Cylinder Head JEEP LIBERTY 2002 KJ / 1.G Manual Online

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: LIBERTY, Model: JEEP LIBERTY 2002 KJ / 1.GPages: 1803, PDF Size: 62.3 MB

Page 1273 of 1803

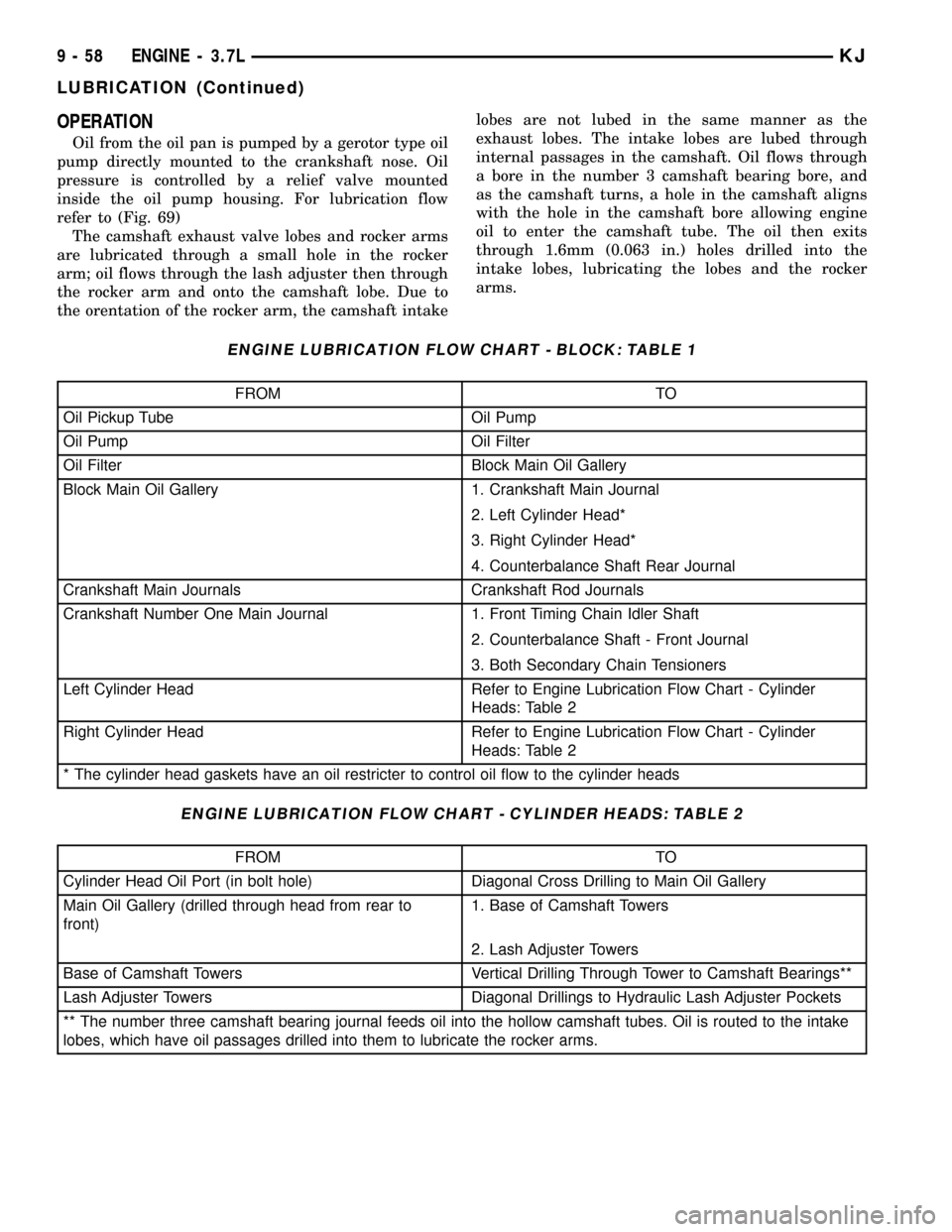

OPERATION

Oil from the oil pan is pumped by a gerotor type oil

pump directly mounted to the crankshaft nose. Oil

pressure is controlled by a relief valve mounted

inside the oil pump housing. For lubrication flow

refer to (Fig. 69)

The camshaft exhaust valve lobes and rocker arms

are lubricated through a small hole in the rocker

arm; oil flows through the lash adjuster then through

the rocker arm and onto the camshaft lobe. Due to

the orentation of the rocker arm, the camshaft intakelobes are not lubed in the same manner as the

exhaust lobes. The intake lobes are lubed through

internal passages in the camshaft. Oil flows through

a bore in the number 3 camshaft bearing bore, and

as the camshaft turns, a hole in the camshaft aligns

with the hole in the camshaft bore allowing engine

oil to enter the camshaft tube. The oil then exits

through 1.6mm (0.063 in.) holes drilled into the

intake lobes, lubricating the lobes and the rocker

arms.

ENGINE LUBRICATION FLOW CHART - BLOCK: TABLE 1

FROM TO

Oil Pickup Tube Oil Pump

Oil Pump Oil Filter

Oil Filter Block Main Oil Gallery

Block Main Oil Gallery 1. Crankshaft Main Journal

2. Left Cylinder Head*

3. Right Cylinder Head*

4. Counterbalance Shaft Rear Journal

Crankshaft Main Journals Crankshaft Rod Journals

Crankshaft Number One Main Journal 1. Front Timing Chain Idler Shaft

2. Counterbalance Shaft - Front Journal

3. Both Secondary Chain Tensioners

Left Cylinder Head Refer to Engine Lubrication Flow Chart - Cylinder

Heads: Table 2

Right Cylinder Head Refer to Engine Lubrication Flow Chart - Cylinder

Heads: Table 2

* The cylinder head gaskets have an oil restricter to control oil flow to the cylinder heads

ENGINE LUBRICATION FLOW CHART - CYLINDER HEADS: TABLE 2

FROM TO

Cylinder Head Oil Port (in bolt hole) Diagonal Cross Drilling to Main Oil Gallery

Main Oil Gallery (drilled through head from rear to

front)1. Base of Camshaft Towers

2. Lash Adjuster Towers

Base of Camshaft Towers Vertical Drilling Through Tower to Camshaft Bearings**

Lash Adjuster Towers Diagonal Drillings to Hydraulic Lash Adjuster Pockets

** The number three camshaft bearing journal feeds oil into the hollow camshaft tubes. Oil is routed to the intake

lobes, which have oil passages drilled into them to lubricate the rocker arms.

9 - 58 ENGINE - 3.7LKJ

LUBRICATION (Continued)

Page 1274 of 1803

Fig. 69 LUBRICATION OIL FLOW

1 - OIL FLOW TO RIGHT CYLINDER HEAD

2 - CYLINDER BLOCK MAIN OIL GALLERY

3 - LEFT CYLINDER HEAD OIL GALLERY

4 - OIL FLOW TO BOTH SECONDARY TENSIONERS

5 - OIL FLOW TO LEFT CYLINDER HEAD

6 - OIL PRESSURE SENSOR LOCATION

7 - OIL FLOW TO COUNTER BALANCE SHAFT8 - OIL PUMP OUTLET TO CYLINDER BLOCK

9 - OIL PUMP

10 - OIL FLOW TO CRANKSHAFT MAIN JOURNALS

11 - CRANKSHAFT MAIN BEARING JOURNALS

12 - RIGHT CYLINDER HEAD OIL GALLERY

KJENGINE - 3.7L 9 - 59

LUBRICATION (Continued)

Page 1275 of 1803

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat inspection.If the oil leak source is not pos-

itively identified at this time, proceed with the air

leak detection test method.

Air Leak Detection Test Method

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(5) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, camshaft bore

cup plugs oil galley pipe plugs, oil filter runoff, and

main bearing cap to cylinder block mating sur-

faces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE

(1) Remove oil pressure sending unit (Fig. 70)and

install gauge assembly C-3292.

(2) Run engine until thermostat opens.

(3) Oil Pressure:

²Curb IdleÐ25 Kpa (4 psi) minimum

²3000 rpmÐ170 - 550 KPa (25 - 80 psi)

(4) If oil pressure is 0 at idle, shut off engine.

Check for a clogged oil pick-up screen or a pressure

relief valve stuck open.

9 - 60 ENGINE - 3.7LKJ

LUBRICATION (Continued)

Page 1283 of 1803

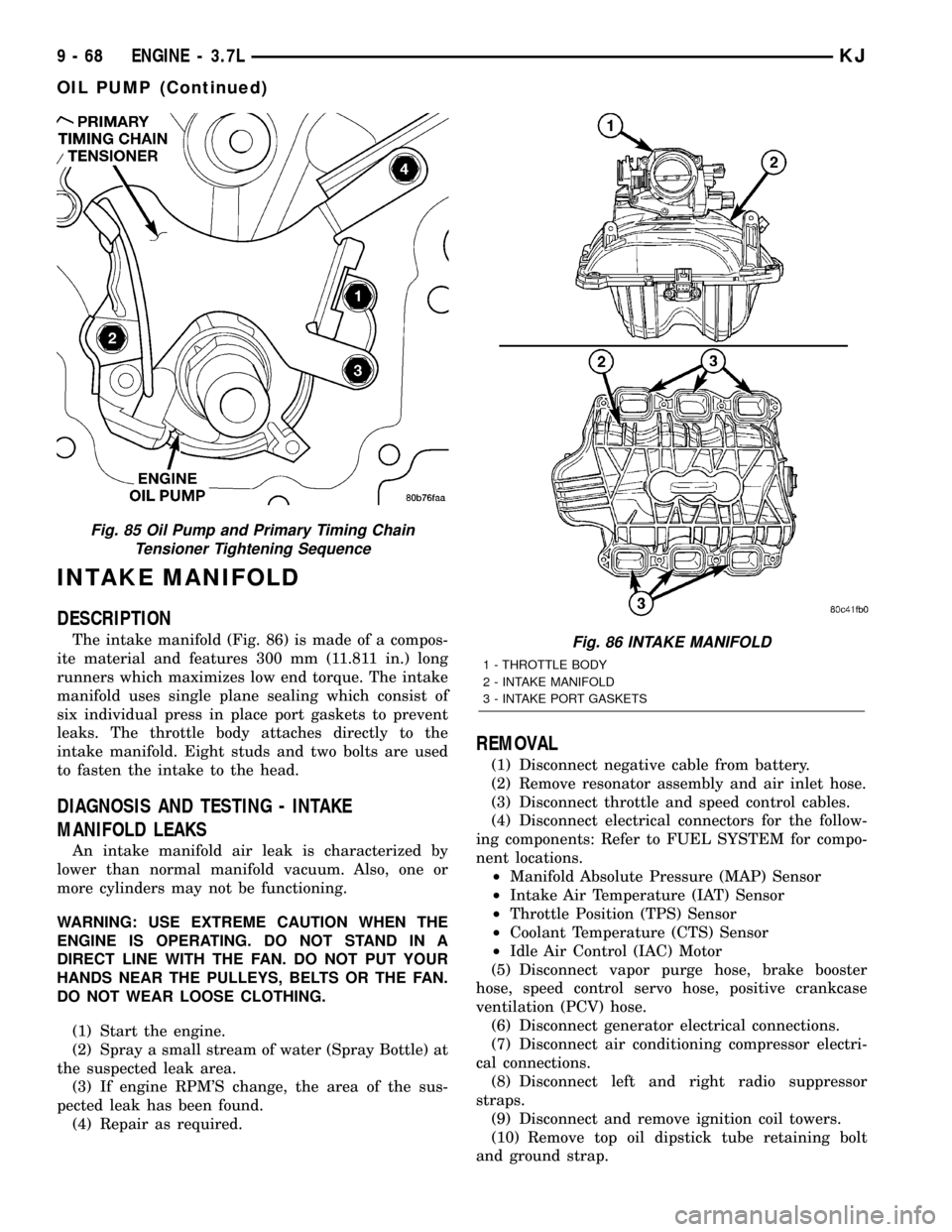

INTAKE MANIFOLD

DESCRIPTION

The intake manifold (Fig. 86) is made of a compos-

ite material and features 300 mm (11.811 in.) long

runners which maximizes low end torque. The intake

manifold uses single plane sealing which consist of

six individual press in place port gaskets to prevent

leaks. The throttle body attaches directly to the

intake manifold. Eight studs and two bolts are used

to fasten the intake to the head.

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove resonator assembly and air inlet hose.

(3) Disconnect throttle and speed control cables.

(4) Disconnect electrical connectors for the follow-

ing components: Refer to FUEL SYSTEM for compo-

nent locations.

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Disconnect vapor purge hose, brake booster

hose, speed control servo hose, positive crankcase

ventilation (PCV) hose.

(6) Disconnect generator electrical connections.

(7) Disconnect air conditioning compressor electri-

cal connections.

(8) Disconnect left and right radio suppressor

straps.

(9) Disconnect and remove ignition coil towers.

(10) Remove top oil dipstick tube retaining bolt

and ground strap.

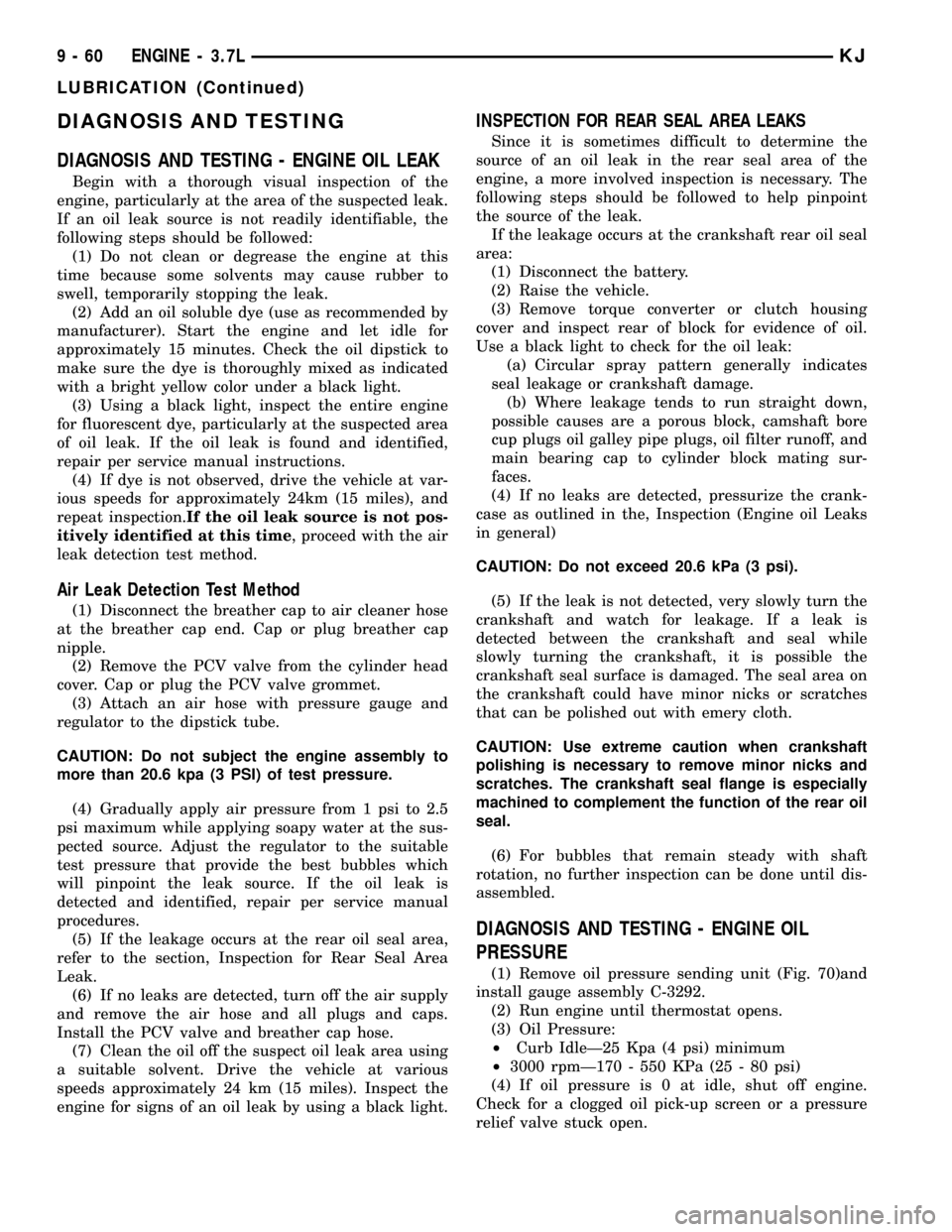

Fig. 85 Oil Pump and Primary Timing Chain

Tensioner Tightening Sequence

Fig. 86 INTAKE MANIFOLD

1 - THROTTLE BODY

2 - INTAKE MANIFOLD

3 - INTAKE PORT GASKETS

9 - 68 ENGINE - 3.7LKJ

OIL PUMP (Continued)

Page 1284 of 1803

(11) Bleed fuel system. Refer to FUEL SYSTEM.

(12) Remove fuel rail.

(13) Remove throttle body assembly and mounting

bracket.

(14) Drain cooling system below coolant tempera-

ture level. Refer to COOLING SYSTEM.

(15) Remove the heater hoses from the engine

front cover and the heater core.

(16) Unclip and remove heater hoses and tubes

from intake manifold.

(17) Remove coolant temperature sensor. Refer to

FUEL SYSTEM.

(18) Remove intake manifold retaining fasteners in

reverse order of tightening sequence.

(19) Remove intake manifold.

INSTALLATION

(1) Install intake manifold gaskets.

(2) Install intake manifold.

(3) Install intake manifold retaining bolts and

tighten in sequence shown in to 12 N´m (105 in. lbs.).

(4) Install left and right radio suppressor straps.

(5) Install throttle body assembly.

(6) Install throttle cable bracket.

(7) Connect throttle cable and speed control cable

to throttle body.

(8) Install fuel rail.

(9) Install ignition coil towers.

(10) Position and install heater hoses and tubes

onto intake manifold.

(11) Install the heater hoses to the heater core and

engine front cover.

(12) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(13) Install top oil dipstick tube retaining bolt and

ground strap.

(14) Connect generator electrical connections.

(15) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(16) Fill cooling system.

(17) Install resonator assembly and air inlet hose.

(18) Connect negative cable to battery.

EXHAUST MANIFOLD

DESCRIPTION

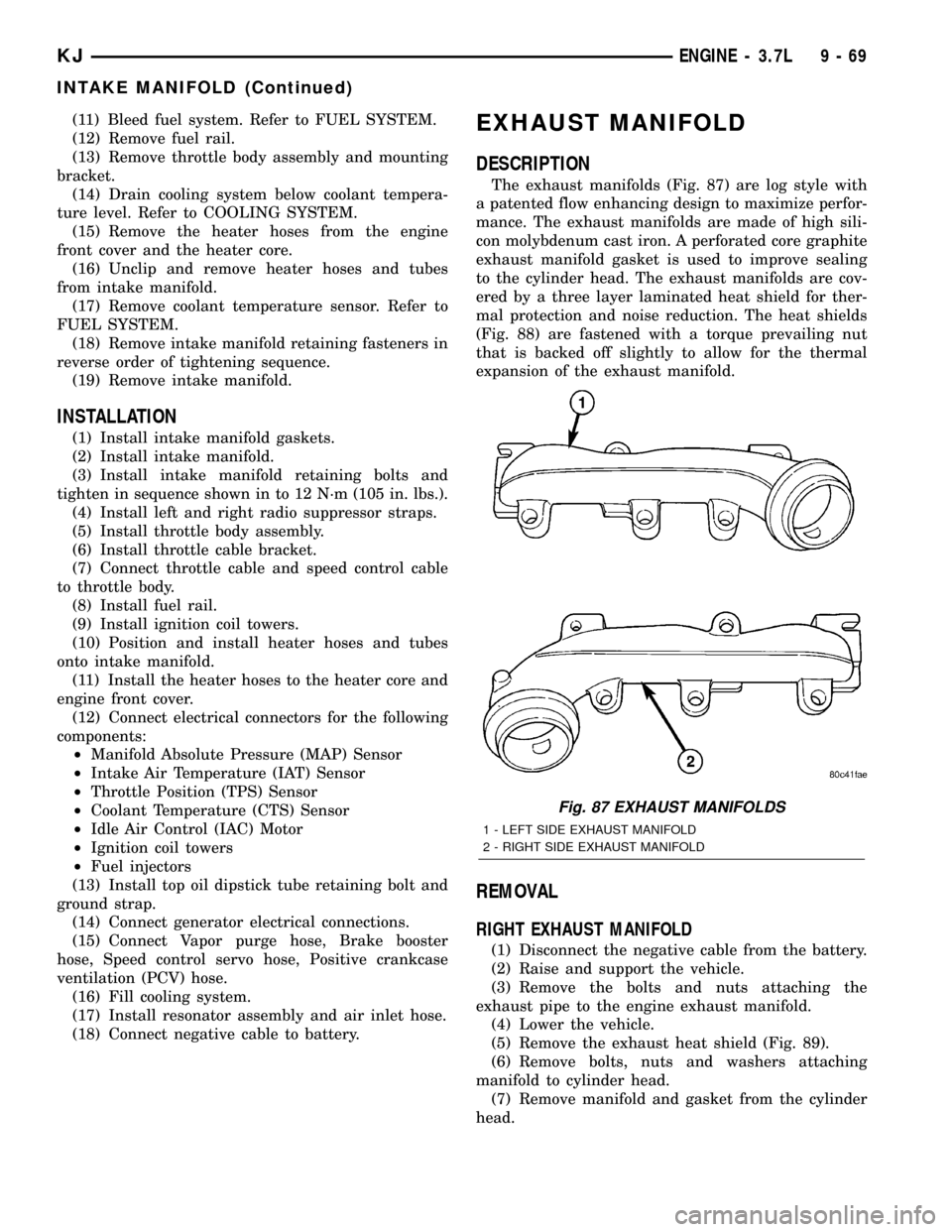

The exhaust manifolds (Fig. 87) are log style with

a patented flow enhancing design to maximize perfor-

mance. The exhaust manifolds are made of high sili-

con molybdenum cast iron. A perforated core graphite

exhaust manifold gasket is used to improve sealing

to the cylinder head. The exhaust manifolds are cov-

ered by a three layer laminated heat shield for ther-

mal protection and noise reduction. The heat shields

(Fig. 88) are fastened with a torque prevailing nut

that is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

REMOVAL

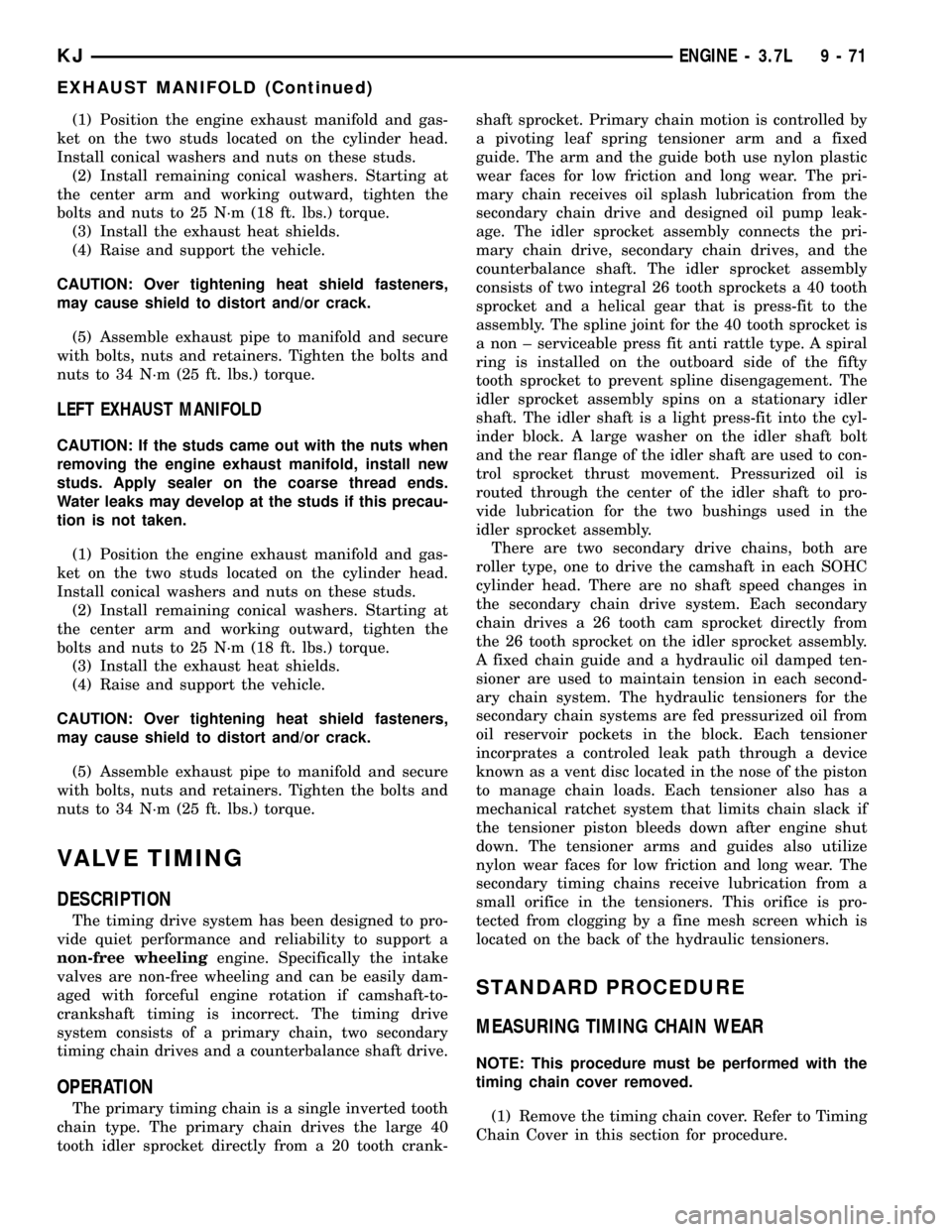

RIGHT EXHAUST MANIFOLD

(1) Disconnect the negative cable from the battery.

(2) Raise and support the vehicle.

(3) Remove the bolts and nuts attaching the

exhaust pipe to the engine exhaust manifold.

(4) Lower the vehicle.

(5) Remove the exhaust heat shield (Fig. 89).

(6) Remove bolts, nuts and washers attaching

manifold to cylinder head.

(7) Remove manifold and gasket from the cylinder

head.

Fig. 87 EXHAUST MANIFOLDS

1 - LEFT SIDE EXHAUST MANIFOLD

2 - RIGHT SIDE EXHAUST MANIFOLD

KJENGINE - 3.7L 9 - 69

INTAKE MANIFOLD (Continued)

Page 1285 of 1803

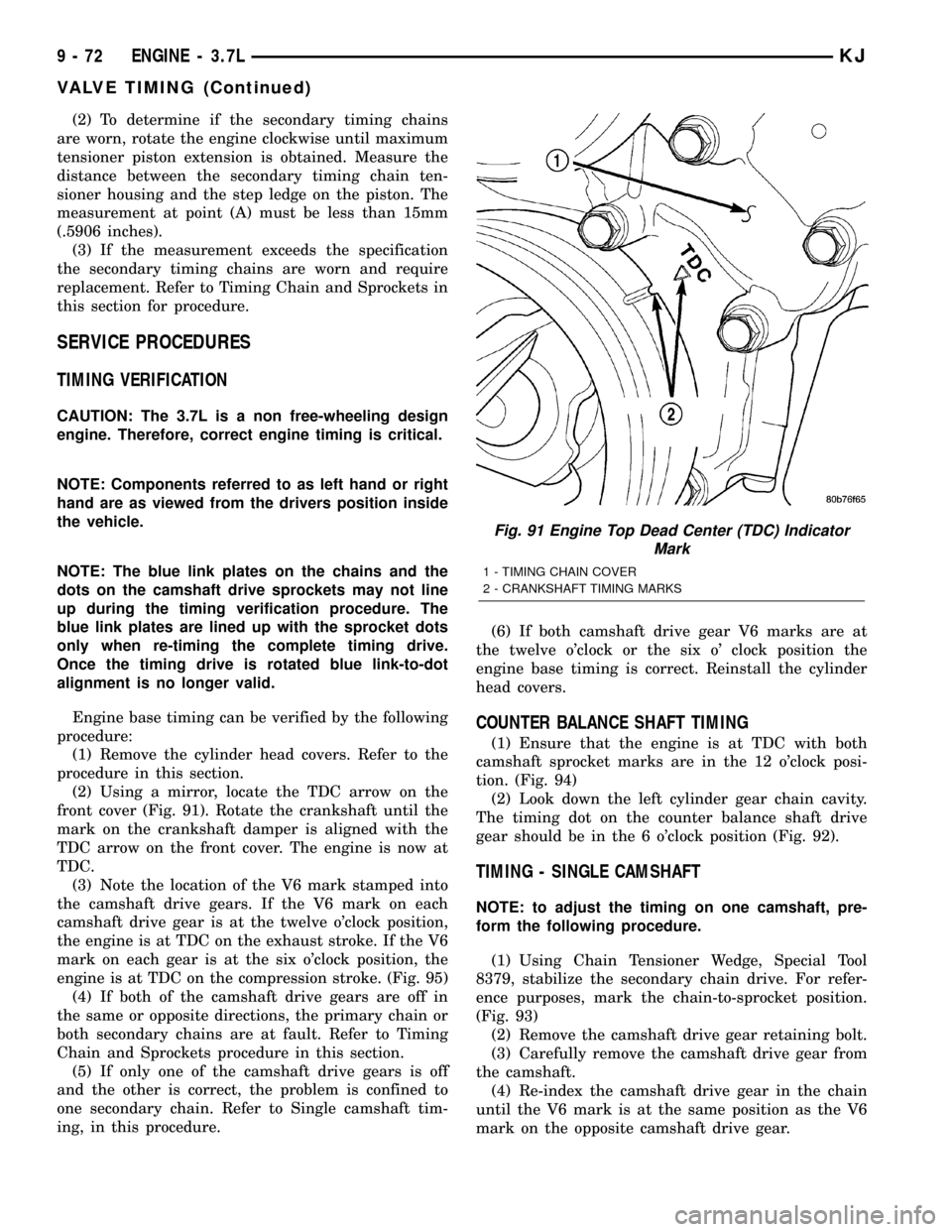

LEFT EXHAUST MANIFOLD

(1) Disconnect the negative cable from the battery.

(2) Raise and support the vehicle.

(3) Remove the bolts and nuts attaching the

exhaust pipe to the engine exhaust manifold.

(4) Lower the vehicle.

(5) Remove the exhaust heat shields (Fig. 90).

(6) Remove bolts, nuts and washers attaching

manifold to cylinder head.

(7) Remove manifold and gasket from the cylinder

head.

INSTALLATION

RIGHT EXHAUST MANIFOLD

CAUTION: If the studs came out with the nuts when

removing the engine exhaust manifold, install new

studs. Apply sealer on the coarse thread ends.

Water leaks may develop at the studs if this precau-

tion is not taken.

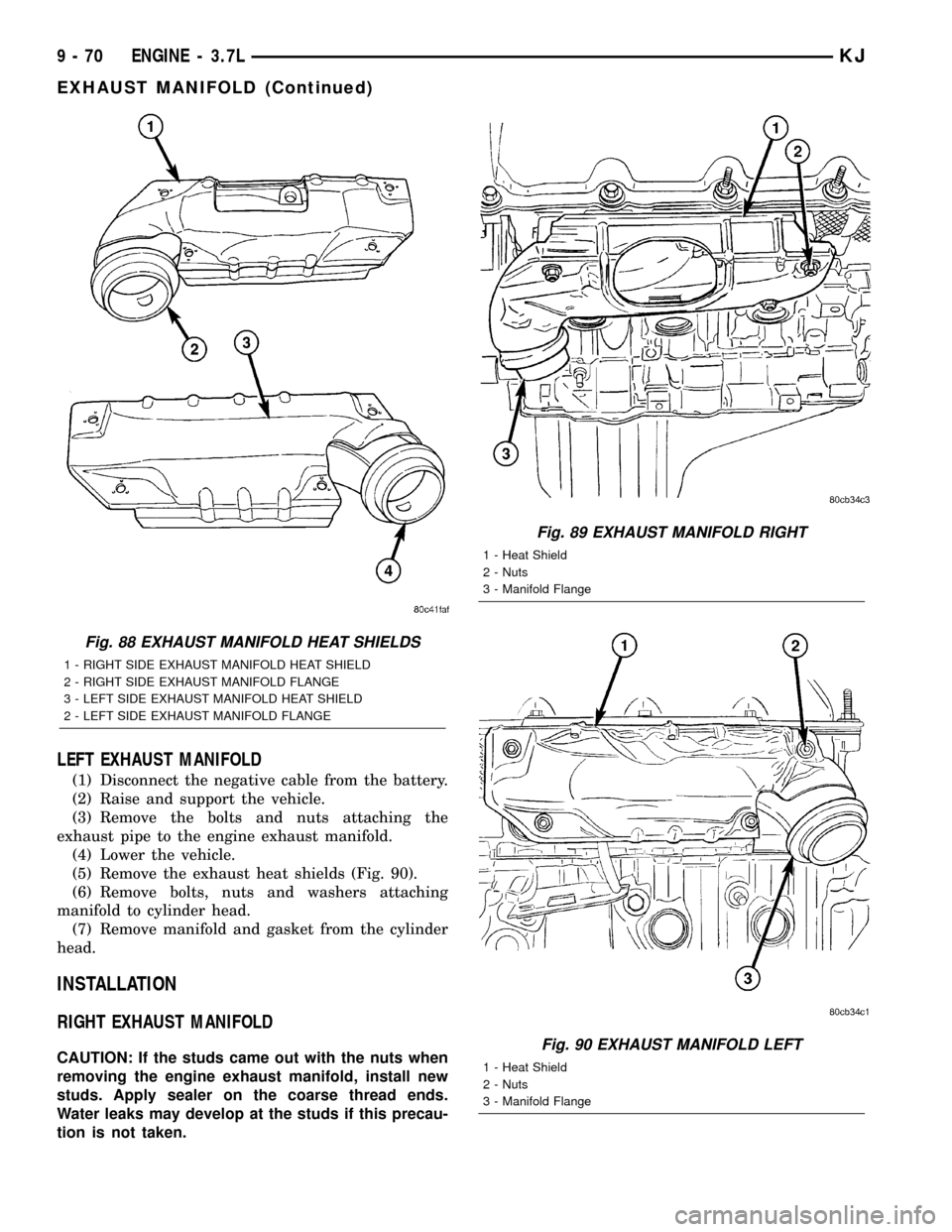

Fig. 88 EXHAUST MANIFOLD HEAT SHIELDS

1 - RIGHT SIDE EXHAUST MANIFOLD HEAT SHIELD

2 - RIGHT SIDE EXHAUST MANIFOLD FLANGE

3 - LEFT SIDE EXHAUST MANIFOLD HEAT SHIELD

2 - LEFT SIDE EXHAUST MANIFOLD FLANGE

Fig. 89 EXHAUST MANIFOLD RIGHT

1 - Heat Shield

2 - Nuts

3 - Manifold Flange

Fig. 90 EXHAUST MANIFOLD LEFT

1 - Heat Shield

2 - Nuts

3 - Manifold Flange

9 - 70 ENGINE - 3.7LKJ

EXHAUST MANIFOLD (Continued)

Page 1286 of 1803

(1) Position the engine exhaust manifold and gas-

ket on the two studs located on the cylinder head.

Install conical washers and nuts on these studs.

(2) Install remaining conical washers. Starting at

the center arm and working outward, tighten the

bolts and nuts to 25 N´m (18 ft. lbs.) torque.

(3) Install the exhaust heat shields.

(4) Raise and support the vehicle.

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(5) Assemble exhaust pipe to manifold and secure

with bolts, nuts and retainers. Tighten the bolts and

nuts to 34 N´m (25 ft. lbs.) torque.

LEFT EXHAUST MANIFOLD

CAUTION: If the studs came out with the nuts when

removing the engine exhaust manifold, install new

studs. Apply sealer on the coarse thread ends.

Water leaks may develop at the studs if this precau-

tion is not taken.

(1) Position the engine exhaust manifold and gas-

ket on the two studs located on the cylinder head.

Install conical washers and nuts on these studs.

(2) Install remaining conical washers. Starting at

the center arm and working outward, tighten the

bolts and nuts to 25 N´m (18 ft. lbs.) torque.

(3) Install the exhaust heat shields.

(4) Raise and support the vehicle.

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(5) Assemble exhaust pipe to manifold and secure

with bolts, nuts and retainers. Tighten the bolts and

nuts to 34 N´m (25 ft. lbs.) torque.

VALVE TIMING

DESCRIPTION

The timing drive system has been designed to pro-

vide quiet performance and reliability to support a

non-free wheelingengine. Specifically the intake

valves are non-free wheeling and can be easily dam-

aged with forceful engine rotation if camshaft-to-

crankshaft timing is incorrect. The timing drive

system consists of a primary chain, two secondary

timing chain drives and a counterbalance shaft drive.

OPERATION

The primary timing chain is a single inverted tooth

chain type. The primary chain drives the large 40

tooth idler sprocket directly from a 20 tooth crank-shaft sprocket. Primary chain motion is controlled by

a pivoting leaf spring tensioner arm and a fixed

guide. The arm and the guide both use nylon plastic

wear faces for low friction and long wear. The pri-

mary chain receives oil splash lubrication from the

secondary chain drive and designed oil pump leak-

age. The idler sprocket assembly connects the pri-

mary chain drive, secondary chain drives, and the

counterbalance shaft. The idler sprocket assembly

consists of two integral 26 tooth sprockets a 40 tooth

sprocket and a helical gear that is press-fit to the

assembly. The spline joint for the 40 tooth sprocket is

a non ± serviceable press fit anti rattle type. A spiral

ring is installed on the outboard side of the fifty

tooth sprocket to prevent spline disengagement. The

idler sprocket assembly spins on a stationary idler

shaft. The idler shaft is a light press-fit into the cyl-

inder block. A large washer on the idler shaft bolt

and the rear flange of the idler shaft are used to con-

trol sprocket thrust movement. Pressurized oil is

routed through the center of the idler shaft to pro-

vide lubrication for the two bushings used in the

idler sprocket assembly.

There are two secondary drive chains, both are

roller type, one to drive the camshaft in each SOHC

cylinder head. There are no shaft speed changes in

the secondary chain drive system. Each secondary

chain drives a 26 tooth cam sprocket directly from

the 26 tooth sprocket on the idler sprocket assembly.

A fixed chain guide and a hydraulic oil damped ten-

sioner are used to maintain tension in each second-

ary chain system. The hydraulic tensioners for the

secondary chain systems are fed pressurized oil from

oil reservoir pockets in the block. Each tensioner

incorprates a controled leak path through a device

known as a vent disc located in the nose of the piston

to manage chain loads. Each tensioner also has a

mechanical ratchet system that limits chain slack if

the tensioner piston bleeds down after engine shut

down. The tensioner arms and guides also utilize

nylon wear faces for low friction and long wear. The

secondary timing chains receive lubrication from a

small orifice in the tensioners. This orifice is pro-

tected from clogging by a fine mesh screen which is

located on the back of the hydraulic tensioners.

STANDARD PROCEDURE

MEASURING TIMING CHAIN WEAR

NOTE: This procedure must be performed with the

timing chain cover removed.

(1) Remove the timing chain cover. Refer to Timing

Chain Cover in this section for procedure.

KJENGINE - 3.7L 9 - 71

EXHAUST MANIFOLD (Continued)

Page 1287 of 1803

(2) To determine if the secondary timing chains

are worn, rotate the engine clockwise until maximum

tensioner piston extension is obtained. Measure the

distance between the secondary timing chain ten-

sioner housing and the step ledge on the piston. The

measurement at point (A) must be less than 15mm

(.5906 inches).

(3) If the measurement exceeds the specification

the secondary timing chains are worn and require

replacement. Refer to Timing Chain and Sprockets in

this section for procedure.

SERVICE PROCEDURES

TIMING VERIFICATION

CAUTION: The 3.7L is a non free-wheeling design

engine. Therefore, correct engine timing is critical.

NOTE: Components referred to as left hand or right

hand are as viewed from the drivers position inside

the vehicle.

NOTE: The blue link plates on the chains and the

dots on the camshaft drive sprockets may not line

up during the timing verification procedure. The

blue link plates are lined up with the sprocket dots

only when re-timing the complete timing drive.

Once the timing drive is rotated blue link-to-dot

alignment is no longer valid.

Engine base timing can be verified by the following

procedure:

(1) Remove the cylinder head covers. Refer to the

procedure in this section.

(2) Using a mirror, locate the TDC arrow on the

front cover (Fig. 91). Rotate the crankshaft until the

mark on the crankshaft damper is aligned with the

TDC arrow on the front cover. The engine is now at

TDC.

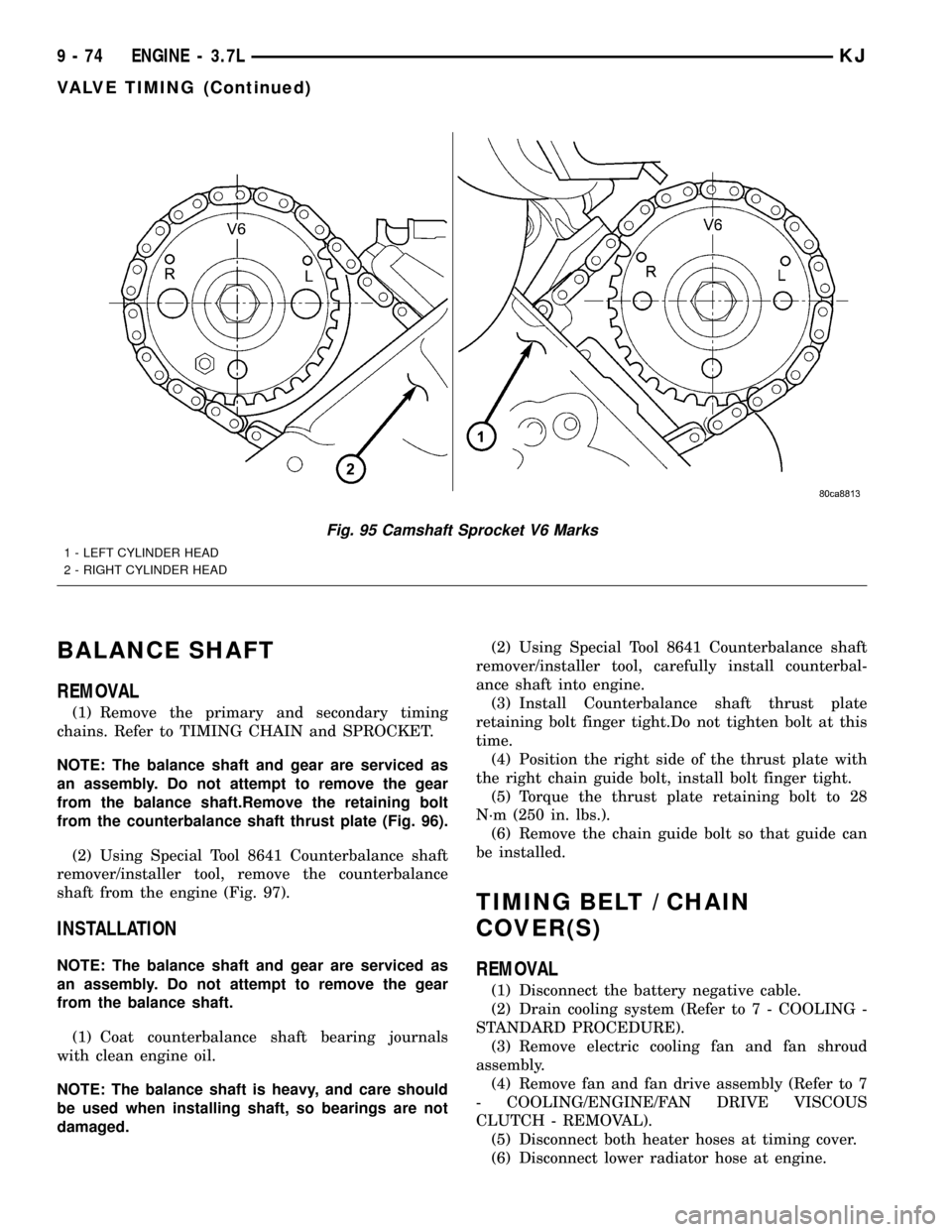

(3) Note the location of the V6 mark stamped into

the camshaft drive gears. If the V6 mark on each

camshaft drive gear is at the twelve o'clock position,

the engine is at TDC on the exhaust stroke. If the V6

mark on each gear is at the six o'clock position, the

engine is at TDC on the compression stroke. (Fig. 95)

(4) If both of the camshaft drive gears are off in

the same or opposite directions, the primary chain or

both secondary chains are at fault. Refer to Timing

Chain and Sprockets procedure in this section.

(5) If only one of the camshaft drive gears is off

and the other is correct, the problem is confined to

one secondary chain. Refer to Single camshaft tim-

ing, in this procedure.(6) If both camshaft drive gear V6 marks are at

the twelve o'clock or the six o' clock position the

engine base timing is correct. Reinstall the cylinder

head covers.

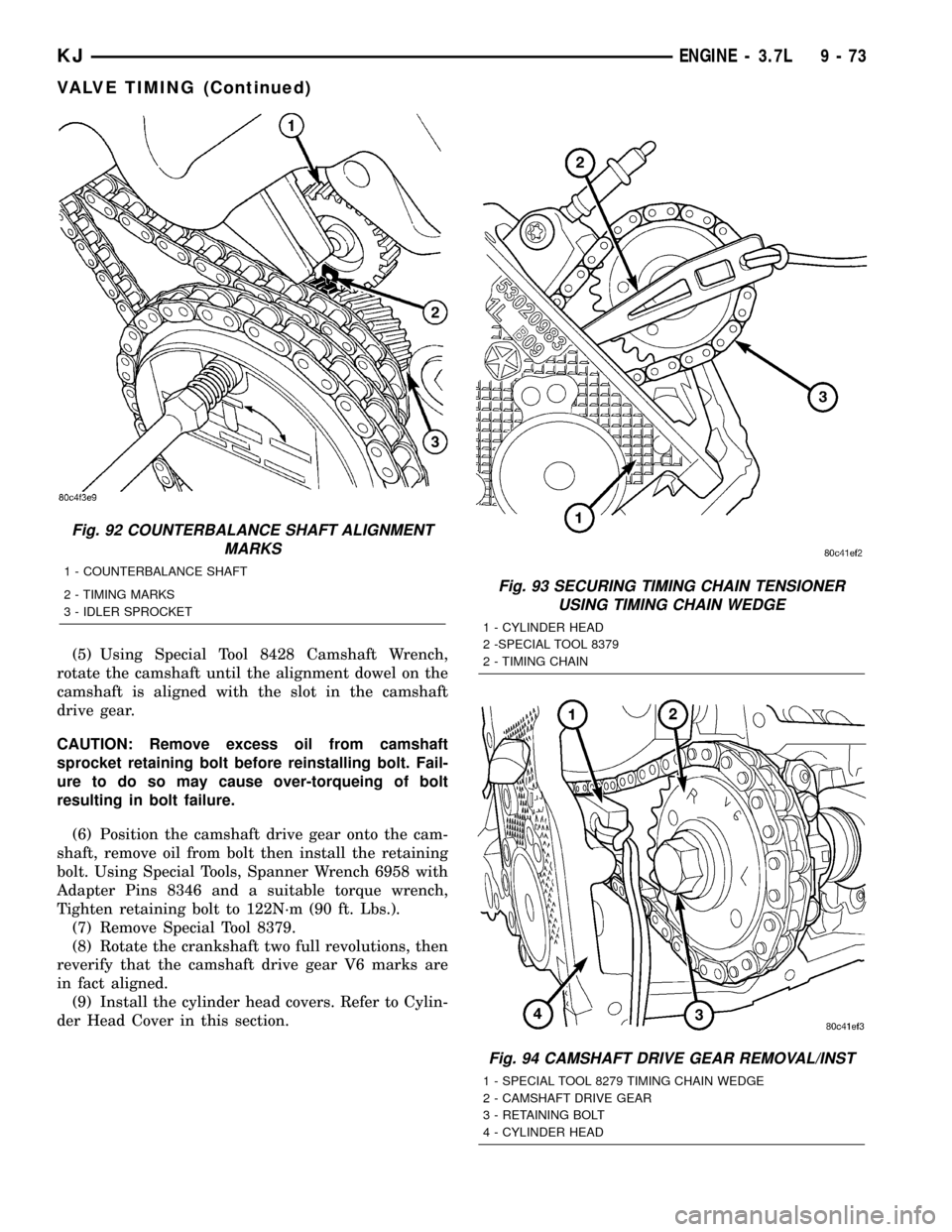

COUNTER BALANCE SHAFT TIMING

(1) Ensure that the engine is at TDC with both

camshaft sprocket marks are in the 12 o'clock posi-

tion. (Fig. 94)

(2) Look down the left cylinder gear chain cavity.

The timing dot on the counter balance shaft drive

gear should be in the 6 o'clock position (Fig. 92).

TIMING - SINGLE CAMSHAFT

NOTE: to adjust the timing on one camshaft, pre-

form the following procedure.

(1) Using Chain Tensioner Wedge, Special Tool

8379, stabilize the secondary chain drive. For refer-

ence purposes, mark the chain-to-sprocket position.

(Fig. 93)

(2) Remove the camshaft drive gear retaining bolt.

(3) Carefully remove the camshaft drive gear from

the camshaft.

(4) Re-index the camshaft drive gear in the chain

until the V6 mark is at the same position as the V6

mark on the opposite camshaft drive gear.

Fig. 91 Engine Top Dead Center (TDC) Indicator

Mark

1 - TIMING CHAIN COVER

2 - CRANKSHAFT TIMING MARKS

9 - 72 ENGINE - 3.7LKJ

VALVE TIMING (Continued)

Page 1288 of 1803

(5) Using Special Tool 8428 Camshaft Wrench,

rotate the camshaft until the alignment dowel on the

camshaft is aligned with the slot in the camshaft

drive gear.

CAUTION: Remove excess oil from camshaft

sprocket retaining bolt before reinstalling bolt. Fail-

ure to do so may cause over-torqueing of bolt

resulting in bolt failure.

(6) Position the camshaft drive gear onto the cam-

shaft, remove oil from bolt then install the retaining

bolt. Using Special Tools, Spanner Wrench 6958 with

Adapter Pins 8346 and a suitable torque wrench,

Tighten retaining bolt to 122N´m (90 ft. Lbs.).

(7) Remove Special Tool 8379.

(8) Rotate the crankshaft two full revolutions, then

reverify that the camshaft drive gear V6 marks are

in fact aligned.

(9) Install the cylinder head covers. Refer to Cylin-

der Head Cover in this section.

Fig. 92 COUNTERBALANCE SHAFT ALIGNMENT

MARKS

1 - COUNTERBALANCE SHAFT

2 - TIMING MARKS

3 - IDLER SPROCKET

Fig. 93 SECURING TIMING CHAIN TENSIONER

USING TIMING CHAIN WEDGE

1 - CYLINDER HEAD

2 -SPECIAL TOOL 8379

2 - TIMING CHAIN

Fig. 94 CAMSHAFT DRIVE GEAR REMOVAL/INST

1 - SPECIAL TOOL 8279 TIMING CHAIN WEDGE

2 - CAMSHAFT DRIVE GEAR

3 - RETAINING BOLT

4 - CYLINDER HEAD

KJENGINE - 3.7L 9 - 73

VALVE TIMING (Continued)

Page 1289 of 1803

BALANCE SHAFT

REMOVAL

(1) Remove the primary and secondary timing

chains. Refer to TIMING CHAIN and SPROCKET.

NOTE: The balance shaft and gear are serviced as

an assembly. Do not attempt to remove the gear

from the balance shaft.Remove the retaining bolt

from the counterbalance shaft thrust plate (Fig. 96).

(2) Using Special Tool 8641 Counterbalance shaft

remover/installer tool, remove the counterbalance

shaft from the engine (Fig. 97).

INSTALLATION

NOTE: The balance shaft and gear are serviced as

an assembly. Do not attempt to remove the gear

from the balance shaft.

(1) Coat counterbalance shaft bearing journals

with clean engine oil.

NOTE: The balance shaft is heavy, and care should

be used when installing shaft, so bearings are not

damaged.(2) Using Special Tool 8641 Counterbalance shaft

remover/installer tool, carefully install counterbal-

ance shaft into engine.

(3) Install Counterbalance shaft thrust plate

retaining bolt finger tight.Do not tighten bolt at this

time.

(4) Position the right side of the thrust plate with

the right chain guide bolt, install bolt finger tight.

(5) Torque the thrust plate retaining bolt to 28

N´m (250 in. lbs.).

(6) Remove the chain guide bolt so that guide can

be installed.

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Remove electric cooling fan and fan shroud

assembly.

(4) Remove fan and fan drive assembly (Refer to 7

- COOLING/ENGINE/FAN DRIVE VISCOUS

CLUTCH - REMOVAL).

(5) Disconnect both heater hoses at timing cover.

(6) Disconnect lower radiator hose at engine.

Fig. 95 Camshaft Sprocket V6 Marks

1 - LEFT CYLINDER HEAD

2 - RIGHT CYLINDER HEAD

9 - 74 ENGINE - 3.7LKJ

VALVE TIMING (Continued)