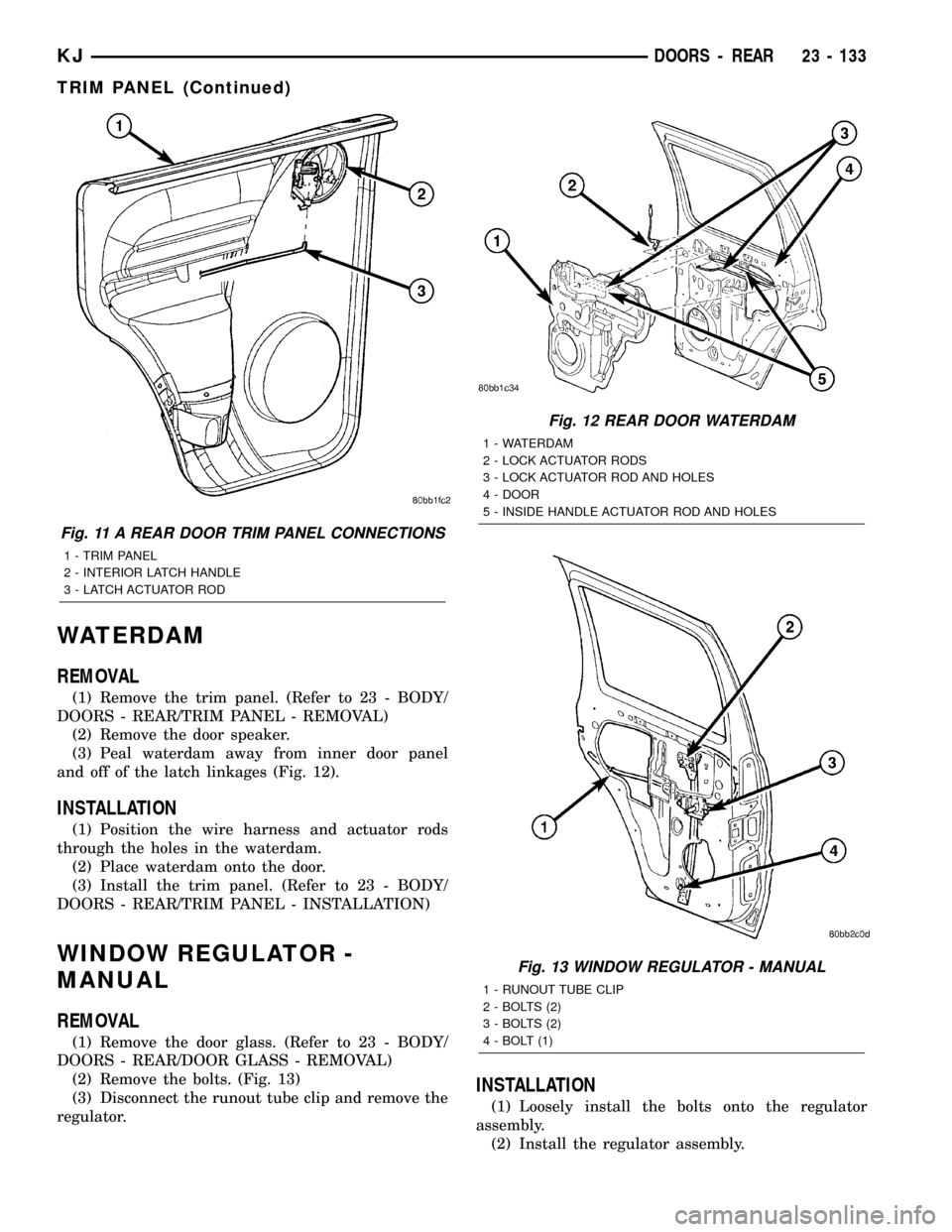

TRIM PANEL

REMOVAL

(1) Remove the inside handle screw plug and

remove the screw. (Fig. 10)

(2) Remove the pull handle screw.

(3) Using a trim stick C-4755 or equivalent, disen-

gage the trim panel clips and remove the trim panel.

(4) Disconnect the electrical connectors and the

inside handle actuator rod. (Fig. 11)

INSTALLATION

(1) Connect the inside handle actuator rod and the

electrical connectors.

(2) Position the trim panel and seat the clips fully.

(3) Instal the screws and install the screw plug.

Fig. 8 LATCH ADJUSTMENT SCREW

1 - DOOR LATCH

2 - MYLAR TAPE

3 - ADJUSTMENT SCREW

Fig. 9 LATCH STRIKER

1 - C-PILLAR

2 - SPACER

3 - STRIKER

4 - SCREWS

Fig. 10 A REAR TRIM PANEL

1 - WATERDAM

2 - TRIM PANEL CLIP HOLES

3 - INTERIOR HANDLE AND ACTUATOR ROD

4 - SCREWS (2)

5 - TRIM PANEL CLIPS

6 - INTERIOR HANDLE SCREW PLUG

23 - 132 DOORS - REARKJ

LATCH (Continued)

Page 1598 of 1803

WATERDAM

REMOVAL

(1) Remove the trim panel. (Refer to 23 - BODY/

DOORS - REAR/TRIM PANEL - REMOVAL)

(2) Remove the door speaker.

(3) Peal waterdam away from inner door panel

and off of the latch linkages (Fig. 12).

INSTALLATION

(1) Position the wire harness and actuator rods

through the holes in the waterdam.

(2) Place waterdam onto the door.

(3) Install the trim panel. (Refer to 23 - BODY/

DOORS - REAR/TRIM PANEL - INSTALLATION)

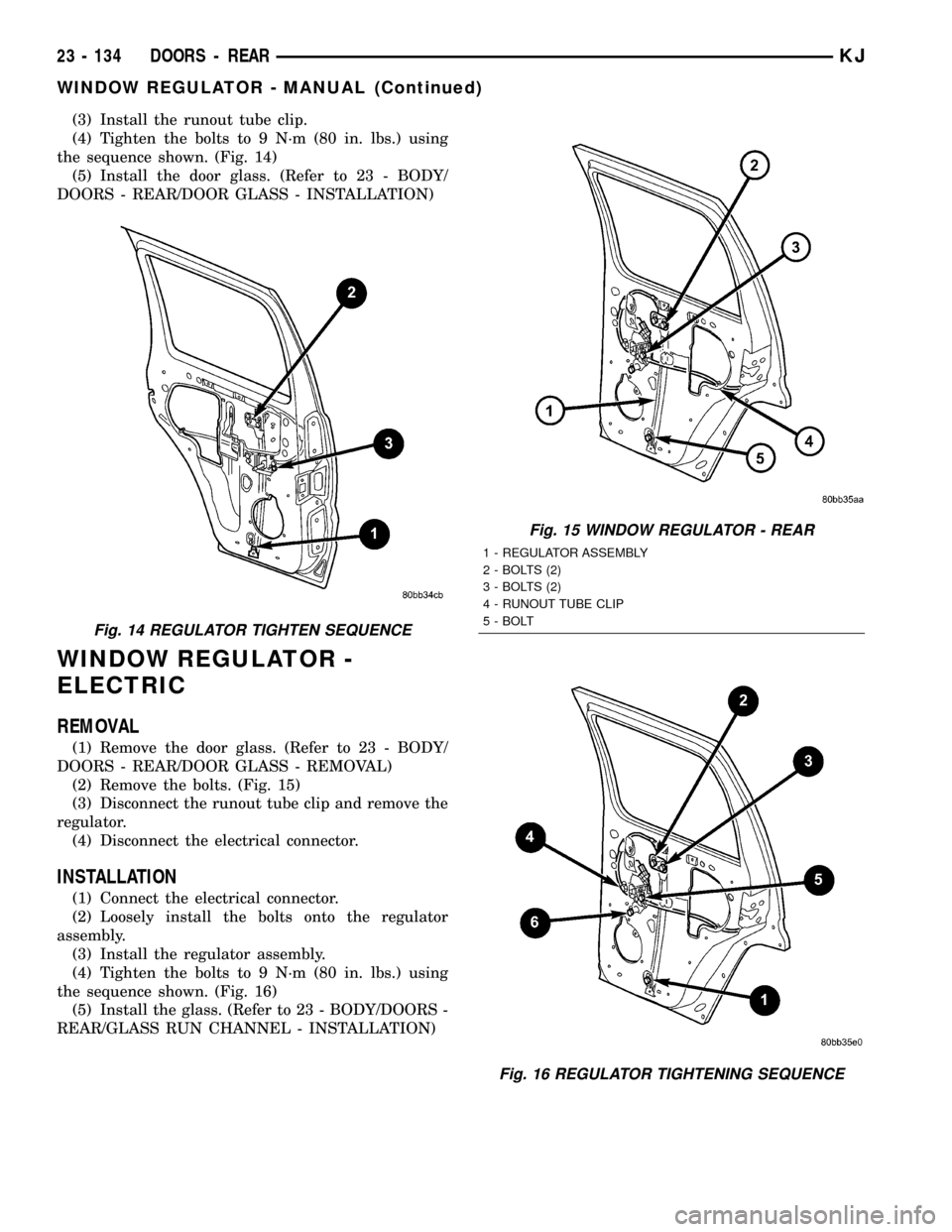

WINDOW REGULATOR -

MANUAL

REMOVAL

(1) Remove the door glass. (Refer to 23 - BODY/

DOORS - REAR/DOOR GLASS - REMOVAL)

(2) Remove the bolts. (Fig. 13)

(3) Disconnect the runout tube clip and remove the

regulator.

INSTALLATION

(1) Loosely install the bolts onto the regulator

assembly.

(2) Install the regulator assembly.

Fig. 11 A REAR DOOR TRIM PANEL CONNECTIONS

1 - TRIM PANEL

2 - INTERIOR LATCH HANDLE

3 - LATCH ACTUATOR ROD

Fig. 12 REAR DOOR WATERDAM

1 - WATERDAM

2 - LOCK ACTUATOR RODS

3 - LOCK ACTUATOR ROD AND HOLES

4 - DOOR

5 - INSIDE HANDLE ACTUATOR ROD AND HOLES

Fig. 13 WINDOW REGULATOR - MANUAL

1 - RUNOUT TUBE CLIP

2 - BOLTS (2)

3 - BOLTS (2)

4 - BOLT (1)

KJDOORS - REAR 23 - 133

TRIM PANEL (Continued)

Page 1599 of 1803

(3) Install the runout tube clip.

(4) Tighten the bolts to 9 N´m (80 in. lbs.) using

the sequence shown. (Fig. 14)

(5) Install the door glass. (Refer to 23 - BODY/

DOORS - REAR/DOOR GLASS - INSTALLATION)

WINDOW REGULATOR -

ELECTRIC

REMOVAL

(1) Remove the door glass. (Refer to 23 - BODY/

DOORS - REAR/DOOR GLASS - REMOVAL)

(2) Remove the bolts. (Fig. 15)

(3) Disconnect the runout tube clip and remove the

regulator.

(4) Disconnect the electrical connector.

INSTALLATION

(1) Connect the electrical connector.

(2) Loosely install the bolts onto the regulator

assembly.

(3) Install the regulator assembly.

(4) Tighten the bolts to 9 N´m (80 in. lbs.) using

the sequence shown. (Fig. 16)

(5) Install the glass. (Refer to 23 - BODY/DOORS -

REAR/GLASS RUN CHANNEL - INSTALLATION)

Fig. 14 REGULATOR TIGHTEN SEQUENCE

Fig. 15 WINDOW REGULATOR - REAR

1 - REGULATOR ASSEMBLY

2 - BOLTS (2)

3 - BOLTS (2)

4 - RUNOUT TUBE CLIP

5 - BOLT

Fig. 16 REGULATOR TIGHTENING SEQUENCE

23 - 134 DOORS - REARKJ

WINDOW REGULATOR - MANUAL (Continued)

Page 1600 of 1803

SWING GATE

TABLE OF CONTENTS

page page

CHECK STRAP

REMOVAL............................135

INSTALLATION........................135

EXTERIOR HANDLE

REMOVAL............................136

INSTALLATION........................136

FLIP-UP GLASS

REMOVAL............................136

INSTALLATION........................136

FLIP-UP GLASS LATCH

REMOVAL............................136

INSTALLATION........................136

HINGE

REMOVAL............................137

INSTALLATION........................137

LATCH

REMOVAL............................137

INSTALLATION........................137

LATCH STRIKER

REMOVAL............................137INSTALLATION........................137

LOCK CYLINDER

REMOVAL............................137

INSTALLATION........................138

SWING GATE

REMOVAL............................138

INSTALLATION........................138

TRIM PANEL

REMOVAL............................138

INSTALLATION........................138

LATCH - ACCESS PANEL

DESCRIPTION........................139

REMOVAL............................139

INSTALLATION........................139

FLIP-UP GLASS SUPPORT CYLINDER

REMOVAL............................139

INSTALLATION........................139

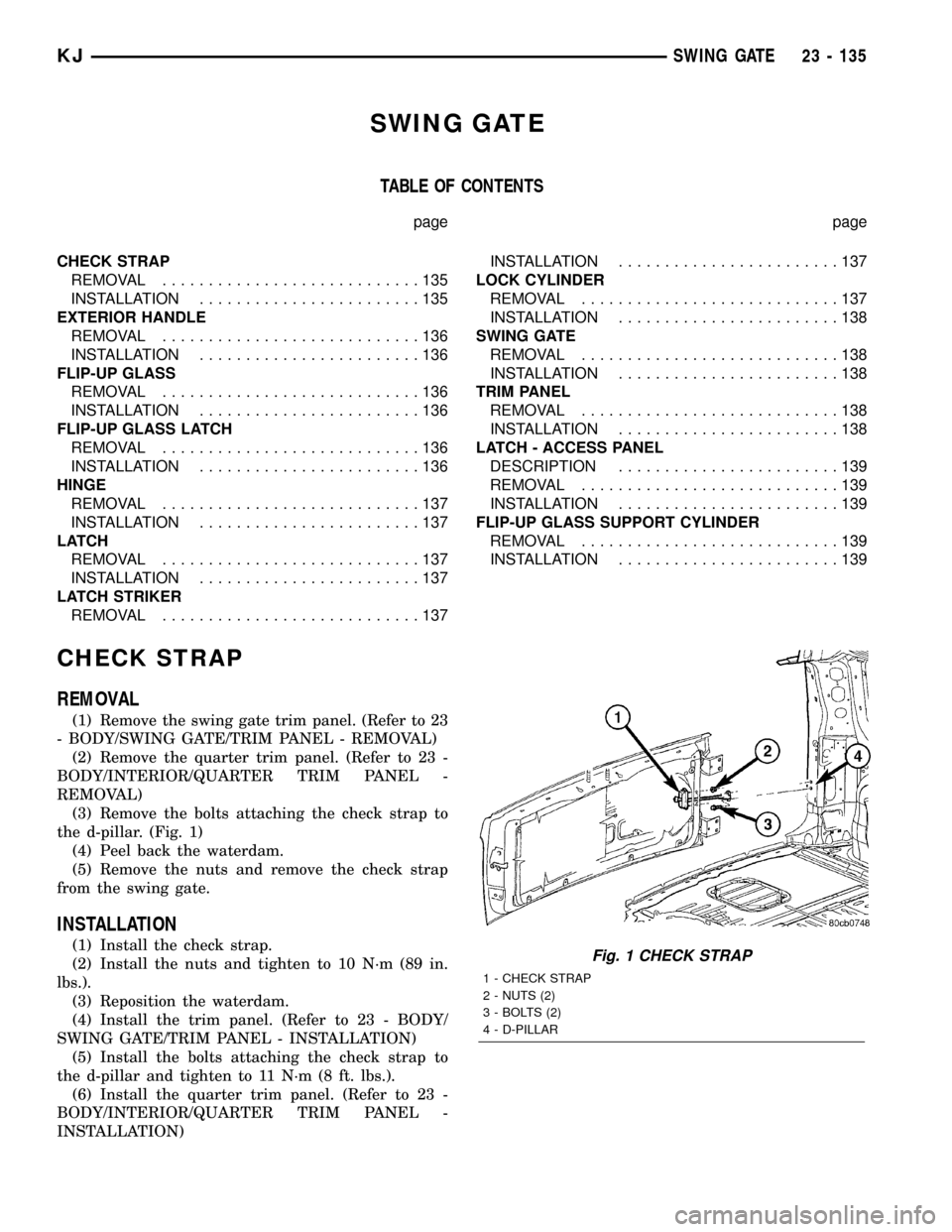

CHECK STRAP

REMOVAL

(1) Remove the swing gate trim panel. (Refer to 23

- BODY/SWING GATE/TRIM PANEL - REMOVAL)

(2) Remove the quarter trim panel. (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

REMOVAL)

(3) Remove the bolts attaching the check strap to

the d-pillar. (Fig. 1)

(4) Peel back the waterdam.

(5) Remove the nuts and remove the check strap

from the swing gate.

INSTALLATION

(1) Install the check strap.

(2) Install the nuts and tighten to 10 N´m (89 in.

lbs.).

(3) Reposition the waterdam.

(4) Install the trim panel. (Refer to 23 - BODY/

SWING GATE/TRIM PANEL - INSTALLATION)

(5) Install the bolts attaching the check strap to

the d-pillar and tighten to 11 N´m (8 ft. lbs.).

(6) Install the quarter trim panel. (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

INSTALLATION)Fig. 1 CHECK STRAP

1 - CHECK STRAP

2 - NUTS (2)

3 - BOLTS (2)

4 - D-PILLAR

KJSWING GATE 23 - 135

Page 1601 of 1803

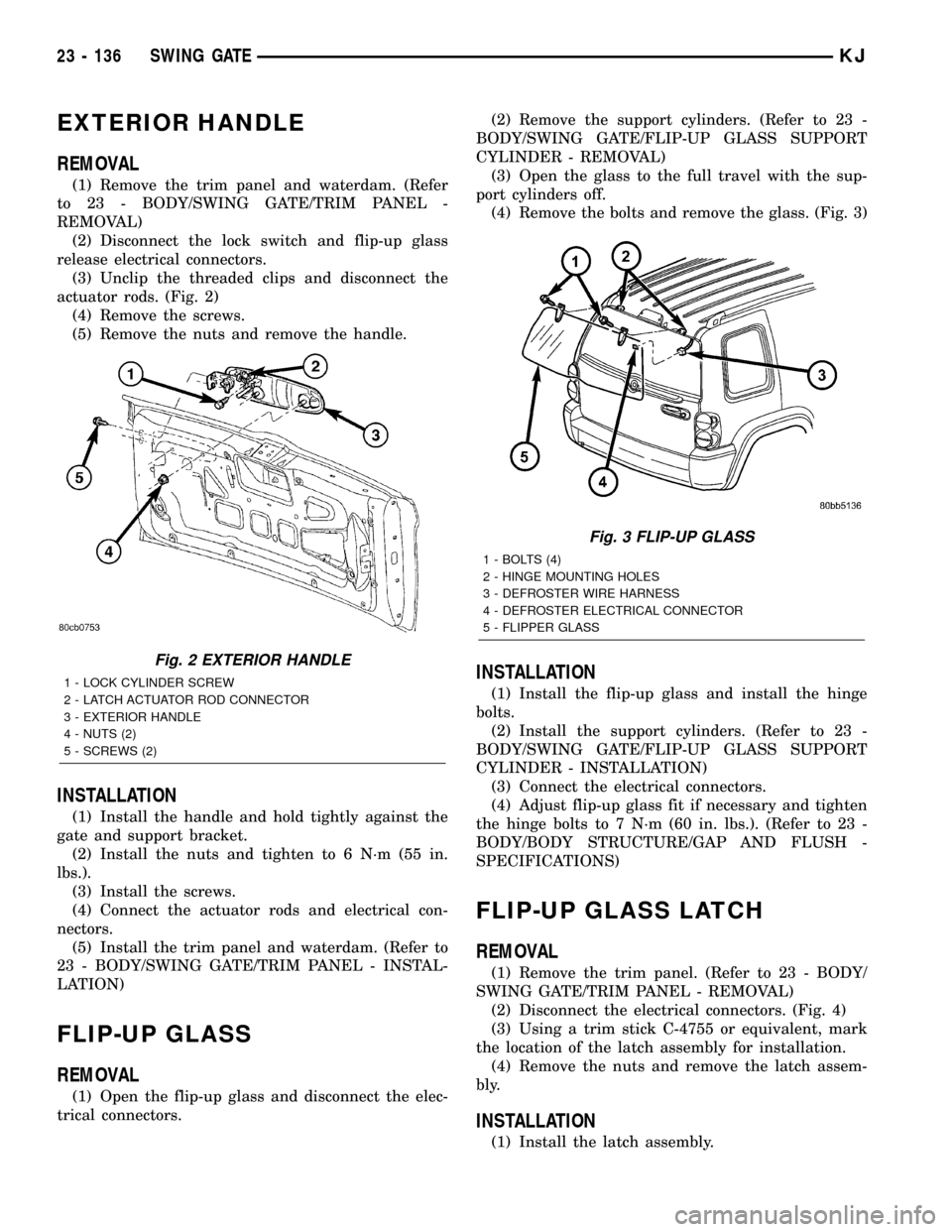

EXTERIOR HANDLE

REMOVAL

(1) Remove the trim panel and waterdam. (Refer

to 23 - BODY/SWING GATE/TRIM PANEL -

REMOVAL)

(2) Disconnect the lock switch and flip-up glass

release electrical connectors.

(3) Unclip the threaded clips and disconnect the

actuator rods. (Fig. 2)

(4) Remove the screws.

(5) Remove the nuts and remove the handle.

INSTALLATION

(1) Install the handle and hold tightly against the

gate and support bracket.

(2) Install the nuts and tighten to 6 N´m (55 in.

lbs.).

(3) Install the screws.

(4) Connect the actuator rods and electrical con-

nectors.

(5) Install the trim panel and waterdam. (Refer to

23 - BODY/SWING GATE/TRIM PANEL - INSTAL-

LATION)

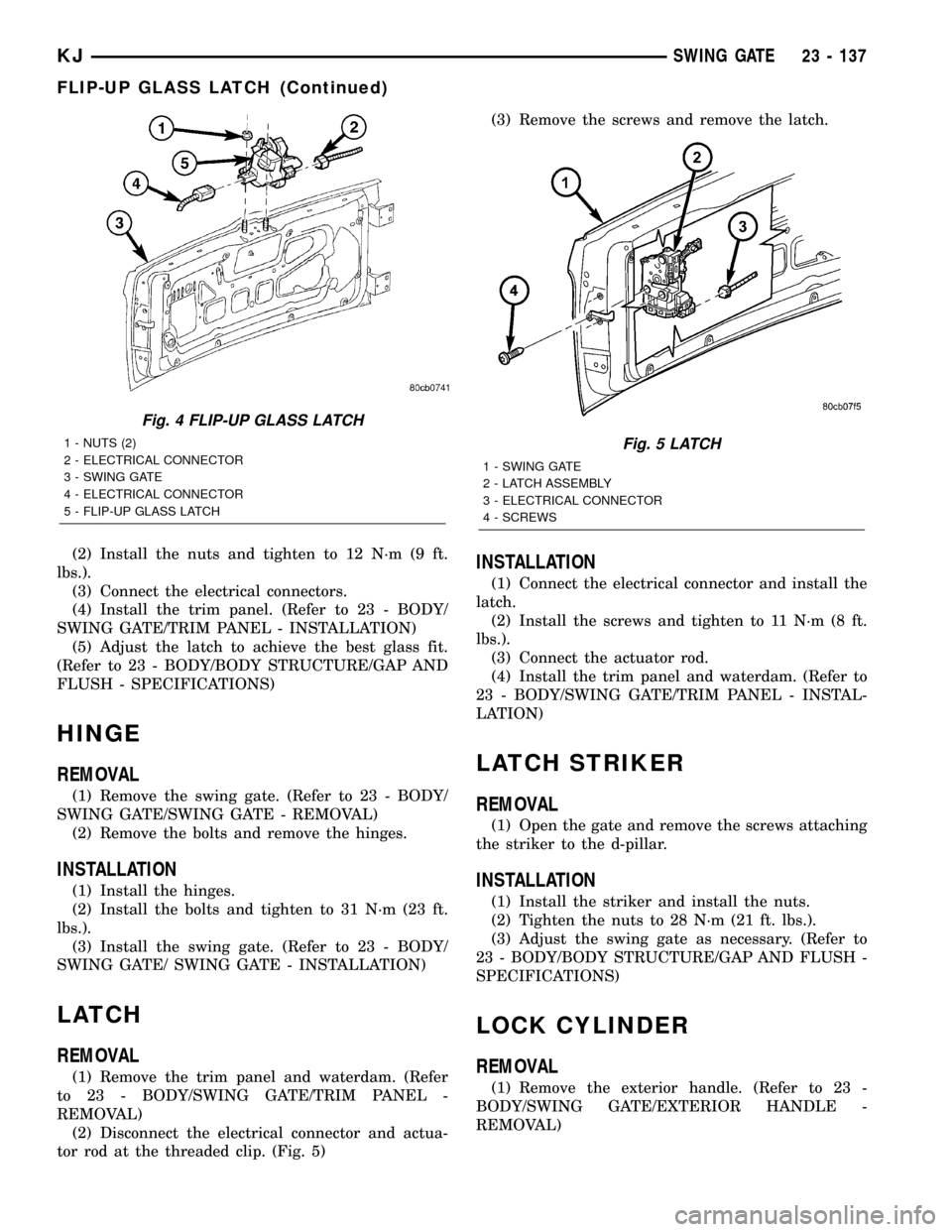

FLIP-UP GLASS

REMOVAL

(1) Open the flip-up glass and disconnect the elec-

trical connectors.(2) Remove the support cylinders. (Refer to 23 -

BODY/SWING GATE/FLIP-UP GLASS SUPPORT

CYLINDER - REMOVAL)

(3) Open the glass to the full travel with the sup-

port cylinders off.

(4) Remove the bolts and remove the glass. (Fig. 3)

INSTALLATION

(1) Install the flip-up glass and install the hinge

bolts.

(2) Install the support cylinders. (Refer to 23 -

BODY/SWING GATE/FLIP-UP GLASS SUPPORT

CYLINDER - INSTALLATION)

(3) Connect the electrical connectors.

(4) Adjust flip-up glass fit if necessary and tighten

the hinge bolts to 7 N´m (60 in. lbs.). (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

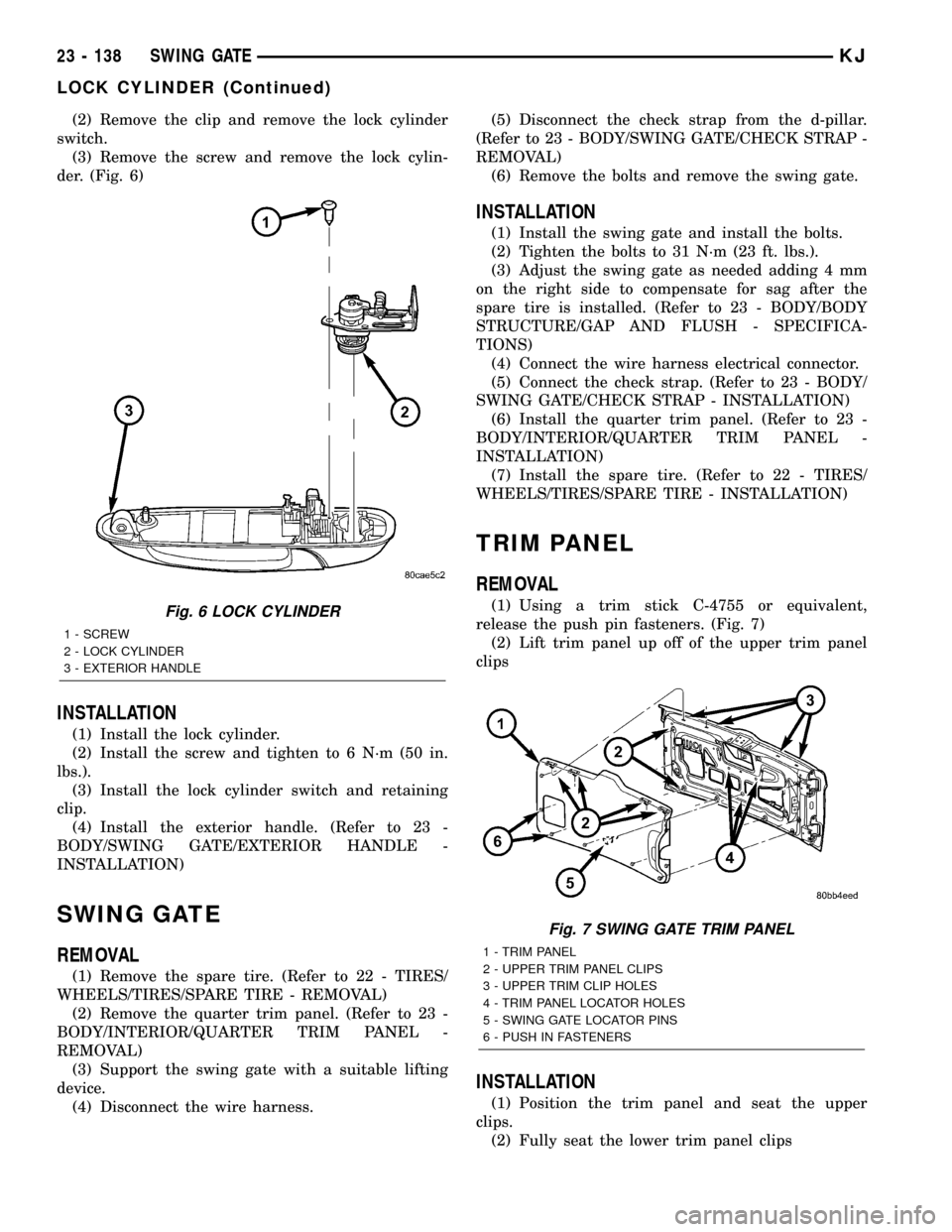

FLIP-UP GLASS LATCH

REMOVAL

(1) Remove the trim panel. (Refer to 23 - BODY/

SWING GATE/TRIM PANEL - REMOVAL)

(2) Disconnect the electrical connectors. (Fig. 4)

(3) Using a trim stick C-4755 or equivalent, mark

the location of the latch assembly for installation.

(4) Remove the nuts and remove the latch assem-

bly.

INSTALLATION

(1) Install the latch assembly.

Fig. 2 EXTERIOR HANDLE

1 - LOCK CYLINDER SCREW

2 - LATCH ACTUATOR ROD CONNECTOR

3 - EXTERIOR HANDLE

4 - NUTS (2)

5 - SCREWS (2)

Fig. 3 FLIP-UP GLASS

1 - BOLTS (4)

2 - HINGE MOUNTING HOLES

3 - DEFROSTER WIRE HARNESS

4 - DEFROSTER ELECTRICAL CONNECTOR

5 - FLIPPER GLASS

23 - 136 SWING GATEKJ

Page 1602 of 1803

(2) Install the nuts and tighten to 12 N´m (9 ft.

lbs.).

(3) Connect the electrical connectors.

(4) Install the trim panel. (Refer to 23 - BODY/

SWING GATE/TRIM PANEL - INSTALLATION)

(5) Adjust the latch to achieve the best glass fit.

(Refer to 23 - BODY/BODY STRUCTURE/GAP AND

FLUSH - SPECIFICATIONS)

HINGE

REMOVAL

(1) Remove the swing gate. (Refer to 23 - BODY/

SWING GATE/SWING GATE - REMOVAL)

(2) Remove the bolts and remove the hinges.

INSTALLATION

(1) Install the hinges.

(2) Install the bolts and tighten to 31 N´m (23 ft.

lbs.).

(3) Install the swing gate. (Refer to 23 - BODY/

SWING GATE/ SWING GATE - INSTALLATION)

LATCH

REMOVAL

(1) Remove the trim panel and waterdam. (Refer

to 23 - BODY/SWING GATE/TRIM PANEL -

REMOVAL)

(2) Disconnect the electrical connector and actua-

tor rod at the threaded clip. (Fig. 5)(3) Remove the screws and remove the latch.

INSTALLATION

(1) Connect the electrical connector and install the

latch.

(2) Install the screws and tighten to 11 N´m (8 ft.

lbs.).

(3) Connect the actuator rod.

(4) Install the trim panel and waterdam. (Refer to

23 - BODY/SWING GATE/TRIM PANEL - INSTAL-

LATION)

LATCH STRIKER

REMOVAL

(1) Open the gate and remove the screws attaching

the striker to the d-pillar.

INSTALLATION

(1) Install the striker and install the nuts.

(2) Tighten the nuts to 28 N´m (21 ft. lbs.).

(3) Adjust the swing gate as necessary. (Refer to

23 - BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

LOCK CYLINDER

REMOVAL

(1) Remove the exterior handle. (Refer to 23 -

BODY/SWING GATE/EXTERIOR HANDLE -

REMOVAL)

Fig. 4 FLIP-UP GLASS LATCH

1 - NUTS (2)

2 - ELECTRICAL CONNECTOR

3 - SWING GATE

4 - ELECTRICAL CONNECTOR

5 - FLIP-UP GLASS LATCHFig. 5 LATCH

1 - SWING GATE

2 - LATCH ASSEMBLY

3 - ELECTRICAL CONNECTOR

4 - SCREWS

KJSWING GATE 23 - 137

FLIP-UP GLASS LATCH (Continued)

Page 1603 of 1803

(2) Remove the clip and remove the lock cylinder

switch.

(3) Remove the screw and remove the lock cylin-

der. (Fig. 6)

INSTALLATION

(1) Install the lock cylinder.

(2) Install the screw and tighten to 6 N´m (50 in.

lbs.).

(3) Install the lock cylinder switch and retaining

clip.

(4) Install the exterior handle. (Refer to 23 -

BODY/SWING GATE/EXTERIOR HANDLE -

INSTALLATION)

SWING GATE

REMOVAL

(1) Remove the spare tire. (Refer to 22 - TIRES/

WHEELS/TIRES/SPARE TIRE - REMOVAL)

(2) Remove the quarter trim panel. (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

REMOVAL)

(3) Support the swing gate with a suitable lifting

device.

(4) Disconnect the wire harness.(5) Disconnect the check strap from the d-pillar.

(Refer to 23 - BODY/SWING GATE/CHECK STRAP -

REMOVAL)

(6) Remove the bolts and remove the swing gate.

INSTALLATION

(1) Install the swing gate and install the bolts.

(2) Tighten the bolts to 31 N´m (23 ft. lbs.).

(3) Adjust the swing gate as needed adding 4 mm

on the right side to compensate for sag after the

spare tire is installed. (Refer to 23 - BODY/BODY

STRUCTURE/GAP AND FLUSH - SPECIFICA-

TIONS)

(4) Connect the wire harness electrical connector.

(5) Connect the check strap. (Refer to 23 - BODY/

SWING GATE/CHECK STRAP - INSTALLATION)

(6) Install the quarter trim panel. (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

INSTALLATION)

(7) Install the spare tire. (Refer to 22 - TIRES/

WHEELS/TIRES/SPARE TIRE - INSTALLATION)

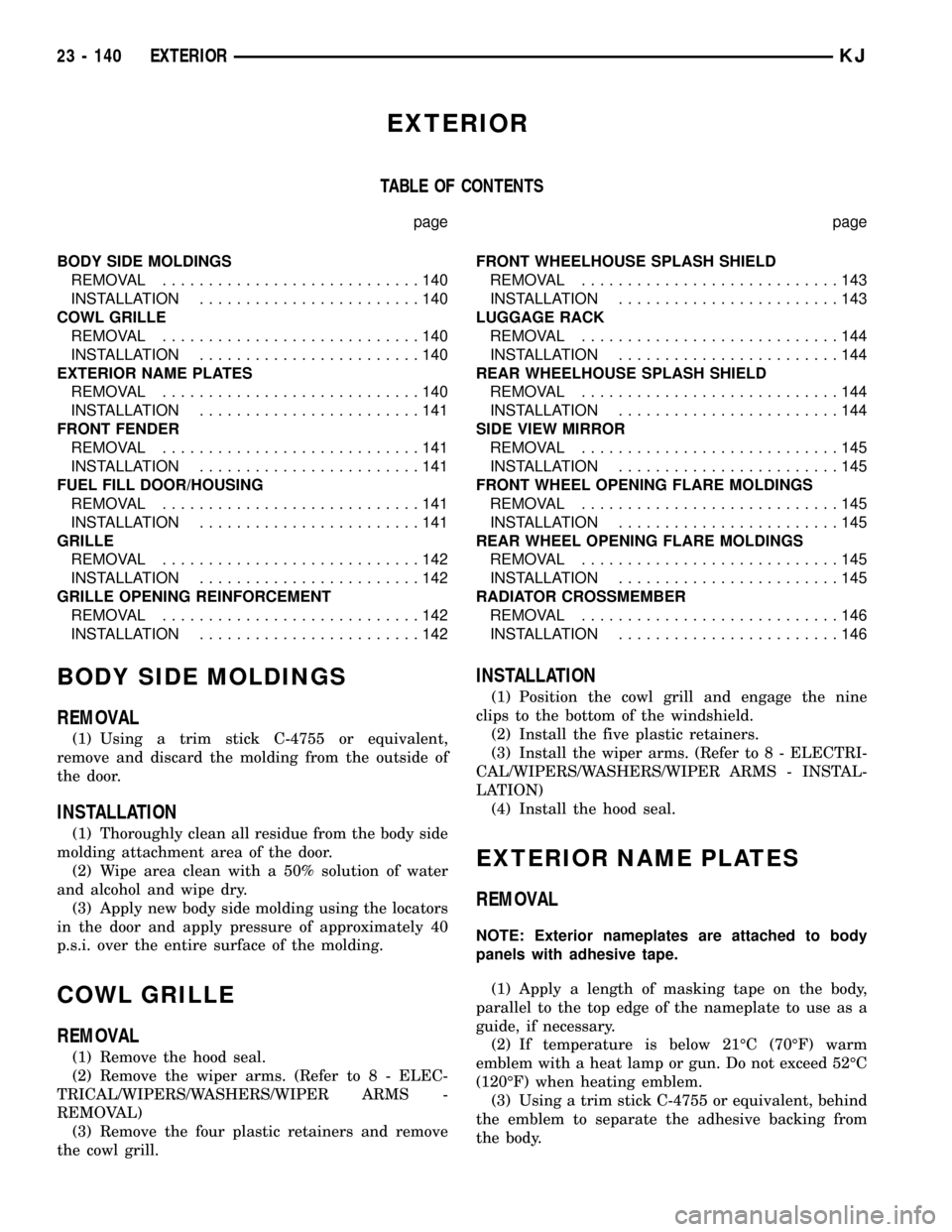

TRIM PANEL

REMOVAL

(1) Using a trim stick C-4755 or equivalent,

release the push pin fasteners. (Fig. 7)

(2) Lift trim panel up off of the upper trim panel

clips

INSTALLATION

(1) Position the trim panel and seat the upper

clips.

(2) Fully seat the lower trim panel clips

Fig. 6 LOCK CYLINDER

1 - SCREW

2 - LOCK CYLINDER

3 - EXTERIOR HANDLE

Fig. 7 SWING GATE TRIM PANEL

1 - TRIM PANEL

2 - UPPER TRIM PANEL CLIPS

3 - UPPER TRIM CLIP HOLES

4 - TRIM PANEL LOCATOR HOLES

5 - SWING GATE LOCATOR PINS

6 - PUSH IN FASTENERS

23 - 138 SWING GATEKJ

LOCK CYLINDER (Continued)

Page 1605 of 1803

EXTERIOR

TABLE OF CONTENTS

page page

BODY SIDE MOLDINGS

REMOVAL............................140

INSTALLATION........................140

COWL GRILLE

REMOVAL............................140

INSTALLATION........................140

EXTERIOR NAME PLATES

REMOVAL............................140

INSTALLATION........................141

FRONT FENDER

REMOVAL............................141

INSTALLATION........................141

FUEL FILL DOOR/HOUSING

REMOVAL............................141

INSTALLATION........................141

GRILLE

REMOVAL............................142

INSTALLATION........................142

GRILLE OPENING REINFORCEMENT

REMOVAL............................142

INSTALLATION........................142FRONT WHEELHOUSE SPLASH SHIELD

REMOVAL............................143

INSTALLATION........................143

LUGGAGE RACK

REMOVAL............................144

INSTALLATION........................144

REAR WHEELHOUSE SPLASH SHIELD

REMOVAL............................144

INSTALLATION........................144

SIDE VIEW MIRROR

REMOVAL............................145

INSTALLATION........................145

FRONT WHEEL OPENING FLARE MOLDINGS

REMOVAL............................145

INSTALLATION........................145

REAR WHEEL OPENING FLARE MOLDINGS

REMOVAL............................145

INSTALLATION........................145

RADIATOR CROSSMEMBER

REMOVAL............................146

INSTALLATION........................146

BODY SIDE MOLDINGS

REMOVAL

(1) Using a trim stick C-4755 or equivalent,

remove and discard the molding from the outside of

the door.

INSTALLATION

(1) Thoroughly clean all residue from the body side

molding attachment area of the door.

(2) Wipe area clean with a 50% solution of water

and alcohol and wipe dry.

(3) Apply new body side molding using the locators

in the door and apply pressure of approximately 40

p.s.i. over the entire surface of the molding.

COWL GRILLE

REMOVAL

(1) Remove the hood seal.

(2) Remove the wiper arms. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER ARMS -

REMOVAL)

(3) Remove the four plastic retainers and remove

the cowl grill.

INSTALLATION

(1) Position the cowl grill and engage the nine

clips to the bottom of the windshield.

(2) Install the five plastic retainers.

(3) Install the wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS - INSTAL-

LATION)

(4) Install the hood seal.

EXTERIOR NAME PLATES

REMOVAL

NOTE: Exterior nameplates are attached to body

panels with adhesive tape.

(1) Apply a length of masking tape on the body,

parallel to the top edge of the nameplate to use as a

guide, if necessary.

(2) If temperature is below 21ÉC (70ÉF) warm

emblem with a heat lamp or gun. Do not exceed 52ÉC

(120ÉF) when heating emblem.

(3) Using a trim stick C-4755 or equivalent, behind

the emblem to separate the adhesive backing from

the body.

23 - 140 EXTERIORKJ

Page 1606 of 1803

(4) Clean adhesive residue from body with MOPAR

Super Clean solvent or equivalent.

INSTALLATION

(1) Remove protective cover from adhesive tape on

back of emblem.

(2) Position emblem properly on body.

(3) Press emblem firmly to body with palm of

hand.

(4) If temperature is below 21ÉC (70ÉF) warm

emblem with a heat lamp or gun to assure adhesion.

Do not exceed 52ÉC (120ÉF) when heating emblem.

FRONT FENDER

REMOVAL

(1) Remove the wheel opening splash shield. (Refer

to 23 - BODY/EXTERIOR/FRONT WHEELHOUSE

SPLASH SHIELD - REMOVAL)

(2) Remove the fascia assembly. (Refer to 13 -

FRAME & BUMPERS/BUMPERS/FRONT FASCIA -

REMOVAL)

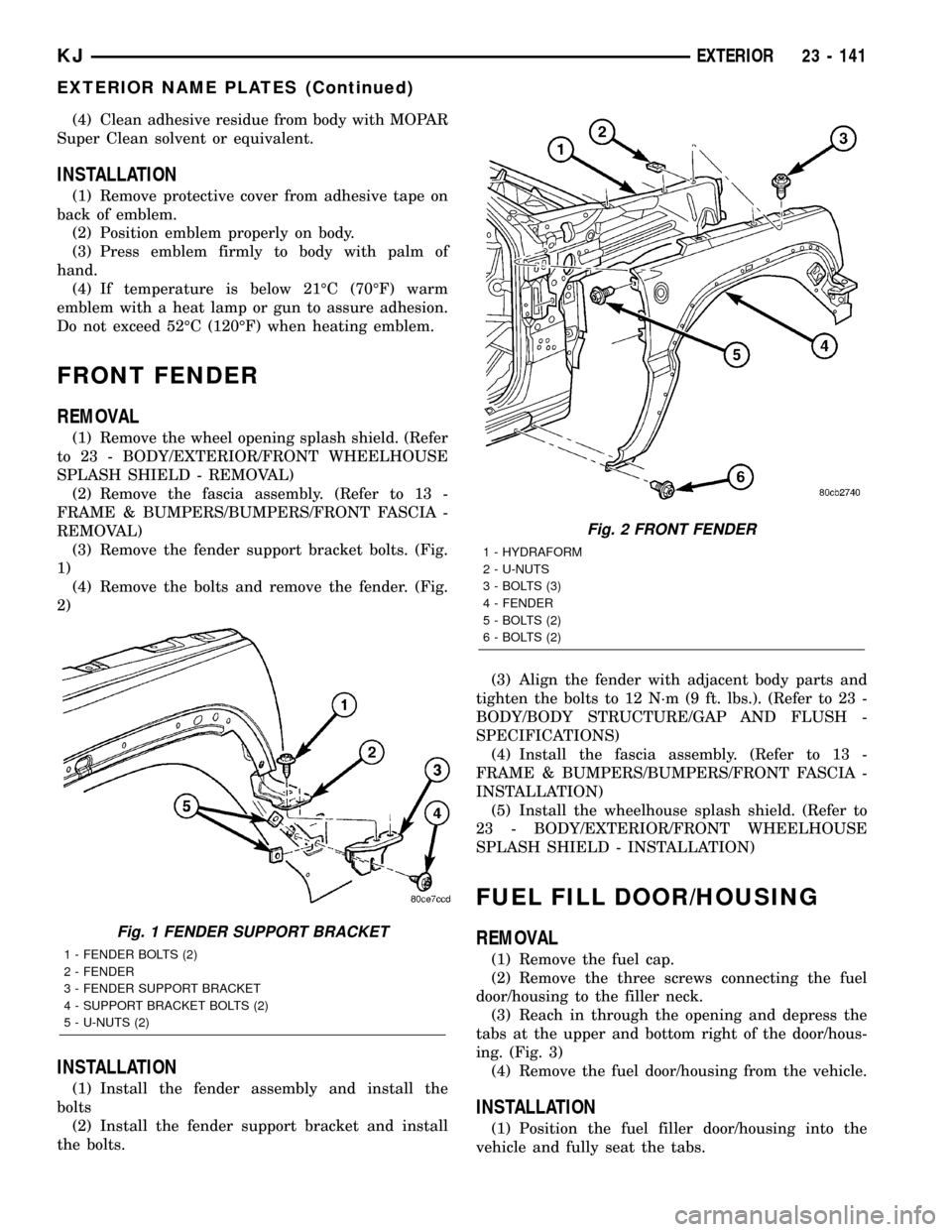

(3) Remove the fender support bracket bolts. (Fig.

1)

(4) Remove the bolts and remove the fender. (Fig.

2)

INSTALLATION

(1) Install the fender assembly and install the

bolts

(2) Install the fender support bracket and install

the bolts.(3) Align the fender with adjacent body parts and

tighten the bolts to 12 N´m (9 ft. lbs.). (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS)

(4) Install the fascia assembly. (Refer to 13 -

FRAME & BUMPERS/BUMPERS/FRONT FASCIA -

INSTALLATION)

(5) Install the wheelhouse splash shield. (Refer to

23 - BODY/EXTERIOR/FRONT WHEELHOUSE

SPLASH SHIELD - INSTALLATION)

FUEL FILL DOOR/HOUSING

REMOVAL

(1) Remove the fuel cap.

(2) Remove the three screws connecting the fuel

door/housing to the filler neck.

(3) Reach in through the opening and depress the

tabs at the upper and bottom right of the door/hous-

ing. (Fig. 3)

(4) Remove the fuel door/housing from the vehicle.

INSTALLATION

(1) Position the fuel filler door/housing into the

vehicle and fully seat the tabs.

Fig. 1 FENDER SUPPORT BRACKET

1 - FENDER BOLTS (2)

2 - FENDER

3 - FENDER SUPPORT BRACKET

4 - SUPPORT BRACKET BOLTS (2)

5 - U-NUTS (2)

Fig. 2 FRONT FENDER

1 - HYDRAFORM

2 - U-NUTS

3 - BOLTS (3)

4 - FENDER

5 - BOLTS (2)

6 - BOLTS (2)

KJEXTERIOR 23 - 141

EXTERIOR NAME PLATES (Continued)

Page 1607 of 1803

(2) Install the three screws.

(3) Install the fuel cap.

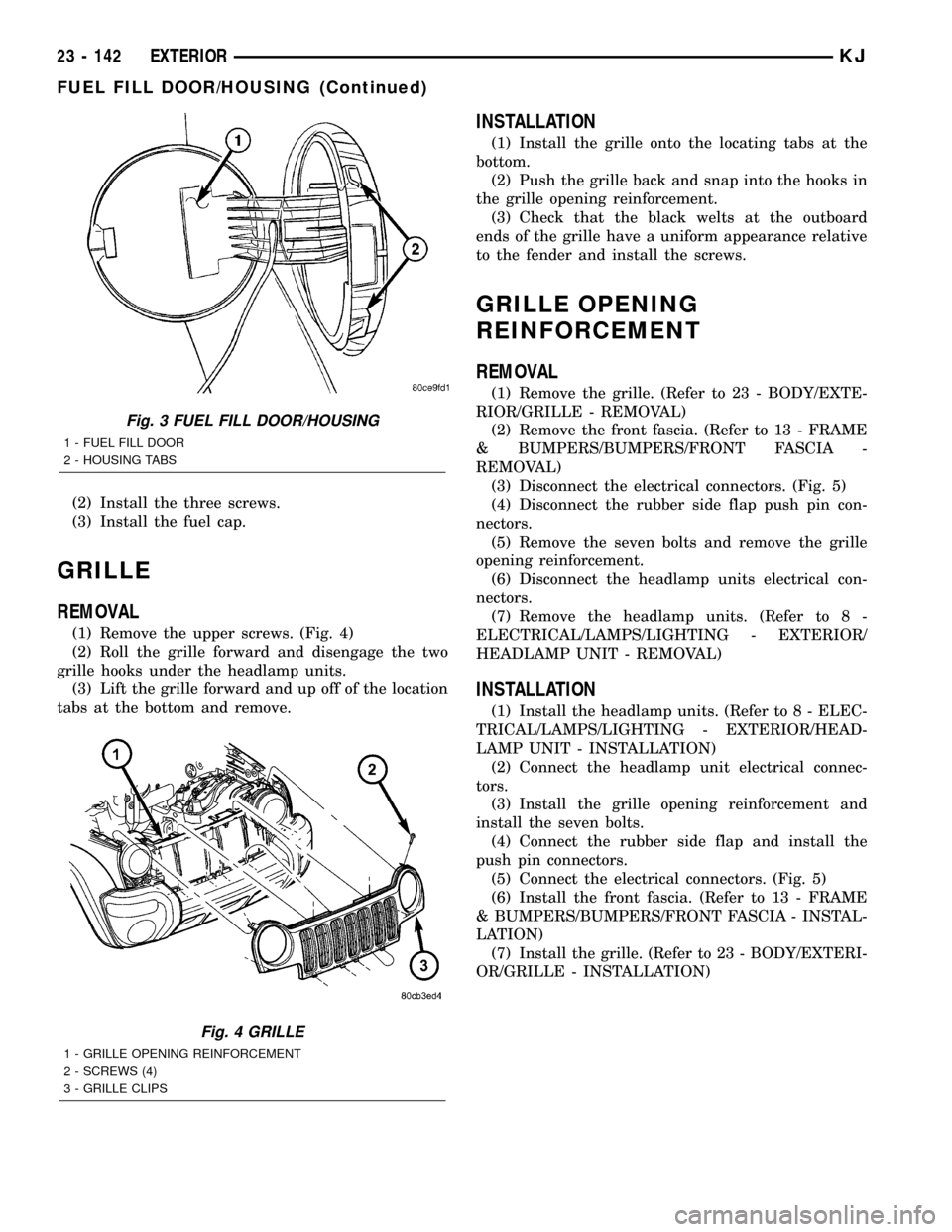

GRILLE

REMOVAL

(1) Remove the upper screws. (Fig. 4)

(2) Roll the grille forward and disengage the two

grille hooks under the headlamp units.

(3) Lift the grille forward and up off of the location

tabs at the bottom and remove.

INSTALLATION

(1) Install the grille onto the locating tabs at the

bottom.

(2) Push the grille back and snap into the hooks in

the grille opening reinforcement.

(3) Check that the black welts at the outboard

ends of the grille have a uniform appearance relative

to the fender and install the screws.

GRILLE OPENING

REINFORCEMENT

REMOVAL

(1) Remove the grille. (Refer to 23 - BODY/EXTE-

RIOR/GRILLE - REMOVAL)

(2) Remove the front fascia. (Refer to 13 - FRAME

& BUMPERS/BUMPERS/FRONT FASCIA -

REMOVAL)

(3) Disconnect the electrical connectors. (Fig. 5)

(4) Disconnect the rubber side flap push pin con-

nectors.

(5) Remove the seven bolts and remove the grille

opening reinforcement.

(6) Disconnect the headlamp units electrical con-

nectors.

(7) Remove the headlamp units. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - REMOVAL)

INSTALLATION

(1) Install the headlamp units. (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/HEAD-

LAMP UNIT - INSTALLATION)

(2) Connect the headlamp unit electrical connec-

tors.

(3) Install the grille opening reinforcement and

install the seven bolts.

(4) Connect the rubber side flap and install the

push pin connectors.

(5) Connect the electrical connectors. (Fig. 5)

(6) Install the front fascia. (Refer to 13 - FRAME

& BUMPERS/BUMPERS/FRONT FASCIA - INSTAL-

LATION)

(7) Install the grille. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION)

Fig. 3 FUEL FILL DOOR/HOUSING

1 - FUEL FILL DOOR

2 - HOUSING TABS

Fig. 4 GRILLE

1 - GRILLE OPENING REINFORCEMENT

2 - SCREWS (4)

3 - GRILLE CLIPS

23 - 142 EXTERIORKJ

FUEL FILL DOOR/HOUSING (Continued)