axle JEEP LIBERTY 2002 KJ / 1.G Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 115 of 1803

AXLE BEARING/SEAL

REMOVAL

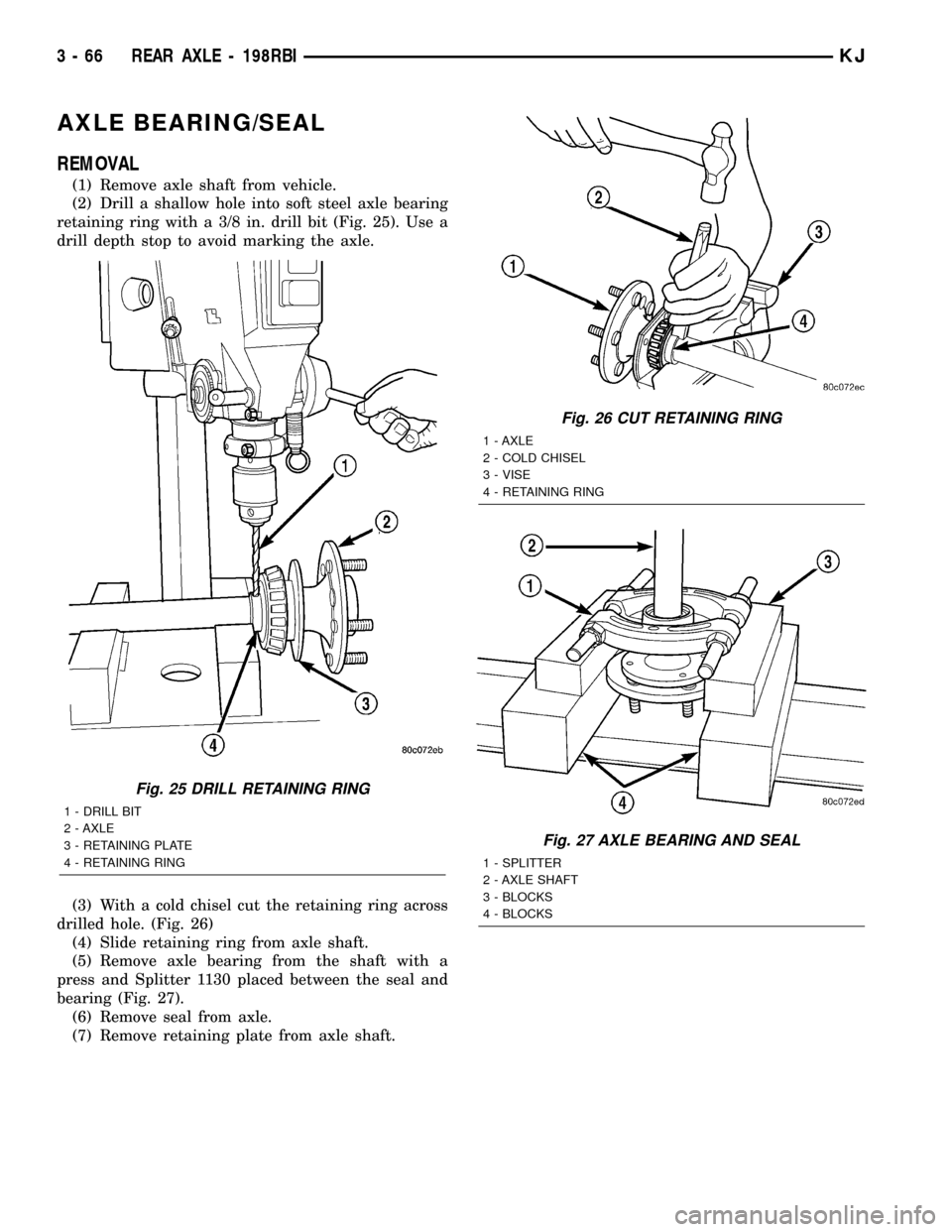

(1) Remove axle shaft from vehicle.

(2) Drill a shallow hole into soft steel axle bearing

retaining ring with a 3/8 in. drill bit (Fig. 25). Use a

drill depth stop to avoid marking the axle.

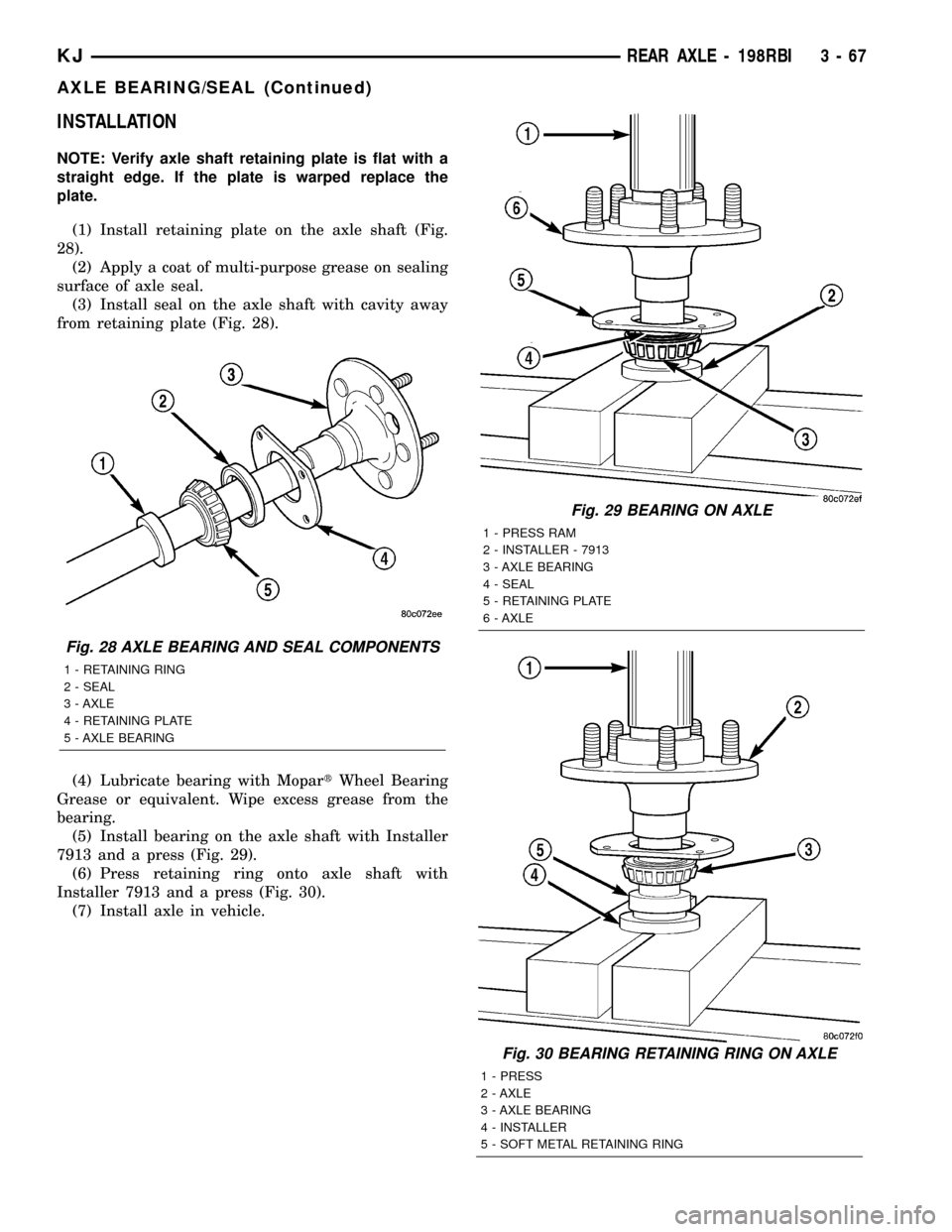

(3) With a cold chisel cut the retaining ring across

drilled hole. (Fig. 26)

(4) Slide retaining ring from axle shaft.

(5) Remove axle bearing from the shaft with a

press and Splitter 1130 placed between the seal and

bearing (Fig. 27).

(6) Remove seal from axle.

(7) Remove retaining plate from axle shaft.

Fig. 25 DRILL RETAINING RING

1 - DRILL BIT

2 - AXLE

3 - RETAINING PLATE

4 - RETAINING RING

Fig. 26 CUT RETAINING RING

1 - AXLE

2 - COLD CHISEL

3 - VISE

4 - RETAINING RING

Fig. 27 AXLE BEARING AND SEAL

1 - SPLITTER

2 - AXLE SHAFT

3 - BLOCKS

4 - BLOCKS

3 - 66 REAR AXLE - 198RBIKJ

Page 116 of 1803

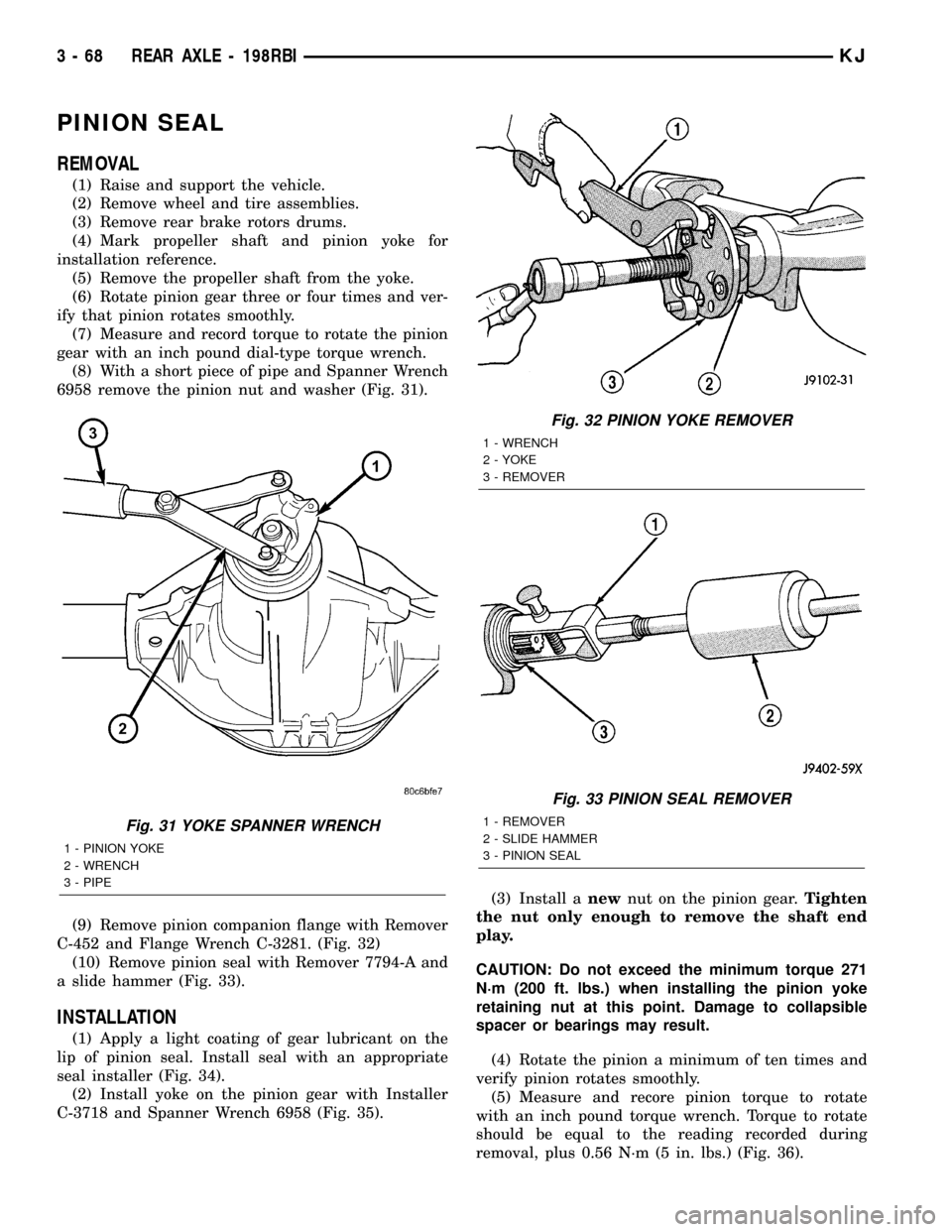

INSTALLATION

NOTE: Verify axle shaft retaining plate is flat with a

straight edge. If the plate is warped replace the

plate.

(1) Install retaining plate on the axle shaft (Fig.

28).

(2) Apply a coat of multi-purpose grease on sealing

surface of axle seal.

(3) Install seal on the axle shaft with cavity away

from retaining plate (Fig. 28).

(4) Lubricate bearing with MopartWheel Bearing

Grease or equivalent. Wipe excess grease from the

bearing.

(5) Install bearing on the axle shaft with Installer

7913 and a press (Fig. 29).

(6) Press retaining ring onto axle shaft with

Installer 7913 and a press (Fig. 30).

(7) Install axle in vehicle.

Fig. 29 BEARING ON AXLE

1 - PRESS RAM

2 - INSTALLER - 7913

3 - AXLE BEARING

4 - SEAL

5 - RETAINING PLATE

6 - AXLE

Fig. 30 BEARING RETAINING RING ON AXLE

1 - PRESS

2 - AXLE

3 - AXLE BEARING

4 - INSTALLER

5 - SOFT METAL RETAINING RING

Fig. 28 AXLE BEARING AND SEAL COMPONENTS

1 - RETAINING RING

2 - SEAL

3 - AXLE

4 - RETAINING PLATE

5 - AXLE BEARING

KJREAR AXLE - 198RBI 3 - 67

AXLE BEARING/SEAL (Continued)

Page 117 of 1803

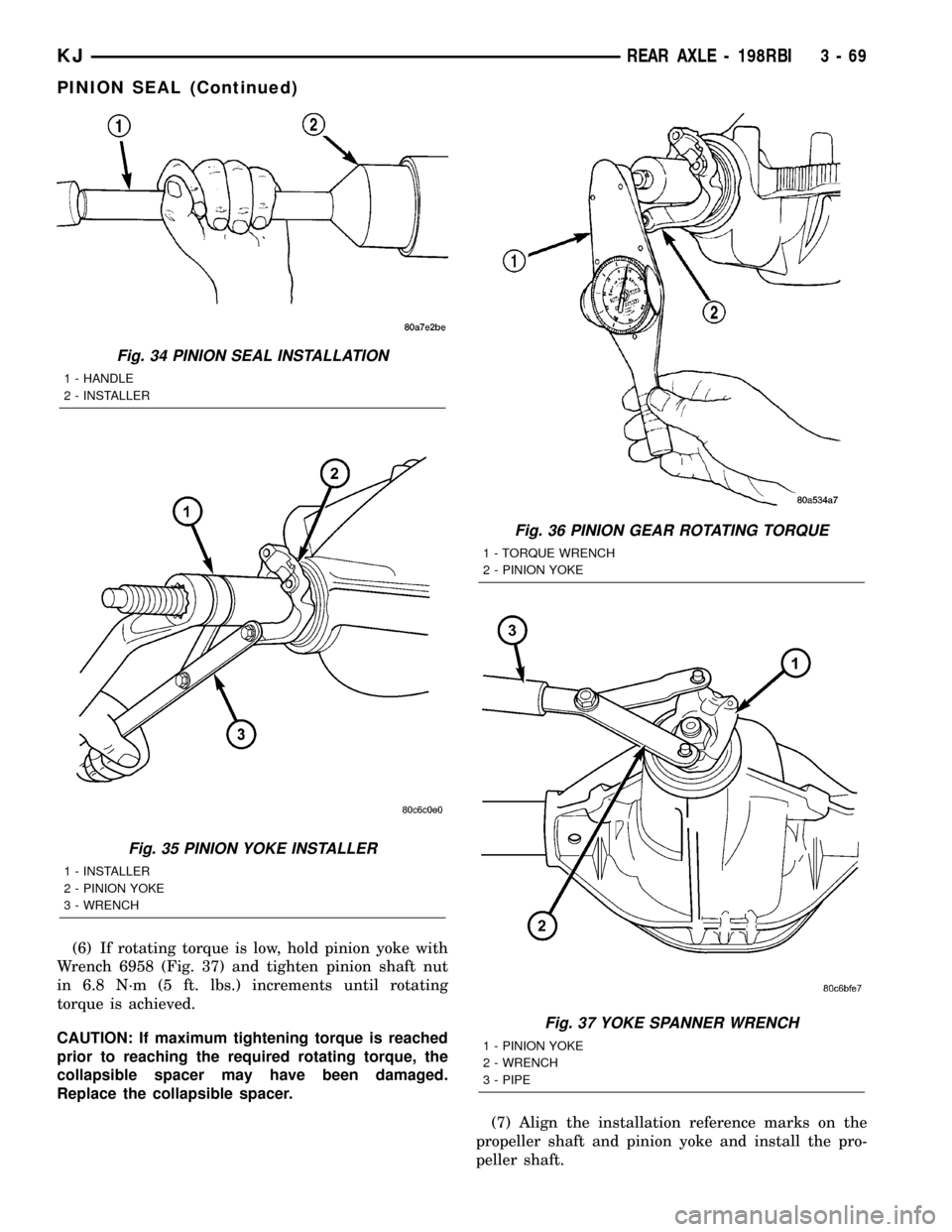

PINION SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove rear brake rotors drums.

(4) Mark propeller shaft and pinion yoke for

installation reference.

(5) Remove the propeller shaft from the yoke.

(6) Rotate pinion gear three or four times and ver-

ify that pinion rotates smoothly.

(7) Measure and record torque to rotate the pinion

gear with an inch pound dial-type torque wrench.

(8) With a short piece of pipe and Spanner Wrench

6958 remove the pinion nut and washer (Fig. 31).

(9) Remove pinion companion flange with Remover

C-452 and Flange Wrench C-3281. (Fig. 32)

(10) Remove pinion seal with Remover 7794-A and

a slide hammer (Fig. 33).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with an appropriate

seal installer (Fig. 34).

(2) Install yoke on the pinion gear with Installer

C-3718 and Spanner Wrench 6958 (Fig. 35).(3) Install anewnut on the pinion gear.Tighten

the nut only enough to remove the shaft end

play.

CAUTION: Do not exceed the minimum torque 271

N´m (200 ft. lbs.) when installing the pinion yoke

retaining nut at this point. Damage to collapsible

spacer or bearings may result.

(4) Rotate the pinion a minimum of ten times and

verify pinion rotates smoothly.

(5) Measure and recore pinion torque to rotate

with an inch pound torque wrench. Torque to rotate

should be equal to the reading recorded during

removal, plus 0.56 N´m (5 in. lbs.) (Fig. 36).

Fig. 31 YOKE SPANNER WRENCH

1 - PINION YOKE

2 - WRENCH

3 - PIPE

Fig. 32 PINION YOKE REMOVER

1 - WRENCH

2 - YOKE

3 - REMOVER

Fig. 33 PINION SEAL REMOVER

1 - REMOVER

2 - SLIDE HAMMER

3 - PINION SEAL

3 - 68 REAR AXLE - 198RBIKJ

Page 118 of 1803

(6) If rotating torque is low, hold pinion yoke with

Wrench 6958 (Fig. 37) and tighten pinion shaft nut

in 6.8 N´m (5 ft. lbs.) increments until rotating

torque is achieved.

CAUTION: If maximum tightening torque is reached

prior to reaching the required rotating torque, the

collapsible spacer may have been damaged.

Replace the collapsible spacer.

(7) Align the installation reference marks on the

propeller shaft and pinion yoke and install the pro-

peller shaft.

Fig. 34 PINION SEAL INSTALLATION

1 - HANDLE

2 - INSTALLER

Fig. 35 PINION YOKE INSTALLER

1 - INSTALLER

2 - PINION YOKE

3 - WRENCH

Fig. 36 PINION GEAR ROTATING TORQUE

1 - TORQUE WRENCH

2 - PINION YOKE

Fig. 37 YOKE SPANNER WRENCH

1 - PINION YOKE

2 - WRENCH

3 - PIPE

KJREAR AXLE - 198RBI 3 - 69

PINION SEAL (Continued)

Page 119 of 1803

(8) Fill differential with gear lubricant.

(9) Install the brake drums

(10) Install wheel and tire assemblies.

(11) Lower the vehicle.

COLLAPSIBLE SPACER

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove rear brake drums.

(4) Mark the propeller shaft and pinion yoke for

installation reference.

(5) Remove the propeller shaft from the yoke.

(6) Rotate the pinion gear three or four times.

(7) Measure and record torque to rotate the pinion

gear with an inch pound dial-type torque wrench.

(8) Hold pinion yoke with Spanner Wrench 6958

and remove pinion nut and washer.

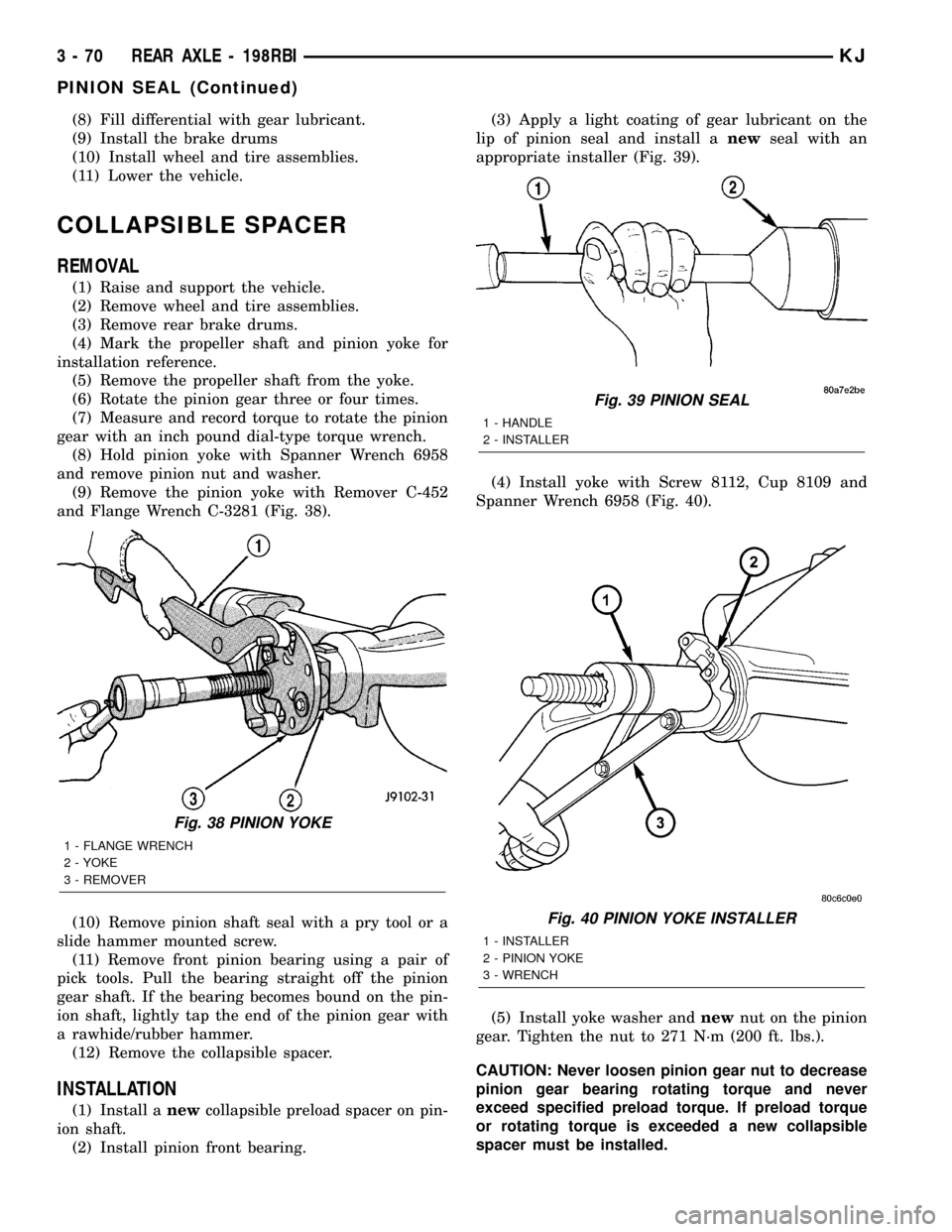

(9) Remove the pinion yoke with Remover C-452

and Flange Wrench C-3281 (Fig. 38).

(10) Remove pinion shaft seal with a pry tool or a

slide hammer mounted screw.

(11) Remove front pinion bearing using a pair of

pick tools. Pull the bearing straight off the pinion

gear shaft. If the bearing becomes bound on the pin-

ion shaft, lightly tap the end of the pinion gear with

a rawhide/rubber hammer.

(12) Remove the collapsible spacer.

INSTALLATION

(1) Install anewcollapsible preload spacer on pin-

ion shaft.

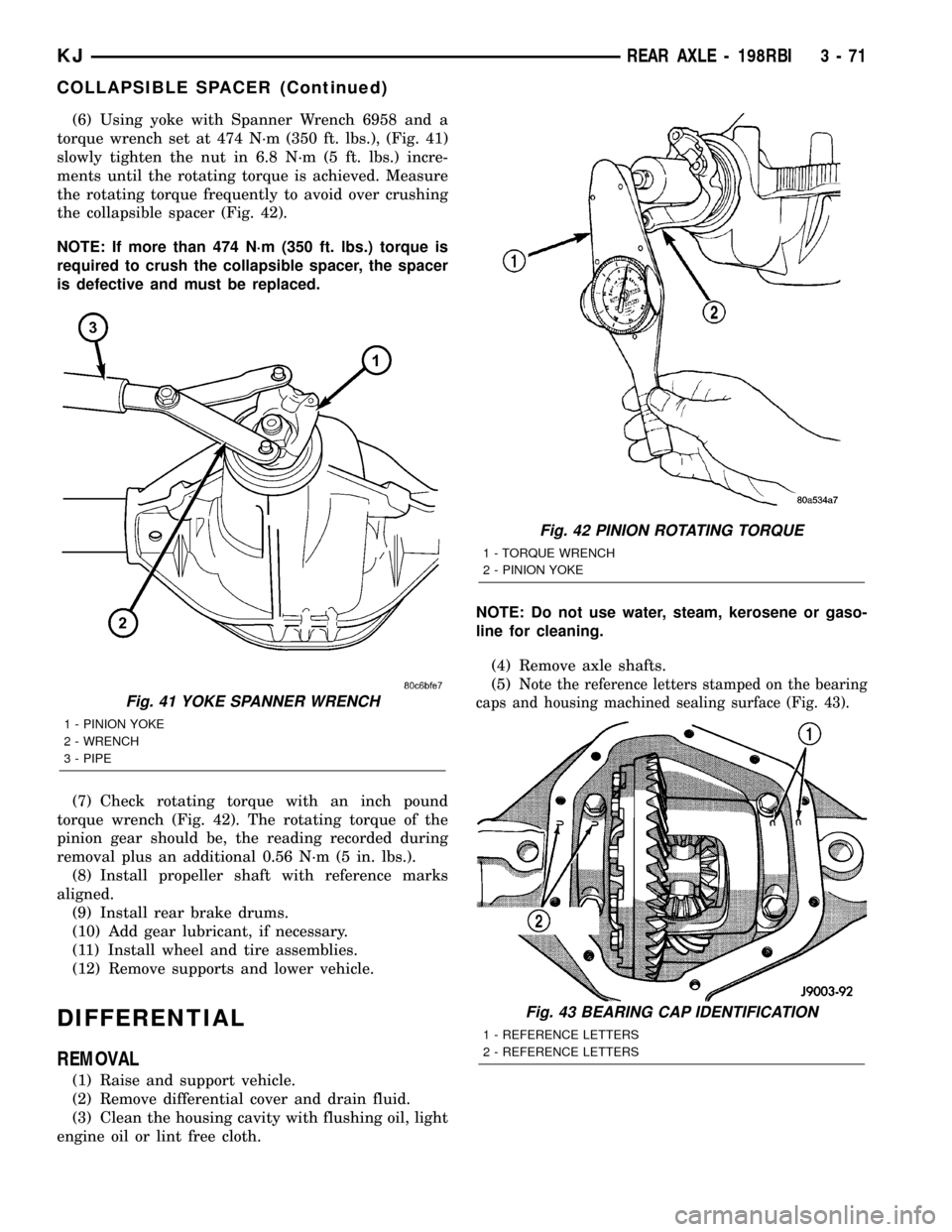

(2) Install pinion front bearing.(3) Apply a light coating of gear lubricant on the

lip of pinion seal and install anewseal with an

appropriate installer (Fig. 39).

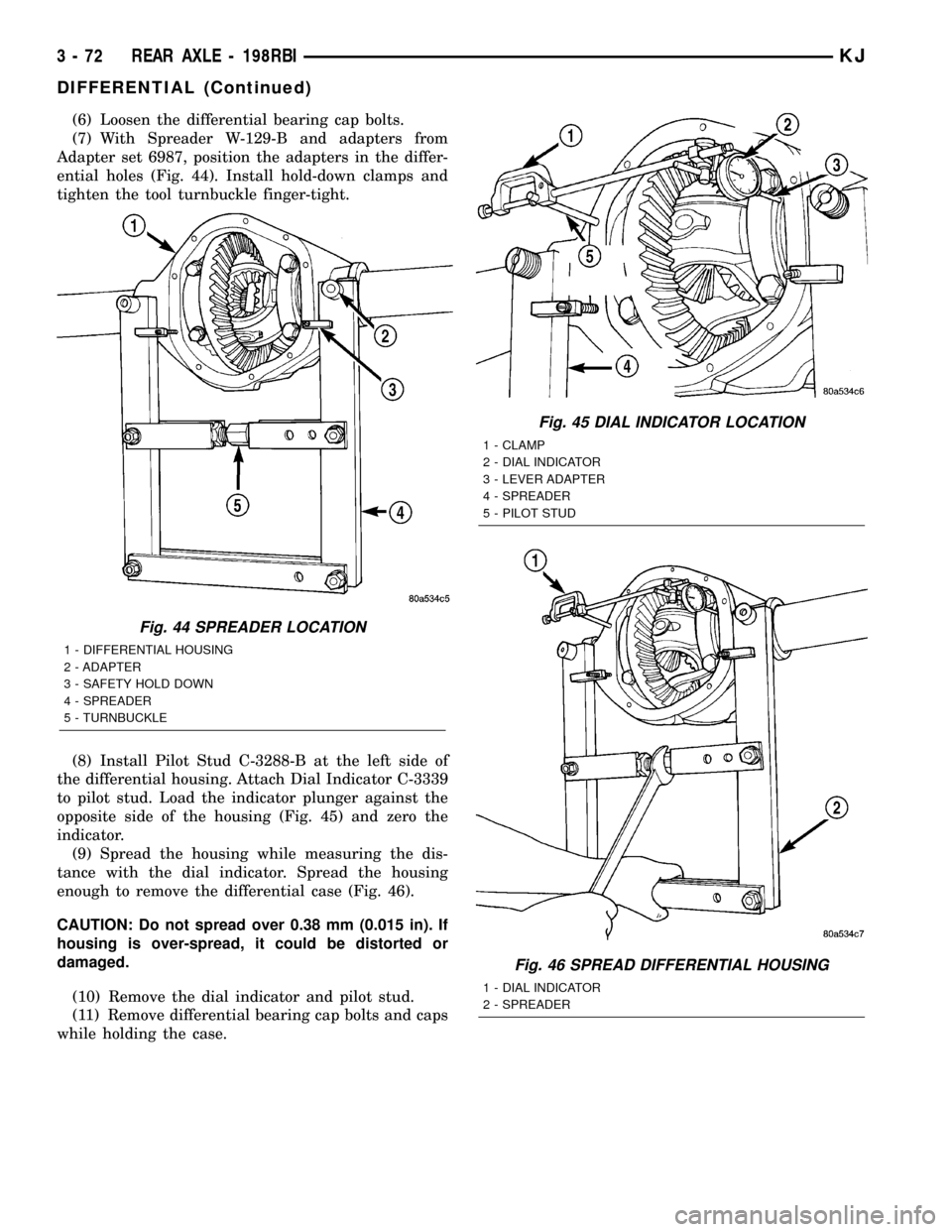

(4) Install yoke with Screw 8112, Cup 8109 and

Spanner Wrench 6958 (Fig. 40).

(5) Install yoke washer andnewnut on the pinion

gear. Tighten the nut to 271 N´m (200 ft. lbs.).

CAUTION: Never loosen pinion gear nut to decrease

pinion gear bearing rotating torque and never

exceed specified preload torque. If preload torque

or rotating torque is exceeded a new collapsible

spacer must be installed.

Fig. 38 PINION YOKE

1 - FLANGE WRENCH

2 - YOKE

3 - REMOVER

Fig. 39 PINION SEAL

1 - HANDLE

2 - INSTALLER

Fig. 40 PINION YOKE INSTALLER

1 - INSTALLER

2 - PINION YOKE

3 - WRENCH

3 - 70 REAR AXLE - 198RBIKJ

PINION SEAL (Continued)

Page 120 of 1803

(6) Using yoke with Spanner Wrench 6958 and a

torque wrench set at 474 N´m (350 ft. lbs.), (Fig. 41)

slowly tighten the nut in 6.8 N´m (5 ft. lbs.) incre-

ments until the rotating torque is achieved. Measure

the rotating torque frequently to avoid over crushing

the collapsible spacer (Fig. 42).

NOTE: If more than 474 N´m (350 ft. lbs.) torque is

required to crush the collapsible spacer, the spacer

is defective and must be replaced.

(7) Check rotating torque with an inch pound

torque wrench (Fig. 42). The rotating torque of the

pinion gear should be, the reading recorded during

removal plus an additional 0.56 N´m (5 in. lbs.).

(8) Install propeller shaft with reference marks

aligned.

(9) Install rear brake drums.

(10) Add gear lubricant, if necessary.

(11) Install wheel and tire assemblies.

(12) Remove supports and lower vehicle.

DIFFERENTIAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove differential cover and drain fluid.

(3) Clean the housing cavity with flushing oil, light

engine oil or lint free cloth.NOTE: Do not use water, steam, kerosene or gaso-

line for cleaning.

(4) Remove axle shafts.

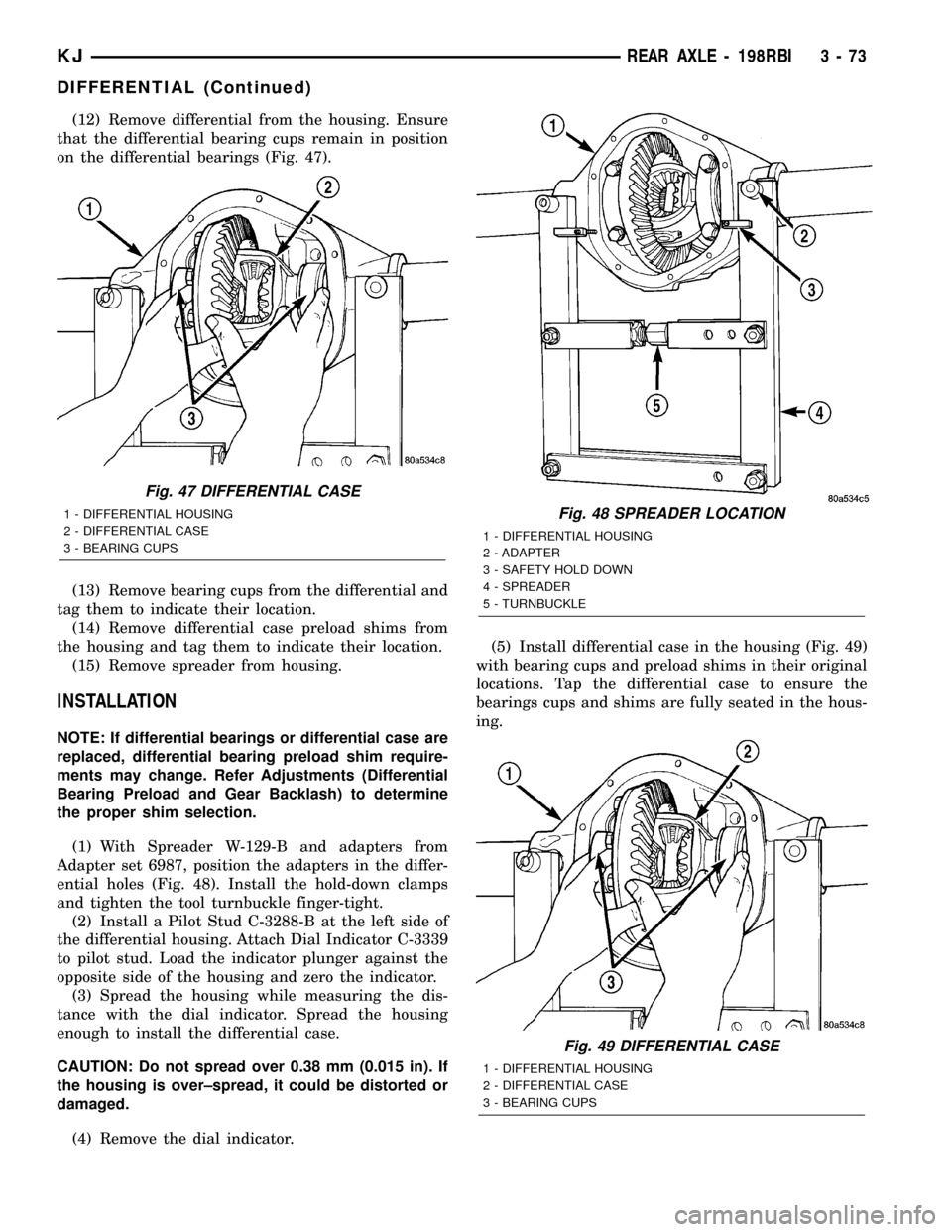

(5)

Note the reference letters stamped on the bearing

caps and housing machined sealing surface (Fig. 43).

Fig. 41 YOKE SPANNER WRENCH

1 - PINION YOKE

2 - WRENCH

3 - PIPE

Fig. 42 PINION ROTATING TORQUE

1 - TORQUE WRENCH

2 - PINION YOKE

Fig. 43 BEARING CAP IDENTIFICATION

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

KJREAR AXLE - 198RBI 3 - 71

COLLAPSIBLE SPACER (Continued)

Page 121 of 1803

(6) Loosen the differential bearing cap bolts.

(7) With Spreader W-129-B and adapters from

Adapter set 6987, position the adapters in the differ-

ential holes (Fig. 44). Install hold-down clamps and

tighten the tool turnbuckle finger-tight.

(8) Install Pilot Stud C-3288-B at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load the indicator plunger against the

opposite side of the housing (Fig. 45) and zero the

indicator.

(9) Spread the housing while measuring the dis-

tance with the dial indicator. Spread the housing

enough to remove the differential case (Fig. 46).

CAUTION: Do not spread over 0.38 mm (0.015 in). If

housing is over-spread, it could be distorted or

damaged.

(10) Remove the dial indicator and pilot stud.

(11) Remove differential bearing cap bolts and caps

while holding the case.

Fig. 44 SPREADER LOCATION

1 - DIFFERENTIAL HOUSING

2 - ADAPTER

3 - SAFETY HOLD DOWN

4 - SPREADER

5 - TURNBUCKLE

Fig. 45 DIAL INDICATOR LOCATION

1 - CLAMP

2 - DIAL INDICATOR

3 - LEVER ADAPTER

4 - SPREADER

5 - PILOT STUD

Fig. 46 SPREAD DIFFERENTIAL HOUSING

1 - DIAL INDICATOR

2 - SPREADER

3 - 72 REAR AXLE - 198RBIKJ

DIFFERENTIAL (Continued)

Page 122 of 1803

(12) Remove differential from the housing. Ensure

that the differential bearing cups remain in position

on the differential bearings (Fig. 47).

(13) Remove bearing cups from the differential and

tag them to indicate their location.

(14) Remove differential case preload shims from

the housing and tag them to indicate their location.

(15) Remove spreader from housing.

INSTALLATION

NOTE: If differential bearings or differential case are

replaced, differential bearing preload shim require-

ments may change. Refer Adjustments (Differential

Bearing Preload and Gear Backlash) to determine

the proper shim selection.

(1) With Spreader W-129-B and adapters from

Adapter set 6987, position the adapters in the differ-

ential holes (Fig. 48). Install the hold-down clamps

and tighten the tool turnbuckle finger-tight.

(2) Install a Pilot Stud C-3288-B at the left side of

the differential housing. Attach Dial Indicator C-3339

to pilot stud. Load the indicator plunger against the

opposite side of the housing and zero the indicator.

(3) Spread the housing while measuring the dis-

tance with the dial indicator. Spread the housing

enough to install the differential case.

CAUTION: Do not spread over 0.38 mm (0.015 in). If

the housing is over±spread, it could be distorted or

damaged.

(4) Remove the dial indicator.(5) Install differential case in the housing (Fig. 49)

with bearing cups and preload shims in their original

locations. Tap the differential case to ensure the

bearings cups and shims are fully seated in the hous-

ing.

Fig. 47 DIFFERENTIAL CASE

1 - DIFFERENTIAL HOUSING

2 - DIFFERENTIAL CASE

3 - BEARING CUPSFig. 48 SPREADER LOCATION

1 - DIFFERENTIAL HOUSING

2 - ADAPTER

3 - SAFETY HOLD DOWN

4 - SPREADER

5 - TURNBUCKLE

Fig. 49 DIFFERENTIAL CASE

1 - DIFFERENTIAL HOUSING

2 - DIFFERENTIAL CASE

3 - BEARING CUPS

KJREAR AXLE - 198RBI 3 - 73

DIFFERENTIAL (Continued)

Page 123 of 1803

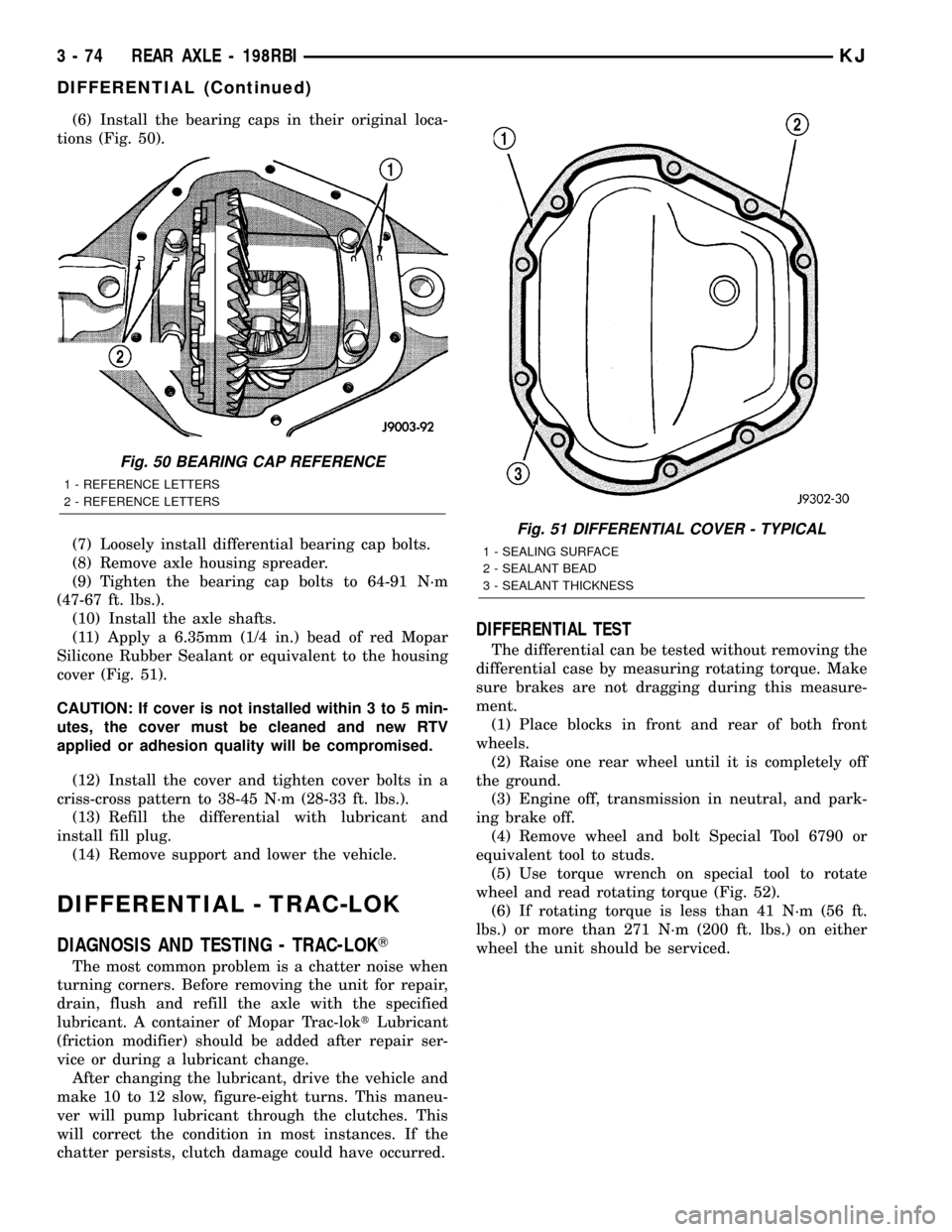

(6) Install the bearing caps in their original loca-

tions (Fig. 50).

(7) Loosely install differential bearing cap bolts.

(8) Remove axle housing spreader.

(9) Tighten the bearing cap bolts to 64-91 N´m

(47-67 ft. lbs.).

(10) Install the axle shafts.

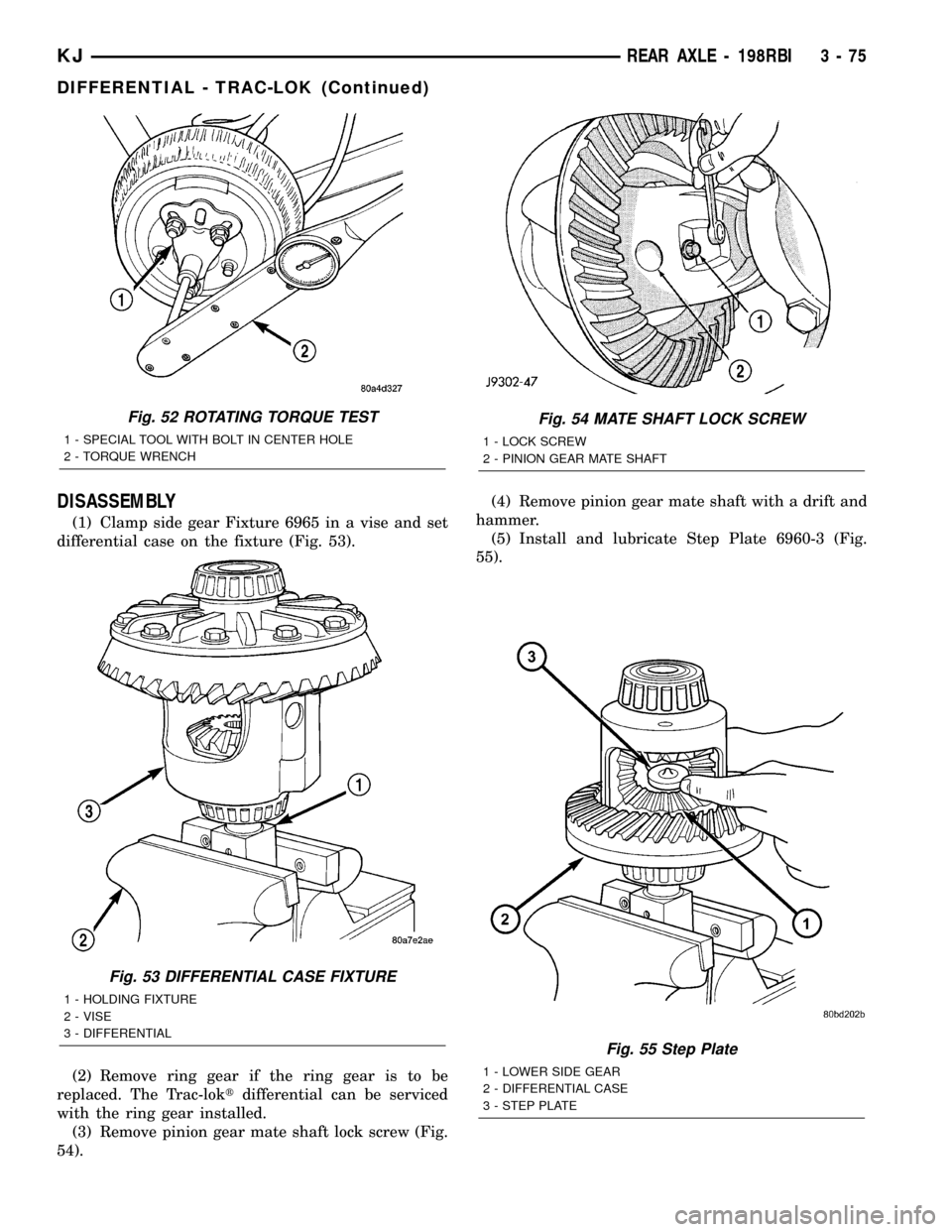

(11) Apply a 6.35mm (1/4 in.) bead of red Mopar

Silicone Rubber Sealant or equivalent to the housing

cover (Fig. 51).

CAUTION: If cover is not installed within 3 to 5 min-

utes, the cover must be cleaned and new RTV

applied or adhesion quality will be compromised.

(12) Install the cover and tighten cover bolts in a

criss-cross pattern to 38-45 N´m (28-33 ft. lbs.).

(13) Refill the differential with lubricant and

install fill plug.

(14) Remove support and lower the vehicle.

DIFFERENTIAL - TRAC-LOK

DIAGNOSIS AND TESTING - TRAC-LOKT

The most common problem is a chatter noise when

turning corners. Before removing the unit for repair,

drain, flush and refill the axle with the specified

lubricant. A container of Mopar Trac-loktLubricant

(friction modifier) should be added after repair ser-

vice or during a lubricant change.

After changing the lubricant, drive the vehicle and

make 10 to 12 slow, figure-eight turns. This maneu-

ver will pump lubricant through the clutches. This

will correct the condition in most instances. If the

chatter persists, clutch damage could have occurred.

DIFFERENTIAL TEST

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Place blocks in front and rear of both front

wheels.

(2) Raise one rear wheel until it is completely off

the ground.

(3) Engine off, transmission in neutral, and park-

ing brake off.

(4) Remove wheel and bolt Special Tool 6790 or

equivalent tool to studs.

(5) Use torque wrench on special tool to rotate

wheel and read rotating torque (Fig. 52).

(6) If rotating torque is less than 41 N´m (56 ft.

lbs.) or more than 271 N´m (200 ft. lbs.) on either

wheel the unit should be serviced.

Fig. 50 BEARING CAP REFERENCE

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 51 DIFFERENTIAL COVER - TYPICAL

1 - SEALING SURFACE

2 - SEALANT BEAD

3 - SEALANT THICKNESS

3 - 74 REAR AXLE - 198RBIKJ

DIFFERENTIAL (Continued)

Page 124 of 1803

DISASSEMBLY

(1) Clamp side gear Fixture 6965 in a vise and set

differential case on the fixture (Fig. 53).

(2) Remove ring gear if the ring gear is to be

replaced. The Trac-loktdifferential can be serviced

with the ring gear installed.

(3) Remove pinion gear mate shaft lock screw (Fig.

54).(4) Remove pinion gear mate shaft with a drift and

hammer.

(5) Install and lubricate Step Plate 6960-3 (Fig.

55).

Fig. 52 ROTATING TORQUE TEST

1 - SPECIAL TOOL WITH BOLT IN CENTER HOLE

2 - TORQUE WRENCH

Fig. 53 DIFFERENTIAL CASE FIXTURE

1 - HOLDING FIXTURE

2 - VISE

3 - DIFFERENTIAL

Fig. 54 MATE SHAFT LOCK SCREW

1 - LOCK SCREW

2 - PINION GEAR MATE SHAFT

Fig. 55 Step Plate

1 - LOWER SIDE GEAR

2 - DIFFERENTIAL CASE

3 - STEP PLATE

KJREAR AXLE - 198RBI 3 - 75

DIFFERENTIAL - TRAC-LOK (Continued)