signal JEEP LIBERTY 2002 KJ / 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 477 of 1803

OPERATION

The controller board and logic circuitry of the

headlamp leveling motor will energize the motor and

extend or retract the motor pushrod through the

integral screw-drive transmission based upon the

voltage signal input received from the resistor multi-

plexed headlamp leveling switch. The ball formation

on the end of the headlamp leveling motor pushrod is

snapped into a socket formation on the back of the

movable reflector within the headlamp unit housing.

The headlamp leveling motors and switch have a

path to ground at all times. The headlamp leveling

components operate on battery current received

through the fused park lamp relay output circuit so

that the system will only operate when the exterior

lighting is turned On.

Because of active electronic elements within the

headlamp leveling motor, it cannot be tested with

conventional automotive electrical test equipment. If

the headlamp leveling motor is believed to be faulty,

replace the motor with a known good unit to confirm

system operation.

REMOVAL

The headlamp leveling motors are integral to the

headlamp units on vehicles manufactured for certain

markets where headlamp leveling is required.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the headlamp bulb from the headlamp

unit housing. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/HEADLAMP BULB -

REMOVAL).

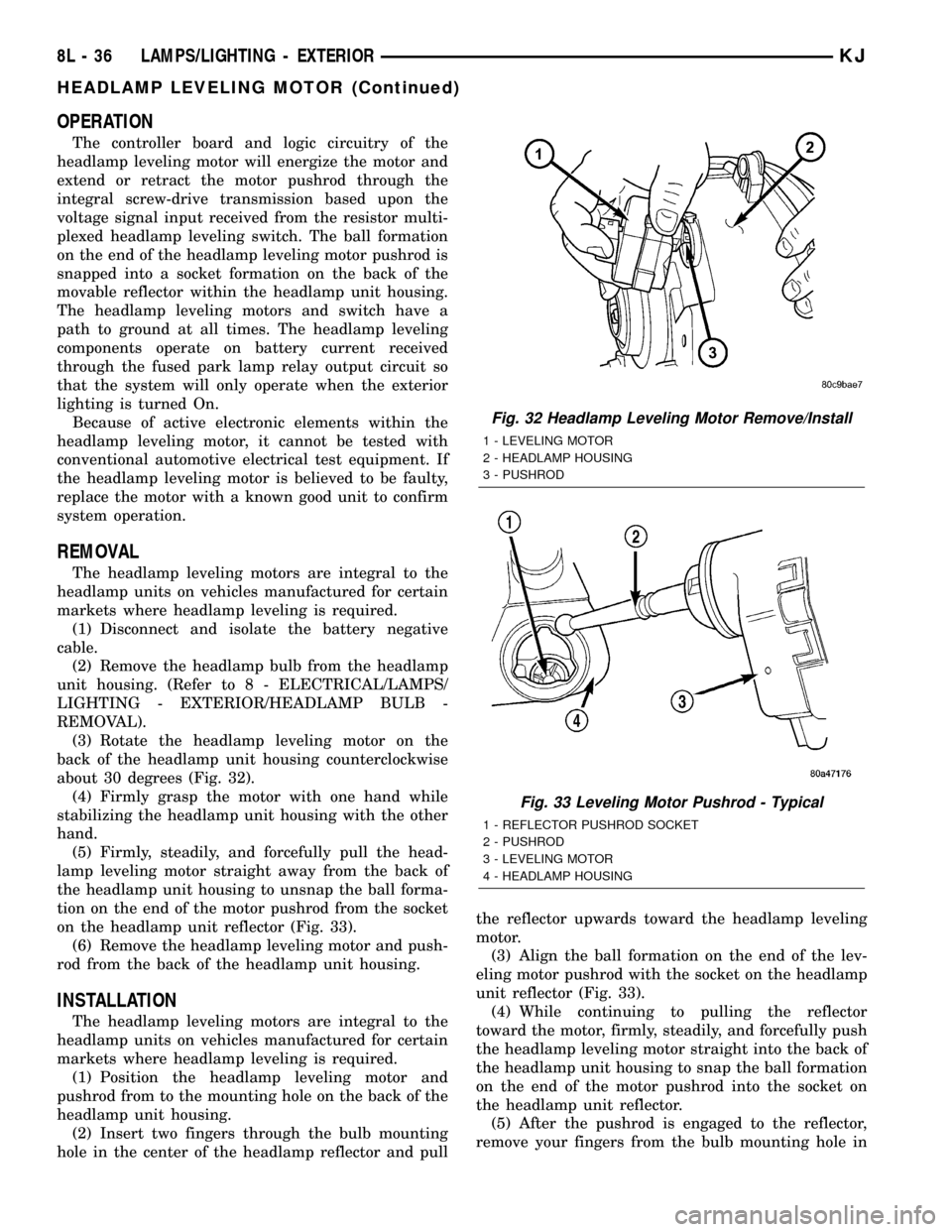

(3) Rotate the headlamp leveling motor on the

back of the headlamp unit housing counterclockwise

about 30 degrees (Fig. 32).

(4) Firmly grasp the motor with one hand while

stabilizing the headlamp unit housing with the other

hand.

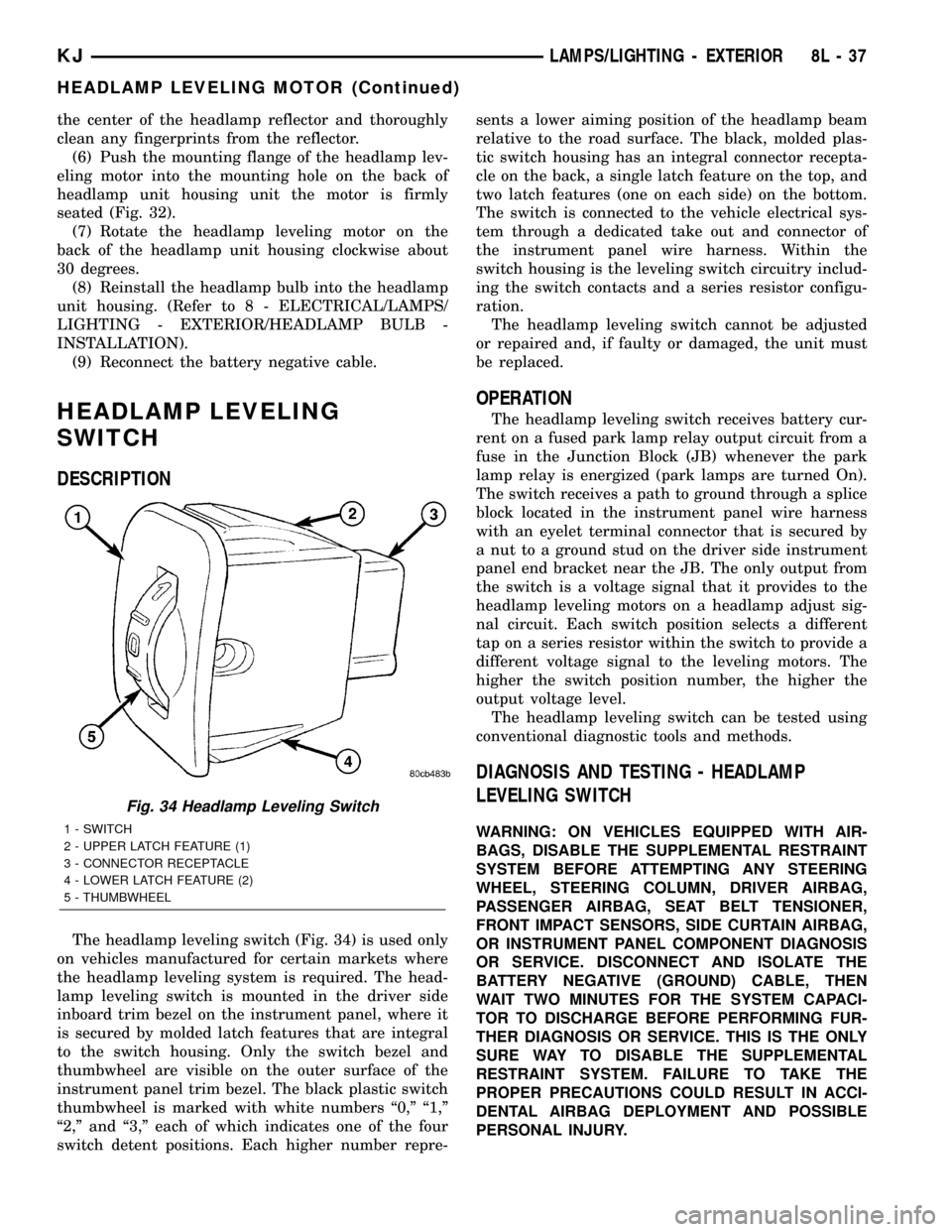

(5) Firmly, steadily, and forcefully pull the head-

lamp leveling motor straight away from the back of

the headlamp unit housing to unsnap the ball forma-

tion on the end of the motor pushrod from the socket

on the headlamp unit reflector (Fig. 33).

(6) Remove the headlamp leveling motor and push-

rod from the back of the headlamp unit housing.

INSTALLATION

The headlamp leveling motors are integral to the

headlamp units on vehicles manufactured for certain

markets where headlamp leveling is required.

(1) Position the headlamp leveling motor and

pushrod from to the mounting hole on the back of the

headlamp unit housing.

(2) Insert two fingers through the bulb mounting

hole in the center of the headlamp reflector and pullthe reflector upwards toward the headlamp leveling

motor.

(3) Align the ball formation on the end of the lev-

eling motor pushrod with the socket on the headlamp

unit reflector (Fig. 33).

(4) While continuing to pulling the reflector

toward the motor, firmly, steadily, and forcefully push

the headlamp leveling motor straight into the back of

the headlamp unit housing to snap the ball formation

on the end of the motor pushrod into the socket on

the headlamp unit reflector.

(5) After the pushrod is engaged to the reflector,

remove your fingers from the bulb mounting hole in

Fig. 32 Headlamp Leveling Motor Remove/Install

1 - LEVELING MOTOR

2 - HEADLAMP HOUSING

3 - PUSHROD

Fig. 33 Leveling Motor Pushrod - Typical

1 - REFLECTOR PUSHROD SOCKET

2 - PUSHROD

3 - LEVELING MOTOR

4 - HEADLAMP HOUSING

8L - 36 LAMPS/LIGHTING - EXTERIORKJ

HEADLAMP LEVELING MOTOR (Continued)

Page 478 of 1803

the center of the headlamp reflector and thoroughly

clean any fingerprints from the reflector.

(6) Push the mounting flange of the headlamp lev-

eling motor into the mounting hole on the back of

headlamp unit housing unit the motor is firmly

seated (Fig. 32).

(7) Rotate the headlamp leveling motor on the

back of the headlamp unit housing clockwise about

30 degrees.

(8) Reinstall the headlamp bulb into the headlamp

unit housing. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/HEADLAMP BULB -

INSTALLATION).

(9) Reconnect the battery negative cable.

HEADLAMP LEVELING

SWITCH

DESCRIPTION

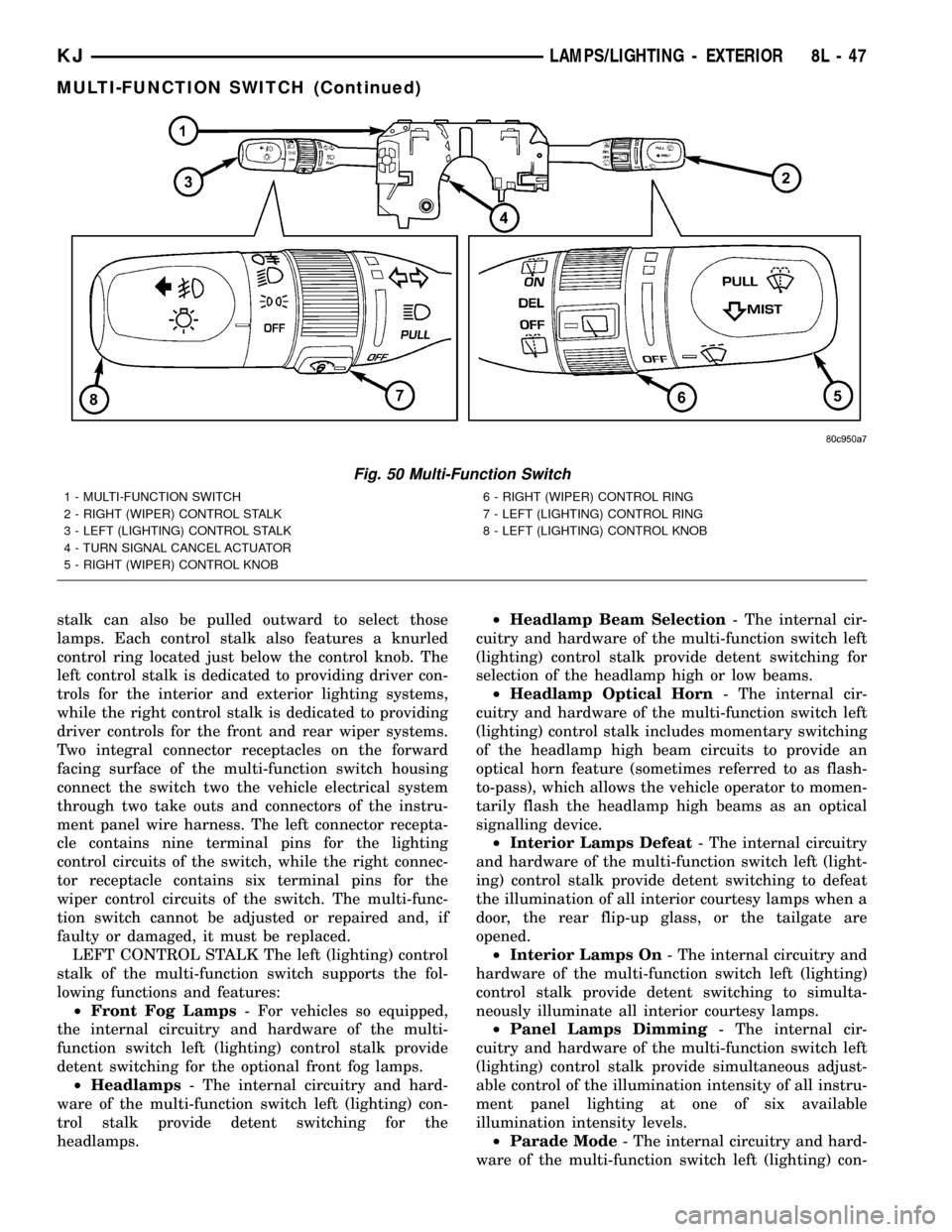

The headlamp leveling switch (Fig. 34) is used only

on vehicles manufactured for certain markets where

the headlamp leveling system is required. The head-

lamp leveling switch is mounted in the driver side

inboard trim bezel on the instrument panel, where it

is secured by molded latch features that are integral

to the switch housing. Only the switch bezel and

thumbwheel are visible on the outer surface of the

instrument panel trim bezel. The black plastic switch

thumbwheel is marked with white numbers ª0,º ª1,º

ª2,º and ª3,º each of which indicates one of the four

switch detent positions. Each higher number repre-sents a lower aiming position of the headlamp beam

relative to the road surface. The black, molded plas-

tic switch housing has an integral connector recepta-

cle on the back, a single latch feature on the top, and

two latch features (one on each side) on the bottom.

The switch is connected to the vehicle electrical sys-

tem through a dedicated take out and connector of

the instrument panel wire harness. Within the

switch housing is the leveling switch circuitry includ-

ing the switch contacts and a series resistor configu-

ration.

The headlamp leveling switch cannot be adjusted

or repaired and, if faulty or damaged, the unit must

be replaced.

OPERATION

The headlamp leveling switch receives battery cur-

rent on a fused park lamp relay output circuit from a

fuse in the Junction Block (JB) whenever the park

lamp relay is energized (park lamps are turned On).

The switch receives a path to ground through a splice

block located in the instrument panel wire harness

with an eyelet terminal connector that is secured by

a nut to a ground stud on the driver side instrument

panel end bracket near the JB. The only output from

the switch is a voltage signal that it provides to the

headlamp leveling motors on a headlamp adjust sig-

nal circuit. Each switch position selects a different

tap on a series resistor within the switch to provide a

different voltage signal to the leveling motors. The

higher the switch position number, the higher the

output voltage level.

The headlamp leveling switch can be tested using

conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - HEADLAMP

LEVELING SWITCH

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

Fig. 34 Headlamp Leveling Switch

1 - SWITCH

2 - UPPER LATCH FEATURE (1)

3 - CONNECTOR RECEPTACLE

4 - LOWER LATCH FEATURE (2)

5 - THUMBWHEEL

KJLAMPS/LIGHTING - EXTERIOR 8L - 37

HEADLAMP LEVELING MOTOR (Continued)

Page 488 of 1803

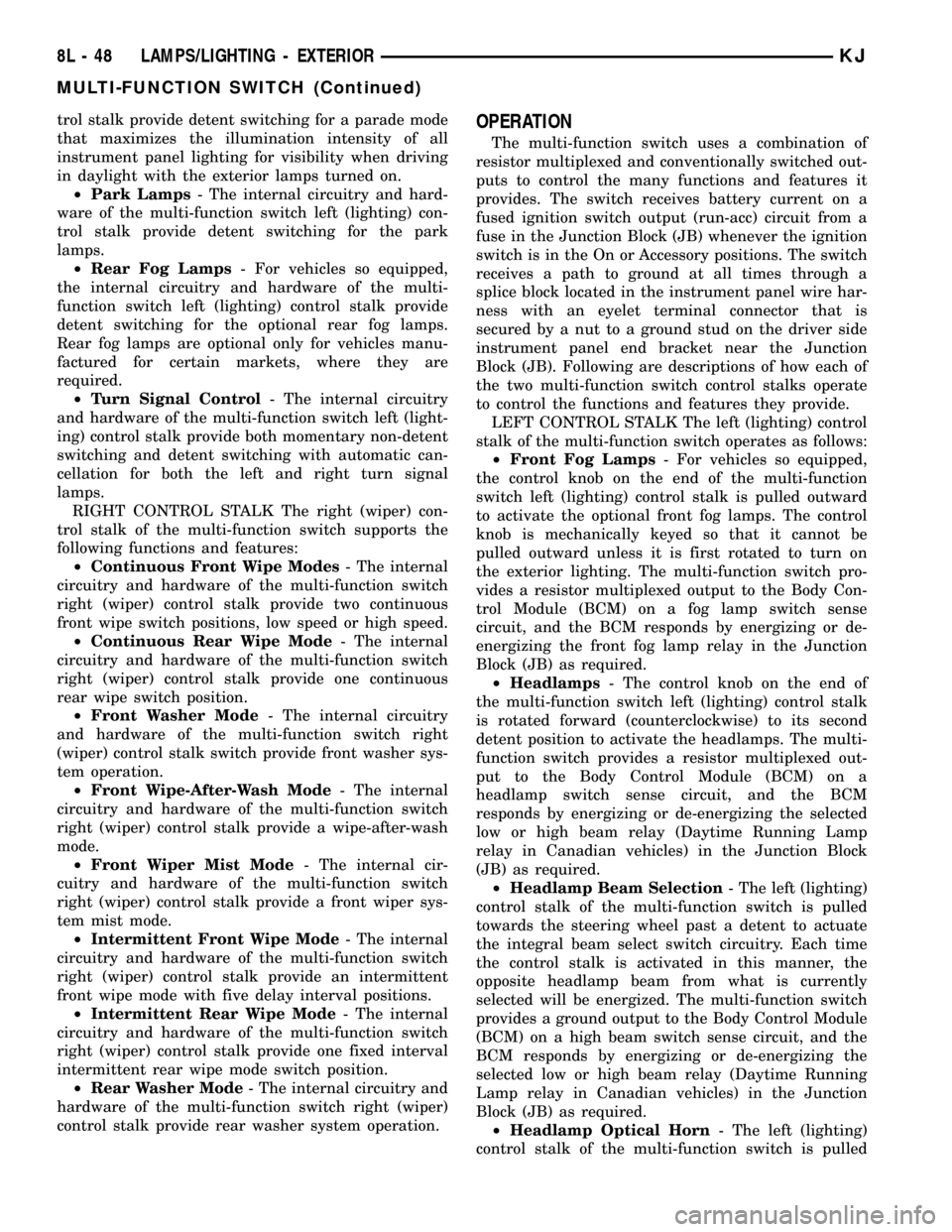

stalk can also be pulled outward to select those

lamps. Each control stalk also features a knurled

control ring located just below the control knob. The

left control stalk is dedicated to providing driver con-

trols for the interior and exterior lighting systems,

while the right control stalk is dedicated to providing

driver controls for the front and rear wiper systems.

Two integral connector receptacles on the forward

facing surface of the multi-function switch housing

connect the switch two the vehicle electrical system

through two take outs and connectors of the instru-

ment panel wire harness. The left connector recepta-

cle contains nine terminal pins for the lighting

control circuits of the switch, while the right connec-

tor receptacle contains six terminal pins for the

wiper control circuits of the switch. The multi-func-

tion switch cannot be adjusted or repaired and, if

faulty or damaged, it must be replaced.

LEFT CONTROL STALK The left (lighting) control

stalk of the multi-function switch supports the fol-

lowing functions and features:

²Front Fog Lamps- For vehicles so equipped,

the internal circuitry and hardware of the multi-

function switch left (lighting) control stalk provide

detent switching for the optional front fog lamps.

²Headlamps- The internal circuitry and hard-

ware of the multi-function switch left (lighting) con-

trol stalk provide detent switching for the

headlamps.²Headlamp Beam Selection- The internal cir-

cuitry and hardware of the multi-function switch left

(lighting) control stalk provide detent switching for

selection of the headlamp high or low beams.

²Headlamp Optical Horn- The internal cir-

cuitry and hardware of the multi-function switch left

(lighting) control stalk includes momentary switching

of the headlamp high beam circuits to provide an

optical horn feature (sometimes referred to as flash-

to-pass), which allows the vehicle operator to momen-

tarily flash the headlamp high beams as an optical

signalling device.

²Interior Lamps Defeat- The internal circuitry

and hardware of the multi-function switch left (light-

ing) control stalk provide detent switching to defeat

the illumination of all interior courtesy lamps when a

door, the rear flip-up glass, or the tailgate are

opened.

²Interior Lamps On- The internal circuitry and

hardware of the multi-function switch left (lighting)

control stalk provide detent switching to simulta-

neously illuminate all interior courtesy lamps.

²Panel Lamps Dimming- The internal cir-

cuitry and hardware of the multi-function switch left

(lighting) control stalk provide simultaneous adjust-

able control of the illumination intensity of all instru-

ment panel lighting at one of six available

illumination intensity levels.

²Parade Mode- The internal circuitry and hard-

ware of the multi-function switch left (lighting) con-

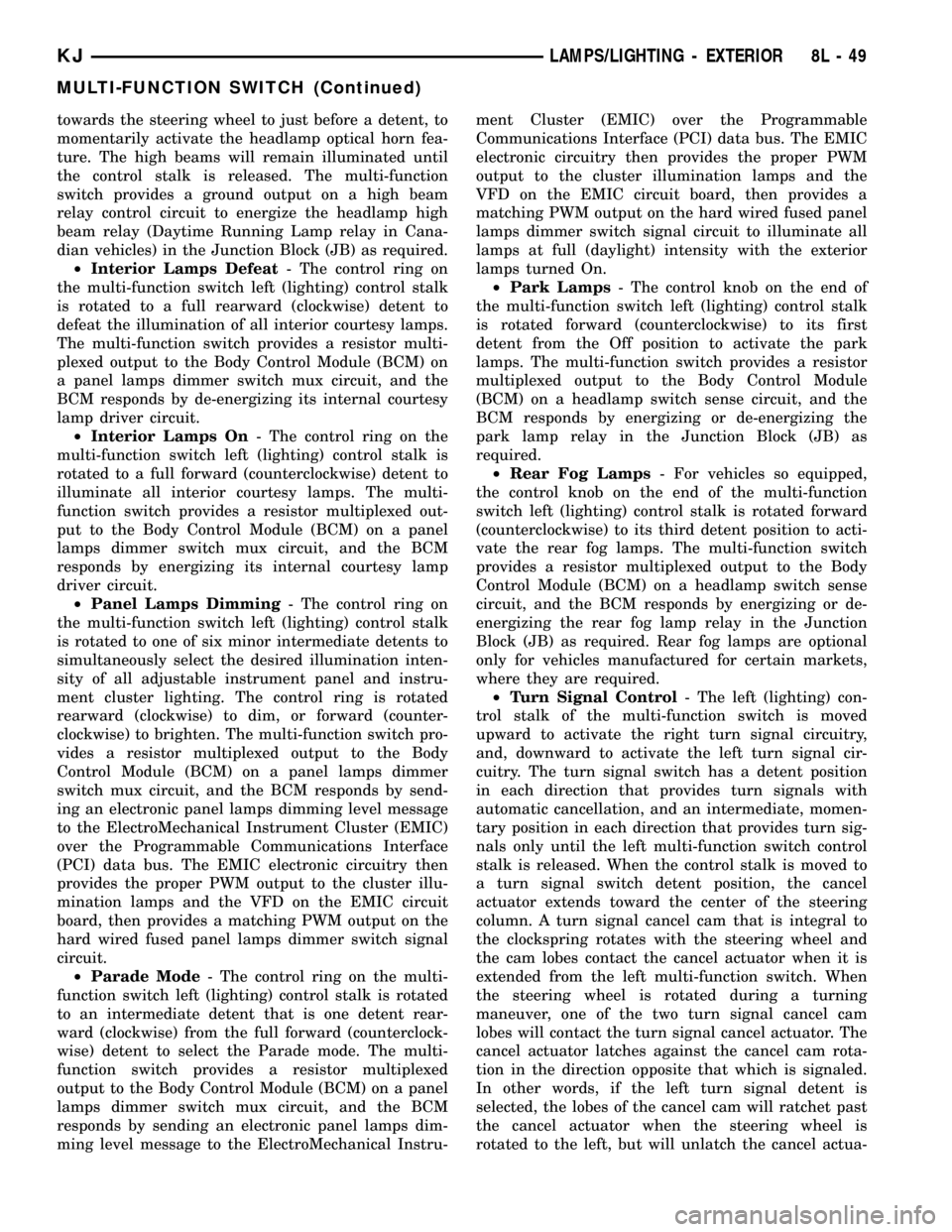

Fig. 50 Multi-Function Switch

1 - MULTI-FUNCTION SWITCH

2 - RIGHT (WIPER) CONTROL STALK

3 - LEFT (LIGHTING) CONTROL STALK

4 - TURN SIGNAL CANCEL ACTUATOR

5 - RIGHT (WIPER) CONTROL KNOB6 - RIGHT (WIPER) CONTROL RING

7 - LEFT (LIGHTING) CONTROL RING

8 - LEFT (LIGHTING) CONTROL KNOB

KJLAMPS/LIGHTING - EXTERIOR 8L - 47

MULTI-FUNCTION SWITCH (Continued)

Page 489 of 1803

trol stalk provide detent switching for a parade mode

that maximizes the illumination intensity of all

instrument panel lighting for visibility when driving

in daylight with the exterior lamps turned on.

²Park Lamps- The internal circuitry and hard-

ware of the multi-function switch left (lighting) con-

trol stalk provide detent switching for the park

lamps.

²Rear Fog Lamps- For vehicles so equipped,

the internal circuitry and hardware of the multi-

function switch left (lighting) control stalk provide

detent switching for the optional rear fog lamps.

Rear fog lamps are optional only for vehicles manu-

factured for certain markets, where they are

required.

²Turn Signal Control- The internal circuitry

and hardware of the multi-function switch left (light-

ing) control stalk provide both momentary non-detent

switching and detent switching with automatic can-

cellation for both the left and right turn signal

lamps.

RIGHT CONTROL STALK The right (wiper) con-

trol stalk of the multi-function switch supports the

following functions and features:

²Continuous Front Wipe Modes- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide two continuous

front wipe switch positions, low speed or high speed.

²Continuous Rear Wipe Mode- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide one continuous

rear wipe switch position.

²Front Washer Mode- The internal circuitry

and hardware of the multi-function switch right

(wiper) control stalk switch provide front washer sys-

tem operation.

²Front Wipe-After-Wash Mode- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide a wipe-after-wash

mode.

²Front Wiper Mist Mode- The internal cir-

cuitry and hardware of the multi-function switch

right (wiper) control stalk provide a front wiper sys-

tem mist mode.

²Intermittent Front Wipe Mode- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide an intermittent

front wipe mode with five delay interval positions.

²Intermittent Rear Wipe Mode- The internal

circuitry and hardware of the multi-function switch

right (wiper) control stalk provide one fixed interval

intermittent rear wipe mode switch position.

²Rear Washer Mode- The internal circuitry and

hardware of the multi-function switch right (wiper)

control stalk provide rear washer system operation.OPERATION

The multi-function switch uses a combination of

resistor multiplexed and conventionally switched out-

puts to control the many functions and features it

provides. The switch receives battery current on a

fused ignition switch output (run-acc) circuit from a

fuse in the Junction Block (JB) whenever the ignition

switch is in the On or Accessory positions. The switch

receives a path to ground at all times through a

splice block located in the instrument panel wire har-

ness with an eyelet terminal connector that is

secured by a nut to a ground stud on the driver side

instrument panel end bracket near the Junction

Block (JB). Following are descriptions of how each of

the two multi-function switch control stalks operate

to control the functions and features they provide.

LEFT CONTROL STALK The left (lighting) control

stalk of the multi-function switch operates as follows:

²Front Fog Lamps- For vehicles so equipped,

the control knob on the end of the multi-function

switch left (lighting) control stalk is pulled outward

to activate the optional front fog lamps. The control

knob is mechanically keyed so that it cannot be

pulled outward unless it is first rotated to turn on

the exterior lighting. The multi-function switch pro-

vides a resistor multiplexed output to the Body Con-

trol Module (BCM) on a fog lamp switch sense

circuit, and the BCM responds by energizing or de-

energizing the front fog lamp relay in the Junction

Block (JB) as required.

²Headlamps- The control knob on the end of

the multi-function switch left (lighting) control stalk

is rotated forward (counterclockwise) to its second

detent position to activate the headlamps. The multi-

function switch provides a resistor multiplexed out-

put to the Body Control Module (BCM) on a

headlamp switch sense circuit, and the BCM

responds by energizing or de-energizing the selected

low or high beam relay (Daytime Running Lamp

relay in Canadian vehicles) in the Junction Block

(JB) as required.

²Headlamp Beam Selection- The left (lighting)

control stalk of the multi-function switch is pulled

towards the steering wheel past a detent to actuate

the integral beam select switch circuitry. Each time

the control stalk is activated in this manner, the

opposite headlamp beam from what is currently

selected will be energized. The multi-function switch

provides a ground output to the Body Control Module

(BCM) on a high beam switch sense circuit, and the

BCM responds by energizing or de-energizing the

selected low or high beam relay (Daytime Running

Lamp relay in Canadian vehicles) in the Junction

Block (JB) as required.

²Headlamp Optical Horn- The left (lighting)

control stalk of the multi-function switch is pulled

8L - 48 LAMPS/LIGHTING - EXTERIORKJ

MULTI-FUNCTION SWITCH (Continued)

Page 490 of 1803

towards the steering wheel to just before a detent, to

momentarily activate the headlamp optical horn fea-

ture. The high beams will remain illuminated until

the control stalk is released. The multi-function

switch provides a ground output on a high beam

relay control circuit to energize the headlamp high

beam relay (Daytime Running Lamp relay in Cana-

dian vehicles) in the Junction Block (JB) as required.

²Interior Lamps Defeat- The control ring on

the multi-function switch left (lighting) control stalk

is rotated to a full rearward (clockwise) detent to

defeat the illumination of all interior courtesy lamps.

The multi-function switch provides a resistor multi-

plexed output to the Body Control Module (BCM) on

a panel lamps dimmer switch mux circuit, and the

BCM responds by de-energizing its internal courtesy

lamp driver circuit.

²Interior Lamps On- The control ring on the

multi-function switch left (lighting) control stalk is

rotated to a full forward (counterclockwise) detent to

illuminate all interior courtesy lamps. The multi-

function switch provides a resistor multiplexed out-

put to the Body Control Module (BCM) on a panel

lamps dimmer switch mux circuit, and the BCM

responds by energizing its internal courtesy lamp

driver circuit.

²Panel Lamps Dimming- The control ring on

the multi-function switch left (lighting) control stalk

is rotated to one of six minor intermediate detents to

simultaneously select the desired illumination inten-

sity of all adjustable instrument panel and instru-

ment cluster lighting. The control ring is rotated

rearward (clockwise) to dim, or forward (counter-

clockwise) to brighten. The multi-function switch pro-

vides a resistor multiplexed output to the Body

Control Module (BCM) on a panel lamps dimmer

switch mux circuit, and the BCM responds by send-

ing an electronic panel lamps dimming level message

to the ElectroMechanical Instrument Cluster (EMIC)

over the Programmable Communications Interface

(PCI) data bus. The EMIC electronic circuitry then

provides the proper PWM output to the cluster illu-

mination lamps and the VFD on the EMIC circuit

board, then provides a matching PWM output on the

hard wired fused panel lamps dimmer switch signal

circuit.

²Parade Mode- The control ring on the multi-

function switch left (lighting) control stalk is rotated

to an intermediate detent that is one detent rear-

ward (clockwise) from the full forward (counterclock-

wise) detent to select the Parade mode. The multi-

function switch provides a resistor multiplexed

output to the Body Control Module (BCM) on a panel

lamps dimmer switch mux circuit, and the BCM

responds by sending an electronic panel lamps dim-

ming level message to the ElectroMechanical Instru-ment Cluster (EMIC) over the Programmable

Communications Interface (PCI) data bus. The EMIC

electronic circuitry then provides the proper PWM

output to the cluster illumination lamps and the

VFD on the EMIC circuit board, then provides a

matching PWM output on the hard wired fused panel

lamps dimmer switch signal circuit to illuminate all

lamps at full (daylight) intensity with the exterior

lamps turned On.

²Park Lamps- The control knob on the end of

the multi-function switch left (lighting) control stalk

is rotated forward (counterclockwise) to its first

detent from the Off position to activate the park

lamps. The multi-function switch provides a resistor

multiplexed output to the Body Control Module

(BCM) on a headlamp switch sense circuit, and the

BCM responds by energizing or de-energizing the

park lamp relay in the Junction Block (JB) as

required.

²Rear Fog Lamps- For vehicles so equipped,

the control knob on the end of the multi-function

switch left (lighting) control stalk is rotated forward

(counterclockwise) to its third detent position to acti-

vate the rear fog lamps. The multi-function switch

provides a resistor multiplexed output to the Body

Control Module (BCM) on a headlamp switch sense

circuit, and the BCM responds by energizing or de-

energizing the rear fog lamp relay in the Junction

Block (JB) as required. Rear fog lamps are optional

only for vehicles manufactured for certain markets,

where they are required.

²Turn Signal Control- The left (lighting) con-

trol stalk of the multi-function switch is moved

upward to activate the right turn signal circuitry,

and, downward to activate the left turn signal cir-

cuitry. The turn signal switch has a detent position

in each direction that provides turn signals with

automatic cancellation, and an intermediate, momen-

tary position in each direction that provides turn sig-

nals only until the left multi-function switch control

stalk is released. When the control stalk is moved to

a turn signal switch detent position, the cancel

actuator extends toward the center of the steering

column. A turn signal cancel cam that is integral to

the clockspring rotates with the steering wheel and

the cam lobes contact the cancel actuator when it is

extended from the left multi-function switch. When

the steering wheel is rotated during a turning

maneuver, one of the two turn signal cancel cam

lobes will contact the turn signal cancel actuator. The

cancel actuator latches against the cancel cam rota-

tion in the direction opposite that which is signaled.

In other words, if the left turn signal detent is

selected, the lobes of the cancel cam will ratchet past

the cancel actuator when the steering wheel is

rotated to the left, but will unlatch the cancel actua-

KJLAMPS/LIGHTING - EXTERIOR 8L - 49

MULTI-FUNCTION SWITCH (Continued)

Page 491 of 1803

tor as the steering wheel rotates to the right and

returns to center, which will cancel the turn signal

event and release the control stalk from the detent so

it returns to the neutral Off position. When a turn

signal is activated, the multi-function switch provides

a ground output on a right or left turn switch sense

circuit to the combination flasher circuitry within the

hazard switch, and the combination flasher flashes

the turn signal lamps.

RIGHT CONTROL STALK The right (wiper) con-

trol stalk of the multi-function switch operates as fol-

lows:

²Continuous Front Wipe Modes- The control

knob on the end of the multi-function switch right

(wiper) control stalk is rotated to an intermediate

detent that is one detent rearward (counterclockwise)

from the full forward (clockwise) detent to select the

low speed continuous front wiper mode, or to its full

forward (clockwise) detent to select the high speed

continuous front wiper mode. The multi-function

switch provides a resistor multiplexed output to the

Body Control Module (BCM) on a front wiper switch

mux circuit, and the BCM responds by energizing the

wiper on/off relay in the Power Distribution Center

(PDC) for the front low speed continuous wipe mode,

or the wiper on/off relay and the wiper high/low relay

in the PDC for the front high speed continuous wipe

mode as required.

²Continuous Rear Wipe Mode- The control

ring on the multi-function switch right (wiper) con-

trol stalk is rotated to the most forward (clockwise)

detent to select the continuous rear wiper mode. The

multi-function switch provides a battery current out-

put to the rear wiper motor on a rear wiper on driver

circuit to signal the rear wiper motor to operate in

the continuous wipe mode.

²Front Washer Mode- The right (wiper) control

stalk of the multi-function switch is pulled towards

the steering wheel to momentarily activate the

washer pump in the front washer mode. The washer

pump will continue to operate in the front washer

mode until the control stalk is released. The multi-

function switch provides a ground output on a

washer pump sense circuit, and battery current on a

washer pump driver circuit to energize the washer

pump in the front washer mode.

²Front Wiper Mist Mode- The right (wiper)

control stalk of the multi-function switch is pushed

towards the floor to momentarily activate the front

wiper motor in the mist mode. The front wiper motor

will continue to operate in the mist mode until the

control stalk is released. The multi-function switch

provides a resistor multiplexed output to the Body

Control Module (BCM) on a front wiper switch mux

circuit, and the BCM responds by energizing the

wiper on/off relay in the Power Distribution Center(PDC) to operate the front wiper motor momentarily

at low speed to provide the front wiper mist mode.

²Intermittent Front Wipe Mode- The control

knob on the end of the multi-function switch right

(wiper) control stalk is rotated to one of five minor

intermediate detents to select the desired intermit-

tent front wipe delay interval. The control knob is

rotated rearward (counterclockwise) to increase the

delay, or forward (clockwise) to decrease the delay.

The multi-function switch provides a resistor multi-

plexed output to the Body Control Module (BCM) on

a front wiper switch mux circuit, and the BCM

responds by energizing the wiper on/off relay in the

Power Distribution Center (PDC) to operate the front

wiper motor at the selected delay intervals.

²Intermittent Rear Wipe Mode- The control

ring on the multi-function switch right (wiper) con-

trol stalk is rotated to the center detent to select the

intermittent rear wiper mode. The multi-function

switch provides a battery current output to the rear

wiper motor on a rear wiper intermittent driver cir-

cuit to signal the rear wiper motor to operate in the

intermittent wipe mode.

²Rear Washer Mode- The control ring on the

multi-function switch right (wiper) control stalk is

rotated to either the full forward (clockwise) or full

rearward (counterclockwise) momentary positions to

activate the washer pump in the rear washer mode.

The washer pump will continue to operate in the rear

washer mode until the control ring is released. The

multi-function switch provides a ground output on a

washer pump driver circuit, and battery current on a

washer pump sense circuit to energize the washer

pump in the rear washer mode.

DIAGNOSIS AND TESTING - MULTI-FUNCTION

SWITCH

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

8L - 50 LAMPS/LIGHTING - EXTERIORKJ

MULTI-FUNCTION SWITCH (Continued)

Page 493 of 1803

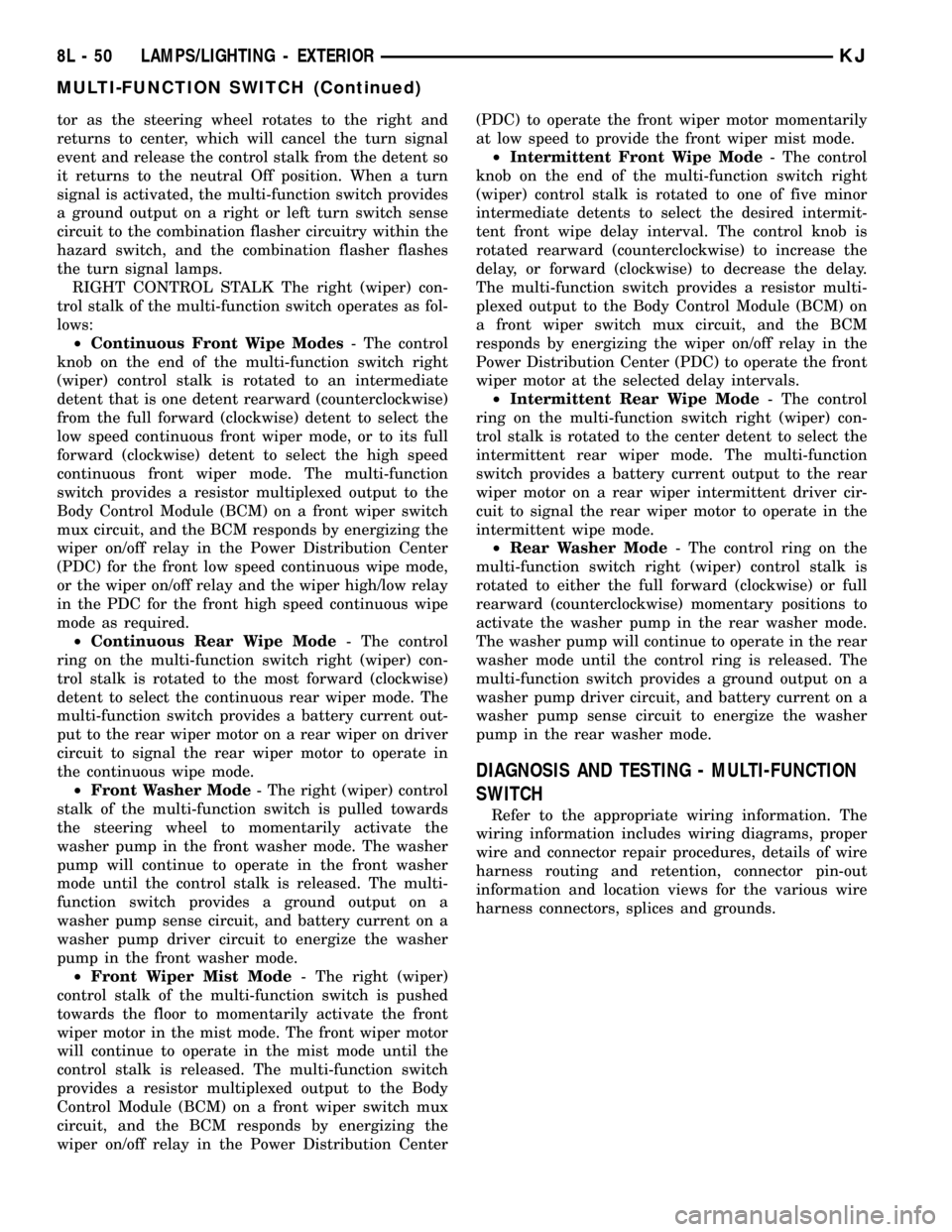

MULTI-FUNCTION SWITCH TESTS

EXTERIOR LIGHTING FUNCTIONS

SWITCH POSITION CONNECTOR C-1 PINS RESISTANCE (OHMS) 10%

Off 4 & 5 3781

Park Lamps On 4 & 5 911

Headlamp Low Beams On 4 & 5 349

Rear Fog Lamps On 4 & 5 75

Headlamp High Beams On 8 & 9 0 - 1

Front Fog Lamps On 2 & 4 0 - 1

Optical Horn (Flash-to-Pass) On 7 & 8 0 - 1

Turn Signal Neutral 6 & 8,8&10Infinite (Open)

Turn Signal Left 6 & 8 0 - 1

Turn Signal Right 8 & 10 0 - 1

INTERIOR LIGHTING FUNCTIONS

SWITCH POSITION CONNECTOR C-1 PINS RESISTANCE (OHMS) 10%

Off (Courtesy Disable) 1 & 4 63

Dimming 1 1 & 4 200

Dimming 2 1 & 4 557

Dimming 3 1 & 4 914

Dimming 4 1 & 4 1271

Dimming 5 1 & 4 1628

Dimming 6 1 & 4 1985

Parade Mode On 1 & 4 3565

Courtesy On 1 & 4 7885

FRONT WIPER FUNCTIONS

SWITCH POSITIONCONNECTOR C-1 & C-2

PINSRESISTANCE (OHMS) 10%

Front Wiper Off C-1 Pin 4 & C-2 Pin 4 4587

Delay 1 C-1 Pin 4 & C-2 Pin 4 1267

Delay 2 C-1 Pin 4 & C-2 Pin 4 792

Delay 3 C-1 Pin 4 & C-2 Pin 4 531

Delay 4 C-1 Pin 4 & C-2 Pin 4 369

Delay 5 C-1 Pin 4 & C-2 Pin 4 262

Front Wiper Low C-1 Pin 4 & C-2 Pin 4 125

Front Wiper High C-1 Pin 4 & C-2 Pin 4 38

Front Wiper Mist C-1 Pin 4 & C-2 Pin 4 125

Front Washer On C-2 Pins5&7 0-1

REAR WIPER FUNCTIONS

SWITCH POSITION CONNECTOR C-2 PINS RESISTANCE (OHMS) 10%

Rear Wiper Off 1 & 5,2&5Infinite (Open)

Rear Wiper Intermittent 2 & 5 0 - 1

Rear Wiper On 1 & 5 0 - 1

Rear Washer On 2 & 5,3&5 0-1

8L - 52 LAMPS/LIGHTING - EXTERIORKJ

MULTI-FUNCTION SWITCH (Continued)

Page 494 of 1803

(4) If the multi-function switch fails any of the

continuity or resistance tests, replace the faulty

switch unit as required.

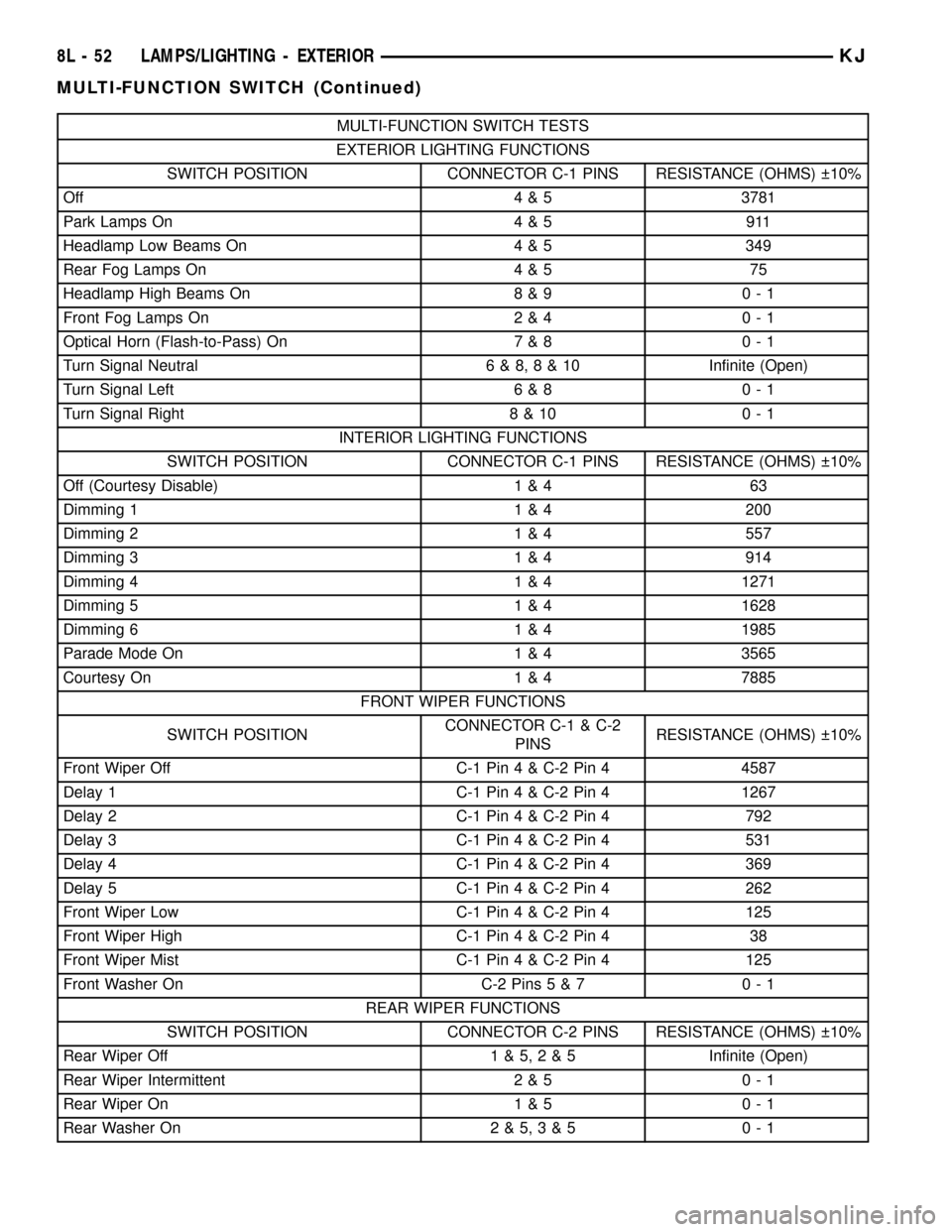

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) If the vehicle is equipped with the optional tilt

steering column, move the tilt steering column to the

fully lowered position and leave the tilt release lever

in the released (down) position.

(3) From below the steering column, remove the

two screws that secure the lower shroud to the upper

shroud (Fig. 52).

(4) Using hand pressure, push gently inward on

both sides of the upper shroud near the parting line

between the upper and lower shrouds to release the

snap features that secure the two halves to each

other.

(5) Remove both the upper and lower shrouds from

the steering column.

(6) Disconnect the two instrument panel wire har-

ness connectors for the multi-function switch from

the two connector receptacles on the back of the

switch housing.

(7) Remove the multi-function switch from the

steering column lock housing by carefully rocking the

switch and pulling the switch housing upward far

enough to disengage its alignment posts and locator

tabs from the lock housing.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

CAUTION: Before attempting to install the multi-

function switch, be certain that the left control stalk

is in the neutral turn signal position and the turn

signal cancel actuator is in the retracted (neutral)

position.

(1) Position the multi-function switch to the steer-

ing column.

(2) Reconnect the two instrument panel wire har-

ness connectors for the multi-function switch to the

two connector receptacles on the back of the switch

housing (Fig. 52).

Fig. 52 Multi-Function Switch Remove/Install

1 - UPPER SHROUD

2 - MULTI-FUNCTION SWITCH

3 - CLOCKSPRING

4 - LOWER SHROUD

5 - SCREW (2)

6 - STEERING COLUMN

7 - WIRE HARNESS CONNECTOR (2)

KJLAMPS/LIGHTING - EXTERIOR 8L - 53

MULTI-FUNCTION SWITCH (Continued)

Page 502 of 1803

repeater lamp wire harness connector from the con-

nector receptacle on the back of the repeater lamp

unit socket.

(4) Remove the repeater lamp unit from the front

fender panel.

INSTALLATION

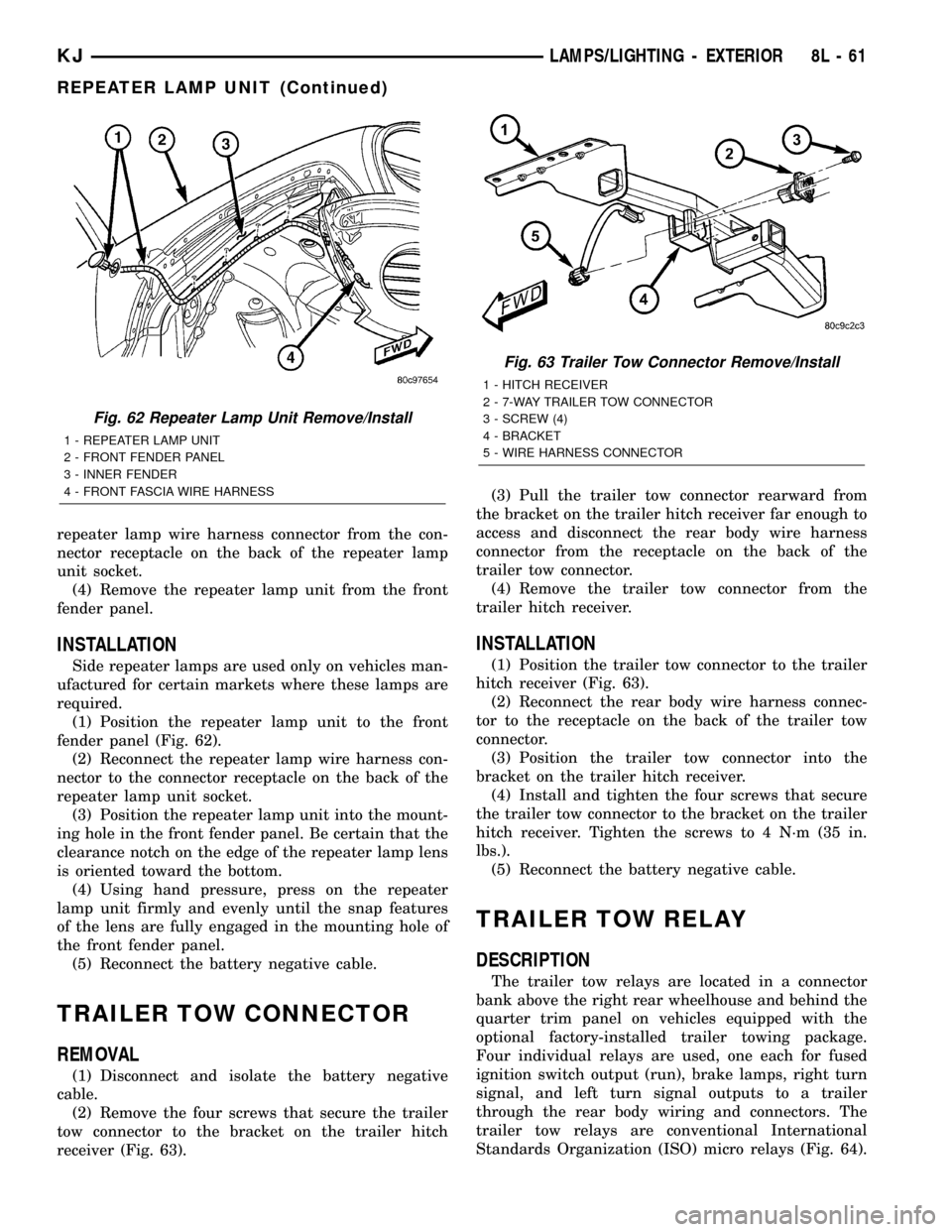

Side repeater lamps are used only on vehicles man-

ufactured for certain markets where these lamps are

required.

(1) Position the repeater lamp unit to the front

fender panel (Fig. 62).

(2) Reconnect the repeater lamp wire harness con-

nector to the connector receptacle on the back of the

repeater lamp unit socket.

(3) Position the repeater lamp unit into the mount-

ing hole in the front fender panel. Be certain that the

clearance notch on the edge of the repeater lamp lens

is oriented toward the bottom.

(4) Using hand pressure, press on the repeater

lamp unit firmly and evenly until the snap features

of the lens are fully engaged in the mounting hole of

the front fender panel.

(5) Reconnect the battery negative cable.

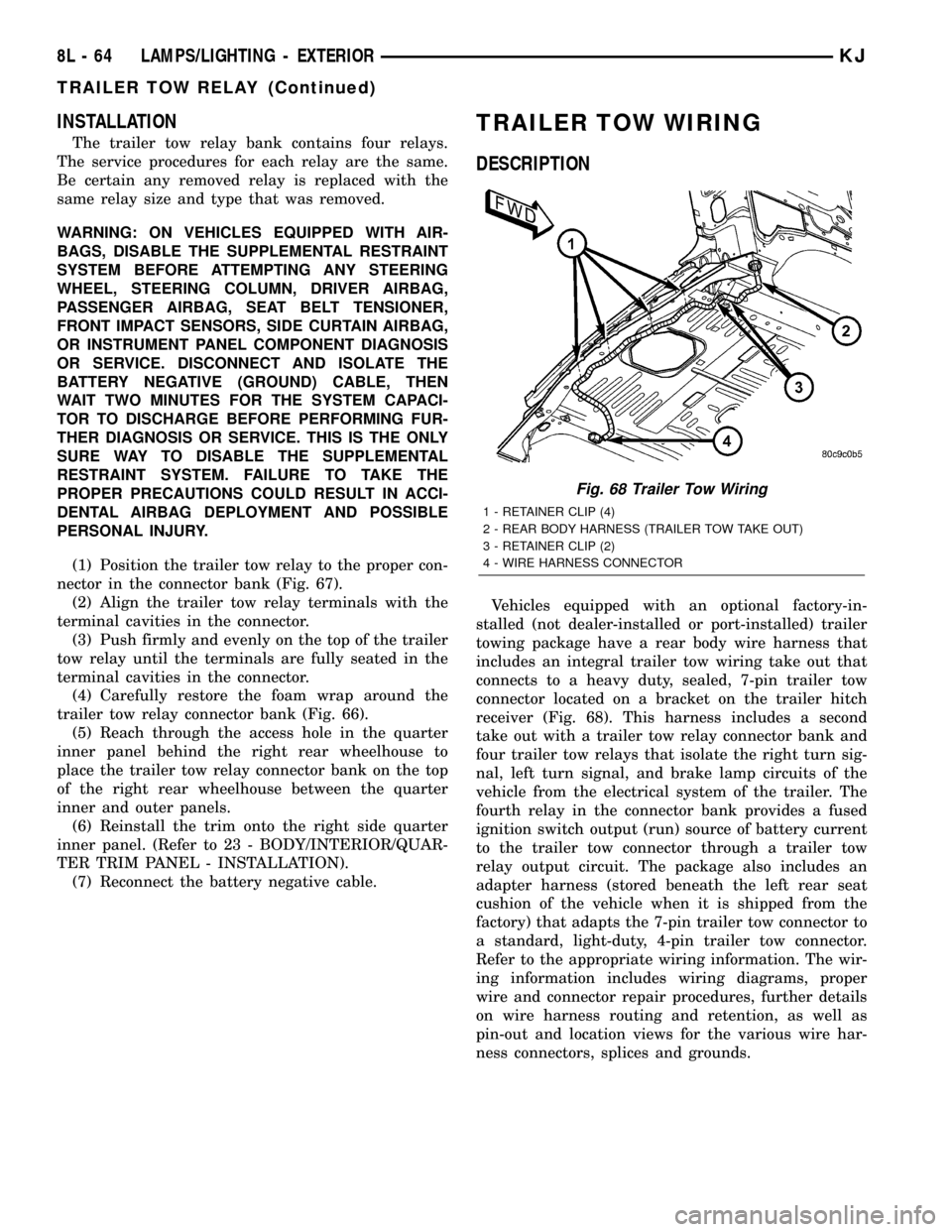

TRAILER TOW CONNECTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the four screws that secure the trailer

tow connector to the bracket on the trailer hitch

receiver (Fig. 63).(3) Pull the trailer tow connector rearward from

the bracket on the trailer hitch receiver far enough to

access and disconnect the rear body wire harness

connector from the receptacle on the back of the

trailer tow connector.

(4) Remove the trailer tow connector from the

trailer hitch receiver.

INSTALLATION

(1) Position the trailer tow connector to the trailer

hitch receiver (Fig. 63).

(2) Reconnect the rear body wire harness connec-

tor to the receptacle on the back of the trailer tow

connector.

(3) Position the trailer tow connector into the

bracket on the trailer hitch receiver.

(4) Install and tighten the four screws that secure

the trailer tow connector to the bracket on the trailer

hitch receiver. Tighten the screws to 4 N´m (35 in.

lbs.).

(5) Reconnect the battery negative cable.

TRAILER TOW RELAY

DESCRIPTION

The trailer tow relays are located in a connector

bank above the right rear wheelhouse and behind the

quarter trim panel on vehicles equipped with the

optional factory-installed trailer towing package.

Four individual relays are used, one each for fused

ignition switch output (run), brake lamps, right turn

signal, and left turn signal outputs to a trailer

through the rear body wiring and connectors. The

trailer tow relays are conventional International

Standards Organization (ISO) micro relays (Fig. 64).

Fig. 62 Repeater Lamp Unit Remove/Install

1 - REPEATER LAMP UNIT

2 - FRONT FENDER PANEL

3 - INNER FENDER

4 - FRONT FASCIA WIRE HARNESS

Fig. 63 Trailer Tow Connector Remove/Install

1 - HITCH RECEIVER

2 - 7-WAY TRAILER TOW CONNECTOR

3 - SCREW (4)

4 - BRACKET

5 - WIRE HARNESS CONNECTOR

KJLAMPS/LIGHTING - EXTERIOR 8L - 61

REPEATER LAMP UNIT (Continued)

Page 505 of 1803

INSTALLATION

The trailer tow relay bank contains four relays.

The service procedures for each relay are the same.

Be certain any removed relay is replaced with the

same relay size and type that was removed.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SEAT BELT TENSIONER,

FRONT IMPACT SENSORS, SIDE CURTAIN AIRBAG,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Position the trailer tow relay to the proper con-

nector in the connector bank (Fig. 67).

(2) Align the trailer tow relay terminals with the

terminal cavities in the connector.

(3) Push firmly and evenly on the top of the trailer

tow relay until the terminals are fully seated in the

terminal cavities in the connector.

(4) Carefully restore the foam wrap around the

trailer tow relay connector bank (Fig. 66).

(5) Reach through the access hole in the quarter

inner panel behind the right rear wheelhouse to

place the trailer tow relay connector bank on the top

of the right rear wheelhouse between the quarter

inner and outer panels.

(6) Reinstall the trim onto the right side quarter

inner panel. (Refer to 23 - BODY/INTERIOR/QUAR-

TER TRIM PANEL - INSTALLATION).

(7) Reconnect the battery negative cable.

TRAILER TOW WIRING

DESCRIPTION

Vehicles equipped with an optional factory-in-

stalled (not dealer-installed or port-installed) trailer

towing package have a rear body wire harness that

includes an integral trailer tow wiring take out that

connects to a heavy duty, sealed, 7-pin trailer tow

connector located on a bracket on the trailer hitch

receiver (Fig. 68). This harness includes a second

take out with a trailer tow relay connector bank and

four trailer tow relays that isolate the right turn sig-

nal, left turn signal, and brake lamp circuits of the

vehicle from the electrical system of the trailer. The

fourth relay in the connector bank provides a fused

ignition switch output (run) source of battery current

to the trailer tow connector through a trailer tow

relay output circuit. The package also includes an

adapter harness (stored beneath the left rear seat

cushion of the vehicle when it is shipped from the

factory) that adapts the 7-pin trailer tow connector to

a standard, light-duty, 4-pin trailer tow connector.

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds.

Fig. 68 Trailer Tow Wiring

1 - RETAINER CLIP (4)

2 - REAR BODY HARNESS (TRAILER TOW TAKE OUT)

3 - RETAINER CLIP (2)

4 - WIRE HARNESS CONNECTOR

8L - 64 LAMPS/LIGHTING - EXTERIORKJ

TRAILER TOW RELAY (Continued)