insid JEEP LIBERTY 2002 KJ / 1.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1407 of 1803

REMOVAL

Fuel Tank Draining

WARNING: THE FUEL SYSTEM MAY BE UNDER

CONSTANT FUEL PRESSURE EVEN WITH THE

ENGINE OFF. THIS PRESSURE MUST BE

RELEASED BEFORE SERVICING FUEL TANK.

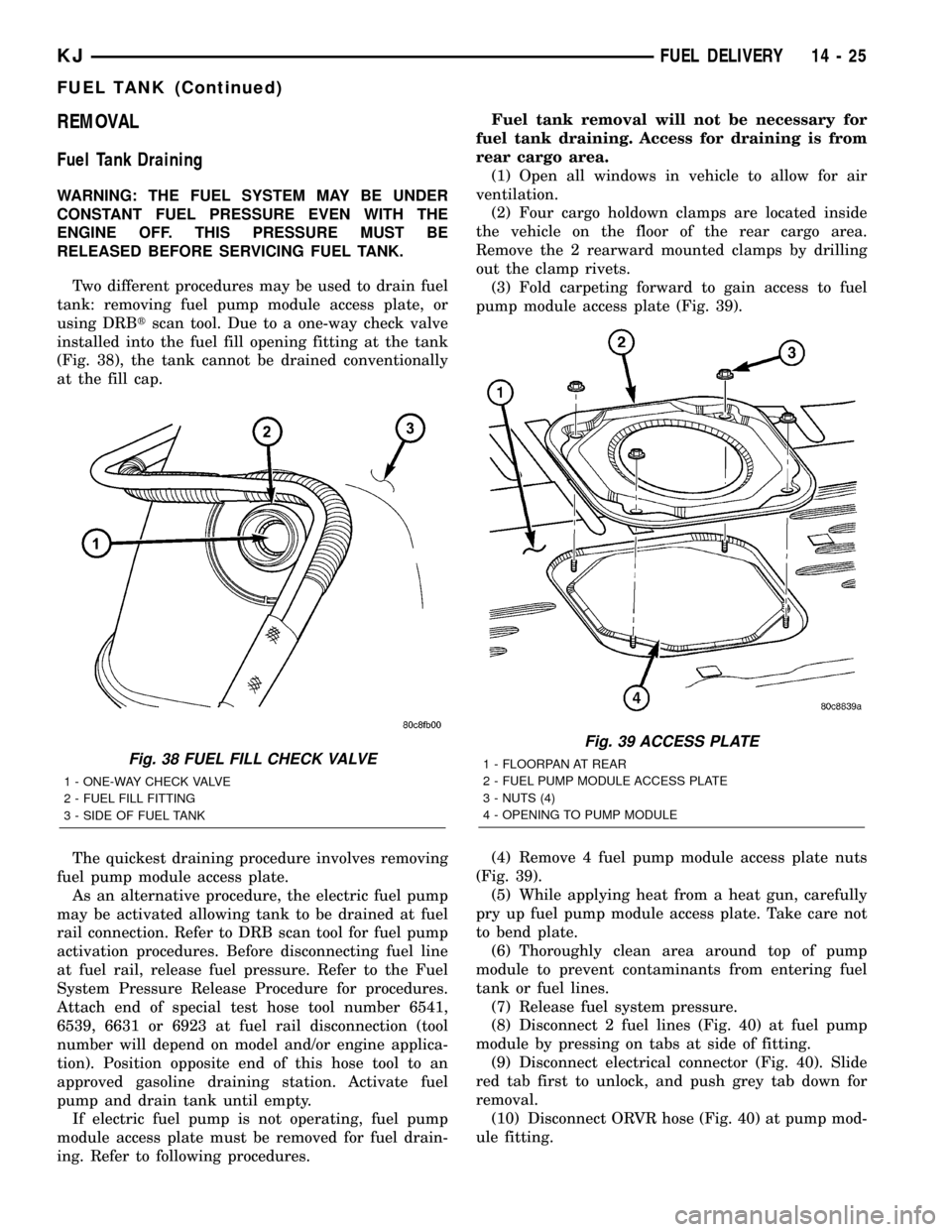

Two different procedures may be used to drain fuel

tank: removing fuel pump module access plate, or

using DRBtscan tool. Due to a one-way check valve

installed into the fuel fill opening fitting at the tank

(Fig. 38), the tank cannot be drained conventionally

at the fill cap.

The quickest draining procedure involves removing

fuel pump module access plate.

As an alternative procedure, the electric fuel pump

may be activated allowing tank to be drained at fuel

rail connection. Refer to DRB scan tool for fuel pump

activation procedures. Before disconnecting fuel line

at fuel rail, release fuel pressure. Refer to the Fuel

System Pressure Release Procedure for procedures.

Attach end of special test hose tool number 6541,

6539, 6631 or 6923 at fuel rail disconnection (tool

number will depend on model and/or engine applica-

tion). Position opposite end of this hose tool to an

approved gasoline draining station. Activate fuel

pump and drain tank until empty.

If electric fuel pump is not operating, fuel pump

module access plate must be removed for fuel drain-

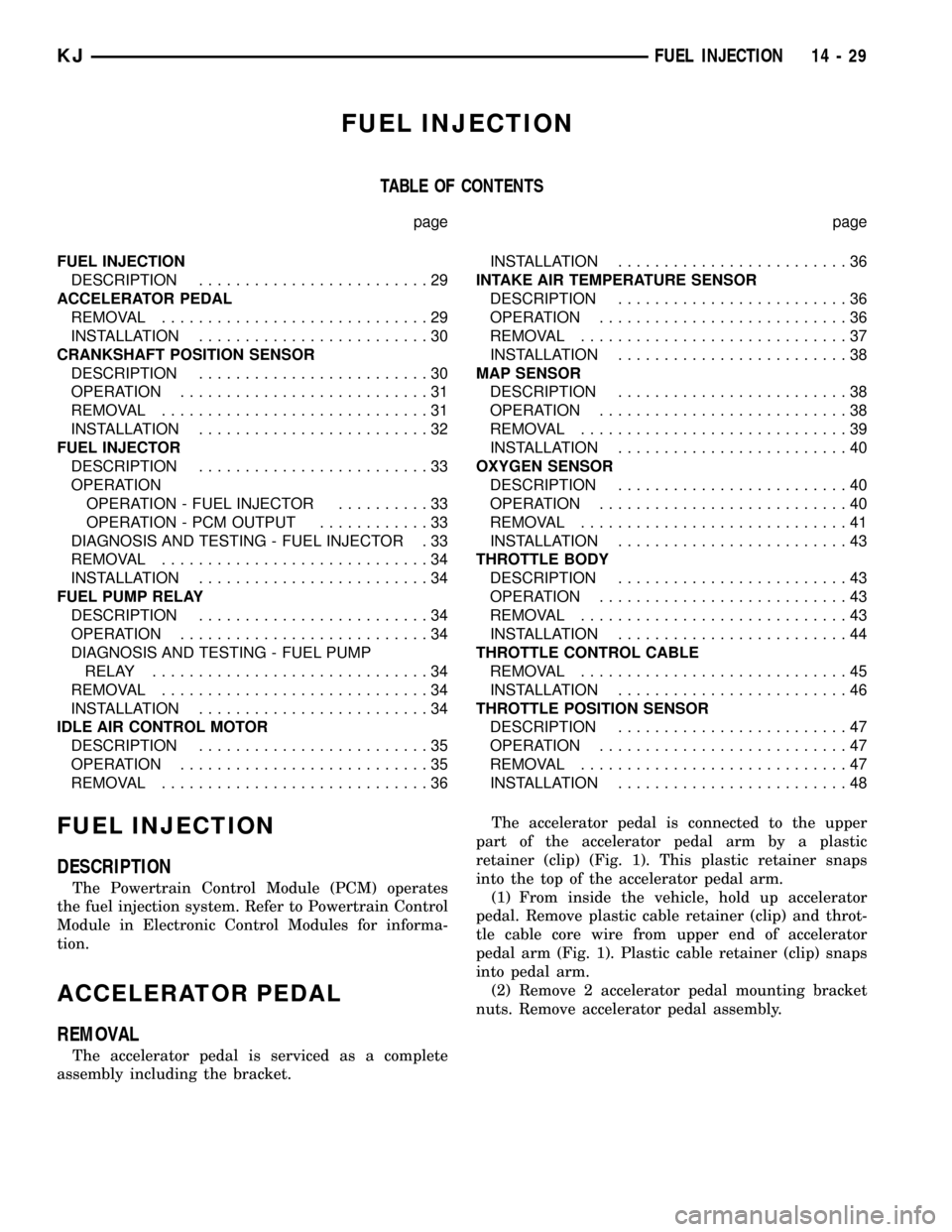

ing. Refer to following procedures.Fuel tank removal will not be necessary for

fuel tank draining. Access for draining is from

rear cargo area.

(1) Open all windows in vehicle to allow for air

ventilation.

(2) Four cargo holdown clamps are located inside

the vehicle on the floor of the rear cargo area.

Remove the 2 rearward mounted clamps by drilling

out the clamp rivets.

(3) Fold carpeting forward to gain access to fuel

pump module access plate (Fig. 39).

(4) Remove 4 fuel pump module access plate nuts

(Fig. 39).

(5) While applying heat from a heat gun, carefully

pry up fuel pump module access plate. Take care not

to bend plate.

(6) Thoroughly clean area around top of pump

module to prevent contaminants from entering fuel

tank or fuel lines.

(7) Release fuel system pressure.

(8) Disconnect 2 fuel lines (Fig. 40) at fuel pump

module by pressing on tabs at side of fitting.

(9) Disconnect electrical connector (Fig. 40). Slide

red tab first to unlock, and push grey tab down for

removal.

(10) Disconnect ORVR hose (Fig. 40) at pump mod-

ule fitting.

Fig. 38 FUEL FILL CHECK VALVE

1 - ONE-WAY CHECK VALVE

2 - FUEL FILL FITTING

3 - SIDE OF FUEL TANK

Fig. 39 ACCESS PLATE

1 - FLOORPAN AT REAR

2 - FUEL PUMP MODULE ACCESS PLATE

3 - NUTS (4)

4 - OPENING TO PUMP MODULE

KJFUEL DELIVERY 14 - 25

FUEL TANK (Continued)

Page 1411 of 1803

FUEL INJECTION

TABLE OF CONTENTS

page page

FUEL INJECTION

DESCRIPTION.........................29

ACCELERATOR PEDAL

REMOVAL.............................29

INSTALLATION.........................30

CRANKSHAFT POSITION SENSOR

DESCRIPTION.........................30

OPERATION...........................31

REMOVAL.............................31

INSTALLATION.........................32

FUEL INJECTOR

DESCRIPTION.........................33

OPERATION

OPERATION - FUEL INJECTOR..........33

OPERATION - PCM OUTPUT............33

DIAGNOSIS AND TESTING - FUEL INJECTOR . 33

REMOVAL.............................34

INSTALLATION.........................34

FUEL PUMP RELAY

DESCRIPTION.........................34

OPERATION...........................34

DIAGNOSIS AND TESTING - FUEL PUMP

RELAY..............................34

REMOVAL.............................34

INSTALLATION.........................34

IDLE AIR CONTROL MOTOR

DESCRIPTION.........................35

OPERATION...........................35

REMOVAL.............................36INSTALLATION.........................36

INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................37

INSTALLATION.........................38

MAP SENSOR

DESCRIPTION.........................38

OPERATION...........................38

REMOVAL.............................39

INSTALLATION.........................40

OXYGEN SENSOR

DESCRIPTION.........................40

OPERATION...........................40

REMOVAL.............................41

INSTALLATION.........................43

THROTTLE BODY

DESCRIPTION.........................43

OPERATION...........................43

REMOVAL.............................43

INSTALLATION.........................44

THROTTLE CONTROL CABLE

REMOVAL.............................45

INSTALLATION.........................46

THROTTLE POSITION SENSOR

DESCRIPTION.........................47

OPERATION...........................47

REMOVAL.............................47

INSTALLATION.........................48

FUEL INJECTION

DESCRIPTION

The Powertrain Control Module (PCM) operates

the fuel injection system. Refer to Powertrain Control

Module in Electronic Control Modules for informa-

tion.

ACCELERATOR PEDAL

REMOVAL

The accelerator pedal is serviced as a complete

assembly including the bracket.The accelerator pedal is connected to the upper

part of the accelerator pedal arm by a plastic

retainer (clip) (Fig. 1). This plastic retainer snaps

into the top of the accelerator pedal arm.

(1) From inside the vehicle, hold up accelerator

pedal. Remove plastic cable retainer (clip) and throt-

tle cable core wire from upper end of accelerator

pedal arm (Fig. 1). Plastic cable retainer (clip) snaps

into pedal arm.

(2) Remove 2 accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.

KJFUEL INJECTION 14 - 29

Page 1427 of 1803

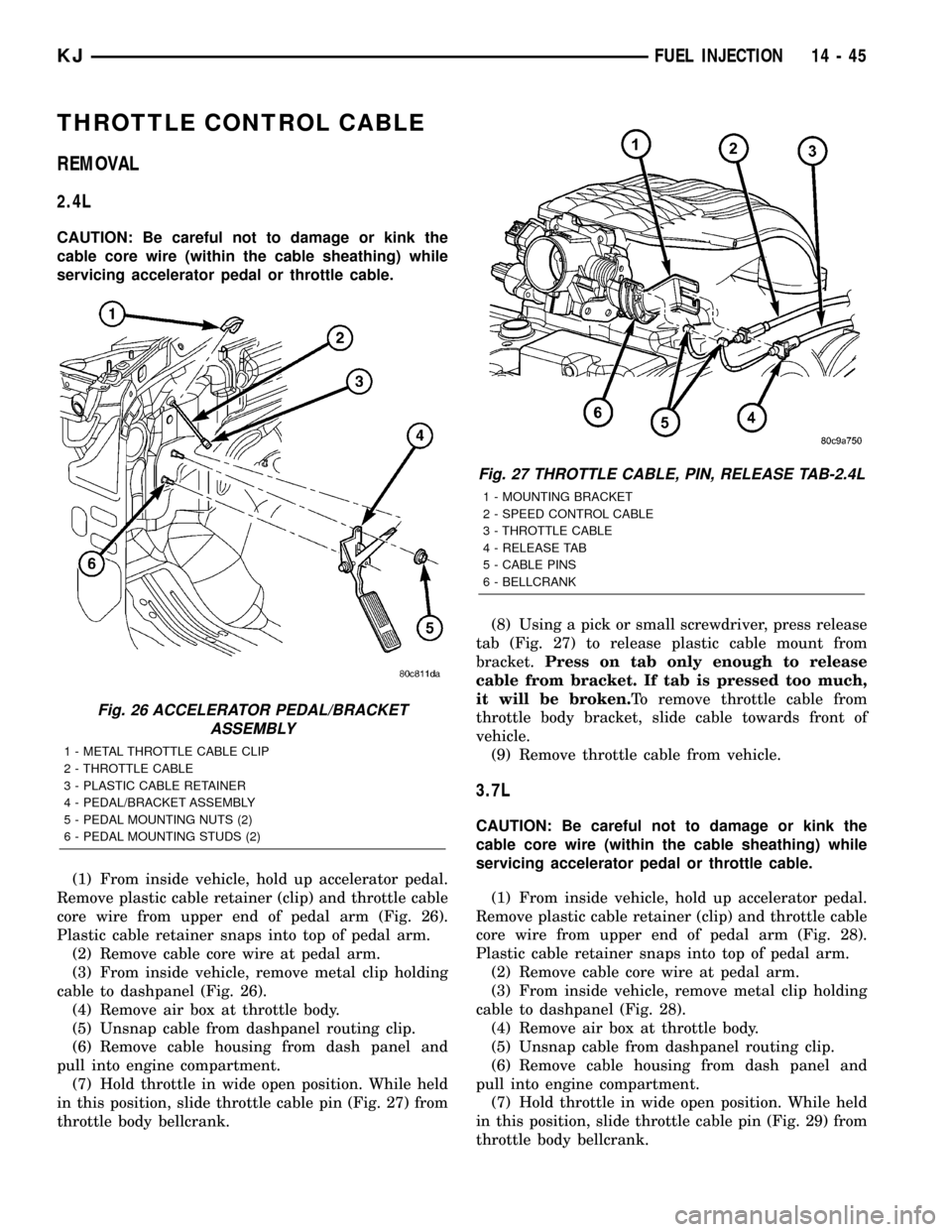

THROTTLE CONTROL CABLE

REMOVAL

2.4L

CAUTION: Be careful not to damage or kink the

cable core wire (within the cable sheathing) while

servicing accelerator pedal or throttle cable.

(1) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer (clip) and throttle cable

core wire from upper end of pedal arm (Fig. 26).

Plastic cable retainer snaps into top of pedal arm.

(2) Remove cable core wire at pedal arm.

(3) From inside vehicle, remove metal clip holding

cable to dashpanel (Fig. 26).

(4) Remove air box at throttle body.

(5) Unsnap cable from dashpanel routing clip.

(6) Remove cable housing from dash panel and

pull into engine compartment.

(7) Hold throttle in wide open position. While held

in this position, slide throttle cable pin (Fig. 27) from

throttle body bellcrank.(8) Using a pick or small screwdriver, press release

tab (Fig. 27) to release plastic cable mount from

bracket.Press on tab only enough to release

cable from bracket. If tab is pressed too much,

it will be broken.To remove throttle cable from

throttle body bracket, slide cable towards front of

vehicle.

(9) Remove throttle cable from vehicle.

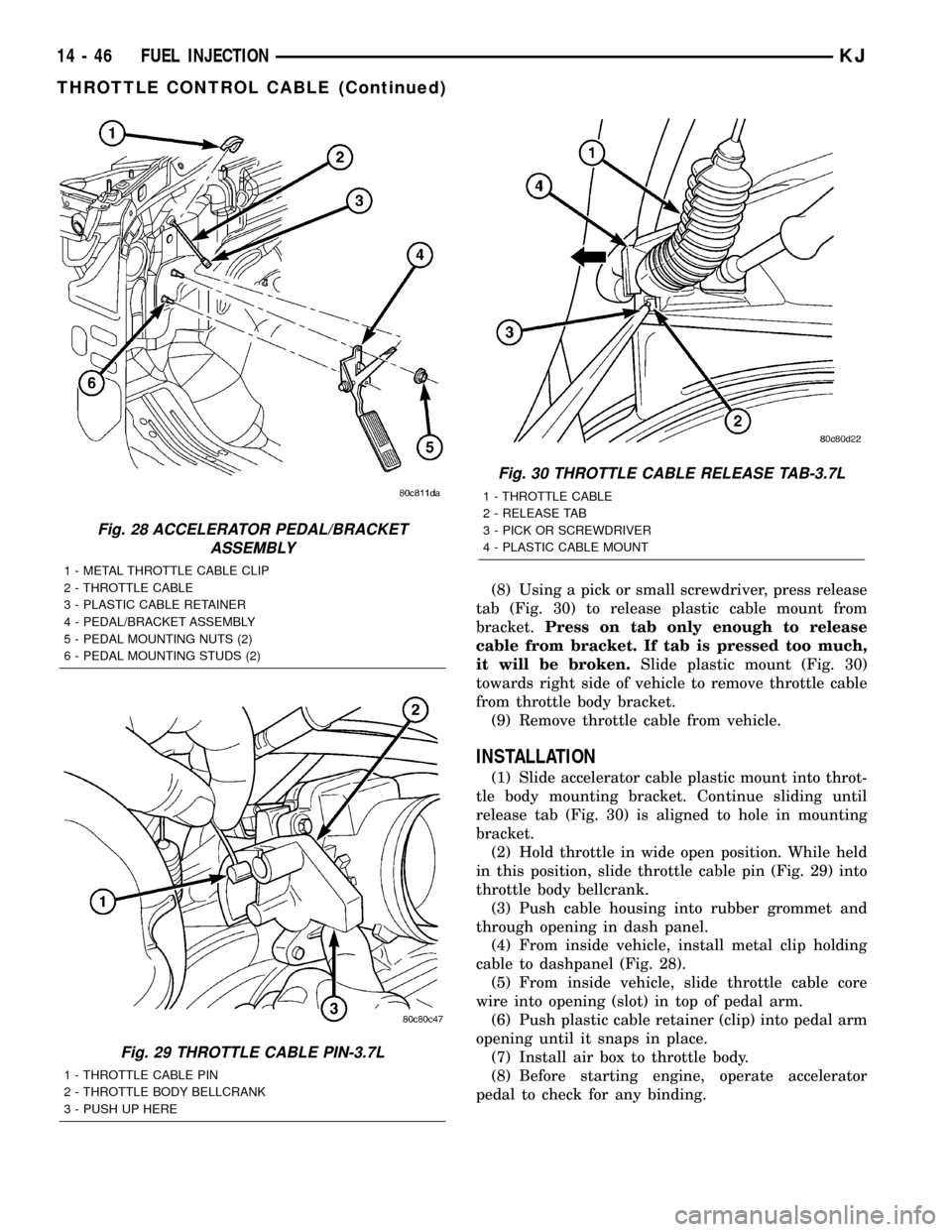

3.7L

CAUTION: Be careful not to damage or kink the

cable core wire (within the cable sheathing) while

servicing accelerator pedal or throttle cable.

(1) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer (clip) and throttle cable

core wire from upper end of pedal arm (Fig. 28).

Plastic cable retainer snaps into top of pedal arm.

(2) Remove cable core wire at pedal arm.

(3) From inside vehicle, remove metal clip holding

cable to dashpanel (Fig. 28).

(4) Remove air box at throttle body.

(5) Unsnap cable from dashpanel routing clip.

(6) Remove cable housing from dash panel and

pull into engine compartment.

(7) Hold throttle in wide open position. While held

in this position, slide throttle cable pin (Fig. 29) from

throttle body bellcrank.

Fig. 26 ACCELERATOR PEDAL/BRACKET

ASSEMBLY

1 - METAL THROTTLE CABLE CLIP

2 - THROTTLE CABLE

3 - PLASTIC CABLE RETAINER

4 - PEDAL/BRACKET ASSEMBLY

5 - PEDAL MOUNTING NUTS (2)

6 - PEDAL MOUNTING STUDS (2)

Fig. 27 THROTTLE CABLE, PIN, RELEASE TAB-2.4L

1 - MOUNTING BRACKET

2 - SPEED CONTROL CABLE

3 - THROTTLE CABLE

4 - RELEASE TAB

5 - CABLE PINS

6 - BELLCRANK

KJFUEL INJECTION 14 - 45

Page 1428 of 1803

(8) Using a pick or small screwdriver, press release

tab (Fig. 30) to release plastic cable mount from

bracket.Press on tab only enough to release

cable from bracket. If tab is pressed too much,

it will be broken.Slide plastic mount (Fig. 30)

towards right side of vehicle to remove throttle cable

from throttle body bracket.

(9) Remove throttle cable from vehicle.

INSTALLATION

(1) Slide accelerator cable plastic mount into throt-

tle body mounting bracket. Continue sliding until

release tab (Fig. 30) is aligned to hole in mounting

bracket.

(2) Hold throttle in wide open position. While held

in this position, slide throttle cable pin (Fig. 29) into

throttle body bellcrank.

(3) Push cable housing into rubber grommet and

through opening in dash panel.

(4) From inside vehicle, install metal clip holding

cable to dashpanel (Fig. 28).

(5) From inside vehicle, slide throttle cable core

wire into opening (slot) in top of pedal arm.

(6) Push plastic cable retainer (clip) into pedal arm

opening until it snaps in place.

(7) Install air box to throttle body.

(8) Before starting engine, operate accelerator

pedal to check for any binding.

Fig. 28 ACCELERATOR PEDAL/BRACKET

ASSEMBLY

1 - METAL THROTTLE CABLE CLIP

2 - THROTTLE CABLE

3 - PLASTIC CABLE RETAINER

4 - PEDAL/BRACKET ASSEMBLY

5 - PEDAL MOUNTING NUTS (2)

6 - PEDAL MOUNTING STUDS (2)

Fig. 29 THROTTLE CABLE PIN-3.7L

1 - THROTTLE CABLE PIN

2 - THROTTLE BODY BELLCRANK

3 - PUSH UP HERE

Fig. 30 THROTTLE CABLE RELEASE TAB-3.7L

1 - THROTTLE CABLE

2 - RELEASE TAB

3 - PICK OR SCREWDRIVER

4 - PLASTIC CABLE MOUNT

14 - 46 FUEL INJECTIONKJ

THROTTLE CONTROL CABLE (Continued)

Page 1447 of 1803

PUMP

TABLE OF CONTENTS

page page

PUMP

DESCRIPTION.........................17

OPERATION...........................17

STANDARD PROCEDURE - POWER

STEERING PUMP - INITIAL OPERATION....18

REMOVAL

REMOVAL - 3.7L......................18

REMOVAL - 2.4L......................18

INSTALLATION

INSTALLATION - 3.7L..................19

INSTALLATION - 2.4L..................19

SPECIFICATIONS

TORQUE CHART......................19

SPECIAL TOOLS

POWER STEERING PUMP..............20

FLUID COOLER

DESCRIPTION.........................20

OPERATION...........................20

REMOVAL.............................20

INSTALLATION.........................20

HOSES

REMOVAL

REMOVAL - PRESSURE HOSE...........21

REMOVAL - RETURN HOSE (GEAR TO THE

COOLER)...........................21REMOVAL - RETURN HOSE (RESERVOIR

TO THE COOLER).....................21

INSTALLATION

INSTALLATION - PRESSURE HOSE.......21

INSTALLATION - RETURN HOSE (GEAR TO

THE COOLER)........................22

INSTALLATION - RETURN HOSE

(RESERVOIR TO THE COOLER)..........22

POWER STEERING PRESSURE SWITCH

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................22

PULLEY

REMOVAL.............................23

INSTALLATION.........................23

RESERVOIR

REMOVAL

REMOVAL - 3.7L......................24

REMOVAL - 2.4L......................24

INSTALLATION

INSTALLATION - 3.7L..................24

INSTALLATION - 2.4L..................24

PUMP

DESCRIPTION

Hydraulic pressure for the power steering system

is provided by a belt driven power steering pump

(Fig. 1). The pump shaft has a pressed-on high

strength plastic drive pulley that is belt driven by

the crankshaft pulley. The integral reservoir used on

the 3.7L only is attached to the pump body with

spring clips (Fig. 1). The 2.4L uses a remote fluid res-

ervoir (Fig. 2). The power steering pump is connected

to the steering gear by the pressure and return

hoses.

OPERATION

The power steering pump is a constant flow rate

and displacement, vane-type pump. The pump inter-

nal parts operate submerged in fluid. The flow con-

trol orifice is part of the high pressure line fitting.

The pressure relief valve inside the flow control valve

limits the pump pressure.Fig. 1 POWER STEERING PUMP ASSEMBLY

1 - RESERVOIR

2 - CAP

3 - PULLEY

4 - PUMP BODY

5 - RESERVOIR RETAINING CLIPS

KJPUMP 19 - 17

Page 1457 of 1803

STANDARD PROCEDURE - MATCH MOUNTING

Tires and wheels are currently match mounted at

the factory. Match mounting is a technique used to

reduce runout in the wheel/tire assembly. This means

that the high spot of the tire is aligned with the low

spot on the wheel rim. The high spot on the tire is

marked with a paint mark or a bright colored adhe-

sive label on the outboard sidewall. The low spot on

the rim is identified with a label on the outside of the

rim and a dot on the inside of the rim. If the outside

label has been removed the tire will have to be

removed to locate the dot on the inside of the rim.

Before dismounting a tire from its wheel, a refer-

ence mark should be placed on the tire at the valve

stem location. This reference will ensure that it is

remounted in the original position on the wheel.

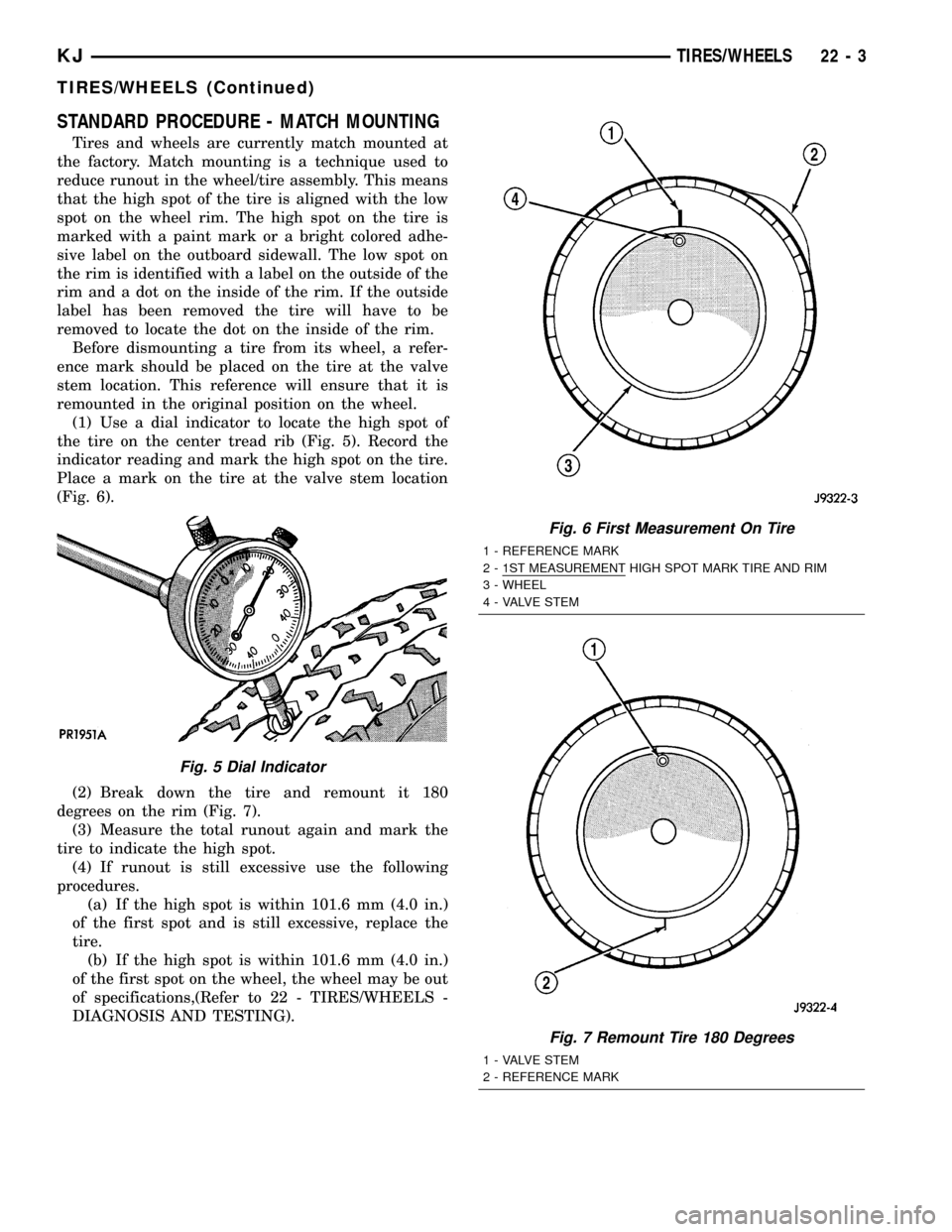

(1) Use a dial indicator to locate the high spot of

the tire on the center tread rib (Fig. 5). Record the

indicator reading and mark the high spot on the tire.

Place a mark on the tire at the valve stem location

(Fig. 6).

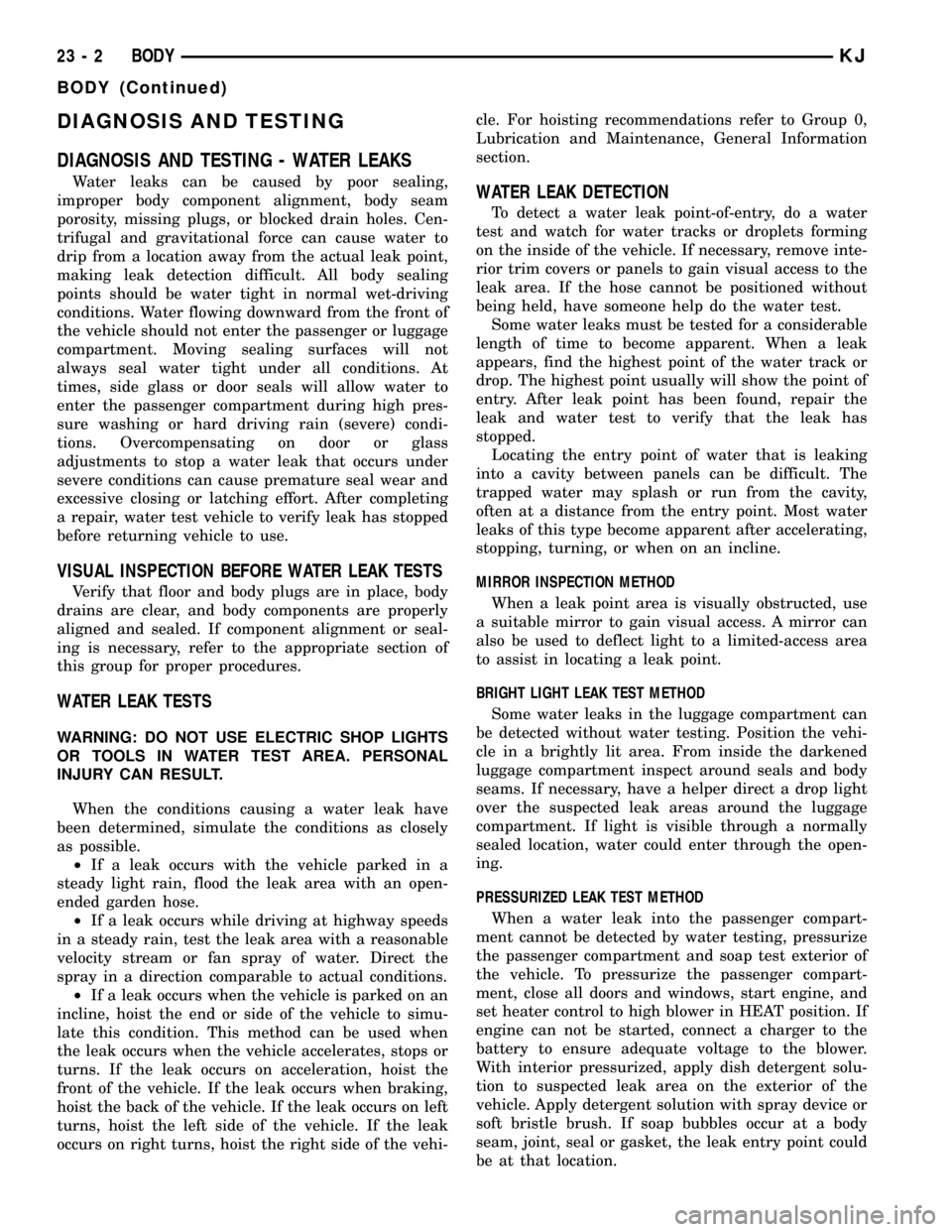

(2) Break down the tire and remount it 180

degrees on the rim (Fig. 7).

(3) Measure the total runout again and mark the

tire to indicate the high spot.

(4) If runout is still excessive use the following

procedures.

(a) If the high spot is within 101.6 mm (4.0 in.)

of the first spot and is still excessive, replace the

tire.

(b) If the high spot is within 101.6 mm (4.0 in.)

of the first spot on the wheel, the wheel may be out

of specifications,(Refer to 22 - TIRES/WHEELS -

DIAGNOSIS AND TESTING).

Fig. 5 Dial Indicator

Fig. 6 First Measurement On Tire

1 - REFERENCE MARK

2 - 1ST MEASUREMENT HIGH SPOT MARK TIRE AND RIM

3 - WHEEL

4 - VALVE STEM

Fig. 7 Remount Tire 180 Degrees

1 - VALVE STEM

2 - REFERENCE MARK

KJTIRES/WHEELS 22 - 3

TIRES/WHEELS (Continued)

Page 1467 of 1803

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

23 - 2 BODYKJ

BODY (Continued)

Page 1585 of 1803

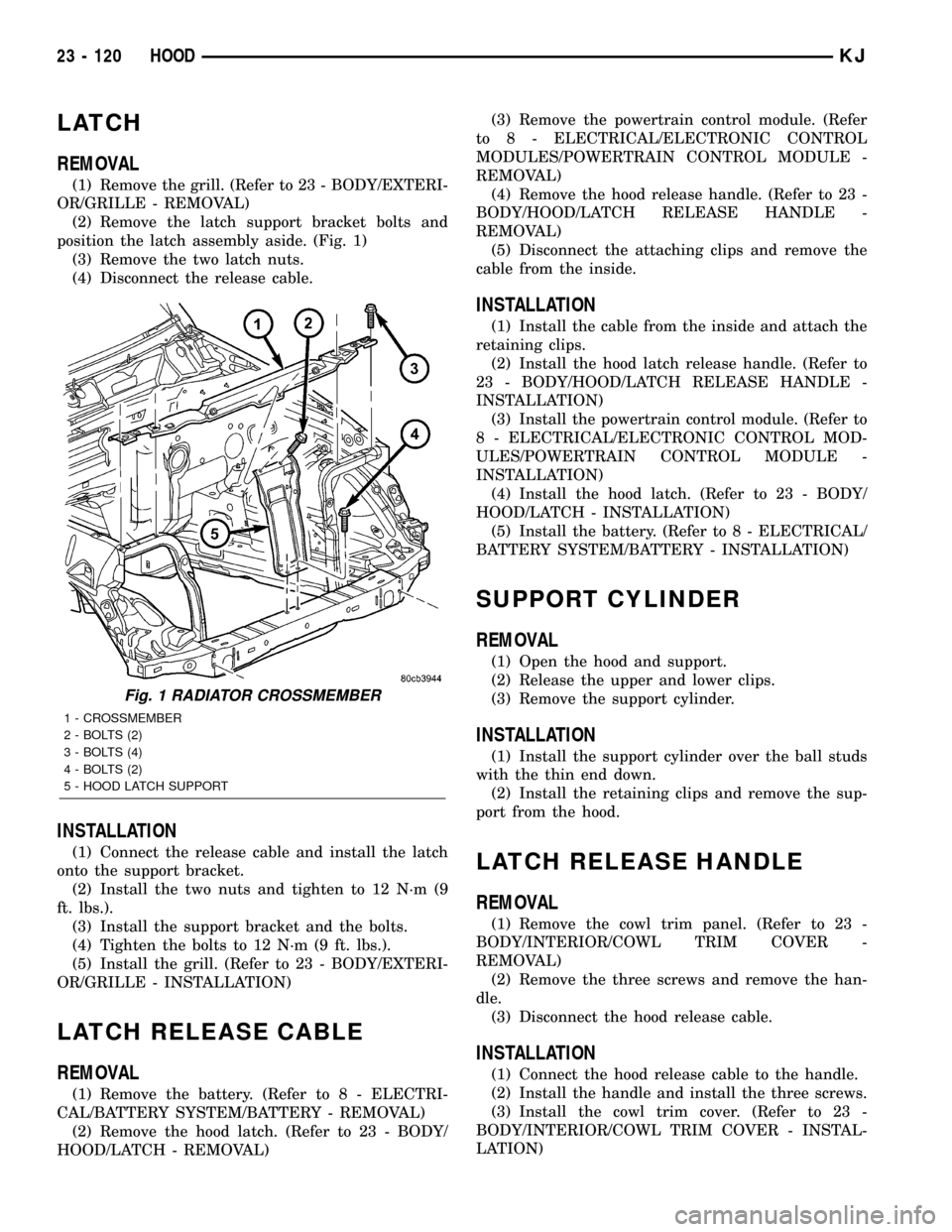

LATCH

REMOVAL

(1) Remove the grill. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - REMOVAL)

(2) Remove the latch support bracket bolts and

position the latch assembly aside. (Fig. 1)

(3) Remove the two latch nuts.

(4) Disconnect the release cable.

INSTALLATION

(1) Connect the release cable and install the latch

onto the support bracket.

(2) Install the two nuts and tighten to 12 N´m (9

ft. lbs.).

(3) Install the support bracket and the bolts.

(4) Tighten the bolts to 12 N´m (9 ft. lbs.).

(5) Install the grill. (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION)

LATCH RELEASE CABLE

REMOVAL

(1) Remove the battery. (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL)

(2) Remove the hood latch. (Refer to 23 - BODY/

HOOD/LATCH - REMOVAL)(3) Remove the powertrain control module. (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/POWERTRAIN CONTROL MODULE -

REMOVAL)

(4) Remove the hood release handle. (Refer to 23 -

BODY/HOOD/LATCH RELEASE HANDLE -

REMOVAL)

(5) Disconnect the attaching clips and remove the

cable from the inside.

INSTALLATION

(1) Install the cable from the inside and attach the

retaining clips.

(2) Install the hood latch release handle. (Refer to

23 - BODY/HOOD/LATCH RELEASE HANDLE -

INSTALLATION)

(3) Install the powertrain control module. (Refer to

8 - ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/POWERTRAIN CONTROL MODULE -

INSTALLATION)

(4) Install the hood latch. (Refer to 23 - BODY/

HOOD/LATCH - INSTALLATION)

(5) Install the battery. (Refer to 8 - ELECTRICAL/

BATTERY SYSTEM/BATTERY - INSTALLATION)

SUPPORT CYLINDER

REMOVAL

(1) Open the hood and support.

(2) Release the upper and lower clips.

(3) Remove the support cylinder.

INSTALLATION

(1) Install the support cylinder over the ball studs

with the thin end down.

(2) Install the retaining clips and remove the sup-

port from the hood.

LATCH RELEASE HANDLE

REMOVAL

(1) Remove the cowl trim panel. (Refer to 23 -

BODY/INTERIOR/COWL TRIM COVER -

REMOVAL)

(2) Remove the three screws and remove the han-

dle.

(3) Disconnect the hood release cable.

INSTALLATION

(1) Connect the hood release cable to the handle.

(2) Install the handle and install the three screws.

(3) Install the cowl trim cover. (Refer to 23 -

BODY/INTERIOR/COWL TRIM COVER - INSTAL-

LATION)

Fig. 1 RADIATOR CROSSMEMBER

1 - CROSSMEMBER

2 - BOLTS (2)

3 - BOLTS (4)

4 - BOLTS (2)

5 - HOOD LATCH SUPPORT

23 - 120 HOODKJ

Page 1590 of 1803

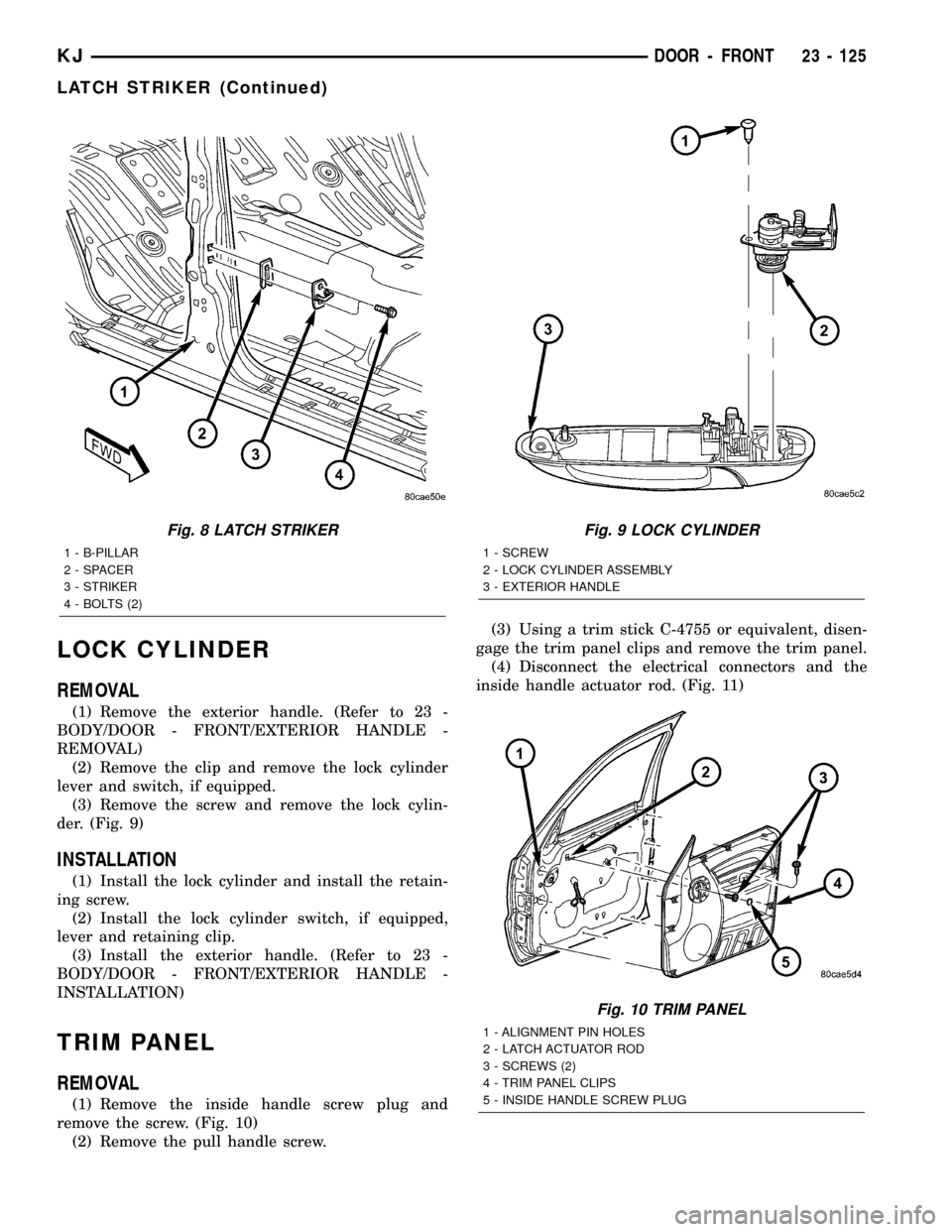

LOCK CYLINDER

REMOVAL

(1) Remove the exterior handle. (Refer to 23 -

BODY/DOOR - FRONT/EXTERIOR HANDLE -

REMOVAL)

(2) Remove the clip and remove the lock cylinder

lever and switch, if equipped.

(3) Remove the screw and remove the lock cylin-

der. (Fig. 9)

INSTALLATION

(1) Install the lock cylinder and install the retain-

ing screw.

(2) Install the lock cylinder switch, if equipped,

lever and retaining clip.

(3) Install the exterior handle. (Refer to 23 -

BODY/DOOR - FRONT/EXTERIOR HANDLE -

INSTALLATION)

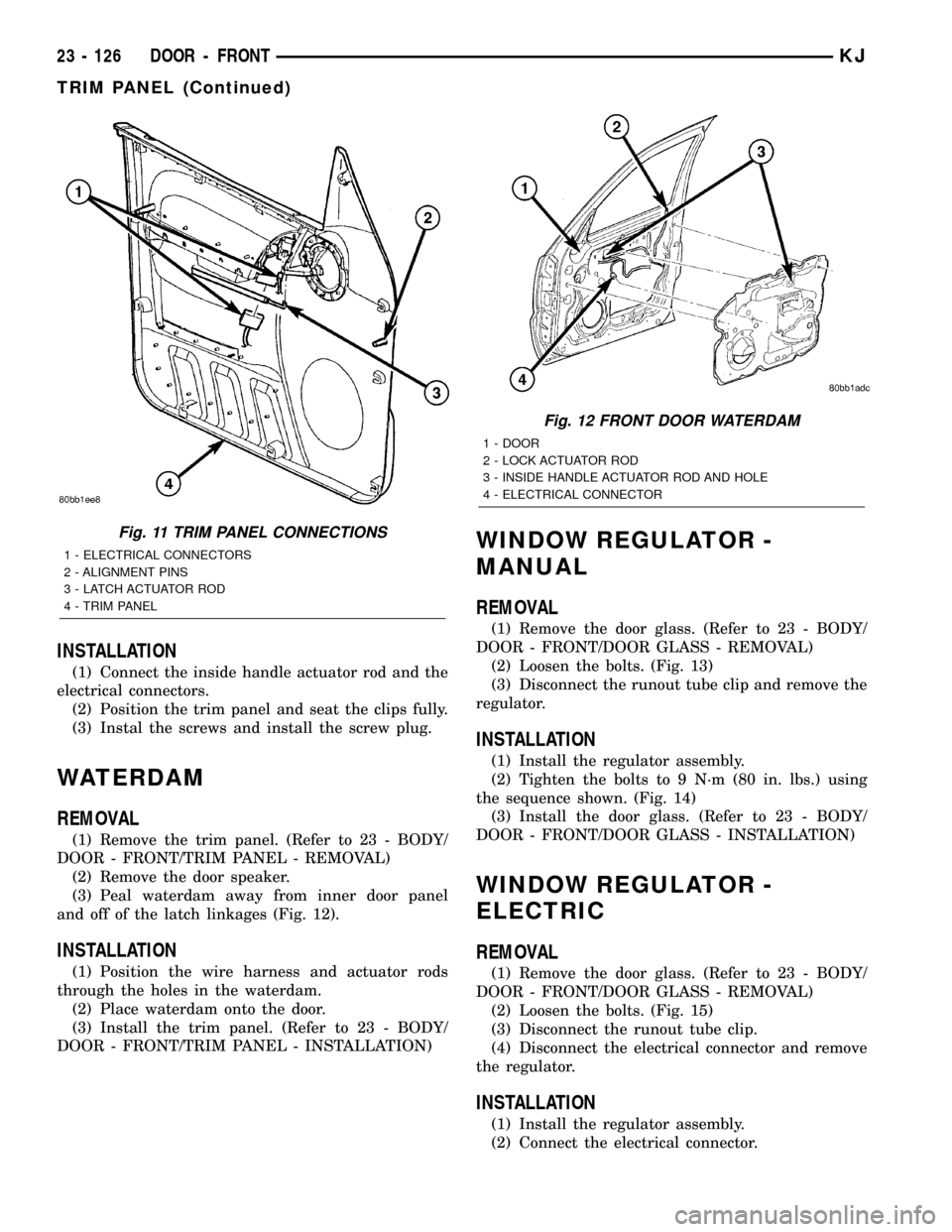

TRIM PANEL

REMOVAL

(1) Remove the inside handle screw plug and

remove the screw. (Fig. 10)

(2) Remove the pull handle screw.(3) Using a trim stick C-4755 or equivalent, disen-

gage the trim panel clips and remove the trim panel.

(4) Disconnect the electrical connectors and the

inside handle actuator rod. (Fig. 11)

Fig. 8 LATCH STRIKER

1 - B-PILLAR

2 - SPACER

3 - STRIKER

4 - BOLTS (2)

Fig. 9 LOCK CYLINDER

1 - SCREW

2 - LOCK CYLINDER ASSEMBLY

3 - EXTERIOR HANDLE

Fig. 10 TRIM PANEL

1 - ALIGNMENT PIN HOLES

2 - LATCH ACTUATOR ROD

3 - SCREWS (2)

4 - TRIM PANEL CLIPS

5 - INSIDE HANDLE SCREW PLUG

KJDOOR - FRONT 23 - 125

LATCH STRIKER (Continued)

Page 1591 of 1803

INSTALLATION

(1) Connect the inside handle actuator rod and the

electrical connectors.

(2) Position the trim panel and seat the clips fully.

(3) Instal the screws and install the screw plug.

WATERDAM

REMOVAL

(1) Remove the trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL)

(2) Remove the door speaker.

(3) Peal waterdam away from inner door panel

and off of the latch linkages (Fig. 12).

INSTALLATION

(1) Position the wire harness and actuator rods

through the holes in the waterdam.

(2) Place waterdam onto the door.

(3) Install the trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION)

WINDOW REGULATOR -

MANUAL

REMOVAL

(1) Remove the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - REMOVAL)

(2) Loosen the bolts. (Fig. 13)

(3) Disconnect the runout tube clip and remove the

regulator.

INSTALLATION

(1) Install the regulator assembly.

(2) Tighten the bolts to 9 N´m (80 in. lbs.) using

the sequence shown. (Fig. 14)

(3) Install the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - INSTALLATION)

WINDOW REGULATOR -

ELECTRIC

REMOVAL

(1) Remove the door glass. (Refer to 23 - BODY/

DOOR - FRONT/DOOR GLASS - REMOVAL)

(2) Loosen the bolts. (Fig. 15)

(3) Disconnect the runout tube clip.

(4) Disconnect the electrical connector and remove

the regulator.

INSTALLATION

(1) Install the regulator assembly.

(2) Connect the electrical connector.

Fig. 11 TRIM PANEL CONNECTIONS

1 - ELECTRICAL CONNECTORS

2 - ALIGNMENT PINS

3 - LATCH ACTUATOR ROD

4 - TRIM PANEL

Fig. 12 FRONT DOOR WATERDAM

1 - DOOR

2 - LOCK ACTUATOR ROD

3 - INSIDE HANDLE ACTUATOR ROD AND HOLE

4 - ELECTRICAL CONNECTOR

23 - 126 DOOR - FRONTKJ

TRIM PANEL (Continued)